pauly CPV1038 01 Series, CPV1038 Operating Instructions Manual

Fotoelektrik Pauly – Light barriers

pauly

Features

Functionalities

Cat. 2, PL=c, SIL 1

in acc. with EN ISO 13849 and

EN 62061

Two optical systems in one

enclosure

Two adjustable independent

clearance distances

Clearance distance up to 50 m

High performance in terms of

detection

Pollution warning/ Anti Sabotage

system

Integrated test system – a highly

dynamic process reproduces the

light reflected by the reflector

Safe mounting of reflectors

o Collision protection

o Distance monitoring

Only for cranes that run on a common crane

track or rail.

Revision Index:

2019

-29

Revision date:

12.04.2019

Processed by:

tb

Operating instructions

Optical Anti-Collision Device

Type CPV1038

E_52692.pdf

E_52692 Ref. 2019-29 1/24

Fotoelektrik Pauly GmbH, Wahrbrink 6, D-59368 Werne, T: +49 2389/402 27-70, F: +49 2389/402 27-77

http://www.fotoelektrik-pauly.de, eMail: info@fotoelektrik-pauly.de

Fotoelektrik Pauly – Light barriers

Table of Contents

1. Identification / General Remarks 3

1.1 Product versions / Plates representations 3

1.2 Name and address of the manufacturer 3

1.3 Applied standards and technical specifications: 4

1.4 Definition of symbols: 4

2. Product description 4

2.1 Product mark 4

2.2 Intended use, general function and area of application 5

2.3 Incorrect use and foreseeable misuse 5

2.4 Safety information 6

3. Definitions – technical data 7

4. Operating instructions 9

4.1 Information on this technical description 9

4.2 Device description 9

4.3 Description of function 10

4.3.1 Triangulation triangle 10

4.3.2 Approach movement 11

4.3.3 Continually self-testing 12

4.3.4 Possible movement of the crane 12

4.3.5 Movement of the crane is stopped 12

4.4 Pollution control function 13

4.4.1 Principle 13

4.4.2 Pollution example 13

4.4.3 Pollution Indicator – meaning of the different circuit states 14

4.5 Assembly 15

4.5.1 Horizontal arrangement of the triangulation triangle 15

4.5.2 Distance monitoring accuracy 16

4.5.3 Taking the tolerances into consideration with respect to clearance distance 17

4.6 Information on assembly 18

4.7 Adjustment using the “light beam method” 19

4.8 Electrical connection 20

4.9 Applicable documents 22

5. Maintenance and cleaning 22

6. Contents of the EU Declaration of Conformity 23

7. Decommissioning 24

8. Spare parts 24

E_52692 Ref. 2019-29 2/24

Fotoelektrik Pauly GmbH, Wahrbrink 6, D-59368 Werne, T: +49 2389/402 27-70, F: +49 2389/402 27-77

http://www.fotoelektrik-pauly.de, eMail: info@fotoelektrik-pauly.de

Fotoelektrik Pauly – Light barriers

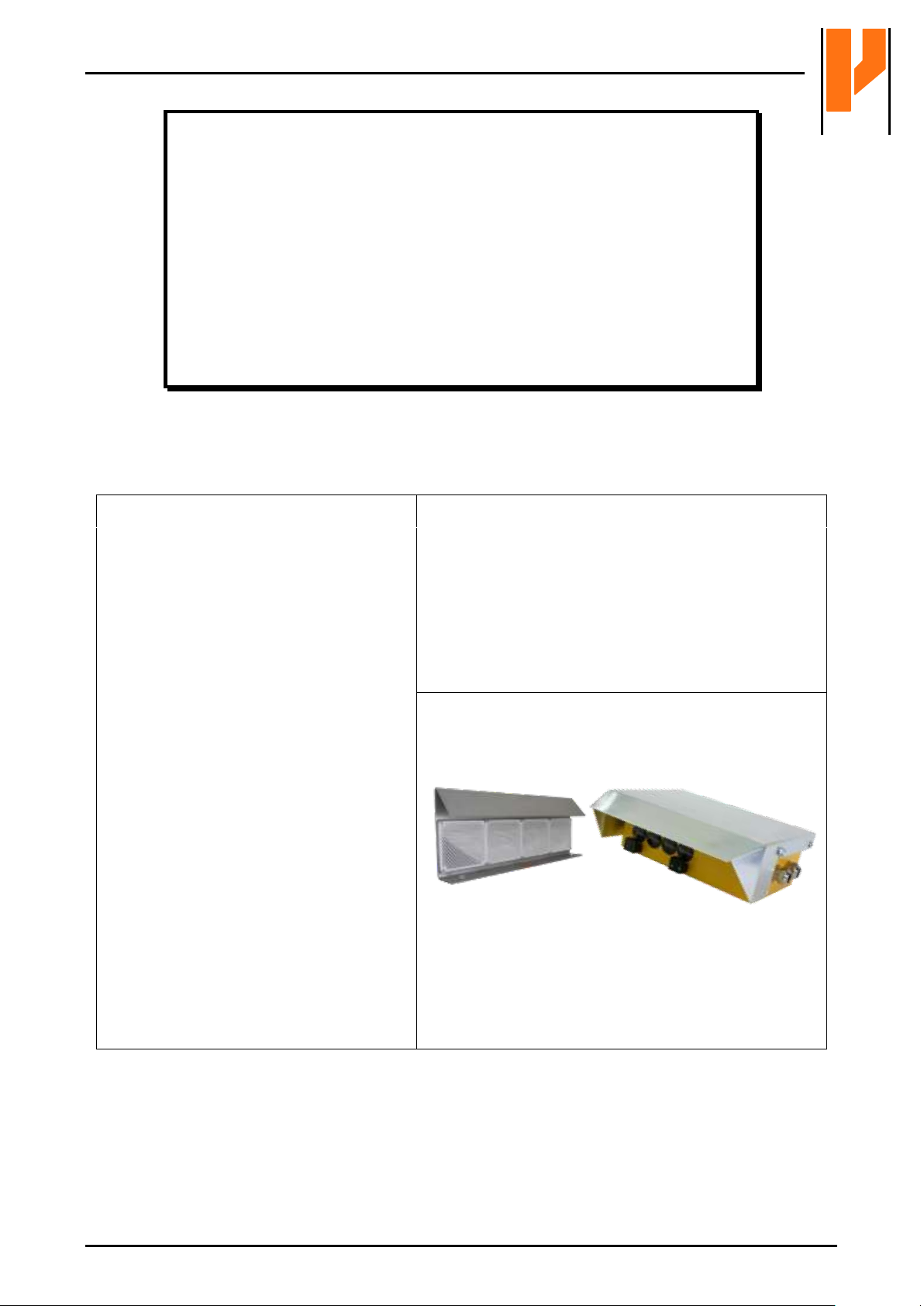

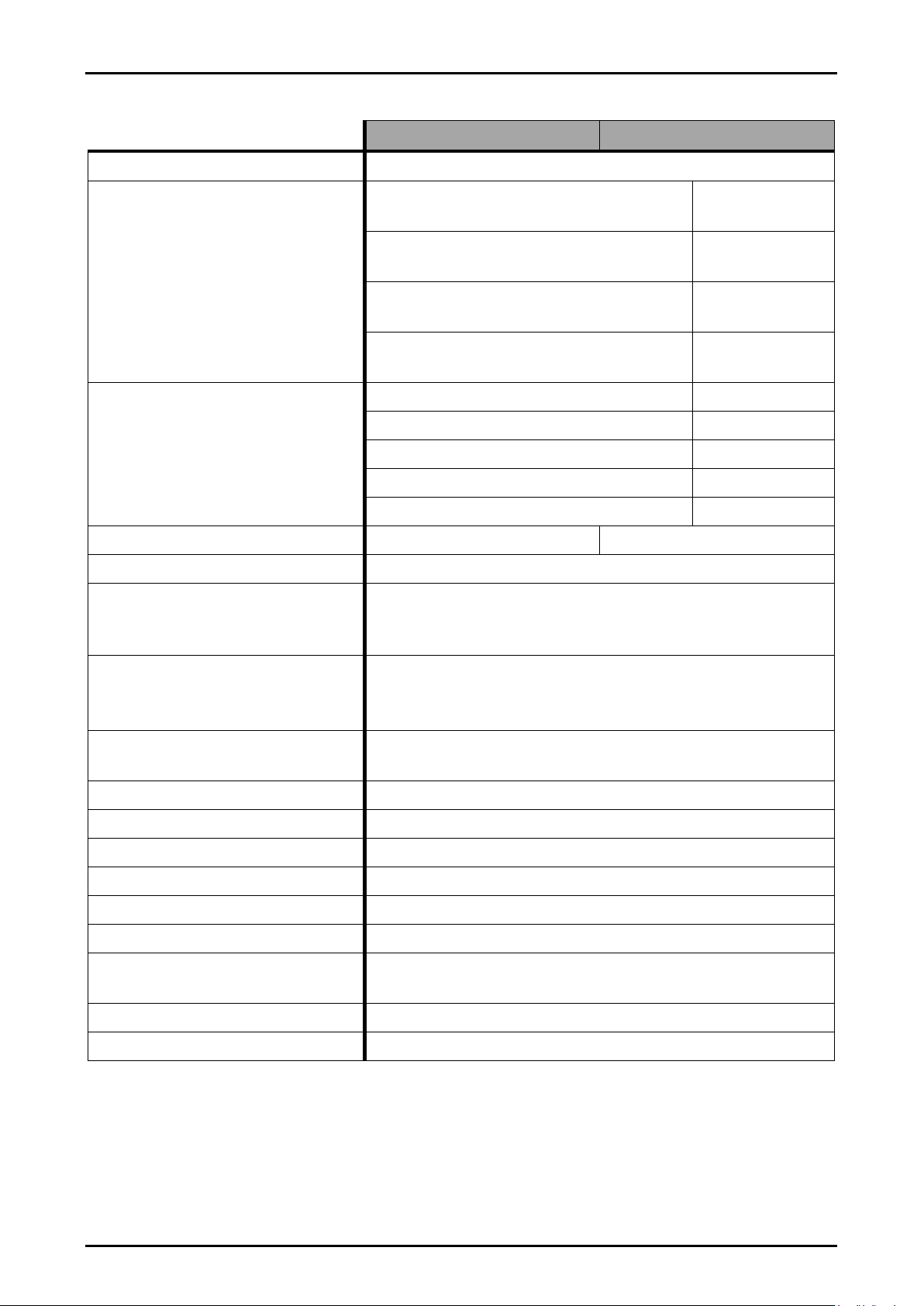

Bezeichnung

General description

Optical Anti-Collision Device

Typ

Type

CPV1038

CPV1038 /R/2M20/i/… 5269x…

0393

Seriennummer

Serial number

Baujahr

Year of manufacture

Reichweite

Range

0,5…25/50m

Versorgung

Supply

Schutzart

Protection mode

IP65

Reaktionszeit

Response time

80ms

Fotoelektrik Pauly

59368 Werne / Germany

www.fotoelektrik-pauly.de

Bescheinigungsnummer

Certificate number

HSM 09 079

Sicherheits-Integritätslevel

Safety Integrity Level

1

gemäß DIN EN 62061

according to DIN EN 62061

Sicherheitskategorie

Safety category

2

Performance

Level

c

MTTFd [a]

86

gemäß DIN EN ISO 13849-1

according to DIN EN ISO 13849 -1

Bezeichnung

General description

Optical Anti-Collision Device

Typ

Type

CPV1038*01

CPV1038*01 /R/2M20/i/… 5269M01x…

0393

Seriennummer

Serial number

Baujahr

Year of manufacture

Reichweite

Range

1…25m

Versorgung

Supply

Schutzart

Protection mode

IP65

Reaktionszeit

Response time

80ms

Fotoelektrik Pauly

59368 Werne / Germany

www.fotoelektrik-pauly.de

Bescheinigungsnummer

Certificate number

HSM 09 079

Sicherheits-Integritätslevel

Safety Integrity Level

1

gemäß DIN EN 62061

according to DIN EN 62061

Sicherheitskategorie

Safety category

2

Performance

Level

c

MTTFd [a]

86

gemäß DIN EN ISO 13849-1

according to DIN EN ISO 13849 -1

1. Identification / General Remarks

1.1 Product versions / Plates representations

CPV1038

CPV1038*01

1.2 Name and address of the manufacturer

Fotoelektrik Pauly GmbH

Wahrbrink 6

59368 Werne, Germany

E_52692 Ref. 2019-29 3/24

Fotoelektrik Pauly GmbH, Wahrbrink 6, D-59368 Werne, T: +49 2389/402 27-70, F: +49 2389/402 27-77

http://www.fotoelektrik-pauly.de, eMail: info@fotoelektrik-pauly.de

Fotoelektrik Pauly – Light barriers

EN ISO 13849

Safety of machinery – Safety-Related Parts of Control

Systems

EN 62061

Safety of machinery - Functional safety of safety-related

electrical, electronic and programmable electronic control

systems

Must follow – Critical information

This symbol describes safety warning of dangerous situations and indicates

necessary measures and / or appropriate precautionary measures.

Failure to comply can result in death or property damage.

Must know – Important information

This symbol describes e.g. situations that could damage the product or

devices in its vicinity, and accordingly provide appropriate action.

The sign identifies particularly important passages.

1.3 Applied standards and technical specifications:

1.4 Definition of symbols:

2. Product description

2.1 Product mark

CPV1038 und CPV1038*01: high performance reflex light barriers for distance monitoring tasks

using the triangulation method.

E_52692 Ref. 2019-29 4/24

Fotoelektrik Pauly GmbH, Wahrbrink 6, D-59368 Werne, T: +49 2389/402 27-70, F: +49 2389/402 27-77

http://www.fotoelektrik-pauly.de, eMail: info@fotoelektrik-pauly.de

Fotoelektrik Pauly – Light barriers

2.2 Intended use, general function and area of application

Acknowledgement of the contents of these operating instructions forms part of the intended use.

Notes and safety information must be observed in particular.

The Model CPV1038 System is

a mechanism for collision protection or distance monitoring exclusively for stationary power

driven cranes that run on a common crane track. The reflector centre on the other crane must

be situated at the optical device (lens) level.

intended for use in weatherproof applications where the direct influence of the weather is

prevented

exclusively intended for use in machinery within the meaning of the scope of EN 60204-32

(Electrical Equipment of Cranes), EN 15011 (Bridge and gantry cranes) and EN 12077-2

(Limiting devices).

When used as collision protection device, the moving crane is prevented from colliding e.g. brought

to a standstill in reference to the other crane (opposite crane).

When used as a distance monitoring device, a risk triggering approach of cranes is detected.

At least one device is required for each crane and the corresponding reflector is positioned at the

opposite wall/crane.

2.3 Incorrect use and foreseeable misuse

It is not permissible to use the device in any manner that deviates from the contents of the

operating instructions or operate it outside the prescribed areas of application.

The CPV1038 is not suitable for operation in

areas with significant challenging environmental requirements (e. g. potentially explosive

areas).

areas of excessive pollution influence where a proper function may not be ensured, despite

regular cleaning of the optical elements.

applications where normal operation due to excessive fog, excessive steam or excessive

smoke cannot be guaranteed.

systems where disconnecting the current does not lead to a safe mode.

collision protection and distance monitoring for cranes which run on a curved crane/rail track.

collision protection and distance monitoring for cranes which do not run on a common

crane/rail track.

collision protection of e.g. Industrial trucks or similar transport equipment.

use without reflector (please refer section 3)

Any technical alteration will result in cancellation of the product warranty!

E_52692 Ref. 2019-29 5/24

Fotoelektrik Pauly GmbH, Wahrbrink 6, D-59368 Werne, T: +49 2389/402 27-70, F: +49 2389/402 27-77

http://www.fotoelektrik-pauly.de, eMail: info@fotoelektrik-pauly.de

Fotoelektrik Pauly – Light barriers

System-related movement tolerances of crane system components and the possible

associated effects on the switching behaviour of the distance monitoring system

must be taken into consideration when planning crane systems.

A correct assembly and alignment of the system are essential for the correct

operation of the system’s safety function.

The set clearance distance could be reduced, e.g. by fog, steam or smoke.

During limited vision, e.g. caused by fog, steam or smoke, the function of the

distance monitoring system must be checked by moving the cranes together.

The light beam on the system must not be interrupted, for example by obstructions

or suspended objects. It is essential that proper attention is paid to this during

assembly and operation of the system.

Before commencement of work, the system’s safety function must be checked by

moving the cranes together (daily functional check).

The installation of the light barriers may only be performed by authorized technical

personnel who have the requisite professional expertise to install electrical devices on

crane systems.

The device must be immediately taken out of operation in the event of damage or leaks in

the housing, cable or line entries.

Requirements resulting from provisions relating to cranes must be applied under all

circumstances.

All different components with safety functions must be taken into account of the safety

parameters (PL, PFHd, MTTFd), e.g. an optionally required additional external power supply

or output side follow-up circuit.

Further or supplementary protective measures may be required on the basis of risk

assessments for special areas of application, e.g. restart inhibit. According to

EN ISO 13849, an automatic restart may only take place, if no hazardous situation exists.

The distancing system may not be bridged.

The crane operator and/or the crane manufacturer must be aware and comply to the

information that applies to his area of deployment; this also applies to the product, cables

and lines installation

If condensation on the reflector surface cannot be excluded for an application with high air

humidity or/and abrupt change in temperature then an anti-fogging coated reflector version

must be used. A suitable reflector type will be model 4R100BLAF or model 18R100BLAF

(see catalog of applicable documents in section 4.9).

If the device is operated in conjunction with other components such as control systems or

sensors, the corresponding user instructions must be heeded.

2.4 Safety information

E_52692 Ref. 2019-29 6/24

Fotoelektrik Pauly GmbH, Wahrbrink 6, D-59368 Werne, T: +49 2389/402 27-70, F: +49 2389/402 27-77

http://www.fotoelektrik-pauly.de, eMail: info@fotoelektrik-pauly.de

Fotoelektrik Pauly – Light barriers

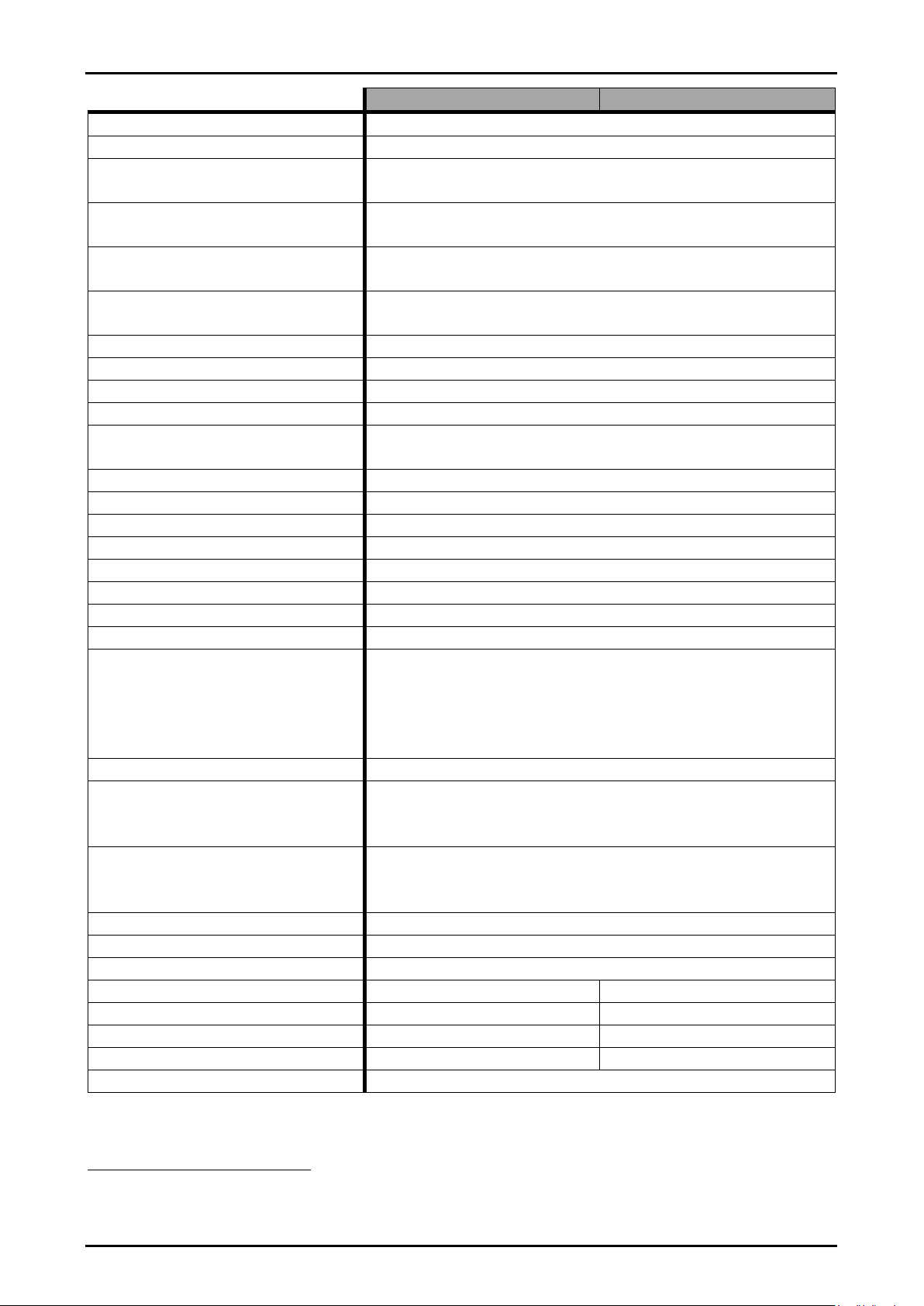

CPV1038

CPV1038*01

Certificate no.

HSM 09 079

Safety ratings of complete system

in acc. with EN 62061 respectively

EN ISO 13849-1

Safety Integrity Level (SIL)

SIL 1 in acc. with

EN 62061

Performance Level (PL)

PL c in acc. with

EN ISO 13849-1

Category

Cat. 2 in acc. with

EN ISO 13849-1

DC [%]:

60 in acc. With

EN ISO 13849-1

Safety ratings of the electronic

device

in acc. with EN ISO 13849-1

PFHd [h-1]:

6,61 x 10-7

MTTFd [a]:

86

nop [n/a]

8760

CCF

95

Mission time TM [a]

20

Maximum clearance distance

50 m

25 m

Optical systems

2

Safety-related tolerance of the

systematically distancing

accuracy

Maximum 9%

(in accordance with diagram fig. 4.4.3)

Safety-related tolerance of the

distancing accuracy due to

environmental influences

Additional 8%

(by reason of environmental influences,

e.g. fog, steam, smoke)

Power supply / output or current

consumption

(: Option)

230VAC ± 10 %

/ 16VA

115VAC ± 10 %

/ 16VA

42…48VAC ± 10 %

/ 16VA

24VDC + 20 % / - 10 %

/ ~ 700mA

Connection

2 x cable glands; terminal strip

Switching outputs

Main contact (to switch off the

crane movement)

for each optical system: 2 x relay NO contacts;

supervised and force guided

Status message

for each optical system: 1 x relay NC contact

Pollution warning

1 x relay change-over contact

3. Definitions – technical data

E_52692 Ref. 2019-29 7/24

Fotoelektrik Pauly GmbH, Wahrbrink 6, D-59368 Werne, T: +49 2389/402 27-70, F: +49 2389/402 27-77

http://www.fotoelektrik-pauly.de, eMail: info@fotoelektrik-pauly.de

Fotoelektrik Pauly – Light barriers

CPV1038

CPV1038*01

Switching capacity

Min. switching current

10 mA @ > 5 V

Main contact (to switch off the

travel movement)

AC1: 5 A @ 230 VAC DC1: 6 A @ 24 VDC

AC15: 2 A @ 230 VAC DC13: 1 A @ 24 VDC

Status message

AC1: 5 A @ 230 VAC DC1: 6 A @ 24 VDC

AC15: 1 A @ 230 VAC DC13: 1 A @ 24 VDC

Pollution warning

AC1: 6 A @ 250 VAC DC1: 6 A @ 24 VDC

AC15: 2 A @ 250 VAC DC131: 1 A @ 24 VDC

Electrcal life

DC1: > 1 x 106 @ max. switching capacity

AC1, AC15, DC13:> 2 x 105 @ max. switching capacity

Switching rate

3 / s

Access time

≤ 80 ms

Switching displays

Switch indicator

for each optical system: 2 x LED green

Level indicator (for sighting

reflector)

for each optical system: 4 x LED red (DIANA)

Transmitted light

850 … 880 nm, invisible

Steady light resistance

> 80 k lux

Operating mode

Alternating light, dynamic, continually self-testing

Signal mode

Dark switching

Housing

Cast aluminum

Protection mode

IP65 – protection against dust and jets of water

Weight

~ 5000 g (without adjustment flange)

Operating temperature

- 25 °C … + 60 °C, non-condensing

Climatic conditions

in acc. with EN 60721-3-3:1995, table 1

max. relative humidity (d): 95%;

max. solar radiation (j): 700W/m²;

Condensation (m): none;

Wind-driven precipitation (n): none;

Formation of ice and frost (including freeze-thaw) (p): none

Special functions

Exterior test system

The safety-related switching outputs will be switched off and

the movement of the crane will be halted if there is

insufficient detection capacity

Sabotage protection

Covering of light barriers is detected and will lead to the

switching off of the safety-related switching outputs and the

crane movement will be halted

Pollution warning

The light signal level is evaluated continuously

Accessories

Reflectors

(intended use as per the clearance distance)

4R100BL

0.5 … 25 m

1 … 25 m

4R100BLAF

0.5 … 25 m

1 … 25 m

18R100BL

0.5 … 50 m

1 … 25 m

18R100BLAF

0.5 … 50 m

1 … 25 m

Adjustment flange

JF57S

1

Regarding CPV1038*01: Device without optical sensing behaviour in range 1 to 6 m.

With spark suppressor only, see Section Fehler! Verweisquelle konnte nicht gefunden werden.

E_52692 Ref. 2019-29 8/24

Fotoelektrik Pauly GmbH, Wahrbrink 6, D-59368 Werne, T: +49 2389/402 27-70, F: +49 2389/402 27-77

http://www.fotoelektrik-pauly.de, eMail: info@fotoelektrik-pauly.de

Loading...

Loading...