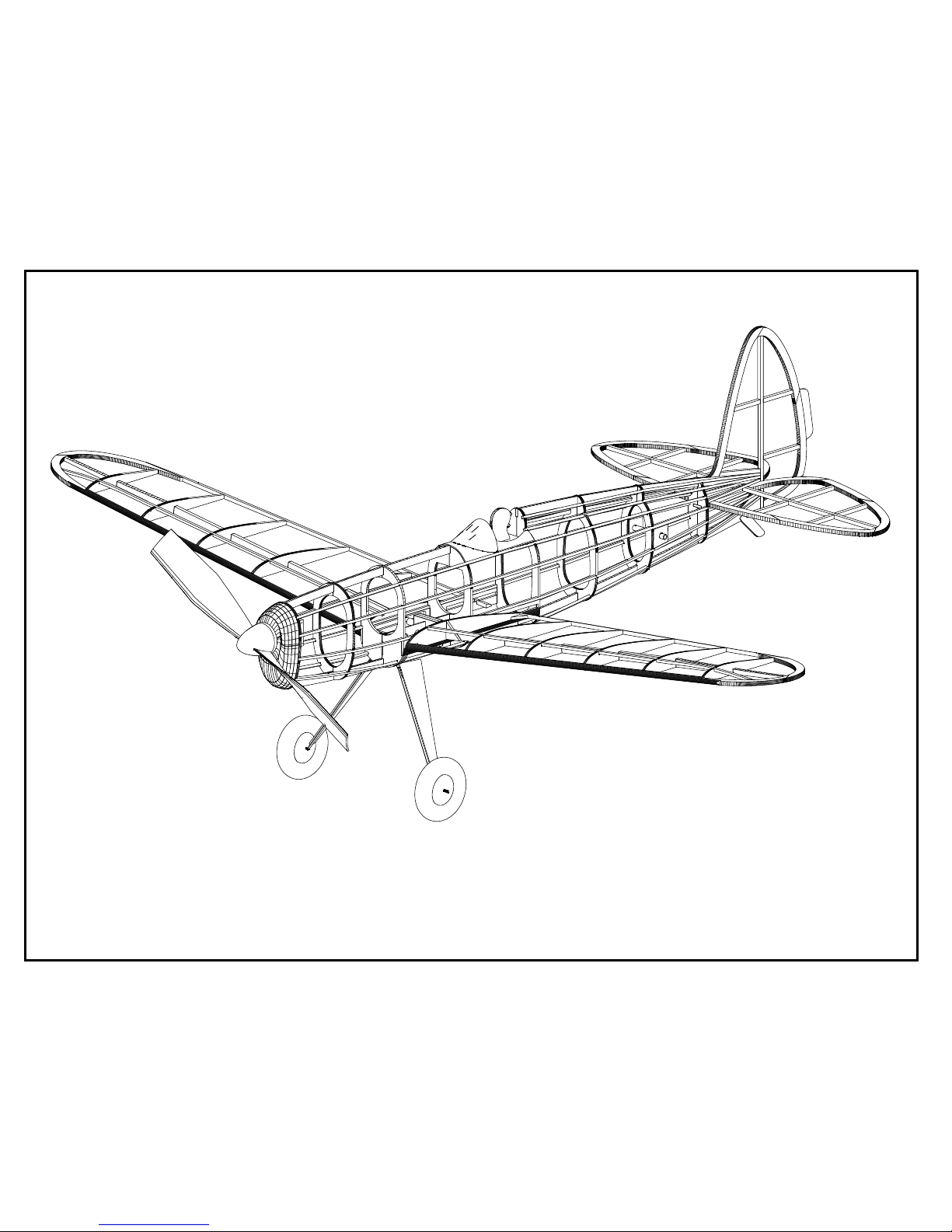

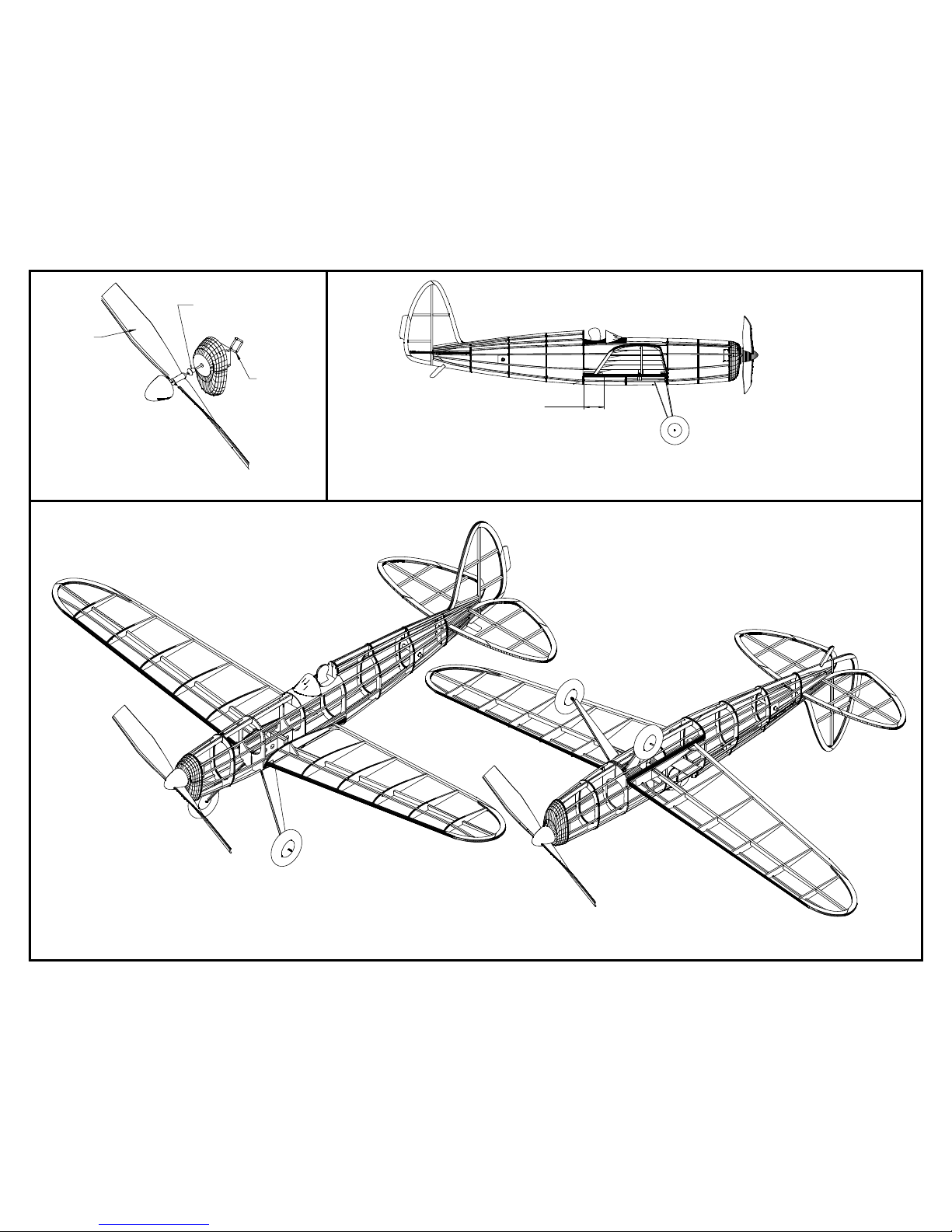

COMET SENIOR DART

REPRODUCTION

BY PAUL BRADLEY

ASSEMBLY GUIDE

JANUARY 2018

A RUBBER POWERED

24" WING SPAN MODEL

CHANGES MADE TO THE ORIGINAL

The following changes were made to the original Comet kit structural design. Most of the original kit design has been retained. The

changes made are intended to improve strength, make it easier to wind the model in a winding stooge, and in general take advantage of

techniques commonly used when building current day models.

1. The nose block has been set up for 3/32" blasa laminations rather than solid block.

2. The wing is set up to be removable rather than perminately attached to the fuselage. The ability to move the wing fore and aft hs been

retained.

3. A stab platform has been added to improve the strength and accuracy of the stab alignment.

4. 1/16" square sub spars have been added to the top of the wing to improve strength and to help reduce tissue sag between the ribs.

5. A motor peg has been used to anchor the rear end of the rubber motor as opposed to the method shown on the original kit plan. Sheet

balsa motor peg supports have been added.

6. Piano wire landing gear legs are used rather than straight pins through balsa legs. Retention of the landing gear legs has also been

strengthened.

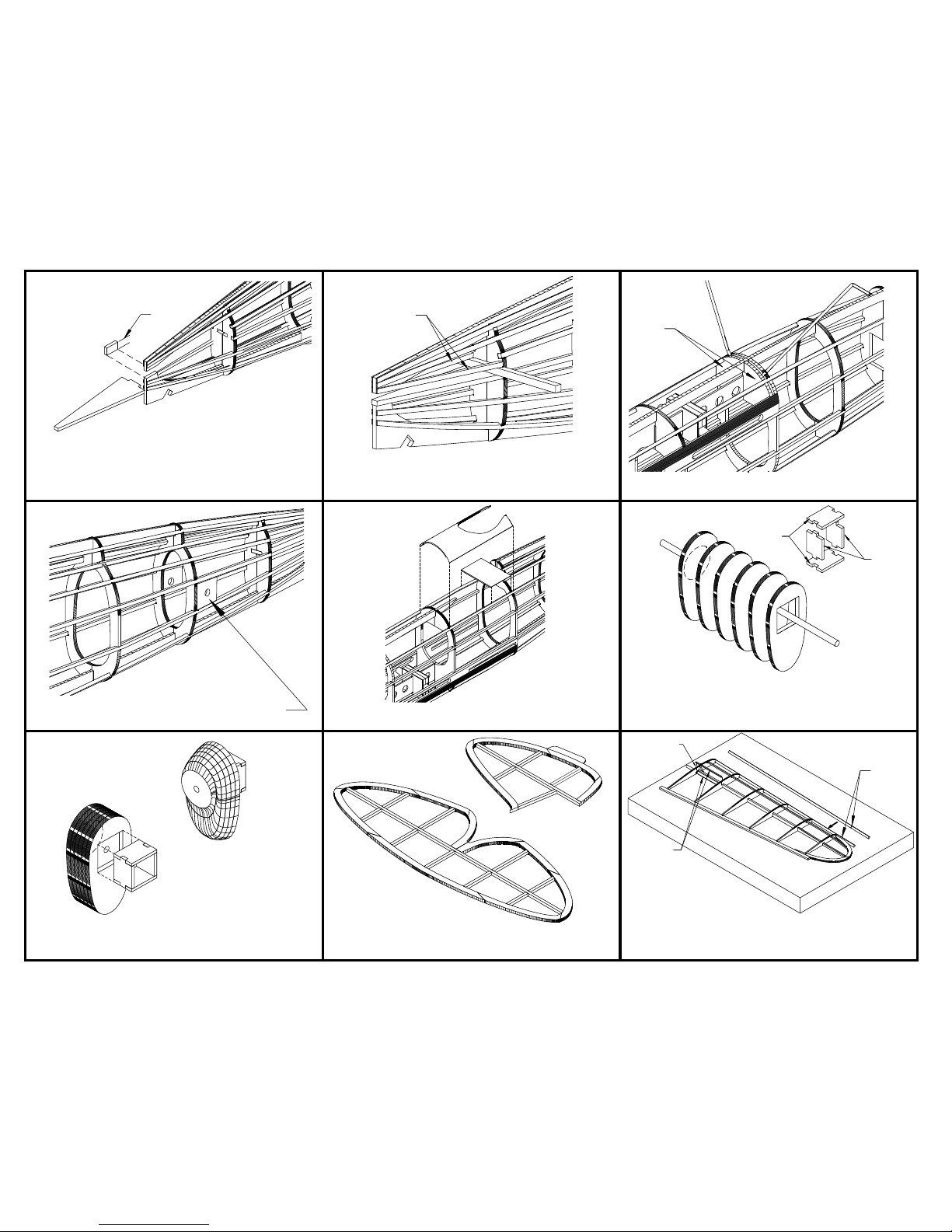

1.

Tape the six plan pages together to form three building plan pages.

Use the "+" marks for alignment of the pages.

Pin the keel parts to the plan. Glue the keel joints as the parts

are placed on the plan. Also glue the right former halves to the

keel using the plan as a location guide.

2.

3.

4.

5.

6.

7.

8.

9.

Remove the fuselage from the assembly fixture. Glue the top two

rear stringers on each side to the assembly.

Remove the fuselage assembly from the plan. Glue the wing

mount assembly to formers 3 and 4. Make sure the end of B-5

with the 3/64" hole faces former 3.

If you don't already have a fuselage assembly fixture, build one

like the one shown in the sketch. The cross pieces are held in

place with rubber bands. Place the fuselage on the fixture and

pin the keel to the fixture cross pieces. Add the main stringers

and the wing plate. Do not add the two top rear stringers at this

time.

Remove the fuselage assembly from the fixture. Flip the

assembly and insert the fixture cross pieces. Glue the stringers

in place. Again, do not glue the two top rear stringers to the

assembly at this time.

Assemble the wing mount components. The wing joiner slides

fore and aft on the plywood keel B-5. Make sure the wing joiner

moves easily on B-5.

1/64" Ply

5/32" OD

Aluminum

3/32" Balsa

Bend the landing gear legs from 1/32" piano wire. Insert the

gear legs through the hole in B-5. Glue the left side of each

former to the corresponding right side former. Line up the

landing gear legs and glue them to former 3.

3/64" Hole

Glue

Wing plate

Wing plate

Sand the stringers to a taper at the rear of the fuselage. Also

sand the wing plates so they blend with the fuselage curve.

Sand

These stringers

end at former 8

These stringers

end at former 8

3

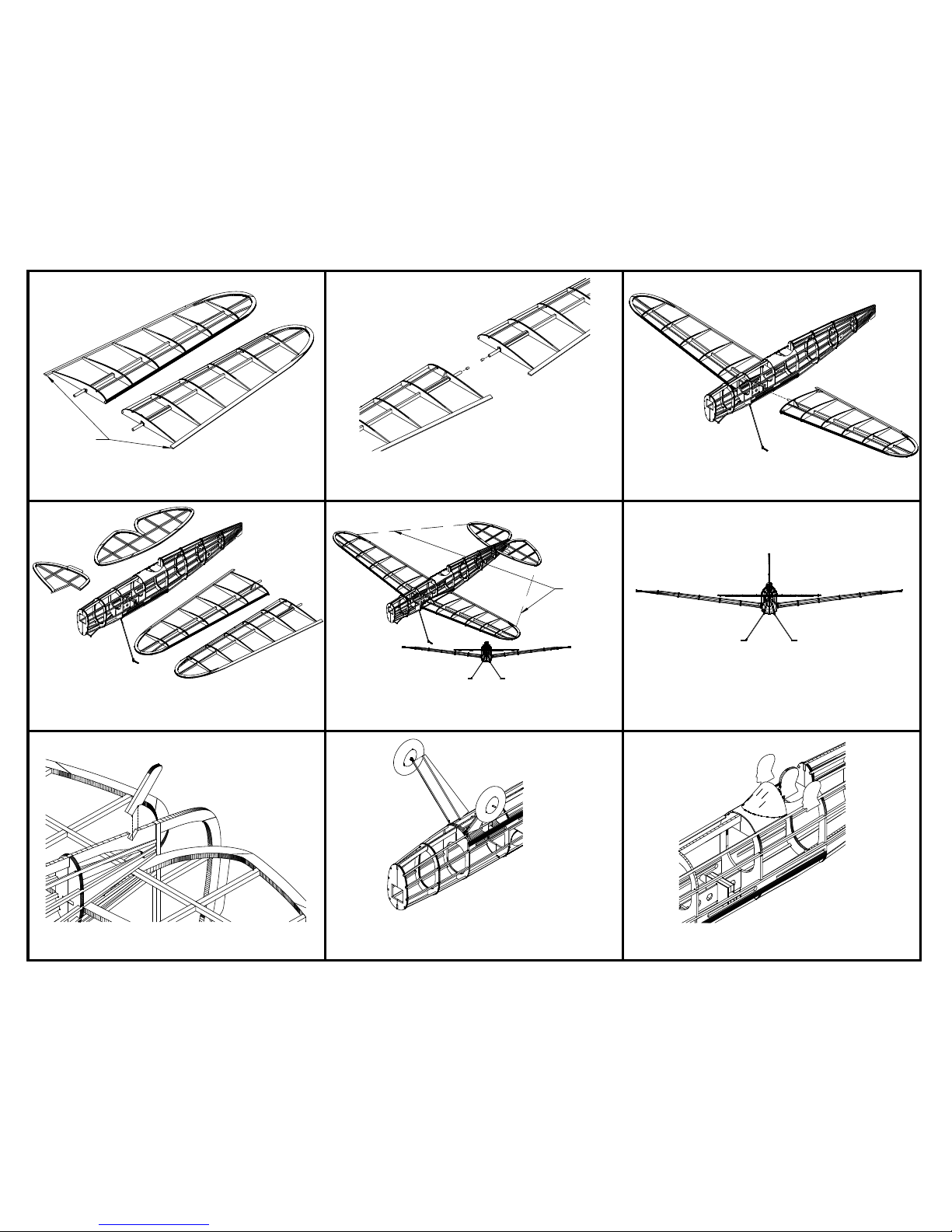

10.

11.

12.

13.

14.

15.

16.

17.

18.

Remove a 5/32" wide piece from the rear of the lower keel piece.

Start at the joint between the lower and upper keel pieces. Glue

the stab platform to former 8 and the lower keel piece.

Glue formers 3A behind the landing gear legs.

Build the wing panels over the plan. Use W5 to set the angle of

rib A. The 1/8" diameter wing tubes are secured to the main

spar with strips of 1/16"x1/32" balsa.

Glue the nose block key to the back of the nose block. It fits inside

the square hole. Once the glue is dry, shape the nose block using

the plan top and side views as a guide.

Place a strip of 3/32" square balsa at the leading edge of the stab

platform. Glue a 1/16" square stringer on each side of the fuselage

as shown. Use the piece of 3/32" balsa as a guide. Once the

stringers are in place remove the piece of 3/32" balsa.

5/32"

Build the stab and fin. Sand the stab and fin to a symmetrical airfoil

shape (not shown in these illustrations).

Glue the motor peg supports to the fuselage on each side as

shown.

Add these

stringers

3A

Glue the pilot platform and 1/32" balsa cockpit faring to the

fuselage.

NB1

NB2

Flatten LE

here

1/16"x1/32" top

and bottom

W5

Glue the nose block laminations together. The lamination with the

square square hole is the back. The lamination with the circle

marked on a face is the front. Use a length of 1/8" dowel to align

the laminations. Remove the dowel before the glue sets. Also glue

the nose block key pieces together (NB1 and NB2).

19.

20.

21.

22.

23. 24.

25.

26.

27.

Remove the wing panels from the plan when the glue is dry. Shape

the LE, TE, and tips. Do not sand the TE extensions beyond rib A.

They ride in the wing plate slot and should remain rectangular.

A .1" x 1/8" round magnet is glued in center section end of each

wing panel aluminum tube. Orient the magnets so the wing panels

will attract each other. The tubes will have to drilled out for the

mgnets.

Check the fit of each wing panel in the wing joiner and the trailing

edge slots in the fuselage. Make any necessary adjustments.

Cover the wings, tail surfaces, and fusealge with tissue. Cut the

fuselage tissue away from the openings in the wing plates. This

illustration and subsequent illustrations will not show the tissue

covering.

Insert the wings into the wing joiner. Slide the stab into the stab

slot. Check to be sure the stab is square with the wings when

viewed from the rear. Adjust the stab slot if necessary. When the

alignment is correct, glue the stab in place.

Glue the fin to the fuselage. When viewed from the rear, make sure

the fin is vertical.

Glue the tail skid into the slot at the rear of the bottom fuselage keel

piece B-4.

Install the wheels. The original plan called out 1 1/2" diameter

wheels. Using 1" diameter wheels will be lighter and less drag. Also

install the landing gear leg covers. Wrap tissue around the covers

and leg wire to add strength.

Glue the pilot profiles to each side of the 1/16" balsa profile pilot

head. Glue the pilot head to the pilot platform. Also glue the

windshield to the fuselage using an adhesive like Forumula 560.

Equal

Lengths

DO NOT SAND

THE TE EXTENSIONS

The original kit did not show where the Center of Gravity (CG) should be placed. The wing is moved forward and back to achieve a

smooth glide slope when a loop of rubber is in the fuselage. The magnets in the wing tubes will pull the wing panels tight against the

fuselage. Once you have the best position for the wing established, mark the location on the fuselage. The wing joiner can also be

glued to the beam if desired.

28.

29.

The propeller/nose block assembly is set up as shown. The prop

shaft hook can be your preferred style.

Peck thrust bearing

for 3/64" shafts

Spinner is optional

3/64" Piano wire

prop shaft

7" Prop

Move the wing forward and back

to obtain a smooth glide profile.

Loading...

Loading...