Patty-O-Matic Protege Owner's Manual

Patty-O-Matic, Inc. ®

The World’s Finest Food Machines

Model Protégé

Owner’s Manual

Revised April 2006

Route 547 P.O. Box 404 Farmingdale NJ,07727

Tel: (732) 938-2757 Fax: (732) 938-5809

Toll Free in USA: 877-938-5244

Congratulations on the purchase of your new Model Protégé Patty

Molding Machine from Patty-O-Matic, Inc! The Model Protégé will form,

interleave paper between, and stack food patties. This machine is designed

for easy operation and cleaning. Please become familiar with this manual

and your machine will give you years of service.

The Model Protégé is shipped to you in at least two cartons which

contain the patty machine, feed tray complete with mold plate guard, parts

box, receiving table, and this manual. If you purchased your machine with

any other accessories, such as a mobile table or patty paper, these items may

be in a separate carton. The parts box that comes with the machine should

include a bottle of machine lubricant, a speed driver, samples of patty paper,

and a spare parts kit.

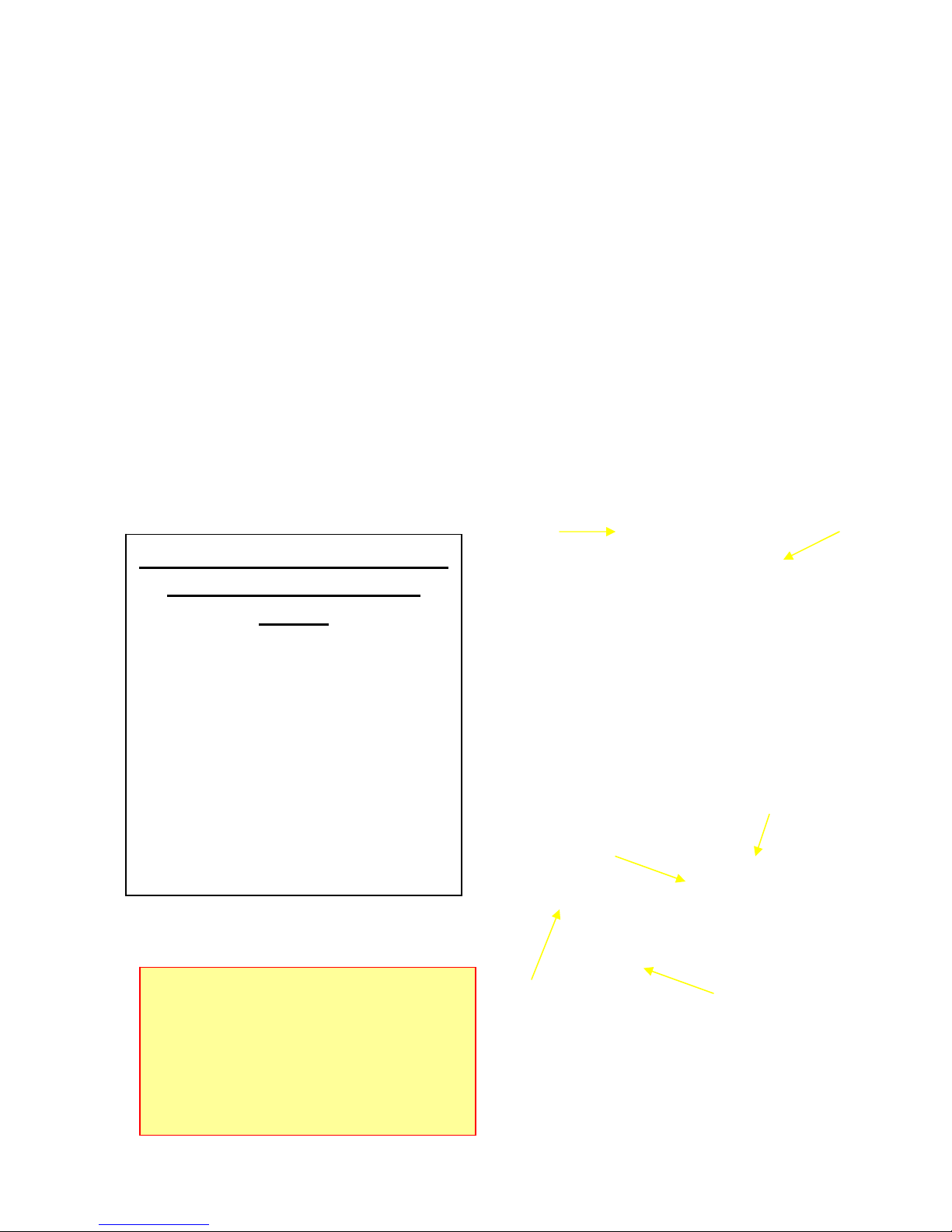

Your machine is equipped with one interlock. This interlock is

located on the top left side of the machine. The Feed Tray with the attached

Mold Plate Guard must be installed on the machine to engage the interlock

on top of the machine.

Installing the Feed Tray with

Interlock

Tower

2

Hopper

the attached Mold Plate

Guard

Place tube of Feed Tray over the

Hopper. Line up the plunger that

is located on the underside of the

feed tray with the Tower Sleeve.

This will push down on the

interlock Tower located inside

the Tower Sleeve of the

Machine.

DO NOT ATTEMPT TO RUN THIS

MACHINE WITHOUT THE FEED

TRAY AND THE MOLD PLATE

GUARD IN THEIR PLACE!!

FAILURE TO DO SO COULD

RESULT IN SERIOUS BODILY

INJURIES!!

Feed Tray

Plunger

located

here

Feed Tray Guard

Mold Plate

Guard

3

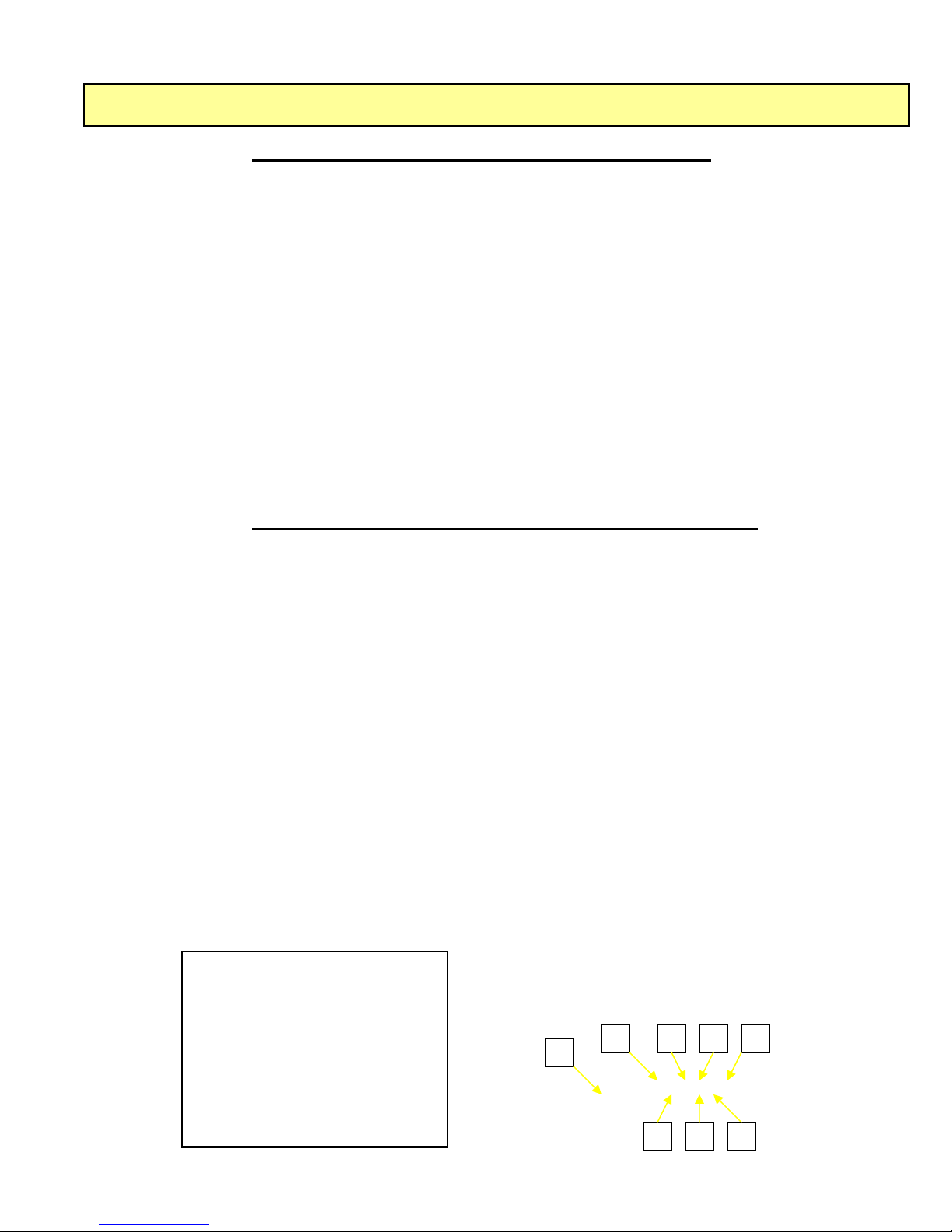

Please become familiar with some of the parts

Pressure

Hopper

Mold Plate Assembly Underside View

of your machine prior to operation.

Feeder

Mold Plate

Protégé

Back Drive

T-Knob

Hole

Feeder

Washer

Meat Stop

Mixer

Collar

T-Knob

Feeder Top

View

Feeder Side

Transition Plate Protégé Mold Plate Assembly Side View

Ring Pin Pressure Plate

Feed Tray Guard and Mold Plate Guard are installed for

your safety. Do not tamper with them in any way!

Feed Tray Guard

Feed Tray with

Mold Plate Guard

Protégé Knock Out

Cup Assembly

17

4

Proper Label Location for a Model Protégé

1

2

3

9

4

10

7

8

13

16

18

10

14

11

12

5

14

15

6

2

5

Item # Description Part #

1. Danger Tag 514-09

2. Warning Orange 514-02

3. Patty-O-Matic 514-08

4. Warning 514-06

5. Danger Label 1 514-03

6. Danger Label 2 514-00

7. Serial Tag 514-15

8. Store Tool 514-14

9. Warning Manual 514-01

10. Danger on/off 514-05

11. Do Not Pressure Wash 514-04

12. Keep Hands 514-07

13. Pro Warning and Always 514-13

14. Danger Keep Clear 514-16

15. Pro Position 514-11

16. Pro Caution TI Plate 514-10

17. Pro Risk 514-17

18. Pro If Sign is Visible 514-14

These Labels are available through the

factory, at no charge. Contact the factory for

replacements if something is to happen to the

originals. Please contact the factory for

further information:

Toll Free in the U.S.A. 877-938-5244

Outside the U.S.A. 732-938-2757

6

7

Always Disconnect Machine From its Power Source Before Cleaning or Adjusting!

Proper Procedure for Operating a Model Protégé

When the Model Protégé is fully assembled with all guards secured in their proper

place, put product in the Feed Tray. Push the product through the holes in the Feed Tray

Guard into the hopper opening. DO NOT PUT HANDS OR FINGERS, OR

FOREIGN OBJECTS, SUCH AS STOMPERS OR PLUNGERS INTO THE

HOPPER. THERE ARE NO STOMPERS OR PLUNGERS NEEDED WHEN

USING THIS UNIT, THEREFORE NONE ARE SUPPLIED. After you allow

product to drop into hopper turn the machine on by moving the On/Off switch down

towards the on position. The machine may need to cycle a few times to prime the

machine with product. As patties are being formed continue to push product through the

holes and under the Feed Tray Guard. Patty paper may be added to the machine as

needed. The machine can hold up to 1 inch of paper at a time.

As the Mold Plate moves back and forth to form patties, a thin coating of product

may accumulate over its surface. This coating may also accumulate on the edges of the

Knock Out Cup or on the front of the hopper and spacer plate. This accumulation does

occur on all molding machines. It is nothing to be concerned with. There are certain

machine settings that may lessen this accumulation.

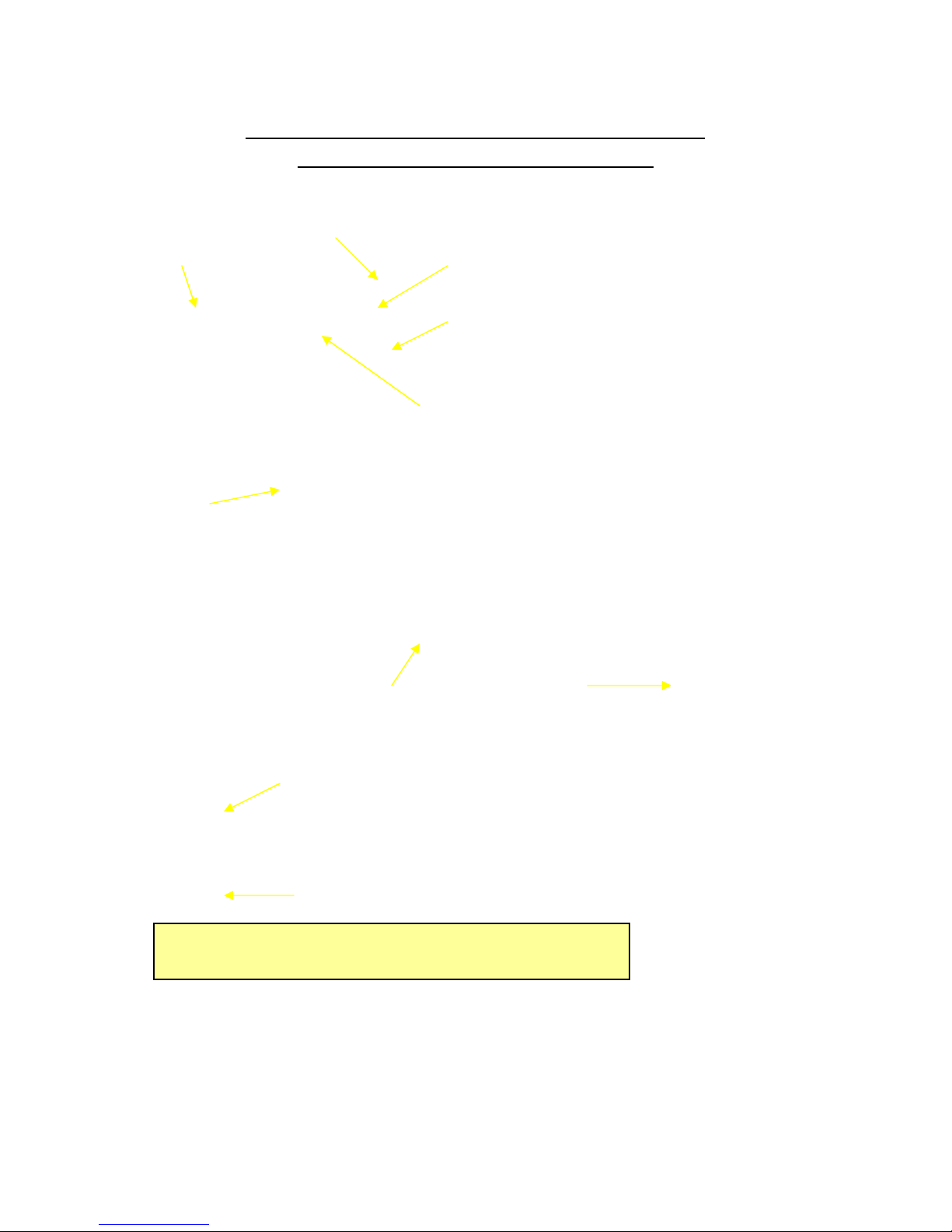

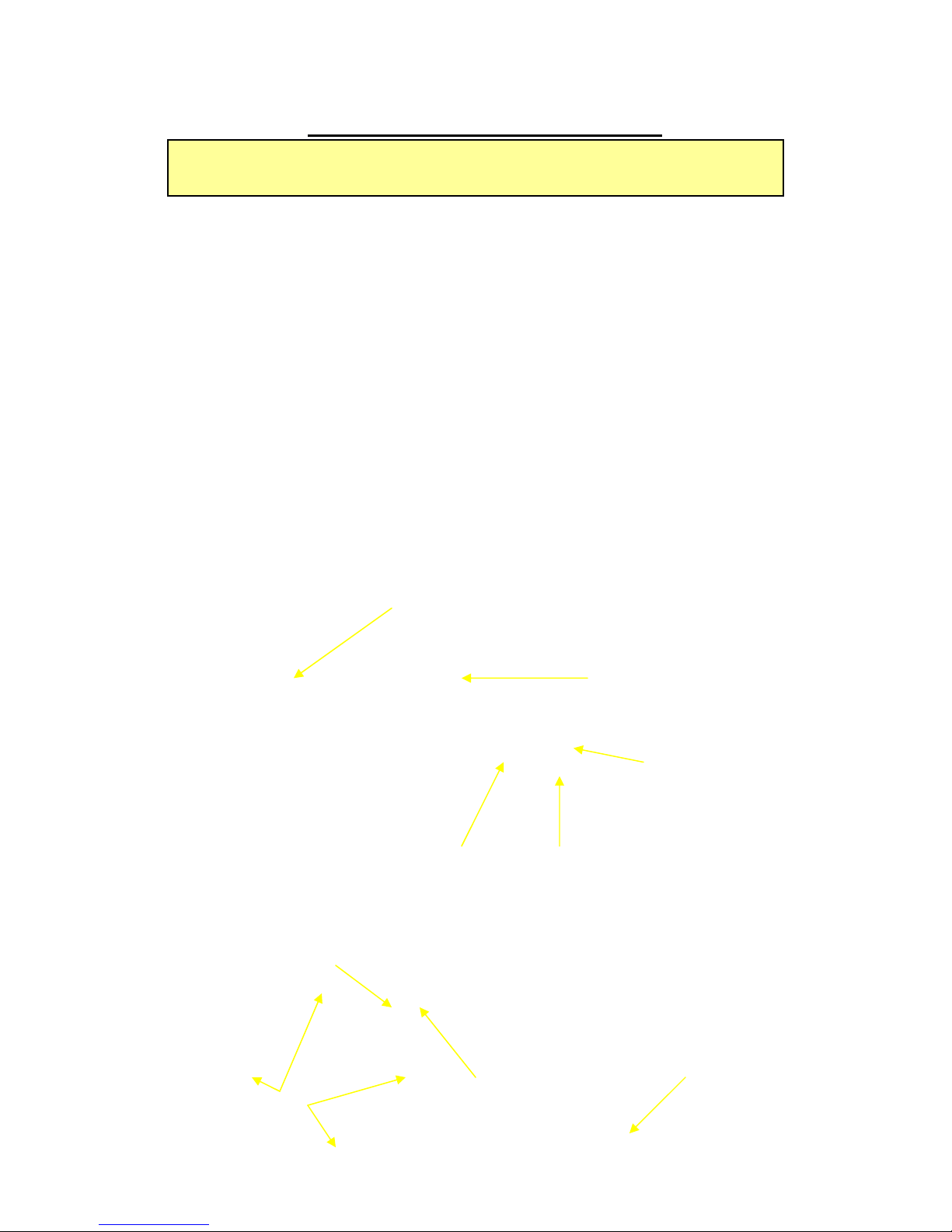

Setting the Ring Pin Pressure Plate for your Patty Size

The Purpose of the Pressure Plate is to entrap the amount of product necessary to form your patty.

This part is also used in controlling the firmness of your patty. With the Pressure Plate set

correctly you will in turn have:

- less leakage, oozing, and coating of parts

- less kneading of your product

- and less strain on your machine.

-----------------------------------------------------------

picture. This will allow the Pressure Plate to move all the way into the hopper and stop into the

welded stud which is the maximum setting.

ounce hole.

If you would like to have a tightly packed patty, move the ring pin to a higher than

recommended setting for that particular weight.

THESE ARE ONLY RECOMMENDED SETTINGS. A VARIETY OF CIRCUMSTANCES

ggggggggggggggggggggggg

MAY CALL FOR YOU TO INSERT THE RING PIN IN A DIFFERENT LOCATION.

If your patty weight is 8 ounces, keep the ring pin in the storage hole as described in the

If your patty is 4 ounces remove the ring pin from the storage hole and place it in the 4

If you patty weight is to be 6 ounces, place the ring pin in the 6 ounce hole.

1 - Ring Pin in storage hole

2 - 2 ounce hole

3 - 3 ounce hole

4 - 4 ounce hole

5 - 5ounce hole

6 - 6 ounce hole

7 - 7 ounce hole

8 - 8 ounce welded stop

1

8

6

3

5

7

2

4

8

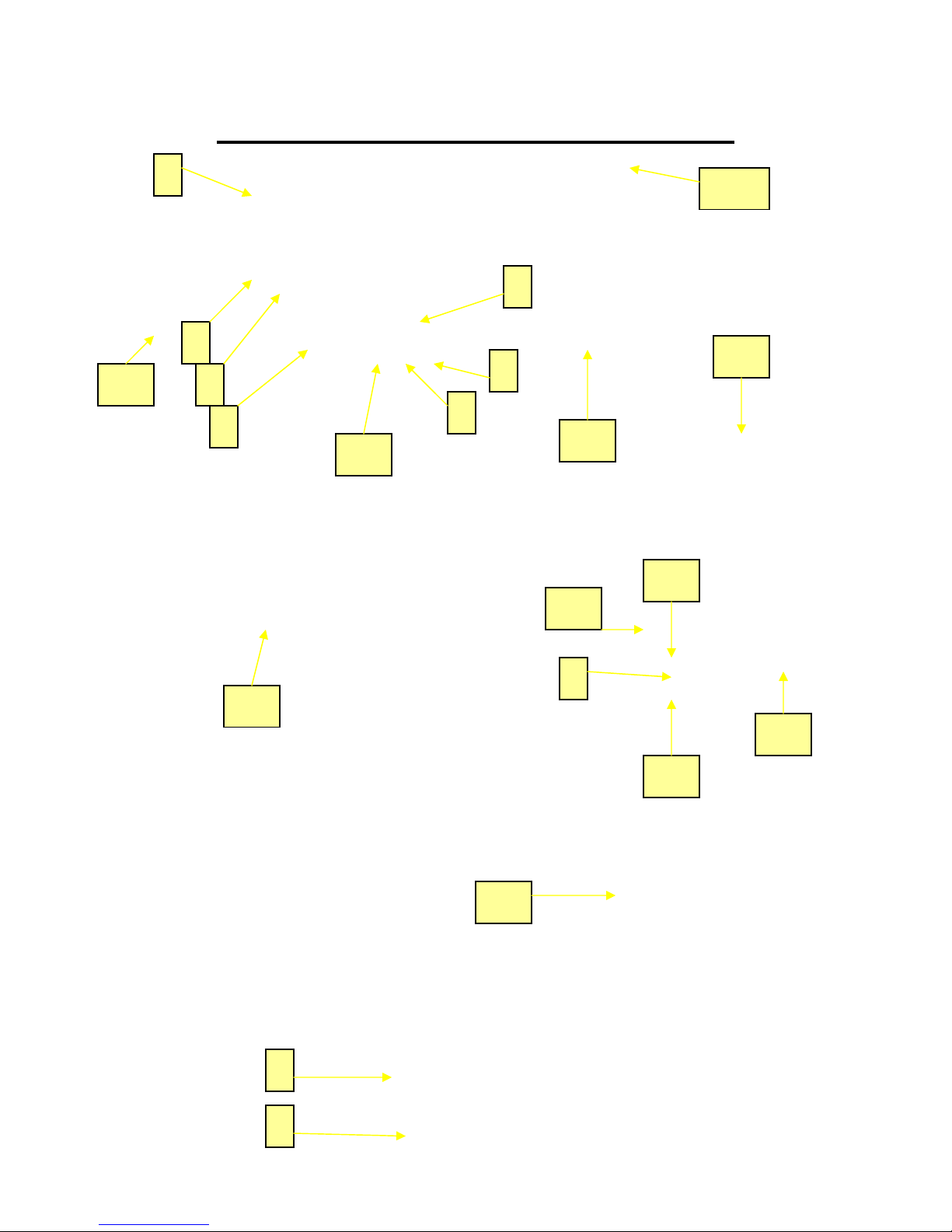

Changing Your Machine’s Mold Plate

Always disconnect the machine from its power source

First remove the T-Knob from the Back Drive of the Mold Plate, then pull the

Mold Plate out from the rear of the machine. If you prefer, remove the Mold Plate from

the machine without removing the T-Knob from the Back Drive. Simply unhook

Connecting Arm from the T-Knob and slide the Mold Plate from the rear of the machine.

before attempting to change any of the machines component parts.

When changing the Mold Plate always use the corresponding Transition Plate.

The thickness fraction stamped on the Transition Plate should match the fraction stamped

on the front right corner of the Mold Plate. For example: if your Mold Plate is stamped

“4F ½” then the Transition Plate should be stamped “1/2” The Transition Plate is

removed by removing the four Hopper hold down Bolts and the Feeder Hold Down Bolt.

Once these bolts are removed lift the Feeder from the Hopper and the hopper from the

machine. Once the Hopper and Feeder are removed lift the Transition Plate and repl ace it

with the new one. Make sure the fraction that is stamped on the plate is facing the front

of the machine. After putting the new Transition Plate in place replace the Hopper and

Feeder, then install the same thickness mold plate mold plate. Be sure to replace the

Knock Out Cup to match the new Mold Plate size.

Knock Out

Cup

Transition

Plate

Back Drive

Connecting

Arm

Connecting Arm

T-Knob

Feeder Bolt

Transition Plate Shown

in the Up Position

Feeder

Hopper

Bolt Holes

Thickness

Stamp

Loading...

Loading...