Page 1

USER

MANUAL

MODEL 1186RC

G.703/G.704 to Multi-mode

Fiber Rack Mount Modem Card

Part# 07M1186RC-A

Doc# 017171UA

Revised 12/01/00

SALES OFFICE

(301)975-1000

TECHNICAL SUPPORT

(301)975-1007

http://www.patton.com

An ISO-9001

Certified

Company

Page 2

TABLE OF CONTENTSTABLE OF CONTENTS

Section Page

1.0Warranty Information.............................................................2

1.1Radio and TV Interference

1.2. CE Notice

1.3Service

2.0General Information...............................................................4

2.1Features

2.2Description

3.0Configuration.........................................................................5

3.1Configure the Hardware DIP Switches

3.1.1 Configuration of the Model 1186RC

3.2 Configure the Rear Interface Card

4.0Installation.............................................................................9

4.1The Model 1001R14 Rack Chassis

4.1.1 The Rack Power Supply

4.1.2

Installing Model 1186RC Series Into the Chassis

4.2 Connect the G.703/G.704 Network

4.2.1 Connect Twisted Pair (120 Ohm) to G.703/G.704

Network

4.2.2 Connect Coax Cable to the G.703/G.704 Network

4.3 Connect the Fiber Interface

4.3.1 Universal ACPower (100-240VAC)

4.3.2 DC Power

5.0Operation.............................................................................13

5.1LED Status Monitors

5.2 Test Modes

5.2.1 Local Loopback

5.2.2 Remote Digital Loopback

5.2.3 V.52 Test Pattern Generator

Appendix A - Specifications........................................................17

Appendix B - Factory Replacement Parts and Accessories.......19

1

1.0 WARRANTY INFORMATION 1.0 WARRANTY INFORMATION

Patton Electronicswarrants all Model 1186RC components to be

free from defects, and will—at our option—repair or replace the product should it fail within one year from the first date of shipment.

This warranty is limited to defects in workmanship or materials,

and does not cover customer damage, abuse or unauthorized modification. If this product fails or does not perform as warranted, your sole

recourse shall be repair or replacement as described above. Under no

condition shallPatton Electronicsbe liable for any damages incurred

by the use of this product. These damages include, but are not limited

to, the following: lost profits, lost savings and incidental or consequential damages arising from the use of or inability to use this product.

Patton Electronicsspecifically disclaims all other warranties,

expressed or implied, and the installation or use of this product shall

be deemed an acceptance of these terms by the user.

1.1 RADIO AND TV INTERFERENCE

The Model 1186RC generates and uses radio frequency energy,

and if not installed and used properly—that is, in strict accordance with

the manufacturer's instructions—may cause interference to radio and

television reception. The Model 1186RC has been tested and found to

comply with the limits for a Class A computing device in accordance

with the specifications in Subpart J of Part 15 of FCC rules, which are

designed to provide reasonable protection from such interference in a

commercial installation. However, there is no guarantee that interference will not occur in a particular installation. If the Model 1186RC

does cause interference to radio or television reception, which can be

determined by disconnecting the unit, the user is encouraged to try to

correct the interference by one or more of the following measures:

moving the computing equipment away from the receiver, re-orienting

the receiving antenna and/or plugging the receiving equipment into a

different AC outlet (such that the computing equipment and receiver

are on different branches).

1.2 CE NOTICE

The CE symbol on your Patton Electronics equipment indicates

that it is in compliance with the Electromagnetic Compatibility (EMC)

directive and the Low Voltage Directive (LVD) of the European Union

(EU). A Certificate of Compliance is available by contacting Technical

Support.

2

Page 3

1.3 SERVICE

All warranty and non-warranty repairs must be returned freight

prepaid and insured to Patton Electronics. All returns must have a

Return Materials Authorization number on the outside of the shipping

container. This number may be obtained from Patton Electronics

Technical Support at:

tel: (301)975-1007

email: support@patton.com

www: http://www.patton.com

Patton Electronics' technical staff is also available to answer any

questions that might arise concerning the installation or use of your

Model 1186RC. Technical Support hours: 8AM to 5PM EST, Monday

through Friday.

3

2.0 GENERAL INFORMATION2.0 GENERAL INFORMATION

Thank you for your purchase of this Patton Electronics product. This

product has been thoroughly inspected and tested and is warranted for

one year parts and labor. If any questions or problems arise during installation or use of this product, please do not hesitate to contact Patton

Electronics Technical Support at (301) 975-1007.

2.1 FEATURES

· ITU G.703/G.704 (E1) transport over Multi-Mode fiber

· Full duplex operation over a single string of fiber

· Multi-Mode fiber with max distance 2.5km (1.5 miles)

· Two fiber connection options available: ST or SMA

· 120 Ohm (RJ-48C) and 75 Ohm (dual coax) G.703/G.704 terminations

· Clocking Options: Internal, Network (G.703/G.704) or Receive

Recover (fiber link)

· Optional AMI or HDB3 G.703/G.704 data coding

· Six Front Panel LED status indicators: Fiber line, E1 line, LOS, TM,

ER, and NS

· Testing/troubleshooting tools: V.54 compliant local/remote loop

backs, V.52 compliant 511/511E test patterns

2.2 DESCRIPTION

The Patton Electronics Model 1186RCoffers the ability to extend E1

(G.703/G.704) service over Multi-Mode fiber. A pair of 1186RC Multi-Mode

Fiber Modems provides G.703/G.704 Network "extension" between remote

locations (Figure 1).

The Model 1186RC is designed to transmit/receive G.703/G.704 data

over one string of fiber. The Model 1186RC allows transmission over MultiMode fiber with distances up to 2.5 km (1.5 miles). The clocking options

for the Model 1186RC include Internal, Network (from G.703/G.704

Network) or Receive Recovered clock (from fiber line).

The Model 1186RC also incorporates V.54 compliant local/remote

loopbacks and V.52 compliant 511/511E test patterns. Front panel switches

activate test patterns and loopbacks. LED status indicators monitor the

fiber and G.703/G.704 links. The Model 1186RC is supplied with a

1001RCM703ST (with an ST fiber connector) or a 1001RCM703SMA (with

an SMA fiber connector) rear card.

4

NOTE: Packages received without an RMA number will not be

accepted.

Figure 1. Network extension remote location

G.703/G.704 G.703/G.704

Fiber Optic Line

Modem

Modem

Page 4

3.0 CONFIGURATION3.0 CONFIGURATION

The Model 1186RC is equipped with eight DIP switches, which

allow configuration of the unit for a wide variety of applications. This

section describes the switch location and explains all possible configurations.

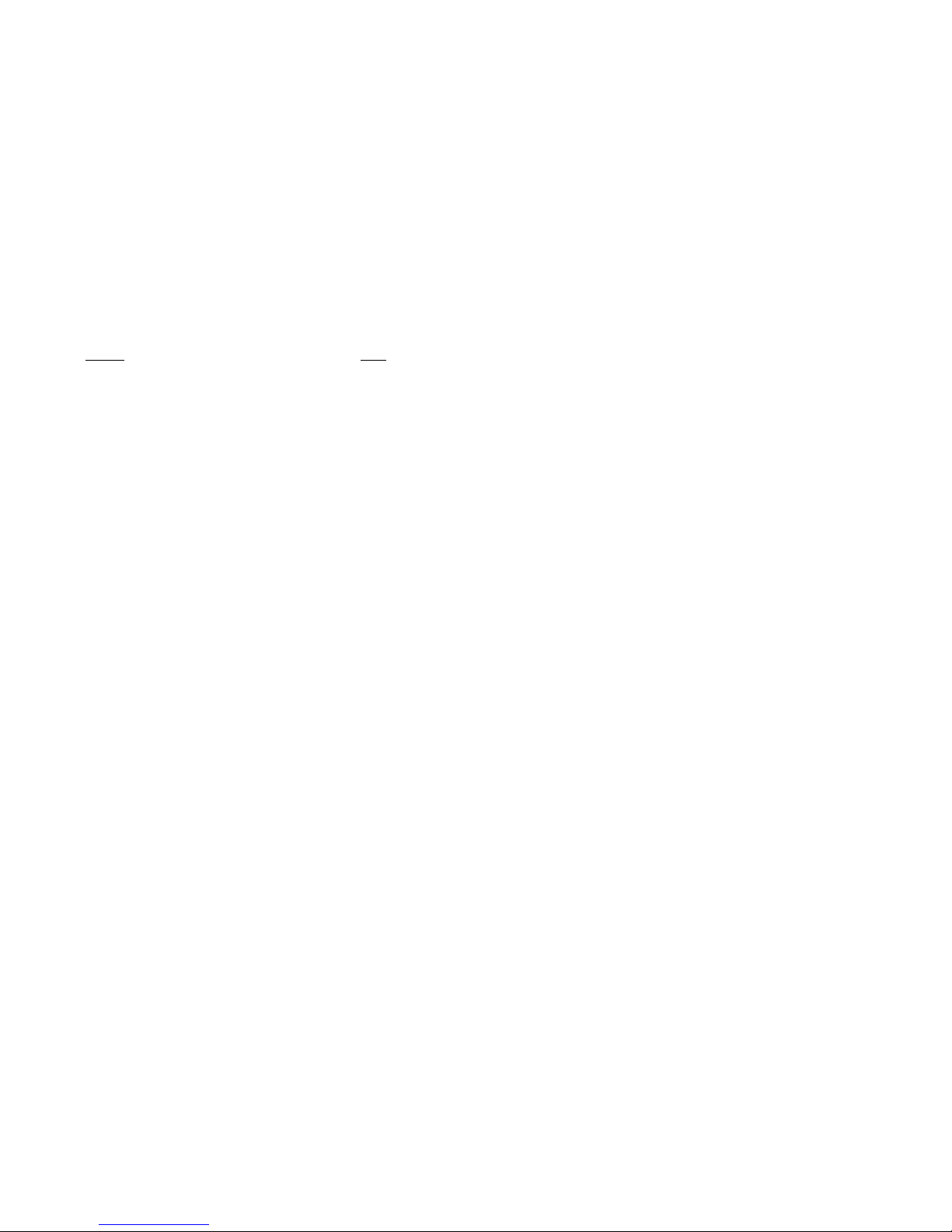

3.1 CONFIGURE THE HARDWARE DIP SWITCHES

The 8 external dip switches are accessible from the underside of

the Model 1186RC (See Figure 2, below).

Figure 3 shows the orientation of the DIP switches in the “ON” and

“OFF” positions.

5

Figure 3. Close-up of configuration switches

Figure 2.Underside of Model 1186RC, showing location of the DIP Switches

Front

Rear

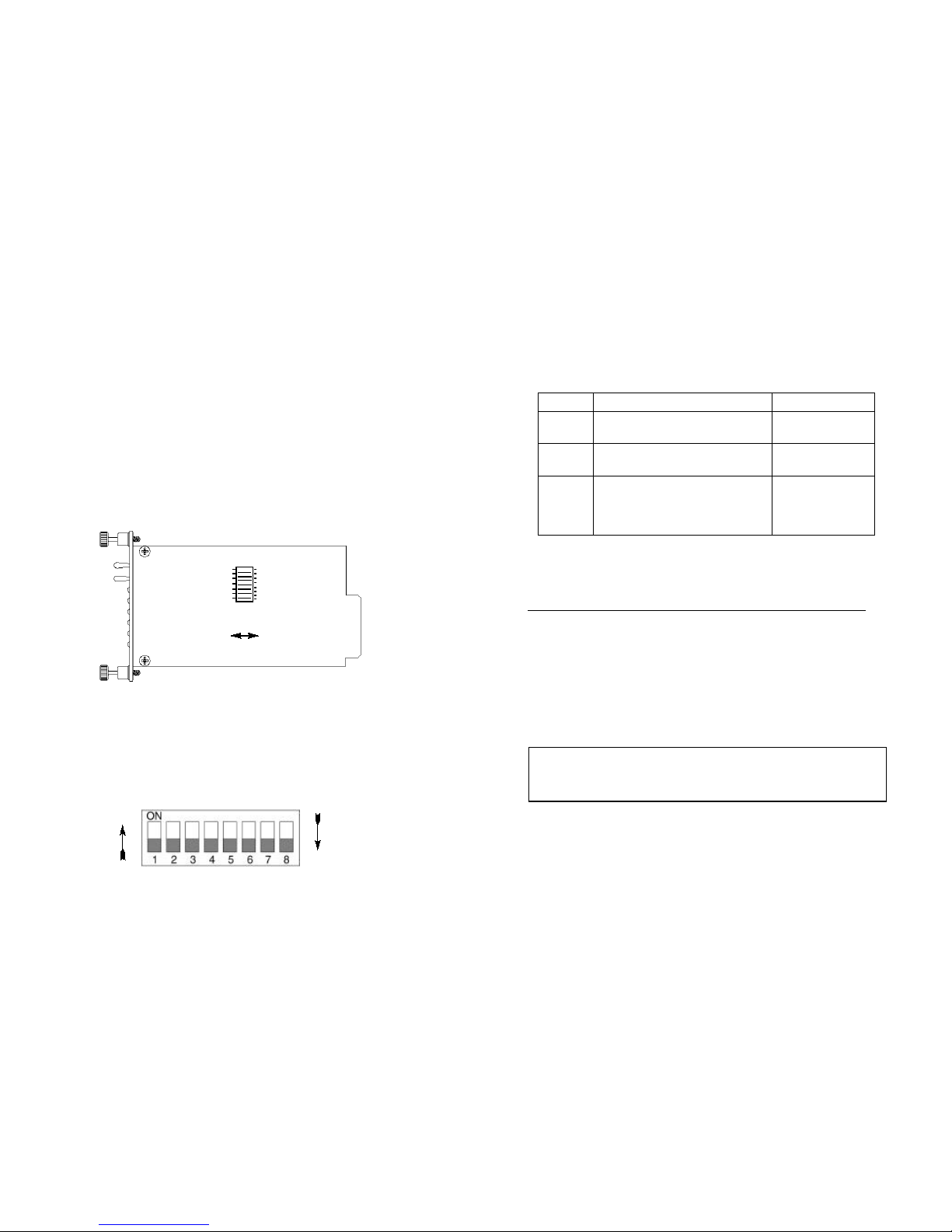

3.1.1 Configuration of Model 1186RC

Switches S1 through S8 may be used to configure clocking modes

and line coding. Default settings of the switches are shown in the table

below. A description of the switch options follows the table.

Switches S1 and S2: Clock Mode

Use Switches S1 and S2 to determine clock mode of the 1186RC.

S1 S2 Setting Description

OnOnInternal Transmit clock generated internally

OnOffReceive Recover Transmit clock derived from the line

OffOn Network Transmit clock derived from G.703/G.704

equipment interface

Off OffNot Used Internal use only

Switch S3 and S4: Line Coding Options

Use Switches S3 and S4 to determine whether the G.703/G.704 line

coding is HDB3 or AMI (for older telecommunications equipment). The

line coding must be the same line coding prescribed by the NAP

(Network Access Provider). Most applications will use HDB3.

High Density Bipolar 3 (HDB3): In HDB3 coding, the transmitter

deliberately inserts a bipolar violation when excessive zeros in the

data stream are detected.

6

Position Function Default Setting

S1

Clock Source

ON

S2

Clock Source

ON

S3

Line

OFF

S4

Coding

OFF

S5

S6

Reserved for Future Applications

OFF

S7

S8

OFF

ON

S1

Note: The Model 1186RC units are intended to work in pairs. When setting the clock modes for the Model 1186RC units, one end of the link

must be set for Receive Recover and the other end must be set for either

Internal or Network.

}

}

Internal

Clock

HDB3

On

Off

Page 5

The receiver recognizes these special violations and decodes

them as zeros. This method enables the network to meet minimum pulse density requirements. Use HDB3 unless AMI is

required in your application.

Alternate Mark Inversion (AMI): AMI defines a pulse as a

“mark,” a binary one, as opposed to a zero. In an E1 Network connection, signals are transmitted as a sequence of ones and zeros.

Ones are sent as pulses, and zeros are sent as spaces, i.e., no

pulse. Every other pulse is inverted from the previous pulse in

polarity, so that the signal can be effectively transmitted. This

means, however, that a long sequence of zeros in the data stream

will cause problems, since the modem receiving the signal relies

on the signal to recover the 2.048 Mbps clock.

If you must use AMI, ensure that the data terminal equipment connected to the unit provides a minimally acceptable pulse density.

For this reason, there are advantages to using HDB3 instead. AMI

coding does not account for ones density. To meet this requirement, ensure that the data meets pulse density requirements.

S3 S4 DTE Line Coding

Off Off HDB3

Off On Internal use only

On Off Internal use only

On On AMI

Switches S5 through S8: Reserved

Switches S5 through S8 are reserved for future applications and

should be set to OFF.

3.2 CONFIGURE THE REAR INTERFACE CARD

The Model 1186RC has two interface card options: the Model

1001RCM703ST (with ST fiber connector) and 1001RCM703SMA (with

SMA fiber connector). See Figure 4, at upper right. Each of these interface cards support one fiber connector, two BNC and one RJ-48C line

connectors.

The interface card for the Model 1186RC is shipped configured for

use with a BNC connection to the G.703/G.704 Network. If your

Network connection is using BNC, skip this section.

Jumper Configuration

The rear interface card for the Model 1186RC has four internal

jumpers: JP2, JP3, JP4 and JP5. These jumpers are used to match

input/output impedance between the module and external line on the

G.703/G.704 Interface. The jumper settings select either a BNC (75ohm) or an RJ-48C (120-ohm) interface. Figure 5 below shows the top

view of the printed circuit board (PCB) and the location of the jumpers.

The following is a description of the jumper settings and the interface

selection:

1. For a 75-ohm connection (BNC/coax), insert all jumpers (default).

2. For a 120-ohm connection (RJ-48C/twisted pair), remove all

jumpers.

8

Figure 5:Top view of 1186RC circuit board and location of jumpers

Note: Electronic equipment is sensitive to ESD (electrostatic discharge). When you change the internal jumpers on the

1001RCM703XX, use a grounding strap to avoid damages. For more

information call Patton Technical Support (301) 975-1007.

NOTE: The 1186RC Series rear cards are specifically

designed to operate with the Model 1186RC function card and

must not be swapped with other Patton function cards.

Figure 4:Interface cards for Model 1186RC.

Model

1000RCM703SMA

Model

1000RCM703ST

RJ-45

TX

RX

JP3

JP2

JP4

JP5

RJ

TX

RX

7

Page 6

9

10

4.0 INSTALLATION

This section describes the functions of the Model 1001R14 rack

chassis, tells how to install front and rear Model 1186RC Series cards

into the chassis, and how to connect to the G.703/G.704 Network and

to fiber optic cable.

4.1 THE MODEL 1001R14 RACK CHASSIS

The Model 1001R14 Rack Chassis (Figure 6, below) has fourteen

short range modem card slots, plus its own power supply. Measuring

only 3.5” high, the Model 1001R14 is designed to occupy only 2U in a

19” rack. Sturdy front handles allow the Model 1001R14 to be extracted and transported conveniently.

4.1.1 The Rack Power Supply

The power supply included in the Model 1001R14 rack uses the

same mid-plane architecture as the modem cards. The front card of

the power supply slides in from the front, and the rear card slides in

from the rear. They plug into one another in the middle of the rack.

The front card is then secured by thumb screws and the rear card by

conventional metal screws.

Powering Up Your 1001R14 Rack

The power supplies that come with your 1001R14 rack system

are equipped with a power entry connector on the rear card. The

power supplies are Hot-Swappable, so you are not required to

remove the cards from the rack while applying power to the system.

The power switch is located on the front panel. When plugged in

and switched on, a red front panel LEDwill glow. Since the Model

1001R14 is a "hot swappable" rack, it is not necessary for any cards to

be installed before switching on the power supply. The power supply

may be switched off at any time without harming the installed cards.

4.1.2 Installing Model 1186RC Series Into the Rack Chassis

The Model 1186RC Series is comprised of a front card and a rear

card. The two cards meet inside the rack chassis and plug into each

other by way of mating 50 pin card edge connectors. Use the following

steps as a guideline for installing each Model 1186RC Series into the

rack chassis:

1.Slide the rear card into the back of the chassis along the

metal rails provided.

2.Secure the rear card using the metal screws provided.

3.Slide the front card into the front of the chassis. It should

meet the rear card when it’s almost all the way into the chassis.

4.Push the front card gentlyinto the card-edge receptacle of the

rear card. It should “click” into place.

5.Secure the front card using the thumb screws.

Figure 6: Model 1001R14 Rack Chassis with power supply

WARNING!There are no user-serviceable parts in the

power supply section of the Model 1186RC Series.

Voltage setting changes and fuse replacement should

only be performed by qualified service personnel.

Contact Patton Electronics Technical Support at (301)9751007 for more information.

NOTE: Please refer to the Model 1001RP14 Series User

Manual AC & DC Rack Mount Power Supplies for fuse and

power card replacement information.

Page 7

4.2 CONNECT THE G.703/G.704 NETWORK

There are two ways to connect to the G.703/G.704 Network. This

section describes both options. After selecting the appropriate connection, set the internal jumpers as described in section 3.2 of this manual.

4.2.1 Connect Twisted Pair (120 Ohm) to G.703/G.704 Network

The rear interface card for the Model 1186RC is equipped with a

single RJ-48C jack option for connections to a G.703/G.704 Network. If

your G.703/G.704 Network terminates via an RJ-48C, use the diagram

below (Figure 7).

4.2.2

Connect Coax Cable to the G.703/G.704 Network

The rear interface card for the Model 1186RC is also equipped

with dual female BNCs (TX and RX) for connection to a 75 ohm dual

coax G.703/G.704 Network interface. If your G.703/G.704 Network terminates via dual coaxial cable, use the diagram below to make the

proper connections. The connector pinout and signals are shown in

Figure 8, below.

RX

(Data FROM

G.703/G.704

Network)

TX

(Data TO

G.703/G.704

Network)

Network

Figure 8. Fiber cable to G.703/G.704 Interface connection

Figure 7.G.703/G.704 Network Interface.

1 RX Data (TIP)

2 RX Data (RING)

3 (no connection)

4 TX Data (TIP)

5 TX Data (RING)

6 (no connection)

7 (no connection)

8 (no connection)

1

2

3

4

5

6

7

8

}

}

From Network

To Network

4.3CONNECT THE FIBER INTERFACE

The Model 1186RC is designed to be connected to another Model

1186RC or Model 1186. The Model 1186RC supports communication

between G.703/G.704 equipment over one string of multi-mode fiber at

distances up to 2.5 km (1.5 miles). One modem can connect to another on the end of a single string of fiber optic cable.

To connect two Model 1186RCs, use one string of 62.5/125

micron multi-mode fiber. The fiber connects to the rear interface card

using either an ST or an SMA connector.

Figure 9 below shows a close-up of both connector types.

Figure 9:Close up of ST and SMA connectors

1211

Alignment pin

faces down

Page 8

14

5.0 OPERATION

5.1 LED STATUS MONITORS

The Model 1186RC features six front panel status LEDs that indicate

the condition of the modem and communication link. Figure 10 shows the

front panel location of each LED.

Functions of LEDs are as follows:

Fiber The green Fiber LED indicates reliable data on the fiber

side

E1 The green E1 LED indicates reliable data on the

G.703/G.704 side

LOS The red LOS indicates that syncronization between

modems has not been established. Blinking red LOS LED

indicates the presense of coding errors

NS The red NS LED indicates that the signal on the fiber side

is too weak to be detected, which can be due to any of the

following reasons:

- break in the fiber optic cable

- length of the fiber optic cable exceeds the maximum distance

- problem with Fiber LED.

ER Flashing red ER LED indicates errors in 511 test pattern

TM The yellow TM LED indicates that modem is in a test mode

(Local/Remote Loopback or 511/511E test pattern). Opaque

TM indicates normal operation.

When the local and remote units have established a link and are passing

reliable data, the following LED conditions will exsit:

· Fiber = GREEN

· E1 = GREEN

· LOS = OFF

· NS = OFF

· ER = OFF

· TM = OFF

5.2 TEST MODES

The following section describes the test patterns and loopbacks

used in the Model 1186RC. The Model 1186RC offers V.54 compliant

local/remote loopback tests, plus a built-in V.52 BER test pattern generator to evaluate the condition of the modems and the communication

link. These tests can be activated physically from the front panel.

5.2.1 Local Loopback

The local loopback test checks the operation of the local Model

1186RC, and is performed separately on each unit. The following section describes how to perform a local loopback test between the

Network and a local connection.

Any data sent to the local Model 1186RC in this test mode will be

echoed (returned) back to the user (see Figure 11). If two Model

1186RC units are linked when the LAL is activated, data sent from the

remote modem will also be looped back to the remote terminal equipment.

Figure 10.Front Panel of 1186RC

Figure 11.Local Loopback Diagram

G.703/G.704

Network

To test the local connection, follow these steps:

1. Activate LAL by moving the front panel toggle switch UP to "Local".

Once the Local Loopback is activated, the Model 1186RC transmit output will be connected to its own receiver. The TM LED will light up.

2. Perform a BER (Bit Error Rate) test on each unit using a separate

BER tester. If the BER test equipment indicates no faults, but the data

indicates a fault, follow the manufacturer's checkout procedures for the

data terminal. Also, check the interface cable between the terminal and

the Model 1186RC. The BER test can also be performed using a built-in

511/511E pattern generator. (See section 5.2.3 on how to use the built-in

511/511E pattern generator.)

3. Upon completion of the LAL test, return the front panel switch to the

NORMAL position. The TM LED should turn off.

13

Fiber Line

Page 9

5.2.2 Remote Digital Loopback (RDL)

The Remote Digital Loopback test checks the performance of both

the local and remote Model 1186RCs, and the communication link

between them. In this test, any characters sent from the originating

device to the remote unit will be returned (see Figure 12). Any data

sent from the remote DTE wil be ignored.

To perform a RDL test, follow these steps:

1. Activate RDL by moving front panel toggle switch DOWN to

"Remote". The TM LED on both local and remote units will light up.

2. Perform a BER (Bit Error Rate) test on the system, using BER tester

on the local end. BER test can also be performed using built-in

511/511E pattern generator. (See section 5.2.3 on how to use the builtin 511/511E pattern generator.)

3. If the BER test equipment indicates a fault and the Local Analog

Loopback test was successful for both Model 1186RCs, there may be

a problem with the line between the units.

4. Upon completion of the RDL test, return the front panel switch to

the NORMAL position. The TM LED should turn off on both local and

remote units.

5.2.3 V.52 Test Pattern Generator

To use the V.52 BER test in conjunction with the Local or Remote

Loopbacks, turn on one of the loopbacks, and follow these instructions:

1. Locate the "511/511E" toggle switch on the front panel of the Model

1186RC and move it UP. This activates the V.52 BER test mode and

transmits a "511" test pattern into the loop. If any errors are present,

the local modem's red "ER" LED will blink intermittently.

2. If the above test indicates no errors, move the V.52 toggle switch

15

DOWN, activating the "511/E" test with errors present. If the test is

working properly, the local modem's red "ER" LED will blink once every

two seconds. A successful "511/E" test will confirm that the link is in

place, and that the built-in "511" generator and detector are working

properly.

16

Figure 12.Remote Loopback Diagram

G.703/G.704

Network

Note: When the unit is set for Network Clock Mode, the unit will derive

its timing from the G.703/G.704 Interface. Failure to connect to

G.703/G.704 may result in bit errors during the 511 or 511/E test.

Fiber Line

Page 10

APPENDIX AAPPENDIX A

PATTON ELECTRONICS MULTI-MODE FIBER RACK MOUNT

MODEM WITH G.703/G.704 INTERFACE

SPECIFICATIONS

Clocking Modes: Network (G.703/G.704), Internal, Receive

Recover

Line Rate: 2048 kbps

Diagnostics: V.52 compliant (511/511E) pattern generator

and detector with error injection mode.

Remote Loopback (toward fiber line) and

local loopback (toward G.703/G.704 network) controlled by a single front panel

switch

LEDStatus: The following LEDs are displayed on the

front panel:

Fiber:The green Fiber LED indicates reliable data on the fiber side

E1:The green E1 LED indicates reliable

data on the G.703/G.704 side

LOS:The red LOS indicates that syncronization between modems has not been

established. Blinking red LOS LED indicates

the presense of coding errors

NS:The red NS LED indicates that the sig

nal on the fiber side is too weak to be

detected

ER:Flashing red ER LED indicates errors in

511 test pattern

TM:The yellow TM LED indicates that

modem is in a test mode

(Local/Remote Loopback or 511/511E test

pattern). Opaque TM LED indicates normal

operation.

Compliance: FCC Part 15, CE, CTR12

Transmission Line: Single fiber

Line Coding: 8B10B

Line Interface: Transformer coupled, 1500 VAC isolation

Fiber Physical

Connection: One string of 62.5/125µm fiber with SMA

or ST connectors

17

G.703/G.704 Specific

Interface: Female Dual Coaxial 75 ohm or

Female RJ-48C 120 ohm

Line rate:

2.048 Mbps

Line coding:

AMI or HDB3 (HDB3 is the default)

Isolation:

1500 Vrms

Physical Connection:

pin 1 Rx Data +

pin 2 Rx Data pin 4 Tx Data pin 5 Tx Data pins 3, 6, 7, 8 no connection

18

Page 11

APPENDIX BAPPENDIX B

PATTON ELECTRONICSMODEL 1186RC

FACTORY REPLACEMENT PARTS

AND ACCESSORIES

Patton Electronics Model # Description

1186....................................multi-mode fiber optic modem

1186RC................................multi-mode fiber rack card modem

1001RCM703ST..................interface card with ST fiber connector

1001RCM703SMA...............interface card with SMA fiber connector

1001RPEM-RAC..................120/240V Rear Power Entry Module

1001RPSM-RUI...................120/240V Front Power Supply Module

1001RPEM-RDC..................DC Rear Power Entry Module

1001RPSM-R48A.................48V Front Power Supply Module

1001R14P............................Rack 14 Slot 2U Chassis Only

1001R14P/R48V..................Rack 14 Slot 2U w/Dual Universal

Input 48VDC Power Supplies

1001R14P/RUIA...................Rack 14 Slot 2U w/Dual Universal

Input 90-260VAC Power Supplies

European Power Cord

1001R14P/RUIC..................Rack 14 Slot 2U w/Dual Universal

Input 90-260VAC Power Supplies

Austrialia Power Cord

1001R14P/RUID..................Rack 14 Slot 2U w/Dual Universal

Input 90-260VAC Power Supplies

UK Power Cord

1001R14P/RUIG..................Rack 14 Slot 2U w/Dual Universal

Input 90-260VAC Power Supplies

India Power Cord

1001R14P/RUIK...................Rack 14 Slot 2U w/Dual Universal

Input 90-260VAC Power Supplies

US Power Cord

0516FPB1............................Single Width Blank Front Panel

0516FPB4............................4-Wide Blank Front Panel

0516RPB1............................Single Width Blank Rear Panel

0516RPB4............................4-Wide Blank Rear Panel

056S1...................................Set of 16 #4 pan head screws/washers

07M1186RC.........................User Manual

Copyright © 2000

Patton Electronics Company

All Rights Reserved

19

Loading...

Loading...