Page 1

See Chapter 2 for installa-

tion procedures & Chapter 3

for configuration procedures

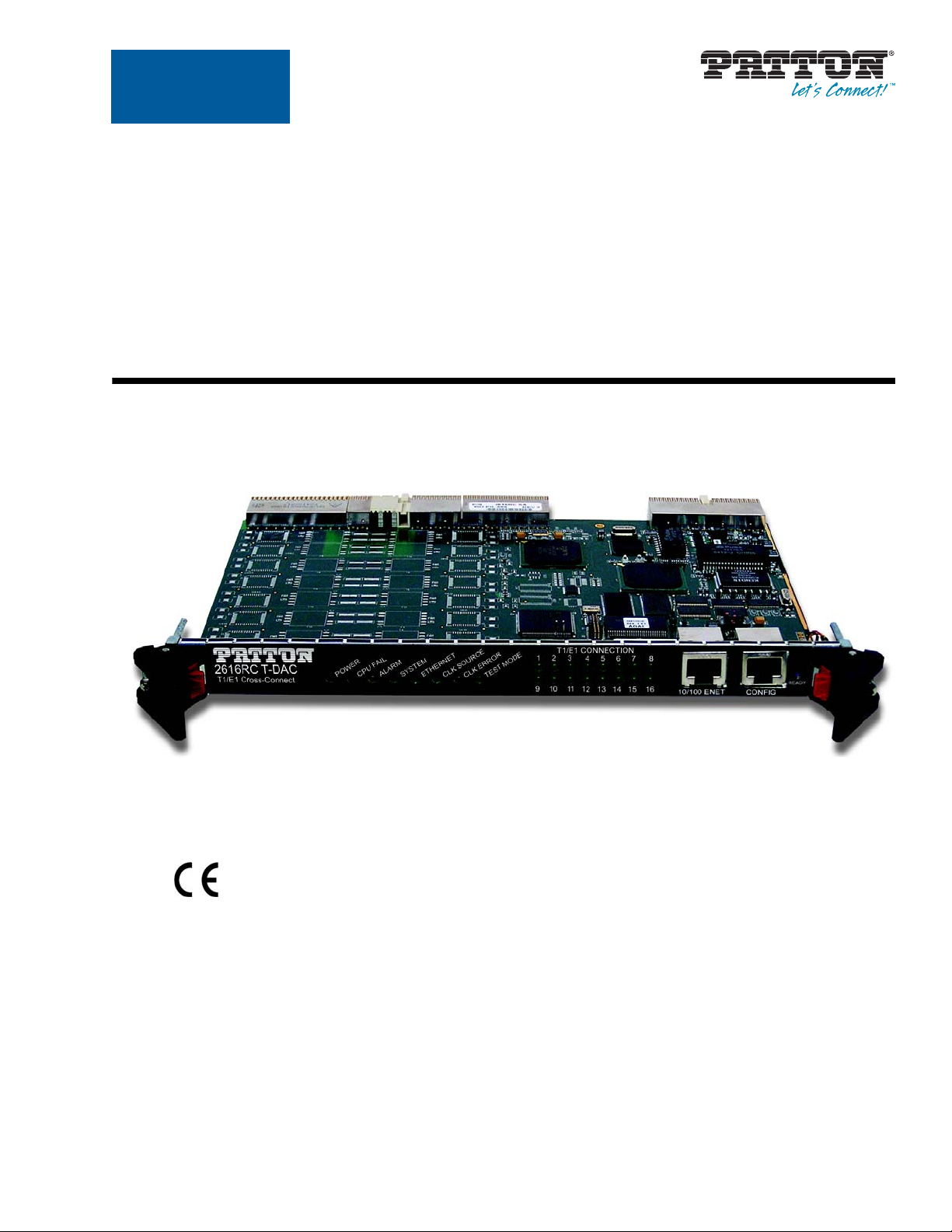

Model 2616RC

T1/E1 TDM-Digital Access

Concentrator (T-DAC)

User Manual

Important

This is a Class A device and is intended for use in a light industrial environment. It is not intended nor approved for use in an industrial

or residential environment.

Sales Office: +1 (301) 975-1000

Technical Support: +1 (301) 975-1007

E-mail: support@patton.com

WWW: www.patton.com

Part Number: 07MD2616RC-GSG, Rev. E

Revised: February 16, 2012

Page 2

Patton Electronics Company, Inc.

7622 Rickenbacker Drive

Gaithersburg, MD 20879 USA

Tel: +1 (301) 975-1000

Fax: +1 (301) 869-9293

Support: +1 (301) 975-1007

Web: www.patton.com

E-Mail: support@patton.com

Copyright © 2012, Patton Electronics Company. All rights reserved.

The information in this document is subject to change without notice. Patton Electronics assumes no liability for errors that may appear in this document.

Warranty Information

The software described in this document is furnished under a license and may be used

or copied only in accordance with the terms of such license.

Patton Electronics warrants all Model 2616RC components to be free from defects,

and will—at our option—repair or replace the product should it fail within one year

from the first date of the shipment.

This warranty is limited to defects in workmanship or materials, and does not cover

customer damage, abuse or unauthorized modification. If the product fails to perform

as warranted, your sole recourse shall be repair or replacement as described above.

Under no condition shall Patton Electronics be liable for any damages incurred by

the use of this product. These damages include, but are not limited to, the following:

lost profits, lost savings and incidental or consequential damages arising from the use

of or inability to use this product. Patton Electronics specifically disclaims all other

warranties, expressed or implied, and the installation or use of this product shall be

deemed an acceptance of these terms by the user.

Page 3

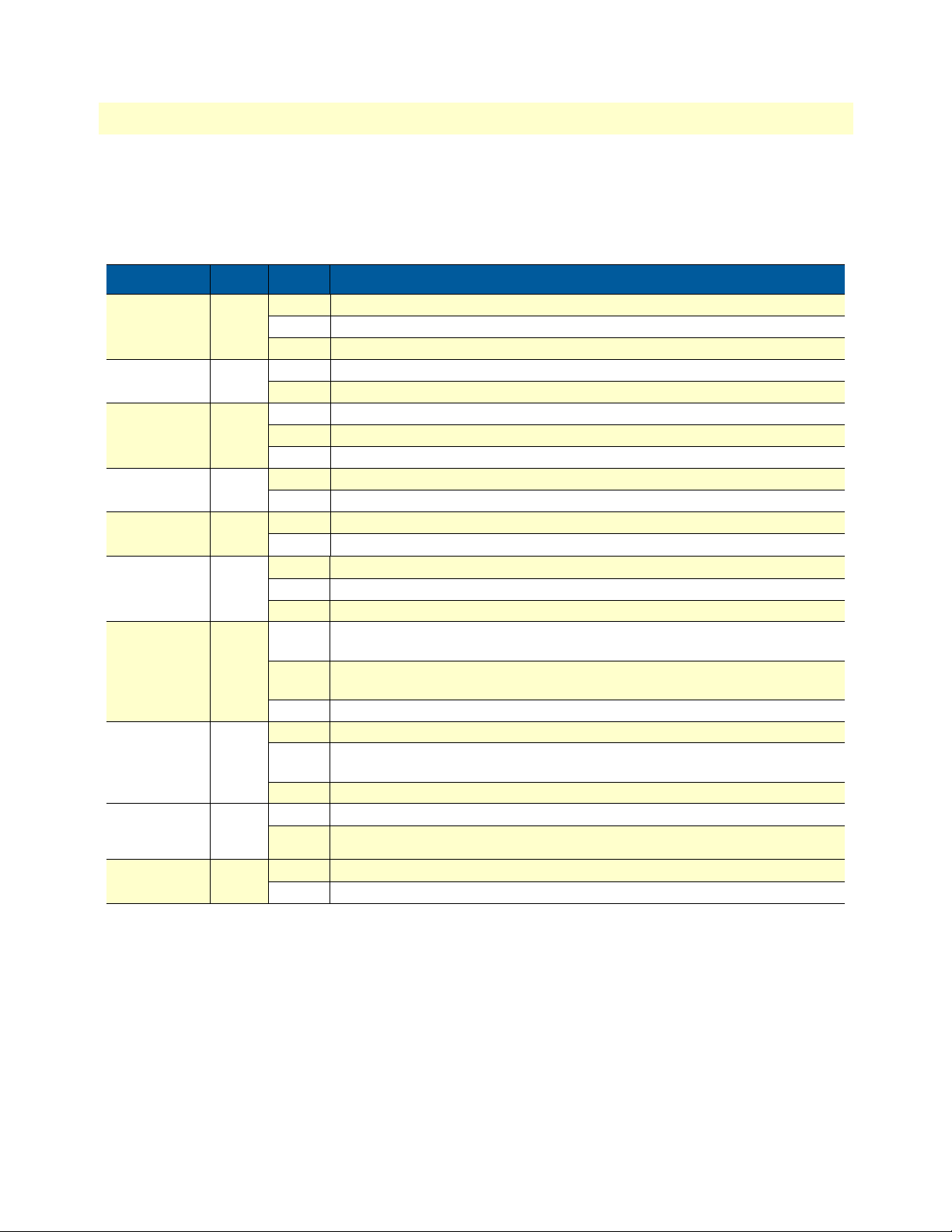

Summary Table of Contents

1 Introduction.................................................................................................................................................. 13

2 Hardware installation.................................................................................................................................... 19

3 Configuring the T-DAC for operation .......................................................................................................... 31

4 Operation and shutdown............................................................................................................................... 58

5 Troubleshooting and maintenance................................................................................................................ 60

6 Contacting Patton for assistance ................................................................................................................... 72

A Compliance information .............................................................................................................................. 75

B 68-pin SCSI-to-open-end 6-foot cable (part #10-3096TM68-6) .................................................................. 78

3

Page 4

Contents

About this guide...................................................................................................................................................10

Audience............................................................................................................................................................... 10

Structure............................................................................................................................................................... 10

Precautions........................................................................................................................................................... 11

Typographical conventions used in this document................................................................................................ 12

General conventions .......................................................................................................................................12

Mouse conventions .........................................................................................................................................12

1 Introduction.................................................................................................................................................. 13

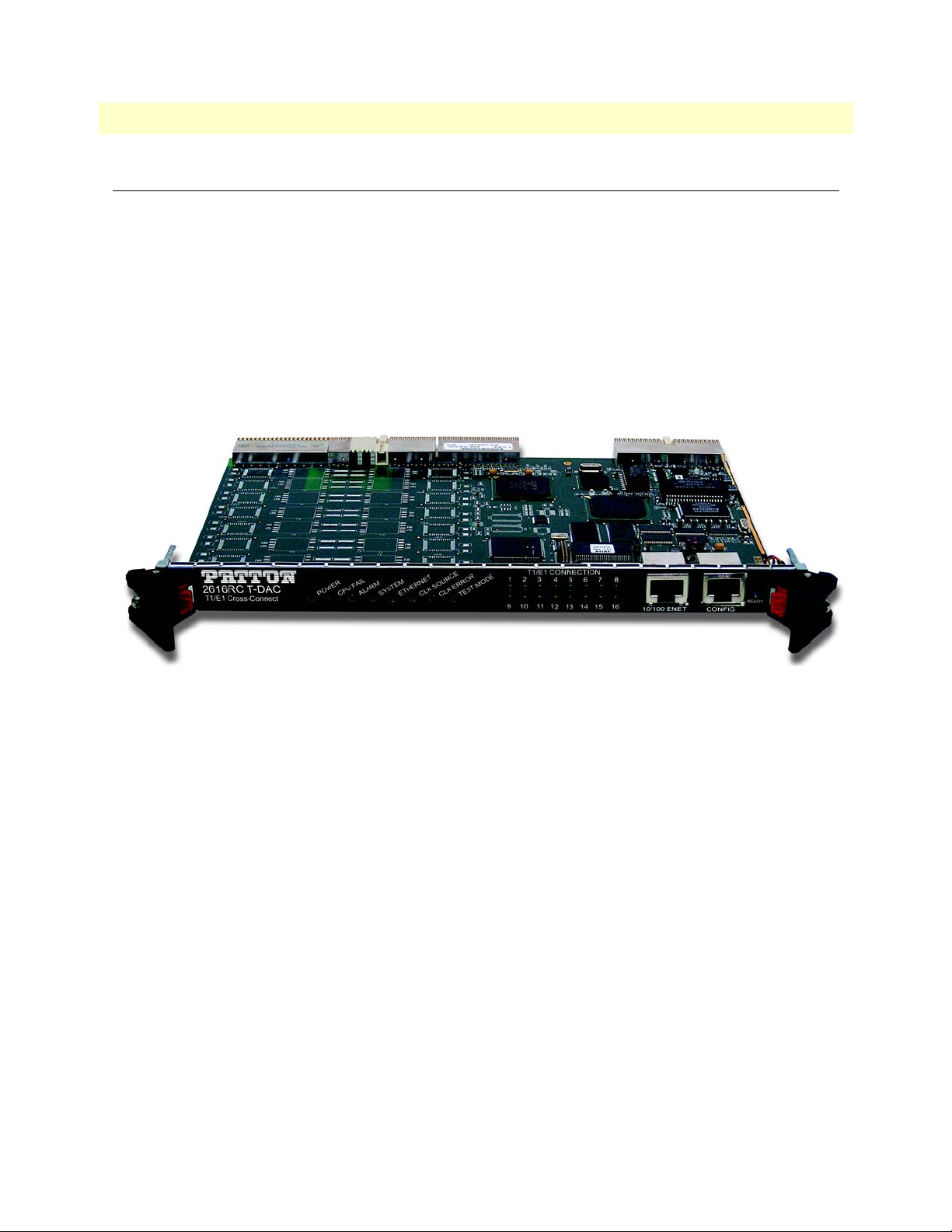

Model 2616RC T1/E1 T-DAC overview ..............................................................................................................14

Hardware overview................................................................................................................................................15

WAN ..............................................................................................................................................................15

LAN ...............................................................................................................................................................15

RS-232 control port ........................................................................................................................................16

Power system ..................................................................................................................................................16

Central processing unit ...................................................................................................................................16

System timing .................................................................................................................................................16

Temperature ...................................................................................................................................................16

Altitude ...........................................................................................................................................................16

Humidity ........................................................................................................................................................16

Physical dimensions ........................................................................................................................................16

Management services ......................................................................................................................................16

LED display ....................................................................................................................................................18

2 Hardware installation.................................................................................................................................... 19

Introduction..........................................................................................................................................................20

Unpacking the Model 2616RC T-DAC................................................................................................................20

T-DAC blades installation.....................................................................................................................................20

Cable installation...................................................................................................................................................22

Connecting the Ethernet ports ........................................................................................................................22

Connecting the 10/100Base-T Ethernet port to an Ethernet switch or hub ...............................................22

Connecting the 10/100Base-T Ethernet port to an Ethernet-capable workstation or PC ................................23

Connecting the EIA-561 RS-232 configuration port (DCE configured) .........................................................23

Connecting the T1/E1 WAN ports .................................................................................................................24

68-pin SCSI to 8 RJ-45 connectors cable ..................................................................................................24

68-pin SCSI to open end cable ..................................................................................................................26

Installing the WAN cable to a punch-down block ...........................................................................................28

68-pin SCSI to open end, 6 foot cable (part #10-3096TM68-6)—Obsolete ...................................................29

68-pin SCSI to 64-pin female Telco (part #10-3096TM68/64-6) ..................................................................29

Completing the hardware installation....................................................................................................................30

3 Configuring the T-DAC for operation .......................................................................................................... 31

4

Page 5

Model 2616RC T-DAC User Manual Contents

Introduction..........................................................................................................................................................32

Configuration prerequisites ...................................................................................................................................32

Initial configuration through the RS-232 control port...........................................................................................33

Connecting the DB9-RJ45 adapter with the included cable ............................................................................33

Setting up the HyperTerminal (or similar program) session ............................................................................34

Using a browser to complete Model 2616RC configuration..................................................................................37

Displaying the T-DAC 2616RC web administration pages .............................................................................38

Home page overview .................................................................................................................................38

Configuring the default gateway .....................................................................................................................40

Configuring the system clocking parameters ...................................................................................................41

Configuring the DS0 mapping ........................................................................................................................44

Configuring line settings and signaling for E1 .................................................................................................46

Accessing the Line Interface Settings .........................................................................................................46

Configuring the E1 line interface settings ........................................................................................................47

Configuring line settings and signaling for T1 ................................................................................................49

Accessing the Line Interface Settings .........................................................................................................49

Configuring the T1 line settings ................................................................................................................50

Enabling/disabling the alarm card ...................................................................................................................52

Saving your configuration......................................................................................................................................53

Backing up your configuration parameters.............................................................................................................53

Backing up the configuration store in flash memory .......................................................................................55

Completing the installation ...................................................................................................................................56

4 Operation and shutdown............................................................................................................................... 58

Introduction..........................................................................................................................................................59

Activating the Model 2616RC...............................................................................................................................59

De-activating the Model 2616RC .........................................................................................................................59

5 Troubleshooting and maintenance................................................................................................................ 60

Introduction..........................................................................................................................................................61

Fault analysis.........................................................................................................................................................62

T1/E1 port test modes...........................................................................................................................................64

DSX1 payload loop (dsx1PayloadLoop) ..........................................................................................................64

DSX1 line loop (dsxLineLoop) .......................................................................................................................65

Periodic maintenance ............................................................................................................................................66

Calibration ......................................................................................................................................................66

Maintenance..........................................................................................................................................................66

Exporting the current Model 2616RC configuration ......................................................................................66

Removing the defective Model 2616RC ....................................................................................................69

Installing the replacement Model 2616RC ................................................................................................70

Importing a saved configuration ................................................................................................................70

Completing the installation .......................................................................................................................71

6 Contacting Patton for assistance ................................................................................................................... 72

Introduction..........................................................................................................................................................73

Contact information..............................................................................................................................................73

5

Page 6

Model 2616RC T-DAC User Manual Contents

Warranty Service and Returned Merchandise Authorizations (RMAs)...................................................................73

Warranty coverage ..........................................................................................................................................73

Out-of-warranty service .............................................................................................................................73

Returns for credit ......................................................................................................................................73

Return for credit policy .............................................................................................................................74

RMA numbers ................................................................................................................................................74

Shipping instructions ................................................................................................................................74

A Compliance information .............................................................................................................................. 75

Compliance ...........................................................................................................................................................76

EMC ...............................................................................................................................................................76

Safety ..............................................................................................................................................................76

PSTN Regulatory ............................................................................................................................................76

Radio and TV Interference ....................................................................................................................................76

Industry Canada Notice ........................................................................................................................................76

FCC Part 68 (ACTA) Statement ...........................................................................................................................77

CE Declaration of Conformity..............................................................................................................................77

Authorized European Representative.....................................................................................................................77

B 68-pin SCSI-to-open-end 6-foot cable (part #10-3096TM68-6) .................................................................. 78

Introduction..........................................................................................................................................................79

6

Page 7

List of Figures

1 Model 2616RC T-DAC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2 Model 2616RC T-DAC features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

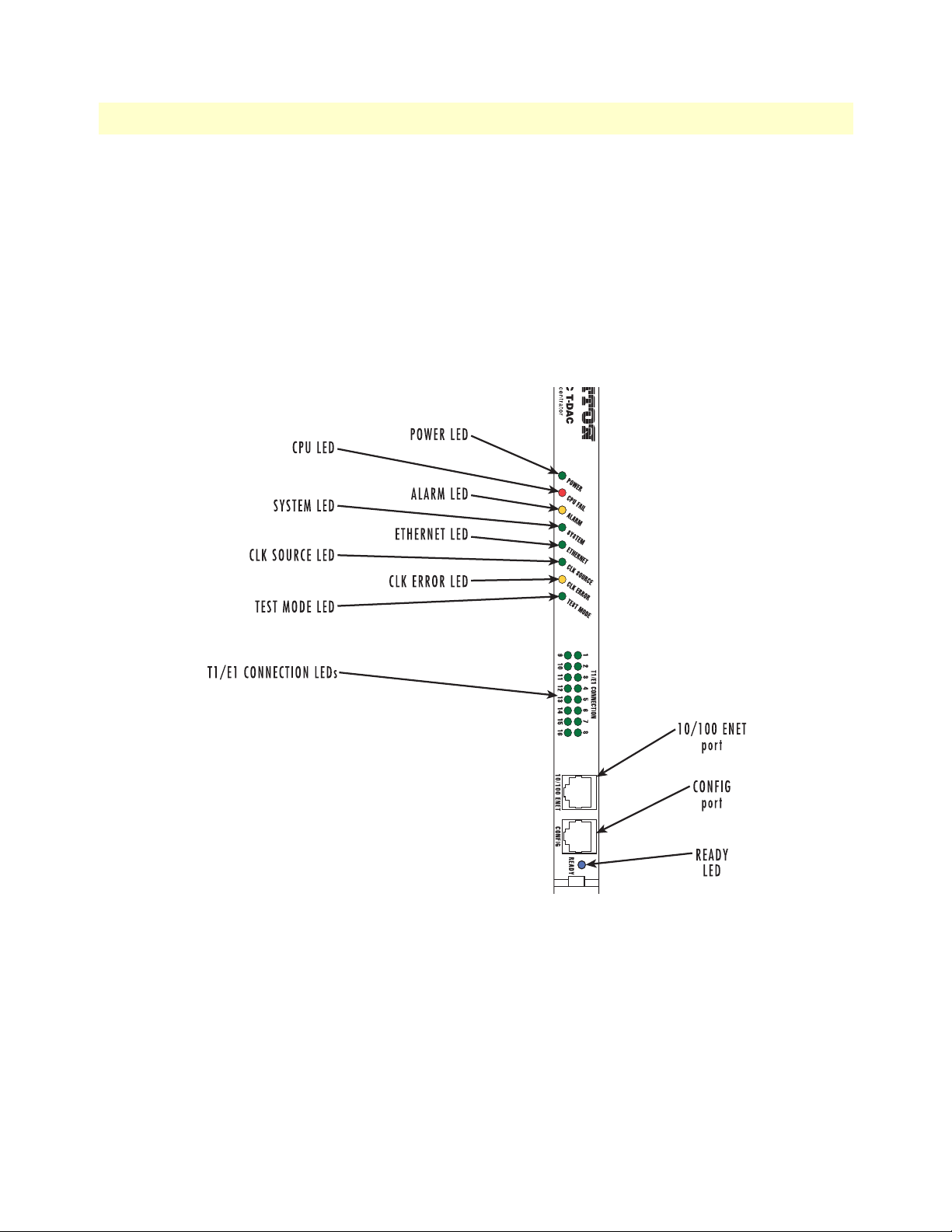

3 Model 2616RC front panel LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

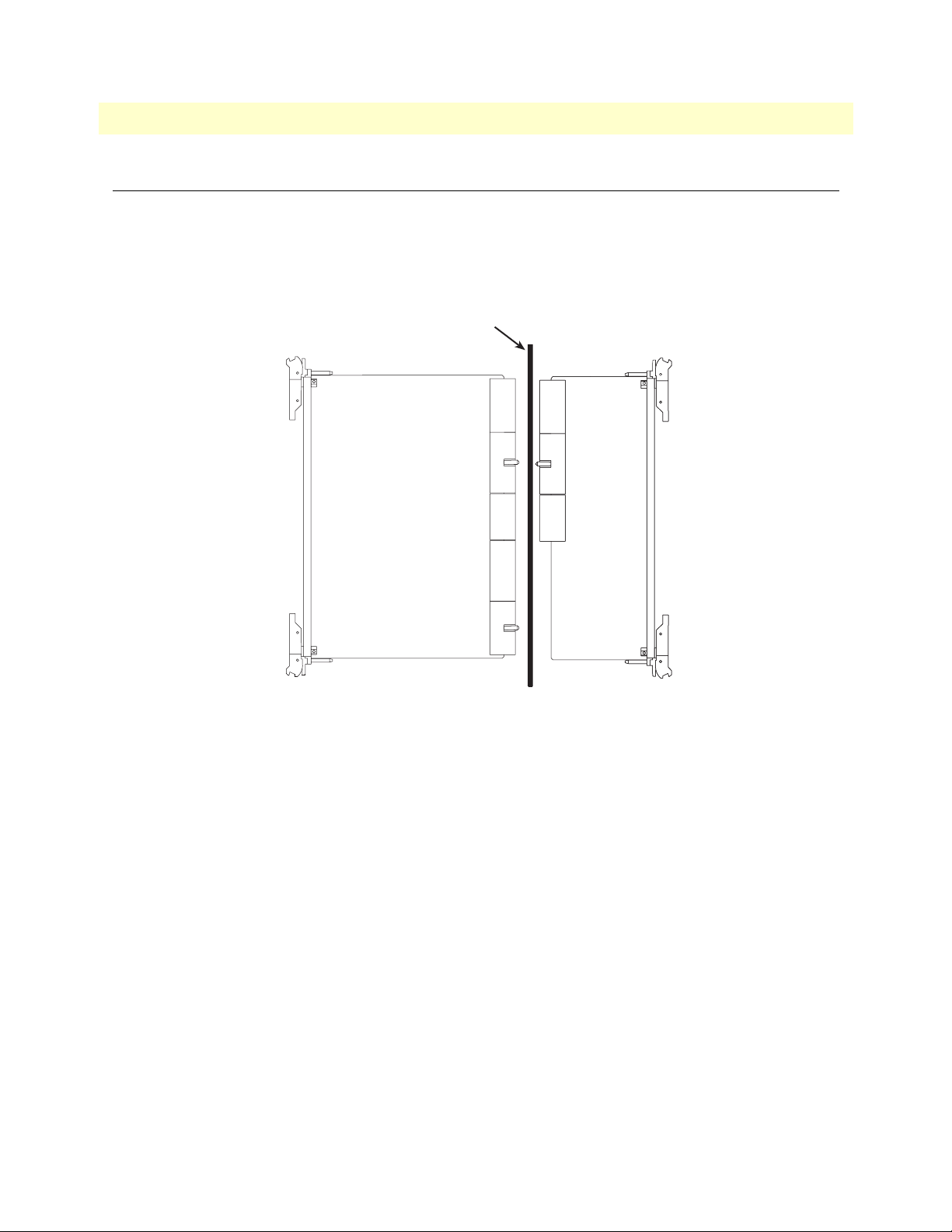

4 Alignment/ESD pin and card handle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

5 Model 2616RC network and configuration ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

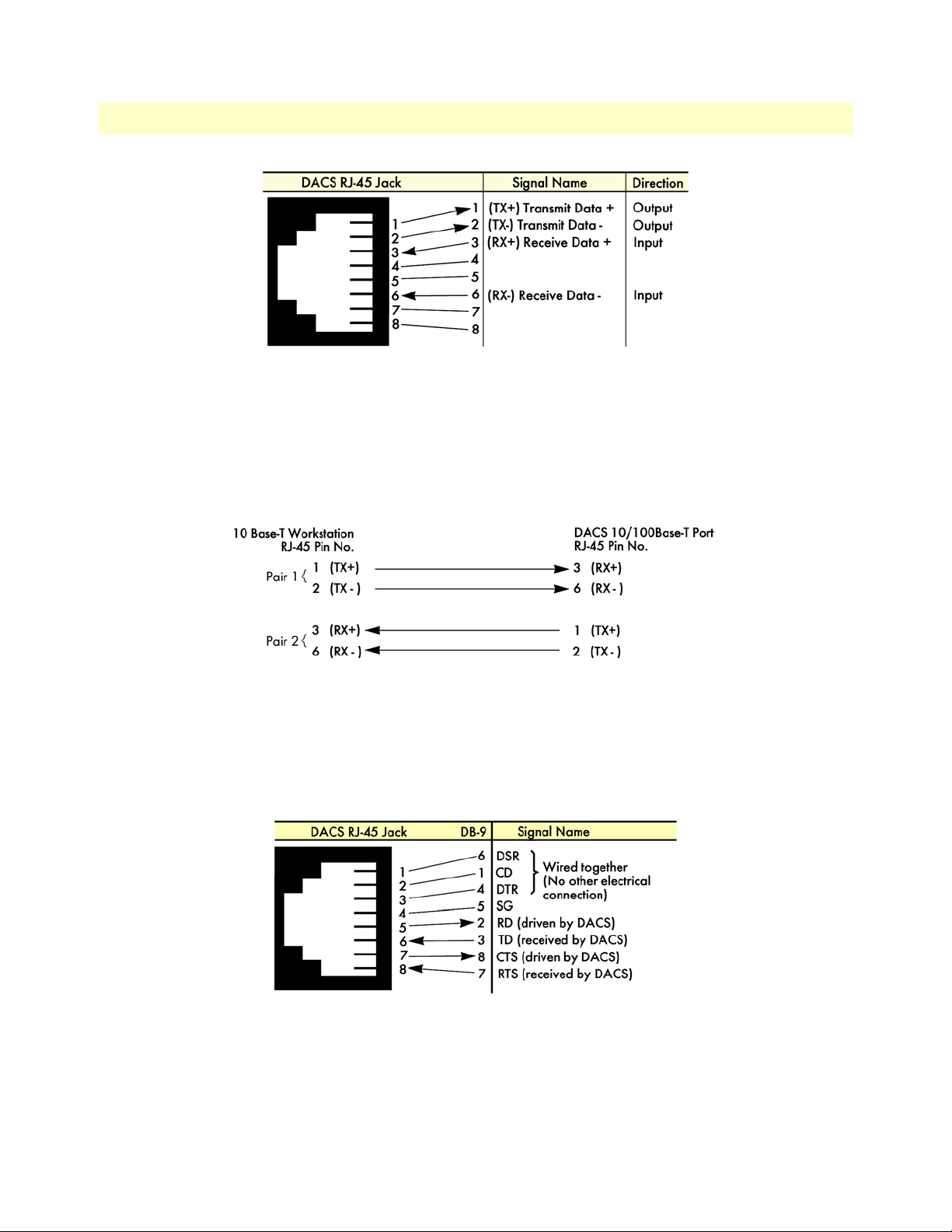

6 Ethernet RJ-45 pin and signal definitions for T-DAC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

7 Cross-over RJ-45-to-RJ-45 Ethernet cable diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

8 DB-9-to-RJ-45 cable diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

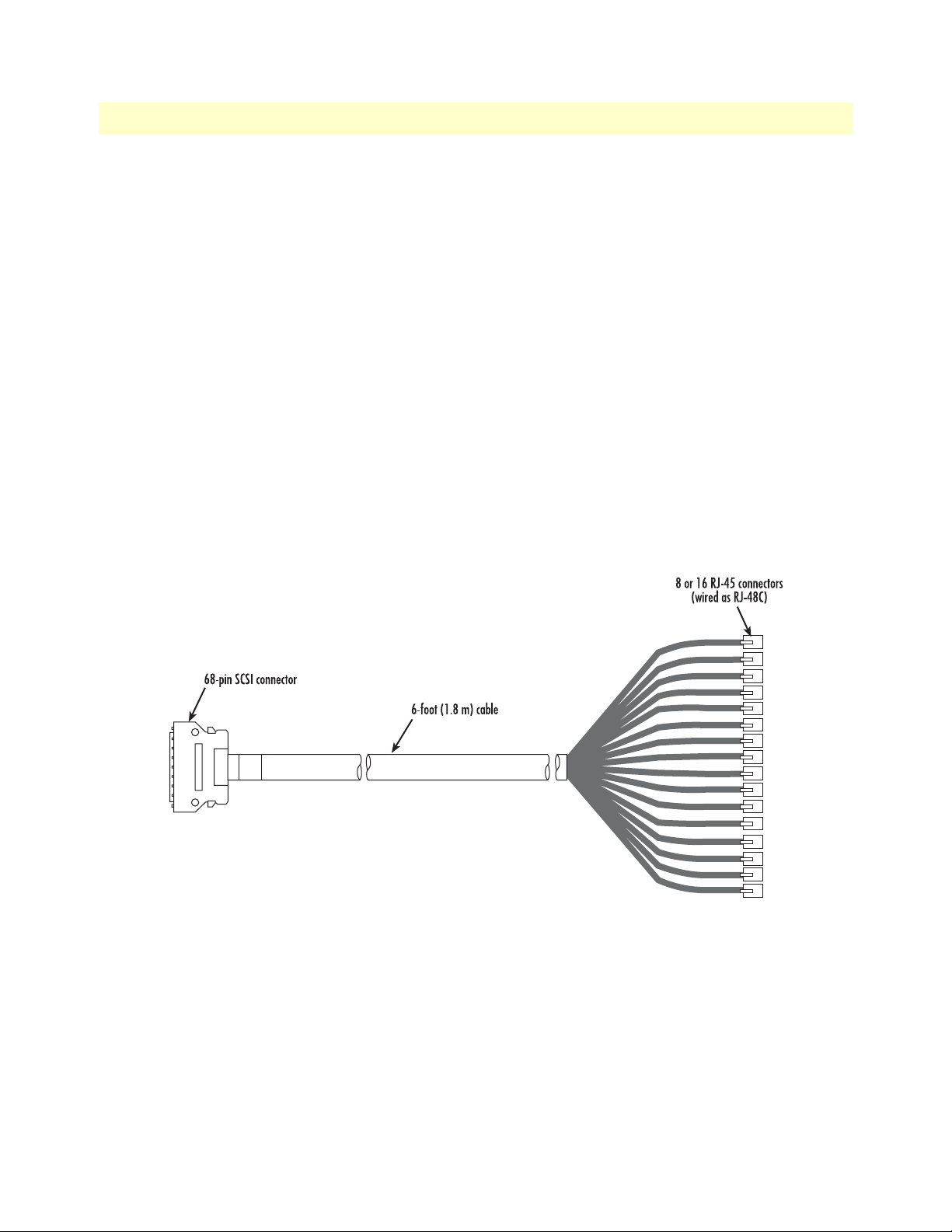

9 SCSI-to-RJ45 6-foot WAN cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

10 WAN cable‘s 68-pin SCSI connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

11 RJ-45 plug . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

12 SCSI-to-open-end WAN cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

13 68-pin SCSI connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

14 Punch-down block wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

15 SCSI-to-open-end 6-foot WAN cable (obsolete) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

16 Model 2616RC interface ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

17 Connection Description window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

18 Connect To window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

19 COM1 Properties window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

20 Terminal keys configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

21 Login window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

22 VT-100 top level management window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

23 Ethernet configuration window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

24 2616RC Configuration Menu home page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

25 HOME page window panes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

26 Operator Actions buttons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

27 IP Routing Information Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

28 IP Routing Information window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

29 System Clocking Configuration page, example 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

30 System Clocking Configuration page, example 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

31 Clock Reference Submit Query button . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

32 Clock Reference Submit Query button . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

33 DS0 Mapping Overview window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

34 Display Option menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

35 T1/E1 Link Activity Overview page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

36 T1/E1 Link Activity Ports 1 – 4 page. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

37 WAN Circuit Configuration page, Line Interface Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

38 Line Type pull-down menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

39 Line Coding pull-down menu with dsx1HDB3(3) selected . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

40 Line Build Out pull-down menu with e1pulse(1) selected . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

41 E1 ALARMS PRESENT indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

42 T1/E1 Link Activity Overview page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

43 T1/E1 Link Activity Ports 1 – 4 page. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

44 WAN Circuit Configuration page, Line Interface Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

45 Line Type pull-down menu with dsx1ESF(2) selected . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

46 Line Coding pull-down menu with dsx1B8ZS(2) selected . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

47 Line Build Out pull-down menu with t1pulse0dB(1) selected . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

7

Page 8

Model 2960 RAS Getting Started Guide

48 T1 ALARMS PRESENT indicator on T1/E1 LINK ACTIVITY page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

49 Alarm Card Information window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

50 2616RC Configuration Menu home page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

51 IMPORT/EXPORT page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

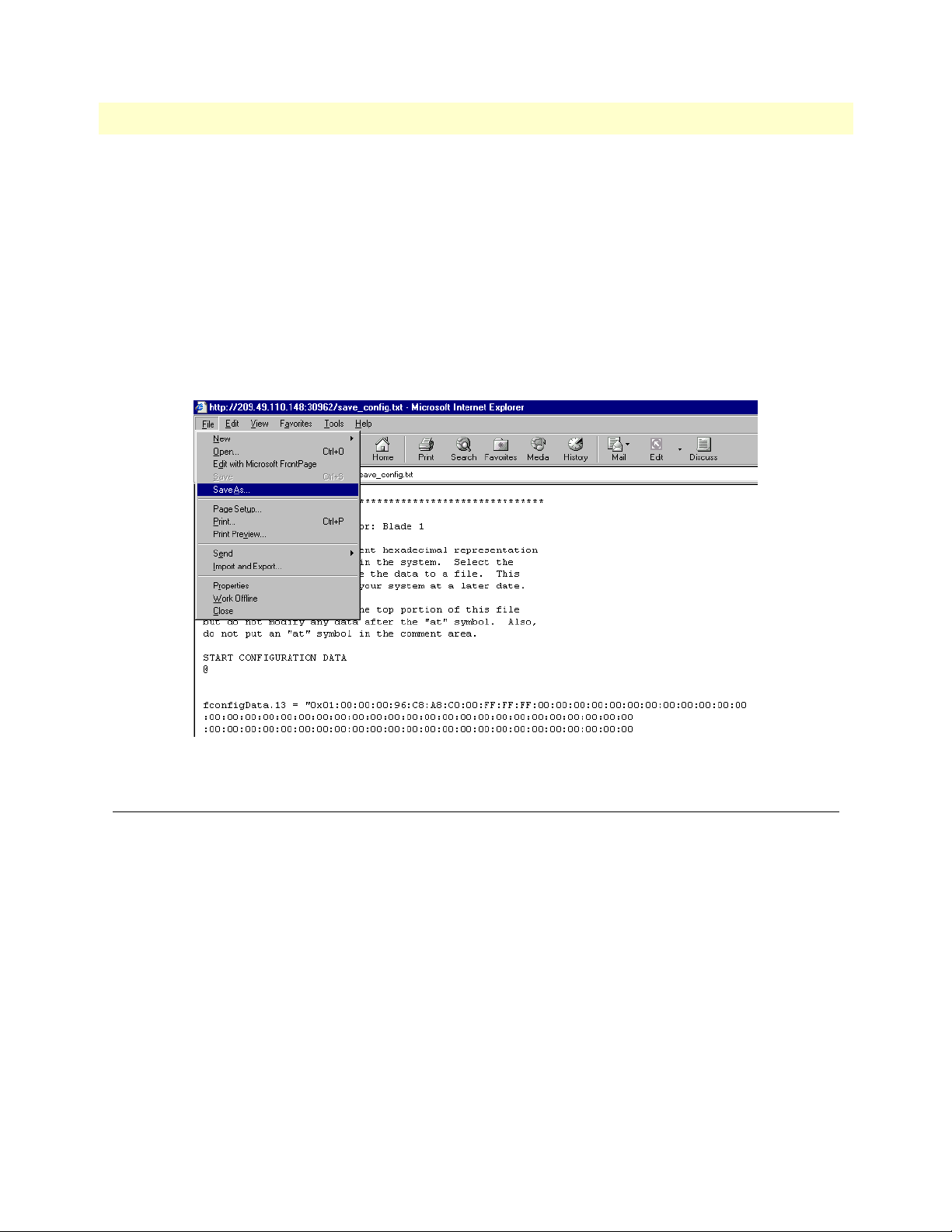

52 Example T-DAC flash memory configuration file displayed in a browser . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

53 Saving the access server flash memory configuration data as a text file . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

54 Payload loopback . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

55 Line Loop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

56 IMPORT/EXPORT page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

57 Example T-DAC flash memory configuration file displayed in a browser . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

58 Saving the access server flash memory configuration data as a text file . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

8

Page 9

List of Tables

1 General conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2 Mouse conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3 LED definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4 RJ-45 plug pin-out . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

5 WAN cable’s 68 non-terminated twisted-pairs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

6 Symptoms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

7 LED definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

8 WAN cable’s 68 non-terminated twisted-pairs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

9

Page 10

About this guide

This guide describes installing and configuring a Patton Electronics Model 2616RC TDM-Digital Access

Concentrator (T-DAC). By the time you are finished with this guide, your T-DAC will be connected to T1/

E1 lines and transferring data. The instructions in this guide are based on the following assumptions:

• The T-DAC will connect to T1/E1 lines

• There is a LAN connected to the Ethernet port of the T-DAC

Audience

This guide is intended for the following users:

• Operators

• Installers

• Maintenance technicians

Structure

This guide contains the following chapters and appendices:

• Chapter 1 describes the T-DAC

• Chapter 2 describes installing the T-DAC hardware

• Chapter 3 describes configuring the T-DAC for use

• Chapter 4 details how to power up and deactivate the T-DAC

• Chapter 5 contains troubleshooting and maintenance information

• Chapter 6 contains information on contacting Patton technical support for assistance

For best results, read the contents of this guide before you install the T-DAC.

10

Page 11

Model 2616RC T-DAC User Manual About this guide

Precautions

Notes and cautions, which have the following meanings, are used throughout this guide to help you become

aware of potential T-DAC problems. Warnings relate to personal injury issues, and Cautions refer to potential

property damage.

Note

WARNING

WARNING

CAUTION

CAUTION

Calls attention to important information.

The shock hazard symbol and WARNING heading indicate a potential electric

shock hazard. Strictly follow the warning instructions to avoid injury caused

by electric shock.

The alert symbol and WARNING heading indicate a potential safety hazard.

Strictly follow the warning instructions to avoid personal injury.

The shock hazard symbol and CAUTION heading indicate a

potential electric shock hazard. Strictly follow the instructions to

avoid property damage caused by electric shock.

The alert symbol and CAUTION heading indicate a potential hazard. Strictly follow the instructions to avoid property damage.

Safety when working with electricity

•

The Model 2616RC shall be installed in a restricted access location accessible only to authorized personnel.

WARNING

•

This unit contains no user-serviceable parts. Refer servicing to qualified

personnel.

•

When removing cards from a shelf under power, some of the components

such as the DC converters may be extremely hot. Handle by the card guides

only.

•

To prevent accidental electrical short circuits, align the card correctly

between the card guides before you insert it in the slot.

In accordance with the requirements of council directive 2002/

96/EC on Waste of Electrical and Electronic Equipment (WEEE),

ensure that at end-of-life you separate this product from other

waste and scrap and deliver to the WEEE collection system in

your country for recycling.

11

Page 12

Model 2616RC T-DAC User Manual About this guide

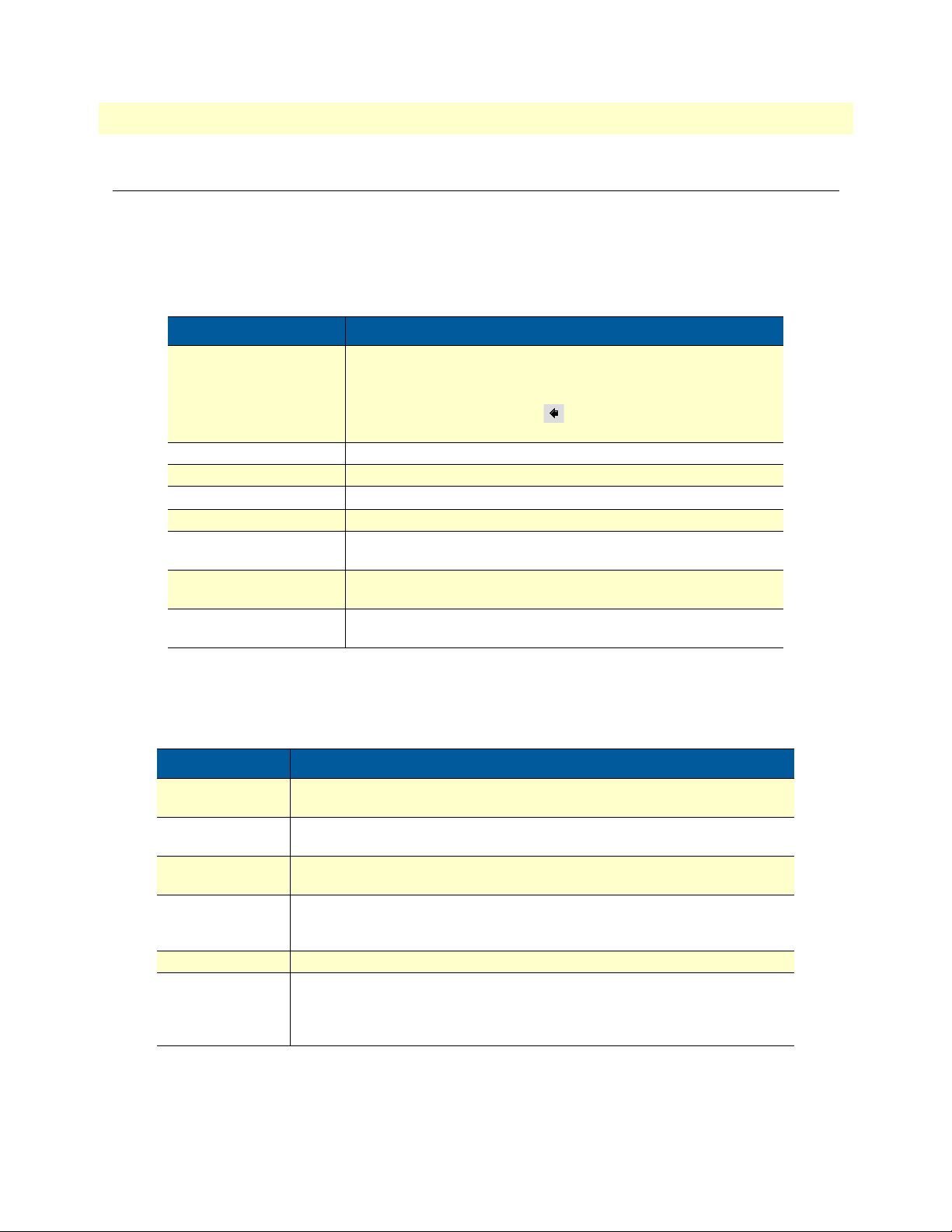

Typographical conventions used in this document

This section describes the typographical conventions and terms used in this guide.

General conventions

The procedures described in this manual use the following text conventions:

Table 1. General conventions

Convention Meaning

Garamond blue type

Futura bold type Indicates the names of menu bar options.

Italicized Futura type Indicates the names of options on pull-down menus.

Futura type

Garamond bold type Indicates the names of command buttons that execute an action.

< >

Are you ready? All system messages and prompts appear in the Courier font as the

% dir *.* Bold Courier font indicates where the operator must type a response or

Indicates a cross-reference hyperlink that points to a figure, graphic,

table, or section heading. Clicking on the hyperlink jumps you to the ref

erence. When you have finished reviewing the reference, click on the

Go to Previous View button

toolbar to return to your starting point.

Indicates the names of fields or windows.

Angle brackets indicate function and keyboard keys, such as <SHIFT>,

<CTRL>, <C>, and so on.

system would display them.

command

in the Adobe® Acrobat® Reader

-

Mouse conventions

The following conventions are used when describing mouse actions:

Table 2. Mouse conventions

Convention Meaning

Left mouse button This button refers to the primary or leftmost mouse button (unless you have

changed the default configuration).

Right mouse button This button refers the secondary or rightmost mouse button (unless you have

changed the default configuration).

Point This word means to move the mouse in such a way that the tip of the pointing

arrow on the screen ends up resting at the desired location.

Click Means to quickly press and release the left or right mouse button (as instructed in

the procedure). Make sure you do not move the mouse pointer while clicking a

mouse button.

Double-click Means to press and release the same mouse button two times quickly

Drag This word means to point the arrow and then hold down the left or right mouse but-

ton (as instructed in the procedure) as you move the mouse to a new location.

When you have moved the mouse pointer to the desired location, you can release

the mouse button.

12

Page 13

Chapter 1 Introduction

Chapter contents

Model 2616RC T1/E1 T-DAC overview ..............................................................................................................14

Hardware overview................................................................................................................................................15

WAN ..............................................................................................................................................................15

LAN ...............................................................................................................................................................15

RS-232 control port ........................................................................................................................................16

Power system ..................................................................................................................................................16

Central processing unit ...................................................................................................................................16

System timing .................................................................................................................................................16

Temperature ...................................................................................................................................................16

Altitude ...........................................................................................................................................................16

Humidity ........................................................................................................................................................16

Physical dimensions ........................................................................................................................................16

Management services ......................................................................................................................................16

LED display ....................................................................................................................................................18

13

Page 14

Model 2616RC T-DAC User Manual 1 • Introduction

Model 2616RC T1/E1 T-DAC overview

The Model 2616RC (see figure 1) provides 16 T1/E1 ports. A built-in digital cross-connect switch provides

completely flexible grooming: the capability to connect any DS0-channel to any other DS0-channel from the

WAN uplink ports or the T1/E1 ports. The T-DAC combines a time-slot multiplexer and a centralized webbased management system on a front and rear blade for insertion in a Patton ForeFront chassis with a chassis

mid-plane architecture. The front blade contains LED status indicators, an RS-232 configuration port and a

10/100 Ethernet management port. The rear blade contains the T1/E1 WAN port connections. The 16 T1/E1

ports connect to channelized T1 or E1 network connections.

Each WAN port terminates T1/E1 with flexible any-to-any DS0 mapping. The entire system can be managed

in-band (via T1/E1 Frame Relay/PPP links) or out-of-band from a web browser by means of SNMP/HTTPbased management screens.

Figure 1. Model 2616RC T-DAC

Model 2616RC T1/E1 T-DAC overview 14

Page 15

Model 2616RC T-DAC User Manual 1 • Introduction

Hardware overview

The Model 2616RC combines transmission and networking technology concentrating 16 T1/E1 WAN links

into a single slot blade for a Patton ForeFront chassis. The T-DAC front blade (see

of LED status indicators presented on the front panel, and an RS-232 async control port. The rear blade presents electrical connections for T1/E1 WAN ports as well as an alarm LED.

Midplane

figure 2) contains a full set

Front Blade

Front Rear

Side view

Figure 2. Model 2616RC T-DAC features

Rear Blade

WAN

The 2616RC includes 4, 8, 12, or 16 ports selectable for T1 or E1 operation. The T1/E1 ports may be connected to ATM/FR/DDN/IP network backbones and are accessible via the 68-pin SCSI connector in the rear

of the unit. Also included are:

• 4 to 16 built-in T1/E1 CSU/DSUs

• T1 1.544 Mbps with D4 or ESF framing, AMI or B8ZS line coding, FCC part 68 compliant

• E1 2.048 Mbps multi-framing with or without CRC4 framing, AMI/HDB3 line coding, CTR-12, and

CTR-13 compliant

• Built-in fuses and surge protectors

LAN

The 10/100-Mbps Ethernet LAN port is presented on an RJ-45 connector with an auto-sensing/full-duplex

10Base-T or 100Base-T interface. Also included are:

• 100Base-TX half-/full-duplex operation (100 + 100)

Hardware overview 15

Page 16

Model 2616RC T-DAC User Manual 1 • Introduction

• 10Base-T half-/full-duplex operation (10 + 10)

• Auto detection and fallback

• 10/100 Mbps link and status indicators

RS-232 control port

The RS-232 port provides for initial configuration of the Model 2616RC. The RS-232 port supports:

• Asynchronous data rates of 19.2 kbps, 8 data bits, no parity, 1 stop bit.

• An RJ-45 connector with EIA-561 pinouts

• A management interface that supports VT-100 terminals

• Hardware flow control (RTS and CTS)

Power system

The 2616RC obtains power from the Patton ForeFront chassis. Total power consumption is a maximum of

43

watts provided by modular power supplies installed in the Patton ForeFront chassis.

Central processing unit

The 2616RC employs an Intel i960VH RISC processor operating at 100 MHz/100 Mips. The CPU controls

the memory, front/back-panel and management interface for WAN time slot mapping, local switching, loop

-

back and the management system. The memory holds:

• 4 MB Flash ROM

• 8 MB EDO DRAM

System timing

The T1/E1 T-DAC’s system timing may be derived from an internal clock from an on-board chip, external

BITS clock, or a network clock from one of the T1/E1 WAN ports or from the ForeFront system chassis clock.

The clock source may be configured in primary, secondary, or slave mode.

The system timing is configured through the NMS.

Temperature

Operating range: 32–122°F (0–50°C)

Altitude

Maximum operating altitude: 15,000 feet (4,752 meters)

Humidity

5 to 95% relative humidity (RH), non-condensing

Physical dimensions

• 1.75 inches (4.44 cm) height, standard 19-inch (48.26 cm) width, 12-inch (30.48 cm) depth

Management services

• Out-of-Band RS-232 configuration port for management and control

Hardware overview 16

Page 17

Model 2616RC T-DAC User Manual 1 • Introduction

• SNMP version 1 configuration management

• MIB II

• TELNET via Ethernet

• SYSLOG Client

• Remote Software Upgrade via FTP

• Built-in HTTP server for complete configuration and control using a standard web browser

• Frame Relay or PPP in-band management via T1/E1 DS0s.

Figure 3. Model 2616RC front panel LEDs

Hardware overview 17

Page 18

Model 2616RC T-DAC User Manual 1 • Introduction

LED display

Front panel LEDs (figure 3 on page 17) display the status of the WAN ports, the T1/E1 ports, the Ethernet

LAN port, power, and the alarms. The LEDs are described in table 3.

Table 3. LED definitions

LED Color Status Meaning

POWER Green On solid Power is being applied. No action recommended.

Flashing The 2616RC has detected a power failure on a power bus.

Off No input power is being applied.

CPU FAIL Red On solid CPU is unable to load the software from FLASH to RAM for operation.

Off The CPU is operating normally.

ALARM Yellow On solid A minor alarm condition has been detected.

Flashing A major alarm condition has been detected.

Off The Model 2616RC is operating normally.

SYSTEM Green Flashing The Model 2616RC is operating normally.

Off The Model 2616RC is not functioning properly.

ETHERNET Green On solid Link status is nominal for the Ethernet port. No action recommended.

Off

A valid link has not been detected.

CLK SOURCE Green On solid The 2616RC is set as the Master Clock source.

Flashing The 2616RC is set as the secondary clock source.

Off The 2616RC is set as the slave, getting its clock from the H.110 Bus.

CLK ERROR Yellow On solid Master Clock source has been lost and the 2616RC is using the secondary source

for its clock.

Flashing Master Clock source and the Secondary Clock source have been lost and the 2616RC

is using its internal crystal for its clock.

Off No clock errors currently detected.

TEST MODE Green On solid One or more T1/E1 ports or T1/E1 ports is in test mode.

Flashing One or more of the T1/E1 ports or the T1/E1 ports is in test mode and errors have

been received.

Off None of the T1/E1 ports is operating in test mode.

T1/E1

CONNECTION

(LEDs 1–16)

READY Blue On Card ready for removal from Patton ForeFront chassis.

Green On solid The port is activated, linked, and operating normally.

Flashing The port is activated but not linked or in an error state.

Off Card not ready for removal from Patton ForeFront chassis.

Hardware overview 18

Page 19

Chapter 2 Hardware installation

Chapter contents

Introduction..........................................................................................................................................................20

Unpacking the Model 2616RC T-DAC................................................................................................................20

T-DAC blades installation.....................................................................................................................................20

Cable installation...................................................................................................................................................22

Connecting the Ethernet ports ........................................................................................................................22

Connecting the 10/100Base-T Ethernet port to an Ethernet switch or hub ...............................................22

Connecting the 10/100Base-T Ethernet port to an Ethernet-capable workstation or PC ................................23

Connecting the EIA-561 RS-232 configuration port (DCE configured) .........................................................23

Connecting the T1/E1 WAN ports .................................................................................................................24

68-pin SCSI to 8 RJ-45 connectors cable ..................................................................................................24

68-pin SCSI to open end cable ..................................................................................................................26

Installing the WAN cable to a punch-down block ...........................................................................................28

68-pin SCSI to open end, 6 foot cable (part #10-3096TM68-6)—Obsolete ...................................................29

68-pin SCSI to 64-pin female Telco (part #10-3096TM68/64-6) ..................................................................29

Completing the hardware installation....................................................................................................................30

19

Page 20

Model 2616RC T-DAC User Manual 2 • Hardware installation

Introduction

This chapter contains the following procedures for installing the Model 2616RC T-DAC:

Note

Before installing the T-DAC, you will need to obtain the line type and

encoding of the T1/E1 line from your local telephone company (Telco).

• “Unpacking the Model 2616RC T-DAC”—lists the contents in the T-DAC shipping container

• “T-DAC blades installation”—describes installing the T-DAC on a flat surface or in a standard 19-inch

rack

• “Cable installation” on page 22—describes installing the power and network interface cables

• “Completing the hardware installation” on page 30—describes testing the T-DAC hardware to verify that it

is ready for software configuration

Unpacking the Model 2616RC T-DAC

Inspect the shipping carton for external damage. Note any damage before removing the container contents.

Report equipment damage to the shipping carrier immediately for claim purposes. Save all packing materials in

case you need to return an item to the factory for servicing.

The T-DAC comes with the following items:

• The Model 2616RC Digital Cross-Connect (T-DAC)

• One RJ45-to-RJ45 cable for use with the console and Ethernet ports

• A DB9-RJ45 (EIA-561) adapter for connecting a PC's serial port to the T-DAC console port

• Model 2616RC T-DAC User Manual

T-DAC blades installation

Do the following:

Note

1. If you have not done so already, remove the T-DAC from its shipping container.

Note

Introduction 20

Verify that the rack chassis is properly grounded before installing the

T-DAC blades. An adequate ground can be achieved by connecting a

#10 AWG ground wire between the rack chassis grounding stud and

one of the following ground sources:

•

The building ground rod (generally located at the site’s main service entrance)

•

A sprinkler system pipe

•

A cold-water pipe

•

Building structural steel

Be sure to wear the anti-static strap to prevent electrostatic damage to

the blade.

Page 21

Model 2616RC T-DAC User Manual 2 • Hardware installation

Note

The T-DAC should be installed as close as possible to the termination

jack provided by the Telco. The location should be well ventilated.

Do not block the rack chassis’ cooling vents.

2. Insert the rear blade into the desired slot in the rack chassis. Make sure the blade is seated properly in the

slot guides.

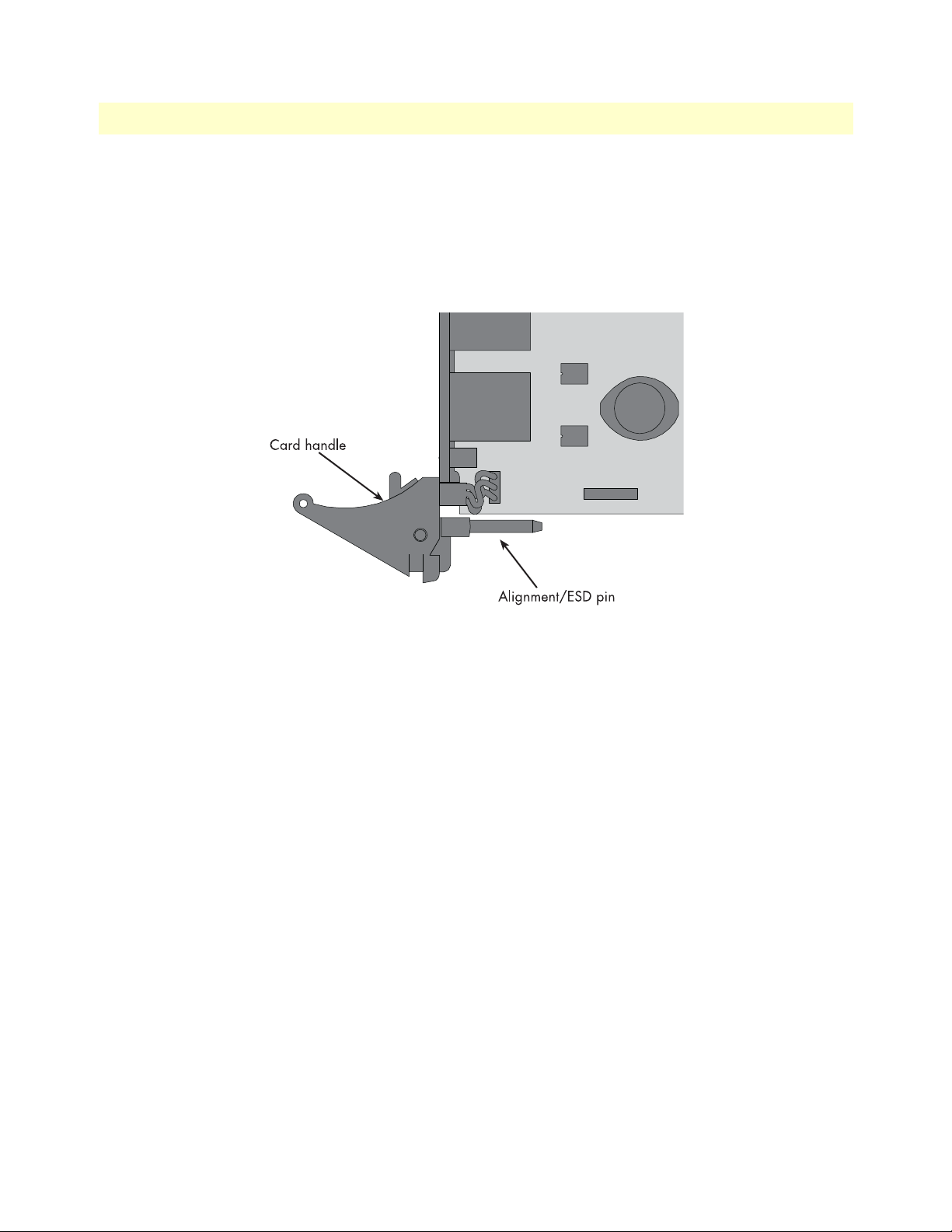

Figure 4. Alignment/ESD pin and card handle

3. Gently press the blade into the chassis until the alignment/ESD pin (see figure 4) engages the chassis.

When the blade is fully seated, the red buttons in the handles click up automatically, thus locking the handle and activating the switch (closed position). The click of the button gives a visual and audible confirmation that the board is fully seated.

4. Insert the front blade into the rack chassis slot that corresponds to the slot in which you installed the rear

blade. Verify that the buttons in both handles click up to indicate that the board is fully seated and locked

into place.

T-DAC blades installation 21

Page 22

Model 2616RC T-DAC User Manual 2 • Hardware installation

Cable installation

This section describes installing the network interface cables.

Connecting the Ethernet ports

The T-DAC has a single 10/100 Ethernet interface for connection to your LAN (figure 5). The Ethernet port will

autosense the correct speed of the local LAN and automatically negotiate half or full-duplex operation. This section describes connecting the T-DAC to the Ethernet LAN via an Ethernet hub, switch, or workstation.

Figure 5. Model 2616RC network and configuration ports

Connecting the 10/100Base-T Ethernet port to an Ethernet switch or hub

The 10/100Base-T Ethernet port (see figure 5) is designed to connect to an Ethernet switch or hub. The

Ethernet RJ-45 pin and signal definitions for the T-DAC or for a NIC card in a workstation/PC are shown

in

figure 6 on page 23. Connect a straight-through CAT-5 cable (one wired as shown in figure 6) between

the T-DAC and the hub/switch.

Cable installation 22

Page 23

Model 2616RC T-DAC User Manual 2 • Hardware installation

Figure 6. Ethernet RJ-45 pin and signal definitions for T-DAC

Connecting the 10/100Base-T Ethernet port to an Ethernet-capable

workstation

or PC

The 10/100Base-T Ethernet port can connect to a single Ethernet-capable workstation or PC by means of a

cross over cable. Refer to

figure 7 to assemble a cross-connect cable that will connect between the NIC Ether-

net port in the workstation and the T-DAC 10/100Base-T Ethernet port.

Figure 7. Cross-over RJ-45-to-RJ-45 Ethernet cable diagram

Connecting the EIA-561 RS-232 configuration port (DCE configured)

Install the supplied RJ-45-to-RJ-45 cable with the DB9-RJ45 adapter between the T-DAC RS-232 port (see

figure 5 on page 22) and an open serial port on your computer. If you need to assemble your own cable, refer

to the pinout diagram in figure 8.

Figure 8.

DB-9-to-RJ-45 cable

diagram

Cable installation 23

Page 24

Model 2616RC T-DAC User Manual 2 • Hardware installation

Connecting the T1/E1 WAN ports

An active T1/E1 is not necessary to configure the T-DAC. However, active T1/E1 connections are required when

mapping WAN time slots to other WAN time slots. The factory-set default configuration of the Model 2616RC

has the T1/E1 ports disabled.

The following types of cables can used to connect the 2616RC to T1/E1 lines:

• 68-pin SCSI to 8 RJ-45 connectors cable, 6 foot (1.8 m) (part #10-3096TM68/8RJ45-6) (see section “68-

pin SCSI to 8 RJ-45 connectors cable” for installation details)

• 68-pin SCSI to 16 RJ-45 connectors cable, 6 foot (1.8 m) (part #10-3096TM68/16RJ45-6) (see section

“68-pin SCSI to 8 RJ-45 connectors cable” for installation details)

• 68-pin SCSI to open end, 12 foot (3.6 m) (part #10-3096TM68-12) (see section “68-pin SCSI to open end

cable” for installation details)

68-pin SCSI to 8 RJ-45 connectors cable

The SCSI-to-RJ-45 cable (see figure 9) connects to the 2616RC via a male SCSI connector (see figure 10). At

the other end of the cable, T1/E1 lines terminate on 8 or 16 individual RJ-45 connectors (wired as RJ-48C)

(see

figure 9). Each RJ-45 terminated T1/E1 line connects directly to a local patch panel or to another

T1/E1 device.

Figure 9. SCSI-to-RJ45 6-foot WAN cable

Cable installation 24

Page 25

Model 2616RC T-DAC User Manual 2 • Hardware installation

Figure 10. WAN cable‘s 68-pin SCSI connector

1. Connect the 68-pin SCSI connector (see figure 10) of the 6-foot WAN cable (see figure 9 on page 24) to

the connector on the rear panel of the Model 2616RC.

2. Connect the WAN cable RJ-45 connectors (see figure 11) to the corresponding ports on a patch panel or

local T1/E1 device.

Figure 11. RJ-45 plug

Table 4. RJ-45 plug pin-out

Description Pin

Transmit pair (TX) 1

Transmit pair (TX) 2

Receive pair (RX) 4

Receive pair (RX) 5

Cable installation 25

Page 26

Model 2616RC T-DAC User Manual 2 • Hardware installation

68-pin SCSI to open end cable

The SCSI-to-open-end cable (see figure 12) connects the 2616RC T1/E1 lines to a punch-down block via 24

gauge solid wire (0.5mm). The other end will be unterminated, open-end twisted pairs. Refer to table 5 for

punch-down block wiring information.

68-pin SCSI connector

Figure 12. SCSI-to-open-end WAN cable

Figure 13. 68-pin SCSI connector

Cable installation 26

Page 27

Model 2616RC T-DAC User Manual 2 • Hardware installation

Note

The 64 wires in this cable are grouped into blue and orange binders of

32 wires each. Wires in the blue binder have the same color scheme as

wires in the orange binder, so it is important to keep each binder sepa

rated to avoid confusion when connecting to a punch-down block.

Table 5. WAN cable’s 68 non-terminated twisted-pairs

Port/Directio

n

Pairs

Port 1/TX 1 1

Port 1/RX 2 2

Port 2/TX 3 3

Port 2/RX 4 4

Port 3/TX 5 5

Port 3/RX 6 6

Port 4/TX 7 7

Port 4/RX 8 8

Port 5/TX 9 9

Port 5/RX 10 10

Port 6/TX 11 11

Port 6/RX 12 12

Port 7/TX 13 13

Port 7/RX 14 14

Port 8/TX 15 15

Port 8/RX 16 16

68 Pin

Positions

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

Wire Color

Code

White/Tan

Tan/White

White/Brown

Brown/White

White/Pink

Pink/White

White/Orange

Orange/White

White/Violet

Violet/White

White/Blue

Blue/White

White/Yellow

Yellow/White

White/Green

Green/White

White/Gray

Gray/White

Tan/Brown

Brown/Tan

Tan/Pink

Pink/Tan

Tan/Orange

Orange/Tan

Tan/Violet

Violet/Tan

Tan/Blue

Blue/Tan

Tan/Yellow

Yellow/Tan

Tan/Green

Green/Tan

Port/Directio

n

Pairs

68 Pin

Positions

Port 9/TX 17 17

Port 9/RX 18 18

Port 10/TX 19 19

Port 10/RX 20 20

Port 11/TX 21 21

Port 11/RX 22 22

Port 12/TX 23 23

Port 12/RX 24 24

Port 13/TX 25 25

Port 13/RX 26 26

Port 14/TX 27 27

Port 14/RX 28 28

Port 15/TX 29 29

Port 15/RX 30 30

Port 16/TX 31 31

Port 16/RX 32 32

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

-

Wire Color

Code

Tan/Gray

Gray/Tan

Brown/Pink

Pink/Brown

Brown/Orange

Orange/Brown

Brown/Violet

Violet/Brown

Brown/Blue

Blue/Brown

Brown/Yellow

Yellow/Brown

Brown/Green

Green/Brown

Brown/Gray

Gray/Brown

Pink/Orange

Orange/Pink

Pink/Violet

Violet/Pink

Pink/Blue

Blue/Pink

Pink/Yellow

Yellow/Pink

Pink/Green

Green/Pink

Pink/Gray

Gray/Pink

Orange/Violet

Violet/Orange

Orange/Blue

Violet/Blue

Cable installation 27

Page 28

Model 2616RC T-DAC User Manual 2 • Hardware installation

Table 5. WAN cable’s 68 non-terminated twisted-pairs (Continued)

Port/Directio

n

Pairs

—

68 Pin

Positions

33

67

Wire Color

Code

Port/Directio

n

Pairs

NOT USED —

68 Pin

Positions

34

68

Wire Color

Code

NOT USED

Installing the WAN cable to a punch-down block

Materials required:

• punch-down tool

• Plastic tie wraps

• WAN cable pin-out specification

Procedure:

1. Measure the distance between SCSI cable entry point on the punch-down block frame and the farthest

port to be wired on the punch-down block (see

figure 14).

Figure 14. Punch-down block wiring

2. Strip SCSI cable insulation and shielding based on the measurement made in step 1.

Cable installation 28

Page 29

Model 2616RC T-DAC User Manual 2 • Hardware installation

3. Review SCSI pin-out (see table 5 on page 27) and punch-block pin-out and cut wires to the required

length to reach their respective ports on the punch-down block.

4. Use punch-down tool to press wires down into block terminals.

5. Use cable ties to secure the wires and SCSI cable to the punch-down block (see table 5 on page 27).

Note

Cable ties should not allow movement of wires or SCSI cable.

6. Connect the 68-pin SCSI connector of the WAN cable to the connector on the rear panel of the

Model

2616RC.

68-pin SCSI to open end, 6 foot cable (part #10-3096TM68-6)—Obsolete

1. This 6-foot WAN cable (see figure 15) connects the 2616RC T1/E1 lines to a punch-down block via 28

gauge wire (0.3mm). Check your punch-down block wire gauge requirements as most punch-down blocks

will not hold 28-gauge wire securely in place.

Figure 15. SCSI-to-open-end 6-foot WAN cable (obsolete)

2. See appendix B, “68-pin SCSI-to-open-end 6-foot cable (part #10-3096TM68-6)” on page 78 for pin-

out information.

68-pin SCSI to 64-pin female Telco (part #10-3096TM68/64-6)

Do the following to install the 6-foot cable adapter for connection of the 2616RC to a Patton E1 balun rack

Models 464RC and 466RC.

1. Connect the 68-pin SCSI connector of the WAN cable to the connector on the rear panel of the

Model

2616RC.

2. Connect the WAN cable 64-pin Telco connector to the corresponding port on a the balun rack.

Cable installation 29

Page 30

Model 2616RC T-DAC User Manual 2 • Hardware installation

Completing the hardware installation

This section verifies that the T-DAC hardware is operational to the point where you can begin configuring the

software settings.

Power is delivered from the Patton ForeFront chassis backplane through the 47-pin PICMG 2.11 power connectors on the 2616RC blades. Upon insertion into the Patton ForeFront chassis, the Model 2616RC immediately powers up and begins its boot cycle. During the boot cycle the following should occur:

1. The POWER LED illuminates, indicating normal power is being applied to the 2616RC.

2. The green SYSTEM LED begins flashing, indicating the 2616RC is operating normally.

Hardware installation is now complete. To configure the 2616RC for operation, refer to chapter 3, “Configur-

ing the T-DAC for operation” on page 31.

Completing the hardware installation 30

Page 31

Chapter 3 Configuring the T-DAC for operation

Chapter contents

Introduction..........................................................................................................................................................32

Configuration prerequisites ...................................................................................................................................32

Initial configuration through the RS-232 control port...........................................................................................33

Connecting the DB9-RJ45 adapter with the included cable ............................................................................33

Setting up the HyperTerminal (or similar program) session ............................................................................34

Using a browser to complete Model 2616RC configuration..................................................................................37

Displaying the T-DAC 2616RC web administration pages .............................................................................38

Home page overview .................................................................................................................................38

Configuring the default gateway .....................................................................................................................40

Configuring the system clocking parameters ...................................................................................................41

Configuring the DS0 mapping ........................................................................................................................44

Configuring line settings and signaling for E1 .................................................................................................46

Accessing the Line Interface Settings .........................................................................................................46

Configuring the E1 line interface settings ........................................................................................................47

Configuring line settings and signaling for T1 ................................................................................................49

Accessing the Line Interface Settings .........................................................................................................49

Configuring the T1 line settings ................................................................................................................50

Enabling/disabling the alarm card ...................................................................................................................52

Saving your configuration......................................................................................................................................53

Backing up your configuration parameters.............................................................................................................53

Backing up the configuration store in flash memory .......................................................................................55

Completing the installation ...................................................................................................................................56

31

Page 32

Model 2616RC T-DAC User Manual 3 • Configuring the T-DAC for operation

Introduction

This chapter contains the following procedures that describe configuring the Model 2616RC T-DAC for

operation:

• “Configuration prerequisites”—lists the items you need to have on hand before configuring the T-DAC.

• “Initial configuration through the RS-232 control port” on page 33—describes how to define the

2616RC’s LAN IP address and netmask parameters.

• “Using a browser to complete Model 2616RC configuration” on page 37—describes how to define the

remaining basic configuration parameters in order to bring your T-DAC on-line. The steps are:

- Defining E1 WAN link parameters (see “Configuring line settings and signaling for E1” on page 46) or

T1 WAN link parameters (see “Configuring line settings and signaling for T1” on page 49)

- Defining static connections with DS0 mapping (see page 43)

- Configuring the system clocking parameters (see page 41)

- Defining the IP default gateway (see page 52)

- Enabling the alarm card (see page 40)

• “Saving your configuration” on page 53—describes how to save your configuration settings.

• “Backing up your configuration parameters” on page 53—describes how save your configuration parame-

ters to a file

• “Completing the installation” on page 56—describes how to verify that your 2616RC T-DAC is fully

operational.

Configuration prerequisites

You will need the following to configure the 2616RC T-DAC:

• A PC equipped with the following:

- RS-232/V.24 serial port

- VT-100 terminal program, e.g., HyperTerminal

- Ethernet port

- Web browser (e.g., Netscape Communicator or Microsoft Internet Explorer)

• You will need the following information to configure the Model 2616RC:

- The IP address and subnet mask for the 2616RC’s Ethernet port

- The IP address of the default gateway

• If you are using a T1 WAN line, you will need the following information from the telephone company

(central office):

- Line Type: either ESF or D4

- Line Coding: either B8ZS or AMI

• If you are using a E1 WAN line, you will need the following information from the Telco:

Introduction 32

Page 33

Model 2616RC T-DAC User Manual 3 • Configuring the T-DAC for operation

- Line Type: either E1 or E1-CRC

- Line Coding: either HDB3 or AMI

Initial configuration through the RS-232 control port

Initially you must configure the 2616RC’s IP address and—in rare instances—change the netmask from the

default settings.

Note

Do not connect power or the Ethernet connection to the Model

2616RC at this time.

Connecting the DB9-RJ45 adapter with the included cable

Do the following:

1. Find the DB9-RJ45 adapter for your PC and RJ-45-to-RJ45 cable shipped with your 2616RC T-DAC.

2. Connect the DB9-RJ45 adapter to your PC’s RS-232 serial port.

3. Connect the RJ45-RJ45 cable between the adapter which you installed in step 1 and the RS-232 Config

port on the front of the Model 2616RC (

figure 16).

Figure 16. Model 2616RC interface ports

Initial configuration through the RS-232 control port 33

Page 34

Model 2616RC T-DAC User Manual 3 • Configuring the T-DAC for operation

Setting up the HyperTerminal (or similar program) session

Do the following:

1. At your PC, find the file HYPERTRM.EXE. Open a HyperTerminal session by double-clicking on the file

name.

Figure 17. Connection Description window

2. Type a connection name (e.g., 2616RC Config), select an icon, then click OK (figure 18).

Figure 18. Connect To window

3. On the Connect To window (figure 18), set Connect using: to one of the options named Direct to ComX

(where the “X” refers to the number identifying the RS-232 serial port on the PC). In the following procedure, Com1 will be the used as the port identifier.

4. Click OK.

5. The COM1 Properties window displays.

Initial configuration through the RS-232 control port 34

Page 35

Model 2616RC T-DAC User Manual 3 • Configuring the T-DAC for operation

6. Configure your COM port settings as shown in figure 19, then click OK.

Figure 19. COM1 Properties window

7. Click on the

File

menu, then select Properties.

8. Configure the settings for Function, arrow and ctrl keys act as to Terminal keys as shown in figure 20, then

click OK.

Figure 20. Terminal keys configuration

Initial configuration through the RS-232 control port 35

Page 36

Model 2616RC T-DAC User Manual 3 • Configuring the T-DAC for operation

9. Connect the male end of the 2616RC T-DAC’s power cables to the power outlets.

10. Boot up information will display on your HyperTerminal connection window, eventually followed by a

login request window (see

figure 21).

Figure 21. Login window

11. For the user name, type

12. For the password, type

superuser

superuser

Figure 22. VT-100 top level management window

.

; the top level management window then appears (see figure 22).

Initial configuration through the RS-232 control port 36

Page 37

Model 2616RC T-DAC User Manual 3 • Configuring the T-DAC for operation

13. Type e for Ethernet, then press

14. Enter a for

PrimaryIpAddress

<Enter>

Figure 23. Ethernet configuration window

, then press

. The

<Enter>

Ethernet

.

configuration window displays (see figure 22).

15. Type your LAN IP address followed by pressing <Enter>.

16. Press the left-arrow cursor key on your keyboard to return to the previous screen.

17. If you do not need to change the PrimaryIpMask from the default of 255.255.255.0, go to step 20. Other-

wise, type b and type the new LAN Mask in the same manner as when entering a LAN IP address.

18. Press the left-arrow cursor key until the top level management window displays (see figure 22 on page 36).

19. Type a for HOME, then press

<Enter>

.

20. Under the Current Status page, type 1 (store Config(1)) to save the changes you have just made to

configuration.

the

This completes the initial configuration of the Model 2616RC. The next steps in configuration will be done

using your Web browser connected via Ethernet to the 2616RC.

Using a browser to complete Model 2616RC configuration

This section describes the following procedures:

• Displaying the T-DAC home page (see “Displaying the T-DAC 2616RC web administration pages” on

page 38)

• Configuring the T1/E1 WAN links (see “Configuring line settings and signaling for E1” on page 46 or

“Configuring line settings and signaling for T1” on page 49)

• Setting static connections with DS0 mapping (see “” on page 43)

Using a browser to complete Model 2616RC configuration 37

Page 38

Model 2616RC T-DAC User Manual 3 • Configuring the T-DAC for operation

• Setting the system clocking parameters (see “Configuring the system clocking parameters” on page 41)

• Configuring the IP default gateway (see “Configuring the default gateway” on page 40)

Displaying the T-DAC 2616RC web administration pages

Do the following:

1. Connect your PCs Ethernet connection to the Ethernet LAN.

2. Connect the 2616RC’s T-DAC 10/100 Ethernet connection to the Ethernet LAN.

3. At your PC, open a Web browser session. In your browser’s URL/address field type the IP address of the

Model 2616RC (for example, if the Model 2616RC’s IP address 123.124.221.10, you would type

123.124.221.10

to

“Initial configuration through the RS-232 control port” on page 33.

in the browser’s URL/address field). If you do not have an IP address in your TDAC, refer

4. A login prompt will appear. In the username field type

Password field

. In the password field type

superuser

superuser

then press

then press

<Enter>

.

5. The 2616RC Configuration Menu home page will appear (see figure 24).

<Tab> to move the cursor to the

Figure 24. 2616RC Configuration Menu home page

Home page overview

The

HOME

tion

pane (see figure 25 on page 39). The

subsystems, while in the

changes to the system configuration. Unlike the

which subsystem page you may select, the

window is divided into two panes: the

Configuration Menu

Configuration/information

Configuration Menu

Configuration/information

Configuration Menu

pane and the

Configuration/informa-

contains the links to the various Model 2616RC

pane, you can view status and other information or make

pane, which appears the same no matter

pane contents will change as you move

from one subsystem page to another.

Using a browser to complete Model 2616RC configuration 38

Page 39

Model 2616RC T-DAC User Manual 3 • Configuring the T-DAC for operation

Figure 25. HOME page window panes

Figure 26. Operator Actions buttons

From the

Home

page, the following actions can be performed:

• Record Current Configuration—clicking on this button (see figure 26) saves the current configuration

from volatile DRAM memory to FLASH memory. Once the configuration is saved into FLASH memory,

the configuration will not be lost even if the power is cycled on the 2616RC. Initially, changes made to the

2616RC configuration are stored in volatile DRAM, enabling the user to set the box up with a working

configuration before committing it to storage in FLASH. When you select Record Current Configuration,

the 2616RC stores your changes to FLASH memory.

Note

If you want to save the configuration changes that you have made,

you must click on

Record Current Configuration

, otherwise all configuration changes will be lost if the power to the Model 2616RC is

turned off.

Using a browser to complete Model 2616RC configuration 39

Page 40

Model 2616RC T-DAC User Manual 3 • Configuring the T-DAC for operation

• Hard Reset—this button (see figure 26) causes the Model 2616RC to perform a cold restart. When you

select Hard Reset, the T-DAC confirms that you want to execute this command. Then, the T-DAC will

disconnect all current sessions, re-initialize the interfaces, and re-load configuration parameters from

FLASH.

• Set Factory Default Configuration—this button (see figure 26) clears out the configuration in FLASH and

loads the factory default parameters into FLASH memory. The factory default settings will not execute on

the Model 2616RC until it is re-booted by doing a Hard Reset.

Note

Set Factory Default Configuration (figure 26) will delete any routing

information, the Model 2616RC’s Ethernet IP address, and any other

site-specific settings made for your particular installation. You will

have to re-enter the Model 2616RC’s Ethernet IP address and net

mask using the rear panel control port before using the

HTTP/HTML Management

pages.

Configuring the default gateway

The default gateway IP address, if defined, is used solely for managing the 2616RC remotely via the Ethernet

port. The 2616RC does not transmit or receive user data nor any other traffic via the default gateway IP

address or the Ethernet port.

Do the following to add the default gateway:

1. On the 2616RC Configuration Menu, click the IP hyperlink to open the IP Configuration page.

2. Click the Routing Info hyperlink to open the IP Routing Information page (figure 27).

Figure 27. IP Routing Information Page

3. The existing route you see in the table is the LAN IP address you assigned to the 2616RC during initial

configuration through the RS-232 control port, earlier in this chapter.

4. To enter the default gateway, use the first

Add a route line

. The Destination shall remain 0.0.0.0, and there

is no mask to enter.

Using a browser to complete Model 2616RC configuration 40

Page 41

Model 2616RC T-DAC User Manual 3 • Configuring the T-DAC for operation

5. In the Gateway box, type your default gateway IP address for the 2616RC.

6. Click the Add Route button to save your configuration.

Figure 28. IP Routing Information window

7. The route which you already see in the table appeared upon the configuration of the LAN IP address.

8. To enter the default gateway, use the first Add Route line. The Destination shall remain as 0.0.0.0. There is

no mask to enter.

9. Enter the IP address in the Gateway box. This is the default gateway.

10. Click on the

Add Route

button.

Configuring the system clocking parameters

In this section you will define clocking sources for the main reference and fallback reference on the 2616RC TDAC. Clocking source selection will depend on the clocking role you assign to the blade: master(1), second

-

ary(2), or slave(3). The master will drive the main reference clock for the chassis. Should the master fail, the