Page 1

USER

MANUAL

MODEL 3088RC

RocketLink-G NTU

Rack Mount G.SHDSL

Modem Card

SALES OFFICE

(301) 975-1000

TECHNICAL SUPPORT

(301) 975-1007

Part# 07M3088R C-UM, Rev. B

Revised 2/1 6/ 1 2

Page 2

2

1.0 Warranty Information ................................................................. 5

1.1 Compliance................................................................................... 5

EMC Compliance:.................... ...... ...... ..... .................................... 5

Low-Voltage Directive (Safety):........................... ......................... 5

PSTN Regulatory:......................................................................... 5

1.2 FCC Part 68 (ACTA) Statement ................................................... 6

1.3 Radio and TV Interference (FCC Part 15).................................... 6

1.4 Industry Canada Notice................................................................ 7

1.5 CE Declaration of Conformity....................................................... 7

1.6 Authorized European Representative........................................... 8

1.7 Service.......................................................................................... 8

1.8 Safety When Working With Electricity .......................................... 9

2.0 General Information.................................................................. 11

2.1 Features...................................................................................... 11

2.2 Description.................................................................................. 11

2.3 Serial Interface Types................................................................. 12

3.0 Configuration ............................................................................ 13

3.1 About Software (CLI) Configuration............................................ 13

3.2 About Harware (DIP Switch) Configuration ................................ 13

3.3 Configuring the DIP Switches (V.35, X.21, and Ethernet Models)...

14

S1-1 through S1-7: Data Rate.................................................... 15

S1-8: TX Clock ........................................................................... 17

S2-1: Front Panel Switches........................................................ 17

S2-2: Line Probe......................................................................... 17

S2-3: Annex A/B......................................................................... 17

S2-4 through S2-5: Clock Mode................................................. 18

X.21 operation. .................................................................... 18

Ethernet operation ............................................................... 18

S2-6: DTE Loops........................................................................ 19

S2-7: DTE Interface Type........................................................... 19

S3-1 through S3-8: Management Address................................. 19

3.4 About System Reset Mode......................................................... 19

Software Upgrades..................................................................... 20

Configuration Reset to Factory Defaults..................................... 20

3.5 Configuring through the Console................................................ 20

Console Help Commands........................................................... 22

System Configuration Commands.............................................. 23

System Status Commands......................................................... 24

DSL Configuration Commands................................................... 24

DSL Status Command................................................................ 25

DSL Clear Errcntrs Command.................. ...... ............................ 25

3.6 Configuring the V.35 Rear Card .......................... ...... ................. 26

Model 1001RCM13445 & 1001RCM134TB Strap Settings........ 26

DTE Shield (M/34 Pin A) & FRGND (JB3) .......................... 26

SGND & FRGND (JB4) ....................................................... 27

Page 3

3

3.7 Configuring the X.21 Rear Card .......................... ...... ................. 27

Model 1001RCM11545& 1001RCM115TB Strap Settings......... 27

DTE Shield (DB-15 Pin 1) & FRGND (JB3) ......................... 28

SGND & FRGND (JB4) ....................................................... 28

3.8 Configuring the E1 Rear Card .................................................... 28

DIP Switch Configuration............................................................ 28

Switch S1-1 : Line Coding .................................................. 28

Switch S1-2 : CRC-4 Multiframe ........................................ 29

Switch S1-3 : Clear Channel Mode .................................... 29

Switch S1-4 Through S1-8 : Reserved ................................ 29

Jumper Configuration................................................................. 29

Making Interface Connections.................................................... 30

Connect Twisted Pair (120 ohm) to G.703/G .7 04 Ne twork . 30

Connect Dual Coaxial Cable (75 ohm) to G.703/G.704 Net-

work. .................................................................................... 31

3.9 Connecting the Ethernet Rear Card ........................................... 32

Connecting the Interface Driver Board....................................... 33

Connecting to the 10Base-T Ethernet Port................................. 34

Connecting the 10Base-T Ethernet Port to a Hub ............... 35

Connecting the 10Base-T Ethernet Port to a PC (DTE) ...... 35

Connecting the Line Interface .............................................35

LED Status Monitors................................................................... 36

Status. ................................................................................. 37

Link. ..................................................................................... 37

3.10 Connecting the 10/100 Ethernet Rear Card............................... 38

Connecting the Interface Driver Board....................................... 39

Connecting to the 10/100BaseTX Ethernet Port........................ 40

Connecting the 10/100BaseTX Ethernet Port to a Hub ....... 41

Connecting the 10/100BaseTX Ethernet Port to a PC (DTE) ..

41

Connecting the Line Interface .............................................41

LED Status Monitors................................................................... 42

4.0 Installation................................................................................. 43

4.1 The Model 1001R14 rack chassis .............................................. 43

The Rack Power Supply............................................................. 43

Powering Up Your 1001R14 Rack.............................................. 44

4.2 Installing Model 3088RC series into the chassis........................ 44

4.3 Connecting the Twisted Pair Interface........................................ 45

4.4 Connecting the Model 3088RC/A/I (V.35) serial interface.......... 47

Connecting the Model 3088RC/A/I (V.35) to a “DTE” device..... 47

Connecting the Model 3088RC/A/I (V.35) to a “DCE” device..... 48

4.5 Connecting the Model 3088RC/D/V (X.21) serial interface ........ 49

Connecting the Model 3088RC/D/V (X.21) to a “DCE” or “DTE” de-

vice............................................................................................. 49

4.6 Connecting the 3088RC/K/K (E1) Interface................................ 50

4.7 Connecting the 3088RC/C/AI (Ethernet) Interface ..................... 50

Page 4

4

5.0 Operation................................................................................... 51

5.1 LED status indicators.................................................................. 51

5.2 Test Modes................................................................................. 52

Loopbacks.................................................................................. 52

Patterns...................................................................................... 53

5.3 Remote Console Operation........................................................ 53

Establishing a Remote Console Session.................................... 53

How to Connect ..................... .................................. ............ 53

How to Disconnect ...................... ..... ...... ..... ........................ 55

Differences in Local and Remote Control Session Behavior...... 56

5.4 Software Upgrade....................................................................... 57

5.5 Reset Configuration to Factory Default....................................... 58

A

Specifications ........................................................................... 59

A.1 Clocking modes .......................................................................... 59

A.2 DTE rate ...................................................................................... 59

A.3 Serial interface ............................................................................ 59

A.4 Serial connector .......................................................................... 59

A.5 Diagnostics ................................................................................. 59

A.6 Status LEDs ................................................................................ 59

A.7 Configuration .............................................................................. 60

A.8 Transmission line ........................................................................ 60

A.9 Line coding ................................................................................. 60

A.10 Line rates (DSL line) ................................................................... 60

A.11 Line interface .............................................................................. 60

A.12 G.SHDSL physical connection ................................................... 60

A.13 Environment ................................................................................ 60

B

Model 3088RC Interface Pin Assignments ............................. 61

B.1 RJ-11 non-shielded DSL port ..................................................... 61

B.2 V.35 interface .............................................................................. 61

B.3 E1 interface ................................................................................. 62

B.4 X.21 interface .............................................................................. 62

B.5 RS-232 console interface ........................................................... 63

B.6 Ethernet interface ....................................................................... 63

Page 5

5

1.0 WARRANTY INFORMATION

Patton Electronics warrants all Model 3088RC components to be free

from defects, and will—at our opti on —repair or replace the product

should it fail within one year from the first date of the shipment.

This warranty is lim ited to defect s in workman ship or mate rials, and do es

not cover customer damage, abuse or unauthorized modification. If this

product fails o r do es not p erforms as w arrante d, you r sole re cours e shal l

be repair or replacem ent as des cr ibed above. Under no conditio n shall

Patton Electronics be liable for any damages incurred by the use of this

product. These da mages incl ude, but are no t limited to, the foll owing: lost

profits, lost savings and incidental or consequential damages arising

from the use of or inability to use this product. Patton Electronics specifically disclaims all other warranties, expressed or implied, and the

installation or use of this product shall be deemed an acceptance of

these terms by the user.

1.1 COMPLIANCE

Note The compliance information in this document applies to Models

3088RC/C/IA and 3088RC/K/K only.

EMC Compliance:

• FCC Part 15, Class A

• EN55022, Class A

Low-Voltage Directive (Safety):

• UL 60950-1/CSA C22.2 N0. 60950-1 listed

• IEC/EN60950-1 2nd edition

• AS/NZS 60950-1

PSTN Regulatory:

• ACTA TIA/EIA/IS-968 A5

• This device is not intended nor approved for connection to the PSTN

Page 6

6

1.2 FCC PART 68 (ACTA) STATEMENT

This equipme nt complies with Part 68 of FCC rules an d the re quirement s

adopted by ACTA. On the bottom side of this equipment is a label that

contains—among other information—a product identifier in the format

US: AAAEQ##TXXXX. If requested, this number must be pro vided to the

telephon e company.

The method used to connect this equipment to the premises wiring and

telephone network must comply with the applicable FCC Part 68 rules

and requirements adopted by the ACTA.

If this equipment causes harm to the telephone network, the telephone

company will notify you in advance that temp orary di sc on tinuance of service may be required. But if advance notice isn’t practical, the telephone

company will notify the customer as soon as possible. Also, you will be

advised of your right to file a complaint with the FCC if you believe it is

necessary.

The telephone company may make changes in its facilities, equipment,

operations or procedures that could affect the operation of the equipment. If this hap pens the tel ephone co mpany will provi de advanc e notice

in order for you to make necessary modifications to maintain uninterrupted service.

If trouble is experienced with this equipment, fo r repair or warranty information, pleas e con tac t our co mp any. If the equipm ent is caus ing ha rm to

the telephone ne twork , the tel ephon e comp any may re quest that you di sconnect the equipment until the problem is resolved.

Connection to party line service is subject to state tariffs. Contact the

state public utility commission, public service commission or corporation

commission for information.

1.3 RADIO AND TV INTERFERENCE (FCC PART 15)

This device generates and uses radio frequency energy, and if not

installed and use d proper ly- that is, in s trict ac corda nce w ith the m anufa cturer’s instructions-may cause interference to radio and television reception. The de vi ce h as b een tested and fo und t o co mply wi th the lim its for a

Class A com puting devi ce i n accord ance with s pecifi catio ns in Subp art B

of Part 15 of FCC rules, which are de signed to provide reasonable protection from such interference in a commercial installation. However,

there is no gua ran tee that interference will not occur in a particula r in st a llation. If the device does cause interference to radio or television reception, which can be determined by disconnecting the unit, the user is

encouraged to try to corr ect the interf erence by on e o r more of the follow ing measures : m ov ing the c omp uti ng equipment away from the receive r,

re-orienting the receiving antenna and/or plugging the receiving equip-

Page 7

7

ment into a different AC outlet (such that the computing e quipment and

receiver are on different branches).

1.4 INDUSTRY CANADA NOTICE

This equipment meets the applicable Industry Canada Terminal Equipment Technical Specifications. This is confirmed by the registration number. The abbreviation, IC, before the registration number signifies that

registration was p erformed based on a Declaration of Conf orm ity ind ic ating that Industry Canada technical specifications were met. It does not

imply that Industry Canada approved the equipment.

This Declaration of Conformity means that the equipment meets certain

telecommunications network protective, operational and safety requirements. The Department does not guarantee the equipment will operate

to the user's satisfaction. Before installing this equipment, users should

ensure that it is permissible to be connected to the facilities of the local

telecommunications company. The equipment must also be installed

using an acceptable method of connection. In some cases, the company’s inside wiring associated with a single line individual service may

be extended by means of a certified connector assembly (telephone

extension cord). T he customer sh ould be awa re that compl iance wit h the

above condition may not prevent degradation of service in some situations. Repairs to some certified equipment should be made by an authorized maintenance facility designated by the supplier. Any repairs or

alterations made by the user to this equipment, or equipment malfunctions, may give the telecommunications company cause to request the

user to disconn ect the equipm ent. Use rs shou ld ens ure for the ir own pr otection that the ground connections of the power utility, telephone lines

and internal metallic water pipe system, are connected together. This

protection may be particularly important in rural areas.

1.5 CE DECLARATION OF CONFORMITY

We certify that the apparatus identified in this document conforms to the

requirement s of Council Directiv e 1999/5/EC on th e approxim ation of the

laws of the member states relating to Radio and Telecommunication Terminal Equipment and the mutual recognition of their conformity.

The safety adv ic e in the doc um entation accompanying this pro duc t s hal l

be obeyed. The conformity to the above directive is indicated by the CE

sign on the device.

Page 8

8

1.6 AUTHORIZED EUROPEAN REPRESENTATIVE

D R M Green

European Compliance Services Limited.

Oakdene House, Oak Road

Watchfield,

Swindon, Wilts SN6 8TD, UK

1.7 SERVICE

All warranty and no n-warranty repairs must be return ed freight prepaid

and insured to Patto n Elec tro nics. All returns must have a Return Materials Authorization number on the outside of the shipping container. This

number may be obtained from Patton Electronics Technical Services at:

•Tel: +1 (301) 975-1007

•Email: support@patton.com

• URL: http://www.patton.com

Note Packages received without an RMA number will not be

accepted.

Page 9

9

1.8 SAFETY WHEN WORKING WITH ELECTRICITY

• Do not open the device when the power cord is connected. For systems without a power switch and

without an external power adapter, line voltages

are present within the device when the power cord

is connected.

• For devices with an external power adapter, the

power adapter shall be a listed Limited Power

Source The mains outlet that is utilized to power

the device shall be within 10 feet (3 meters) of the

device, shall be easily accessible, and protected

by a circuit breaker in compliance with local regulatory requirements.

• For AC powered devices, ensure that the power

cable used meets all applicable standards for the

country in which it is to be installed.

• For AC powered devices which have 3 conductor

power plugs (L1, L2 & GND or Hot, Neutral &

Safety/Protective Ground), the wall outlet (or

socket) must have an earth ground.

• For DC powered devices, ensure that the interconnecting cables are rated for proper voltage, current, anticipated temperature, flammability, and

mechanical serviceability.

• WAN, LAN & PSTN ports (connections) may have

hazardous voltages present regardless of whether

the device is powered ON or OFF. PSTN relates to

interfaces such as telephone lines, FXS, FXO, DSL,

xDSL, T1, E1, ISDN, Voice, etc. These are known

as “hazardous network voltages” and to avoid

electric shock use caution when working near these

ports. When disconnecting cables for these ports,

detach the far end connection first.

• Do not work on the device or connect or disconnect

cables during periods of lightning activity.

WARNING

Page 10

10

This device contains no user serviceable parts. This device can

only be repaired by qualified service personnel.

This device is NOT intended nor approved for connection to the

PSTN. It is intended only for connection to customer premise

equipment.

Electrostatic Discharge (ESD) can damage equipment and impair

electrical circuitry. It occurs when electronic printed circuit cards

are improperly handled and can result in complete or intermittent

failures. Do the following to prevent ESD:

• Always follow ESD prevention procedures when removing and

replacing cards.

• Wear an ESD-preventive wrist strap, ensuring that it makes

good skin contact. Connect the clip to an unpainted surface of

the chassis frame to safely channel unwanted ESD voltages

to ground.

• To properly guard against ESD damage and shocks, the wrist

strap and cord must operate effectively. If no wrist strap is

available, ground yourself by touching the metal part of the

chassis.

In accordance with the requirements of council directive 2002/96/EC on Waste of Electrical and Electronic

Equipment (WEEE), ensure that at end-of-life you separate this product from other waste and scrap and deliver

to the WEEE collection system in your country for recycling.

WARNING

WARNING

CAUTION

Page 11

11

2.0 GENERAL INFORMATION

Thank you for your purchase of this Patton Electronics product. This

product has been thoroughly inspected and tested and is warranted for

One Year parts and labor. If any questions arise during in sta llation or use

of this product, please contac t Patton Electronics Technical Support at:

(301) 975-1007.

2.1 FEATURES

• Symmetrical high data rate DSL (G.SHDSL)

• Data rates up to 4.6Mbps in 64-kbps intervals

• Serial V.35 (DCE only) , X.21 (selectable DCE or DTE), Ethernet (RJ-

45), or T1/E1 interface

• RS-232 console port for manageme nt and configuration

• Built-in testing and diagnostics

• RocketLink Plug ‘n’ Play for easy installations

• Interoperable with other Patton G.SHDSL modems

•CE marked

2.2 DESCRIPTION

The Patton Electronics Model 3088RC G.SHDSL RocketLink provides

high speed 2-wire connectivity to ISPs, PTTs, and enterprise environments using Symmetrical High-data-rate Digital Subscriber Line

(G.SHDSL) technology.

As a symmetric DSL NTU, RocketLink DSL offers the same data rates in

both directions over a single pair of regular twisted pair lines u s ing TCP AM modu lation. Line co nnection is made with an RJ-45 ja ck. The Model

3088RC is designed to fit into Patton’s 2U (3.5”) high rack chassis. This

chassis uses a mid-plane architecture which allows front cards to be

plugged into d iffere nt rear c ards. For m ore informa tion, refe r to the Model

1001RP14 Manual for more inf ormation on th e power supp ly option s that

are available.

The NTU features exte rnally -acce ssibl e DIP switch es, lo opbac k diag no stics, SNMP/HTTP remote-management capabilities using RocketLink

Plug ‘n’ Play, as well as in-band management.

Page 12

12

2.3 SERIAL INTERFACE TYPES

The Model 3088RC versions listed below provide the following types of

built-in serial interfaces:

• 3088RC/A/I provides a V.35 interface on an M/34 female connector

• 3088RC/C/AI provides a Ethernet interface on an RJ45 connector

• 3088RC/D/V/V p rov ide s a X. 21 inte rfac e on a DB-15 female connector

• 3088RC/K/K prov ides a E1 interf ace on ei ther a n RJ48 -C con nector or

dual BNC

Page 13

13

3.0 CONFIGURATION

This section describes the location and orientation of the Model

3088RC’s configuration switches and jumpers, and provides detailed

instructions for all possible settings. Each 3088RC model has different

configuration requirements, depending on the card’s serial interface.

You can configure the 3088RC using either the software (CLI via a

1001CC port) or the hardware (via DIP switches).

3.1 ABOUT SOFTWARE (CLI) CONFIGURATION

To use software configuration you must set DIP switches S1 and S2 to

the ON position, and set DIP Switch S3 to the management address,

before powering-up the RocketLink-G. When DIP switches S1 and S2

are set to ON, the RocketLink-G will operate in software-configuration

mode. When set for software-configuration mode the RocketLink-G will

read any configuration data previously saved to FLASH memory during

system power-up. If no configuration data was previously saved to

FLASH, then the Rocket Lin k-G w il l loa d th e fac tory -de fau lt c onf igu r ati on

from FLASH memory. After power-up, you may use console commands

or the Embedd ed Operations Channel (EOC) to mo dif y the c on f igu rati on

parameters.

3.2 ABOUT HARWARE (DIP SWITCH) CONFIGURATION

To use DIP-switch configuration you must first set the DIP switches to a

position other than all OFF or all ON before powering-up the RocketLink-

G. When all the DIP switch es are se t to any po sitio n other than all OFF or

all ON the RocketLin k-G will ope rate in ha rdwa re (DIP-s witc h)-c onf igu ration mode. In DIP-switch-configuration mode the RocketLink-G will read

the DIP-switch setti ngs du rin g system st artup an d confi gure its elf ac cording to the switch settings.

Once you power-up the RocketLink-G in DIP-switch mode it will operate

in DIP-switch mode until powered down. When operating in DIP-switch

mode you cannot change any configuration settings:

• Changing the DIP switch settings while the device is running will not

modify the operating configuration because the RocketLink-G only

reads the DIP switches during s ystem startup.

• If you attempt to modify the configuration by issuing console commands, the dev ice wil l not e xecut e your c omma nds. Inste ad , the Roc ketLink-G will respond with a message indicating the device is

operating in DIP-switch-configuration mode.

Page 14

14

• If you atte mpt to mo dify any confi gu rati on parameters via the EOC (by

changing (EOC variables), the RocketLink-G will not execute your

changes.

3.3 CONFIGURING THE DIP SWITCHES

(V.35, X.21, and Ethernet

Models)

The Model 3088RC is equipped with three sets of DIP switches, which

you can use to configure the RocketLink-G for a broad range of applications. This section describes switch locations and discusses the configuration options available.

Note By default, the RocketLink-G’s DIP switches are all set to “ON”

so the NTU can be configured via the console. If that is how you

will be configuring the NTU, skip ahead to the section on configuring the console.. Otherwise, read the following sections to

manually configure the DIP switch settings.

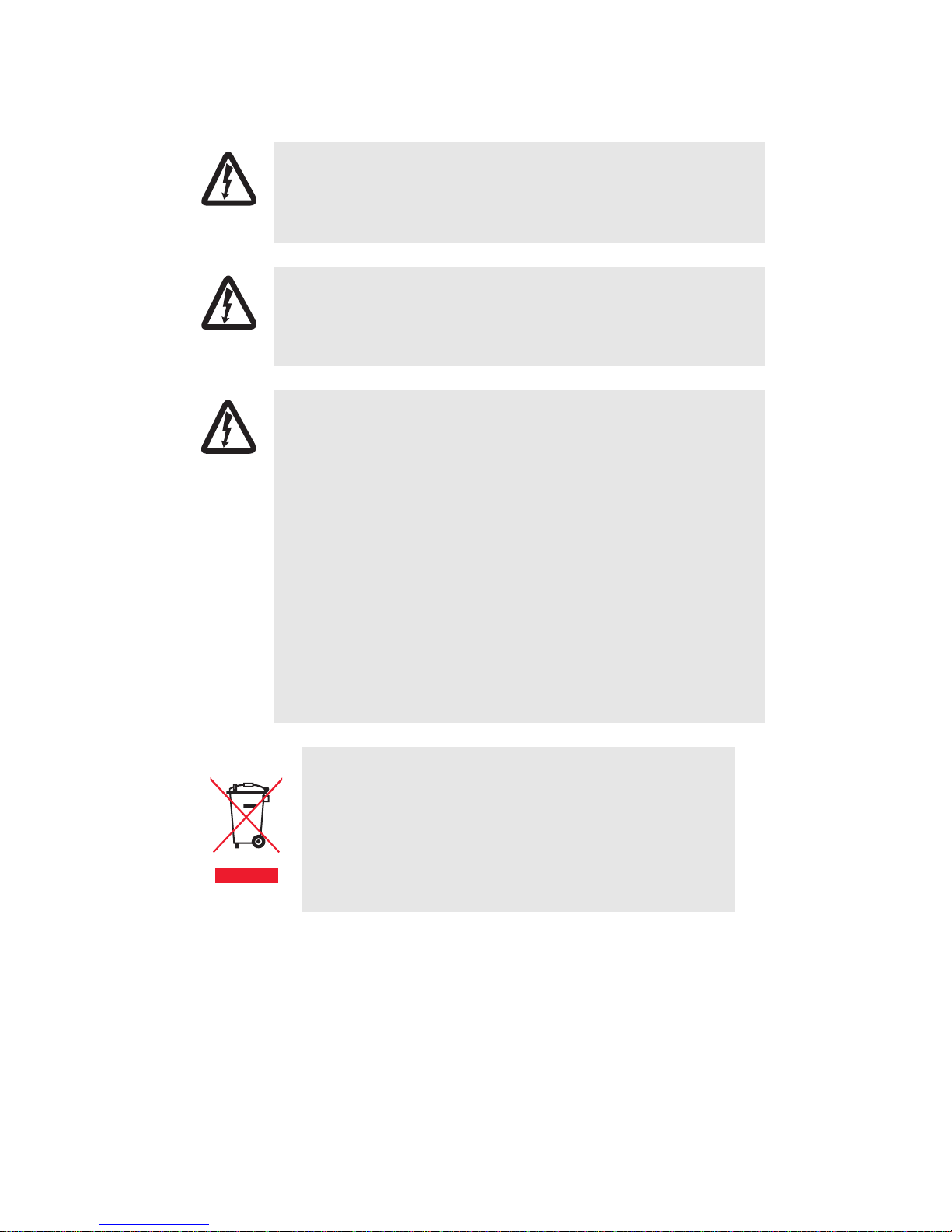

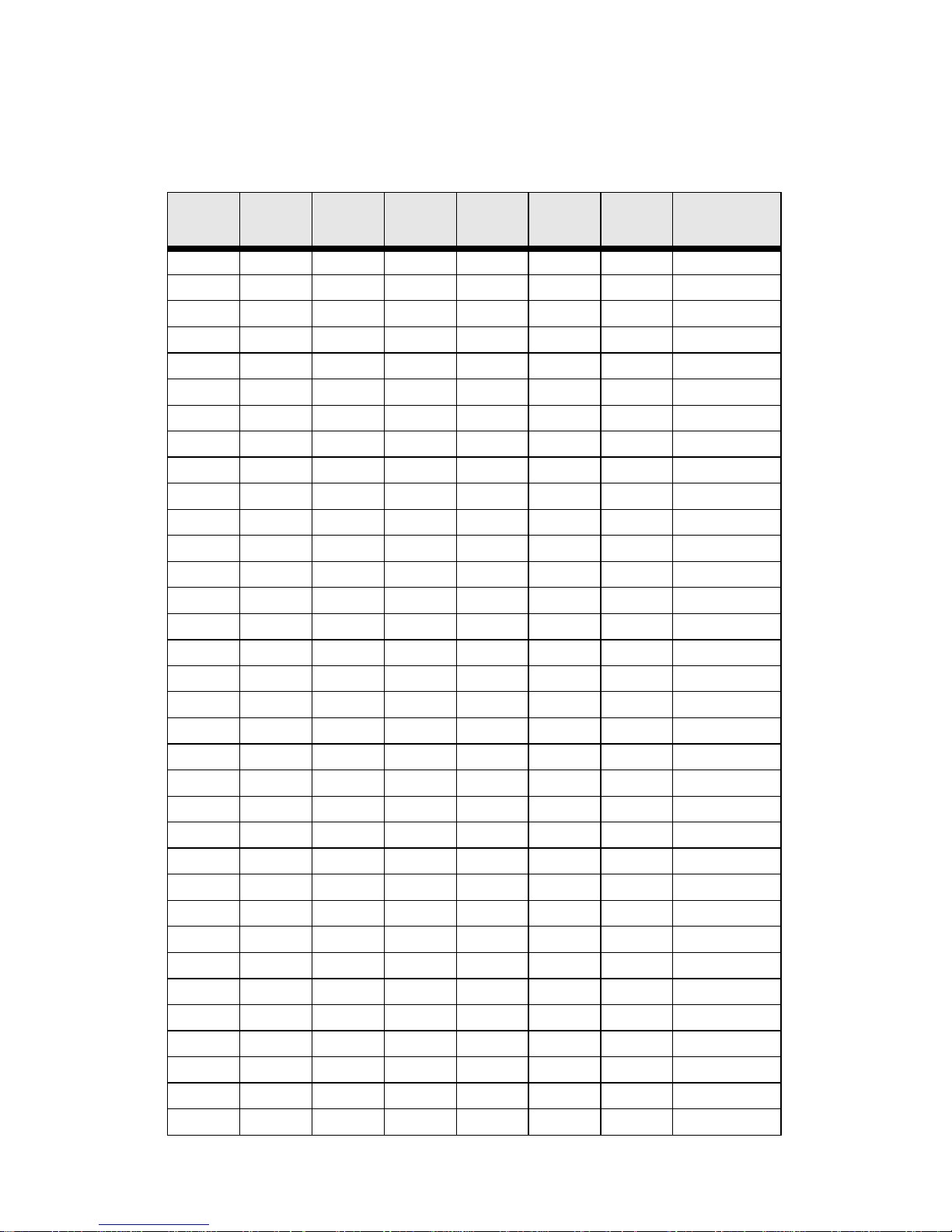

Figure 1. Location of DIP switches on Model 3088RC

The three sets of DIP switches on the Model 3088RC are referred to as

S1, S2 and S3. DIP switch orientation with respect to ON and OFF positions is consistent for all switches.

The DIP switches S1 and S2 can be configured as either ON or OFF.

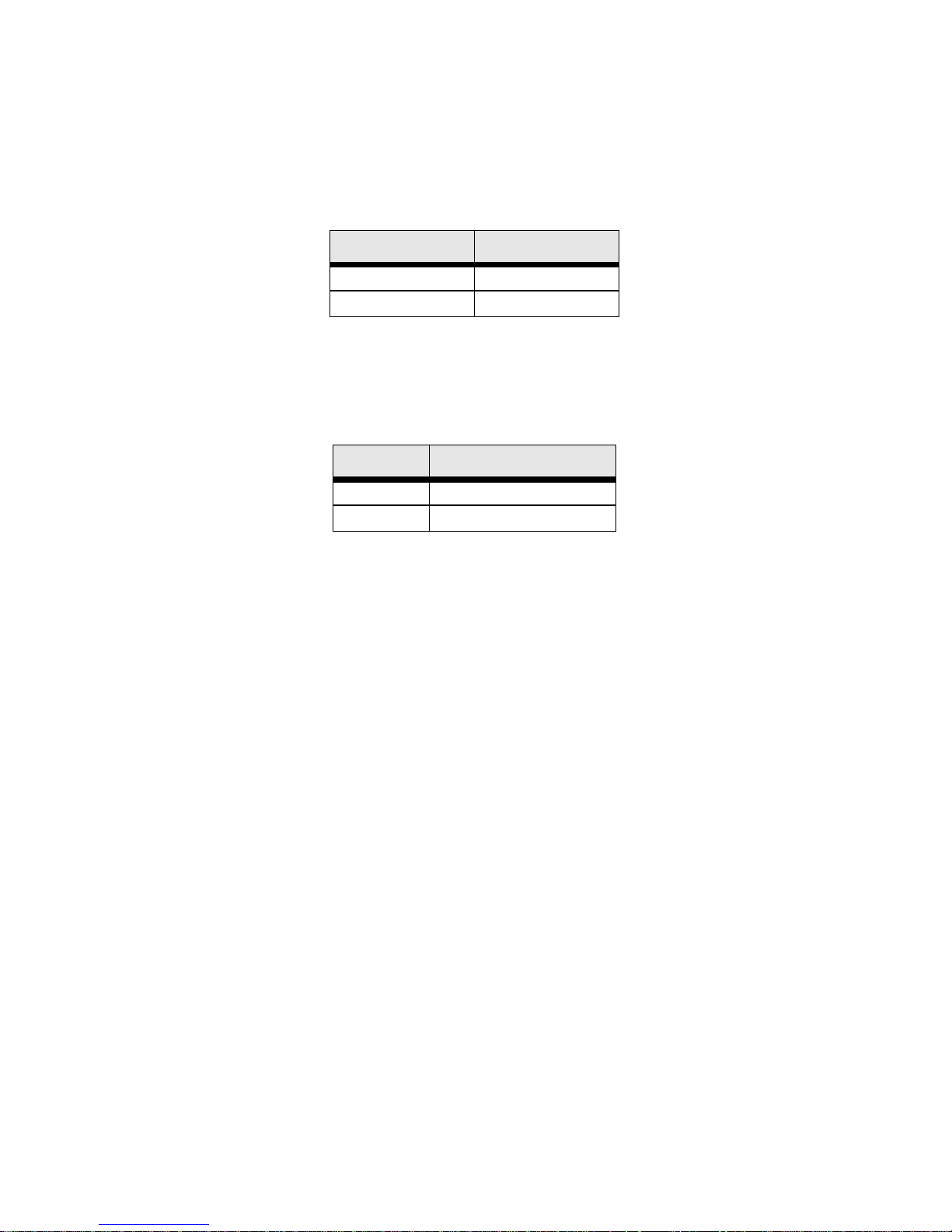

S1 S2

Position Function Position Function

S1-1 Data Rate S2-1 Front Panel Switches

S1-2 S2-2 Line Probe

S1-3 S2-3 Annex

S1-4 S2-4 Clock Mode

S1-5 S2-5

S1-6 S2-6 DTE Loops

S1-7 S2-7 DTE Interface Type

S1-8 TX Clock S2-8 Reserved

S1

S2

S3

Page 15

15

S1-1 through S1-7: Data Rate

Switches S1-1 throug h S1-7 def ine both the DSL data rate and the seri al

data rate.

S1-1 S1-2 S1-3 S1-4 S1-5 S1-6 S1-7

Data Rate

(kbps)

OFFONONONONONON64

ONOFFONONONONON128

OFF OFF ON ON ON ON ON 192

ONONOFFONONONON256

OFF ON OFF ON ON ON ON 320

ON OFF OFF ON ON ON ON 384

OFFOFFOFFONONONON448

ON ON ON OFF ON ON ON 512

OFF ON ON OFF ON ON ON 576

ON OFF ON OFF ON ON ON 640

OFF OFF ON OFF ON ON ON 704

ON ON OFF OFF ON ON ON 768

OFFONOFFOFFONONON832

ON OFF OFF OFF ON ON ON 896

OFF OFF OFF OFF ON ON ON 960

ON ON ON ON OFF ON ON 1024

OFFONONONOFFONON1088

ON OFF ON ON OFF ON ON 1152

OFF OFF ON ON OFF ON ON 1216

ON ON OFF ON OFF ON ON 1280

OFF ON OFF ON OFF ON ON 1344

ON OFF OFF ON OFF ON ON 1408

OFF OFF OFF ON OFF ON ON 1472

ON ON ON OFF OFF ON ON 1536

OFFONONOFFOFFONON1600

ON OFF ON OFF OFF ON ON 1664

OFF OFF ON OFF OFF ON ON 1728

ON ON OFF OFF OFF ON ON 1792

OFF ON OFF OFF OFF ON ON 1856

ON OFF OFF OFF OFF ON ON 1920

OFF OFF OFF OFF OFF ON ON 1984

ON ON ON ON ON OFF ON 2048

OFFONONONONOFFON2112

ONOFFONONONOFFON2176

Page 16

16

OFF OFF ON ON ON OFF ON 2240

ON ON OFF ON ON OFF ON 2304

OFF ON OFF ON ON OFF ON 2368

ON OFF OFF ON ON OFF ON 2432

OFF OFF OFF ON ON OFF ON 2496

ON ON ON OFF ON OFF ON 2560

OFF ON ON OFF ON OFF ON 2624

ON OFF ON OFF ON OFF ON 2688

OFF OFF ON OFF ON OFF ON 2752

ON ON OFF OFF ON OFF ON 2816

OFF ON OFF OFF ON OFF ON 2880

ON OFF OFF OFF ON OFF ON 2944

OFF OFF OFF OFF ON OFF ON 3008

ON ON ON ON OFF OFF ON 3072

OFFONONONOFFOFFON3136

ON OFF ON ON OFF OFF ON 3200

OFF OFF ON ON OFF OFF ON 3264

ON ON OFF ON OFF OFF ON 3328

OFF ON OFF ON OFF OFF ON 3392

ON OFF OFF ON OFF OFF ON 3456

OFF OFF OFF ON OFF OFF ON 3520

ON ON ON OFF OFF OFF ON 3584

OFF ON ON OFF OFF OFF ON 3648

ON OFF ON OFF OFF OFF ON 3712

OFF OFF ON OFF OFF OFF ON 3776

ON ON OFF OFF OFF OFF ON 3840

OFF ON OFF OFF OFF OFF ON 3904

ON OFF OFF OFF OFF OFF ON 3968

OFF OFF OFF OFF OFF OFF ON 4032

ON ON ON ON ON ON OFF 4096

OFFONONONONONOFF4160

ONOFFONONONONOFF4224

OFF OFF ON ON ON ON OFF 4288

ON ON OFF ON ON ON OFF 4352

OFF ON OFF ON ON ON OFF 4416

ON OFF OFF ON ON ON OFF 4480

OFFOFFOFFONONONOFF4544

ON ON ON OFF ON ON OFF 4608

S1-1 S1-2 S1-3 S1-4 S1-5 S1-6 S1-7

Data Rate

(kbps)

Page 17

17

S1-8: TX Clock

S2-1: Front Panel Switches

The 3088RC uses front panel switches to control test modes. They may

be disabled so that the 3088RC ignores them.

S2-2: Line Probe

Line probe is a mechanism that determines the highest rate (192K to

2304K) that the DSL link can reliab ly support. This takes place during

training. The DSL rate will be set to the rate that line probe determines.

Note that both the CO and CPE unit must have line probe enabled for it

to take effect.

Line probe co uld be us ed to determine the best rate the lin e will support,

and then the user could set the units for that rate and disable line probe

so that the rate won’t change without the us er’s knowle dge.

S2-3: Annex A/B

Annex A is typically used in North American-like networks, whereas

Annex B is typically used in European-like networks. The different

annexes specify different PSD (power spectral density) masks because

of the difference in T1 and E1 PSDs.

S1-8 Setting Description

ON Normal TD sampled on falling edge of TX clock.

OFF Inverted TD sampl ed on ris ing edge of TX clock .

S2-1 Front Panel Switches

ON Disabled

OFF Enabled

S2-2 Line Probe

ON Disabled

OFF Enabled

S2-3 Annex

ON A

OFF B

Page 18

18

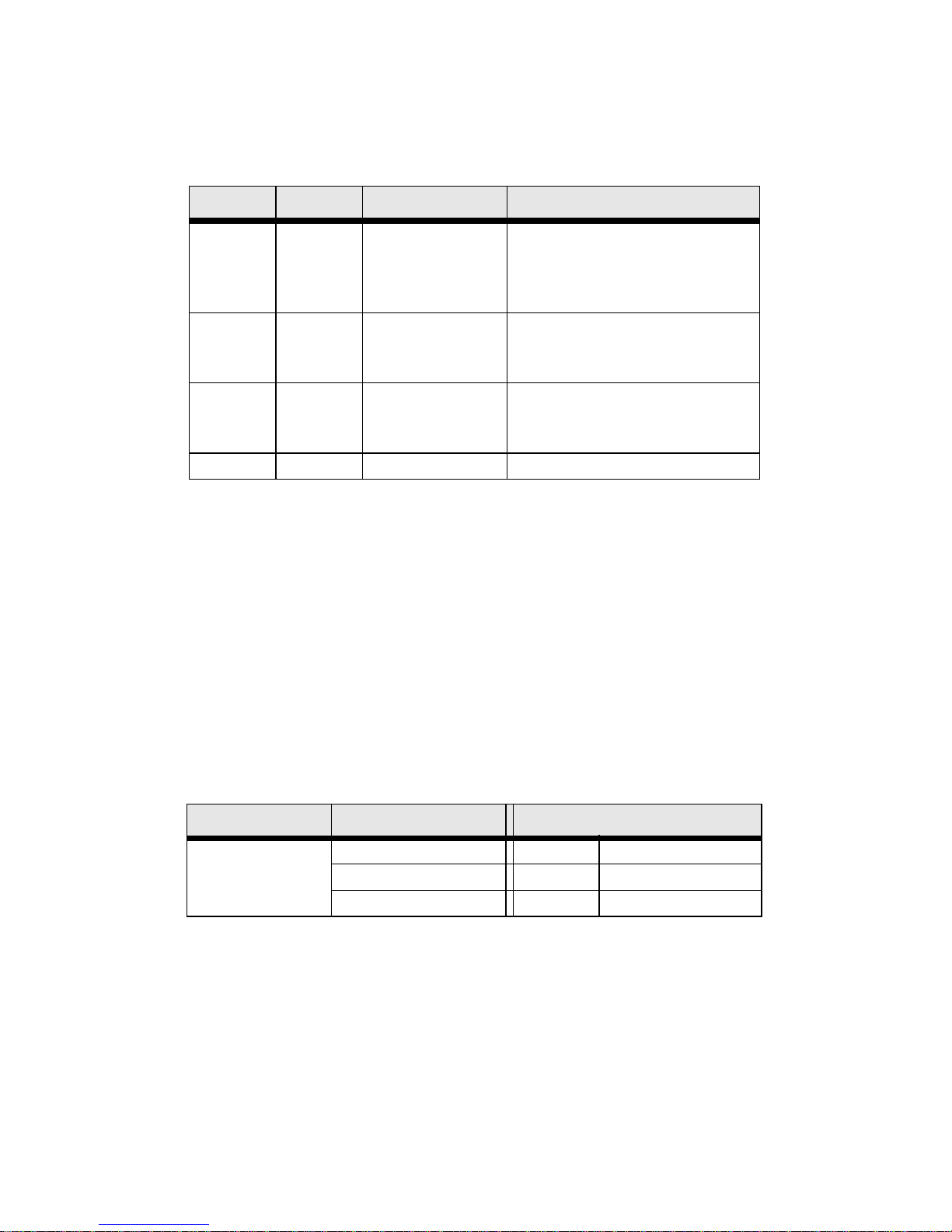

S2-4 through S2-5: Clock Mode

The RocketLink-G can operate in one of three clock modes: internal,

external, or receive-recover.

X.21 operation. There are a few things to note about clock modes and

X.21 operation.

— One X.21 modem must be set to Receive-Recover. The other

X.21 modem must be set to either Internal or External/Network

clock mode.

— The X.21 modem that is configured as Receive-Recover must

be DCE.

— The X.21 modem that is configured as Internal must also be

DCE, but if it is an External/Network clock, then the modem

must be configured as DTE.

Ethernet operation. The 3088RC/C/AI model does not recover clock

from the Ethernet network because it is packet-based rather than TDM.

Therefore, the external clock mode is not valid.

S2-4 S2-5 Clock Mode Description

ON ON Internal The on-board oscillator in

the 3088RC provides clock

for both serial and DSL

lines.

OFF ON External 3088RC uses the RX clock

from the serial interface as

the clock for the DSL link.

ON OFF Receive-

Recover

3088RC uses the RX cloc k

from the DSL line as the

clock for the serial interface .

OFF OFF Reserved

CPE-Side Modem CO-Side Modem

Modem’s X.21

Orientation

Receive-Recover Internal External/Network

DCE DCE x

DCE x DTE

Page 19

19

S2-6: DTE Loops

The V.35 interface provides two pins, one to request an LAL and the

other to request an RDL. If DTE loops are enabled, the 3088RC/A/I will

start a local loopback or a remote loopback when these pins are

asserted. If DTE loops are disabled, these requests will be ignored.

S2-7: DTE Interface Type

The DTE interface type nee ds to be set based on th e rear modul e. Set to

E1 if using the /K model. Set to normal if using any other model.

S3-1 through S3-8: Management Address

Each rack card in a chassis must have a unique management address.

The 1001CC and 1001MC use this address to activate and deactivate

the rack card's management interface. This is necessary because all

rack cards in a chassis communicate over the same bus, so only one

card can be active at a time.

This address can be set to any value between 0 and 255. Set S3 to the

binary representation of the number (ON=0 and OFF=1). S3-8 is the

most significant bit.

3.4 ABOUT SYSTEM RESET MODE

To enter system reset mode, switch all DIP switches to the OFF position

and power cycle the unit. You can use a VT100 emulator configured for

19200 bps/1 stop bit/ no parity/ XON-XOFF flow control to access the

console. Upon restart, you will see the message “Reset Mode”. The

3088RC automatically communicates through the 1001CC in reset

mode, and does not wait for its address.

System reset mode provides two functions: software upgrades and configuration reset to factory defaults.

S2-6 Setting

ON Enabled

OFF Disabled

S2-7 DTE Interface Type

ON E1

OFF Normal

Page 20

20

Software Upgrades

The softwa re is upgra ded by wait ing for the Res et Mode m essage. Then,

the user can send an Intel HEX file supplied by Patton. After the VT100

emulator has finished sending this file, the 3088RC will respond with a

mes-sage stating how many errors were detected. The user may then

set the DIP switches to the desired configuration and power cycle the

unit to run the upgraded software.

Configuration Reset to Factory Defaults

To recover from a forgotten password, the user may reset the unit to its

factory configuration. After se eing the Reset Mode message, the user

should type the ‘*’ key. This will result in a ‘:’ prompt. At the prompt, the

user should ent er the co mman d reset. This wil l restore the uni t to the fa ctory configuration. The unit can then be restarted with the settings in

place.

3.5 CONFIGURING THROUGH THE CONSOLE

The 3088RC offers a console command line interface. To access the

console, use a VT100 emulator configured to 9600 bps, 1 stop bit, no

parity, and XON-XOFF flow control. Use the 1001CC to access the console. Type CTRL+B <address> <enter> to activate the console. Log into

the unit using the default password. No username will be needed.

Note Log in with the default password superuser.

You can configure the following variables through the console:

• Password: The password used to login to the console.

• Circuit ID: The circuit ID communicated to other units via EOC. EOC

(Embedded Operations Channel) is an out-of-band channel specified

in the G.991.2 standard for SHDSL. We use standard EOC messages

for our remote loopback. The 3088RC also supports proprietary EOC

messages that allow a 3096RC to configure it.

• Clock Mode: The following options are available:

— Internal: The internal oscillator in the 3088RC provid es the

clock to both the serial/T1/E1 and DSL interfaces.

— External: The serial interface provides the clock for the DSL

interface (V.35, X.21). It must be set to DTE for the X.21 interface. (This mode is invalid for the Ethernet model).

— Receive Recover: The 3088RC recovers the clock from the

DSL interface and provides it to the serial/E1 interface.

Page 21

21

• Data Rate: Both the seria l/E1 and DSL dat a rates ar e set by sp ecifying

the number of 64k timeslots.

• Annex: Either G.991.2 Annex A or Annex B.

• DTE Interface Type: Either E1 or a normal serial interface.

• DSL Error Monitor Max Interval Errors: The number of errors

allowed in an interval before considering the interval errored. A value

of ‘0’ disables the DSL error monitor.

• DSL Error Monitor Interval Time: The length in seconds of

an interval.

• DSL Error Monitor Interval Count: The number of errored intervals

allowed before restarting the DSL link.

• DSL Error Monitor Total Intervals: The number of i ntervals to insp ect

before disabling the error monitor.

• DSL Error Monitor Startup Delay: The length in seco nds t o wa it af ter

the DSL link is established before starting the error monitor.

• Test Modes: Loopbacks (LAL or RDL) and PRBS (pseudo-random

binary sequence) BER tests (511 or 511 with errors)

• Line Probe: Enable or disable Line Probe for rate

adaptive applications.

The following status information is available through the command

line interface:

• LEDs: Which software controlled LEDs are currently on.

• FPSW Settings: What the fro nt p a nel switches are set to (if the unit is

populated with them).

• Configuration Mode: Whether the 3088RC is configured by DIP

switches or software.

• DSL Link State: In Progress, Success, Deactivated, or Idle.

• DSL Sync State: Out of Sync, Acquiring Sync, In Sync, or Losing

Sync.

Note DSL Link State vs. DSL Sync State—The DSL link state

describes whether the DSL is training (in progress), linked (success), deactivated (we don’t have an option to deactivate the

modem, so the user should not see this), or idle.

The DSL sync state describes whether no sync words have

Page 22

22

been found (out of sync), there are no sync word errors (in

sync), or whether we are transitioning from out of sync to in sync

(acquiring sync) or vice versa (losing sync). Typically, when the

link is training, the sync state goes from out of sync to acquiring

sync to in sync.

• DSL Actual Rate: The actual rate at which the DSL link is running

(minus DSL overhead).

• DSL Line Condition: Good or Poor.

• Noise Margin Ratio: the maximum tolerable increase in external

noise power that still allows for BER of less than 1x 10–7.

• DSL Error Counters: The following error counters are available:

— CRC

— LOSW (Loss of Sync Word)

— TX FIFO Full

— TX FIFO Empty

— TX FIFO Slip

—TX Stuff

— RX FIFO Full

— RX FIFO Empty

— RX FIFO Slip

Console Help Commands

The following commands are provided to help the user find the

correct command:

• help: Lists all the commands that the console recognizes.

• system help: Lists all the commands that start with system that the

console recognizes.

• system set help: Lists all the commands that start with system set

that the console recogn iz es.

• system show help: Lists all the commands that start with system

show that the console recognizes.

Page 23

23

• dsl help: Lists all the commands that start with dsl that the

console recognizes.

• dsl set help: Lists all the commands that start with dsl set that the

console recognizes.

• dsl show help: Lists all the commands that start with dsl show that

the console recognizes.

• dsl show errcntr help: Lists all the commands that start with dsl

show errcntr that the console recognizes.

System Configuration Commands

The following commands allow the user to configure the system:

• system set password <password>: Set s the sy ste m p assword.

• system set circuitid <circuitid>: Sets the circuit ID.

• system set clockmode <internal|external|receiverecover>: Sets

the clock mode. Internal clock mode means the 3088RC provides the

clock to both the DSL and the serial interface. External clock mode

means the 3088RC uses the serial transmit clock as its DSL transmit

clock. Receive recover clock mode means that the 3088RC uses the

DSL receive clock as its DSL transmit clock and as the serial receive

clock.

Note X.21 External Clock Mode—The X.21 interface expects the

DCE to provide the clock used for both transmitting data and for

sampling receive data. When the 3088RC/D/V is set as a DCE,

it may be used in internal or receive recover clock modes. The

DSL generates a clock that is provided to the X.21 interface.

When the 3088RC/D/V is a DTE, it may be used in external

clock mode. The X.21 interface needs to provide the clock. This

clock is used by the DSL to sample the serial data and also to

update the receive data.

The 3088RC is set for either DCE or DTE by flipping the daughter-card. The 3088RC is a DCE if DCE points toward the front of

the 3088RC.

• system set dteif <normal|e1>: Set to E1 if the rear card is Model

3088RC/K/K. Set to normal for all other models.

• system set fpsw <enabled|disabled>: Enable or disable initiating

test modes using the front panel switches.

Page 24

24

The following commands allow the user to view the current

system configuration:

• system show config: Shows the configuration of the entire system,

including DSL and serial/T1/E1 lines.

Any changes to the sys tem config uration or the DSL co nfiguratio n will be

lost on the next power cycle unless the changes are saved. The command system save config is used to save the changes.

System Status Commands

The following commands show system status:

• system show status: Shows the following system status information:

LEDs, DSL test mode, front panel switch settings, DSL link state, and

configurati on mo de.

DSL Configuration Commands

The following commands are used to configure the DSL:

• dsl set timeslots <1–72>: Sets the number of timeslots. The data rate

is calcul ated by the equation: data-rate = #timeslots x 64k.

• dsl set annex <a|b>: Set the annex.

• dsl set lineprobe <enabled|disabled>: Enable or disable line probe.

• dsl set link <enabled|disabled>: Enable or disable the DSL port.

When disabled, a DSL link cannot be established.

• dsl set loopback <off|lal|rdl>: Start or stop loopbacks.

• dsl set pattern <off|511|511e>: Start or stop PRBS generator and

BER meter.

• DSL Error Monitor

The DSL error monitor i nspect s interva ls to see if the y have met the error

threshold (maxint). If the error monitor finds a certain number (intcnt) of

intervals that meet or exceed the error threshold, it will restart the DSL

link. The error monitor will wait (startdelay) seconds after the DSL link

comes up before it b egins mo nitoring erro rs. After th e startu p delay, it will

Startup Delay Interval 1 Interval 2 …

Interval

totint

?startdelay⇒ ?inttime

⇒

?inttime

⇒

?inttime

⇒

?inttime

⇒

Page 25

25

check the number of errors that hav e occurred during each (inttime) seconds to see if they meet the error threshold. The error monitor inspects

(totint) intervals before it stops.

Note Setting maxint to 0 disables the error monitor and setting totint

to 0 causes the error monitor to run continuously.

The following commands configure the error monitor:

• dsl set errmon maxint <maxint>: Sets the number of errors al lowed

in an interval causes it to be considered an errored interval. If this is

set to ‘0’, then the error monitor is disabled.

• dsl set errmon inttime <inttime>: Sets the length of each interval.

• dsl set errmon intcnt <intcnt>: Sets the number of errored intervals

that causes the DSL link to restart.

• dsl set errmon totint <totint>: Set s the number of intervals to ins pect

for errors before di sabli ng the er ror moni tor. If this is set to ‘0’, then the

error monitor will run continuously.

• dsl set errmon startdelay <startdelay>: Sets the number of sec onds

to wait after the DSL link comes up before the error monitor starts

inspecting intervals.

Changing the d at a rate (dsl set timeslots), the clock mode (system set

clockmode), the Annex (dsl set annex), or Line Probe (dsl set

lineprobe), or the DSL error monitor settings will not take effect on the

DSL link until the link restarts. The dsl start command restarts the

DSL link.

DSL Status Command

The dsl show status command shows the following DSL stat us inform a-

tion: link stat e, sync sta te, link speed, error co unters, l ine con dition , noise

margin, and test mode status.

DSL Clear Errcntrs Command

The dsl clear errcntrs command clears the error counte r s.

Page 26

26

3.6 CONFIGURING THE V.35 REAR CARD

The V.35 interface card is configured by setting the configuration straps

and dip switches located on the PC board.

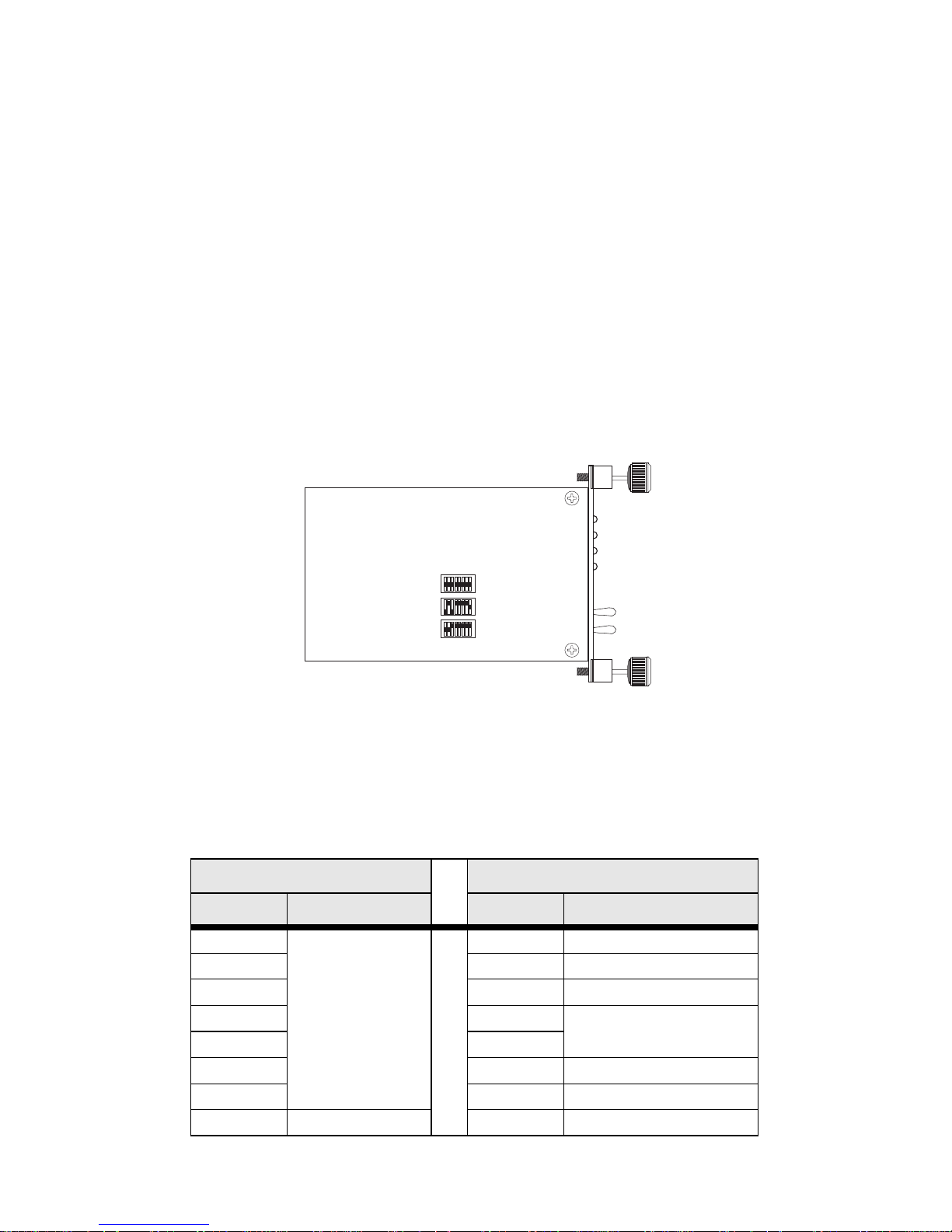

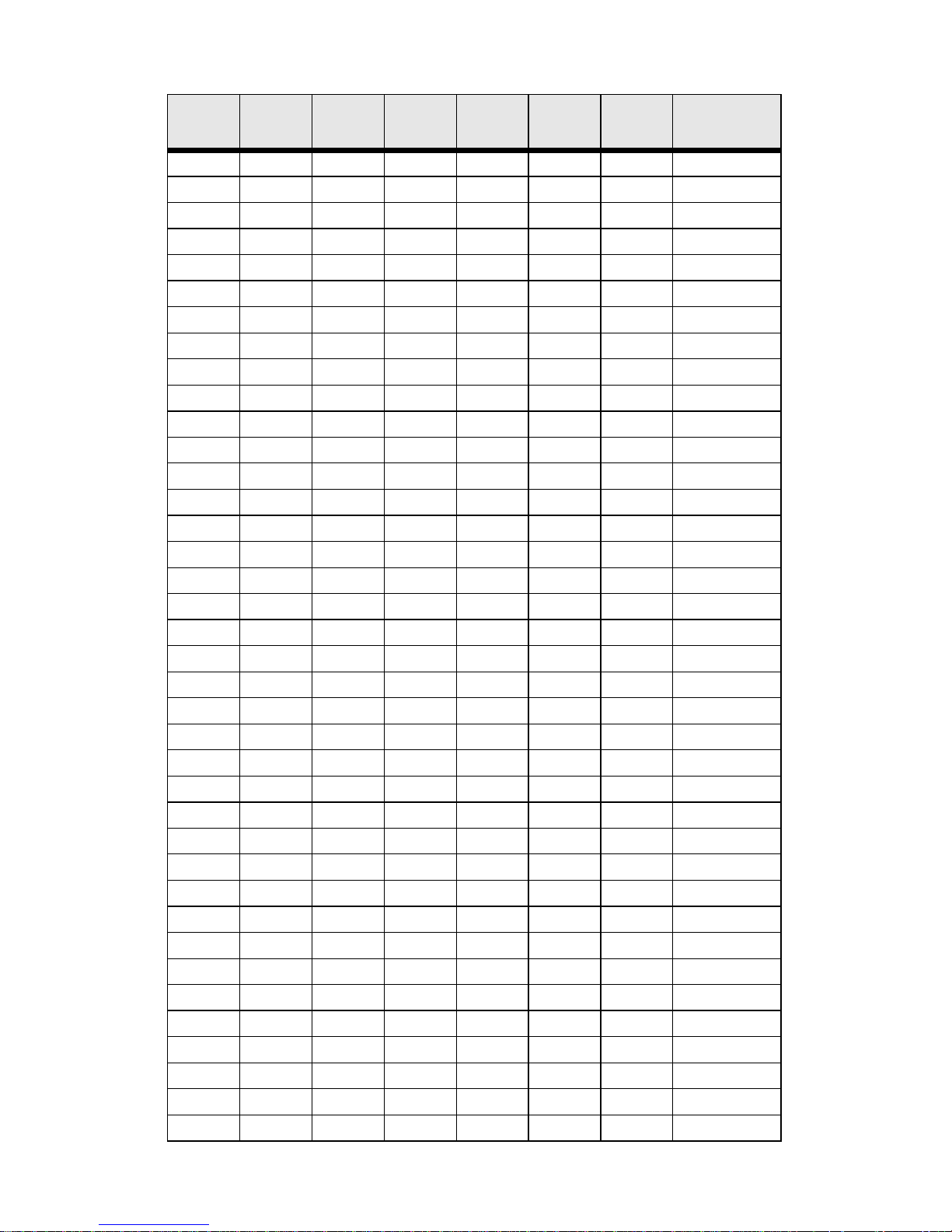

Model 1001RCM13445 & 1001RCM134TB Strap Settings

Figure 2 shows the strap location for the Model 1001RCM134XX (M/34)

rear card. This strap determines whether Signal Ground and Frame

Ground will be connected.

Figure 2. 1001RCM134XX strap locations

The table below pro vi des an ov erv iew of interface strap functions for the

rear interface cards. Following the table overview are detailed descriptions of each strap’s function.

* Indicates default setting

DTE Shield (M/34 Pin A) & FRGND (JB3). In the connected position,

this strap links M/34 pin A & frame ground. In the open position, pin A is

disconnected from frame ground.

Strap Function Position 1&2 Position 2&3

JB3 DTE Shield (Pin A) & FRGND Connected Open*

JB4 FRG ND & SGND (Pin B) Connected Open*

JB3 Description

Position 1&2 DTE Shield (Pin A) and FRGND Connected

Position 2&3 DTE Shield (Pin A) and FRGND Not Connected

123

123

JB3

JB4

Page 27

27

SGND & FRGND (JB4). In the conne cted pos ition, th is strap links Signal

Ground and frame ground through a 100 ohm resistor. In the open position, signal ground is disconnected from frame ground.

3.7 CONFIGURING THE X.21 REAR CARD

The X.21 interface card is configured by setting the configuration straps

located on the PC board.

Model 1001RCM11545& 1001RCM115TB Strap Settings

Figure 3 shows strap locations for the Model 1001RCM115XX (DB-15)

rear cards. Thes e st ra p s det erm ine va rio us grou nd ing characteristics for

the terminal interface and twisted pair lines. JB3 and JB4 are user configurable.

Figure 3. 1001RCM115XX strap locations

The table below pro vi des an ov erv iew of interface strap functions for the

rear interface cards. Following the table overview are detailed descriptions of each strap’s function.

* Indicates default setting

JB4 Description

Position 1&2 SGND and FRGND Connected

Position 2&3 SGND and FRGND Not Connected

Strap Function Position 1&2 Position 2&3

JB3 DTE Shield (Pin1) & FRGND Connected Open*

JB4 FRGND & SGND (Pin 8) Connected Open*

123

JB3

JB4

123

Page 28

28

DTE Shield (DB-15 Pin 1) & FRGND (JB3). In the connected position,

this strap links DB-15 pin 1 & frame ground . In the open position, pi n 1 is

disconnected from frame ground.

SGND & FRGND (JB4). In the connecte d position, th is strap link s DB-15

pin 8 (Signal Ground) and frame ground through a 100 ohm resistor. In

the open position, pin 8 is connected directly to frame ground.

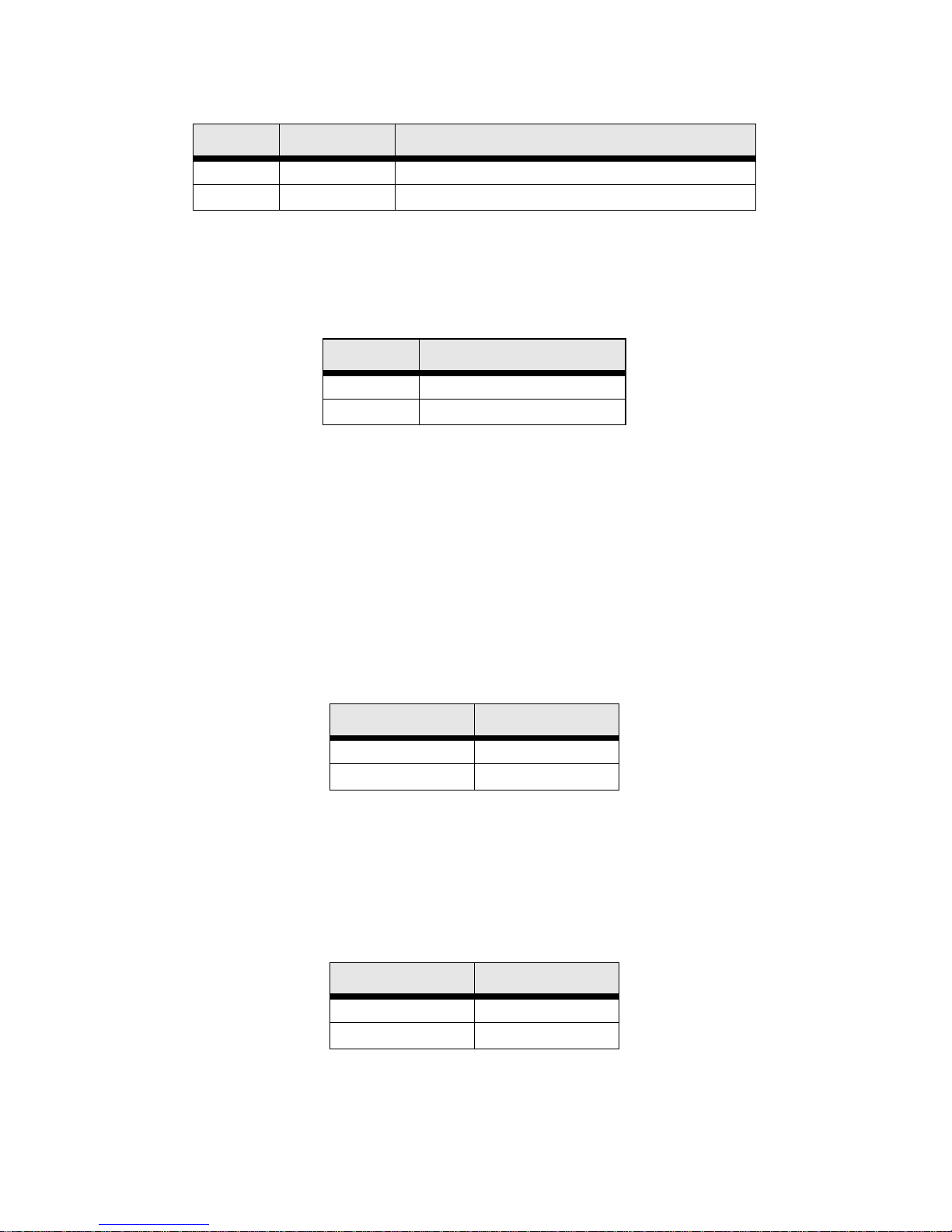

3.8 CONFIGURING THE E1 REAR CARD

The E1 rear card features co nfigura tion capabi lit y via hard ware swi tches

and jumpers. Sec tions 4.1 and 4.2 de sc rib e al l sw it ch a nd ju mp er co nfi g urations for the 3088RC/K model. Section 4.3 describes the configuration required for your mDSL modem.

DIP Switch Configuration

The E1 card has eight internal DIP switches (S1-1 through S1-8). The

DIP switches can be configured as either “On” or “Off.”

Switch S1-1 : Line Coding. Use Switch S1-1 to control the Network

Line Coding options. Set these options to be the same as the Line Coding that has been provided by your Service Provider.

Line Coding Options:

• High Density Bipolar 3 (HDB3): In HDB3 coding, the transm itt er

deliberately inserts a bipolar violation when excessive zeros in the

data stream ar e detected. The receiver reco gni zes these special violations and dec odes th em as zeros . This method enabl es the net work to

meet minimum pulse density requirements. Use HDB3 unless AMI is

required in your application .

JB3 Description

Position 1&2 DTE Shield (Pin 1) and FRGND Connected

Position 2&3 DTE Shield (Pin 1) and FRGND Not Connected

JB4 Description

Position 1&2 SGND (Pin 8) and FRGND Connected through a 100-ohm resistor

Position 2&3 SGND (Pin 8) and FRGND Directly Connected

S1-1 Line Framing & Coding

Off HDB3

On AMI

Page 29

29

• Alternate Mark Inversion (AMI): AMI coding does not inherently

account for ones dens ity . To meet thi s requirement, you should ensure

that the data inherently meets pulse density requirements.

Switch S1-2 : CRC-4 Multiframe. CRC-4 Multiframe uses Time Slot

zero to carry CRC-4 information. When CRC-4 is enabled (ON), the u nit

synchronizes to the CRC-4 multi-frame protocol.

Note When the data rate is set to 2048 Kbps, K Module transmits

user data on all 32 timeslots, ignoring framing information. In

this case, Switch S1-2 will be ignored.

Switch S1-3 : Clear Channel Mode. When S1-3 is at Off position, the

K Module is running in G.703 clear channel mode. When S1-3 is at On

position, the K Module is running in G.704 framed mode. When the K

Module is set to framed mode, channel 0 will be used to pass G.704

framing information which results in a maximum bandwidth of 1984kbps

for user data.

Switch S1-4 Through S1-8 : Reserved. Reserved for future use and

should be set to OFF.

Jumper Configuration

The 3088RC/K mode l has four jumper s (two position he aders): JP4, JP5,

JP6, and JP7. These jump ers are used to selec t input and output impedance matching between the module and external line. See Appendix E

for jumper locations.

The following is a description of the jumper settings with respect to the

front panel connectors.

1. For a 75 ohm connection (coax) install JP4 - JP7 (default).

2. For a 120 ohm connection (RJ-48C) remove JP4 - JP7.

S1-2 Option

Off On

Disabled Enabled

S1-3 Option

Off On

Clear Channel Mode (G.703) Framed Mode

(G.704)

Page 30

30

Making Interface Connections

The 3088RC/K model may be connected to G.703/G.704 ports using a

single 120 ohm RJ-48C or a dual 75 ohm coax (BNC). The 3088RC/K

model rear panels and the location of these connectors are show below.

Figure 4. K Module Rear Panels, Showing Location of Connectors

Connect Twisted Pair (120 ohm) to G.703/G.704 Network . The

3088RC/K model is equipped with a single RJ-48C jack for connections

to a 120 ohm twisted pair G.703/G.704 network interface. If your G.703/

G.704 network terminates via RJ-48 C , use the diagram belo w and the

table on the following page to make the proper connections. The connector pinout and signals are shown in Figure 5.

Use the following connection diagram to connect the 120 ohm G.703/

G.704 network channel.

Figure 5. 120 ohm RJ-48C G.703/G.704 Interface

Page 31

31

Connect Dual Coaxial Cable (75 ohm) to G.703/G.704 Network. The

3088RC/K model is also equipped with dual female BNCs (TX and RX)

for connection to a 75 ohm dual coax G.703/G.704 network interface. If

your G.703/G.704 network terminates via dual coaxial cable, use the diagram below to make the proper connections. The connector pinout and

signals are shown in Figure 6.

Figure 6. 75 ohm Dual Coaxial G.703 Interfac e

Note The outer conductor of the coax cables are isolated

from system earth ground.

Page 32

32

3.9 CONNECTING THE ETHERNET REAR CARD

The Model 3088RC/C/AI module plugs into Patton’s1092ARC and

3088RC modem s to pro vide Et hernet L AN ex tensio n. The 3 088RC /C/AI

has no switches or jumpers and does not need to be configured. However, factors such as the type of med iu m, th rou ghp ut across the lin k an d

clocking mode must be determined by the settings of the baseband

modems. Please refer to yo ur baseba nd modem (i.e. 109 2, and 109 5) to

make the following settings.

1. Bit Rate: The DTE rate setting of y our bas e unit c orresp onds to the

throughput of your 3088RC/C/AI bridge module. Use higher speeds

to allow maximum throughput to your extended LAN. Use lower

speeds to limit the access of your extended LAN.

Note The 3088RC/C/AI only supports synchronous speeds.

2. Clocking Mode: Set the clocking modes on the base units so that

one unit is c onfigured for Internal clocki ng mode and the oth er unit is

set for Receive Recover clocking mode.

3. When using the 3088RC/C/AI, DISABLE, the “Enable Loop from

DTE” Switch on the front function card (1092ARC or 3088RC).

4. All other base unit s ettings depe nd up on yo ur app licat ion an d on the

application medium (twisted pair or coaxial cable)

Page 33

33

Connecting the Interface Driver Board

This package co nta ins an interfa ce driv er board that al lows y ou to co nfi gure your front function card for ethernet operation. Figure 7 shows the

Interface Driver Board connected to a Model 3088RC front function card.

Figure 7. Driver Board mounted on Model 3088RC

Follow the instruc t ion s be low to con nec t the inte rfac e dri ver b oard to the

front function card:

1. With the function card (such as 30 88RC, shown above) pull ed out of

the NetLink rack or clus terb ox cha ssis , loc ate the dri ver board to be

replaced on the top of the base unit front card.

2. Lift the old interface board gently off of the printed circuit board.

3. Position the 3088RC/C/AI driver board on top of the function card’s

pc board with the sockets oriented toward the male pins. Please be

sure the label marked FRONT is pointed toward the front of the

function card (toward the LEDs).

4. Push the In terfa ce Driver Board gent ly o nto the socket a nd re -ins t a ll

the function card into the rack or cluster system.

Page 34

34

Connecting to the 10Base-T Ethernet Port

The Model 3088RC/C/AI provides line side connections through a terminal block or through a RJ-45 connector. Figure 8 below, shows the rear

panel options and the locations of the connectors.

Figure 8. 3088RC/C/AI Ethernet Port

The RJ-45 Ethernet port on Model 3088RC/C/AI is designed to connect

directly to a 10BaseT network. Figure 9 shows the 10BaseT RJ-45 port

pin description. You may make connections up to 33 0 feet us ing Type 4

or 5 cable .

Figure 9. Model 3088RC Ethernet Connector Pinout

Page 35

35

Connecting the 10Base-T Ethernet Port to a Hub . The Model

3088RC/C/AI 10Base-T interface is configured as DTE (Data Terminal

Equipment), just like a 10Base-T network interface card in a PC. Therefore, it “expects” to connect to a 10Base-T Hub using a straight-through

RJ-45 cable. Use th e diagram below to construct a cable to co nne ct t he

3088RC/C/AI to a 10Base-T Hub.

Connecting the 10Base-T Ethernet Port to a PC (DTE). The Model

3088RC/C/AI 10Base-T interface is configured as DTE (Data Terminal

Equipment). If you wish to connect the 3088RC/C/AI to another DTE

device such as a 10Base-T network interface card in a PC, you must

construct a 10Base-T crossover cable as shown in the diagram below.

Connecting the Line Interface. The Model 3088RC/C/AI is to be used

with Patton function card access products (i.e. 1092ARC) There are two

essential requirements for connecting th e line interface on Model

3088RC/C/AI:

1. These units work in pairs with one 3088RC/C/AI connected to

another 3088RC/C/AI (or IM1/I) over 2 or 4-Wire Twisted pair (2 or

4-Wire operation is determined by the front function card).

2. To function properly, the Model 3088RC/C/AI needs one or two

twisted pairs of metallic wire (two or four wire). The twisted pairs

must be unconditioned, dry, metallic wire, between 19 (.9mm) and

26 AWG (.4mm) (Ap pendix B describe s cabl e require ments ) . Standard dial-up telephone circuits, or leased circuits that run through

Page 36

36

signal equalization equipment, or standard, flat modular telephone

type cable, are not acceptable.

Figure 10. RJ-45 Line Interface

Note T wo-Wire Modems use RJ-45 pins 4 and 5 and 4-Wire Modems

use RJ-45 pins 3, 4, 5 and 6, as shown above. Please see the

Function Card User Manual for more details.

LED Status Monitors

The Model 3088RC/ C/AI feature s two LEDs that moni tor general operating status and the 10Base-T twisted pair link integrity. Figure 11 shows

the LEDs located directly beneath the RJ-45 jack.

Figure 11. 3088RC Rear Panel, LED Locations

Page 37

37

Status. Blinks yellow from one to ele ven times to indicate system stat us.

Each pulse pattern is separated by a 2 second “off” period. Greater

pulse patterns have higher priority (buffer saturation has greater priority

than an empty MAC table). Valid system st atus es are:

• 1 pulse = system status ok

• 2 pulses = No MAC entries in the MAC address table

• 3 pulses = Clear to send (CTS) or Carrier Detect (DCD) from base unit

are not asserted

• 4 pulses = IMRC2/IA buffer is saturated

• 5 pulses = WAN receive frame(s) too large

• 6 pulses = WAN receive frame(s) not Octet aligned

• 7 pulses = WAN receive frame(s) aborted

• 8 pulses = Detected WAN receive frame(s) with bad CRC

• 9 pulses = Detected LAN receive frame(s) too large

• 10 pulses = Detected LAN receive frame(s) not Octet aligned

• 11 pulses = Detected LAN receive frame(s) with bad CRC

After a statu s c od e is dis pl aye d ei ght times and the associated condition

is removed, the status code will no longer appear.

Link. Glows green to indicate good link integrity on the 10Base-T

twisted pair line.

Page 38

38

3.10 CONNECTING THE 10/100 ETHERNET REAR CARD

The Model 3088RC/C/AI-100B module plugs into Patton’s 3088RC

modem to provide Eth ernet LAN exten sion. The 3 088RC/C/AI-10 0B has

a jumper that needs to be configu red. The jump er at J7 shoul d be factor y

installed on pins 1 and 2. Factors such as the type of medium, throughput across the link and clocking mode must be determined by the settings of the 3088 standalone modem. Please refer to your 3088

standalone modem to make the following settings.

1. Bit Rate: The DTE rate setting of y our bas e unit c orresp onds to the

throughput of your 3088RC/C/AI-100B bridge module. Use higher

speeds to allow maximum throughput to your extended LAN. Use

lower speeds to limit the access of your extended LAN.

Note The 3088RC/C/AI-100B only supports synchronous speeds.

2. Clocking Mode: Set the clocking modes on the base units so that

one unit is c onfigured for Internal clocki ng mode and the oth er unit is

set for Receive Recover clocking mode.

3. When using the 3088RC/C/AI-100B, DISABLE, the “Enable Loop

from DTE” Switch on the front function card.

4. All other base unit s ettings depe nd up on yo ur app licat ion an d on the

application medium (twisted pair).

Page 39

39

Connecting the Interface Driver Board

This package co nta ins an interfa ce driv er board that al lows y ou to co nfi gure your front function card for ethernet operation. Figure 12 shows the

Interface Driver Board connected to a Model 3088RC front function card.

Figure 12. Driver Board mounted on Model 3088RC

Follow the instruc t ion s be low to con nec t the inte rfac e dri ver b oard to the

front function card:

1. With the function card pulled out of the NetLink rack or clusterbox

chassis, locate the driver board to be replaced on the top of the

base unit front card.

2. Lift the old interface board gently off of the printed circuit board.

3. Position the 3088RC/C/AI-100B driver board on top of the function

card’s pc board with the sockets oriented toward the male pins.

Please be sure the label marked FRONT is pointe d towa rd the front

of the function card (toward the LEDs).

4. Push the In terfa ce Driver Board gent ly o nto the socket a nd re -ins t a ll

the function card into the rack or cluster system.

Page 40

40

Connecting to the 10/100BaseTX Ethernet Port

The Model 3088RC/C/AI-100B provides line side connections through a

terminal bloc k or th rough a RJ-45 conne ctor. Figure 13 below, show s the

rear panel options and the locations of the connectors.

Figure 13. 3088RC/C/AI-100B Ethernet Port

The RJ-45 Ethernet port on Model 3088RC/C/AI-100B is designed to

connect directly to a 10/100BaseTX network. Figure 14 shows the 10/

100BaseTX RJ-45 port pin description. Y ou may make connections up to

330 feet using CAT5 cable.

Figure 14. Model 3088RC Ethernet Connector Pinout

Page 41

41

Connecting the 10/100BaseTX Ethernet Port to a Hub. The Model

3088RC/C/AI-100B 10/100BaseTX interface is auto-sensing, meaning

that it can connect to eith er a 10/1 00 BaseTX switch, hub or a PC. Use a

straight-through or cross-over cable to connect the 10/100BaseTX port.

Refer to the wiring diagram below.

Connecting the Line Interface. The Model 3088RC/C/AI-100B is to be

used with Patton function card access products.There are two essential

requirements for connecting the line interface on Model 3088RC/C/AI100B:

1. These unit s work in p ai rs w i th o ne 3 088 R C/ C/AI-10 0B c onn ec ted to

another 3088RC/C/AI-100B (or 3088/I standalone modem) over 2wire twisted pair.

2. To function properly, the Model 3088RC/C/AI-100B needs one

twisted pair of metallic wire (two wire). The twisted pairs must be

unconditione d, dry, metallic wire, between 19 (.9mm) and 26 AWG

(.4mm) (Appendix B describes cable requirements). Standard dialup telephone circuits, or leased circuits that run through signal

equalization equipment, or standard, flat modular telephone type

cable, are not accept ab le.

Figure 15. RJ-45 Line InterfaceTwo-Wire Modems use RJ-45 pins 4 and 5 and 4-Wire

Modems use RJ-45 pins 3, 4, 5 and 6, as shown above. Please see the Function Card User

Manual for more details.

Page 42

42

LED Status Monitors

The Model 3088RC/C/IA-100B features two LEDs that monitor general

operating status and the 10/100BaseTX twisted pair link integrity.

Figure 16 shows the LEDs located directly beneath the RJ-45 jack.

Figure 16. 3088RC/C/IA-100B Rear Panel, LED Locations

Activity LED

Yellow

Link LED

Green

Page 43

43

4.0 INSTALLATION

This section d escrib es the fu nctio ns of the Mo del 100 1R14 rack chas sis,

tells how to install front and rear Model 3088RC Series cards into the

chassis, and how to connect to the twisted pair interface and the serial

interface.

4.1 THE MODEL 1001R14 RACK CHASSIS

The Model 1001R14 Rack Chassis (Figure 17) has fourteen short range

modem card slots, plus its own power supply. Measuring only 3.5” high,

the Model 1001R14 is designed to occupy only 2U in a 19” rack. Sturdy

front handles allow the Model 1001R14 to be extracted and transported

conveniently.

Figure 17. Model 1001R14 Rack Chassis with power supply

The Rack Power Supply

The power supply included in the Model 1001R14 rack uses the same

mid-plane archit ec ture as the modem cards . The fron t card of the powe r

supply slides in from the front, and the rear card slides in from the rear.

They plug into one another in the middle of the rack. The front card is

then secured by thumb screws and the rear card by conventional metal

screws.

There are no user-serviceable parts in the power supply

section of the Model 3088RC Series. Voltage setting

changes and fuse replacement should only be performed by qualified service personnel. Contact Patton

Electronics Technical support at (301) 975-1007 for

more information.

WARNING

Page 44

44

Powering Up Your 1001R14 Rack

Note The power supplies that come with your 1001R14 rack system

are equipped with a power entry connector on the rear card. The

power supplies are Hot-Swappable, so you are not required to

remove the cards from the rack while applying power to the system.

When a power cabl e is connected between the unit, and an appropriate

power source, a green LED on the front panel will glow to indicate that

the unit is working properly. Since the Model 1001R14 is a "hot swappable" rack, it is not neces sary for an y cards to be inst alled before app lying

power. The power may be removed at any time without harming the

installed cards.

Note Please refer to the Model 1001RP14 Series User Manual AC &

DC Rack Mount Power Supplies for fuse and power card

replacement information.

4.2 INSTALLING MODEL 3088RC SERIES INTO THE CHASSIS

The Model 3088RC Series is comprised of a front card and a rear card.

The two cards meet inside the rack chassis and plug into each other by

way of mating 50 pin card edge connecto rs. Us e the foll owing ste ps as a

guideline for installing each Model 3088RC Series into the rack chassis:

1. Slide the rear card into the back of the chassis along the metal rails

provided.

2. Secure the rear card using the metal screws provided.

3. Slide the front card into the front of the chassis. It should meet the

rear card when it’s almost all the way into the chassis.

4. Push the front card gently into the card-edge receptacle of the rear

card. It should “click” into place.

5. Secure the front card using the thumb screws.

Page 45

45

4.3 CONNECTING THE TWISTED PAIR INTERFACE

The Model 3088RC supports communication between two DTE devices

as follows:

Using 24 AWG (0.5 mm) wire up to:

• 32,000 feet (9.7 km) at 192 kbps

• 18,500 feet (5.6 km) at 2.312 Mbps

Using 26 AWG (0.4 mm) wire up to:

• 23,000 feet (7 km) at 192 kbps

• 13,200 feet (4 km) at 2.312 Mbps

Two things are essential:

1. These units work in pairs. Both units at the end of the twisted pair

DSL span must be set for the same DTE rate—one unit set as CO,

the other as CP.

2. To function properly, the Model 3088RC needs one twisted pair of

metallic wire. This twisted pair must be unconditioned, dry, metallic

wire, between 19 (0.9mm) an d 26 AWG (0.4m m) (the higher number

gauges will limit distance). Standard dial-up telephone circuits, or

leased circuits that run through signal equalization equipment, or

standard, flat modular telephone type cable, are not acceptable.

The interconnecting cables shall be acceptable for

external use and shall be rated for the proper application with respect to voltage, current, anticipated temperature, flammability, and mechanical serviceability.

CAUTION

Page 46

46

The RJ-45 connector on the Model 3088RC’s twisted pair interface is

polarity insensitive and is wired for a two-wire interface. The signal/pin

relationships are shown in Figure 18.

Figure 18. Model 3088RC V.35/X.21 interfaces

3088RC/D/V

(X.21, female DB-15)

3088RC/A/I

(V.35, female DB-25

)

Page 47

47

4.4 CONNECTING THE MODEL 3088RC/A/I (V.35) SERIAL INTER-

FACE

Model 3088RC/A/I supports V.35 serial port connections. This section

describes how to connect the serial ports to your V.35 equipment.

Connecting the Model 3088RC/A/I (V.35) to a “DTE” device

The Model 3088RC/A/I provides a V.35 DCE (data circuit terminating

equipment) interface on a M/34 connector. As a DCE, this interface is

designed to co nnect to DTE equipment, su ch as a ro ute r. When connecting the V.35 interfac e of t he Model 3088RC/ A/I to you r DTE dev ice, us e a

V.35 straight-through cable. Appendix B.2 on page 61 describes pin

assignments and signal sources for the Model 3088RC/A/I V.35 interface.

Figure 19. Connecting the Model 3088RC/A/I to V.35 Serial DTE

The interconnecting cables shall be acceptable for

external use and shall be rated for the proper application with respect to voltage, current, anticipated temperature, flammability, and mechanical serviceability.

CAUTION

Straight-Through Cable

DSL Span

3088RC (DCE)

Remote G.SHDSL NTU

V.35 Router (DTE)

3088RC

RocketLink-G NTU

–Power

–DSL

–TERM

–TM/ER

Remote Local

511 511/E

3088RC

RocketLink-G NTU

–Power

–DSL

–TERM

–TM/ER

Remote Local

511 511/E

Page 48

48

Connecting the Model 3088RC/A/I (V.35) to a “DCE” device

The Model 3088RC/A/I provides a V.35 DCE (data circuit terminating

equipment) interface on a M/34 connector. As a DCE, this interface is

designed to connect to DTE equipment, such as a router. However, connecting the 3088RC/A/I to another DCE device, such as a multiplexer or

G.703 E1 NTU, requires a tailcircuit cable. When connecting the V.35

interface of the Model 3088RC/A/I to your DCE device, use a V.35 tail

circuit cable . Som e ap pli ca tio ns m ay al so require the installation of a t ai lcircuit buf fer to ac cou nt fo r sm al l differences in clock frequency betwe en

the 3088RC/A/I and the V.35 DCE (multiplexer).

Figure 20. Connecting the Model 3088RC/A/I to V.35 Serial DCE

Tail-circuit cable

DSL Span

Model 3088RC/A (DCE)

Remote Model 3088RC

(DCE)

G.703 E1 NTU

3088RC

RocketLink-G NTU

–Power

–DSL

–TERM

–TM/ER

Remote Local

511 511/E

3088RC

RocketLink-G NTU

–Power

–DSL

–TERM

–TM/ER

Remote Local

511 511/E

Page 49

49

4.5 CONNECTING THE MODEL 3088RC/D/V (X.21) SERIAL INTER-

FACE

Model 3088RC/D/V supports X.21 serial port connectio ns. This section

describes how to connect the serial ports to your X.21 equipment.

Connecting the Model 3088RC/D/V (X.21) to a “DCE” or “DTE”

device

The Model 3088RC/D/V provides an X.21 interface on a DB-15 female

connector . The X.21 interface default conf iguration is DCE for connectio n

to DTE (data terminal equipment) such as a router. However, the X.21

interface on the Model 3088 R C/D /V m ay be c onf igu r ed as DTE (data terminal equipment) for connection to DCE such as a modem or multiplexer. When connecting the X.21 interface of th e Model 3088RC/D/V to

your DTE or DCE device, use an X.21 straight-through cable.

Figure 21. Connecting the Model 3088RC/D/V to X.21 DTE or DCE

The DCE/DTE s trap is loca ted on the dau ghter b oar d. The a rrows on the

top of the strap indi cate th e confi guratio n of the X.21 port (f or example , if

the DCE arrows are pointing toward the front of the rack card, the unit is

configured as a DCE). Similarly, if the DTE arrows are pointing toward

the front of the rack card, the unit is configured as a DTE.

The interconnecting cables shall be acceptable for

external use and shall be rated for the proper application with respect to voltage, current, anticipated temperature, flammability, and mechanical serviceability.

CAUTION

Straight-Through 15-pin

D-Sub Cable

Model 3088RC/D (DCE or DTE)

DSL Span

Remote Model 3088RC

Router (DTE)

OR

Mux (DCE)

3088RC

RocketLink-G NTU

–Power

–DSL

–TERM

–TM/ER

Remote Local

511 511/E

3088RC

RocketLink-G NTU

–Power

–DSL

–TERM

–TM/ER

Remote Local

511 511/E

Page 50

50

4.6 CONNECTING THE 3088RC/K/K (E1) INTERFACE

The Model 3088RC/K/K is a rear-mountable G.703/G.704 interface card

that works with the Patton Model 3088RC function card. The two cards

meet inside the rack chassis and plug into each other by way of mating

50 pin card edge connectors. Use the following steps as a guideline for

installing each Model 3088RC/K/K and its function card mate into the

rack chassis:

1. Slide the rear card into the back of the chassis along the metal rails

provided.

2. Secure the rear card using the metal screws provided.

3. Slide the front card into the front of the chassis. It should meet the

rear card when it’s almost all the way into the chassis.

4. Push the front card gently into the card-edge receptacle of the rear

card. It should “click” into place.

5. Secure the front card using the thumb screws.

4.7 CONNECTING THE 3088RC/C/AI (ETHERNET) INTERFACE

The Model 3088RC/C/AI is a rear-moun table ethernet interface card.

The two cards meet inside the rack chassis and plug into each other by

way of matin g 50 pin ca rd edge con nectors. Us e the follo wing st eps as a

guideline for installing each Model 3088RC/C/AI and its function card

mate into the rack chassis:

1. Slide the 3088RC/C/AI rear card into the back of the chassis al ong

the metal rails provided.

2. Secure the 3088RC/C/AI rear card using the metal screws provided.

3. Slide the front function card into the front of the chassis. It should

meet the 3088RC/C/AI rear card when it is almost all the way into

the chassis.

4. Push the front card gently into the card-edge receptacle of the rear

card. It should “click” into place.

5. Secure the front card using the thumb screws.

Page 51

51

5.0 OPERATION

Once the Model 3088RC is properly configured and installed, it should

operate transparently. These sections describes functions of the LED

status indicators, and the use of the built-in loopback test modes.

5.1 LED STATUS INDICATORS

The Model 3088RC features four front panel LEDs that monitor the operation of the rack card. Figure 22 shows the front panel location of each LED.

Table 1 describes each LED’s function.

Figure 22. The Model 3088RC Series’ front panel LEDs

Table 1: Model 3088RC front panel LED descriptiont

LED Color Description

Power Green Flashing = POST

Solid = Power is on

DSL Green Flashing = Training

Solid = DSL Link

TERM Yellow Solid = Serial port is active

TM/ER Green Solid = Test mode is active

Blinking = Test mode error

3088RC

RocketLink-G NTU

–Power

–DSL

–TERM

–TM/ER

Remote Local

511 511/E

Page 52

52

5.2 TEST MODES

The 3088RC offers test modes in the form of loopbacks, PRBS pattern

generators, and combinations of bo th (see Figure 22 on page 51).