Page 1

Model 6676

ForeFront Xtreme

Chassis Assembly

User Guide

Sales Office: +1 (301) 975-1000

Technical Support: +1 (301) 975-1007

E-mail: support@patton.com

URL: www.patton.com

Document Number: 120031U Rev. C

Part Number: 07M6676

Revised: December 17, 2004

Page 2

Patton Electronics Company, Inc.

7622 Rickenbacker Drive

Gaithersburg, MD 20879 USA

tel: +1 (301) 975-1000

fax: +1 (301) 869-9293

support: +1 (301) 975-1007

url: www.patton.com

e-mail: support@patton.com

Copyright Statement

Copyright © 2003–2004, Patton Electronics Company. All rights reserved.

Trademark Statement

The terms ForeFront and ForeFront Xtreme are trademarks of Patton Electronics Company. CompactPCI and PICMG are registered trademarks of the PCI Industrial Computer Manufacturers Group. All other trademarks presented in this document are the

property of their respective owners.

Notices

The information contained in this document is not designed or intended for use as

critical components in human life-support systems, equipment used in hazardous

environments, or nuclear control systems. Patton Electronics Company disclaims any

express or implied warranty of fitness for such uses.

The information in this document is subject to change without notice. Patton Electronics assumes no liability for errors that may appear in this document.

Any software described in this document is furnished under license and may be used

or copied only in accordance with the terms of such license.

Page 3

Contents

Contents ......................................................................................................................................................... 3

Compliance Information ................................................................................................................................ 5

Radio and TV Interference ...............................................................................................................................5

Industry Canada Notice ....................................................................................................................................5

FCC Part 68 Compliance Statement .................................................................................................................5

CE Notice .........................................................................................................................................................5

About this guide .....................................................................................................................................................7

Audience................................................................................................................................................................. 7

Structure................................................................................................................................................................. 7

Precautions ............................................................................................................................................................. 8

Style conventions used in this document................................................................................................................. 8

Typographical conventions used in this document.................................................................................................. 9

General conventions .........................................................................................................................................9

Mouse conventions ...........................................................................................................................................9

1 Introduction.................................................................................................................................................. 11

Introduction..........................................................................................................................................................13

Description of chassis front side ......................................................................................................................14

Description of chassis rear side ........................................................................................................................16

Electromagnetic compatibility (EMC) ............................................................................................................17

Electrostatic discharge (ESD) protection .........................................................................................................18

Hot-swap capability ........................................................................................................................................19

Major system components .....................................................................................................................................20

ForeFront AIS blades ......................................................................................................................................20

Mid-plane architecture ....................................................................................................................................21

Power supply module ......................................................................................................................................22

Fan tray module ..............................................................................................................................................22

System specifications .............................................................................................................................................23

6U chassis specifications ..................................................................................................................................23

Power input and power supply specifications ..................................................................................................24

Fan tray specifications .....................................................................................................................................24

2 Installation checklist ..................................................................................................................................... 25

6U quick set-up checklist.......................................................................................................................................27

Power cable installation ...................................................................................................................................28

Installing the power cables .........................................................................................................................28

Grounding the Model 6676 ......................................................................................................................29

3 Maintenance.................................................................................................................................................. 31

Preventive Maintenance.........................................................................................................................................33

Cleaning the fan filter .....................................................................................................................................33

3

Page 4

Contents

Model 6676 6U CPCI Chassis Assembly User Guide

Troubleshooting....................................................................................................................................................33

System won’t power up ...................................................................................................................................33

4 Contacting Patton for assistance ................................................................................................................... 35

Introduction..........................................................................................................................................................37

Contact information..............................................................................................................................................37

Service ............................................................................................................................................................37

Warranty Service and Returned Merchandise Authorizations (RMAs)...................................................................37

Warranty coverage ..........................................................................................................................................38

Out-of-warranty service .............................................................................................................................38

Returns for credit ......................................................................................................................................38

Return for credit policy .............................................................................................................................38

RMA numbers ................................................................................................................................................38

Shipping instructions ................................................................................................................................38

A Replacement parts and accessories ............................................................................................................... 39

Replacement parts .................................................................................................................................................40

ForeFront chassis power supplies .....................................................................................................................40

ForeFront chassis fan/filter components ..........................................................................................................40

Accessories.............................................................................................................................................................40

B Glossary ........................................................................................................................................................ 41

C ...........................................................................................................................................................................43

CFM ...............................................................................................................................................................43

CSA ................................................................................................................................................................43

CT ..................................................................................................................................................................43

D...........................................................................................................................................................................43

Dual Redundant .............................................................................................................................................43

E............................................................................................................................................................................43

EIA .................................................................................................................................................................43

EMC ...............................................................................................................................................................43

EMI ................................................................................................................................................................43

EN ..................................................................................................................................................................43

ESD ................................................................................................................................................................43

H...........................................................................................................................................................................43

Hot-Swap .......................................................................................................................................................43

HP ..................................................................................................................................................................43

I.............................................................................................................................................................................43

IEC .................................................................................................................................................................43

IEEE ...............................................................................................................................................................43

K ...........................................................................................................................................................................43

Keying ............................................................................................................................................................43

N...........................................................................................................................................................................44

N+1 Redundant ..............................................................................................................................................44

NEBS .............................................................................................................................................................44

4

Page 5

5

Model 6676 6U CPCI Chassis Assembly User Guide

Contents

P............................................................................................................................................................................44

PCI .................................................................................................................................................................44

PCI SIG ..........................................................................................................................................................44

PICMG ..........................................................................................................................................................44

Platform ..........................................................................................................................................................44

S............................................................................................................................................................................44

SELV ..............................................................................................................................................................44

S-HAZ ............................................................................................................................................................44

Shroud ............................................................................................................................................................44

T ...........................................................................................................................................................................44

TDM ..............................................................................................................................................................44

TNV ...............................................................................................................................................................44

U...........................................................................................................................................................................45

U ....................................................................................................................................................................45

W..........................................................................................................................................................................45

Warm-Swap ....................................................................................................................................................45

C Bibliography ................................................................................................................................................. 47

Publications referenced in this guide......................................................................................................................48

Page 6

6

Contents

Model 6676 6U CPCI Chassis Assembly User Guide

Page 7

Compliance Information

and TV

Radio

The Model 6676 ForeFront™ Xtreme™ Chassis generates and uses radio frequency energy, and if not

installed and used properly—that is, in strict accordance with the manufacturer’s instructions—may cause

interference to radio and television reception. The Model 6676 ForeFront Xtreme has been tested and found to

comply with the limits for a Class A computing device in accordance with the specifications in Subpart B of

Part 15 of FCC rules, which are designed to provide reasonable protection from such interference in a commercial installation. However, there is no guarantee that interference will not occur in a particular installation.

If the Model 6676 ForeFront Xtreme Chassis causes interference to radio or television reception, which can be

determined by disconnecting the cables, try to correct the interference by one or more of the following measures: moving the computing equipment away from the receiver, re-orienting the receiving antenna, and/or

plugging the receiving equipment into a different AC outlet (such that the computing equipment and receiver

are on different branches).

Industry Canada Notice

The Canadian Department of Communications label identifies certified equipment. This certification means

that the equipment meets certain telecommunications network protective, operational and safety requirements. The Department does not guarantee the equipment will operate to the user's satisfaction. Before installing this equipment, users should ensure that it is permissible to be connected to the facilities of the local

telecommunications company. The equipment must also be installed using an acceptable method of connection. In some cases, the company’s inside wiring associated with a single line individual service may be

extended by means of a certified connector assembly (telephone extension cord). The customer should be

aware that compliance with the above condition may not prevent degradation of service in some situations.

Repairs to some certified equipment should be made by an authorized maintenance facility designated by the

supplier. Any repairs or alterations made by the user to this equipment, or equipment malfunctions, may give

the telecommunications company cause to request the user to disconnect the equipment. Users should ensure

for their own protection that the ground connections of the power utility, telephone lines and internal metallic

water pipe system, are connected together. This protection may be particularly important in rural areas.

Interference

Users should not attempt to establish or modify ground connections

themselves, instead they should contact the appropriate electric

inspection authority or electrician.

FCC Part 68 Compliance Statement

This equipment complies with Part 68 of the FCC rules and the requirements adopted by the ACTA. Refer to the plugin cards’ user guide for details.

CE Notice

The CE symbol on your Patton Electronics equipment indicates that it is in compliance with the Electromagnetic Compatibility (EMC) directive and the Low Voltage Directive (LVD) of the European Union (EU). A

Certificate of Compliance is available by contacting Technical Support.

5

Page 8

6

Model 6676 6U CPCI Chassis Assembly User Guide

Page 9

About this guide

This manual is a comprehensive hardware reference tool for the Patton Electronics 6U cPCI Redundant Backplane/Midplane and Chassis line of products.

Audience

This guide is intended for the following users:

• System developers installing and integrating the products into their systems

• Operators

• Installers

• Maintenance technicians

Structure

This guide contains the following chapters and appendices:

• Chapter 1, "Introduction" on page 11 provides an overview of the product

• Chapter 2, "Installation checklist" on page 25 provides a quick set-up checklist for installing the

Model 6676.

• Chapter 3, "Maintenance" on page 31 provides a quick set-up checklist, tips for troubleshooting, warranty

information, and where to get help.

• Chapter 4, "Contacting Patton for assistance" on page 35 contains information on contacting Patton tech-

nical support for assistance

• Appendix A, "Replacement parts and accessories" on page 39 provides model numbers and descriptions for

replaceable components and accessories

• Appendix B, "Glossary" on page 41 defines terms and acronyms used in this document.

• Appendix C, "Bibliography" on page 47 provides a list publications used in conjunction with this manual

For best results, read the contents of this guide before you install the enclosure.

7

Page 10

About this guide

Model 6676 6U CPCI Chassis Assembly User Guide

Precautions

Notes and cautions, which have the following meanings, are used throughout this guide to help you become aware

of potential problems. Warnings relate to personal injury issues, and Cautions refer to potential property damage.

Note

Calls attention to additional or noteworthy information or tips.

The shock hazard symbol and WARNING heading indicate a potential electric

shock hazard. Strictly follow the warning instructions to avoid injury caused

by electric shock.

The alert symbol and WARNING heading indicate a potential safety hazard.

Strictly follow the warning instructions to avoid personal injury.

The shock hazard symbol and CAUTION heading indicate a

potential electric shock hazard. Strictly follow the instructions to

avoid property damage caused by electric shock.

The alert symbol and CAUTION heading indicate a potential hazard. Strictly follow the instructions to avoid property damage.

This symbol and the CAUTION heading indicates a situation

where damage to equipment can be caused by electrostatic discharge.

.

This symbol and the IMPORTANT heading provides information

which should be followed for best results when installing, configuring, or operating the Patton product.

Style conventions used in this document

Cross-references, figure titles, and table titles are hyperlinked. This means that if you have the on-line version of

this document, you can click on the cross-reference and it will “jump” you to that reference within the document.

This feature only works with references to sections/tables/figures within this document. References to other documents (for example, PICMG 2.5 R1.0 CompactPCI Computer Telephony Specification ) are not hyperlinked.

Specific safety-related terms, traceable to certain safety regulatory agency requirements (i.e., IEC950 and harmonized derivative specifications) are used within this manual. Refer to the referenced document for a definition of these terms.

8

Page 11

9

Model 6676 6U CPCI Chassis Assembly User Guide

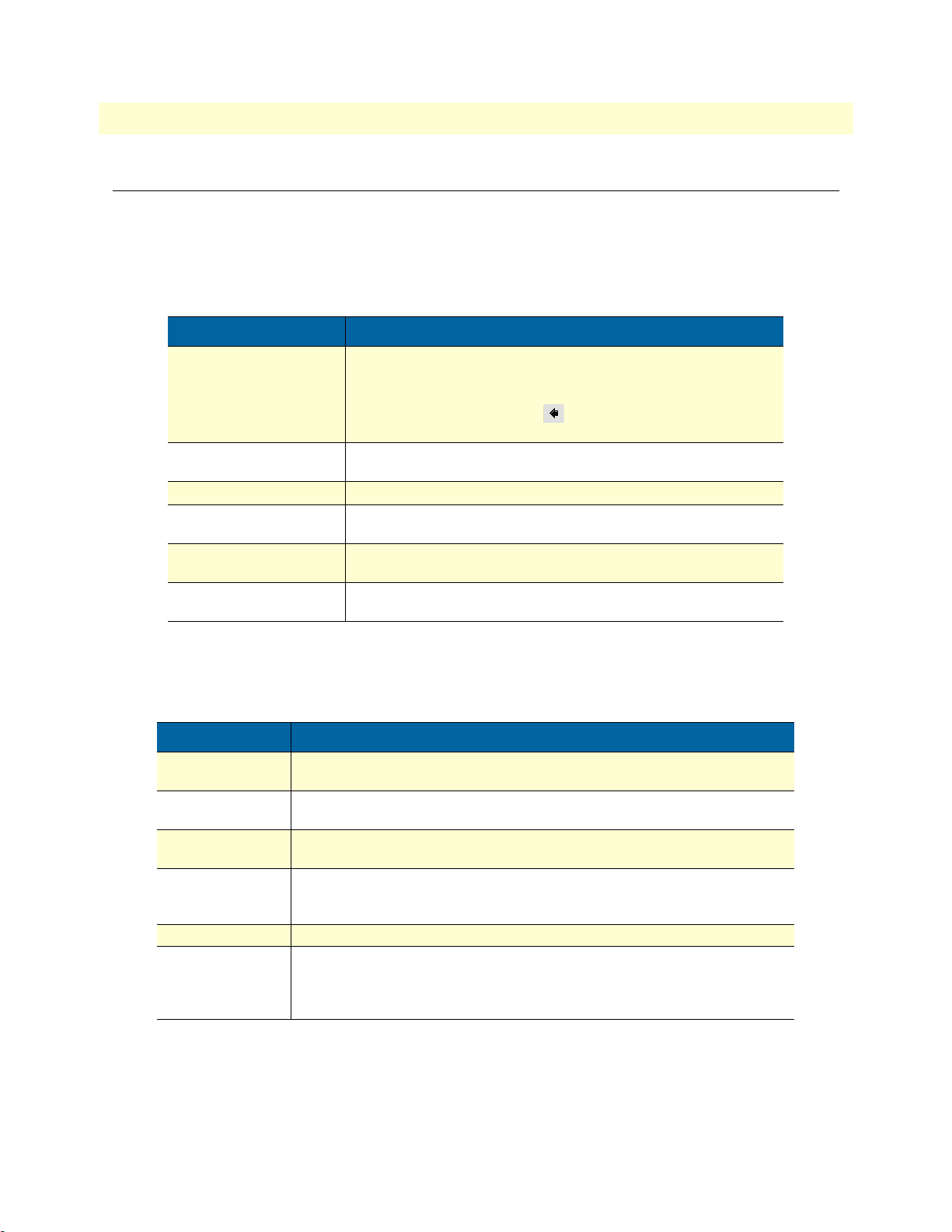

Typographical conventions used in this document

This section describes the typographical conventions and terms used in this guide.

General conventions

The procedures described in this manual use the following text conventions:

Table 1. General conventions

Convention Meaning

Garamond blue type

Garamond italicized type

Garamond bold type

< > Angle brackets indicate function and keyboard keys, such as <SHIFT>,

Are you ready?

% dir *.*

Indicates a cross-reference hyperlink that points to a figure, graphic,

table, or section heading. Clicking on the hyperlink jumps you to the reference source. When you have finished with the source, click on the

Go to Previous View button in the Adobe® Acrobat® Reader

toolbar to return to your starting point.

Indicates the names of options on pull-down menus, names of menu bar

options, or the names of fields or windows.

Indicates the names of command buttons that execute an action.

<CTRL>, <C>, and so on.

All system messages and prompts appear in the Courier font as the

system would display them.

Bold Courier font indicates where the operator must type a response or

command

About this guide

Mouse conventions

The following conventions are used when describing mouse actions:

Table 2. Mouse conventions

Convention Meaning

Left mouse button

Right mouse button This button refers the secondary or rightmost mouse button (unless you have

Point This word means to move the mouse in such a way that the tip of the pointing

Click Means to quickly press and release the left or right mouse button (as instructed in

Double-click Means to press and release the same mouse button two times quickly

Drag This word means to point the arrow and then hold down the left or right mouse but-

This button refers to the primary or leftmost mouse button (unless you have

changed the default configuration).

changed the default configuration).

arrow on the screen ends up resting at the desired location.

the procedure). Make sure you do not move the mouse pointer while clicking a

mouse button.

ton (as instructed in the procedure) as you move the mouse to a new location.

When you have moved the mouse pointer to the desired location, you can release

the mouse button.

Page 12

10

About this guide

Model 6676 6U CPCI Chassis Assembly User Guide

Page 13

Chapter 1

Chapter contents

Introduction..........................................................................................................................................................13

Description of chassis front side ......................................................................................................................14

Description of chassis rear side ........................................................................................................................16

Electromagnetic compatibility (EMC) ............................................................................................................17

Electrostatic discharge (ESD) protection .........................................................................................................18

Hot-swap capability ........................................................................................................................................19

Major system components .....................................................................................................................................20

ForeFront AIS blades ......................................................................................................................................20

Mid-plane architecture ....................................................................................................................................21

Power supply module ......................................................................................................................................22

Fan tray module ..............................................................................................................................................22

System specifications .............................................................................................................................................23

6U chassis specifications ..................................................................................................................................23

Power input and power supply specifications ..................................................................................................24

Fan tray specifications .....................................................................................................................................24

Introduction

11

Page 14

12

1 • Introduction

Model 6676 6U CPCI Chassis Assembly User Guide

Page 15

13

Model 6676 6U CPCI Chassis Assembly User Guide

1 • Introduction

Introduction

Thank you for purchasing Patton Electronics Co. Model 6676 ForeFront Xtreme Chassis (see figure 1). The

Model 6676 ForeFront Xtreme Chassis is a modular 9U x 19 inch rackmount subrack-type packaging system

adaptable to a wide array of product configurations.

ForeFront Xtreme Chassis features include:

• Fully compatible with all Patton ForeFront modules

• EMI shielding on entire assembly, with continuous chassis ground

• Lightweight and durable aluminum alloy construction, suitable for rugged environments

• Front mounting flanges for 19 in. rack mount environments

Figure 1. Model 6676

The ForeFront Xtreme Chassis offers a low cost, turnkey solution for customers desiring seventeen 6U x

160mm slots (two separate cPCI bus segments: one segment having 8 slots, the other 9 slots; only the power

and alarm buses are common to both cPCIs) in the least possible vertical rack space. The superior design also

accepts four 3U plug-in power supplies for N+1 redundancy. The power supplies are configured for external

DC power input.

The rear of the chassis provides four 6U x 80mm slots for transition modules. Cooling is provided by the specially designed model 6670-FT plug-in fan tray module.

Introduction

Page 16

14

1 • Introduction

Model 6676 6U CPCI Chassis Assembly User Guide

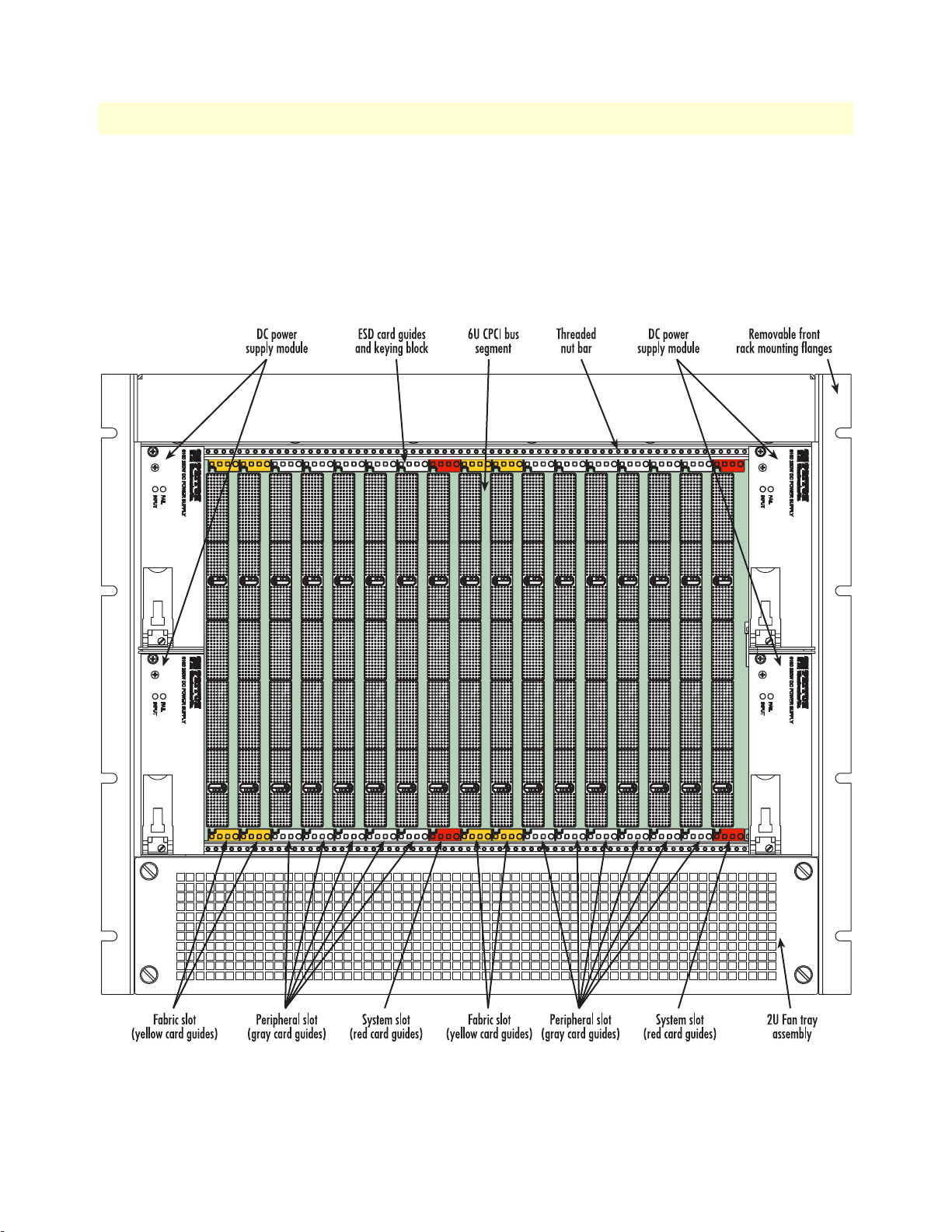

Description of chassis front side

There are 17 6U x 160mm slots at the front of the chassis (see figure 2). Front-entry ForeFront modules, in accordance with PICMG 2.0 CompactPCI specifications, are plugged into these slots.

Figure 2. Model 6676 ForeFront Xtreme Chassis

Introduction

Page 17

15

Model 6676 6U CPCI Chassis Assembly User Guide

1 • Introduction

The front of the chassis also provides four slots suitable for Model 6160 (DC) 3Ux8HP ForeFront power supplies (see figure 2 on page 14). The Model 6160 power supply is described more completely in the Model 6160

and 6161 User Manual.

All slots provide 4HP module spacing and are on 0.80 in. centers (except for the power supply slots, which are

offset 0.1” as per PICMG 2.11 standard). Card guides are molded plastic with metallic ESD contacts per Com-

pactPCI PICMG 2.0 R3.0 & IEEE 1101.10 .

Introduction

Figure 3. Front view of chassis

Page 18

1 • Introduction

Model 6676 6U CPCI Chassis Assembly User Guide

Description of chassis rear side

The rear of the Model 6676 chassis provides seventeen 6U x 80mm slots for ForeFront rear transition modules

for rear-panel I/O (see figure 3). See section “ForeFront AIS blades” on page 20 for more information.

Figure 4. Rear view of chassis

16 Introduction

Page 19

Model 6676 6U CPCI Chassis Assembly User Guide 1 • Introduction

All slots provide 4HP module spacing and are on 0.80 in. centers. Card guides are molded plastic with metallic

ESD contacts at the bottom of the chassis per CompactPCI PICMG 2.0 R3.0 & IEEE 1101.10. Cardguides

provide keying and alignment in accordance with IEEE 1101.10, section 8.

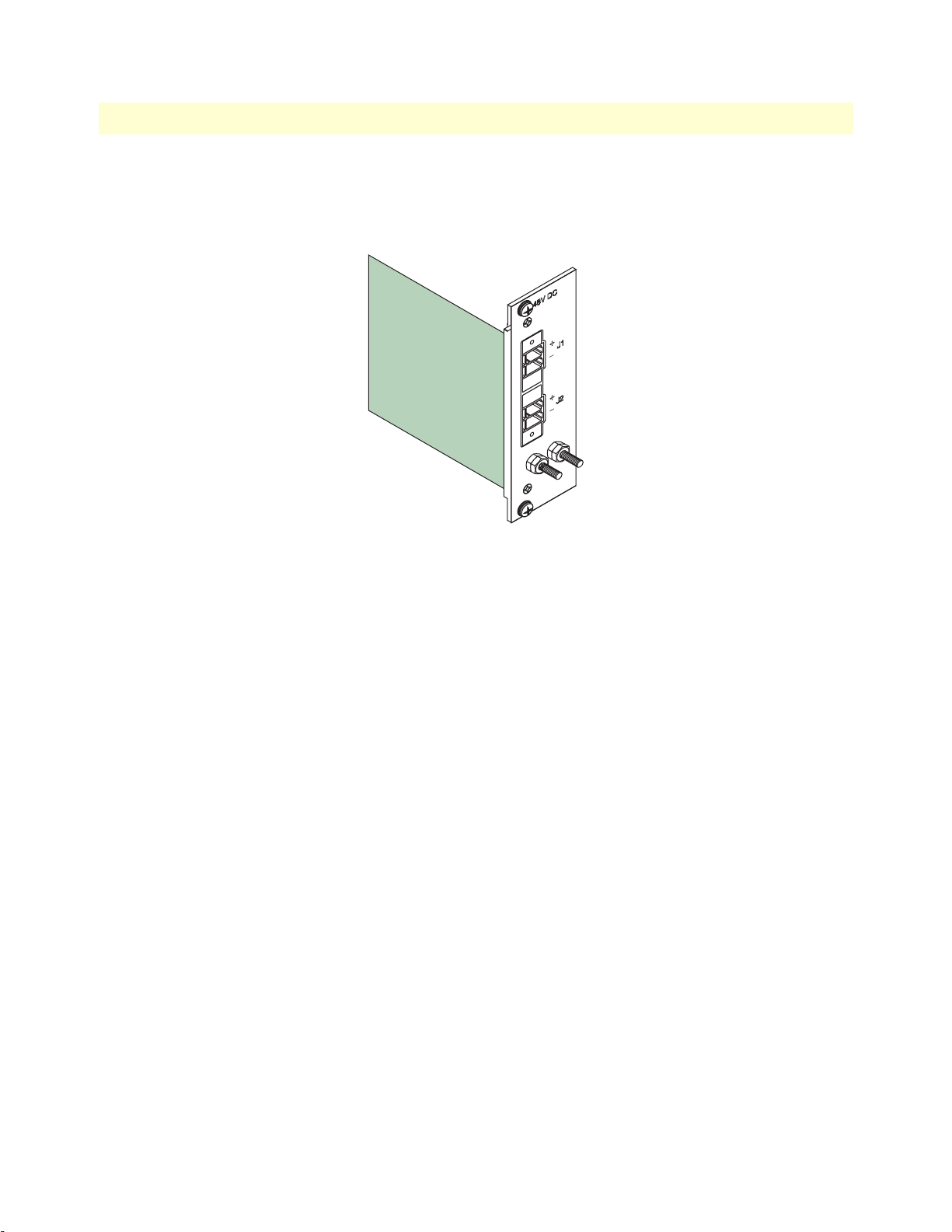

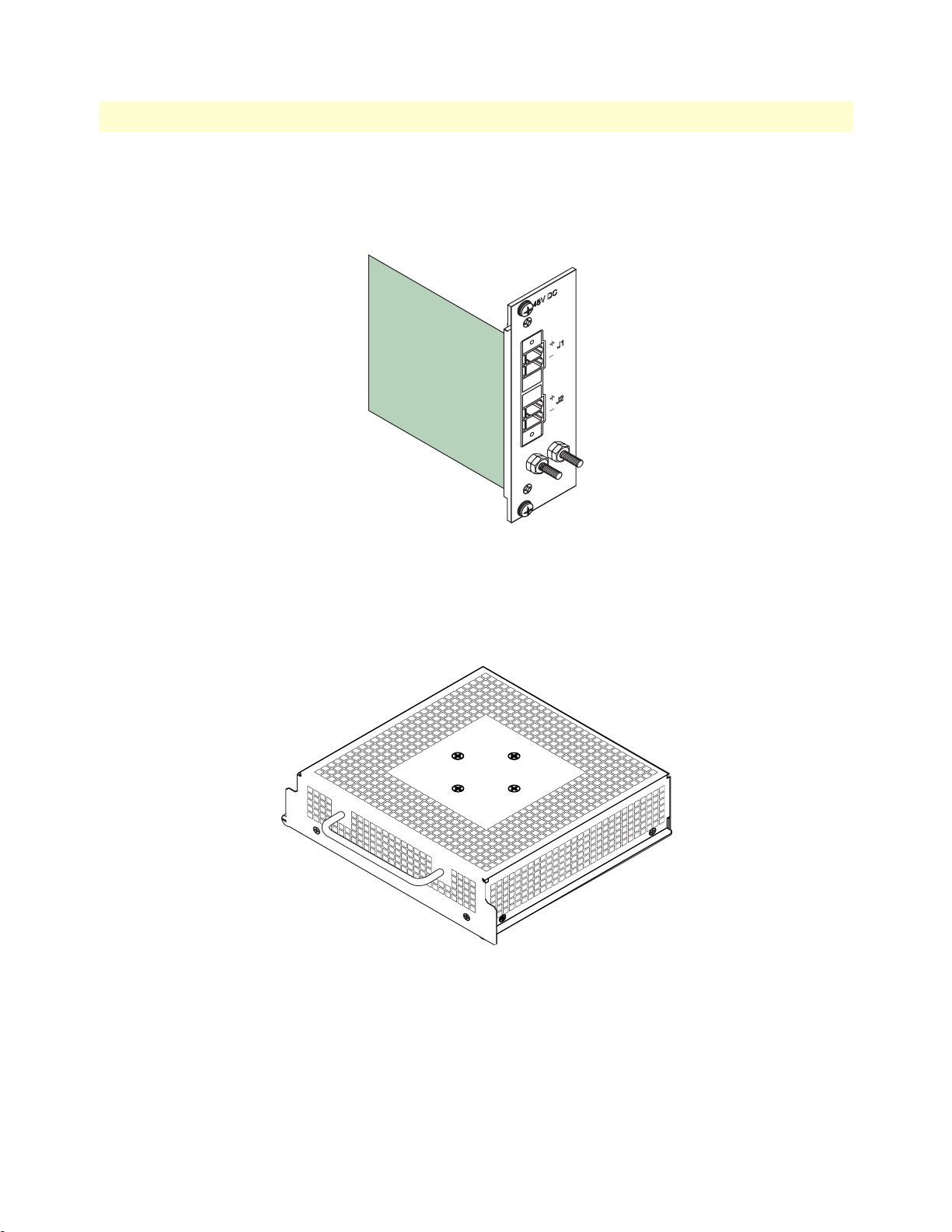

Figure 5. DC rear power entry module (2 per Model 6676)

A set of 3U slots allocated for two Patton Model 6112/HOR (DC) rear power entry modules (see figure 5).

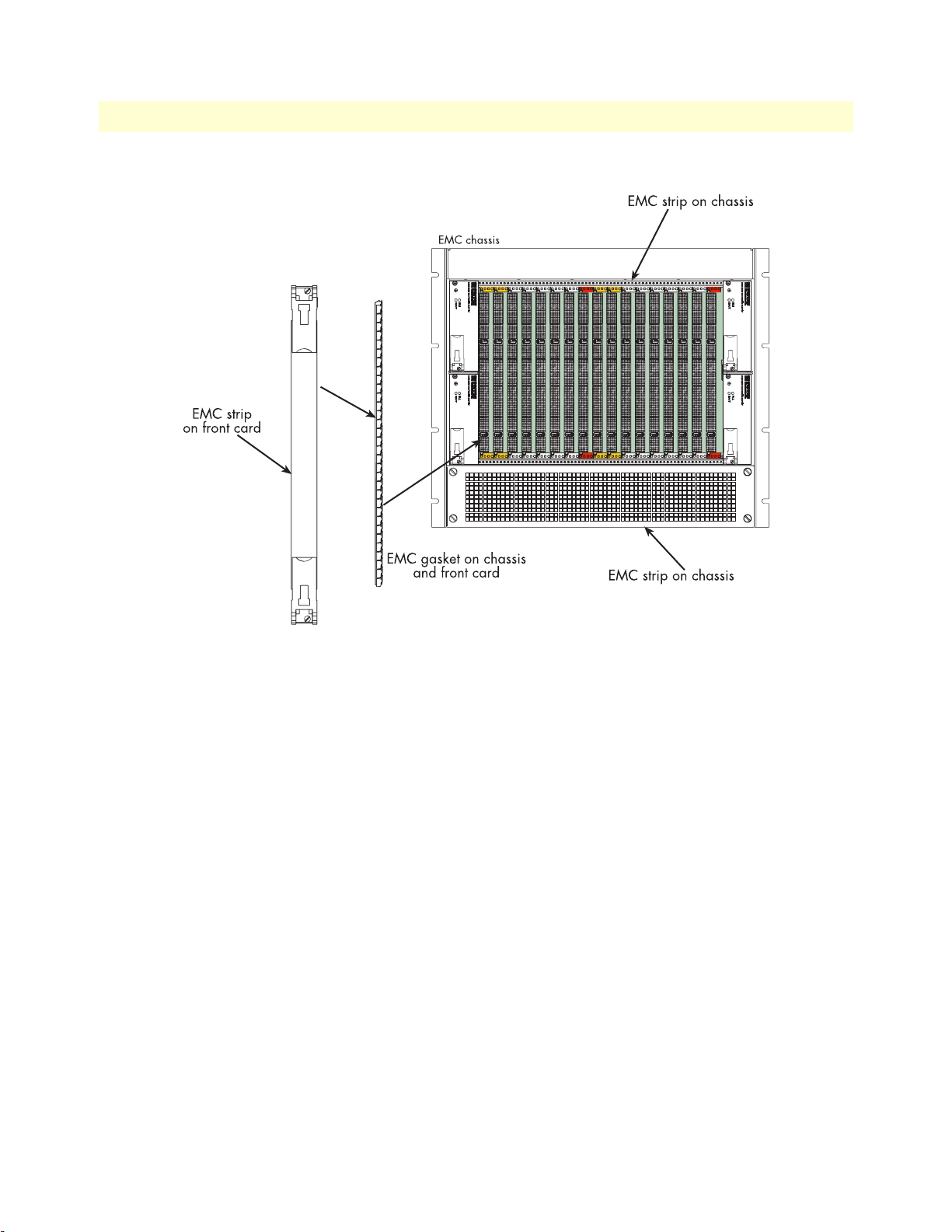

Electromagnetic compatibility (EMC)

The Model 6676 ForeFront Xtreme is designed to provide the highest level of EMC performance—in terms of

both interference and susceptibility. The chassis has the following design features to mitigate the effects of electromagnetic interference (EMI):

• All gaskets, contacts, and contact surfaces are electrically conductive.

• The mating surfaces of the EMC chassis and the EMC plug-in unit front panels and/or optional EMC filler

panels are also conductive by use of gaskets/strips.

• All chassis and plug-in contact surfaces are connected to a common chassis ground.

Introduction 17

Page 20

1 • Introduction Model 6676 6U CPCI Chassis Assembly User Guide

Figure 6. EMC strip and gasket on chassis and cards

The EMC strip on the left side of the board (see figure 6) mates with the EMC gasket attached to the chassis

when it is plugged into the first slot. Each board mates together with corresponding gaskets/strips.

Note EMC gaskets/strips are in reverse order at the rear of the 6U chassis.

That is, the EMC strip is on the left of the chassis and the EMC gasket is on the right. Consequently, rear transition boards are likewise

in reverse order to the front-entry boards. The EMC gasket is on the

left, and the EMC strip is on the right.

In addition, all aluminum and steel components of the subrack are surface treated and conductive. Top, bottom, sides and rear EMC covers provide mechanical protection and EMC shielding on the subrack. Retaining

clips ensure conductive connection.

Electrostatic discharge (ESD) protection

The 6676 ForeFront Xtreme chassis provides ESD protection in compliance with IEEE 1101.10. ESD contacts are embedded inside and in the front section of card guides for making early as possible contact with a

discharge strip on one or both, the upper and/or lower edge of the plug-in board/module. Only the card guides

located at the bottom rail of the chassis (right vertical rail for the 6U chassis), both front and rear (when there

is a transition module present in the chassis), contain the ESD clips. The ESD clip in the card guide is connected to the Chassis GND (ground).

18 Introduction

Page 21

Model 6676 6U CPCI Chassis Assembly User Guide 1 • Introduction

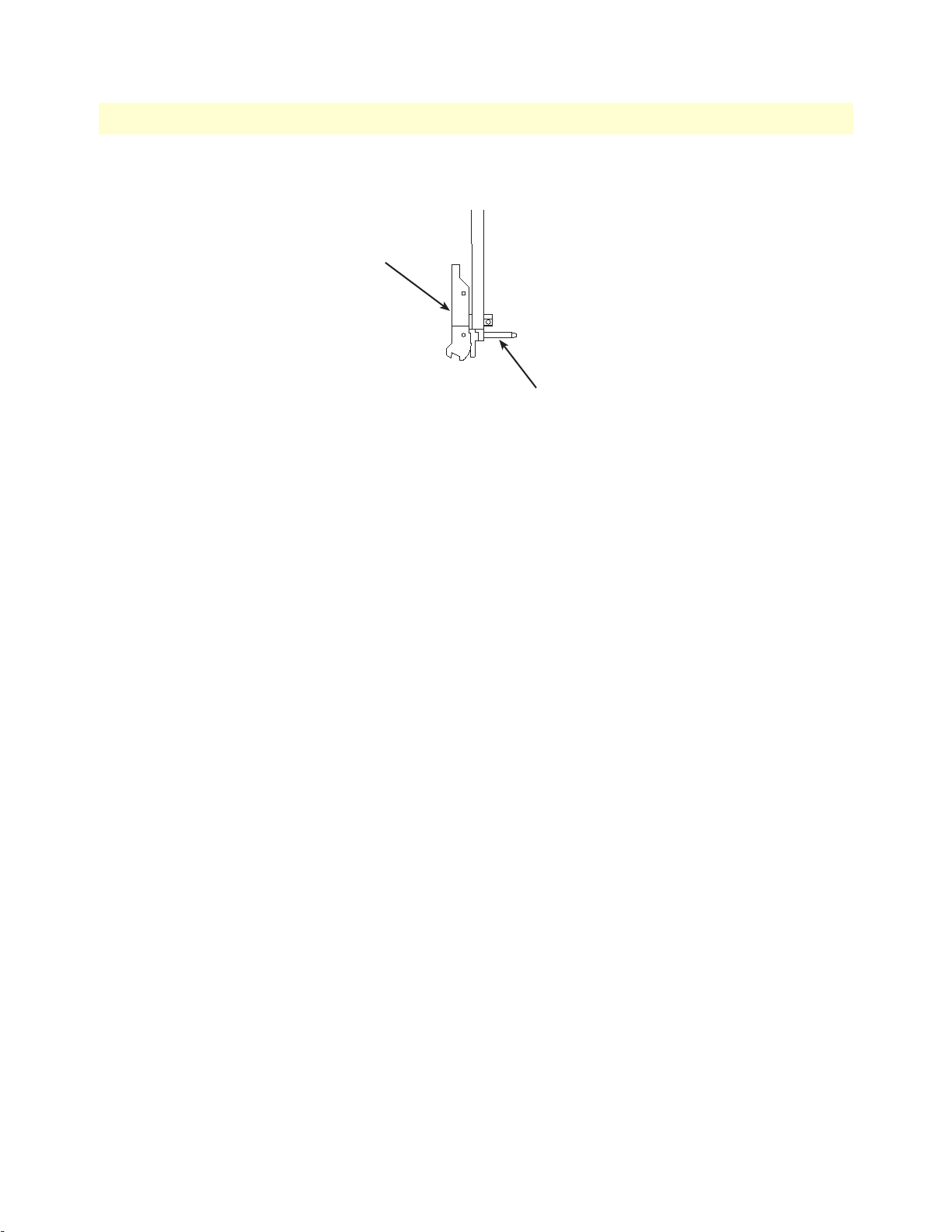

There is an alignment/ESD pin on the injector/ejector handle of boards (see figure 7).

Card handle

Alignment/ESD pin

Figure 7. Alignment/ESD pin on card handle

The alignment pin does the following:

• Ensures that the connectors are correctly aligned before they engage

• Provides solid/protected keying

• Provides board ESD contact

• Ensures that the EMC gasket is properly aligned (see “Electromagnetic compatibility (EMC)” on page 17)

• Ensures that when the board is inserted in the card guide, an integrated ESD clip discharges ESD from the

board to the right vertical rail chassis ground.

Hot-swap capability

Hot-swapping is the capability of removing and replacing components without turning off the system. Hotswap capability is becoming increasingly important in systems requiring continuous operation at some level.

Because boot times of many popular operating systems are long, the hot-swap capability is crucial for high-end

PC servers, and even more so for telecommunication systems, such as base stations, where board-level

exchanges must be made without any downtime. CompactPCI supports dynamic configuration to allow hot

removal/insertion of boards without interrupting backplane transactions or disturbing DC voltages in the

power system.

The hot-swap feature is implemented on the cPCI boards, not on the backplane. The backplane remains passive. Therefore, CompactPCI boards either are or are not hot-swappable.

Introduction 19

Page 22

1 • Introduction Model 6676 6U CPCI Chassis Assembly User Guide

Major system components

Model 6676 ForeFront Xtreme Chassis major system components consist of the following:

• Up to 17 ForeFront blades comprising a wide variety of front-entry and rear-entry modules (see section

“ForeFront AIS blades” on page 20 for details)

• A mid-plane that provides power and I/O for the ForeFront blades (see section “Mid-plane architecture” on

page 21)

• Two power supply modules (see section “Power supply module” on page 22)

• Two fan tray module (see section “Fan tray module” on page 22)

ForeFront AIS blades

The ForeFront Xtreme Chassis accommodates up to 17 ForeFront AIS blades (each comprising a front-entry

module and a rear-entry module). The following blades are available:

• 3096RC—ForeFront AIS blade that offers G.SHDSL and T1/E1 WAN ports

• 3196RC—ForeFront AIS blade that offers iDSL and T1/E1 WAN ports

• 3125RC—ForeFront AIS remote access server blade that provides 96 or 120 ports for dial-up access

• 2616RC—ForeFront AIS E1/T1 DACS

• 6511RC—ForeFront AIS Matrix Switch with STM-1/OC-3 trunk interface

• 6081RC—ForeFront AIS EdgeROUTE Network Access Server

20 Major system components

Page 23

Model 6676 6U CPCI Chassis Assembly User Guide 1 • Introduction

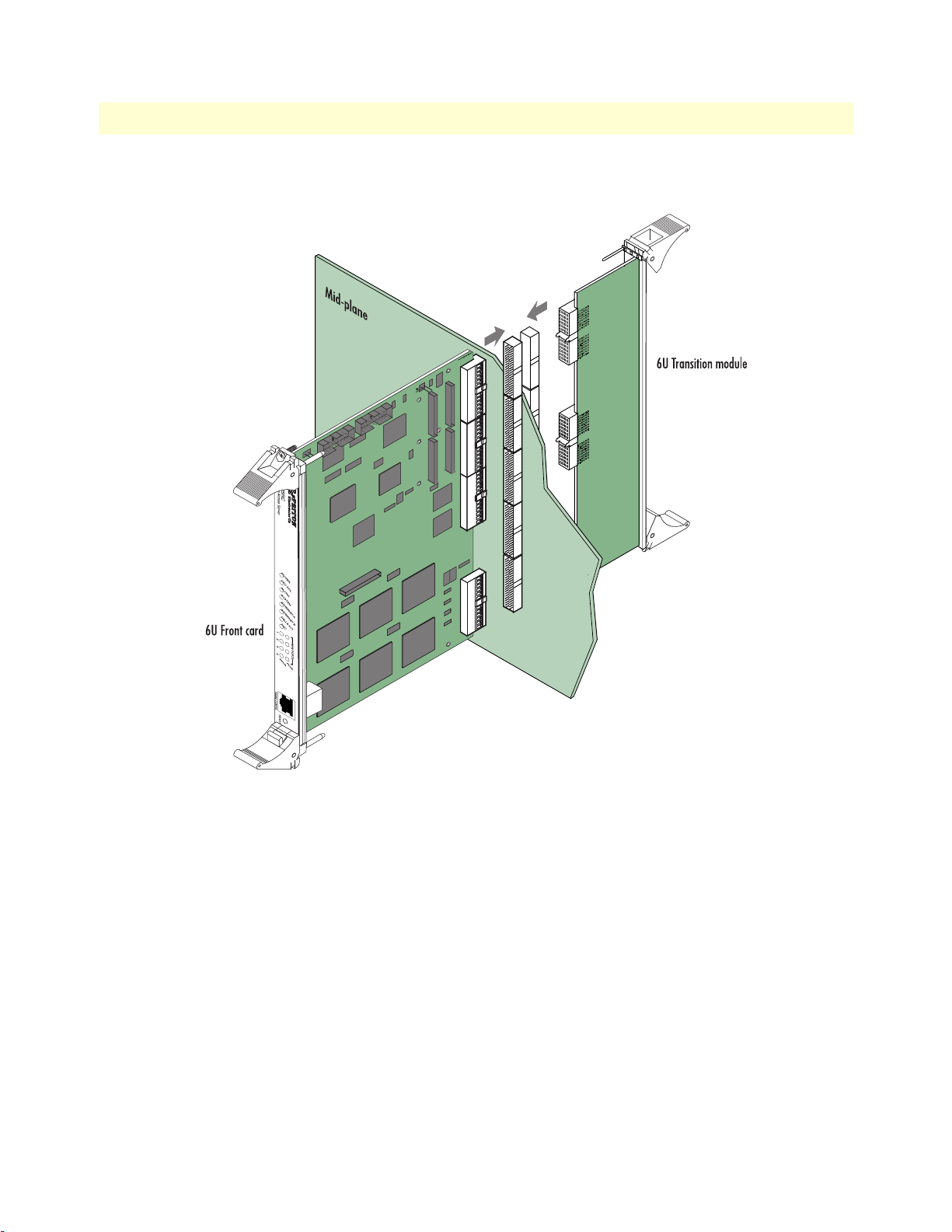

The front-entry boards route I/O through the mid-plane to the rear-entry modules (see figure 8).

T

Figure 8. Front/rear modules and mid-plane interface

Mid-plane architecture

The mid-plane consists of two H.110 bus segments that support 17 6U slots (eight 6U modules for one segment

and nine 6U modules for the other). Both H.110 buses have 20.32 mm (0.8 inch) board center-to-center spacing.

The 6U cards are stacked vertically in the chassis. Power is distributed equally to the H.110 bus segments from

both power supplies.

In addition to the 17 6U slots, there are two 3U x 160 mm slots on the front right and two 3U x 160 slots on

the left of the ForeFront Xtreme Chassis. These slots support two Model 6160 or 6161 DC power supply modules (see figure 3 on page 15).

On the rear of the chassis, the top left and top right slots are for the rear power entry modules (see figure 4 on

page 16). The bottom left slot is used for the Patton Model 6103 Alarm Card.

Major system components 21

Page 24

1 • Introduction Model 6676 6U CPCI Chassis Assembly User Guide

Power supply module

The ForeFront Xtreme Chassis is equipped with two Model 6160 or 6161 DC power supply modules (see

figure 3 on page 15) and two Model 6112/HOR (DC) rear power entry modules (see figure 9).

Figure 9. DC rear power entry module

Fan tray module

ForeFront Xtreme Chassis cooling is provided by two Model 6670-FT Plug-In Fan Tray Modules (see figure 10)

which are positioned for optimum side-to-side air flow through the subrack. Each fan tray is hot-swappable.

Figure 10. Model 6670-FT fan tray module

22 Major system components

Page 25

Model 6676 6U CPCI Chassis Assembly User Guide 1 • Introduction

System specifications

This section provides the following specifications:

• Model 6676 chassis specifications (see section “6U chassis specifications”)

• Power input and power supply specifications (see section “Power input and power supply specifications” on

page 24)

• Fan tray specifications (see section “Fan tray specifications” on page 24)

6U chassis specifications

Table 3. 6U chassis materials specifications

Item Description

Physical

DC interface Rear DC interface panel includes dual ground lugs and -48V DC power inter-

Slot configuration

Module keying and alignment 4HP module spacing, cardguide provides for keying and alignment pin in

Card guides Molded plastic with snap-in ESD contacts for plug-in module and injector/

Plug-in unit injector/ejector handles Subrack dimensional format accepts modules with injector/ejector handles

Operating environment 32–122°F (0–50°C), 5–95% relative humidity, non-condensing

• Height—9U (15.75 in./40 cm)

• Width—19 in. (standard EIA rack mount)

• Depth—11.70 in. (29.70 cm)

face for N+1 redundant power operation.

• Front—6U x 160 mm slots, Qty: 17

• Rear—6U X 80 mm slots, Qty: 17

Slots are on 0.80 in. (2.0 cm) centers, except power slots are 1.6 in. (4.1

cm) center

accordance with IEEE 1101.10, section 6

ejector handle alignment pin

as specified in IEEE 1101.10, section 8

System specifications 23

Page 26

1 • Introduction Model 6676 6U CPCI Chassis Assembly User Guide

Power input and power supply specifications

Table 4. Power input specifications

Item Description

Power input -48 VDC nominal (-36 to -72V)

Maximum current 20 A per power input

Power supply fusing Power supply fusing is not user-replaceable

Table 5. Power supply specifications

Power supply

model

6160 DC 250 3U 36–75 VDC 40A 40A 5.5A 1.5A

6161 DC 300 3U 36–72 VDC 30A 40A 5.0A 1.0A

Power

(watts)

Height

(Profile)

Input

voltage

+5V

current

+3.3V

current

+12V

current

Fan tray specifications

Table 6. Fan tray specifications

Item Description

Physical Height: 2.25 in. (6.35 cm)

Width: 8.25 in. (20.96 cm)

Depth: 19.0 in. (22.86 cm)

Power requirements 1.05 A at 48 VDC (50 W)

Performance 280 CFM per fan

Reliability 59,434 hours at 122°F (50°C)

Operating environment 32–122°F (0–50°C), 5–95% relative humidity, non-condensing

Fan tray model no. 6670-FT

Replacement air filter part no. 6670-AF-6 (6-pack)

-12V

current

24 System specifications

Page 27

Chapter 2 Installation checklist

Chapter contents

6U quick set-up checklist.......................................................................................................................................27

Power cable installation ...................................................................................................................................28

Installing the power cables .........................................................................................................................28

Grounding the Model 6676 ......................................................................................................................29

25

Page 28

2 • Installation checklist Model 6676 6U CPCI Chassis Assembly User Guide

26

Page 29

Model 6676 6U CPCI Chassis Assembly User Guide 2 • Installation checklist

6U quick set-up checklist

The Model 6676 Mid-plane & Chassis can be easily configured according to your system requirements. Due to

the broad application possibilities, the following checklist is provided as a quick set-up guideline.

1. Install 9U chassis on rack—the chassis front mounting flanges should be securely fastened to the rack

with screws.

2. Connect chassis ground—The chassis must be grounded by #12 AWG ground wires attached to a reliable

grounding source.

3. Install power supply modules—For N+1 power operation, install up to four Patton power supply modules

at the front of the chassis.

4. Install modules—Plug the front-entry modules in the 6U slots at the front of the ForeFront Xtreme Chas-

sis. Plug the alarm card in the left-hand slot at the back of the chassis, and plug the rear-entry cards in

remaining slots, if needed.

5. Wire rear panel for power.

To avoid a potential shock hazard, connect the chassis ground before

connecting power.

6U quick set-up checklist 27

Page 30

2 • Installation checklist Model 6676 6U CPCI Chassis Assembly User Guide

Power cable installation

This section describes installing the DC power and ground cables.

.

Verify that the installation site is in compliance with the following

power requirements before installling the ForeFront Xtreme chassis:

• An approved external source must be rated a maximum of 72

VDC, 10 A and provide over current protection upstream of

the equipment.

• An approved disconnect device with a minimum 3.0 mm con-

tact separation must be provided upstream of the device and

rated at least 75 VDC, 7.0 A and be located so it is accessible to the operator.

• This equipment shall be connected directly to the DC supply

system bonding jumper from an earthing terminal bar or bus

to which the DC supply system earthing electrode is connected.

• This equipment shall be located in the same immediate area

as any other equipment that has a connection between the

earthed conductor of the same DC supply circuit and the

earthing conductor, and also the point of earthing of the DC

system. The DC system shall not be earthed elsewhere.

• There shall be no switching or disconnecting devices in the

earthed circuit conductor between the DC source and the

point of connection of the earthing electrode conductor.

Installing the power cables

This section describes installing the power cables into the DC power input module. Do not connect the

remaining end of the power cables to the DC power source at this time. Each DC power supply module

comes with two power input terminal blocks (J1 +/- and J2 +/-). The Model 6676 can draw power from

sources connected to either of these terminal blocks (inputs are diode-ORed and combined to provide for

redundant power input). Although the power supply module is designed to operate normally with one power

source, users may want to connect two independent power sources, one to each terminal block, to provide

uninterrupted operation in the event of one source failure.

Remove power plugs from all power inputs prior to servicing.

Use AWG 12 copper conductors to feed power to the DC supply.

1. Connect the earth ground of the DC source to the grounding stud on the DC power supply as described

in section “Grounding the Model 6676” on page 29.

28 6U quick set-up checklist

Page 31

Model 6676 6U CPCI Chassis Assembly User Guide 2 • Installation checklist

2. Strip back the insulation on each of the supply wires approximately 1/4 inch.

3. Insert the stripped end of the positive lead into the + J1 DC input of the terminal block. Tighten the screw

until the power lead is firmly fastened. Repeat the procedure for the negative lead, using the -J1 DC input”

of the terminal block. Make sure that there is no exposed wire.

Figure 11. DC connector, -DC and +DC input view

4. Repeat steps 1 through 3 to install the remaining DC power connection on J2.

Grounding the Model 6676

Do the following:

1. Assemble a ground wire using #6 AWG wire with green-colored insulation and two ring terminals. Make

the wire long enough to reach one of the following ground sources:

– The building ground rod (generally located at the site’s main service entrance)

– Central office isolated ground plane

– Central office isolated bonding network

To avoid the risk of personal injury, the distance between ground and the

equipment rack must not exceed the distance specified in either local electrical

codes or the National Electrical Code.

6U quick set-up checklist 29

Page 32

2 • Installation checklist Model 6676 6U CPCI Chassis Assembly User Guide

2. Install the ground wire between the grounding studs (see figure 11 on page 29 for DC power entry) and

the grounding source.

30 6U quick set-up checklist

Page 33

Chapter 3 Maintenance

Chapter contents

Preventive Maintenance.........................................................................................................................................33

Cleaning the fan filter .....................................................................................................................................33

Troubleshooting....................................................................................................................................................33

System won’t power up ...................................................................................................................................33

31

Page 34

3 • Maintenance Model 6676 6U CPCI Chassis Assembly User Guide

32

Page 35

Model 6676 6U CPCI Chassis Assembly User Guide 3 • Maintenance

Preventive Maintenance

Cleaning the fan filter

Periodically clean the filter on the Fan Tray Assembly (see figure 2 on page 18). The frequency of cleaning

depends on the environmental conditions of where your equipment is located. Clean filter with a mild detergent and water, then air-dry, or you can use compressed air. It should be completely dry before reuse.

Spare filters (part no. 6670-AF-6) are available from Patton Electronics Company.

Troubleshooting

System won’t power up

If the green LED on the power supply module does not light up, you should: remove the power supply module

from the chassis, then plug it back in, making sure it is seated properly. If the green LED still does not illuminae, verify that the polarity is wired correctly at the back of the chassis.

If the green LED lights up on the power supply module, but the system still isn’t powering-up, then the module may be faulty and should be returned to the manufacturer.

Preventive Maintenance 33

Page 36

3 • Maintenance Model 6676 6U CPCI Chassis Assembly User Guide

34 Troubleshooting

Page 37

Chapter 4 Contacting Patton for assistance

Chapter contents

Introduction..........................................................................................................................................................37

Contact information..............................................................................................................................................37

Service ............................................................................................................................................................37

Warranty Service and Returned Merchandise Authorizations (RMAs)...................................................................37

Warranty coverage ..........................................................................................................................................38

Out-of-warranty service .............................................................................................................................38

Returns for credit ......................................................................................................................................38

Return for credit policy .............................................................................................................................38

RMA numbers ................................................................................................................................................38

Shipping instructions ................................................................................................................................38

35

Page 38

4 • Contacting Patton for assistance Model 6676 6U CPCI Chassis Assembly User Guide

36

Page 39

Model 6676 6U CPCI Chassis Assembly User Guide 4 • Contacting Patton for assistance

Introduction

This chapter contains the following information:

• “Contact information”—describes how to contact Patton technical support for assistance.

• “Warranty Service and Returned Merchandise Authorizations (RMAs)”—contains information about the

RAS warranty and obtaining a return merchandise authorization (RMA).

Contact information

Patton Electronics offers a wide array of free technical services. If you have questions about any of our other

products we recommend you begin your search for answers by using our technical knowledge base. Here, we

have gathered together many of the more commonly asked questions and compiled them into a searchable

database to help you quickly solve your problems.

• Online support—available at www.patton.com.

• E-mail support—e-mail sent to support@patton.com will be answered within 1 business day

• Telephone support—standard telephone support is available from 8AM to 5PM EST (8:00 to 17:00 UTC-5),

Monday through Friday, by calling +1 (301) 975-1007

Service

Patton Electronics' technical staff is also available to answer any questions that might arise concerning the

installation or use of your Model 6676. Technical Service hours: 8AM to 5PM EST (8:00 to 17:00 UTC-5),

Monday through Friday.

All warranty and non-warranty repairs must be returned freight prepaid and insured to Patton Electronics (for

more information about warranty and non-warranty repairs, see section “Warranty Service and Returned Merchandise Authorizations (RMAs)”). All returns must have a Return Materials Authorization number on the

outside of the shipping container. This number may be obtained from Patton Electronics Technical Service at:

• Tel: (301) 975-1007

• E-mail: support@patton.com

• URL: www.patton.com

Note Packages received without an RMA number will not be accepted.

Warranty Service and Returned Merchandise Authorizations (RMAs)

Patton Electronics is an ISO-9001 certified manufacturer and our products are carefully tested before shipment. All of our products are backed by a comprehensive warranty program.

Note If you purchased your equipment from a Patton Electronics reseller,

ask your reseller how you should proceed with warranty service. It is

often more convenient for you to work with your local reseller to

obtain a replacement. Patton services our products no matter how

you acquired them.

Introduction 37

Page 40

4 • Contacting Patton for assistance Model 6676 6U CPCI Chassis Assembly User Guide

Warranty coverage

Our products are under warranty to be free from defects, and we will, at our option, repair or replace the product should it fail within one year from the first date of shipment. Our warranty is limited to defects in workmanship or materials, and does not cover customer damage, lightning or power surge damage, abuse, or

unauthorized modification.

Out-of-warranty service

Patton services what we sell, no matter how you acquired it, including malfunctioning products that are no

longer under warranty. Our products have a flat fee for repairs. Units damaged by lightning or other catastrophes may require replacement.

Returns for credit

Customer satisfaction is important to us, therefore any product may be returned with authorization within 30

days from the shipment date for a full credit of the purchase price. If you have ordered the wrong equipment or

you are dissatisfied in any way, please contact us to request an RMA number to accept your return. Patton is

not responsible for equipment returned without a Return Authorization.

Return for credit policy

• Less than 30 days: No Charge. Your credit will be issued upon receipt and inspection of the equipment.

• 30 to 60 days: We will add a 20% restocking charge (crediting your account with 80% of the purchase

price).

• Over 60 days: Products will be accepted for repairs only.

RMA numbers

RMA numbers are required for all product returns. You can obtain an RMA by doing one of the following:

• Completing a request on the RMA Request page in the Support section at www.patton.com

• By calling +1 (301) 975-1000 and speaking to a Technical Support Engineer

• By sending an e-mail to returns@patton.com

All returned units must have the RMA number clearly visible on the outside of the shipping container. Please

use the original packing material that the device came in or pack the unit securely to avoid damage during

shipping.

Shipping instructions

The RMA number should be clearly visible on the address label. Our shipping address is as follows:

Patton Electronics Company

RMA#: xxxx

7622 Rickenbacker Dr.

Gaithersburg, MD 20879-4773 USA

Patton will ship the equipment back to you in the same manner you ship it to us. Patton will pay the return

shipping costs.

38 Warranty Service and Returned Merchandise Authorizations (RMAs)

Page 41

Appendix A Replacement parts and accessories

Chapter contents

Replacement parts .................................................................................................................................................40

ForeFront chassis power supplies .....................................................................................................................40

ForeFront chassis fan/filter components ..........................................................................................................40

Accessories.............................................................................................................................................................40

39

Page 42

A • Replacement parts and accessories Model 6676 6U CPCI Chassis Assembly User Guide

Replacement parts

ForeFront chassis power supplies

Model Description

6160 DC Power Supply, 250W

6161 DC Power Supply, 300W

ForeFront chassis fan/filter components

Model Description

6670-FT 6U Fan Impeller Assembly (2 per chassis)

6670-AF-6 6U Air Filter (2 per chassis)

Accessories

Model Description

6103 Alarm Card

40 Replacement parts

Page 43

Appendix B Glossary

Chapter contents

C....................................................................................43

CFM .......................................................................43

CSA ........................................................................43

CT ..........................................................................43

D....................................................................................43

Dual Redundant ......................................................43

E ....................................................................................43

EIA ..........................................................................43

EMC .......................................................................43

EMI ........................................................................43

EN ..........................................................................43

ESD ........................................................................43

H ...................................................................................43

Hot-Swap ................................................................43

HP ..........................................................................43

I .....................................................................................43

IEC .........................................................................43

IEEE .......................................................................43

K....................................................................................43

Keying .....................................................................43

N................................................................................... 44

N+1 Redundant ..................................................... 44

NEBS ..................................................................... 44

P.................................................................................... 44

PCI ......................................................................... 44

PCI SIG ................................................................. 44

PICMG .................................................................. 44

Platform ................................................................. 44

S.................................................................................... 44

SELV ...................................................................... 44

S-HAZ ................................................................... 44

Shroud .................................................................... 44

T ................................................................................... 44

TDM ...................................................................... 44

TNV ...................................................................... 44

U................................................................................... 45

U ............................................................................ 45

W .................................................................................. 45

Warm-Swap ............................................................ 45

41

Page 44

B • Glossary Model 6676 6U CPCI Chassis Assembly User Guide

42

Page 45

Model 6676 6U CPCI Chassis Assembly User Guide B • Glossary

C

CFM

Cubic feet per minute—A measurement of how

much air is moved through a fan.

CSA

Canadian Standards Association—Organization

which operates a listing service for electrical and electronic materials and equipment. It is the body that

establishes telephone equipment (and other) standards for use in Canada.

CT

Computer Telephony—is the adding of computer

intelligence to the making, receiving, and managing

of telephone calls.

D

Dual Redundant

An environment containing two power supplies,

with fault tolerance such that one power supply may

fail and the system will continue to operate.

EN

European Norms—Prefix assigned to documents

adopted by the CE designating required standards

(for example, EN 60950 is the safety specification

(equivalent to UL 1950)).

ESD

Electrostatic Discharge—Discharge of a static charge

on a surface or body through a conductive path to

ground. Can be damaging to integrated circuits.

H

Hot-Swap

The capability of removing and replacing components without turning off the system. Hot-swap

capability is increasingly important in systems used

for applications such as telecommunications, which

require that the system be operational at some level

continuously.

HP

Horizontal Positioning—A unit of measurement

used for the width of cPCI cards/modules. 1 HP =

0.2” wide

E

I

EIA

Electronics Industry Association—Trade organization of manufacturers which sets standards for use of

its member companies.

EMC

Electromagnetic Compatibility—Is the ability of

equipment or systems to be used in their intended

environment within designed efficiency levels without causing or receiving degradation due to unintentional EMI.

EMI

Electromagnetic Interference—any electromagnetic

interference, periodic or random, narrow or broadband, which may have a disturbing influence on

devices exposed to it.

C 43

IEC

International Electrotechnical Committee

IEEE

Institute of Electrical and Electronics Engineers

K

Keying

A mechanical means of polarizing connectors in

order to prevent similar connectors from being

mated. This is necessary when 2 or more similar connectors must be connected to a backplane which

requires that the board being connected is unique for

a particular slot.

Page 46

B • Glossary Model 6676 6U CPCI Chassis Assembly User Guide

N

N+1 Redundant

An environment containing more than two power

supplies, where the power supplies typically current

share, with fault tolerance such that one power supply may fail and the system will continue to operate.

NEBS

Network Equipment Building Standards—Defines a

rigid and extensive set of performance, quality, environmental and safety requirements developed by

Bellcore, the R&D and standards organization

owned by the seven regional Bell operating companies (RBOC’s).

P

PCI

Peripheral Component Interconnect. A specification

for defining between logic components. Typically

used for interconnecting high-speed, PC-compatible

chipset components. The PCI specification is issued

through the PCI Special Interest Group (PCI SIG).

S

SELV

Safety Extra Low Voltage—a term generally defined

by the regulatory agencies as the highest voltage that

can be contacted by a person and not cause injury. It

is often specifically defined as 30 VAC or 42.4 VDC.

S-HAZ

Secondary Hazardous—any voltage within a system

that is greater than 60VDC (42.4VAC-peak), NOT

meeting the requirements for a LIMITED CURRENT CIRCUIT, or for a TNV CIRCUIT. Typical

ringing voltage is considered SECONDARY HAZARDOUS unless it is current limited. Raw ringing is

considered SECONDARY HAZARDOUS. (Refer

to IEC950 or PICMG 2.5 R1.0 CompactPCI‚ Computer Telephony Specification for information.)

Shroud

A male connector body designed to fit over the

extended tails of a long tail connector which allows a

female connector to be mated from the rear side for

midplane or rear I/O applications.

PCI SIG

Peripheral Component Interconnect Special Interest

Group

PICMG

PCI Industrial Computers Manufacturers Group—a

consortium of industrial computer product vendors

who develop specifications for PCI-based systems

and boards for use in industrial computing applications.

Platform

Describes the system environment, including the

backplane and related enclosure.

T

TDM

Time Division Multiplex—A technique for transmitting a number of separate data, voice and/or video

signals simultaneously over one communications

medium by quickly interleaving a piece of each signal

one after another.

TNV

Telephone Network Voltages—any voltage present

on the telephone network side of the isolation device

on any device (for example, board) that connects to

the telephone network.

44 N

Page 47

Model 6676 6U CPCI Chassis Assembly User Guide B • Glossary

U

U

An EIA unit of measurement equal to 1.75 in.

(4.45 cm) for equipment racks.

W

Warm-Swap

An environment supporting removal and insertion of

power supplies while under power, wherein the

power supply is disabled during insertion and

removal, avoiding the need for the connectors to

make and break high current connections while

under load.

U 45

Page 48

B • Glossary Model 6676 6U CPCI Chassis Assembly User Guide

46 W

Page 49

Appendix C Bibliography

Chapter contents

Publications referenced in this guide......................................................................................................................48

47

Page 50

C • Bibliography Model 6676 6U CPCI Chassis Assembly User Guide

Publications referenced in this guide

The following publications are used in conjunction with this manual.

• ECTF H.110 (CT Bus) Specification (Revision 1.0)

• CompactPCI Hot Swap Specification—PICMG 2.12 (Revision 1.0)

• CompactPCI Specification—PICMG 2.0 (Revision 3.0)

• Keying of CompactPCI Boards and Backplanes Specification—PICMG 2.10 (Revision 1.0)

• UL60950, Safety of Information Technology Equipment, including Electrical Business Equipment

• IEC 61076-4-101 (1995-05), Specification for 2mm Connector System

• IEEE 1101.10, IEEE Standard for Additional Mechanical Specifications for Microcomputers using IEEE

1101.1 Equipment Practice

48 Publications referenced in this guide

Loading...

Loading...