Page 1

Model 6511RC

Matrix Switch

User Manual

Sales Office: +1 (301) 975-1000

Technical Support: +1 (301) 975-1007

E-mail: support@patton.com

WWW: www.patton.com

Part Number: 07MD6511RC-GS, Rev. B

Revised: February 20, 2012

Page 2

Patton Electronics Company, Inc.

7622 Rickenbacker Drive

Gaithersburg, MD 20879 USA

tel: +1 (301) 975-1000

fax: +1 (301) 869-9293

support: +1 (301) 975-1007

url: www.patton.com

e-mail: support@patton.com

Copyright © 2012, Patton Electronics Company. All rights reserved.

The information in this document is subject to change without notice. Patton

Electronics assumes no liability for errors that may appear in this document.

The software described in this document is furnished under a license and may

be used or copied only in accordance with the terms of such license.

Page 3

Contents

Contents ......................................................................................................................................................... 3

Compliance Information ................................................................................................................................ 7

Radio and TV Interference ...............................................................................................................................7

Industry Canada Notice ....................................................................................................................................7

FCC Part 68 (ACTA) Statement .......................................................................................................................7

CE Notice .........................................................................................................................................................8

About this guide ............................................................................................................................................. 9

Audience................................................................................................................................................................. 9

Structure................................................................................................................................................................. 9

Precautions........................................................................................................................................................... 10

Typographical conventions used in this document................................................................................................ 10

General conventions .......................................................................................................................................10

Mouse conventions .........................................................................................................................................11

1 Introduction.................................................................................................................................................. 13

Model 6511RC Matrix Switch overview................................................................................................................14

Hardware overview................................................................................................................................................16

ForeFront chassis architectures ........................................................................................................................19

ForeFront Model 6476 6U cPCI chassis ...................................................................................................19

The ForeFront Model 6676 9U chassis .....................................................................................................20

Matrix Switch functionality ............................................................................................................................21

TDM mapping and aggregation ................................................................................................................21

TDM bus architecture ...............................................................................................................................22

STM-1 link architecture ............................................................................................................................22

Matrix Switch TDM capacity ....................................................................................................................23

Matrix Switch Ethernet Switching ..................................................................................................................23

Management ...................................................................................................................................................24

Management Services ................................................................................................................................24

Management Interfaces .............................................................................................................................24

Management Approach .............................................................................................................................24

Matrix Switch Interfaces .................................................................................................................................25

WAN Interfaces ........................................................................................................................................25

Mid-Plane Interfaces .................................................................................................................................25

LAN Interface ...........................................................................................................................................25

RS-232 Config port ..................................................................................................................................26

Power system ..................................................................................................................................................26

Central processing unit ...................................................................................................................................26

System timing .................................................................................................................................................26

Clocking Mode .........................................................................................................................................26

Clocking Source ........................................................................................................................................26

3

Page 4

Contents Model 6511RC User Manual

Temperature ...................................................................................................................................................27

Altitude ...........................................................................................................................................................27

Humidity ........................................................................................................................................................27

Physical dimensions ........................................................................................................................................27

LED Indicators ...............................................................................................................................................27

Approvals ..............................................................................................................................................................29

2 Hardware installation.................................................................................................................................... 31

Introduction..........................................................................................................................................................32

Unpacking the Model 6511RC Matrix Switch......................................................................................................32

Verifying that the ForeFront chassis is properly installed .......................................................................................32

Verfying correct electrical grounding ...............................................................................................................33

Verifying correct cover plate installation .........................................................................................................33

Matrix Switch hardware installation ......................................................................................................................34

Installing the network cables..................................................................................................................................35

Connecting the front-panel Ethernet LAN port ..............................................................................................36

Connecting the 10/100Base-T Ethernet port to an Ethernet switch or hub ...............................................36

Connecting the 10/100Base-T Ethernet port to an Ethernet-capable workstation or PC ...........................36

Connecting the front-panel EIA-561 RS-232 configuration port (DCE configured) .......................................37

Connecting the rear-panel STM-1 WAN port to an SDH network ................................................................37

Connecting the STM-1 optical interface to fiber-optic network cables ......................................................37

Connecting the STM-1 electrical interface to coaxial network cables .........................................................38

Connecting the rear-panel Ethernet WAN/management ports ........................................................................39

Connecting the 10/100/1000 Base-T Ethernet ports to a router, hub or switch ........................................40

Completing the hardware installation....................................................................................................................40

3 Configuring the Matrix Switch for operation................................................................................................ 41

Introduction..........................................................................................................................................................42

Configuration prerequisites ...................................................................................................................................42

Initial configuration through the RS-232 control port...........................................................................................43

Connecting the DB9-RJ45 adapter with the included cable ............................................................................43

Setting up the HyperTerminal (or similar program) session ............................................................................44

Using a browser to complete Model 6511RC configuration..................................................................................47

Displaying the Matrix Switch 6511RC web administration pages ...................................................................47

Home page overview .................................................................................................................................49

Configuring the default gateway .....................................................................................................................51

Configuring the system clocking parameters ...................................................................................................52

Module clocking mode ..............................................................................................................................52

Module clocking source and fallback .........................................................................................................53

Example 1 ...........................................................................................................................................53

Example 2 ...........................................................................................................................................54

Configuring the SDH circuit parameters ........................................................................................................54

Accessing the SDH circuit parameters .......................................................................................................55

Configuring the SDH physical interface type ............................................................................................56

Configuring the SDH interface parameters ...............................................................................................56

4

Page 5

Model 6511RC User Manual Contents

Configuring the SDH path trace parameters .............................................................................................57

Configuring DS0 idle codes ............................................................................................................................58

Accessing the idle code configuration ........................................................................................................59

Defining the DS0 idle code configuration .................................................................................................60

Selecting the SDH mapping path ....................................................................................................................60

Defining DS0 mappings .................................................................................................................................62

Defining DS0 mappings using E1 port format ..........................................................................................64

Examples for configuring DS0 mappings. .................................................................................................65

Defining DS0 mappings using TU format ................................................................................................69

Examples for configuring DS0 mappings. .................................................................................................72

Saving your configuration ...............................................................................................................................74

Backing up your configuration parameters.............................................................................................................75

Backing up the configuration store in flash memory .......................................................................................76

Completing the installation ...................................................................................................................................77

4 Operation and shutdown............................................................................................................................... 79

Introduction..........................................................................................................................................................80

Activating the Model 6511RC...............................................................................................................................80

De-activating the Model 6511RC .........................................................................................................................80

5 Troubleshooting and maintenance................................................................................................................ 81

Introduction..........................................................................................................................................................82

Troubleshooting during initial deployment ...........................................................................................................82

General fault analysis .............................................................................................................................................83

Matrix Switch test tools.........................................................................................................................................86

Loopback test modes for the STM-1 port .......................................................................................................86

Facility Loop [sonetFacilityLoop(1)] .........................................................................................................87

Terminal loop [sonetTerminalLoop(2)] ....................................................................................................88

Other Loop [sonetOtherLoop(3)] .............................................................................................................90

SDH section trace and path trace ....................................................................................................................90

Sections and paths .....................................................................................................................................91

Section trace ..............................................................................................................................................91

Path trace ..................................................................................................................................................92

Number of paths per frame .......................................................................................................................93

Periodic maintenance ............................................................................................................................................94

Calibration ......................................................................................................................................................94

Maintenance..........................................................................................................................................................94

Replacing the Model 6511RC .........................................................................................................................94

Exporting the current Model 6511RC configuration ................................................................................94

Removing the defective Model 6511RC ....................................................................................................97

Installing the replacement Model 6511RC ................................................................................................98

Importing a saved configuration ................................................................................................................98

Completing the installation .......................................................................................................................99

6 Contacting Patton for assistance

................................................................................................................. 101

Introduction........................................................................................................................................................102

5

Page 6

Contents Model 6511RC User Manual

Contact information............................................................................................................................................102

Warranty Service and Returned Merchandise Authorizations (RMAs).................................................................102

Warranty coverage ........................................................................................................................................102

Out-of-warranty service ...........................................................................................................................102

Returns for credit ....................................................................................................................................102

Return for credit policy ...........................................................................................................................103

RMA numbers ..............................................................................................................................................103

Shipping instructions ..............................................................................................................................103

6

Page 7

Compliance Information

Radio

and TV

The Model 6511RC generates and uses radio frequency energy, and if not installed and used properly—that is,

in strict accordance with the manufacturer's instructions—may cause interference to radio and television reception. The Model 6511RC has been tested and found to comply with the limits for a Class A computing device

in accordance with the specifications in Subpart B of Part 15 of FCC rules, which are designed to provide reasonable protection from such interference in a commercial installation. However, there is no guarantee that

interference will not occur in a particular installation. If the Model 6511RC causes interference to radio or television reception, which can be determined by disconnecting the cables, try to correct the interference by one or

more of the following measures: moving the computing equipment away from the receiver, re-orienting the

receiving antenna, and/or plugging the receiving equipment into a different AC outlet (such that the computing equipment and receiver are on different branches).

Industry Canada Notice

Interference

Note

FCC Part 68 (ACTA) Statement

This equipment complies with Part 68 of FCC rules and the requirements adopted by ACTA. On the bottom

side of this equipment is a label that contains—among other information—a product identifier in the format

US: AAAEQ##TXXXX. If requested, this number must be provided to the telephone company.

A plug and jack used to connect this equipment to the premises wiring and telephone network must comply

with the applicable FCC Part 68 rules and requirements adopted by the ACTA.

This equipment uses a Universal Service Order Code (USOC) jack: RJ-11C.

If this equipment causes harm to the telephone network, the telephone company will notify you in advance

that temporary discontinuance of service may be required. But if advance notice isn’t practical, the telephone

company will notify the customer as soon as possible. Also, you will be advised of your right to file a complaint

with the FCC if you believe it is necessary.

This equipment meets the applicable Industry Canada Terminal

Equipment Technical Specifications. This is confirmed by the registration number. The abbreviation, IC, before the registration number

signifies that registration was performed based on a Declaration of

conformity indicating that Industry Canada technical specifications

were met. It does not imply that Industry Canada approved the

equipment.

Users should not attempt to establish or modify ground connections

themselves, instead they should contact the appropriate electric

inspection authority or electrician.

The telephone company may make changes in its facilities, equipment, operations or procedures that could

affect the operation of the equipment. If this happens the telephone company will provide advance notice in

order for you to make necessary modifications to maintain uninterrupted service.

7

Page 8

Compliance Information Model 6511RC User Manual

If trouble is experienced with this equipment, for repair or warranty information, please contact our company.

If the equipment is causing harm to the telephone network, the telephone company may request that you disconnect the equipment until the problem is resolved.

Connection to party line service is subject to state tariffs. Contact the state public utility commission, public

service commission or corporation commission for information.

In accordance with FCC rules and regulation CFR 47 68.218(b)(6), you must notify the telephone company

prior to disconnection. The following information may be required when applying to your local telephone

company for leased line facilities. The Universal Service Order Code (USOC) is RJ48. The Facility Interface

Codes (FIC) are 04DU9-BN, 04DU9-DN, 04DU9-1KN, and 04DU9-1SN. The Service Order Code (SOC)

is 6.0N.

Facility

Service

1.544 Mbps SF format without line power 04DU9-BN 6.0N RJ-48C

1.544 Mbps SF and B8ZS without line power 04DU9-DN 6.0N RJ-48C

1.544 Mbps ANSI ESF without line power 04DU9-1KN 6.0N RJ-48C

1.544 Mbps ANSI ESF and B8ZS without line power 04DU9-1SN 6.0N RJ-48C

Interface Code

Service

Code

Network

Connection

CE Notice

The CE symbol on your Patton Electronics equipment indicates that it is in compliance with the Electromagnetic Compatibility (EMC) directive and the Low Voltage Directive (LVD) of the European Union (EU). A

Certificate of Compliance is available by contacting Technical Support.

8

Page 9

About this guide

This guide describes installing and configuring a Patton Electronics Model 6511 TDM-Digital Access Concentrator (Matrix Switch). By the time you are finished with this guide, your Matrix Switch will be connected

to the remote DSL modems and transferring data. The instructions in this guide are based on the following

assumptions:

• The Matrix Switch is installed in a Patton ForeFront chassis

• The Matrix Switch will connect to an SDH/STM-1 network

• There is a LAN connected to one of the Matrix Switch’s Ethernet ports

Audience

This guide is intended for the following users:

• Operators

• Installers

• Maintenance technicians

Structure

This guide contains the following chapters and appendices:

• Chapter 1 describes the Matrix Switch

• Chapter 2 describes installing the Matrix Switch hardware

• Chapter 3 describes configuring the Matrix Switch for use

• Chapter 4 details how to power up and deactivate the Matrix Switch

• Chapter 5 contains troubleshooting and maintenance information

• Chapter 6 contains information on contacting Patton technical support for assistance

For best results, read the contents of this guide before you install the Matrix Switch.

9

Page 10

About this guide Model 6511RC User Manual

Precautions

Notes and cautions, which have the following meanings, are used throughout this guide to help you become

aware of potential Matrix Switch problems. Warnings relate to personal injury issues, and Cautions refer to

potential property damage.

Note

Calls attention to important information.

The shock hazard symbol and WARNING heading indicate a potential electric

shock hazard. Strictly follow the warning instructions to avoid injury caused

by electric shock.

The alert symbol and WARNING heading indicate a potential safety hazard.

Strictly follow the warning instructions to avoid personal injury.

The shock hazard symbol and CAUTION heading indicate a

potential electric shock hazard. Strictly follow the instructions to

avoid property damage caused by electric shock.

The alert symbol and CAUTION heading indicate a potential hazard. Strictly follow the instructions to avoid property damage.

Typographical conventions used in this document

This section describes the typographical conventions and terms used in this guide.

General conventions

The procedures described in this manual use the following text conventions:

Table 1. General conventions

Convention Meaning

Garamond blue type

Futura bold type Indicates the names of menu bar options.

Italicized Futura type Indicates the names of options on pull-down menus.

Futura type

Garamond bold type Indicates the names of command buttons that execute an action.

< >

10

Indicates a cross-reference hyperlink that points to a figure, graphic,

table, or section heading. Clicking on the hyperlink jumps you to the reference. When you have finished reviewing the reference, click on the

Go to Previous View button in the Adobe® Acrobat® Reader

toolbar to return to your starting point.

Indicates the names of fields or windows.

Angle brackets indicate function and keyboard keys, such as <SHIFT>,

<CTRL>, <C>, and so on.

Page 11

Model 6511RC User Manual About this guide

Table 1. General conventions (Continued)

Convention Meaning

Are you ready? All system messages and prompts appear in the Courier font as the

system would display them.

% dir *.* Bold Courier font indicates where the operator must type a response or

command

Mouse conventions

The following conventions are used when describing mouse actions:

Table 2. Mouse conventions

Convention Meaning

Left mouse button This button refers to the primary or leftmost mouse button (unless you have

changed the default configuration).

Right mouse button This button refers the secondary or rightmost mouse button (unless you have

changed the default configuration).

Point This word means to move the mouse in such a way that the tip of the pointing

arrow on the screen ends up resting at the desired location.

Click Means to quickly press and release the left or right mouse button (as instructed in

the procedure). Make sure you do not move the mouse pointer while clicking a

mouse button.

Double-click Means to press and release the same mouse button two times quickly

Drag This word means to point the arrow and then hold down the left or right mouse but-

ton (as instructed in the procedure) as you move the mouse to a new location.

When you have moved the mouse pointer to the desired location, you can release

the mouse button.

11

Page 12

About this guide Model 6511RC User Manual

12

Page 13

Chapter 1 Introduction

Chapter contents

Model 6511RC Matrix Switch overview................................................................................................................14

Hardware overview................................................................................................................................................16

ForeFront chassis architectures ........................................................................................................................19

ForeFront Model 6476 6U cPCI chassis ...................................................................................................19

The ForeFront Model 6676 9U chassis .....................................................................................................20

Matrix Switch functionality ............................................................................................................................21

TDM mapping and aggregation ................................................................................................................21

TDM bus architecture ...............................................................................................................................22

STM-1 link architecture ............................................................................................................................22

Matrix Switch TDM capacity ....................................................................................................................23

Matrix Switch Ethernet Switching ..................................................................................................................23

Management ...................................................................................................................................................24

Management Services ................................................................................................................................24

Management Interfaces .............................................................................................................................24

Management Approach .............................................................................................................................24

Matrix Switch Interfaces .................................................................................................................................25

WAN Interfaces ........................................................................................................................................25

Mid-Plane Interfaces .................................................................................................................................25

LAN Interface ...........................................................................................................................................25

RS-232 Config port ..................................................................................................................................26

Power system ..................................................................................................................................................26

Central processing unit ...................................................................................................................................26

System timing .................................................................................................................................................26

Clocking Mode .........................................................................................................................................26

Clocking Source ........................................................................................................................................26

Temperature ...................................................................................................................................................27

Altitude ...........................................................................................................................................................27

Humidity ........................................................................................................................................................27

Physical dimensions ........................................................................................................................................27

LED Indicators ...............................................................................................................................................27

Approvals ..............................................................................................................................................................29

13

Page 14

1 • Introduction Model 6511RC User Manual

Model 6511RC Matrix Switch overview

The Model 6511RC Matrix Switch (see figure 1) combines TDM aggregation and cross-connection with highspeed packet switching over synchronous digital hierarchy (SDH) and Ethernet uplinks for the Patton ForeFront Access Infrastructure Solutions (AIS) system. The web-manageable Matrix Switch provides a fully nonblocking mapping and switching matrix for TDM and Ethernet traffic traversing the ForeFront chassis or chassis segment. With the Model 6511RC, ForeFront AIS can deliver aggregated TDM and IP traffic on highspeed SDH and Ethernet trunks. The Matrix Switch is designed for installation and operation in either the

ForeFront Xtreme Model 6676 cPCI 9U chassis or the ForeFront FullPipe Model 6476 6U chassis. Each

model 6511RC Matrix Switch includes an on-board TDM multiplexer, a powerful Ethernet switch, a 155

Mbps SDH/STM-1 trunk port, and two 10/100/1000 Mbps Ethernet interfaces for high-speed packetswitched uplinks.

Figure 1. Model 6511RC

14 Model 6511RC Matrix Switch overview

Matrix Switch front blade

Page 15

Model 6511RC User Manual 1 • Introduction

Figure 2 shows the major functions and connections the Matrix Switch provides within the ForeFront chassis.

Each Model 6511RC enables service providers to perform SDH multiplexing and demultiplexing with any-toany timeslot mapping for up to 2048 DS0 channels. The on-board TDM multiplexer can map any of the 4096

DS0 timeslots on the TDM bus in the chassis midplane to any of the 2048 DS0s on the STM-1 uplink. Each

DS0 consists of a 64 kbps communication channel, or timeslot. The integrated SDH aggregator combines

DS0 channels into E1 signal streams, then maps those E1s into a STM-1 signal for high-speed transmission on

the SDH trunk.

Figure 2. Model 6511RC Matrix Switch major functions and interfaces

The Model 6511RC provides an Ethernet-switching fabric for packet-based management and user traffic traversing the ForeFront chassis. The powerful Ethernet switch connects the high-speed packet-switched bus in

the ForeFront chassis midplane with two 10/100/1000 Ethernet uplinks. Offering fast Ethernet switching and

flexible timeslot aggregation, the Model 6511RC Matrix Switch enables the ForeFront AIS system to deliver a

surprisingly compact, high-speed trunking solution at very low cost.

Model 6511RC Matrix Switch overview 15

Page 16

1 • Introduction Model 6511RC User Manual

Hardware overview

The Model 6511RC combines DS0 cross-connection and concentration with powerful Ethernet switching in a

single-slot blade for installation in a standard CPCI chassis. The Matrix Switch card-set comprises two modules, a processor blade (see figure 1 on page 14) inserted from the front of the ForeFront chassis, and a rear

interface blade (see figure 3) inserted opposite to the processor blade. The front and rear blades mate at the

mid-plane, which provides the communication path between front and rear blades (see figure 4).

Figure 3. Model 6511RCT rear blade

Midplane

Front Blade

Front Rear

Side view

Figure 4. Model 6511RC Matrix Switch front and rear blade installation

Rear Blade

16 Hardware overview

Page 17

Model 6511RC User Manual 1 • Introduction

Figure 5. Model 6511RC front panel LEDs and ports

The front panel of the processor blade presents LED status indicators, an RS-232 configuration port and a

10/100 Ethernet management port (see figure 5). The rear entry interface blade (see figure 6 on page 18) presents LEDs indicating alarm and WAN status, physical connectors for the STM-1 port, as well as two

10/100/1000 Ethernet RJ-45 connectors with embedded link and activity status indicator LEDs.

Hardware overview 17

Page 18

1 • Introduction Model 6511RC User Manual

Figure 6. Model 6511RCT rear entry car front panel LEDs and ports

Three versions of the rear card offer the following connector types for the STM-1 port:

• SC20—Optical interface presented on Rx and Tx SC connectors for singlemode fiber with a wavelength of

1310 nm. The interface complies with ITU specifications G.957 and G.652.

• EBNC—Electrical interface presented on Rx and Tx 75-ohm BNC connectors.

• SC20/EBNC—Optical and electrical interfaces as described previously.

The Model 6511RC connects to other blades in the chassis via the ForeFront cPCI chassis midplane. The chassis mid-plane contains two digital communications busses, the H.110 TDM bus, and the PICMG 2.16

Packet-Switched Ethernet bus. The front blade connects to both busses via connectors on the chassis midplane. The blade uses the two mid-plane busses for digital communications with other processor blades

installed and operating in the chassis.

18 Hardware overview

Page 19

Model 6511RC User Manual 1 • Introduction

ForeFront chassis architectures

The Model 6511RC can be installed in the following ForeFront cPCI chassis:

• Model 6476 6U chassis

• Model 6676 9U chassis

ForeFront Model 6476 6U cPCI chassis

The ForeFront Model 6476 6U cPCI chassis provides 8 slots for installing cPCI processor blades (see figure 7).

The Model 6476 chassis accepts up to two Model 6511RC blades, installed in the fabric slots (designated by a

yellow blade guide). Using the H.110 TDM and PICMG 2.16 packet busses residing in the chassis mid-plane,

an installed Model 6511 can communicate with the other blades installed and operating in the remaining slots.

Figure 7. Model 6476 chassis, front view

Hardware overview 19

Page 20

1 • Introduction Model 6511RC User Manual

Figure 8. Model 6676 chassis, front view

The ForeFront Model 6676 9U chassis

The ForeFront Model 6676 9U chassis offers 17 slots for installing cPCI processor blades (see figure 8). The

Model 6676 midplane is divided into segment R (slots 1 through 8) and segment L (slots 9 through 17). Each

mid-plane segment contains its own H.110 and PICMG 2.16 bus, so since each 6511RC connects to one midplane segment, two Matrix Switch blades, installed in each of the two segments, are required to serve an entire

Model 6676 chassis. The Model 6676 chassis can accept up to four Model 6511RC blades installed in slots

called fabric slots (slots 1, 2, 9, and 10) designated by yellow card guides. In each backplane segment, a maximum of two 6511RC blades can be installed for operation to provide switching functions for that segment.

20 Hardware overview

Page 21

Model 6511RC User Manual 1 • Introduction

The Model 6511 communicates with the other blades installed and operating in the same segment over the

H.110 TDM and PICMG 2.16 packet busses residing in the chassis mid-plane.

Matrix Switch functionality

The Model 6511 provides the following functionality:

• TDM mapping and aggregation—The Model 6511RC Matrix Switch concentrates the traffic capacity of

up to 63 E1 lines for delivery on a 155.54 Mbps optical or electrical STM-1 uplink (see section “TDM

mapping and aggregation” for details)

• TDM bus architecture—The Matrix Switch provides an interface to the H.110 bus within the ForeFront

chassis.The total capacity of the H.110 bus is 4096 half-duplex DS0 channels, the equivalent of 64 E1 lines

(see section “TDM bus architecture” for details)

• STM-1 link architecture—The 155.52 Mbps STM-1 uplink carries 2016 full-duplex (4032 half-duplex)

DS0 channels organized into 63 E1 signal streams. Each E1 stream carries 32 full-duplex DS0 channels (64

half-duplex timeslots). The total capacity of the STM-1 uplink on the Model 6511RC is 2016 full-duplex

DS0s, the equivalent of 63 E1 lines (see section “STM-1 link architecture” on page 22 for details)

• Matrix Switch TDM capacity—The Matrix Switch provides the means for you to map any DS0 on the

H.110 TDM bus to any DS0 on the STM-1 trunk and vice-versa (see section “Matrix Switch TDM capac-

ity” on page 23 for details)

TDM mapping and aggregation

The Model 6511RC Matrix Switch concentrates the traffic capacity of up to 63 E1 lines for delivery on a

155.54 Mbps optical or electrical STM-1 uplink. For E1 traffic aggregation, the Matrix Switch performs mul-

tiplexing and demultiplexing for all 63 E1 lines comprising the 155.52 Mbps STM-1 uplink. Each E1 line

comprises 32 DS0 timeslots. Each timeslot comprises a 64 kbps communication channel, or DS0. The Model

6511RC delivers a fully non-blocking switching matrix to the ForeFront system, providing any-to-any mapping between all 4096 half-duplex DS0 timeslots carried in the H.110 bus and all 4032 half-duplex DS0

timeslots in the SDH STM-1 uplink.

Hardware overview 21

Page 22

1 • Introduction Model 6511RC User Manual

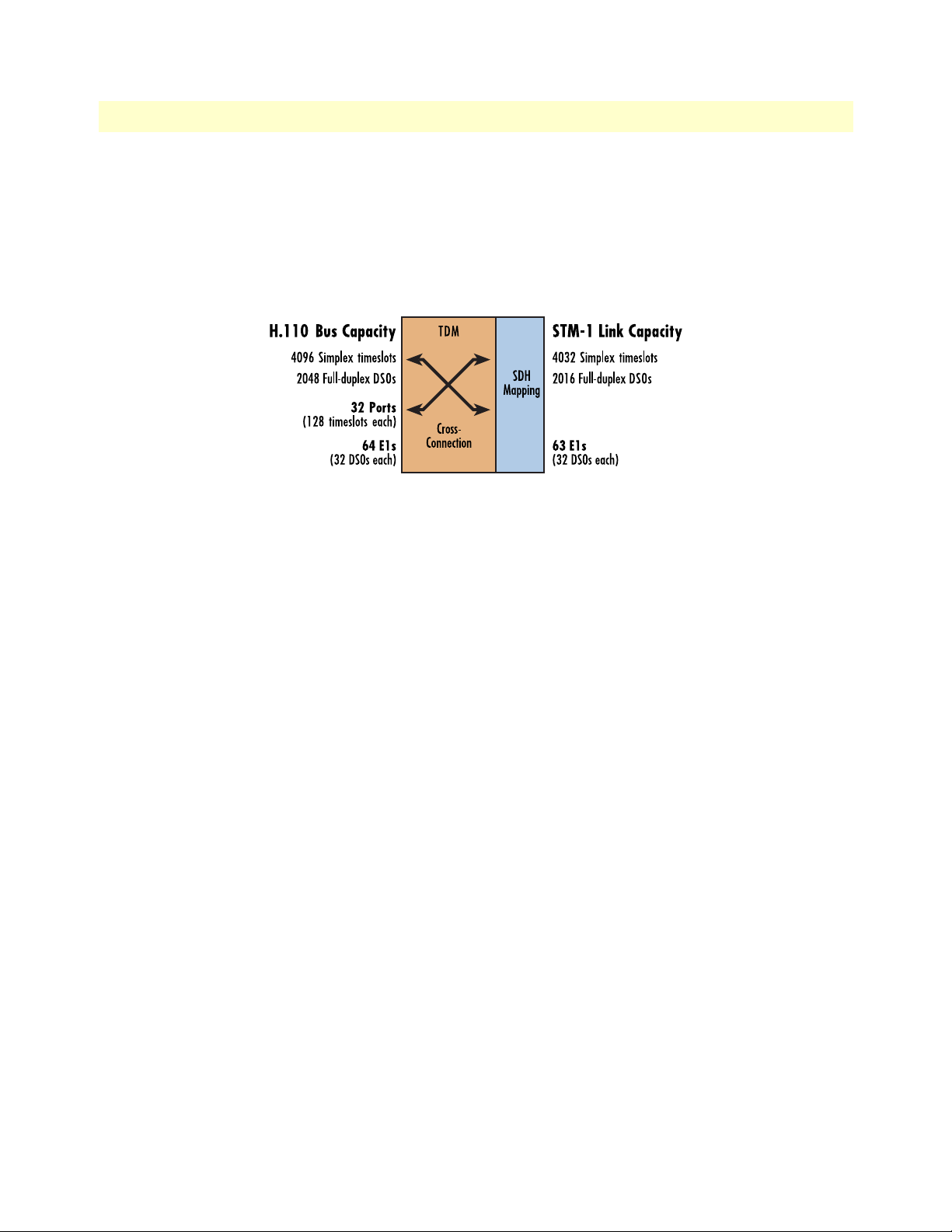

TDM bus architecture

The Matrix Switch provides an interface to the H.110 bus within the ForeFront chassis.The total capacity of

the H.110 bus is 4096 half-duplex DS0 channels, the equivalent of 64 E1 lines (see figure 9). Each DS0 channel can be mapped in either direction, transmitting to the Matrix Switch or receiving from the H.110 bus. The

H.110 bus organizes the 4096 half-duplex DS0 channels into 32 H.110 ports. Each of the 32 H.110 ports carries 128 half-duplex 64 kbps timeslots (DS0s).

Figure 9. H.110 bus and STM-Link capacity

STM-1 link architecture

The 155.52 Mbps STM-1 uplink carries 2016 full-duplex (4032 half-duplex) DS0 channels organized into 63

E1 signal streams. Each E1 stream carries 32 full-duplex DS0 channels (64 half-duplex timeslots). The total

capacity of the STM-1 uplink on the Model 6511RC is 2016 full-duplex DS0s, the equivalent of 63 E1 lines.

The following sequence describes the process by which the Matrix Switch maps and multiplexes 63 E1 streams

into the architecture of the STM-1 signal stream:

• E1 -to- C-12 -to- VC-12 -to- TU-12 -to- TUG-2 -to- VC-3 -to- AU-3 -to- AUG-1 -to- STM-1

Multiplexing occurs at the following points in the mapping sequence:

- Three TU-12s are multiplexed into one tributary unit group-2 (TUG-2).

- Seven TUG-2s are multiplexed into one TUG-3 or administrative unit-3 (AU-3).

- Three AU-3s or TUG-3s are multiplexed into one administrative unit group-1 (AUG-1).

22 Hardware overview

Page 23

Model 6511RC User Manual 1 • Introduction

Figure 10 highlights the multiplexing structure of the STM-1 link by ommitting the intermediate steps in the

SDH mapping sequence

Figure 10. E1-to-STM-1 multiplexing structure

Matrix Switch TDM capacity

The Matrix Switch provides the means for you to map any DS0 on the H.110 TDM bus to any DS0 on the

STM-1 trunk and vice-versa. The difference in capacity between the H.110 bus and the STM-1 link is 64 halfduplex DS0s, the equivalent of one E1 line. The STM-1 uplink provides sufficient capacity to aggregate 98%

of the traffic capacity of the H.110 TDM bus. The Model 6511RC provides the capability to map and aggregate traffic on the H.110 bus up to the full capacity of the STM-1 trunk.

Matrix Switch Ethernet Switching

The Matrix Switch also delivers Ethernet connectivity and switching for any Ethernet traffic traversing the

PICMG 2.16 bus to which the blade is connected. The Model 6511RC provides the Ethernet switching fabric

for all other blades connected to the same PICMG 2.16 packet-switching bus within the chassis mid-plane.

The built-in Ethernet switch switches Ethernet traffic between the PICMG 2.16 bus, the 10/100 Ethernet

LAN port presented on the front panel of the front blade, and the two 10/100/1000 Ethernet WAN uplink

ports presented on the 6511RCrear panel of the rear blade. All three Ethernet ports provide access to the

SNMP agent and HTTP Web Management services within the 6511RC. In addition, all three Ethernet ports

provide access via the Internet Protocol to the other blades on the packet bus, including access to the Web

Management services residing within those blades. When combined with an external network management

system, the Ethernet switching feature on the 6511RC makes it possible to implement a packet-based network

management solution for all system elements connected to the same packet-switched bus in the ForeFront

chassis.

Hardware overview 23

Page 24

1 • Introduction Model 6511RC User Manual

Management

Management Services

By providing a rich set of industry-standard management services accessible by a full menu of physical interfaces, the Model 6511RC offers an extensive selection of management options. The Matrix Switch provides the

following management services:

• HTTP Web-Management Interface accessible via any standard web browser

• SNMP version 1 configuration management (specified in RFC 1157)

• MIB II (specified in RFC 1213)

• Command Line Management Interface (CLI)

• SYSLOG Management Client (specified in RFC 3164)

• Out-of-Band RS-232 configuration port for management and control

• TELNET via Ethernet

• Remote Software Upgrade via FTP/TFTP

Management Interfaces

You can reach the Matrix Switch’s management services via any of the following physical interfaces:

• RS-232 Config Port presented as an RJ-45 connector on the front panel of the front blade

• PICMG 2.16 midplane connector block on the front blade

• 10/100 Ethernet port presented as an RJ-45 connector on the front panel of the front blade.

• Two 10/100/1000 Ethernet ports presented as RJ-45 connectors on the rear panel of the rear blade

Management Approach

Managing the Model 6511RC’s may be approached using one of two schemes, generally referred to as In-band

or Out-of-band management. In-band management refers to those schemes in which management information traverses the same network resources as network user traffic. Out-of-band management refers scenarios in

which management information does not traverse the same resources as network user traffic. In other words,

out-of-band management involves implementing a secondary, special-purpose, management network dedicated to carrying management information about the primary, user network. In-band management is more

efficient. However, because management information is susceptible to failures in the user network., it is less

reliable. Out-of-band management, while more reliable, is also more costly because it involves more equipment.

Management access paths into the Model 6511RC for both In-band and Out-of-band approaches are

described below.

• In-band management access paths include:

- The two RJ-45 10/100/1000 Ethernet trunk ports on the rear panel of the rear blade support in-band

management for applications where the Ethernet link is used as an aggregated trunk for user traffic as well

as a path for management information. An external management workstation communicates with the

management services in the Matrix Switch via a routed-protocol connection within the Ethernet link.

The management connection terminates at the management service within the Matrix Switch.

24 Hardware overview

Page 25

Model 6511RC User Manual 1 • Introduction

- The PICMG 2.16 packet-switched bus (PSB). In order to manage the Matrix Switch in-band via the

PICMG 2.16 PSB, an external management workstation connects to the ForeFront chassis via another

ForeFront blade with management routing capability, such as the Model 6801RC EdgeRoute Network

Access Server or model 3096RC TDM Digital Access Concentrator, operating on the same bus. The

external management workstation communicates with the ForeFront system using either a Frame Relay

or PPP link within a DS0 or within an Ethernet link. The in-band management link terminates on the

module with management routing capability, which in turn communicates with the management services

in the Matrix Switch over the PICMG 2.16 PSB.

• Out-of-band management access paths include:

- The RS-232 config port on the front panel of the front blade

- The RJ-45 10/100 Ethernet LAN port on the front panel of the front blade

- The two RJ-45 10/100/1000 Ethernet LAN ports on the rear panel of the rear blade, in applications

where these Ethernet links are dedicated to management traffic.

Matrix Switch Interfaces

WAN Interfaces

The 6511RC provides connections to the following WAN interfaces:

• One SDH STM-1 uplink trunk port at 155.54 Mbps

-Physical SC or BNC connectors presented on the rear-blade rear panel

• Two Ethernet trunk ports at up to 1 Gbps

-Physical RJ-45 connectors presented on the rear-blade rear panel

The STM-1 WAN uplink port may be connected to an SDH network via the Optical SC ore electrical BNC

connectors presented on the rear blade.

Mid-Plane Interfaces

• Connection to the H.110 Time-Division Multiplexed bus providing 4096 DS0 channels of 64 kbps each

-Physical and electrical connections via the mid-plane connector block on the rear of the front blade

• Connection to the PICMG 2.16 Packet-Switched Bus (PSB)

-Physical and electrical connections via the mid-plane connector block on the rear of the front blade

LAN Interface

The 10/100-Mbps Ethernet LAN port is presented on an RJ-45 connector with an auto-sensing/full-duplex

10Base-T or 100Base-T interface. Also included are:

• 100Base-TX half-/full-duplex operation (100 + 100)

• 10Base-T half-/full-duplex operation (10 + 10)

• Auto detection and fallback

• 10/100 Mbps link and status indicators

Hardware overview 25

Page 26

1 • Introduction Model 6511RC User Manual

RS-232 Config port

The RS-232 Config port provides access to the CLI management service. You will use the Config port to perform initial configuration of the Model 6511RC. The RS-232 port supports:

• Asynchronous data rates of 19.2 kbps, 8 data bits, no parity, 1 stop bit.

• An RJ-45 connector with EIA-561 pinouts

• A management interface that supports VT-100 terminals

• Hardware flow control (RTS and CTS)

Power system

The 6511RC obtains power from the CPCI chassis via PCMG 2.11 47-pin power connectors on the front and

rear blade. Total power consumption is a maximum of 43 Watts, provided by modular power supplies installed

in the cPCI chassis.

Central processing unit

The 6511RC employs an Intel i960VH RISC processor operating at 100 MHz/100 Mips. The CPU controls

the memory, front/back-panel and management interface for DS0 timeslot mapping, Ethernet switching, loopback and management services. System memory provided by:

• 4 MB Flash ROM

• 8 MB EDO DRAM

System timing

The system timing for the Matrix Switch must be configured using the blade’s management services, typically

via Web Management.

Clocking Mode

When configured in Master mode, the Matrix Switch serves as the Master clock source (timing reference) for

all other blades on the same H.100 bus within the Model 6476 chassis or Model 6676 chassis segment. When

configured in Backup mode, the Matrix Switch serves as an alternate Master clocking source (backup) should

the Master clocking source fail. When configured in Slave mode, the Matrix Switch will not provide system

timing over the H.100 bus for any other blades.

Clocking Source

Regardless of its clocking mode, the Matrix Switch can derive its own system timing from several sources. You

will define two clocking sources for the Matrix Switch, a first-choice (Primary Reference) and an alternate

(Fallback Reference). The Matrix switch will derive its own system timing from the Primary Reference as long

as it remains available. Should the Primary Reference become unavailable, the Matrix Switch will switch over

to the Fallback reference as the clock source for its own system timing. The following clocking sources can

serve as either the Primary Reference or Fallback Reference for the Matrix Switch:

• The internal oscillator (clock) residing on the Matrix Switch front blade

• A network clock recovered from the STM-1 SDH signal stream

• Another blade operating in either Primary or Secondary mode on the same bus.

26 Hardware overview

Page 27

Model 6511RC User Manual 1 • Introduction

Temperature

Operating range: 32–104°F (0–40°C)

Altitude

Maximum operating altitude: 15,000 feet (4,752 meters)

Humidity

5 to 95% relative humidity (RH), non-condensing

Physical dimensions

• 1.75 inches (4.44 cm) height, standard 19-inch (48.26 cm) width, 12-inch (30.48 cm) depth

• Weight: 1.55 lbs (0.70 kg)

LED Indicators

LED indicators on the front panel (see figure 5 on page 17) and rear panel (see figure 6 on page 18) display the

status of Matrix Switch system resources. The front-panel LEDs are described in table 3. The rear-panel LEDs

are described in table 4 on page 28.

Table 3. Front-panel LED indicators

LED Color Status Meaning

POWER Green On solid Power is being applied.

Flashing The 6511RC has detected a power failure on a power bus.

Off No input power is being applied.

CPU FAIL Red On solid CPU is unable to load the software from FLASH to RAM for operation.

Off The CPU is operating normally.

ALARM Yellow On solid A minor alarm condition has been detected.

Flashing A major alarm condition has been detected.

Off The Model 6511RC system is operating normally.

SYSTEM Green Flashing The Model 6511RC system is operating normally.

Off The Model 6511RCsystem is not functioning properly.

ENET(NODE) Green On solid Indicates there is Ethernet frame activity on one or more of the 6511RC’s Ethernet inter-

faces, including the two rear-panel 10/100/1000 ports, the front -panel 10/100 port,

and the packet--switched PICMG 2.16 bus.

Off Indicates NO Ethernet frame activity detected on any of the 6511RC’s Ethernet interfaces,

including the PICMG 2.16 bus.

CLK SOURCE Green

CLK ERROR Yellow On solid Primary Master Clock source has been lost and the 6511RC is using the secondary

On solid The 6511RC is defined as the Primary (master) clock source for the H.100 bus

Flashing The 6511RC is defined as the Secondary (alternate master) clock source.

Off The 6511RC is defined as a slave, deriving its clock from the H.110 Bus.

source for its clock.

Flashing Master Clock source and the Secondary Clock source have been lost and the 6511RC

is using its internal crystal for its clock.

Off No clock errors currently detected.

Hardware overview 27

Page 28

1 • Introduction Model 6511RC User Manual

Table 3. Front-panel LED indicators (Continued)

LED Color Status Meaning

TEST MODE Green On solid One or more Ethernet ports or the STM-1 port is in test mode.

Flashing One or more Ethernet ports or the STM-1 port is in test mode and errors have been

received.

Off None of the ports is operating in test mode.

WAN Green On solid Indicates the STM-1 port is activated, synched, and operating normally.

Flashing Indicates that the STM-1 port is detecting the SDH network, but is unable to synchro-

nize with it.

Off Indicates rear blade not present or STM-1 port is not configured

ENET(SWITCH) Green On solid Indicates there is Ethernet frame activity on at least one of the eight PICMG 2.16 connec-

tions to other blades on the PSB bus.

Off

No Ethernet frame activity detected on the PICMG 2.16 bus.

ENET(REAR) Green On Indicates Ethernet frame activity on one or both of the 10/100/1000 Ethernet ports

Off There is NO Ethernet frame activity on either of the 10/100/1000 Ethernet ports

ON LINE On Reserved for future use

Off Reserved for future use

10/100 ENET Green On Ethernet Link is established

Integrated LEDs

on RJ-45

Connector

Yellow On Flashes to indicates Ethernet frame activity on this port

READY Blue On Card ready for removal from cPCI chassis.

Off No Ethernet link is established

Off Indicates no Etherent frame activity on this port

Off Card not ready for removal from cPCI chassis.

Table 4. Rear-panel LED indicators

LED Color Status Meaning

ALARM Red On solid A minor alarm condition has been detected.

Flashing A major alarm condition has been detected

Off The Model 6511RC is operating normally.

WAN Green On solid Indicates the STM-1 port is activated, synched, and operating normally.

Flashing Indicates that the STM-1 port is detecting the SDH network, but is unable to synchro-

nize with it.

Off Indicates rear blade not present or STM-1 port is not configured

ENET 1 Green On Ethernet Link is established

Integrated LEDs

on RJ-45

Connector

ENET 2

Integrated LEDs

on RJ-45

Connector

Ready

Yellow On Flashes to indicates Ethernet frame activity on this port

Green On Ethernet Link is established

Blue On Card ready for removal from cPCI chassis.

Off No Ethernet link is established

Off Indicates no Etherent frame activity on this port

Off No Ethernet link is established

On Flashes to indicates Ethernet frame activity on this port

Off Indicates no Etherent frame activity on this port

Off Card not ready for removal from cPCI chassis.

28 Hardware overview

Page 29

Model 6511RC User Manual 1 • Introduction

Approvals

The Model 6511RC Matrix Switch has achieved the following approvals and certifications:

• Safety

- UL 60950

- Industry Canada CSA C22.2 No. 60950

• RTTE Directive (CE Mark)

- EMC Directive 89/336/EEC

- Low Voltage Directive 73/23/EEC (EN 60950)

- ETSI CTR 12

- ETSI CTR 13

• EMC

- FCC Part 15, Subpart B, Class A

• Telecom

- FCC Part 68

- Industry Canada CS-03

Approvals 29

Page 30

1 • Introduction Model 6511RC User Manual

30 Approvals

Page 31

Chapter 2 Hardware installation

Chapter contents

Introduction..........................................................................................................................................................32

Unpacking the Model 6511RC Matrix Switch......................................................................................................32

Verifying that the ForeFront chassis is properly installed .......................................................................................32

Verfying correct electrical grounding ...............................................................................................................33

Verifying correct cover plate installation .........................................................................................................33

Matrix Switch hardware installation ......................................................................................................................34

Installing the network cables..................................................................................................................................35

Connecting the front-panel Ethernet LAN port ..............................................................................................36

Connecting the 10/100Base-T Ethernet port to an Ethernet switch or hub ...............................................36

Connecting the 10/100Base-T Ethernet port to an Ethernet-capable workstation or PC ...........................36

Connecting the front-panel EIA-561 RS-232 configuration port (DCE configured) .......................................37

Connecting the rear-panel STM-1 WAN port to an SDH network ................................................................37

Connecting the STM-1 optical interface to fiber-optic network cables ......................................................37

Connecting the STM-1 electrical interface to coaxial network cables .........................................................38

Connecting the rear-panel Ethernet WAN/management ports ........................................................................39

Connecting the 10/100/1000 Base-T Ethernet ports to a router, hub or switch ........................................40

Completing the hardware installation....................................................................................................................40

31

Page 32

2 • Hardware installation Model 6511RC User Manual

Introduction

This chapter contains the following procedures for installing the Model 6511RC Matrix Switch:

Note

• “Unpacking the Model 6511RC Matrix Switch”—lists the contents in the Matrix Switch shipping con-

tainer

• “Matrix Switch hardware installation”—describes installing the Matrix Switch on a flat surface or in a stan-

dard 19-inch rack

• “Installing the network cables” on page 35—describes installing the power and network interface cables

• “Completing the hardware installation” on page 40—describes testing the Matrix Switch hardware to verify

that it is ready for software configuration

Before installing the Matrix Switch, you will need to obtain the line

type and encoding of the STM-1 link from your local telephone company (Telco).

Unpacking the Model 6511RC Matrix Switch

Inspect the shipping carton for external damage. Note any damage before removing the container contents.

Report equipment damage to the shipping carrier immediately for claim purposes. Save all packing materials in

case you need to return an item to the factory for servicing.

The Matrix Switch comes with the following items:

• The Model 6511RC Digital Cross-Connect (Matrix Switch)

• One RJ45-to-RJ45 cable for use with the console and Ethernet ports

• A DB9-RJ45 (EIA-561) adapter for connecting a PC's serial port to the Matrix Switch console port

Verifying that the ForeFront chassis is properly installed

You must verify that the ForeFront chassis is correctly installed before installing the Matrix Switch hardware

into the chassis. Check for the following:

• Correct electrical grounding—Improper chassis grounding may impair proper operation of the STM-1

electrical interface, thereby causing data transmission errors on the STM-1 link. See section “Verfying cor-

rect electrical grounding” on page 33 for directions on verify chassis grounding.

• Correctly installed front and rear panels over vacant chassis slots—Absent front or rear panels over vacant

module slots leaves the chassis interior open and thereby vulnerable to the following problems:

- Improper EMI shielding against both incoming and outgoing electromagnetic signals

- Impaired operation of the chassis cooling system, resulting in equipment overheating, including the SHD

laser subsystem on the Matrix Switch

See section “Verifying correct cover plate installation” on page 33 for directions on verifying proper cover

plate installation

32 Introduction

Page 33

Model 6511RC User Manual 2 • Hardware installation

Verfying correct electrical grounding

Do the following to verify correct electrical grounding:

Improper chassis grounding may impair the operation of the

STM-1 electrical interface, thereby causing data transmission

errors on the STM-1 link.

1. Inspect the rack chassis grounding studs on the AC power module or DC power module (see figure 11 for

studs locations) to ensure a #12 AWG ground wire is attached.

Figure 11. AC power module and DC power module grounding studs locations

2. Inspect the remote end the #10 AWG ground wire and verify that it is attached to one of the following

grounding sources:

– The building ground rod (generally located at the site’s main service entrance)

– A sprinkler system pipe

– A cold-water pipe

– Building structural steel

Verifying correct cover plate installation

Missing front or rear panel cover plates leave the chassis interior open and vulnerable to the following problems:

• Impaired EMI shielding against incoming and outgoing electromagnetic signals

• Reduced chassis cooling system efficiency, which can resulting in equipment overheating, especially in the

SHD laser subsystem on the Matrix Switch

Do the following to verify that cover plates are properly installed:

1. Inspect the front of the chassis and verify that a cover plate is installed for each vacant module slot, and

verify that each cover plate’s fasteners are tightened securely to the front panel. Missing cover plates must

be replaced before installing the Matrix Switch.

Verifying that the ForeFront chassis is properly installed 33

Page 34

2 • Hardware installation Model 6511RC User Manual

Note

Missing cover plates can be replaced by calling Patton Sales at

+1 (301) 975-1000. The Sales Department is available Monday

through Friday, from 8:00 A.M. to 5:00 P.M. EST (8:00 to

17:00 UTC-5).

2. Inspect the rear of the chassis and verify that a cover plate is installed for each vacant module slot, and ver-

ify that each cover plate’s fasteners are tightened securely to the rear panel. Missing cover plates must be

replaced before installing the Matrix Switch.

Matrix Switch hardware installation

Do the following to install the Matrix Switch hardware:

1. Remove the Matrix Switch rear blade from its shipping container.

Note

Note

2. Remove the slot cover plate, if present.

3. Unlatch both handles on the Matrix Switch blade by pressing in on the red release button in each handle

(see figure 12).

Be sure to wear the anti-static strap to prevent electrostatic damage to

the blade.

The Matrix Switch should be installed as close as possible to the termination jack provided by the Telco. The location should be well

ventilated. Do not block the rack chassis’ cooling vents.

4. While holding the Matrix Switch from the card handles (see figure 12), align the Matrix Switch with the

guide rails of the appropriate slot and slide it back until it touches the backplane connectors and the alignment/ESD pin (see figure 12) engages the chassis. When the blade is fully seated, the red release buttons in

the handles click up automatically, thus locking the handles.

Figure 12. Alignment/ESD pin and card handle

5. Tighten the screw fastener located inside each handle to secure the blade to the chassis.

34 Matrix Switch hardware installation

Page 35

Model 6511RC User Manual 2 • Hardware installation

6. Insert the front blade into the front chassis slot corresponding to the slot in which you installed the rear

blade. Verify that the release buttons in the handles click up to indicate that the board is fully seated and

locked into place.

Installing the network cables

This section describes installing network interface cables on the following front and rear Matrix Switch

blade ports:

• The Matrix Switch front blade’s 10/100 Ethernet LAN port and an EIA 561 RS-232 CONFIG port

(see figure 13).

• The Matrix Switch rear blade’s STM-1 SDH WAN port (presented in SC optical and 75-ohm BNC electri-

cal formats) and two 10/100/100 Ethernet WAN/LAN management ports (see figure 14)

Figure 13. Matrix Switch front blade network interface ports

Figure 14. Matrix Switch rear blade network interface ports

Installing the network cables 35

Page 36

2 • Hardware installation Model 6511RC User Manual

Connecting the front-panel Ethernet LAN port

The Matrix Switch includes a 10/100Base-T transceiver, accessible via a physical interface on the front panel of

the front blade for connection to an Ethernet LAN. The Ethernet interface complies with IEEE 802.3 and is presented on a 6-pin RJ-45 female receptacle. Once connected to a LAN, the Ethernet port will autosense the speed

of the LAN and automatically negotiate half or full-duplex operation. This port provides access to the Matrix

Switch’s resident management services, including the HTTP/Web Management feature. This port also connects

to the on-board Ethernet Switch, thus providing Ethernet access to other blades within the ForeFront system via

the PICMG 2.16 PSB. This section describes connecting the Matrix Switch to the Ethernet LAN via an Ethernet

hub, switch, or workstation.

Connecting the 10/100Base-T Ethernet port to an Ethernet switch or hub

The 10/100Base-T Ethernet port (see figure 5) is designed to connect to an Ethernet switch or hub. The

Ethernet RJ-45 pin and signal definitions for the Matrix Switch or for a NIC card in a workstation/PC are

shown in figure 15. Connect a straight-through CAT-5 cable (one wired as shown in figure 15) between the

Matrix Switch and the hub/switch.

Figure 15. Ethernet RJ-45 pin and signal definitions for Matrix Switch

Connecting the 10/100Base-T Ethernet port to an Ethernet-capable workstation or PC

The 10/100Base-T Ethernet port can connect to a single Ethernet-capable workstation or PC by means of a

cross-over cable. Refer to figure 16 to assemble a cross-connect cable that will connect between the NIC Ethernet port in the workstation and the Matrix Switch 10/100Base-T Ethernet port.

Figure 16. Cross-over RJ-45-to-RJ-45 Ethernet cable diagram

36 Installing the network cables

Page 37

Model 6511RC User Manual 2 • Hardware installation

Connecting the front-panel EIA-561 RS-232 configuration port (DCE configured)

Install the supplied RJ-45-to-RJ-45 cable with the DB9-RJ45 adapter between the Matrix Switch RS-232 port

(see figure 13 on page 35) and an open serial port on your computer. If you need to assemble your own cable,

refer to the pinout diagram in figure 17.

Figure 17. RJ-45 pin and signal definitions for Matrix Switch CONFIG port

Connecting the rear-panel STM-1 WAN port to an SDH network

The Matrix Switch offers two types of STM-1 interfaces—optical and electrical—presented on the rear panel of

the rear blade. Optical interfaces connect to fiber-optic network cables, while the electrical interfaces connect to

coaxial network cables. The rear-blade connectors must match the type of network cables and connectors used by

the SDH network to which you will connect.

Connecting the STM-1 optical interface to fiber-optic network cables

The following versions of the Matrix Switch rear blade offer an optical interface for the STM-1 port

• Model 6511RC/M155/SC20

• Model /EBNC6511RC/M155/SC20

The designation SC20 in the model code denotes that an optical interface conforming to ITU specification

G.957 and G.652 is present. The Matrix Switch presents the STM-1 optical interface on a pair of SC fiberoptic connectors, one for the transmiting (TX) and one for receiving (RX) signals (see figure 14 on page 35).

Note

The wavelength of the laser signal is 1310 nanometers. The singlemode fiber-optic cable connecting the STM-1 WAN port to the SDH

network must extend no farther than 12.4 miles (20 kilometers).

Installing the network cables 37

Page 38

2 • Hardware installation Model 6511RC User Manual

Figure 18. Fiber-optic SC cable connectors

Do the following to connect the dual singlemode fiber-optic cable (see figure 18) to the STM-1 SC connectors:

1. Remove the protective cap from the fiber optic cable connectors.

2. Attach the transmit fiber-optic cable connector to the TX SC connector on the rear blade (see figure 14 on

page 35).

3. Attach the receive fiber-optic cable connector to the RX SC connector on the rear blade.

Connecting the STM-1 electrical interface to coaxial network cables

The Matrix Switch presents the STM-1 electrical interface on a pair of 75-ohm female BNC connectors, one

for the transmiting (TX) and one for receiving (RX) signals (see figure 14 on page 35).

For most installations, the coaxial cable connecting the STM-1 WAN port to the SDH network can be no

longer than 325 feet (100 meters).

Note

The Matrix Switch electrical interface transmits a STM-1 signal with

an attenuation margin of 12.7dB at 78 MHz over coaxial cable. The

12.7dB attenuation margin typically results in a transmission distance

limitation of approximately 360 feet (110 meters) for RG-59U

coaxial cable.

38 Installing the network cables

Page 39

Model 6511RC User Manual 2 • Hardware installation

Figure 19. BNC coaxial cable connectors

Do the following to connect the dual 75-ohm coaxial cable (see figure 19) to the STM-1 BNC connectors:

1. Attach the transmit connector of the coaxial cable to the TX connector on the rear blade (see figure 14 on

page 35).

2. Attach the transmit connector of the coaxial cable to the RX connector on the rear blade.

Connecting the rear-panel Ethernet WAN/management ports

The Matrix Switch provides two 10/100/1000Base-T Ethernet transceivers, accessible via physical interfaces

on the rear-panel of the rear blade, for connection to an external router, hub, or switch. Both interfaces are presented on RJ-45 6-pin female receptacles. The interfaces comply with IEEE specification 802.3 and are labeled

ENET 1 and ENET 2 (see figure 14 on page 35).

Once connected to a LAN, the Ethernet port will autosense the speed of the LAN and automatically negotiate