Page 1

USER

Part# 07M570/580-B

Doc# 074091UB

Revised 2/16/96

MANUAL

MODEL 570/580

100Base-T (CAT-5)

Surge Protectors

SALES OFFICE

(301) 975-1000

TECHNICAL SUPPORT

(301) 975-1007

Page 2

2.0 GENERAL INFORMATION

Thank you for your purchase of this Patton Electronics product.

This product has been thoroughly inspected and tested and is

warranted for One Year parts and labor. If any questions or problems

arise during installation or use of this product, please do not hesitate to

contact Patton Electronics Customer Service at (301) 975-1007.

2.1 FEATURES

• Multi-level surge protection

• Operation at Speeds up to 100 Mbps

• Optional 2,4,6 or 8 wire versions

• EIA/TIA TSB-40A Category 5 Compliant

• N.E.X.T. better than -43 dB at 100 MHz

• Shunts surges directly to chassis ground

• Easy to install

2.2 DESCRIPTION

Devices that connect to Category-5 cabling systems are routinely

threatened by unwanted electrical energy (lightning, AC power

induction, ESD and more). Higher speed devices–such as those

operating at 100 Mbps–are especially vulnerable to the effects of these

hazards, which can include data loss and hardware damage.

The Patton Model 570 and 580 Series Surge Protectors provide

effective surge protection for devices operating in Category-5 Cabling

Systems. The Model 570 is specifically designed for point-of-use

installation; the Model 580 is designed to be installed at the building

entrance. Both models use a multi-stage Silicon Avalanche Diode

circuit, and will continue functioning while handling the appropriate IEC

801.5 surges applicable to their use (see the tables in Appendix B).

Both the 570 and 580 will additionally protect against surges up to and

exceeding 2kV/1kA in fail-safe mode.

Models 570 and 580 support a wide range of balanced interfaces

from RS-422 to 100Base-T. Highlights include a low insertion loss (less

than 0.4dB at 100MHz) and minimal near end cross talk (greater than

-43 dB at all frequencies up to 100 MHz). Grounding is accomplished

via an external ground strap that provides a separate unit-ground to

chassis-ground connection.

Warning: This product will not provide complete protection should your

equipment or building be subject to a direct lightning hit.

1.0 WARRANTY INFORMATION

Patton Electronics warrants all Model 570/580 components to be

free from defects, and will—at our option—repair or replace the product

should it fail within one year from the first date of shipment. This

warranty is limited to defects in workmanship or materials, and does not

cover customer damage, abuse or unauthorized modification. If this

product fails or does not perform as warranted, your sole recourse shall

be repair or replacement as described above. Under no condition shall

Patton Electronics be liable for any damages incurred by the use of this

product. These damages include, but are not limited to, the following:

lost profits, lost savings and incidental or consequential damages arising

from the use of or inability to use this product. Patton Electronics

specifically disclaims all other warranties, expressed or implied, and the

installation or use of this product shall be deemed an acceptance of

these terms by the user.

1.1 SERVICE

All warranty and non-warranty repairs must be returned freight

prepaid and insured to Patton Electronics. All returns must have a

Return Materials Authorization number on the outside of the shipping

container. This number may be obtained from Patton Electronics

Technical Service at (301) 975-1007. Packages received without an

RMA number will not be accepted.

Patton Electronics' technical staff is also available to answer any

questions that might arise concerning the installation or use of your

Model 570/580. Technical Service hours: 8AM to 5PM EST, Monday

through Friday.

Page 3

3.0 INSTALLATION

Patton's Model 570 & 580 surge protectors are easy to install and

are designed to operate transparently to your network. This section

describes connection procedures for both models.

3.1 PRODUCT APPLICATIONS

Both Models 570 & 580 protect all eight pins on the modular RJ-45

Cat-5 interface, and work in environments with data rates up to 100

Mbps. The following descriptions will give you a general guideline for

installing the units in your Cat-5 environment.

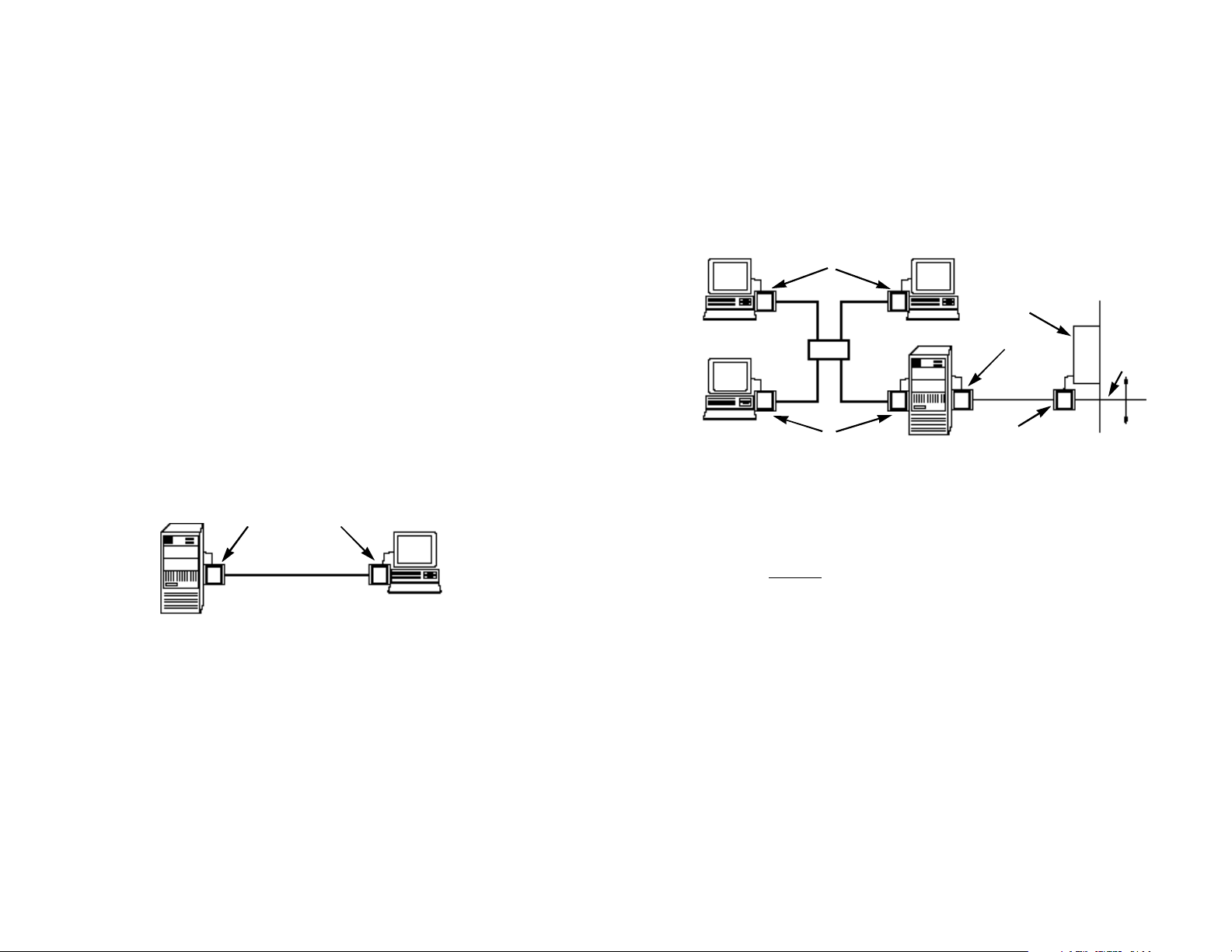

3.1.1 POINT-OF-USE APPLICATION (MODEL 570)

The Model 570 is designed for installation on LAN equipment in a

typical office environment (see Figure 1, below). For best results the

Model 570 should be connected as close as possible to the

communication port of the device to be protected (a 6 inch, Category-5

patch cable is provided with the Model 570). Also, the flat braided

grounding wire on the Model 570 should be attached to the grounded

metal frame of the device being protected.

3.1.2 BARRIER APPLICATION (MODEL 580)

The Model 580 is a more robust protector than the Model 570, and

is designed for use as a barrier protector on LAN equipment in campus

networks. Applications include cable runs between buildings, cable

runs between floors on multi-story structures, and as a higher capacity

replacement for the Model 570 (a 6 inch, Category-5 patch cable is

provided with the Model 580).

(continued)

Figure 1. A typical point-of-use application for the Patton Model 570.

The Model 580 is also well suited for use in severe lightning areas,

heavy industrial environments, and installations with heavy machinery

in the direct vicinity of sensitive LAN equipment and cabling. Figure 2

(below) shows a typical application for the Model 580. For best results,

the braided grounding strap on the Model 580 should be attached to the

grounded metal frame of the device being protected. When installation

is made at a barrier, such as an external wall, the braided strap should

be connected to a nearby electrical ground.

Model 570 Model 570

Model 570 or 580

Exterior Wall

Electrical Panel

Local Hub

Model 570 or 580

Figure 2. A typical barrier application for the Patton Model 580.

Model 570 or 580

Model 580

3.2 INSTALLATION PROCEDURES

In order to operate as designed, the Model 570 and 580 must be

connected correctly to your Cat-5 network. Please read all the

instructions below and follow them carefully.

Connection of the Model 570 or 580 to an I/O Port

1. Turn off equipment power and unplug (disconnect) the existing

connection between the UTP cable and the equipment’s I/O port.

To

other

bldg.

or

floor

(continued)

Page 4

2. Install the Model 570/580 between the incoming UTP line and the

protected equipment (see Figure 3, below). This installation

requires a straight through Cat-5 patch cable with modular RJ-45

connectors (supplied with unit). Note: It doesn’t matter which end

of the Model 570/580 plugs into which cable.

Cat-5 patch cable to

protected equipment

(6 inches or less)

Connection to

chassis ground

Figure 3. Installation of Model 570/580 Surge Protectors.

Cat-5 input

from network

3. Locate a metal chassis ground on the equipment to be protected.

This is often a hex screw on a D-shell or AUI connector.

Sometimes a metal back panel is attached by screws, one of which

can be used for chassis grounding. If you cannot locate a chassis

ground connection on your equipment, contact Patton Technical

Support at (301) 975-1000 to discuss an alternative grounding

solution.

Connection of the Model 580 at a Barrier (Wall, Bldg Entrance, etc.)

1. Disconnect the UTP cable from the wall jack or patch panel jack.

2. Install the Model 580 between the UTP line and the jack. This

installation requires a straight through Cat-5 patch cable with

modular RJ-45 connectors (supplied with unit). Note: It doesn’t

matter which end of the Model 580 plugs into which cable.

3. Locate an electrical ground nearest the jack. Often this will be on

an electrical panel or sub panel. If you cannot locate a nearby

electrical ground, contact Patton Technical Support at

(301) 975-1000 to discuss an alternative grounding solution.

4. Connect the braided ground strap directly to the electrical ground

you have located. The best way to make this connection is to

attach the braided metal strap to a metal panel or wallplate screw

using a hex nut or screw.

Caution: Surge energy may run both directions on the ground

strap. To provide the best protection, it is essential that the ground

strap on the Model 580 be connected to an electrical ground.

4. Connect the braided ground strap directly to the chassis ground

connection you have located (see Figure 3, above). The best way

to make this connection is to attach the braided metal strap using a

hex nut or screw on your device.

Caution: Surge energy may run both directions on the ground

strap. To provide the best protection, it is essential that the ground

strap on the Model 570/580 be connected to the chassis ground of

the protected device. Do not lengthen the ground strap of the

Model 570/580 or connect to a ground other than chassis ground

unless instructed to do so by Patton Technical Support.

Page 5

APPENDIX A

Class

1 1.0 kV

24 A

2 1.0 kV

24 A

3 2.0 kV

48 A

4 (n/a)

(n/a)

5 4.0 Kv

95 A

Wave (1.2 x 50 µs)

Forms (1.2 x 50 µs)

IEC 801-5 Threat Levels as a Function of Class

Sym. Lines Coupling Mode

Line-GND, Zs=42 Ohms

Figure B-1. IEC Threat Levels as a Function of Class.

SPECIFICATIONS

APPENDIX B

INTERNATIONAL ELECTROTECHNICAL COMMISSION (IEC)

COMPLIANCE

Environment: Category-5 Interfaces that utilize the RJ-45

connector, including RS-422, 423, 10Base-T, Token Ring, Fast

Ethernet, 100Base-T and ATM

Connectors: RJ-45 Female

Response Time: Clamped to 13 V after 0.1 µs

Characteristic Impedance: 100 Ohms

NEXT Loss: Model 570 - worst pair Better than -46 dB at 100 MHz;

Model 580 - worst pair Better than -43 dB at 100 MHz

Surge Clamp Voltage: Model 570 - 13 V max with 1 KV Input;

Model 580 - 15 V max with 2 KV Input

Surge Rating: IEC 801.5 Standard Level

DC Clamp Voltage: Common Mode to Gnd, each line

7.5 V @ 50 mA; Differential mode, per pair 8.1 V @ 50 mA

Insertion Loss: Less than 0.4 dB at 100 MHz (including connector)

Return Loss: Better than 14 dB

Group Delay: None, 1 MHz to 100 MHz

Series Resistance: Less than 400 milliohms

Grounding: External ground strap provides separate unit-ground to

chassis-ground contact

Dimensions: 2.25" x 1.69" x .75"

Meets IEC standards 801.2, 801.4 and 801.5 (CE Mark)

Effective January 1996 the European Economic Community will

require that all electronic devices be tested and comply with all

applicable International standards relating to the product type and

category of use. Electromagetic Compatibility Directive 89/336/EEC

specifically addresses communication line surge protection devices,

since conformity to immunity standard EN50082-1:1992 is mandatory.

The EN50082-1:10992 standard incorporates International

Organization for Standardization (ISO) publications 801.2 and 801.4,

which describe Electrostatic Discharge and Electrical Fast Transient

requirements. ISO 801.5 describes Surge Immunity Requirements and

is expected to be adopted as a mandatory requirement under

EN50082-1 by the Technical Committee. in 1996. Any protector sold

into the international community must meet these standards. This

device has been tested* and found to comply with these standards as

evidenced by its CE mark.

*Note: All test results are for the Model 570/580 alone, not including the

standard 6” patch cable that is normally shipped with the unit.

Page 6

APPENDIX B

APPENDIX B (continued)

TSB-40A COMPLIANCE TESTING RESULTS

TYPICAL ATTENUATION MEASUREMENT

EIA/TIA TSB-40A COMPLIANCE

The Model 570/80 series surge protectors have been designed to

conform to stringent EIA/TIA TSB-40 standards as required for all

Category-5 connecting hardware. These standards specify the

capacitance and near end cross-talk (N.E.X.T) to insure proper

operation of ALL connected equipment. Specific test results are shown

in the tables on the following pages*.

TSB-40A COMPLIANCE TESTING RESULTS

TYPICAL NEAR-END CROSSTALK MEASUREMENT

Figure C-1. N.E.X.T. measurements for Patton Model 570.

Figure C-3. Attenuation measurements for Patton Model 570.

Figure C-2. N.E.X.T. measurements for Patton Model 580.

*Note: All test results are for the Model 570/580 alone, not including the

standard 6” patch cable that is normally shipped with the unit.

Figure C-4. Attenuation measurements for Patton Model 580.

Page 7

APPENDIX B (continued)

TSB-40A COMPLIANCE TESTING RESULTS

TYPICAL RETURN LOSS MEASUREMENT

Figure C-5. Return Loss measurements for Patton Model 570.

Figure C-6. Return Loss measurements for Patton Model 580.

Loading...

Loading...