Page 1

USER

MANUAL

MODEL 2450

56/64 Kbps, 4-Wire

DDS & Clear Channel

CSU/DSU

CERTIFIED

An ISO-9001

Certified Company

Part# 07M2450-B

Doc# 099051U,

Rev. C

Revised 1/23/08

SALES OFFICE

(301) 975-1000

TECHNICAL SUPPORT

(301) 975-1007

http://www.patton.com

Page 2

1.0 WARRANTY INFORMATION

Patton Electronics warrants all Model 2450 components to be

free from defects, and will—at our option—repair or replace the product

should it fail within one year from the first date of shipment.

This warranty is limited to defects in workmanship or materials, and

does not cover customer damage, abuse or unauthorized modification.

If this product fails or does not perform as warranted, your sole

recourse shall be repair or replacement as described above. Under no

condition shall Patton Electronics be liable for any damages incurred

by the use of this product. These damages include, but are not limited

to, the following: lost profits, lost savings and incidental or

consequential damages arising from the use of or inability to use this

product. Patton Electronics specifically disclaims all other warranties,

expressed or implied, and the installation or use of this product shall be

deemed an acceptance of these terms by the user.

1.1 RADIO AND TV INTERFERENCE

The Model 2450 generates and uses radio frequency energy, and if

not installed and used properly—that is, in strict accordance with the

manufacturer's instructions—may cause interference to radio and

television reception. The Model 2450 has been tested and found to

comply with the limits for a Class A computing device in accordance

with the specifications in Subpart J of Part 15 of FCC rules, which are

designed to provide reasonable protection from such interference in a

commercial installation. However, there is no guarantee that

interference will not occur in a particular installation. If the Model 2450

does cause interference to radio or television reception, which can be

determined by disconnecting the RS-232 interface, the user is

encouraged to try to correct the interference by one or more of the

following measures: moving the computing equipment away from the

receiver, re-orienting the receiving antenna and/or plugging the

receiving equipment into a different AC outlet (such that the computing

equipment and receiver are on different branches). In the event the

user detects intermittent or continuous product malfunction due to

nearby high power transmitting radio frequency equipment, the user is

strongly advised to use data cables with an exterior outer shield bonded

to a metal or metalized connector

1.2 FCC INFORMATION

The Model 2400 Series has been tested and registered in

compliance with the specifications in Part 68 of the FCC rules. A label

on the equipment bears the FCC registration number. You may be

requested to provide this information to your telephone company.

1

Page 3

Your telephone company may make changes in its facilities,

equipment, operations or procedures that could affect the proper

operation of the Model 2450 Series. If this happens, the telephone

company should give you advance notice to prevent the interruption of

your service.

The telephone company may decide to temporarily discontinue

your service if they believe your Model 2450 Series may cause harm to

the telephone network. Whenever possible, they will contact you in

advance. If you elect to do so, you have the right to file a complaint

with the FCC. The telephone company may ask you to disconnect the

equipment from the telephone network until the problem has been

corrected or until you are certain that the Model 2400 Series is not

malfunctioning.

The following information may be required when applying to your

local telephone company for leased line facilities.

Service Digital Facility Service Order Network

T

ype Interface Code Code Jacks

56 Kbps 04 DU5 - 56 6.0F RJ48S

64 Kbps 04 DU5 - 64 6.0F RJ48S

1.3 SERVICE INFORMATION

All warranty and non-warranty repairs must be returned freight

prepaid and insured to Patton Electronics. All returns must have a

Return Materials Authorization number on the outside of the shipping

container. This number may be obtained from Patton Electronics

Technical Support: (301) 975-1007; http://www.patton.com; or,

support@patton.com. Notice: Packages received without an RMA

number will not be accepted. Patton Electronics' technical staff is also

available to answer any questions that might arise concerning the

installation or use of your Model 2400. Technical Service hours: 8AM

to 5PM EST, Monday through Friday.

1.4 CE NOTICE

The CE symbol on your Patton Electronics equipment indicates

that it is in compliance with the Electromagnetic Compatibility (EMC)

directive and the Low Voltage Directive (LVD) of the Union European

(EU). A Certificate of Compliance is available by contacting Patton

Technical Support.

2

Page 4

2.0 GENERAL INFORMATION

Thank you for your purchase of this Patton Electronics product.

This product has been thoroughly inspected by Patton's qualified

technicians. If any questions or problems arise during installation or

use of this product, please do not hesitate to contact Patton Electronics

Technical Support at (301) 975-1007.

2.1 FEATURES

• Synchronous data rates of 56 or 64 Kbps

• Full duplex communication over two dedicated twisted pairs

• Supports distances to 3.4 miles over 26 AWG wire

• Selectable internal, external or network rcv/recover clock options

• Built-in V.54 loopback tests and V.52 BER test patterns

• Works with 56 Kbps DDS, 64 Kbps Clear Channel, or private

twisted pair circuits

• Switchable Circuit Assurance feature

• Externally accessible configuration switches

• Six front panel LEDs monitor communication and test status

• RJ-48S jack provided for line connection

• RS-232 & RS-422/530 versions have DB-25 connector

• V.35 version has either DB-25 or M/34 connector

• Ultra-compact enclosure fits in tight spaces

2.2 DESCRIPTION

The Model 2450 DDS & Clear Channel CSU/DSU is a standalone ,

AC powered CSU/DSU designed for 4-wire, full duplex communications

over dedicated twisted-pair. Synchronous data rates of 56 and 64 Kbps

are supported, at distances up to 3.4 miles. The Model 2450 provides

selectable timing options of internal, external or network receiverecovered clock. A circuit assurance feature is also provided.

For user convenience, the Model 2450’s DIP switches are

externally accessible, so there is no need to open the case to configure

the unit. The Model 2450’s built-in V.54 loopback test modes and V.52

BER test patterns are accessed using two front panel switches. Six

front panel LEDs monitor test modes and communication status. Line

connections are facilitated by a modular RJ-48S jack on the rear of the

unit.

3

Page 5

3.0 CONFIGURATION

The Model 2450 is easy to install and is ruggedly designed for

excellent reliability: just set it and forget it. The following instructions

will help you set up and install the Model 2450 properly.

3.1 CONFIGURATION SWITCHES

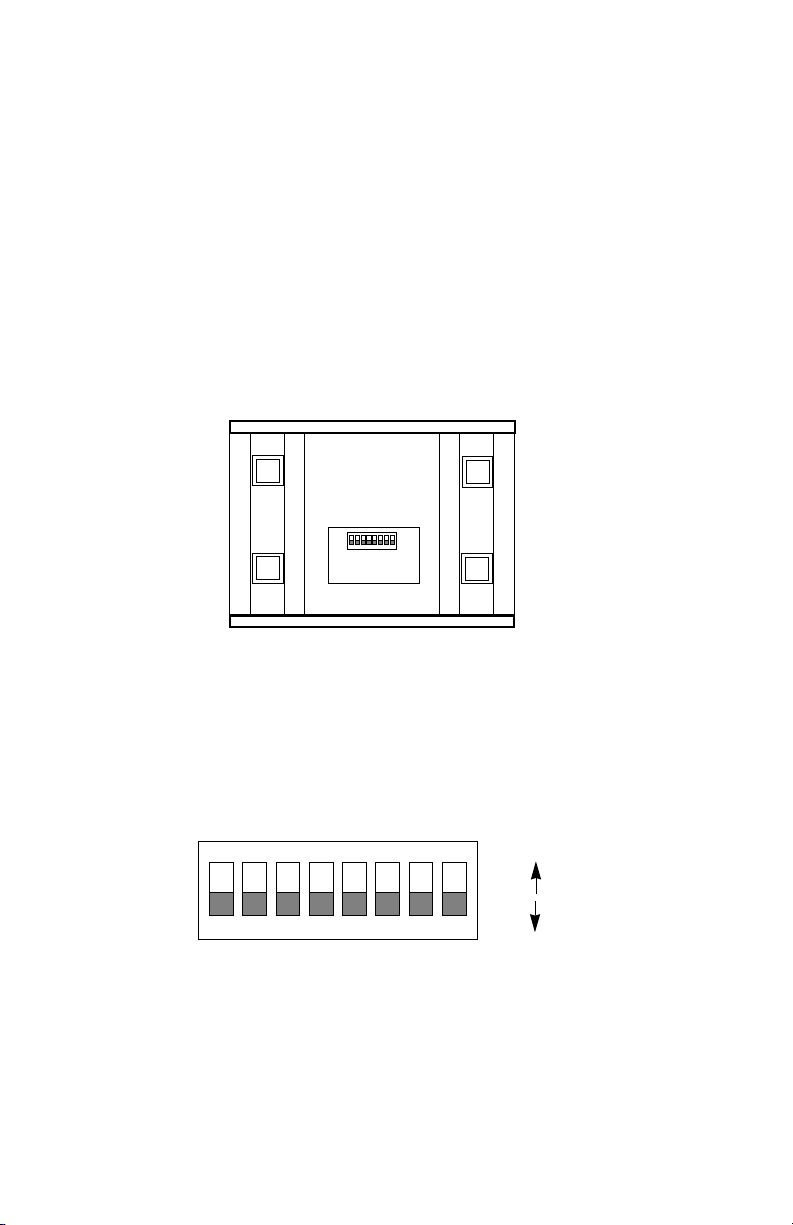

The Model 2450 uses a mini DIP switch package that allows

configuration to a wide range of applications. This DIP switch is

externally accessible from the underside of the Model 2450 (see Figure

1, below), therefore you do not need to open the Model 2450's case

during configuration.

REAR

ON

S1

12345678

FRONT

Figure 1. Underside of Model 2450, showing location of DIP switches

3.2 CONFIGURATION SWITCH SET “S1”

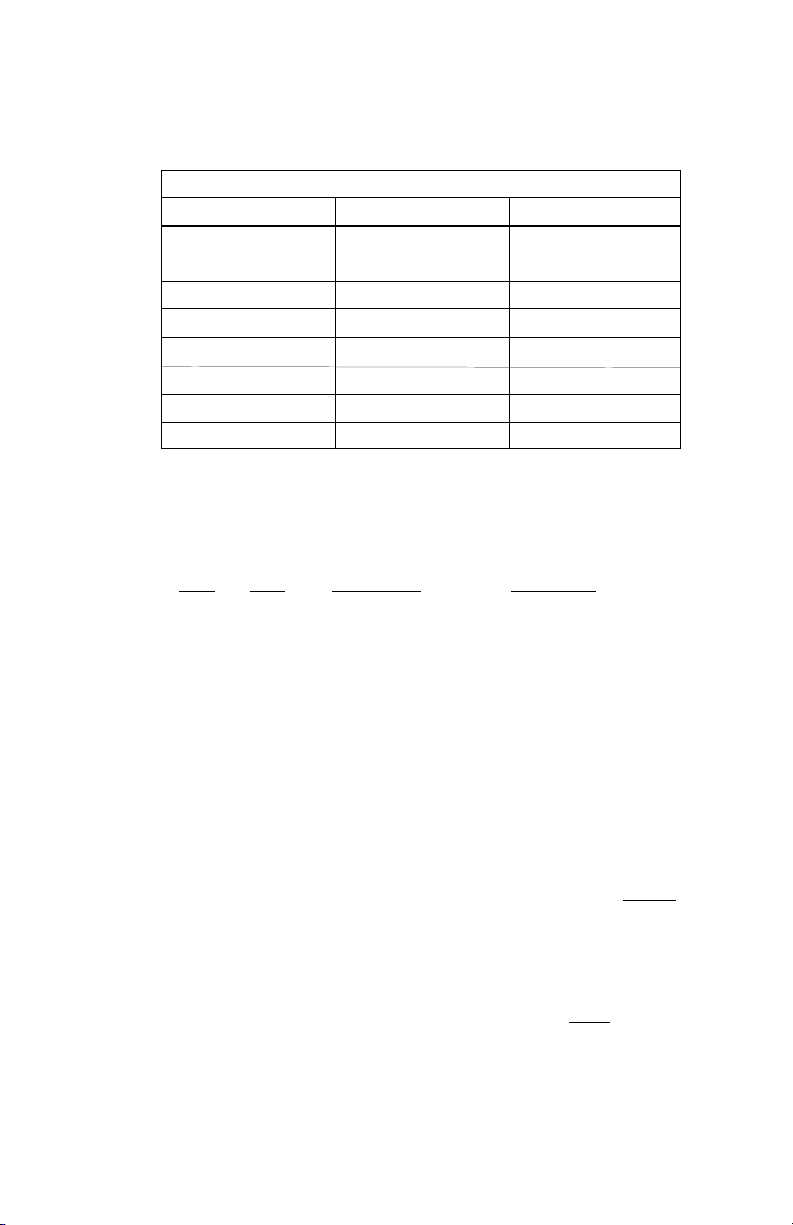

The switches shown in Figure 2 below and on DIP switch S1 control

clock mode, circuit assurance, RTS, data rate and test loop functions.

Following Figure 2 are factory default settings and detailed switch

descriptions for each switch.

ON

ON

12345678

OFF

Figure 2. Close-up of DIP switches showing “ON” and “OFF” positions

4

Page 6

S1 SUMMARY TABLE

Position Function Factory Default

S1-1 Clock Mode Off

S1-2 Clock Mode On

S1-3 Circuit Assurance Off Disabled

S1-4 RTS On Forced On

S1-5 Line Rate Off 56 kbps

S1-6 Front Panel Switches Off Enabled

S1-7 DTE Loop Control On Disabled

S1-8 Receive RDL Off Enabled

Switches S1-1 and S1-2: Clock Mode

The setting for switches S1-1 and S1-2 determines the transmitter

clocking mode for the Model 2450.

}

Network

S1-1

S1-2 Clock Mode Description

On Off External (DTE) Transmit clock derived

from terminal interface

Off On Network (Looped) Transmit clock derived

from the received line

signal; Use this mode

for Dedicated DDS

operation

Off Off Internal (Master) Transmit clock derived

internally

On On Campus Clock Transmit clock derived

from received line

signal. Allows remote

device (in

clock

V.54 loopback. For use

only in campus shorthaul configuration.

(Note: Local

must be in

clock mode.)

5

campus

mode) to initiate

device

internal

Page 7

Switch S1-3: Circuit Assurance

On dedicated circuits, the transmitter and the CTS output can be

configured to go On only when a working communication circuit is

established. If Circuit Assurance is used, enable it on only one end of

the communication link.

Circuit

S1-3

Assurance Description

On Enabled CTS will go low and the

transmitter will be held off if the

receiver is in the No Signal state

or CD is low

Off Disabled The transmitter and CTS will

operate without regard to the

receiver state

Switch S1-4: RTS

The RTS input can be forced on, ignoring the terminal’s RTS

signal. RTS controls the transmitter by either sending the user’s data

or sending an idle code.

S1-4

RTS Description

On Forced On Transmitter is always ON

Off Follows The RTS input controls the

DTE Signal transmitter

Switches S1-5: Data Rate

This switch controls the data rate on the line (RJ-48S port) and

must match the speed of your digital service.

S1-5

Setting

Off 56 kbps

On 64 kbps

6

Page 8

Switch S1-6: Front Panel Switch Enable/Disable

Switch S1-6 determines whether the front panel switches may be

used to perform diagnostic functions.

S1-6

Activation Description

Off Enabled Front panel switches may be used

to activate/terminate diagnostics

On Disabled Front panel switches will have no

effect on operation of the unit

Switch S1-7: DTE Loop Request Line Enable/Disable

The setting for switch S1-7 determines whether the DTE signals

can be used to activate/terminate the loopback diagnostic modes and

BER test patterns.

DTE TM Line

S1-7

Activation Description

Off Enabled DTE Loop request line switches

may be used to activate/terminate

diagnostics.

On Disabled DTE loop request lines will

have no effect on operation of

the unit.

Switch S1-8: Receive RDL Enable/Disable

Switch S1-8 determines whether or not the unit will respond to loop

requests from the remote device.

S1-6

Activation Description

Off Enabled Unit wil respond to loop requests

from the remote device.

On Disabled Unit wil ignore loop requests from

the remote device.

Page 9

4.0 INSTALLATION

The Model 2450 is designed for 4-wire, full duplex communication

over a DDS or Clear Channel carrier circuit, or over dedicated twisted

pair. This section will describe proper connection of the line interface,

the DTE (terminal) interface, and the AC power supply.

4.1 LINE (NETWORK) CONNECTION

The RJ-48S port on a Model 2450 CSU/DSU is prewired for a

standard TELCO wiring environment (see Figure 4, below). Connect

this port to the RJ-48S jack provided by your digital service carrier

using a

straight through

twisted pair cable between 19 and 26 AWG.

To be sure you have the right wiring, use the table below as a guide.

1 (TX+)

1

2

3

4

5

6

7

8

2 (TX-)

3 (N/C)

4 (N/C)

5 (N/C)

6 (N/C)

7 (RX+)

8 (RX-)

Figure 4. Interface pinouts for Model 2450 RJ-48S jack.

4.1.1 CONNECTING OVER PRIVATE TWISTED PAIR

If you are using a pair of Model 2450s as short range modems over

private twisted pair, make the connection between them using a twisted

pair

crossover cable

pinned according to the diagram below.

RJ-48S Cable (4-W

ire)

SIGNAL PIN# PIN# SIGNAL

TX+ 1-----------------------7 RX+

TX- 2-----------------------8 RXRX+ 7-----------------------1 TX+

RX- 8-----------------------2 TX-

87

Page 10

4.2 DTE (TERMINAL) CONNECTION

The Model 2450 is wired to connect to a DTE. If your terminal

device is DCE, call Patton Technical Support at (301) 975-1007 for

specific installation instructions.

Four versions of the Model 2450 are available, with respect to DTE

interface and connector type (see Appendix C). All versions connect to

the DTE using a

purchasing your interface cable, refer to the pinout diagrams in

Appendix D.

4.3 AC POWER CONNECTION

Power is supplied to the Model 2450 by a 10 VAC, 1 A wall mount

transformer. This transformer connects to the Model 2450 by means of

a cannon jack on the rear panel. The Model 2450 is powered-up as

soon as it is plugged into an AC outlet–there is no power switch.

4.3.1 120 VAC Power (US)

The 120 VAC adapter supplied with the standard version of the

Model 2450 is a “wall mount” type, and may be plugged into any

approved 120 VAC wall plug.

4.3.2 230 VAC Power (IEC)

The 230 VAC adapter supplied with the “international” version of the

Model 2450 is equipped with an IEC-320 shrouded male connector.

This connects with one of several available country-specific power

cords (see the ordering information in Appendix C). You may

purchase these power cords from Patton Electronics, or from a local

vendor of your choice.

straight through

cable. When constructing or

9 10

Page 11

5.0 OPERATION

Once you have configured the Model 2450 properly (see Section

3.0) and made line, DTE and power connections correctly (see Section

4.0), you are ready to operate the unit(s). (Note: the unit is operational

as soon as power is applied–there is no power switch.) This section

describes the LED status monitors, and use of the built-in V.54 and V.52

test modes.

5.1 LED STATUS MONITORS

The Model 2450 features six front panel status LEDs that indicate

the condition of the unit and communication link. Figure 6 (below)

shows the front panel location of each LED. Following Figure 6 is a

description of each LED's function.

Model 2450 MiniLink-I 56/64 CSU/DSU

V.54 Test

Modes

Test

TD RD

NS

CD

Figure 6. Front view of Model 2450

Error

511

511E

Remote

Normal

Local

• “TD” (Transmit Data) glows red to indicate an Idle condition or

Binary “1” data. Green indicates Binary “0” data.

• “RD” (Receive Data) glows red to indicate an Idle condition or

Binary “1” data. Green indicates Binary “0” data.

• “CD” (Carrier Detect) glows green when carrier is active. In 64

Kbps mode, CD glows red if there is no carrier, or if a bipolar

violation occurs. In 56 Kbps mode, CD glows red if there is no

carrier, if an Out-of-Service or Out-of-Frame violation occurs,

or if idle code is detected.

• “NS” (No Signal) glows red when there is no valid carrier. This

means the Model 2450 receiver has not detected a valid signal

from the digital service provider, or, in the case of short-haul

operation, from the remote Model 2540. If NS is lit, check for

an unplugged cable, broken wire or an incorrect Line Rate

selection.

Page 12

• “Error” glows red when errors are detected in test mode during

the “511” and 511/E” tests. This indicator also glows during

normal operation to indicated framing errors and/or bipolar

violations in 64 Kbps mode, or invalid bipolar violations in 56

Kbps mode (see Figure 7, below).

• “Test” glows red when the V.54 loopback tests or V.52 BER

tests are initiated.

5.2 TEST MODES

The Model 2450 offers two V.54 test modes, plus a built-in V.52

BER test pattern generator, to evaluate the condition of the modems

and the communication link. These tests can be activated physically

from the front panel, or via the interface.

5.2.1 Using Local Analog Loopback (LAL)

The Local Analog Loopback (LAL) test checks the operation of the

local Model 2450, and is performed separately on each unit. Any data

sent to the local Model 2450 in this test mode will be echoed (returned)

back to the user device. For example, characters typed on the

keyboard of a terminal will appear on the terminal screen. To perform a

LAL test, follow these steps:

1. Activate LAL. This may be done in one of two ways: First, by

moving the front panel toggle switch DOWN to “Local”, and; second, by

raising pin 18 on the interface. (Note: Make sure DIP switch S1-7 is

OFF). Once LAL is activated, the Model 2450 transmitter output is

connected to its own receiver. The “Test” LED should be lit.

2. Verify that the data terminal equipment is operating properly

and can be used for a test. If a fault is indicated, call a technician or

replace the unit.

3. Perform a V.52 BER (bit error rate) test as described in Section

5.2.3. If the BER test equipment indicates no faults, but the data

terminal indicates a fault, follow the manufacturer’s checkout

procedures for the data terminal. Also, check the interface cable

between the terminal and the Model 2450.

11 12

Page 13

5.2.2 Using Remote Digital Loopback (RDL)

The Remote Digital Loopback (RDL) test checks the performance

of both the local and remote Model 2450s, and the communication link

between them. Any characters sent to the remote Model 2450 in this

test mode will be returned back to the originating device. For example,

characters typed on the keyboard of the local terminal will appear on

the local terminal screen after having been passed to the remote Model

2450 and looped back. To perform an RDL test, follow these steps:

1. Activate RDL. This may be done in two ways: First, by moving

the front panel toggle switch UP to “Remote”, and; second, by raising

pin 21 on the interface. (Note: Make sure S1-7 is OFF).

2. Perform a V.52 BER test as described in Section 5.2.3. If the

BER test equipment indicates a fault, and the Local Analog Loopback

test was successful for both Model 2450s, you may have a problem

with the twisted pair line between the modems. You should then check

the twisted pair line for proper connections and continuity.

5.2.3 Using the V.52 BER Test

To use the V.52 BER tests in conjunction with the V.54 loopback

tests, follow these instructions:

1. Locate the “511/511E” toggle switch on the front panel of the

2450 and move it UP. This activates the V.52 BER test mode and

transmits a “511” pseudo-rando test pattern into the loop. If any errors

are present, the local modem’s red “Error” LED will blink sporadically.

2. If the above test indicates no errors are present, move the V.52

toggle switch DOWN, activating the “511/E” test with errors present. If

the test is working properly, the local modem's red “Error” LED will glow.

A successful “511/E” test will confirm that the link is in place, and that

the Model 2450’s built-in “511” generator and detector are working

properly.

Note: The above V.52 BER tests can be used independently of the

V.54 loopback tests. This requires two operators: one to initiate and

monitor the tests at the local Model 2450, and one to do the same at

the remote Model 2450. In this case, the test pattern sent by each

Model 2450 will not be looped back, but will be transmitted down the

line to the other Model 2450. Both operators must initiate and monitor

the tests simultaneously.

Page 14

APPENDIX A

PATTON MODEL 2450 SPECIFICATIONS

DDS Type: Dedicated

Transmission Format: Synchronous, full duplex

Maximum Operating

Distance: 18000 feet (3.4 miles) over 26 AWG twisted

pair

DTE Interface: RS-232 (DB-25 female), RS-422/530 (DB-

25 female), V.35 (M/34 female or DB-25

female)

DDS Line Interface: RJ-48S jack

Standards: AT&T 62310 compliant

DDS Line Rates: 56 and 64 Kbps

DTE Rates: 56 and 64 Kbps

Transmission Line: 4-wire

Applications: DDS, point-to-point or multipoint; Clear

Channel, point-to-point; campus-area pointto-point

Indicators: LED indicators for TD, RD, CD, No Signal,

Error and Test Mode

Diagnostics: V.54 compliant local and remote loopback

tests; V.52 compliant 511/511E BER test

Power Supply: 120 VAC, 60 Hz or 230 VAC, 50 Hz to 10

VAC, 1A wall mount transformer

Dimensions: (RS-232 version) 1.65”H x 4.18”W x 3.55”D;

(V.35 version w/ screws) 1.65”H x 4.18”W x

3.96”D

13 14

Page 15

APPENDIX B

CABLE RECOMMENDATIONS

The following statements apply to the Model 2450 when used as a

short range modem over private twisted pair:

All Patton Electronics Company Short Range Modems (SRMs) are

tested to the distances published in our Catalogs and Specification

Sheets on twisted-pair cable with the following characteristics:

W

ire Gauge Capacitance Resistance

19 AWG 83nF/mi or 15.72 pF/ft. .0163Ω/ft.

22 AWG 83nF/mi or 15.72 pF/ft. .0326Ω/ft.

24 AWG 83nF/mi or 15.72 pF/ft. .05165Ω/ft.

26 AWG 83nF/mi or 15.72 pF/ft. .08235Ω/ft.

We fully expect that the Short Range Modems will operate on lines

with specifications different from those tested, but to reduce the

potential difficulties in the field, one should ensure that the cable being

used has similar or better characteristics (lower capacitance or lower

resistance).

Wire with capacitance of 20pF/ft. or less is suitable for all our Short

Range Modems . However, distances may vary from those published in

our catalog. Variations in wire resistance will also affect distance but

not functionality. Wire should be 26 AWG or larger (smaller AWG#).

Patton products are designed to withstand normal environmental

noise and conditions however, other environmental factors too

numerous to discuss in this format may affect proper operation of the

SRM’s.

Selection of the proper SRM for an application is critical to

maintaining Customer Satisfaction and should be taken seriously.

Certain models are better suited for particular applications and

environments than others.

Page 16

APPENDIX C

FACTORY REPLACEMENT PARTS

AND ACCESSORIES

Patton Model #

Description

2450/A.............................56/64 kbps CSU/DSU (RS-232. DB-25

female connector)

2450/B.............................56/64 kbps CSU/DSU (RS-422/530,

DB-25 female connector)

2450/C.............................56/64 kbps CSU/DSU (V.35, M/34

female connector)

2450/E.............................56/64 kbps CSU/DSU (V.35, DB-25

female connector)

10-2500 ...........................DDS Cable, RJ48S - RJ48S, 6 foot

080510 ACB....................120V Wall Mount AC Adapter

080512 ACIB...................230V AC adapter (No Power Cord)

0805US ...........................American Power Cord

0805EUR.........................European Power Cord CEE 7

0805EURP ......................Europlug Power Cord CEE 7/16

0805UK ...........................United Kingdom Power Cord

0805AUS.........................Australia/New Zealand Power Cord

0805DEN.........................Denmark Power Cord

0805FR............................France/Belgium Power Cord

0805IN.............................India Power Cord

0805IS.............................Israel Power Cord

0805JAP..........................Japan Power Cord

0805SW...........................Switzerland Power Cord

15 16

Page 17

APPENDIX D

INTERFACE PIN ASSIGNMENT

DDS/CLEAR CHANNEL INTERFACE

The DDS/Clear Channel Interface is an RJ-48S modular jack.

Pin #

Signal

1TX+

2TX3 no connection

4 no connection

5 no connection

6 no connection

7RX+

8RX-

MODEL 2450/C

M/34 CONNECTOR (V.35), TERMINAL INTERFACE

Pin #

Signal

A Frame Ground

B SGND (Signal Ground)

CRTS

DCTS

EDSR

FCD

L LL (Local Loop)

M TM (Test Mode)

N RL (Remote Loop)

PTD

RRD

STD/

T RD/

UXTC

VRC

WXTC/

X RC/

YTC

AA TC/

Page 18

(APPENDIX D - Continued)

MODEL 2450/A

DB-25 CONNECTOR (RS-232/V.24), TERMINAL INTERFACE

Pin #

Signal

1 Frame Ground

2TD

3RD

4RTS

5CTS

6DSR

7 SGND (Signal Ground)

8CD

15 TC

17 RC

18 LL (Local Loop)

21 RL (Remote Loop)

24 XTC

25 TM (Test Mode)

MODEL 2450/B

DB-25 CONNECTOR (RS-422/530), TERMINAL INTERFACE

Pin #

Signal

1 Frame Ground

2 Transmit Data A

3 Receive Data A

4RTS

5CTS

6DSR

7 SGND (Signal Ground)

8CD

9 Receive Clock B

11 External Clock B

12 Transmit Clock B

14 Transmit Data B

15 Transmit Clock A

16 Recieve Data B

17 Receive Clock A

18 LL (Local Loop)

21 RL (Remote Loop)

24 External Clock A

25 TM (Test Mode)

17 18

Page 19

(APPENDIX D - Continued)

MODEL 2450/E

DB-25 CONNECTOR (V.35), TERMINAL INTERFACE

Pin #

Signal

1 Frame Ground

2 Transmit Data A

3 Receive Data A

4RTS

5CTS

6DSR

7 SGND (Signal Ground)

8CD

9 Receive Clock B

11 External Clock B

12 Transmit Clock B

14 Transmit Data B

15 Transmit Clock A

16 Recieve Data B

17 Receive Clock A

18 LL (Local Loop)

21 RL (Remote Loop)

24 External Clock A

25 TM (Test Mode)

Copyright ©

Patton Electronics Company

All Rights Reserved

Page 20

Dear Valued Customer,

Thank you for purchasing Patton Electronics products! We do

appreciate your business. I trust that you find this user manual helpful.

We manufacture one of the widest selections of data communications

products in the world including CSU/DSU's, network termination units,

powered and self-powered short range modems, fiber optic modems, interface

converters, baluns, electronic data switches, data-line surge protectors,

multiplexers, transceivers, hubs, print servers and much more. We produce

these products at our Gaithersburg, MD, USA, facility, and can custom

manufacture products for your unique needs.

We would like to hear from you. Please contact us in any of the

following ways to tell us how you like this product and how we can meet your

product needs today and in the future.

Web: http://www.patton.com

Sales E-mail: sales@patton.com

Support E-mail: support@patton.com

Phone - Sales (301) 975-1000

Phone - Support (301) 975-1007

Fax: (301) 869-9293

Mail: Patton Electronics Company

7622 Rickenbacker Drive

Gaithersburg, MD 20879 USA

We are committed to a quality product at a quality price. Patton

Electronics is ISO 9001 certified. We meet and exceed the highest

standards in the industry (CE, UL, etc.).

It is our business to serve you. If you are not satisfied with any

aspect of this product or the service provided from Patton Electronics or its

distributors, please let us know.

Thank you.

Burton A.Patton

Vice President

P.S. Please tell us where you purchased this product.

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

19

Loading...

Loading...