Page 1

USER

MANUAL

MODEL 2073RC

64k/G.703 Access

Converter

An ISO-9001Certified

Company

Part# 07M2073RC

Doc# 031151U Rev. A

Revised 1/23/03

SALES OFFICE

(301) 975-1000

TECHNICAL SUPPORT

(301) 975-1007

Page 2

CONTENTS

1.0 Warranty Information ................................................................. 4

1.1 Radio and TV Interference............................................................ 4

1.2 CE Notice...................................................................................... 4

1.3 Service.......................................................................................... 5

2.0 General Information.................................................................... 6

2.1 Features........................................................................................ 6

2.2 Description.................................................................................... 6

3.0 Configuration .............................................................................. 7

3.1 Configuring the Front Interface Card............................................ 8

Switches SW3-2 and SW3-1: Clocking Mode .............................. 8

Switches SW3-5: Front panel switch enabled/disabled................ 9

Switch SW3-6: Response to DTE Request for Local

and Remote Loop......................................................................... 9

Switch SW3-4 Response to Remote digital (RDL) Loopback....... 9

Switch SW3-3 Terminal (DTE) data sampled using

the 2073RC Transmit clock or External Clock (provided by

V.35 DTEs only) ........................................................................... 9

3.2 Configuring the Rear Interface Card........................................... 10

Model 1001RCM13448C Strap Settings .................................... 12

DTE Shield (M/34 Pin A) & FRGND (JB3). .........................13

SGND & FRGND (JB4). ......................................................13

Model 1001RCM11548C Strap Settings .................................... 13

DTE Shield (DB-15 Pin 1) & FRGND (JB3) ......................... 14

SGND & FRGND (JB4) .......................................................15

Model IM2RC/IA (10Base-T Ethernet Rear Card)...................... 15

Status .................................................................................. 15

Link ...................................................................................... 16

Connecting to the network ................................................... 16

4.0 Installation................................................................................. 18

4.1 The Model 1001R14 Rack Chassis............................................ 18

The Rack Power Supply............................................................. 18

Powering up your 1001R14 rack................................................ 19

4.2 Installing the Model 2073RC into the chassis............................. 19

4.3 Connecting to a DTE device....................................................... 19

4.4 Connecting to a DCE device....................................................... 19

4.5 Connecting to a G.703/64 kbps Network.................................... 20

5.0 Operation................................................................................... 21

5.1 LED Descriptions........................................................................ 21

Loop (V.54 & Telco) Diagnostics................................................ 22

Operating Local Loopback (LLB)................................................ 22

Operating Remote Digital Loopback (RDL)................................ 23

Bit Error Rate (V.52) Diagnostics ............................................... 23

A Model 2073RC Specifications.................................................. 24

A.1 Transmission Format ................................................................... 24

2

Page 3

A.2 Transmission Line ....................................................................... 24

A.3 Clocking ...................................................................................... 24

A.4 Interface Modules ....................................................................... 24

A.5 Line Rates ................................................................................... 24

A.6 DTE Rates ................................................................................... 24

A.7 Diagnostics ................................................................................. 24

A.8 LED Status Indicators ................................................................. 24

A.9 Connectors ................................................................................. 24

A.10 Temperature Range .................................................................... 24

A.11 Altitude ........................................................................................ 24

A.12 Humidity ...................................................................................... 24

A.13 Dimensions ................................................................................. 24

A.14 Weight ......................................................................................... 24

B Interface Pin Assignment......................................................... 25

3

Page 4

1.0 WARRANTY INFORMATION

Patton Electronics

warrants all Model 2073RC components to be free

from defects, and will—at our option—repair or replace the product

should it fail within one year from the first date of the shipment.

This warranty is limited to defects in workmanship or materials, and does

not cover customer damage, abuse or unauthorized modification. If this

product fails or does not performs as warranted, y our sole recourse shall

be repair or replacement as described above. Under no condition shall

Patton Electronics

be liable for any damages incurred b y the use of this

product. These damages include, but are not limited to , the f ollo wing: lost

profits, lost savings and incidental or consequential damages arising

from the use of or inability to use this product.

Patton Electronics

specifically disclaims all other warranties, expressed or implied, and the

installation or use of this product shall be deemed an acceptance of

these terms by the user.

Note

Conformity documents of all Patton products can be viewed

online at www.patton.com under the appropriate product page.

1.1 RADIO AND TV INTERFERENCE

The Model 2073RC generates and uses radio frequency energy, and if

not installed and used properly-that is, in strict accordance with the manufacturer’s instructions-may cause interference to radio and television

reception. The Model 2073RC has been tested and found to comply with

the limits for a Class A computing device in accordance with specifications in Subpart B of Part 15 of FCC rules, which are designed to provide

reasonable protection from such interference in a commercial installation. However, there is no guarantee that interference will not occur in a

particular installation. If the Model 2073RC does cause interference to

radio or television reception, which can be determined by disconnecting

the unit, the user is encouraged to try to correct the interference by one

or more of the following measures: moving the computing equipment

away from the receiver, re-orienting the receiving antenna and/or plugging the receiving equipment into a different AC outlet (such that the

computing equipment and receiver are on different branches).

1.2 CE NOTICE

The CE symbol on your Patton Electronics equipment indicates that it is

in compliance with the Electromagnetic Compatibility (EMC) directive

and the Low Voltage Directive (LVD) of the European Union (EU). A Certificate of Compliance is available by contacting Technical Support.

4

Page 5

1.3 SERVICE

All warranty and non-warranty repairs must be returned freight prepaid

and insured to Patton Electronics. All returns must have a Return Materials Authorization number on the outside of the shipping container. This

number may be obtained from Patton Electronics Technical Services at:

• Tel: +1

• Email:

• URL:

(301) 975-1007

support@patton.com

http://www.patton.com

Note

Packages received without an RMA number will not be

accepted.

Patton Electronics' technical staff is also available to answer any questions that might arise concerning the installation or use of your Model

2073RC. Technical Service hours:

UTC-5), Monday through Friday

8 AM to 5 PM EST (8:00 to 17:00

.

5

Page 6

2.0 GENERAL INFORMATION

Thank you for purchasing this P atton Electronics product. This product has

been thoroughly inspected and tested and is warranted for one y ear for

parts and labor. If questions arise during installation or use of this product,

contact Patton Electronics Technical Support at

2.1 FEATURES

•

Bi-directionally converts X.21,V.35 or 10 Base-T to co-directional G.703

•

LED indicators monitor Data, Network, and Diagnostic signals

•

Internal, external (V.35 only), or network clocking options

•

Test Mode controlled by switch, or by local DTE (V.35 version only)

•

Complies with CCITT/ITU G.823 Jitter Control Specifications

•

Built-in surge protection and transformer isolation

•

Point-to-point distance up to 5250 ft (1600m) on 24 AWG twisted pair

•

120-ohm (twisted pair) network termination

2.2 DESCRIPTION

The Patton Model 2073RC interface converter allow a synchronous V.35,

X.21 or ethernet device to communicate bi-directionally over the G.703 codirectional PCM network. Supporting internal, external DTE timing or

G.703 network generated timing, the Model 2073RC is perfect for netw orking applications that require speeds of 64 kbps. The modular rear cards

style of interchangeable interface modules f or the 2073RC allow various

physical and electrical interfaces to connect to the 64K synchronous

G.703 network.

+1 (301) 975-1007

.

A 120-ohm twisted pair telephone port provides the interface for the G.703

network. Additionally, 75-ohm terminations can be made using the Patton

Model 460 (G.703 balun).

Diagnostics include Local Loopback, V.54 RDL testing, and 511/51E builtin BER patterns. Synchronous clock jitter is atten uated in accordance with

the G.823.

6

Page 7

3.0 CONFIGURATION

The 2073RC features configuration capability via hardware DIP s witches .

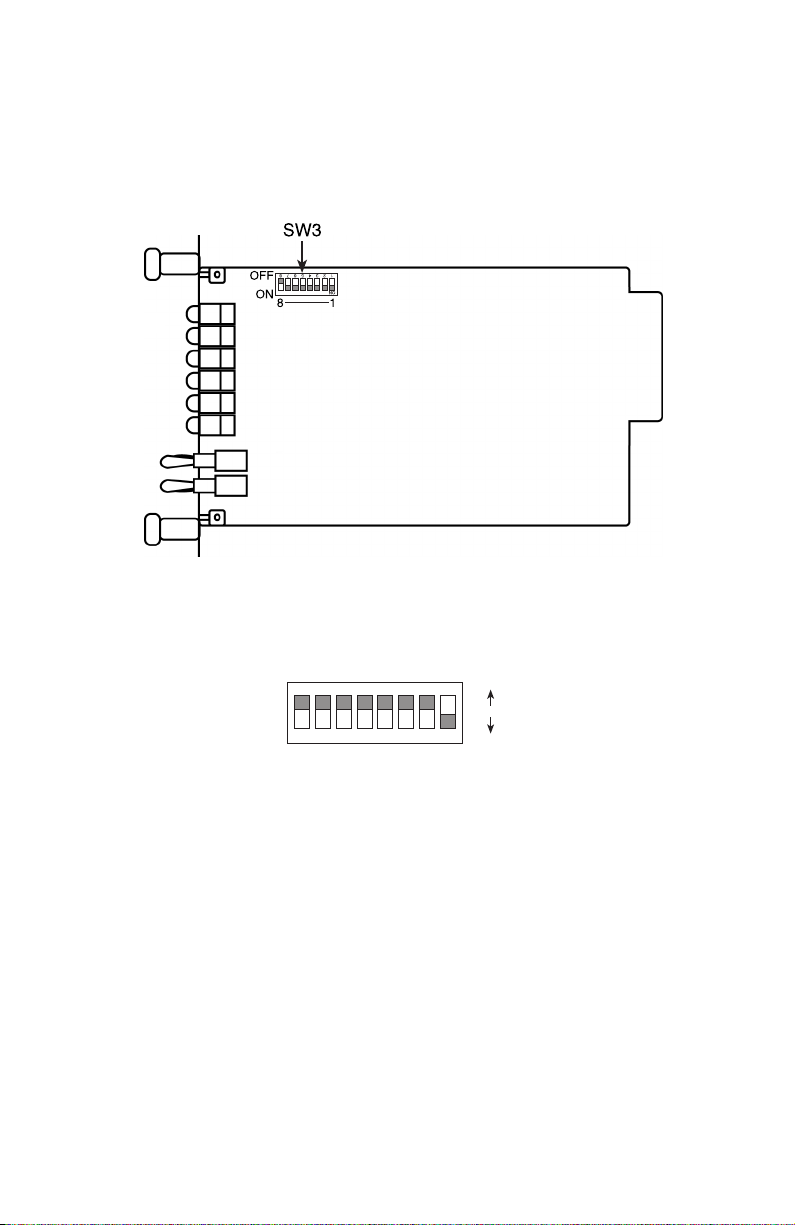

This section describes all possible hardware switch configuration. Figure 1

shows the location of the DIP switches on the top of the printed circuit board

Figure 1.

Model 2073RC top view showing location of DIP switches

Figure 2 shows the orientation of the DIP switches with respect to ON/

OFF positions.

ON

OFF

Figure 2.

ON

12345678

Close-up of DIP switches showing ON/OFF positions

7

Page 8

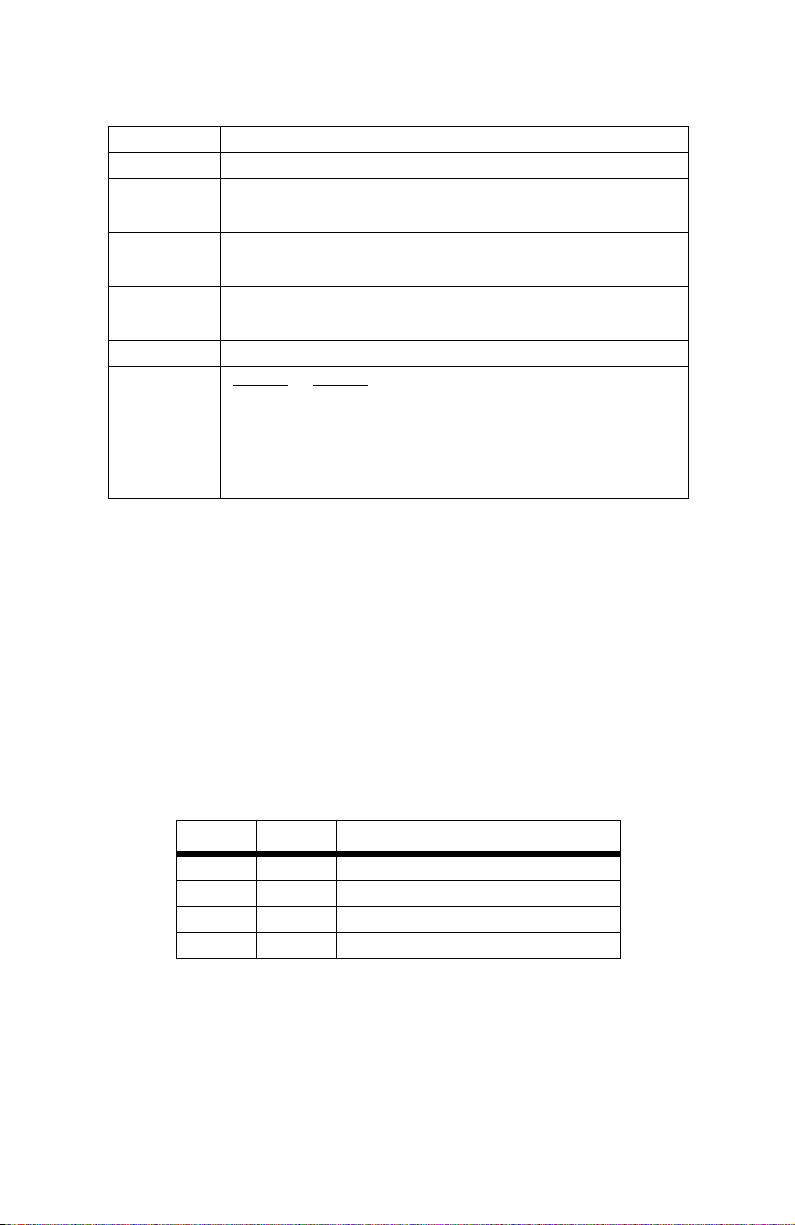

DIP SW3-8

DIP SW3-7

DIP SW3-6

DIP SW3-5

DIP SW3-4

DIP SW3-3

DIP SW3-2

DIP SW3-1

Note

Not Used

Not Used

ON = DTE TM Lines Disabled

OFF = DTE TM Lines Enabled

ON = FP TM Switches Disabled

OFF = FP TM Switches Enabled

ON = V54 RX Disabled

OFF = V54 RX Lines Enabled

Not Used

SW3-2

OFF

OFF

ON

ON

0 = ON, 1 = OFF

SW3-1

OFF

ON

OFF

ON

= Internal (Generated by 2073RC)

= External (From DTE)

= Network (Normal)

= Network (Campus)

Note Boldface

type

indicates a factory-default setting.

3.1 CONFIGURING THE FRONT INTERFACE CARD

Switches SW3-2 and SW3-1: Clocking Mode

Use Switch SW3 to set the system clock for the Model 2073RC. When

using two Model 2073RC together in a point-to-point application as short

range modems, set one unit for either Internal or External transmit clock

and the other unit to Network clock. When connecting directly to the

G.703 network, set the unit to Network clock.

SW3-2 SW3-1 Clocking Description

OFF OFF

OFF ON

ON OFF

ON ON

Internal (Generated by 2073RC)

External (From DTE)

Network (Normal)

Network (Campus)

8

Page 9

Switches SW3-5: Front panel switch enabled/disabled

Use Switch SW3-5 to enable or disable the Model 2073RC Test Mode

(Local Loop, Remote Digital Loop, and 511/511E patterns).

ON Front Panel Test Mode Switches Disabled

OFF Front panel Test Mode Switches Enabled

Switch SW3-6: Response to DTE Request for Local and Remote Loop

Use Switch SW3-6 to enable the Model 2073RC to enter Local Loopback

mode when pin interface (V.35 only) is raised. In the On position, the

Local Loopback may only be enabled manually by Switch SW3-6.

SW3-6 Activation Description

On Disabled Model 2073RC ignores DTE requests to enter

Local Loopback

Off Enabled Model 2073RC enters Local Loopback when the

appropriate interface pin is raised (see appendix for interf ace

pinout)

Switch SW3-4 Response to Remote digital (RDL) Loopback

Use Switch SW3-4 to enable or disable response to Remote digital Loopback by the local 2073RC when a RDL request is sent by a remote

device.

SW3-4 Description

ON RDL Response Disabled

OFF RDL Response Enabled

Switch SW3-3 Terminal (DTE) data sampled using the 2073RC

Transmit clock or External Clock (provided by V.35 DTEs only)

Use Switch SW3-3 to sample data from DTE using the 2073RC Transmit

clock (TC) or External Clock (XC))—normally Transmit clock (from

2073RC) is used.

ON TD Sampled with XC Source,

OFF TD Sampled with TC Source

9

Page 10

3.2 CONFIGURING THE REAR INTERFACE CARD

Your Model 2073RC comes with one of the following rear cards:

• The Model 1001RCM13448C (M/34/ RJ-48C)

• The Model 1001RCM11548C (DB-15/RJ-48C)

• The Model IM2RC/IA (RJ-45/10Base-T RJ-48C)

Each of these options supports one DTE interface connection and one 4-

wire line connection. Figure 3 illustrates the interface options for the

Model 2073RC Series.

Note

The 2073RC Series function card is paired with a specially

designed rear card and must not be swapped with other Patton

rear cards.

Model

1001RCM11548C

RJ-48C

DB-15 F

Figure 3.

Model 2073RC Series interface card options

Model

1001RCM13448C

RJ-48C

M/34 F

Model

IM2RC/IA

RJ-48C

Prior to installation, you will need to examine the rear card and make

sure it is properly configured for your application.

Each rear card is configured by setting straps located on the PC board.

To configure the rear cards, you must set the configuration straps.

Figure 4 shows the orientation of these straps. Each strap can either be

on pegs 1 and 2,or on pegs 2 and 3.

10

Page 11

Figure 4.

Orientation of Interface Card Straps

The following sections describe the strap locations and possible settings

for each rear card.

11

Page 12

Model 1001RCM13448C Strap Settings

Figure 5 shows the strap location for the Model 1001RCM13448C (M/34)

rear card. This strap determines whether Signal Ground and Frame

Ground will be connected.

Figure 5.

1

JB4

123

1001RCM13448C strap locations.

JB3

3

Table 1 provides an overview of interface strap functions for the rear

interface cards. Following the table overview are detailed descriptions of

each strap’s function.

Table 1:

Interface Card Strap Summary

Strap Function Position 1&2 Position 2&3

JB3 DTE Shield (Pin A) & FRGND Connected* Open

JB4 FRGND & SGND (Pin B) Connected* Open

* Indicates default setting

12

Page 13

DTE Shield (M/34 Pin A) & FRGND (JB3).

In the connected position,

this strap links M/34 pin A & frame ground. In the open position, pin A is

disconnected from frame ground (see Table 2).

Table 2:

JB3 strap settings

Position Description

1 & 2 DTE Shield (Pin A) and FRGND Connection

2 & 3 DTE Shield (Pin A) and FRGND Not Connected

SGND & FRGND (JB4).

In the connected position, this strap links Signal

Ground and frame ground through a 100 ohm resistor. In the open position, signal ground is disconnected from frame ground (see Table 3).

Table 3:

JB4 strap settings

Position Description

1 & 2 SGND and FRGND Connected

2 & 3 SGND and FRGND Not Connected

Model 1001RCM11548C Strap Settings

Figure 6 on page 14 shows strap locations for the Model

1001RCM11548C (DB-15) rear cards. These straps determine various

grounding characteristics for the terminal interface and twisted pair lines.

JB3 and JB4 are user configurable.

13

Page 14

JB4

1

123

JB3

3

Figure 6.

1001RCM11548C strap locations.

Table 4 provides an overview of interface strap functions for the rear

interface cards. Following the table overview are detailed descriptions of

each strap’s function.

Table 4:

Interface Card Strap Summary

Strap Function Position 1&2 Position 2&3

JB3 DTE Shield (Pin1) & FRGND Connected* Open

JB4 FRGND & SGND (Pin 8) Connected* Open

* Indicates default setting

DTE Shield (DB-15 Pin 1) & FRGND (JB3).

In the connected position,

this strap links DB-15 pin 1 & frame ground. In the open position, pin 1 is

disconnected from frame ground (see Table 5).

Table 5:

JB3 strap settings

Position Description

1 & 2 DTE Shield (Pin 1) and FRGND Connected

2 & 3 DTE Shield (Pin 1) and FRGND Not Connected

14

Page 15

SGND & FRGND (JB4).

In the connected position, this strap links DB-15

pin 8 (Signal Ground) and frame ground through a 100 ohm resistor. In

the open position, pin 8 is connected directly to frame ground

(see Table 6).

Table 6:

JB4 strap settings

Position Description

1 & 2 SGND (Pin 8) and FRGND Connected through a 100 ohm resistor

2 & 3 SGND (Pin 8) and FRGND Directly Connected

Model IM2RC/IA (10Base-T Ethernet Rear Card)

There are no jumpers to set in the Model IM2RC/IA, for more information, refer to the Model IM2RC/IA user manual

The Model IM2RC/IA provides line side connections through an RJ-45

connector. Figure 7 shows rear panel options and connectors locations.

Descriptions of the 10Base-T connector LEDs follow Figure 7.

Status.

Figure 7.

Blinks yellow from one to elev en times to indicate system status.

IM2RC/A, rear panel options

Each pulse pattern is separated by a 2 second “off” period. Greater

pulse patterns have higher priority (buffer saturation has greater priority

than an empty MAC table). Valid system statuses are:

• 1 pulse = system status ok

• 2 pulses = No MAC entries in the MAC address table

• 3 pulses = Clear to send (CTS) or Carrier Detect (DCD) from base unit

are not asserted

15

Page 16

• 4 pulses = IMRC2/IAbuffer is saturated

• 5 pulses = WAN receive frame(s) too large

• 6 pulses = WAN receive frame(s) not Octet aligned

• 7 pulses = WAN receive frame(s) aborted

• 8 pulses = Detected WAN receive frame(s) with bad CRC

• 9 pulses = Detected LAN receive frame(s) too large

• 10 pulses = Detected LAN receive frame(s) not Octet aligned

• 11 pulses = Detected LAN receive frame(s) with bad CRC

After a status code is displayed eight times and the associated condition

is removed, the status code will no longer appear.

Link.

Glows green to indicate good link integrity on the 10Base-T twisted

pair line.

The RJ-45 Ethernet port on Ethernet Bridge Module is designed to con-

nect directly to a 10Base-T network. Figure 8 shows the 10Base-T RJ-45

port pin description. You may make connections up to 330 feet using

Type 4 or 5 cable.

1 (no connection)

1

2

3

4

5

6

7

8

2 (no connection)

3 (4-Wire ARX-)

4 (2-Wire TIP)/(4-Wire TX+)

5 (2-Wire RING)/(4-Wire TX-)

6 (4-Wire ARX+)

7 (no connection)

8 (no connection)

Figure 8.

Connecting to the network.

Model IMRC2/IA Ethernet Connector Pinout

The Line Interface is an 8-position keyed

modular jack configured as an RJ-48C (see. Figure 9). This interface will

connect to a 64 kbps/G.703, co-directional network running AMI line coding.

1 RX data (TIP)

1

2

3

4

5

6

7

8

2 RX data (RING)

3 (no connection)

4 TX data (TIP)

5 TX data (RING)

6 (no connection)

7 (no connection)

From network

To network

8 (no connection)

Figure 9.

64 kbps Network Interface

16

Page 17

Note

If the 2073RC is being used for private short-range modem

applications, the twisted-pair cable connected to its port will

need to be a cross-over cable.

17

Page 18

4.0 INSTALLATION

This section describes the functions of the Model 1001R14 rack chassis,

tells how to install front and rear Model 2073RC Series cards into the

chassis, and how to connect to the twisted pair interface and the serial

interface.

4.1 THE MODEL 1001R14 RACK CHASSIS

The Model 1001R14 Rack Chassis (see Figure 10) has 14 or 16 device

card slots, plus a single power supply or dual redundant power supplies.

Measuring only 3.5” high, the Model 1001R14 is designed to occupy only

2U in a 19” rack. Sturdy front handles allow the Model 1001R14 to be

extracted and transported conveniently.

Figure 10.

Model 1001R14 Rack Chassis with power supply

The Rack Power Supply

The power supply included in the Model 1001R14 rack uses the same

mid-plane architecture as the modem cards. The front card of the power

supply slides in from the front, and the rear card slides in from the rear.

They plug into one another in the middle of the rack. The front card is

then secured by thumb screws and the rear card by conventional metal

screws.

There are no user-serviceable parts in the power

supply section of the Model 1001R14 rack. Voltage setting changes and fuse replacement

should only be performed by qualified service

personnel. Contact Patton Electronics Technical

support at +1 (301) 975-1007, via our web site at

WARNING

www.patton.com, or by E-mail at

support@patton.com, for more information.

18

Page 19

Powering up your 1001R14 rack

The power supplies that come with your 1001R14 rack system are

equipped with a power entry connector on the rear power supply card.

The power supplies are hot-swappable, so you are not required to

remove the cards from the rack while applying power to the system.

Note Please refer to the Model 1001R14 Series User Manual AC and

DC Rack Mount Power Supplies for fuse and power card

replacement information.

4.2 INSTALLING THE MODEL 2073RC INTO THE CHASSIS

The Model 2073RC is comprised of a front card and a rear card. The tw o

cards meet inside the rack chassis and plug into each other by way of

mating 50 pin card edge connectors. Use the following steps as a guideline for installing each Model 2073RC into the rack chassis:

1. Slide the rear card into the back of the chassis along the metal rails

provided.

2. Secure the rear card using the metal screws provided.

3. Slide the card into the front of the chassis. It should meet the rear

card when it’s almost all the way into the chassis.

4. Push the front card gently into the card-edge receptacle of the rear

card. It should “click” into place.

5. Secure the front card using the thumb screws.

Note Since the Model 1001R14 chassis allows “hot swapping” of

cards,

it is not necessary to power down the rack

install or remove a Model 2073RC.

when you

4.3 CONNECTING TO A DTE DEVICE

The serial port on most rear interface cards are hard-wired as “DCE”

(Data Communications Equipment). The interfaces are designed to plug

into a DTE such as a terminal, PC or host computer. When making the

connection to your DTE device, use a “straight through” cable. When purchasing or constructing an interface cable, refer to the pin diagrams in

Appendix B on page 25 as guides.

4.4 CONNECTING TO A DCE DEVICE

The rear interface cards on most interface modules are hard wired as

“DCE”. Therefore, you must use a tail circuit cable when connecting to a

modem or other DCE device. When purchasing or constructing a tail circuit

interface cable, use the pin diag rams in Appendix B on page 25 as a guide .

19

Page 20

Note Pin-out requirements for tail circuit applications vary between

equipment manufacturers. If you have any questions about a

specific installation, please contact Patton Electronics Technical

Support.

4.5 CONNECTING TO A G.703/64 KBPS NETWORK

The Network Line Interface is an 8-position keyed modular jack configured as an RJ-48C (see Figure 11).

1 RX data (TIP)

1

2

3

4

5

6

7

8

2 RX data (RING)

3 (no connection)

4 TX data (TIP)

5 TX data (RING)

6 (no connection)

7 (no connection)

From network

To network

8 (no connection)

Figure 11. NetLink-E1 twisted-pair interface

Note If the 2073RC is being used for private short-range modem

applications, the twisted-pair cable connected to its port will

need to be a cross-over cable.

20

Page 21

5.0 OPERATION

Once the 2073RC is installed and configured properly it is ready to place

into operation.This section describes the function of the LED indicators,

and the use of the loopback and pattern test modes.

5.1 LED DESCRIPTIONS

The 2073RC is equipped with 12 LED indicators that monitor the status

of communication.

TD When the unit sends a one, the TXD LED is green.When it

sends a zero, the TXD LED is yellow.

RD When the unit receives a one, the RXD LED is green.When it

receives a zero, the RXD LED is yellow.

CTS Glows green to indicate that the clear-to-send signal from the

2073RC is active. Yellow indicates inactive CTS.

CD Glows green to indicate that the a carrier from the remote

modem is being received.

DTR Glows green to indicate that the DTE attached to the 2073RC

is active.

Link The Link LED lights when the unit is synchronized with the

incoming 64k/G.703 network signal.

TM The Test Mode indicator will turn on when the unit enters local

or remote loopbacks. It will also turn on when test patterns 511

or 511ER are activated.

ERR The error LED indicates various error conditions, when send-

ing a test pattern, the LED will remain lit if the unit does not

receive the identical pattern. When it receives the correct pattern, the LED will turn off.If error insertion is on, the LED will

blink once a second if everything is operating properly.

21

Page 22

Loop (V.54 & Telco) Diagnostics

The 2073RC offers two loop diagnostics for diagnosing the 2073RC and

any communication links. These tests can be activated via signals on the

serial port interface or the front panel switch.

Operating Local Loopback (LLB)

The Local Loopback (LLB) test checks the operation of the local 2073RC

and is performed separately on each unit. Any data sent to the local

2073RC in this test mode will be echoed (returned) back to the user

device (i.e.,characters typed on the k eyboard of a terminal will appear on

the terminal screen).

Figure 12. Local loopback

To perform a LL test, follow these steps:

1. The Local Loop can be initiated from the 2073RC unit either by acti-

vating the LL signal on the DTE (if you are not sure which lead is the

RDL signal, please refer to the Appendix,) or by toggling the top

front panel switch towards the label “LLB”. The Yellow TM (Test

mode) LED will turn on to indicate a successful Local loop condition.

2. Verify that the data terminal equipment is operating properly and

can be used for a test.

3. Perform a V.52 BER (bit error rate) test bit error rate (V.52) diagnos-

tics.If the BER test equipment indicates no faults, b ut the data terminal indicates a fault, follow the manufacturer’s checkout procedures

for the data terminal. Also, check the interface cable between the

terminal and the 2073RC.

22

Page 23

Operating Remote Digital Loopback (RDL)

The Remote Digital Loopback (RDL) test checks the performance of both

the local and remote 2073RC as well as a point-to-pointcommunication

link between them. Any characters sent to the remote 2073RC in this test

mode will be returned back to the originating device (i.e,characters typed

on the keyboard of the local terminal will appear on the local terminal

screen after having been passed to the remote 2073RC and looped back).

Figure 13. Remote loopback

1. The Remote Loop (V.54) can be initiated from the 2073RC unit:

either by activating the RDL signal on the DTE (if you are not sure

which lead is the RDL signal, refer to Appendix B “Interface Pin

Assignment” on page 25) or by toggling the top front panel switch

towards the label “RDL”. The Yellow TM (Test mode) LED will turn on

to indicate a successful RDL.

2. Perf orm a bit error rate test (BERT) using the internal V.52 generator

(as described in section “Bit Error Rate (V.52) Diagnostics”, turn the

Bit error rate (V.52) diagnostics on or using a separate BER Tester.If

the BER test indicates a fault, and the Remote Line Loopback test

was successful for both 2073RC you may have a problem with the

twisted pair line connection.

Bit Error Rate (V.52) Diagnostics

The 2073RC offers V.52 Bit Error Rate (BER) test patterns that can be

invoked along with the LLB and RDL tests to evaluate the unit(s) and the

communication links. When a 511 test is invoked, the 2073RC generates

a pseudo-random bit pattern of 511 bits, using a mathematical polynomial.The receiving 2073RC then decodes the received bits using the

same polynomial.If the received bits match the agreed upon pseudo-random pattern, the 2073RC and the communications link are functioning

properly . 511 or 511/E is initiated by setting the bottom front panel switch

towards the label ‘511’ or 511E” respectively. The Yellow TM (Test mode)

LED will turn on to indicate activation of the 511 or 511E test modes.

23

Page 24

APPENDIX A

MODEL 2073RC SPECIFICATIONS

A.1 TRANSMISSION FORMAT

Synchronous 64k/G.703 co-directional

A.2 TRANSMISSION LINE

Four-Wire unconditioned twisted pair

A.3 CLOCKING

Internal, External (V.35 only), or Network

A.4 INTERFACE MODULES

ITU/T V.35, ITU/T X.21, 10Base-T

A.5 LINE RATES

256 kbps

A.6 DTE RATES

64 kbps

A.7 DIAGNOSTICS

V.54 test modes for LAL and RDL; V:52 511/511E BERT pattern generator and detector.

A.8 LED STATUS INDICATORS

TD, RD, CTS, CD, DTR, Link, Error Test Mode

A.9 CONNECTORS

RJ-45 on line side; DB-25 female, M/34 female,RJ-45 female or DB-15

female depending upon which serial interface module is installed.

A.10 TEMPERATURE RANGE

32–122°F (0–50°C)

A.11 ALTITUDE

0–15,000 feet (0–4572 m)

A.12 HUMIDITY

up to 90% non-condensing

A.13 DIMENSIONS

3.5L x 2.1W x 0.78H in. (9.0L x 5.3W x 2.0H mm)

A.14 WEIGHT

1 lb. (0.45 kg)

24

Page 25

APPENDIX B

INTERFACE PIN ASSIGNMENT

V.35 Interface

(M/34F Female Connector)

(DCE Configuration)

Pin # Signal

B SGND (Signal Ground)

C RTS (Request to Send)

D CTS (Clear to Send)

E DSR (Data Set Ready)

F CD (Carrier Detect)

H DTR (Data Terminal Ready)

L LLB (Local Line Loop)

M TM (Test Mode)

N RDL (Remote Digital Loop)

P TD(Transmit Data)

R RD (Receive Data)

S TD/ (Transmit Data-B)

T RD/ (Receive Data-B)

U XTC (External Transmit Clock)

V RC(Receive Timing)

W XTC/ (External Transmit Clock)

X RC/ (Receive Timing)

Y TC(Transmit Clock-A)

AA TC/ (Transmit Clock-B)

25

Page 26

X.21 Interface

(DB-15 Female Connector)

(DTE /DCE Configuration)

Pin # Signal

1 Frame Ground

2 T (Transmit Data-A)

3 C (Control-A)

4 R (Receive Data-A)

5 I (Indication-A)

6 S (Signal Element Timing-A)

7 BT (Byte Timing-A)

8 SGND (Signal Ground)

9 T/ (Transmit Data-B)

10 C/ (Control-B)

11 R/ (Receive Data-B)

12 I/ (Indication-B)

13 S/ (Signal Element Timing-B)

14 BT/ (Byte Timing-B)

26

Page 27

Notes

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

27

Page 28

Notes

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

Copyright © 2003

Patton Electronics Company

All Rights Reserved.

28

Loading...

Loading...