Page 1

USER

MANUAL

MODEL 1194

Single Mode Fiber

Modem With Four

Fixed E1/T1

Interfaces

CERTIFIED

An ISO-9001

Certified

Company

Part# 07M1194-A

Doc# 017151UA

Released 06/04/01

SALES OFFICE

(301) 975-1000

TECHNICAL SUPPORT

(301) 975-1007

Page 2

TABLE OF CONTENTS

1.0 Warranty Information .................................................................. 4

1.1 Industry Canada Notice................................................................ 4

1.2 FCC Information ........................................................................... 5

1.3 DC Power Notice.......................................................................... 5

1.4 Patton Contact Information........................................................... 6

1.5 FCC Part 68 Compliance Statement (1194/T1)............................ 6

1.6 CE Notice...................................................................................... 7

1.7 Service.......................................................................................... 7

2.0 General Information..................................................................... 8

2.1 Features........................................................................................ 8

2.2 Description.................................................................................... 8

3.0 Configuration............................................................................. 10

3.1 Configuring the Hardware DIP Switches .................................... 10

Configuring DIP switch S1.......................................................... 11

Switch S1-1: Line Coding Options ....................................... 11

Switches S1-2 and S1-3: Line Build Out ............................. 12

Switches S1-6 and S1-7: Clock Mode ................................. 12

Configure DIP switch S2............................................................. 13

Switch S2-1: Local/Remote Loop ........................................ 13

Switch S2-7: Response to RDL ........................................... 13

Switch S2-8: Front Panel Switches ..................................... 13

4.0 Installation.................................................................................. 14

4.1 Connect the G.703/G.704 or T1 Network................................... 14

4.2 Connect the Fiber Interface........................................................ 14

4.3 Power Connection ...................................................................... 15

Connecting to an AC Power Source........................................... 15

Connecting to a DC Power Source............................................. 16

5.0 Power-up .................................................................................... 17

6.0 LED Status Monitors ................................................................. 18

7.0 Test Modes................................................................................. 19

7.1 Local Loopback Test................................................................... 19

7.2 Remote Loopback Test............................................................... 20

7.3 The V.52 Test Pattern Generator ............................................... 21

A Model 1194 Quad E1/T1 to Single Mode

Fiber Specifications................................................................... 22

A.1 Configuration ...............................................................................22

A.2 Clocking Modes ...........................................................................22

A.3 Network ports specifications .......................................................22

Network Line Rate...................................................................... 22

Transmit Line Buildout (T1)........................................................ 22

Interface...................................................................................... 22

Line coding................................................................................. 22

Isolation...................................................................................... 22

2

Page 3

Physical Connection................................................................... 22

A.4 Fiber Port Specifications ..............................................................23

Fiber Line Coding....................................................................... 23

Fiber Physical............................................................................. 23

A.5 Diagnostics ..................................................................................23

A.6 Compliance .................................................................................23

A.7 Laser Safety .................................................................................23

A.8 Network Line Interface .................................................................23

A.9 Power ...........................................................................................23

A.10 Temperature Range .....................................................................23

A.11 Altitude .........................................................................................23

A.12 Humidity .......................................................................................24

A.13 Dimensions ..................................................................................24

A.14 Weight ..........................................................................................24

A.15 Mean Time Between Failure (MTBF) ...........................................24

3

Page 4

1.0 WARRANTY INFORMATION

Patton Electronics

defects, and will—at our option—repair or replace the product should it

fail within one year from the first date of shipment.

This warranty is limited to defects in workmanship or materials, and does

not cover customer damage, abuse or unauthorized modification. If this

product fails or does not perform as warranted, your sole recourse shall

be repair or replacement as described above. Under no condition shall

Patton Electronics

product. These damages include, but are not limited to, the f ollo wing: lost

profits, lost savings and incidental or consequential damages arising

from the use of or inability to use this product.

cifically disclaims all other warranties, expressed or implied, and the

installation or use of this product shall be deemed an acceptance of

these terms by the user.

1.1 INDUSTRY CANADA NOTICE

The Canadian Department of Communications label identifies certified

equipment. This certification means that the equipment meets certain

telecommunications network protective, operational and safety requirements. The Department does not guarantee the equipment will operate

to the user's satisfaction. Before installing this equipment, users should

ensure that it is permissible to be connected to the facilities of the local

telecommunications company. The equipment must also be installed

using an acceptable method of connection. In some cases, the company’s inside wiring associated with a single line individual service may

be extended by means of a certified connector assembly (telephone

extension cord). The customer should be aware that compliance with the

above condition may not prevent degradation of service in some situations. Repairs to some certified equipment should be made by an authorized maintenance facility designated by the supplier. Any repairs or

alterations made by the user to this equipment, or equipment malfunctions, may give the telecommunications company cause to request the

user to disconnect the equipment. Users should ensure f or their o wn protection that the ground connections of the power utility, telephone lines

warrants all Model 1194 components to be free from

be liable for any damages incurred b y the use of this

Patton Electronics

spe-

4

Page 5

and internal metallic water pipe system, are connected together. This

protection may be particularly important in rural areas.

Users should not attempt to make such connections

themselves, but should contact the appropriate electric

inspection authority, or electrician, as appropriate.

Caution

1.2 FCC INFORMATION

This equipment has been tested and found to comply with the limits for a

Class A digital device, pursuant to P art 15 of the FCC Rules. These limits

are designed to provide reasonable protection against harmful interference when the equipment is operated in a commercial environment. This

equipment generates, uses, and can radiate radio frequency energy and,

if not installed and used in accordance with the instruction manual, may

cause harmful interference to radio communications. Operation of this

equipment in a residential area is likely to cause harmful interference in

which case the user will be required to correct the interference at his own

expense. If this equipment does cause harmful interference to radio or

television reception, which can be determined by turning the equipment

off and on, the user is encouraged to try to correct the interference by

one or more of the following measures:

• Reorient or relocate the receiving antenna

• Increase the separation between the equipment and receiver

• Connect the equipment into an outlet on a circuit different from that to

which the receiver is connected

Use of controls or adjustments or performance of

procedures other than those specified herein may result

in hazardous laser radiation exposure.

Caution

1.3 DC POWER NOTICE

Connect the equipment to a 36–60 volts direct-current (VDC), 340 mA

source that is electrically isolated from the AC source. The 36–60 VDC

source

must

be connected to a reliable earth ground.

5

Page 6

An approved external SELV power supply that incorporates a disconnect

device must be used and positioned within reach of the operator’ s position.

1.4 PATTON CONTACT INFORMATION

If you have an y troub le operating the Model 1194, please contact

Electronics T echnical Support

pany may ask you to disconnect the equipment from the telephone network until the problem has been corrected or until you are certain that

the Model 1194 is not malfunctioning. In accordance with FCC rules and

regulation CFR 47 68.218(b)(6), you must notify the telephone company

prior to disconnection.

The following information may be required when applying to your local

telephone company for leased line f acilities. The Univ ersal Service Order

Code (USOC) is RJ-48C. The Facility Interface Codes (FIC) are 04DU9BN, 04DU9-DN, 04DU9-1KN, and 04DU9-1SN. The Service Order Code

(SOC) is 6.0N.

at

301-975-1000

. The telephone com-

Patton

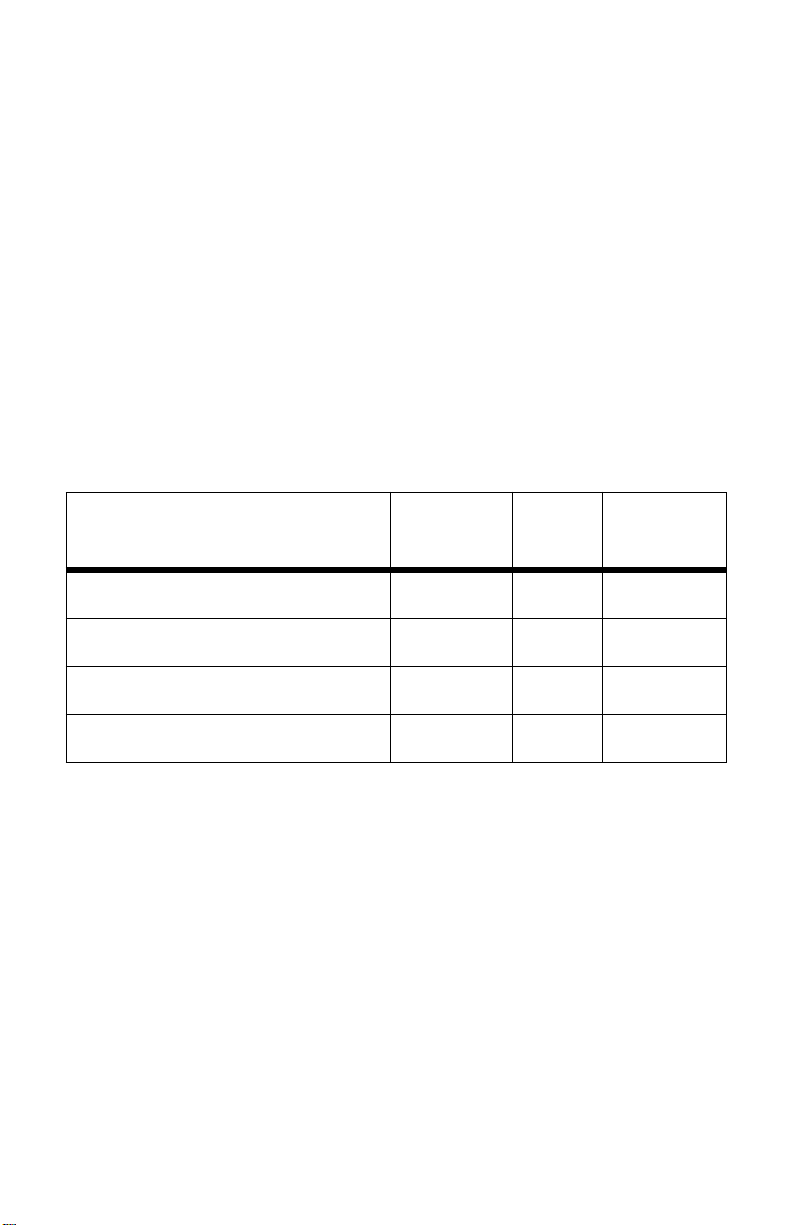

Facility

Service

1.544 Mbps SF format without line

power

1.544 Mbps SF and B8ZS without line

power

1.544 Mbps ANSI ESF without line

power

1.544 Mbps ANSI ESF and B8ZS

without line power

1.5 FCC PART 68 COMPLIANCE STATEMENT (1194/T1)

This equipment complies with Part 68 of FCC Rules. Please note the

following:

1. You are required to request service from the telephone company

before you connect the CSU to a network. When you request service, you must provide the telephone company with the following

data. When you request T1 Service, you must pro vide the telephone

company with the Facility Interface Code. Provide the telephone

company with both of the following codes: 04DU9-B (1.544 MB D4

framing format) and 04DU9-C (1.544 MB ESF format). The telephone company will select the code it has available. The Service

Order Code(s) (SOC): 6.0N. The required Universal Service Order

Code (USOC) jack: RJ 48C. The make, model number, and FCC

Registration number of the CSU.

Interface

Code

04DU9-BN 6.0N RJ48C

04DU9-DN 6.0N RJ48C

04DU9-1KN 6.0N RJ48C

04DU9-1SN 6.0N RJ48C

Service

Code

Network

Connection

6

Page 7

2. Your telephone company may make changes to its facilities, equip-

ment, operations, or procedures that could affect the proper functioning of your equipment. The telephone company will notify you in

advance of such changes to give you and opportunity to maintain

uninterrupted telephone service.

3. If your CSU causes harm to the telephone network, the telephone

company may temporarily discontinue your service. If possible, they

will notify you in advance, but if advance notice is not practical, you

will be notified as soon as possible and will be informed of your right

to file a complaint with the FCC.

4. If you experience trouble with the CSU, please contact Patton Elec-

tronics, Co. for service or repairs. Repairs should be performed only

by Patton Electronics Co.

5. You are required to notify the telephone company when you discon-

nect the CSU from the network.

1.6 CE NOTICE

The CE symbol on your Patton Electronics equipment indicates that it is

in compliance with the Electromagnetic Compatibility (EMC) directive

and the Low Voltage Directive (LVD) of the European Union (EU). A Certificate of Compliance is available by contacting Technical Support.

1.7 SERVICE

All warranty and non-warranty repairs must be returned freight prepaid

and insured to Patton Electronics. All returns must have a Return Materials Authorization number on the outside of the shipping container. This

number may be obtained from Patton Electronics Technical Service at:

tel:

(301)975-1007

E-mail:

support@patton.com

URL:

www.patton.com

Note

Packages received without an RMA number will not be

accepted.

Patton Electronics’ technical staff is also a v ailable to ans wer any questions

that might arise concerning the installation or use of your Model 1194.

Technical Service hours:

8AM to 5PM EST , Monday through Friday

.

7

Page 8

2.0 GENERAL INFORMATION

Thank you for your purchase of this Patton Electronics product. This

product has been thoroughly inspected and tested and is warranted for

One Year parts and labor. If any questions or problems arise during

installation or use of this product, please do not hesitate to contact

Patton Electronics Technical Support at (301) 975-1007

.

2.1 FEATURES

• Four ITU G.703 (E1) or T1 channels over single-mode fiber

• Full duplex operation over a single strand of fiber

• Single-mode fiber with max distance 15.5 miles (25.0 km)

• Two fiber connection options available: FC or SC

• Clocking options: Internal, Network, or Receive Recover (fiber link)

• Local/remote loops: V.52 compliant 511/511E test patterns on each port

• 120-Ohm RJ-48C E1 or 100-Ohm T1 terminations

• AMI, HDB3 (E1), or B8ZS (T1) line coding

• 19 front panel LED status indicators: Fiber line, E1/T1 lines, Test

mode, Error, Loss, No Signal, and Power.

2.2 DESCRIPTION

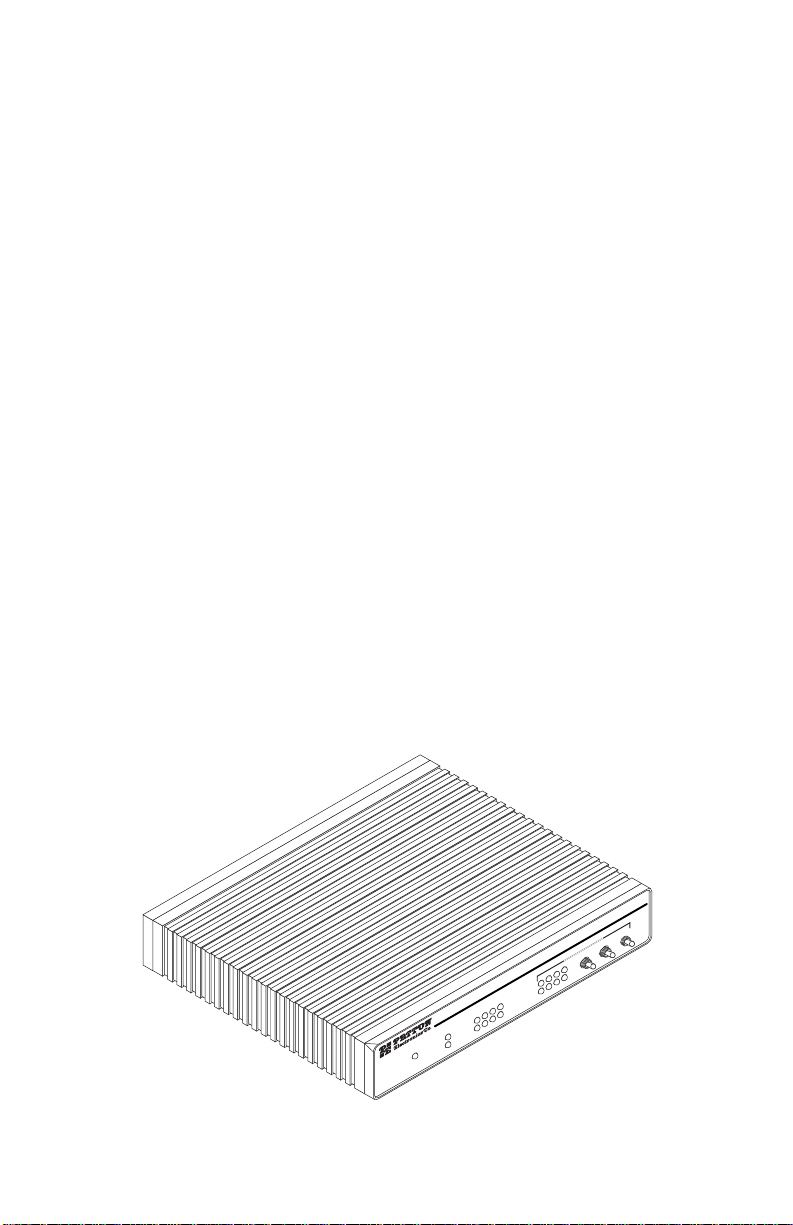

The Model 1194 (see Figure 1) enables service providers to offer cost

effective extension (see Figure 2 on page 9) and distribution of four T1/

E1 network circuits from a Telco’s Central Office to a point of presence

(POP), or in back-haul type operation linking CSU/DSUs, PABXs, routers, or multiplexers located at remote sites.

Figure 1.

b

i

F

k

n

i

L

S

r

N

e

w

o

P

Model 1194

8

m

e

d

o

M

4

0

.7

/G

3

0

.7

G

d

a

u

r - Q

e

1

1

ib

5

F

e

d

o

M

le

3

g

P

in

S

E

4

9

1

l 1

e

d

o

G.703/G.704 Test Modes

M

4

P

3

P

2

P

1

P

4

k

0

n

i

L

7

.

G

/

3

S

0

N

7

.

G

4

P

3

P

2

P

r

e

1

P

E

1

1

5

1

P

4

P

M

T

2

P

R

R

E

Page 9

Fiber Optic

Line

m

e

d

o

M

4

0

7

.

G

/

3

0

7

.

G

d

a

u

Q

r

1

e

1

b

i

5

F

e

d

o

M

e

l

3

g

P

n

i

E

S

1

E

1

4

5

9

1

1

1

l

P

e

d

o

4

G.703/G.704 Test Modes

M

P

M

T

2

P

R

R

E

4

P

3

P

2

P

1

P

k

in

L

.704

S

N

.703/G

G

4

P

3

P

2

P

1

iber

P

F

k

in

L

S

N

er

ow

P

m

e

d

o

M

4

0

7

.

G

/

3

0

7

.

G

d

a

u

Q

-

r

1

e

1

b

i

5

F

e

d

o

M

e

l

3

g

P

n

i

E

S

1

E

1

4

5

9

1

1

1

l

P

e

d

o

4

G.703/G.704 Test Modes

M

P

M

T

2

P

R

R

E

4

P

3

P

2

P

1

P

k

in

L

.704

S

N

.703/G

G

4

P

3

P

2

P

1

P

Fiber

k

in

L

S

r

N

e

ow

P

E1/T1E1/T1

Modem Modem

Figure 2.

Network extension between remote locations

Using a laser transmitter (1300nm) and a single-mode fiber (9/125 micro

meter), the Model 1194 offers a high speed, noise immune, full duple x fiber

link over a single strand of fiber with a reach of up to 15.5 miles (25.0 km).

The Model 1194 is available in two versions: 1194/T1 and 1194/E1, for

connection to T1 and E1 circuits respectively. Features include AMI,

B8ZS/HDB3 line coding; internal, network, and receiver recovered

clocks; all easily configured via DIP switches. Local/Remote loops and

V.52 compliant 511 test patterns are accessible via front panel switches,

allowing quick testing and troubleshooting of the Model 1194 transceivers, and fiber and network links.

The Model 1194 is equipped with 19 front panel LEDs that monitor

power, fiber, network, and diagnostic features status.

The single-mode fiber interface uses either an SC or FC fiber connector ,

while the network interfaces are presented on RJ-48C connectors.

The Model 1194 offers options for universal input (100–240 VAC) and

48 VDC power supplies

9

Page 10

3.0 CONFIGURATION

The Model 1194 has 16 DIP switches that enable configuration of the unit

for a wide variety of applications. This section describes location of the

switches and explains the different configurations.

3.1 CONFIGURING THE HARDWARE DIP SWITCHES

Using a small flat-tip screwdriver , remov e the protectiv e co v er located on

the underside of the Model 1194 (see Figure 3).

Power

Power

NS

NS

Link

Link

P4P3P2P1

P4P3P2P1

G.703/G.704Fiber

G.703/G.704Fiber

NS

NS

Link

Link

P4P3P2P1

P4P3P2P1

ERR

ERR

P

P

2

2

TM

TM

P

P

M

M

G.703/G.704 Test Modes

G.703/G.704 Test Modes

4

4

o

o

d

d

e

e

P

P

l

l

1

1

1

1

1

1

9

9

5

5

4

4

1

1

E

E

1

1

S

S

E

E

i

i

n

n

P

P

g

g

3

3

l

l

e

e

M

M

o

o

d

d

e

e

F

F

5

5

i

i

b

b

1

1

e

e

1

1

r

r

-

-

Q

Q

u

u

a

a

d

d

G

G

.

.

7

7

0

0

3

3

/

/

G

G

.

.

7

7

0

0

4

4

M

M

o

o

d

d

e

e

m

m

Figure 3.

Removing the cover to access DIP switches S1 and S2

Figure 4 shows the orientation of the DIP switches in the “ON” and “OFF”

positions.

S1

Switch toggle

ON

5678

1234

Push toggle up

for ON position

Push toggle

down for

OFF position

1234ON5678

1234ON5678

1234ON5678

S1

S2

1234ON5678

Figure 4.

DIP switches S1 and S2

10

S1

S2

Page 11

Configuring DIP switch S1

Switches S1-1 through S1-8 are used to configure clocking modes and

line coding. Default settings of the switches are shown in Table 1.

Descriptions of the switch options follow the table.

Table 1:

Switch S1 summary

Position

S1-1

S1-2

S1-3

Function Default Setting Selected Option

HDB3(E1)/B8ZS(T1) or

OFF HDB3(E1)/

AMI Line Coding

T1 Line Buildout

T1 Line Buildout

ON

ON

B8ZS(T1)

0 dB

S1-4 Reserved

S1-5 Reserved

S1-6 Clock Mode OFF Network

S1-7 ON

S1-8 Reserved

Switch S1-1: Line Coding Options.

Use switches S1-1 to determine

the line coding of the network interface ports. The setting should be

HDB3

if your unit is an1194/E1,

B8ZS

if your unit is an 1194/T1, or

(common to both T1 and E1 technologies) The line coding must be the

same line coding prescribed by the network access provider (NAP). Most

applications will use HDB3.

S1-1 Setting

ON AMI

OFF HDB3 (E1)/B8ZS(T1)

•

Alternate Mark Inversion (AMI

): AMI defines a pulse as a “mark,” a

binary one, as opposed to a zero. In an E1 Network connection, signals are transmitted as a sequence of ones and zeros. Ones are sent

as pulses, and zeros are sent as spaces, i.e., no pulse. Every other

pulse is inverted from the previous pulse in polarity, so that the signal

can be effectively transmitted. This means, however, that a long

sequence of zeros in the data stream will cause problems, since the

modem receiving the signal relies on the signal to recover the clock. If

you must use AMI, ensure that the data terminal equipment connected

to the unit provides a minimally acceptable pulse density. AMI coding

does not inherently account for ones density. To meet this requirement,

ensure that the data inherently meets pulse density.

AMI

•

High Density Bipolar 3 (HDB3

): In HDB3 coding, the transmitter

deliberately inserts a bipolar violation when excessive zeros in the

data stream are detected. The receiver recognizes these special viola-

11

Page 12

tions and decodes them as zeros. This method enables the network to

meet minimum pulse density requirements.

•

Bipolar 8 Zero Substitution (B8ZS

): This mode assures proper bit

density in the data stream. In this mode any data pattern can be transmitted without causing ones density errors. This mode allows for 64

kbps clear channel timeslots.

Switches S1-2 and S1-3: Line Build Out.

Line buildout (LBO) is a T1

equipment feature, it controls the transmitter signal strength and pulse

shape sent over the T1 line . For most applications, the def ault settings (0

dB) will suffice. When connecting to a carrier’s T1 circuit, the carrier will

determine what LBO is necessary. 0 dB provides the highest signal

strength, and therefore the longest distance, while -15.0 dB provides the

lowest usable signal le vel. -22.5 dB is used to test the line and should not

be used in normal applications.

Transmitted E1 signals are not specified in terms of LBO. Patton’s Model

1194/E1 complies with ITU-T G.703 recommendation for signal pulse

shape and amplitude, and has a reach of 1.6 km. No user configuration

is required

S1-2 S1-3 Function

ON ON 0dB

OFF ON -7.5dB

ON OFF -15.0dB

OFF OFF -22.5dB

Switches S1-6 and S1-7: Clock Mode.

Use switches S1-6 and S1-7 to

determine clock mode of the 1194.

S1-6 S1-7 Setting Description

ON ON Internal Transmit clock generated internally

ON OFF Receive

Recover

Transmit clock derived from the fiber

line link

OFF ON Network Transmit clock derived from E1 or T1

equipment interface

OFF OFF Internal use only

Note

The Model 1194 units are intended to work in pairs. Set the

clock modes for the Model 1194 units with one end of the link set

for receive recover and the other end set for either internal or

network.

12

Page 13

Configure DIP switch S2

Switches S2-1 through S2-8 are for configuring Local/Remote Loop, RDL

response, and front panel switch operation (see Tab le 2). Descriptions of

the switch options follow the table.

Table 2:

Switch S2 summary

Position

S2-1

Function Default Setting Selected Option

Local/Remote Loop OFF Local Loop

S2-2

S2-3

S2-4

Reserved

S2-5

S2-6

S2-7 Response to RDL OFF Enabled

S2-8 Front panel switches OFF Enabled

Switch S2-1: Local/Remote Loop.

Switch S2-1 determines which Loop

can be activated from the front panel loop switches (P1 to P4)

S2-1 Loop selected

OFF Local Loop

ON Remote Loop

Switch S2-7: Response to RDL.

Switch S2-7 enables or disables the

ability of the model 1194 to respond to RDL (Fiber Loop)

S2-7 RDL Response

ON Disabled (no response)

OFF Enabled

Switch S2-8: Front Panel Switches.

Switch S2-8 enables or disables

front panel switches, affecting the operation of P1 to P4 (loop switches)

and test pattern switches. In the ON position, S2-8 disables the operation

of front panel switches preventing the accidental activation of diagnostic

loops and test patterns.

S2-8 Front panel Switches

ON Disabled

OFF Enabled

13

Page 14

4.0 INSTALLATION

Once the Model 1194 is configured, it is ready to connect to the fiber

interface, to the E1/T1 equipment, and to the power source. This section

describes how to make these connections.

The power, network (E1/T1), and fiber line connections are located on

the rear panel of the Model 1194. Figure 5 sho ws the location of each of

these ports.

ON

P1 P2 P3 P4

OFF|O

Power

receptacle

Figure 5.

Network T1/E1

ports

Network, fiber, and power connection ports

FIBER

Fiber line

connector

4.1 CONNECT THE G.703/G.704 OR T1 NETWORK

The Model 1194 is equipped with 4 RJ-48C jacks for connection to an E1

or T1 network. Figure 6 shows the pinout for each of the four network

interface ports.

1 RX Data (TIP)

1

2

3

4

5

6

7

8

2 RX Data (RING)

3 (no connection)

4 TX Data (TIP)

5 TX Data (RING)

6 (no connection)

7 (no connection)

}

From Network

}

To Network

8 (no connection)

Figure 6.

E1 or T1 network interface

4.2 CONNECT THE FIBER INTERFACE

The Model 1194 is designed to be connected to another Model 1194.

The Model 1194 supports communication between T1 or E1 equipment

over single-mode fiber at distances up to 25 km (16 miles). One modem

can connect to another on the end of a single strand of fiber optic cable.

To connect two Model 1194s, use one strand of 9/125 micron singlemode fiber. The fiber connects to each Model 1194 using either an FC or

SC connector. Figure 7 shows a close-up of SC and FC connector types.

14

Page 15

Figure 7.

Single-mode fiber connectors (FC and SC)

.

Use of controls or adjustments or performance of

procedures other than those specified herein may result

in hazardous laser radiation exposure.

Caution

4.3 POWER CONNECTION

The Model 1194 is available with two power supply options:

•

Universal Interface AC Power Supply

option

(Model 1194-UI

) operates in environments ranging from 100 to 240 VAC, with no re-configuration necessary (see

Appendix B

for available domestic and

international power cords).

•

DC Power Supply

option

(Model 1194/48)

operates in 48 VDC (36–

60 VDC) environments and is equipped with a 3-pin “terminal strip”

style connector.

Connecting to an AC Power Source

The Universal Interface AC Supply is equipped with a male IEC-320

power connection. A domestic (US) power supply cord is supplied with

the unit at no extra charge. To connect the standard or universal power

supply, follow these steps:

1. Attach the power cord (supplied) to the shrouded male IEC-320 connector on the rear of the Model 1194.

2. Plug the power cord into a nearby AC power outlet.

15

Page 16

3. Set the ON/OFF power switch (see Figure 8) to ON.

ON/OFF power

switch

O

N

|

O

F

F

O

P

1

P

2

P

3

P

4

F

IB

E

R

Figure 8.

Power switch location

Connecting to a DC Power Source

The 48 VDC pow er supply option uses a 3-pin terminal bloc k with springtype connectors. Please refer to the

Model 1090 Series Service Manual

for the power line voltage connections.

There are no user-serviceable parts in the power supply

section of the Model 1194. Fuse replacement should only

be performed by qualified service personnel. Contact Patton Electronics Technical support at +1 (301) 975-1007,

via our web site at www.patton.com, or by E-mail at

support@patton.com, for more information.

WARNING

DC input power connector

ON

DC Input

+-E

OFF|O

P1 P2 P3 P4

O

N

|

D

C

I

n

+-E

p

u

t

O

F

F

O

P

1

P

2

P

3

FIBER

P

4

F

I

B

E

R

Figure 9.

DC power connection

16

Page 17

5.0 POWER-UP

To apply power to the Model 1194, first be sure that the unit is connected

to the appropriate power source. Then do the following:

1. Set front panel switches to the center position

2. Plug the provided AC or DC power into the Model 1194.

3. Set the ON/OFF power switch (see Figure 8 on page 16) to ON.

After the local and remote Model 1194s are powered up, a synchronization process will occur to establish a link. The synchronization

process should take approximately 5 seconds. If one of the Model

1194s loses power (for example, during a lightning storm), the local

and remote units will re-synchronize before they can resume data

transmission.

17

Page 18

6.0 LED STATUS MONITORS

The Model 1194 features front panel LEDs that monitor power, network,

fiber, and diagnostic signals. Figure 10 shows the front panel location of

each LED. Table 3 describes each LED’s function.

Model 1194E Single Mode Fiber - Quad G.703/G.704 Modem

Power

G.703/G.704Fiber

Link

NS

Link

NS

P4P3P2P1

G.703/G.704 Test Modes

TM

ERR

P4P3P2P1

511

P3P1

511EP4P2

Diagnostics LEDs

Power LED

Fiber LEDs

Figure 10.

Table 3:

Network LEDs

Front panel picture of 1194

Front panel LED descriptions

LED LED color Description

POWER Green Indicates the presence of AC or DC power

FIBER LINK Green Indicates the unit fiber link is synchronized

and operating correctly

FIBER NS Red Indicates the absence or synchronization

or fiber connection

Network Link (4) Green Indicates synchronization of the corre-

sponding E1 or T1 port (P1-P4)

Network Loss (4) Red Loss of synchronization or link of the cor-

responding E1 or T1 port (P1-P4)

Test Mode TM (4) Yellow Indicates the activation of Local, Remote,

or 511/511 pattern for corresponding E1

or T1 port (P1-P4)

Error ERR (4) Red Indicates the presence of errors in test

pattern data received

18

Page 19

7.0 TEST MODES

The following section describes the test patterns and loopbacks used in

the Model 1194. The Model 1194 offers local/remote loopback tests, plus

a built-in V.52 BER test pattern generator to evaluate the condition of the

modems and the network (T1/E1 lines) and fiber links. These tests can

be activated physically from the front panel. Before initiating a loopback

test, the user needs to select Local or Remote loops via DIP switch S2-1

located on the underside of the unit

S2-1 Loop Test Selected

OFF Local

ON Remote

7.1 LOCAL LOOPBACK TEST

This feature is used to test the T1 or E1 link on a per-port basis. Each of

the four T1 or E1 ports can be tested to verify the proper operation of the

line and the device at the remote end of the T1/E1 link. During local loopback the corresponding E1 or T1 port in the Model 1194 will transmit the

data received back to the originating device.

Set S2-1 to the OFF position, this setting prepares the Model 1194 for

local loop. The model 1194 has 3 front panel toggle switches, one of the

switches initiates 511/511E test patterns, the other two switches will initiate loops for a network port, the switches have labels corresponding to

network ports (P1 through P4). For example, to initiate a local loop on

network port 1, move the first switch from the left UP towards label “P1”.

See Figure 11 loop diagram

1

2

3

4

CSU/DSUs

E1/T1

Figure 11.

Fiber

1194 Local loop

19

E1/T1

1

2

11941194

3

4

CSU/DSUs

Page 20

To test the local connection, do the following:

1. Set S2-1 to the OFF position.

2. Locate the port label (P1-P4) above or below the front panel

switches, Activate local loopback for a network port by moving the

appropriate front panel toggle switch UP or DOWN. A yellow TM

LED corresponding to the port under test will turn on.

3. A BER (Bit Error Rate) test can be performed using a BER tester at the

far end of the T1/E1 link. If the BER test equipment indicates no faults

but the data indicates a fault, f ollo w the manufacturer's checkout procedures for the far end de vice. The BER test can also be perf ormed using

a built-in 511/511E pattern generator. (See the following section f or

more on how to use the built-in 511/511E pattern generator.)

4. Upon completion of the LAL test, return the front panel switch to center

position. After appro ximately 30 seconds , the TM LED should turn off.

7.2 REMOTE LOOPBACK TEST

The Remote loopback feature tests the perf ormance of the local and remote

1194 and the fiber optic link. During this test, data transmitted from a T1 or

E1 port at a local 1194 and sent over the fiber link is returned by the remote

1194. F or example , to initiate a remote loop test on network port 1, move the

first switch from the left UP towards label “P1”, data sent from port 1 will go

through the 1194 and fiber link to the remote 1194 (see Figure 12). The

remote 1194 will send port 1 data back to the originating device, as well as

to the corresponding port on it’s E1/T1 network side.

In order to prepare the Model 1194, make sure that fiber connection is in

place. V erify that the “Fiber link” LED on the front panel of the 1194 is ON.

E1/T1

1

2

Fiber

3

E1/T1

1

2

3

11941194

4

CSU/DSUs

Figure 12.

1194 Remote Loop

4

CSU/DSUs

20

Page 21

To test the fiber connection, do the following:

1. Set S2-1 to the ON position.

2. Locate the port label (P1-P4) above or below the front panel

switches, Activate Remote Loopback for a network port by moving

the appropriate front panel toggle switch UP or DOWN. A green TM

LED corresponding to the port under test will turn on. A BER test

can now be initiated using a BER tester or the built-in 511/511E pattern generator.

3. Upon completion of the remote loop test, return the front panel

switch to center position. After appro ximately 30 seconds, the TM LED

should turn off.

7.3 THE V.52 TEST PATTERN GENERATOR

To use the V.52 BER test in conjunction with the Local or Remote Loopbacks, follow these instructions:

1. Locate the “511/511E” toggle switch on the front panel of the Model

1194 and move it UP. This activates the V.52 BER test mode and

transmits a “511” test pattern into the loop . If any errors are present,

the red “ERR” LED corresponding to the port under test will blink

intermittently.

2. If the above test indicates no errors, move the V.52 toggle switch

down, activating the “511/E” test with errors present. If the test is

working properly, the local 1194 red “ERR” LED will blink approximately once every 2 seconds. A successful “511/E” test will confirm

that the link is in place, and that the Model 1194’s built-in “511” generator and detector are working properly.

Note

Note: When the unit is set for Network Clock Mode, the unit will

derive its timing from the Network (T1/E1)Interface. Failure to

connect to the network may result in bit errors during the 511 or

511/E test.

21

Page 22

APPENDIX A

MODEL 1194 QUAD E1/T1 TO SINGLE MODE FIBER SPECIFICATIONS

A.1 CONFIGURATION

Externally accessible dip switches

A.2 CLOCKING MODES

Network (E1/T1), Internal, Receive Recover (fiber Link)

A.3 NETWORK PORTS SPECIFICATIONS

Network Line Rate

2048 kbps (G.703), 1.544Mbps (T1)

Transmit Line Buildout (T1)

0 dB, -7.5 db, -15 db, and -22.5 dB

Interface

RJ-48C 120 ohm (E1), 100 ohm (T1)

Line coding

AMI or HDB3 (E1), B8ZS (T1)

Isolation

1500 Vrms

Physical Connection

• (RJ-48C)

• pin 1 Rx Data Tip

• pin 2 Rx Data Ring

• pin 4 Tx Data Tip

• pin 5 Tx Data Ring

• pins 3, 6, 7, 8 no connection

22

Page 23

A.4 FIBER PORT SPECIFICATIONS

Fiber Line Coding

8B10B

Fiber Physical

• Connection: One str and of 9/125 micron single-mode fiber with FC or

SC connectors

• Transmission Line: Single fiber

• Link Budget: 13 dB

A.5 DIAGNOSTICS

V.52 compliant (511/511E) pattern generator and detector with error

injection mode. Remote Loopback (toward fiber line) and local loopback

(toward T1/E1 Network) controlled by front panel switches

A.6 COMPLIANCE

FCC Part 15, FCC Part 68, CE, CTR12.

UL1950, CAN/CSA C22.2 No. 950

A.7 LASER SAFETY

Complies with 21CFR 1010 and 1040, Class 1 Lasers

A.8 NETWORK LINE INTERFACE

Transformer coupled, 1500 VAC isolation

A.9 POWER

• 100–240 VAC, 400 mA, 50–60 Hz (universal input);

• 48 VDC (option). (36–60) 340 mA input.

A.10 TEMPERATURE RANGE

32–122°F (0–50°C)

A.11 ALTITUDE

0–15,000 feet

23

Page 24

A.12 HUMIDITY

5 to 95%, non-condensing

A.13 DIMENSIONS

7.3 W x 6.6 D x 1.62H in. (185 W x 168 D x 41 H mm)

A.14 WEIGHT

2.01 lbs. (1.0kg)

A.15 MEAN TIME BETWEEN FAILURE (MTBF)

113,258 hours, based on MIL-HDBK-217F, Notice 2.

24

Loading...

Loading...