Page 1

USER

Part# 07M1180-B

Doc# 017071UB

Revised 1/5/96

MANUAL

MODEL 1180

Single Fiber

Short Range Modem

SALES OFFICE

(301) 975-1000

TECHNICAL SUPPORT

(301) 975-1007

Page 2

1.0 WARRANTY INFORMATION

Patton Electronics warrants all Model 1180 components to be

free from defects, and will—at our option—repair or replace the product

should it fail within one year from the first date of shipment.

This warranty is limited to defects in workmanship or materials, and

does not cover customer damage, abuse or unauthorized modification.

If this product fails or does not perform as warranted, your sole

recourse shall be repair or replacement as described above. Under no

condition shall Patton Electronics be liable for any damages incurred

by the use of this product. These damages include, but are not limited

to, the following: lost profits, lost savings and incidental or

consequential damages arising from the use of or inability to use this

product. Patton Electronics specifically disclaims all other warranties,

expressed or implied, and the installation or use of this product shall be

deemed an acceptance of these terms by the user.

1.1 RADIO AND TV INTERFERENCE

The Model 1180 generates and uses radio frequency energy, and if

not installed and used properly—that is, in strict accordance with the

manufacturer’s instructions—may cause interference to radio and

television reception. The Model 1180 has been tested and found to

comply with the limits for a Class A computing device in accordance

with the specifications in Subpart J of Part 15 of FCC rules, which are

designed to provide reasonable protection from such interference in a

commercial installation. However, there is no guarantee that

interference will not occur in a particular installation. If the Model 1180

does cause interference to radio or television reception, which can be

determined by turning the power off, the user is encouraged to try to

correct the interference by one or more of the following measures:

moving the computing equipment away from the receiver, re-orienting

the receiving antenna and/or plugging the receiving equipment into a

different AC outlet (such that the computing equipment and receiver are

on different branches).

1.2 SERVICE

All warranty and non-warranty repairs must be returned freight

prepaid and insured to Patton Electronics. All returns must have a

Return Materials Authorization number on the outside of the shipping

container. This number may be obtained from Patton Electronics

Technical Service at (301) 975-1007.

2.0 GENERAL INFORMATION

Thank you for your purchase of this Patton Electronics product.

This product has been thoroughly inspected by Patton’s qualified

technicians. If any questions or problems arise during installation or

use of this product, please do not hesitate to contact Patton Electronics

Technical Support at (301) 975-1007.

2.1 FEATURES

• Operates over a single optical fiber

• Synchronous or asynchronous operation

• Loopback diagnostics

• Asynchronous data rates to 38.4 Kbps

• Synchronous data rates to 256 kbps

• Distances to 5 Km

• Internal or external clocking

• Hardware and software flow control

• Tri-state front panel LEDs

• Available with ST or SMA connectors

2.2 DESCRIPTION

The Model 1180 Single Fiber Short Range Modem accomplishes

point-to-point RS-232 communication over a

single

optical fiber.

Supporting synchronous data rates to 256 Kbps, and asynchronous

data rates to 38.4 Kbps, the Model 1180 automatically adapts to

hardware or software flow control. Synchronous timing can be set for

internal or external clock.

The Model 1180 features extended data rate circuitry that allows for

single fiber distances between 2.5 and 5 Km. Optical fiber may be

connected to the Model 1180 using an ST or SMA type interface. The

Model 1180 encodes the electrical signal using 3B4B modulation. The

electrical signal is then converted to an optical signal and transmitted

using an 880 nm light emitting diode.

The Model 1180 features two test modes: local and remote

loopback. These loopback tests are activated via a front panel switch.

The local loopback test is used to evaluate the RS-232 to modem

connection. The remote loopback test is used to evaluate the condition

of the connection between the modems.

2

RMA number will not be accepted.

Patton Electronics’ technical staff is also available to answer any

questions that might arise concerning the installation or use of your

Model 1180. Technical Service hours: 8AM to 5PM EST, Monday

through Friday.

Packages received without an

1

Page 3

3.0 CONFIGURATION

1 2 3 4 5 6 7 8

ON

FRONT

REAR

1 2 3 4 5 6 7 8

ON

OFF

ON

3.1 DETAILED SWITCH SETTINGS

This section provides detailed information about the function of

each DIP switch and lists all possible settings. Use this section as

configuration guide for applications where the Model 1180’s default

would not provide correct results.

Switch 1: Reserved for Future Use

Switches 2 though 5: Data Rate (Sync. Mode)

Switches 2 through 5 determine two configuration parameters:

synchronous or asynchronous data rate and the mode of

synchronization (Sync. Mode) between two Model 1180s. The “Sync.

Mode” setting (active in both asynchronous and synchronous operating

modes) defines the packet length of the data stream between the two

Model 1180s.

Simply put, the “2X” setting doubles the space between data

packets when compared with the “1X” setting. A Sync. Mode setting of

“2X” facilitates communication distances up to 5 Km. A Sync. Mode

setting of “1X” limits communication distances to 2.5 Km. The following

table shows every possible data rate/Sync. Mode switch setting for the

Model 1180.

SWITCH SUMMARY TABLE

Position Function Factory Default

Switch 1 RESERVED Off

Switch 2 Data Rate (Sync Mode) On

Switch 3 Data Rate (Sync Mode) Off

Switch 4 Data Rate (Sync Mode) Off

Switch 5 Data Rate (Sync Mode) On

Switch 6 Reset Off

Operating Mode

Switch 7 Handshaking On

Control Signal Mode

Switch 8 Clocking Method Off Internal Clock

0 - 19.2

Async (2x)

}

Figure 1. Switch locations underneath Model 1180

Figure 2. Close up of 1180 DIP switch package showing OFF/ON positions.

Figure 3. Summary of switch settings, showing factory defaults

The Model 1180 uses a set of eight external DIP switches that

allow configuration to a wide range of applications. Because all eight

switches are in one externally accessible DIP package, there is no need

to open the Model 1180’s case for configuration. The switches allow

you to control data rates and clocking methods. Figures 1, 2 and 3

summarize the switch locations, positions and functions.

3 4

Page 4

Switch 8: Clocking Method

On = External Clock

Off = Internal Clock

6

Switch 2 Switch 3 Switch 4 Switch 5 Data Rate (Sync. Mode)

On Off Off On 0 - 19.2 (2X)

Asynchronous

On Off Off Off 0 - 38.4 (1X)

Asynchronous

On On On Off 2.4 (1X)

Off On On Off 9.6 (1X)

Off On On On 9.6 (2X)

On On Off Off 19.2 (1X)

On On Off On 19.2 (2X)

Off On Off Off 38.4 (1X)

Off On Off On 38.4 (2X)

On Off On Off 48.0 (1X)

On Off On On 48.0 (2X)

Off Off On Off 56.0 (1X)

Off Off Off Off 64.0 (1X)

Off Off Off On 64.0 (2X)

Off Off On On 192.0 (1X)

On On On On 256.0 (1X)

Switch 6: Reset

Switch 6 lets you reset the Model 1180 without powering down the

unit. The default position of the switch allows normal operation.

Switch 6

On = Reset Condition

Off = Operating Condition

Switch 7: Handshake Mode

The setting for switch 7 determines whether the Model 1180

operates in Control Signal Mode or Standard Modem Mode. In Control

Signal Mode, the two Model 1180s pass RTS/CTS and DTR/DSR

between each other over the fiber link. In Standard Modem Mode,

handshaking only occurs between each Model 1180 and its DTE, not

over the fiber link.

Switch 7

On = Control Signal Mode

Off = Standard Modem Mode

(continued)

5

Switch 8 is used to specify the clocking method. The Model 1180

can provide an internal clock (pin 15) or receive an external clock (from

pin 24).

Switch 8

Page 5

4.0 INSTALLATION

Figure 4. Rear panel of Model 1180 showing interface connections

Powered Short Range Modem

Made In The USA

Fiber

RS-232 Interface

Power

Model 1180

Single-Fiber Modem

Power

- Remote

- Normal

- Local

Test

Modes

TD RD RTS CD

Figure 5. Close up of ST and SMA connections

ST

SMA

alignment pin

faces down

Local Software Handshaking

RS-232 DCE Model 1180

Local Hardware Handshaking

RS-232 DCE Model 1180

DB-25 Pin No. DB-25 Pin No.

1---------------------------------------------------1

2---------------------------------------------------3

3---------------------------------------------------2

4---------------------------------------------------5

5---------------------------------------------------4

6---------------------------------------------------20

8

20---------------------------------------------------6

8

7---------------------------------------------------7

The Model 1180 is easy to install. After configuring the DIP

switches, simply connect the single fiber cable, hook up the RS-232

interface, and plug the power supply adapter into the 1180. Figure 4

shows the location of the interface connections on the Model 1180 rear

panel.

4.1 SINGLE FIBER CONNECTION

These short range modems are designed to work in

pairs

need one at each end of single multi-mode fiber cable. Depending

upon the data rate setting you select, your cable may be a maximum of

2.5 or 5 Km long. The fiber cable connects to each Model 1180 using

either an ST or an SMA connector. Figure 5 shows a close up of both

connector types.

. You will

4.2 RS-232 CONNECTION

The Model 1180 is configured as a DCE. Therefore it wants to

connect to a DTE. When connecting the Model 1180 to DTE hardware

such as a PC, host or terminal, use a

straight through

RS-232 cable.

When connecting the Model 1180 to DCE hardware such as a modem,

multiplexer or printer, use a

null modem

RS-232 cable. The diagrams

below show some typical RS-232 null modem wiring configurations.

Consult your hardware user manual for the specific pin configuration

you need.

DB-25 Pin No. DB-25 Pin No.

1---------------------------------------------------1

2---------------------------------------------------3

3---------------------------------------------------2

4 4

5 5

6 6

8 8

20 20

7---------------------------------------------------7

87

Page 6

5.0 OPERATION

Model 1180 Single-Fiber Modem

Power

- Remote

- Normal

- Local

Test

Modes

TD RD RTS CD

Once you have configured each Model 1180 properly (see Section

3.0) and connected the fiber and RS-232 cables (see Section 4.0), you

are ready to operate the units. This section describes reading the LED

status monitors, power-up and using the built-in loopback test modes.

5.1 LED STATUS MONITORS

5.2 POWER-UP / SYNCHRONIZATION

Apply AC power to the Model 1180 by plugging the separate AC

power adapter first into the rear panel outlet of the Model 1180 and then

into an acceptable AC power outlet. There is no power switch on the

Model 1180: When the “power” LED is glowing steady, the Model 1180

is powered up. Note: Make sure the front panel toggle switch on

both Model 1180s is set to NORMAL.

The Model 1180 features six front panel status LEDs that indicate

the condition of the modem and communication link. Figure 6 shows

the front panel location of each LED. Following Figure 6 is a description

of each LED’s function.

Figure 6. Front view of Model 1180

• The green “Power” LED glows if power is applied to the modem.

• The green “Test Modes” LED indicates that the modem is in a test

mode.

• The “TD” and “RD” indicators blink red and green with data activity.

Red indicates a low RS-232 logic level, green indicates a high RS-

232 logic level. Note: RS-232 devices idle in a

low

state, so the

LED will glow red if the connections are correct and the RS-232

device is in an idle state.

• The “RTS” and “CD” indicators are also tri-state and glows red for a

“low” signal or green for a “high” signal. RTS lights for an incoming

signal on RS-232 pin 4. CD lights for an incoming signal on the

line side, and the resulting output signal on RS-232 pin 8.

After both the local and remote Model 1180s are powered up, a

synchronization process must occur between the two modems before a

link can be established. Depending upon a number of factors, this

synchronization process can take

as long as 60 seconds.

Any time one

of the Model 1180s loses power (i.e., in a lightning storm), the local and

remote units

must re-synchronize

before they can resume data

transmission. Note: If your application cannot tolerate a 60 second

synchronization phase, turn the front panel “Test Modes” switch to

REMOTE and then back to NORMAL to synchronize the units in a

maximum of 250 mS.

When the local and remote Model 1180s are

are passing data

normally

, the following LED conditions will exist:

both

powered up, and

• PWR = green

• TD & RD = flashing red and green

• RTS & DCD = green

• TEST = off

5.3 LOOPBACK TEST MODES

The Model 1180 offers two loopback test modes to evaluate the

condition of the modems and the communication link. These tests are

activated from the front panel.

5.3.1 LOCAL LOOPBACK

The local loopback test checks the operation of the local Model

1180, and is performed separately on each unit. Any data sent to the

local Model 1180 in this test mode will be echoed (returned) back to the

user device. For example, characters typed on the keyboard of a

terminal will appear on the terminal screen.

9 10

To perform a local loopback test, follow these steps:

Page 7

A. Activate local loopback by moving the front panel toggle switch

RD

TD

TD

RD

Local 1180RC

In Normal Mode

Remote 1180RC

In Normal Mode

TX

RX

RX

TX

RD

TD

TD

RD

Local 1180RC

In Loopback Mode

Remote 1180RC

In Normal Mode

RX

TX

TX

RX

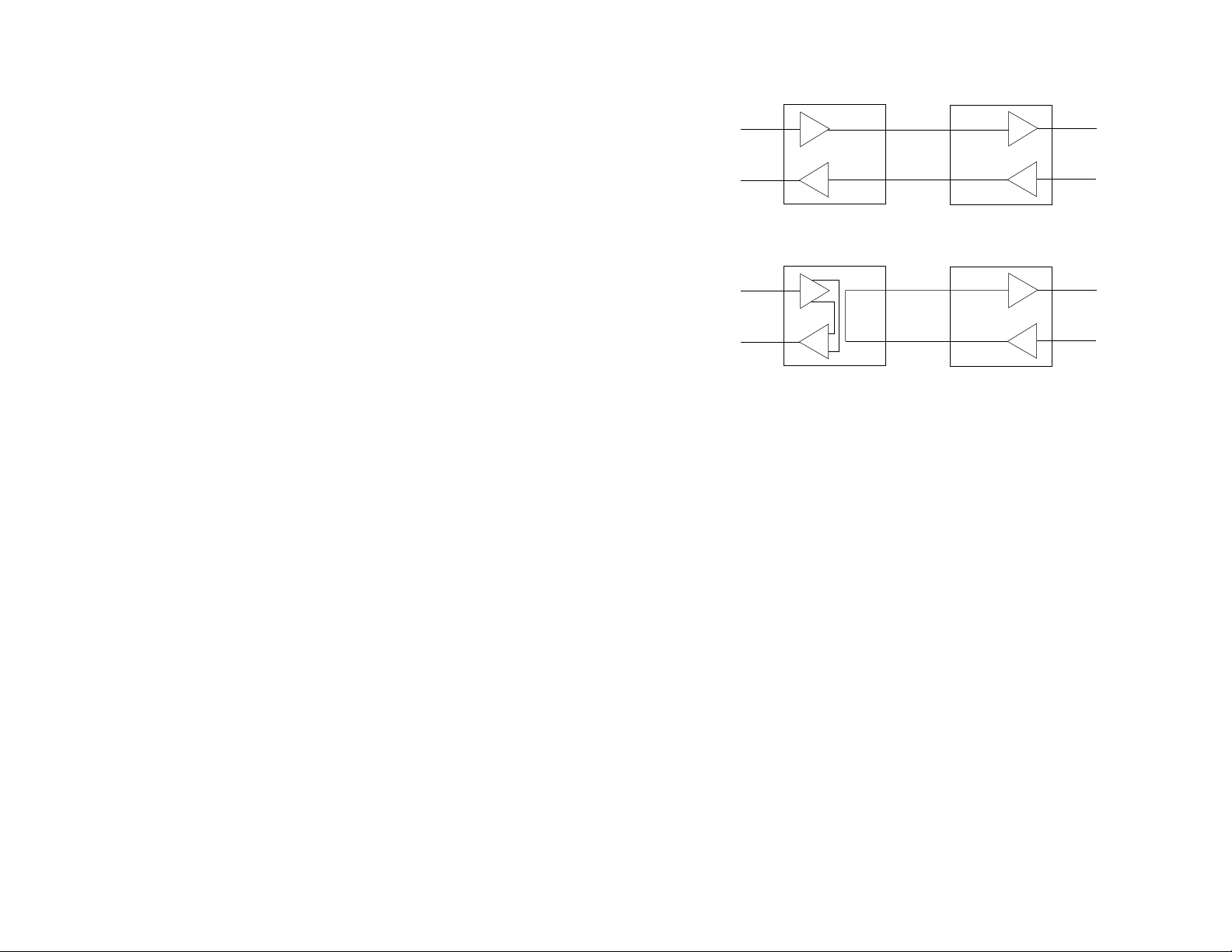

Figure 7. Local and remote loopback test modes

DOWN to “Local”. Once local loopback is activated, the Model 1180

transmit output is connected to its own receiver. The “test” LED should

glow. Note: Even though the local Model 1180 cannot communicate

with the remote Model 1180 in this mode, the synchronized connection

between the two modems remains intact.

B. Verify that the data terminal equipment is operating properly and

can be used for a test. If a fault is indicated, call a technician or replace

the unit.

C. Perform a BERT (bit error rate) test on each unit. If the BERT

test equipment indicates no faults, and the data terminal indicates a

fault, follow the manufacturer’s checkout procedures for the data

terminal. Also, check the RS-232 interface cable between the terminal

and the Model 1180.

5.3.2 REMOTE LOOPBACK

The remote loopback test checks the performance of both the local

and remote Model 1180s,

(Figure 7). Any characters sent to the remote Model 1180 in this test

mode will be returned back to the originating device. For example,

characters typed on the keyboard of the local terminal will appear on

the local terminal screen

1180 and looped back. To perform a remote loopback test, follow these

steps:

A. Activate remote loopback by moving the front panel toggle switch

UP to “Remote”. The “test” LED should glow.

B. Perform a BERT (bit error rate) test on the system.

C. If the BERT test equipment indicates a fault, and the local

loopback test was successful for both Model 1180s, this suggests a

problem with the fiber communication line connecting the modems. You

should then test the fiber line for proper connections and continuity.

5.4 POWER-DOWN

Turn off the Model 1180 by simply unplugging the AC power adapter

from the wall. There is no power switch on the Model 1180.

and

the communication link between them

after

having been passed to the remote Model

11 12

Page 8

SYMPTOM PROBLEM SOLUTION

APPENDIX A

TROUBLESHOOTING

LEDs do not light

when AC power

transformer is

plugged into wall

Carrier Detect (CD)

LED is

low

or

Carrier Detect (CD)

LED is

high

, but

1180s are not

communicating

Loose power

connection

Outlet is defective

AC power cord is

defective

AC transformer is not

plugged into the Model

1180

If CD is low, possible

synchronization loss

Test Mode switch is in

the wrong position

DIP switches are set

improperly

Fiber link is connected

improperly

RS-232 connections

are faulty or cables are

pinned wrong

Make sure the AC

connection is flush

Try a different outlet

Remove the cord from

the outlet and check for

continuity

Plug transformer into

Model 1180

Check for ongoing

power loss or break in

fiber if CD does not go

high within 60

seconds

Make sure the Test

Mode switch is set to

NORMAL on both

Model 1180s

Check all DIP switch

settings, esp. Reset

and Data Rate,

against Section 3;

make sure both Model

1180s are configured

the same way

Check the ST or SMA

connection on the back

of both Model 1180s

Check RS-232 cable

continuity and pinning

13

SYMPTOM PROBLEM SOLUTION

Data passes, but

hardware flow

control doesn’t

work

Model 1180s work

in async. mode,

but not sync. mode

Incorrect DIP switch

setting

Incorrect DIP switch

setting

Switch 7 must be in the

ON condition for

hardware flow control

signals to pass

between Model 1180s;

both units must be set

the same way

Switch 8 (internal/

external clock) must be

set the same way for

both Model 1180s

14

Page 9

APPENDIX B

SPECIFICATIONS

Transmission Format: Asynchronous or synchronous

Range: 2.5 Km at all data rates, 5 Km at specified data rates

Data rates: 0 to 38.4 Kbps (async.); 2.4, 9.6, 19.2, 38.4, 56, 64, 192

and 256 Kbps (sync.)

Interface: EIA RS-232 / CCITT V.24

Transmit Mode: Single 62.5 or 50 µ core, multi-mode fiber cable

Clocking: Internal or external

Handshaking: Software (X-ON/X-OFF) or hardware (RTS/CTS), both

modes available at all times

Application: Point-to-point

Typical Link Budget: 8 dB with 50 µ cable; 12 dB with 62.5 µ cable

Responsivity Minimum: 0.12 A/w

LED Indicators: TD, RD, RTS, CTS, Power, Test

Diagnostics: Local and remote loopback

Connectors: DB-25 female (RS-232), ST or SMA (fiber)

Dimensions: 4.127”w x 1.52”h x 5.0”l

Power Supply: Wall-mount, 10VAC, 700mA

APPENDIX C

RS-232 INTERFACE STANDARD

15 16

1- (FG) Frame Ground

2- (TD) Transmit Data To Model 1180

3- (RD) Receive Data From Model 1180

4- (RTS) Request to Send To Model 1180

5- (CTS) Clear to Send From Model 1180

6- (DSR) Data Set Ready From Model 1180

7- (SG) Signal Ground

8- (DCD) Data Carrier Detect From Model 1180

To Model 1180 Data Term. Ready (DTR) - 20

DIRECTION STANDARD “DCE” SETTING DIRECTION

To Model 1180 Transmitting Timing LXC - 24

From Model 1180 Transmitting Timing - 15

From Model 1180 Receiver Timing - 17

Loading...

Loading...