Page 1

OnSite 1052 &1063 Series

Metro-Optical Transport

Access Nodes

Getting Started Guide

IMPORTANT

The compliance information in this document is incomplete and subject to change.

Sales Office: +1 (301) 975-1000

Technical Support: +1 (301) 975-1007

E-mail: support@patton.com

WWW: www.patton.com

Part Number: 07MOS10xx-GS, Rev. A

Revised: November 20, 2009

Page 2

Patton Electronics Company, Inc.

7622 Rickenbacker Drive

Gaithersburg, MD 20879 USA

Tel: +1 (301) 975-1000

Fax: +1 (301) 869-9293

Support: +1 (301) 975-1007

Web: www.patton.com

E-mail: support@patton.com

Copyright © 2009, Patton Electronics Company. All rights reserved.

The information in this document is subject to change without notice. Patton

Electronics assumes no liability for errors that may appear in this document.

The software described in this document is furnished under a license and may be used

or copied only in accordance with the terms of such license.

Page 3

Summary Table of Contents

1 Product Overview.......................................................................................................................................... 14

2 Application Overview.................................................................................................................................... 18

3 Installation Overview .................................................................................................................................... 23

4 System Management Access........................................................................................................................... 39

5 Contacting Patton for assistance ................................................................................................................... 53

A Compliance information .............................................................................................................................. 56

B Specifications ................................................................................................................................................ 59

C Terms and Acronyms .................................................................................................................................... 64

3

Page 4

Table of Contents

Summary Table of Contents ........................................................................................................................... 3

Table of Contents ........................................................................................................................................... 4

List of Figures ................................................................................................................................................. 7

List of Tables .................................................................................................................................................. 8

About this guide ............................................................................................................................................. 9

Audience................................................................................................................................................................. 9

Structure............................................................................................................................................................... 10

Precautions ........................................................................................................................................................... 10

Typographical conventions used in this document................................................................................................ 11

General conventions .......................................................................................................................................11

Mouse conventions .........................................................................................................................................11

Safety when using electricity ................................................................................................................................. 12

Power Cable ....................................................................................................................................................12

Electrostatic Discharge Damage............................................................................................................................ 13

Optical Safety ....................................................................................................................................................... 13

Fiber-Optic Ports ............................................................................................................................................13

Fiber-Optic Safety Precautions ........................................................................................................................13

1 Product Overview.......................................................................................................................................... 14

Introduction..........................................................................................................................................................15

OnSite Platforms ............................................................................................................................................15

2 Application Overview.................................................................................................................................... 18

OS1052 Application..............................................................................................................................................19

OS1063 Application..............................................................................................................................................21

3 Installation Overview .................................................................................................................................... 23

Introduction..........................................................................................................................................................24

Unpacking and Inspection.....................................................................................................................................24

Site Preparation .....................................................................................................................................................24

Site Environment ..................................................................................................................................................25

Planning Your Site.................................................................................................................................................25

Site Requirements ...........................................................................................................................................25

Operating Environment Requirements ......................................................................................................26

Power Supply Requirements ......................................................................................................................27

Distribution Rack Requirements ...............................................................................................................27

Mechanical Recommendations for the Rack ....................................................................................................28

Protective Grounding for the Rack and Chassis ..............................................................................................28

Space Requirements for the Rack ....................................................................................................................28

Securing the Rack ...........................................................................................................................................28

Tools and Equipment for Installation and Maintenance........................................................................................29

4

Page 5

5

OnSite Series Getting Started Guide

OnSite System Installation ....................................................................................................................................29

Mounting the Chassis to an EIA/TIA 19-Inch Rack .......................................................................................29

Mounting the Chassis to an ETSI Rack ..........................................................................................................30

Mounting the Chassis on the Wall ..................................................................................................................32

Installing the Chassis Ground Connection ......................................................................................................33

Connecting Power to the OS-10 System .........................................................................................................33

Connecting AC Power to the OS-10 System .............................................................................................34

Powering On the OS-10 System with AC Power ......................................................................................35

Connecting DC Power to the OS-10 System ............................................................................................35

Wiring Procedure for DC Input Power .....................................................................................................35

Checking the OS-10 System Installation .........................................................................................................38

4 System Management Access........................................................................................................................... 39

Introduction..........................................................................................................................................................40

General Overview..................................................................................................................................................40

Ethernet LAN Management Port...........................................................................................................................41

Serial Management Port ........................................................................................................................................42

Gaining Access to the System ................................................................................................................................43

Access through the Serial Port .........................................................................................................................43

Access through the Ethernet LAN Management Port ......................................................................................44

Web-Based Management Interface ........................................................................................................................45

Launching the GUI Application .....................................................................................................................45

Autonomous Alarm Messages ................................................................................................................................47

Engineering Orderwire (EOW) .............................................................................................................................49

5 Contacting Patton for assistance ................................................................................................................... 53

Introduction..........................................................................................................................................................54

Contact information..............................................................................................................................................54

Warranty Service and Returned Merchandise Authorizations (RMAs)...................................................................54

Warranty coverage ..........................................................................................................................................54

Out-of-warranty service .............................................................................................................................54

Returns for credit ......................................................................................................................................54

Return for credit policy .............................................................................................................................55

RMA numbers ................................................................................................................................................55

Shipping instructions ................................................................................................................................55

A Compliance information .............................................................................................................................. 56

Compliance ...........................................................................................................................................................57

EMC ...............................................................................................................................................................57

Safety ..............................................................................................................................................................57

Radio and TV Interference ....................................................................................................................................57

FCC Part 68 (ACTA) Statement ...........................................................................................................................57

Declaration of Conformity ....................................................................................................................................58

Authorized European Representative .....................................................................................................................58

B Specifications ................................................................................................................................................ 59

Page 6

6

OnSite Series Getting Started Guide

Model OS1052......................................................................................................................................................60

Trunk Interfaces .............................................................................................................................................60

Client Interfaces ..............................................................................................................................................60

Expansion Modules .........................................................................................................................................60

Configuration & Port Capacity for 2 Expansion Slots .....................................................................................60

Protection .......................................................................................................................................................60

Bandwidth Connectivity and Provisioning ......................................................................................................60

Timing & Synchronization .............................................................................................................................60

System Access .................................................................................................................................................60

Operations ......................................................................................................................................................61

Management ...................................................................................................................................................61

Packet Intelligence ..........................................................................................................................................61

Dimensions .....................................................................................................................................................61

Weight ............................................................................................................................................................61

Cooling ...........................................................................................................................................................61

Mounting .......................................................................................................................................................61

Power ..............................................................................................................................................................61

Environment ...................................................................................................................................................61

Model OS1063......................................................................................................................................................62

Trunk Interfaces .............................................................................................................................................62

Client Interfaces ..............................................................................................................................................62

Expansion Modules .........................................................................................................................................62

Configuration & Port Capacity for 2 Expansion Slots .....................................................................................62

Protection .......................................................................................................................................................62

Bandwidth Connectivity and Provisioning ......................................................................................................62

Timing & Synchronization .............................................................................................................................62

System Access .................................................................................................................................................62

Operations ......................................................................................................................................................63

Management ...................................................................................................................................................63

Packet Intelligence ..........................................................................................................................................63

Dimensions .....................................................................................................................................................63

Weight ............................................................................................................................................................63

Cooling ...........................................................................................................................................................63

Mounting .......................................................................................................................................................63

Power ..............................................................................................................................................................63

Environment ...................................................................................................................................................63

C Terms and Acronyms .................................................................................................................................... 64

Abbreviations.........................................................................................................................................................65

Page 7

List of Figures

1 OnSite Model 1052 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2 OnSite Model 1063 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3 OS1052 Base System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4 OS1063 Base System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5 Typical OS1052 application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

6 OS1052 Map + Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

7 Typical OS1063 application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

8 OS1063 Map + Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

9 Grounding Terminal Location for the OS-10 System Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

10 Mounting the OS-10 System Chassis in an EIA/TIA 19-Inch Rack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

11 Mounting the OS-10 System in an ETSI 300-mm Rack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

12 Mounting the OS-10 System Chassis on a Wall . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

13 Wiring the OS-10 System for DC Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

14 Serial and LAN Management Ports on the Base OS1052 and OS1063 Systems . . . . . . . . . . . . . . . . . . . . . . . . 40

15 Detail of the Management Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

16 Location of Signal Pins on the RJ-45 Plug . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

17 Web-Based Management GUI Frames . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

18 Configuring an SNMP Trap Receiver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

19 Configuring an Authorized OnSight NMS Server . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

20 Location of EOW port (AUX 1) on OS-10 Series Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

21 Location of signal pins on the EOW port (AUX 1) RJ-11 connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

22 Configuring the Engineering Orderwire (EOW) Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

7

Page 8

List of Tables

1 General conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2 Mouse conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3 Base System Configuration for OnSite Platforms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4 Environmental Conditions for Operating the OS-10 System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

5 Power Requirements for the OS-10 System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

6 Ground Wire Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

7 OS-10 Power Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

8 Power Consumption . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

9 DC Wiring Requirements for the OS-10 System Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

10 Ethernet LAN Management Port Cabling Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

11 Pin Assignments for the Ethernet LAN Management Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

12 Pin Assignments for the RS-232 Serial Management Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

13 RS-232 Serial Port Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

14 VT100 Terminal Emulation Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

15 Web-Based Management GUI Frame Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

8

Page 9

About this guide

This guide describes how to install a Patton OnSite Series Model 1052 and1063 Metro-Optical Transport

Access Node. For detailed configuration and management instructions, refer to the OnSite 1052 & 1063 Series

Administrator’s Reference Guide , which is located on the CD-ROM that came with your unit and at www.pat-

ton.com.

Installation, maintenance, and removal of a chassis or its components must be done by qualified service personnel only. Qualified service personnel have had appropriate technical training and experience that is necessary to be aware of the hazards to which they are exposed when performing a task and of measures to minimize

the danger to themselves and other people.

You should consider the following before unpacking your equipment:

• Install the equipment in a secured, enclosed, and restricted access area, ensuring that only qualified service

personnel have access to the equipment.

• Install the equipment only in a temperature and humidity-controlled indoor area that is free of airborne

materials that can conduct electricity.

• When you handle equipment that has expansion modules, put on the electrostatic discharge (ESD) wrist

strap to reduce the risk of electronic damage to the equipment.

Note

WARNING

Leave the ESD strap permanently attached to the chassis or rack so

that it is always available when you need to handle ESD-sensitive

components.

Read the following safety information thoroughly before installing your OS10 system. Failure to follow this safety information can lead to personal

injury or damage to the equipment.

Audience

This guide is intended for the following users:

• Operators

• Installers

• Maintenance technicians

9

Page 10

10

OnSite Series Getting Started Guide

Structure

This guide contains the following chapters and appendices:

• Chapter 1 describes the OnSite Series Metro-Optical Transport Access Nodes

• Chapter 2 describes typical applications for the OS-10 series

• Chapter 3 describes instructions for installing the OS-10

• Chapter 4 describes how to access the OS-10 for configuration and management

• Chapter 5 contains information on contacting Patton technical support for assistance

• Appendix A lists compliance information

• Appendix B contains specifications for the OS-10 series

• Appendix C contains a reference for terms and acronyms found in this guide

For best results, read the contents of this guide before you install the OS-10 platforms.

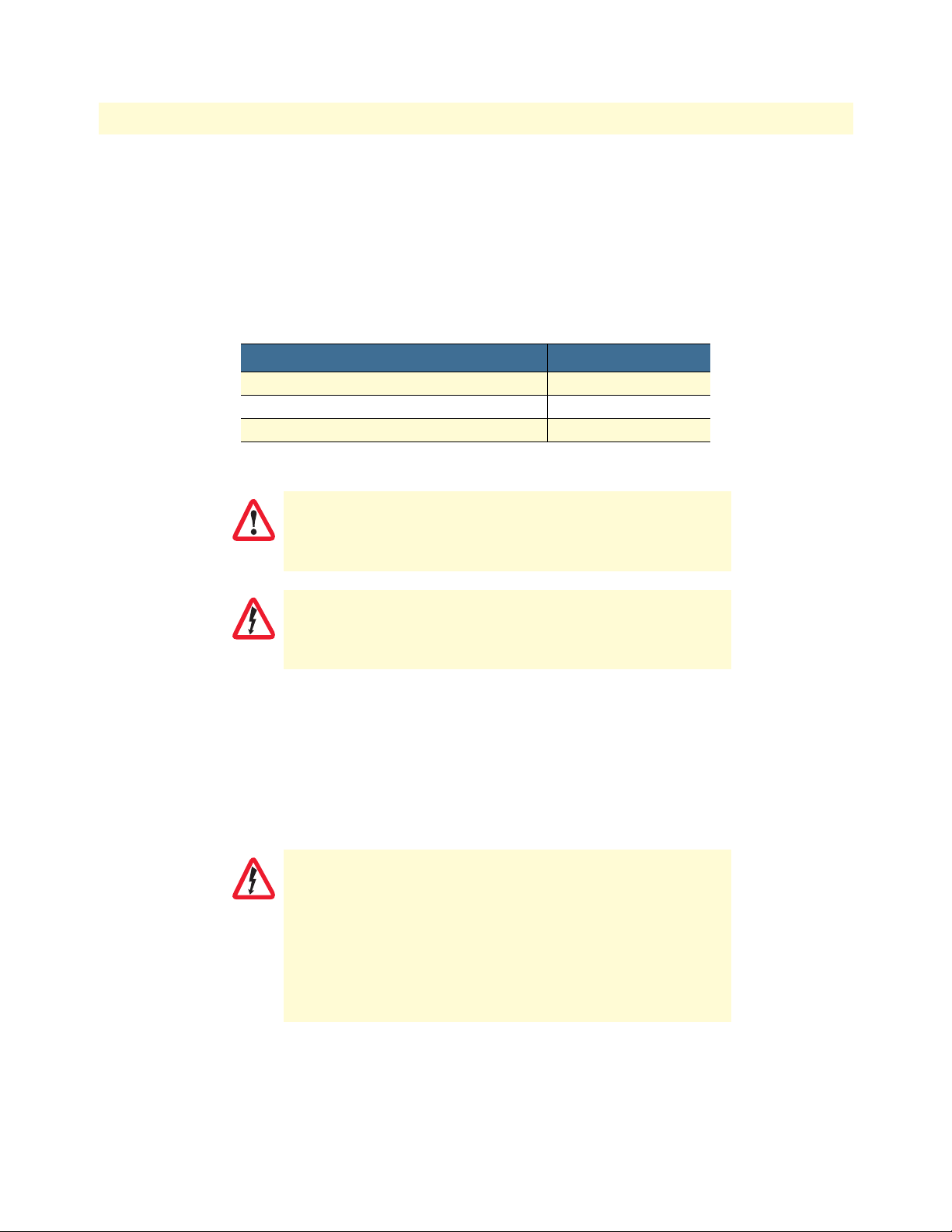

Precautions

Notes and cautions, which have the following meanings, are used throughout this guide to help you become

aware of potential problems. Warnings relate to personal injury issues, and Cautions refer to potential property

damage.

Note

WARNING

WARNING

CAUTION

Calls attention to important information.

The shock hazard symbol and WARNING heading indicate a potential electric

shock hazard. Strictly follow the warning instructions to avoid injury caused

by electric shock.

The alert symbol and WARNING heading indicate a potential safety hazard.

Strictly follow the warning instructions to avoid personal injury.

The shock hazard symbol and CAUTION heading indicate a

potential electric shock hazard. Strictly follow the instructions to

avoid property damage caused by electric shock.

The alert symbol and CAUTION heading indicate a potential hazard. Strictly follow the instructions to avoid property damage.

CAUTION

Page 11

OnSite Series Getting Started Guide

11

Typographical conventions used in this document

This section describes the typographical conventions and terms used in this guide.

General conventions

The procedures described in this manual use the following text conventions:

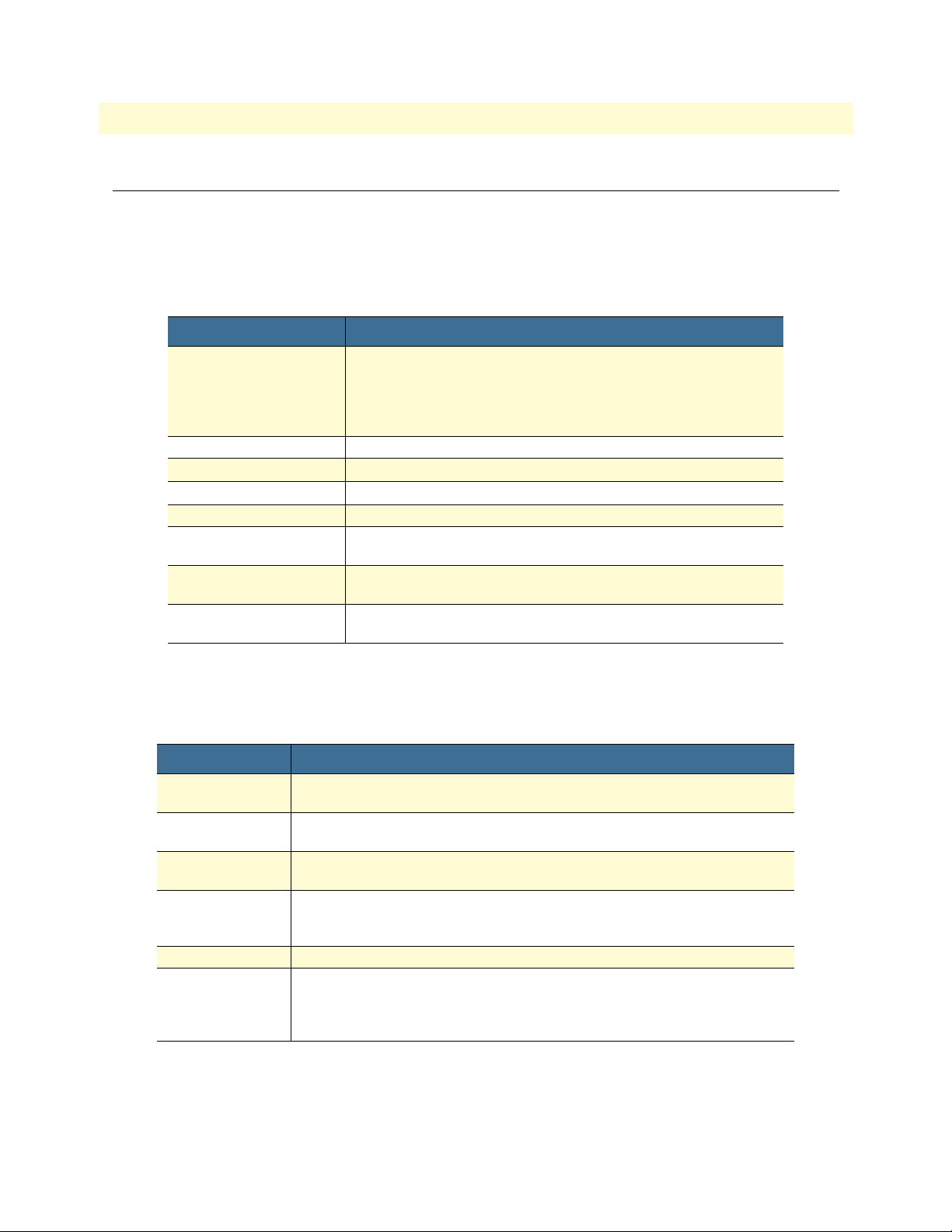

Table 1. General conventions

Convention

Garamond blue type

Futura bold type

Italicized Futura type

Futura type

Garamond bold type

< >

Are you ready?

% dir *.*

Indicates a cross-reference hyperlink that points to a figure, graphic,

table, or section heading. Clicking on the hyperlink jumps you to the reference. When you have finished reviewing the reference, click on the

Go to Previous View button in the Adobe® Acrobat® Reader tool-

bar to return to your starting point.

Indicates the names of menu bar options.

Indicates the names of options on pull-down menus.

Indicates the names of fields or windows.

Indicates the names of command buttons that execute an action.

Angle brackets indicate function and keyboard keys, such as <Shift> ,

<Ctrl> , <C> , and so on.

All system messages and prompts appear in the Courier font as the

system would display them.

Bold Courier font indicates where the operator must type a response or

command

Meaning

Mouse conventions

The following conventions are used when describing mouse actions:

Table 2. Mouse conventions

Convention Meaning

Left mouse button

Right mouse button This button refers the secondary or rightmost mouse button (unless you have

Point This word means to move the mouse in such a way that the tip of the pointing

Click Means to quickly press and release the left or right mouse button (as instructed in

Double-click Means to press and release the same mouse button two times quickly

Drag This word means to point the arrow and then hold down the left or right mouse but-

This button refers to the primary or leftmost mouse button (unless you have

changed the default configuration).

changed the default configuration).

arrow on the screen ends up resting at the desired location.

the procedure). Make sure you do not move the mouse pointer while clicking a

mouse button.

ton (as instructed in the procedure) as you move the mouse to a new location.

When you have moved the mouse pointer to the desired location, you can release

the mouse button.

Page 12

12

OnSite Series Getting Started Guide

Safety when using electricity

Read the installation instructions before connecting your OS-10 system to the

power source.

WARNING

Follow these guidelines when working on equipment powered by electricity:

• Locate the emergency power-off switch in the room in which you are working. Then, if an electrical acci-

dent occurs, you can quickly turn off the power.

• Never assume that power is disconnected from a circuit. Disconnect all power before installing or removing

a chassis or working near power supplies.

• Ground the unit. Do not connect the power supply unit to an AC outlet without a ground connection.

• Connect the unit to a grounded AC outlet to comply with the appropriate regional safety standards.

• Place the unit near the socket outlet to be easily accessible.

• Look carefully for possible hazards in your work area, such as moist floors, ungrounded power extension

cables, frayed power cords, and missing safety grounds.

• Do not work alone if hazardous conditions exist.

In addition, following these guidelines when working on any equipment that is disconnected from a power

source but still connected to telephone wiring or other network cabling:

• Never install telephone wiring during a lightning storm.

• Never touch uninsulated telephone wires or terminals unless the telephone line is disconnected at the net-

work interface.

• Use caution when installing or modifying telephone lines.

Power Cable

If your system comes with the AC power option, use an AC power cable appropriate for your country.

Check your local electrical codes and regulatory agencies for power cable requirements.

Page 13

13

OnSite Series Getting Started Guide

Electrostatic Discharge Damage

Electrostatic discharge (ESD) can damage equipment and impair electrical circuitry. It can occur if electronic

printed circuit cards are improperly handled and can cause complete or intermittent failures. Always follow

these ESD prevention procedures when removing and replacing expansion modules:

• Ensure that the system chassis is electrically connected to earth ground.

• Wear an ESD-preventive wrist strap, ensuring that it makes good skin contact. Connect the clip to an

unpainted surface of the chassis frame or to the rack to channel unwanted ESD voltages safely to ground.

To guard against ESD damage and shocks, the wrist strap and cord must operate effectively.

• If no wrist strap is available, ground yourself by touching an unpainted metal part of the chassis or rack.

To prevent equipment damage because of ESD, periodically

check the resistance value of the antistatic strap. It should be

CAUTION

between 1 and 10 M Ω (Mohm).

Optical Safety

Use fiber-optic ports only for telecommunications applications that require

optical fiber. Use the ports only with the appropriate connector. When not in

WARNING

Fiber-Optic Ports

To protect your eyes, never look at the transmit LED or laser through a magnifying device while it is powered

on. Never look directly at a fiber port on the chassis or at the ends of fiber cable when they are powered on.

Note

Fiber-Optic Safety Precautions

Follow these safety precautions when working with fiber-optic cables:

• Do not eat, drink or smoke in the work area. If fiber particles are ingested they could cause internal hemor-

rhaging.

• Wear safety glasses with side shields to avoid getting fiber-optic splinters in your eyes.

• Do not look into the end of a fiber cable until you are sure that there is no light source at the other end. Use

a fiber-optic power meter to ensure that the fiber is dark (that is, no power is being carried).

use, replace the dust covers. Using these interfaces in ways other than those

described in this guide can cause property damage or personal injury.

The OS-10 system uses a CLASS 1 laser device.

• Ensure that the work area is well ventilated.

• Do not touch your eyes while working with fiber-optic cables.

• Wear disposable aprons to minimize fiber particles on your clothing.

• Dispose of all cut fiber-optic pieces properly.

• Thoroughly clean the work area when the installation is complete.

Page 14

Chapter 1

Chapter contents

Introduction..........................................................................................................................................................15

OnSite Platforms ............................................................................................................................................15

Product Overview

14

Page 15

15

OnSite Series Getting Started Guide

1 • Product Overview

Introduction

The OnSite Series is family of ultra-compact, micro multi-service provisioning platforms (µMSPPs). The supports flexible and economic delivery of time division multiplexing (TDM) and Ethernet-based packet data services over synchronous digital hierarchy (SDH) transport networks.

The OS-10 system has two STM-1 ports for connection to the SDH network. The ports operate at 155.520

Mbit/s and can be configured to operate as dual unprotected ports or as a protected pair using Linear 1+1 MSP.

The STM-1 ports can also be configured in add-drop multiplexer (ADM) mode for operation in a ring network using SNCP path protection switching.

The OS-10 supports clear-channel mapping of E1/T1 and DS3/E3 signals into SDH payloads, and uses nextgeneration SDH features, such as generic framing procedure (GFP), virtual concatenation (VCAT), link capacitiy adjustment scheme (LCAS) and advanced packet intelligence functions for efficient transport of Ethernetbased data services.

The OS-10 has one Ethernet LAN management port and one RS-232 serial port for access to the system management functions. Remote access to OS-10 systems is possible through the use of an inband management

channel that uses either a dedicated E1 link over a VC-12 or the SDH data communications channel (DCC).

The OS-10 chassis can be mounted into a standard 19-inch EIA/TIA or a 300-mm ETSI rack. The chassis also

supports a wall-mounting option and can also be operated in a stand-alone desktop configuration.

The system uses natural convection cooling (that is, it contains no fans) and supports AC or DC power

options.

All cabling, other than AC power, is accessible from the front panel of the chassis. The system also provides

activity and status LEDs for all client-signal and SDH network interfaces. The system weighs approximately 5

kg (11 lbs) and has the following dimensions: 44.45 x 438.2 x 293 mm (height x weight x depth).

You can manage and access the OS-10 system through a simple Web-based graphical user interface (GUI)

called the OnSight Device Manager (DM) or a scalable network management system (NMS).

OnSite Platforms

The OS-10 Series has two modular platforms: the OS1052 and OS1063. Table 2 provides a summary of the

base system configuration for each platform.

Figure 1. OnSite Model 1052

Introduction

Page 16

16

OnSite Series Getting Started Guide

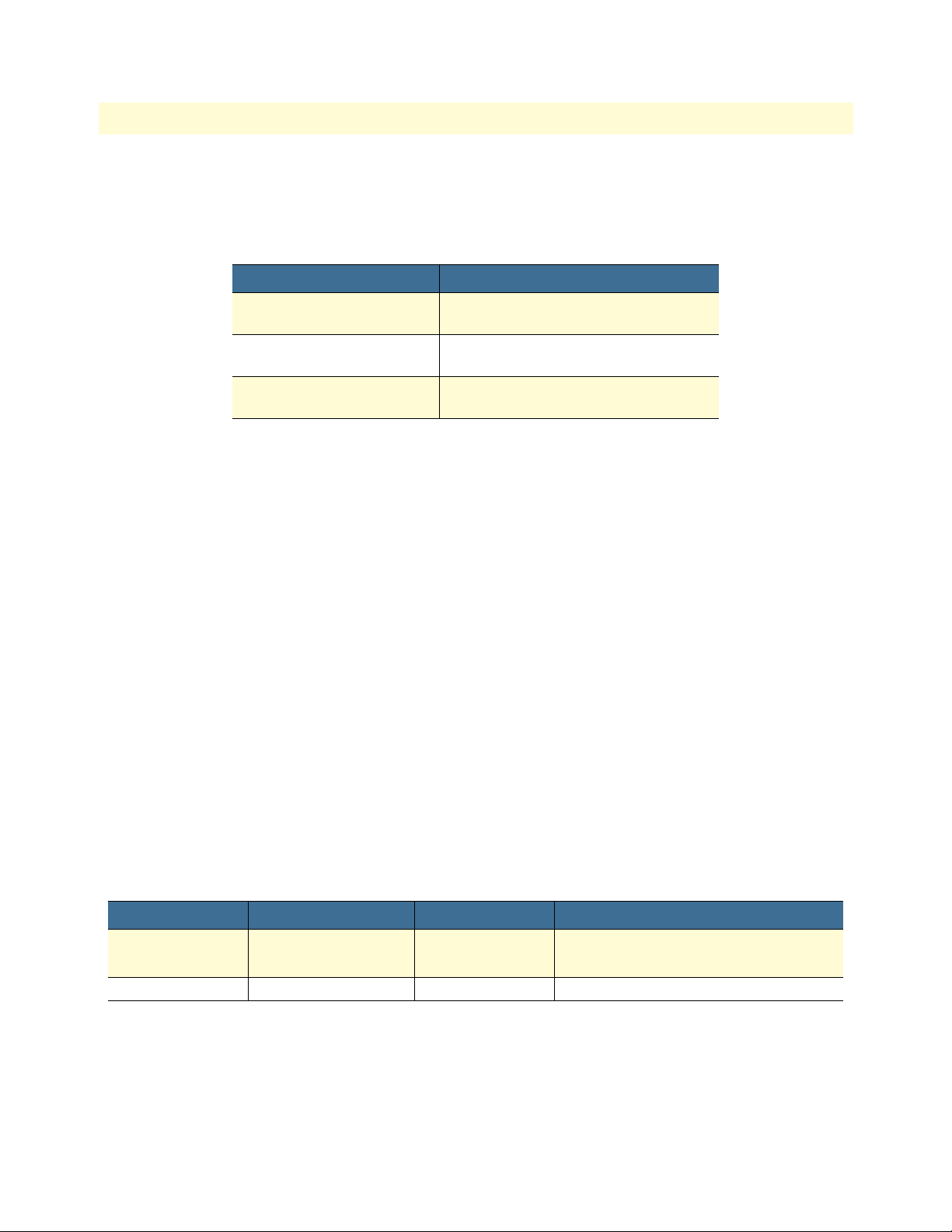

Table 3. Base System Configuration for OnSite Platforms

Type Model OS1052 Model OS1063

SDH Trunks 2 STM-1 2 STM-1

Client Signals 8 E1 or 8 T1 21 E1 or 21 T1

Management Serial RS-232 Serial RS-232

Expansion Slots 2 2

1 • Product Overview

Figure 2. OnSite Model 1063

2 Ethernet –

LAN LAN

The OS1052 and OS1063 systems have two expansion slots. The expansion slots support the insertion of the

following modules for flexible configuration changes and capacity upgrades:

• 21-port E1

• 3-port DS3/E3

• 2-port STM-1 optical and electrical

• 8-port Ethernet 10/100BASE-TX

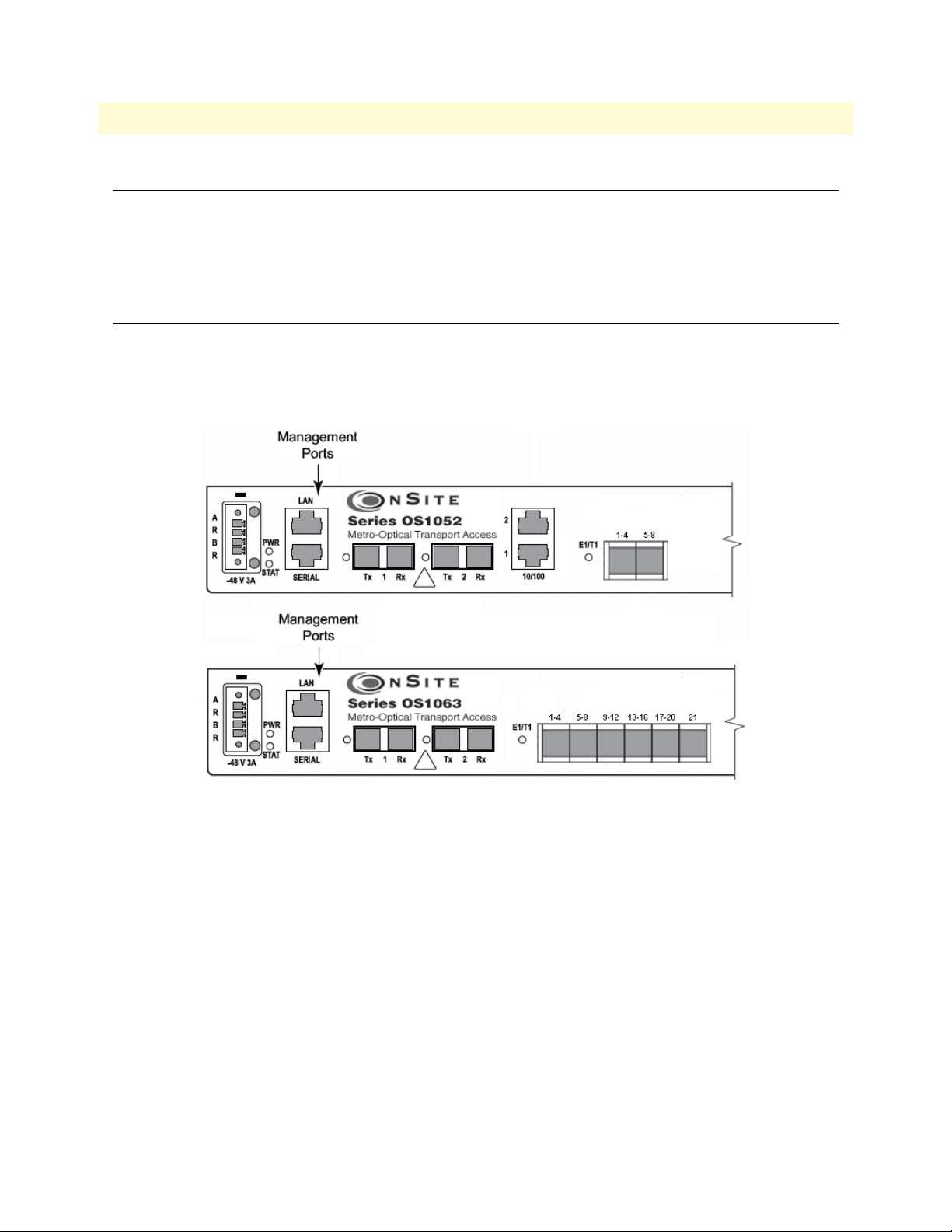

Figure 3 on page 17 shows the front and back panels of the OS1052 base system without the expansion mod-

ules installed. The OS1052 has eight built-in E1 and two built-in Ethernet 10/100BASE-TX interfaces. As a

factory-installed option, the OS1052 is also available with eight T1 ports. The OS1052 uses a future bus connector for access to the 8 E1 or T1 ports on the base system.

Introduction

Page 17

OnSite Series Getting Started Guide 1 • Product Overview

Figure 3. OS1052 Base System

Figure 2 shows the front panel of the OS1063 system. The OS1063 uses a future bus connector for access to

the 21 E1 or T1 ports on the base system. When the system is equipped with two 21-port high-density E1

(HD-E1) expansion modules, the OS1063 provides access for up to 63 E1 ports. (See chapter 12 for a description of the future bus connector and the features of the high-density E1 expansion module.) As a factoryinstalled option, the OS1063 is available with two STM-1 electrical interface (STM-1e) ports on the base system.

Figure 4. OS1063 Base System

Introduction 17

Page 18

Chapter 2 Application Overview

Chapter contents

OS1052 Application..............................................................................................................................................19

OS1063 Application..............................................................................................................................................21

18

Page 19

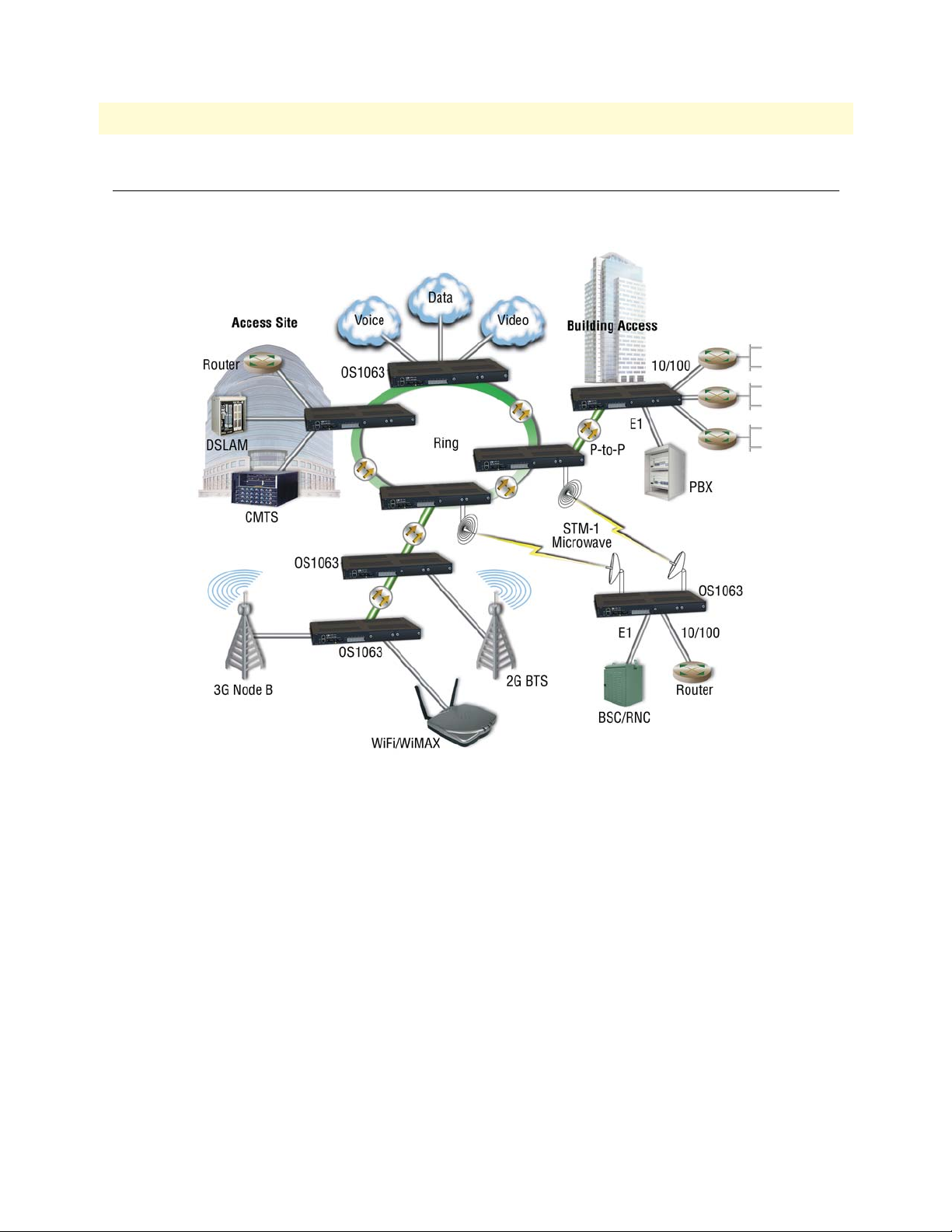

OnSite Series Getting Started Guide 2 • Application Overview

OS1052 Application

The advanced modular design of the Patton OnSite OS1052 provides unequaled flexibility in its class in terms

of service offerings, capacity and functional upgrades.

Figure 5. Typical OS1052 application

OS1052 Application 19

Page 20

OnSite Series Getting Started Guide 2 • Application Overview

The base OS1052 system is configured with:

• 2 STM-1

• 8 E1/T1

• 2 Ethernet

• 10/100Base-TX

Two expansion module slots allow increasing system capacity beyond the initial base configuration. Additional

ports and features only require simple insertion of one of the many available types of TDM and packet data

modules.

In only one RU, the OS1052 supports expansion up to:

• 50 E1 ports

• 18 Ethernet 10/100 ports

The OS1052 incorporates next-generation SDH features such as virtual concatenation (VCAT), link capacity

adjustment scheme (LCAS) and generic framing procedure (GFP) for efficient packet data transport. The platform also incorporates Layer 2 features such as VLAN tagging, rate limiting and statistical multiplexing with

multi-level QoS control. The OS1052 is easily configured and managed through a simple Web-based GUI

interface or the scalable Patton OnSight NMS.

Figure 6. OS1052 Map + Modules

OS1052 Application 20

Page 21

OnSite Series Getting Started Guide 2 • Application Overview

OS1063 Application

The advanced modular design of the Patton OnSite OS1063 provides unequaled flexibility in its class in terms

of service offerings, capacity and functional upgrades.

Figure 7. Typical OS1063 application

OS1063 Application 21

Page 22

OnSite Series Getting Started Guide 2 • Application Overview

The base OS1063 system is configured with:

• 2 STM-1

• 21 E1/T1

Two expansion module slots allow increasing system capacity beyond the initial base configuration. Additional

ports and features only require simple insertion of one of the many available types of TDM and packet data

modules.

In only one RU, the OS1063 supports expansion up to:

• 63 E1 ports

• 16 Ethernet 10/100 ports

The OS1063 incorporates next-generation SDH features such as virtual concatenation (VCAT), link capacity

adjustment scheme (LCAS) and generic framing procedure (GFP) for efficient packet data transport. The platform also incorporates Layer 2 features such as VLAN tagging, rate limiting and statistical multiplexing with

multi-level QoS control. The OS1063 is easily configured and managed through a simple Web-based GUI

interface or the scalable Patton OnSight NMS.

Figure 8. OS1063 Map + Modules

OS1063 Application 22

Page 23

Chapter 3 Installation Overview

Chapter contents

Introduction..........................................................................................................................................................24

Unpacking and Inspection.....................................................................................................................................24

Site Preparation .....................................................................................................................................................24

Site Environment ..................................................................................................................................................25

Planning Your Site.................................................................................................................................................25

Site Requirements ...........................................................................................................................................25

Operating Environment Requirements ......................................................................................................26

Power Supply Requirements ......................................................................................................................27

Distribution Rack Requirements ...............................................................................................................27

Mechanical Recommendations for the Rack ....................................................................................................28

Protective Grounding for the Rack and Chassis ..............................................................................................28

Space Requirements for the Rack ....................................................................................................................28

Securing the Rack ...........................................................................................................................................28

Tools and Equipment for Installation and Maintenance........................................................................................29

OnSite System Installation ....................................................................................................................................29

Mounting the Chassis to an EIA/TIA 19-Inch Rack .......................................................................................29

Mounting the Chassis to an ETSI Rack ..........................................................................................................30

Mounting the Chassis on the Wall ..................................................................................................................32

Installing the Chassis Ground Connection ......................................................................................................33

Connecting Power to the OS-10 System .........................................................................................................33

Connecting AC Power to the OS-10 System .............................................................................................34

Powering On the OS-10 System with AC Power ......................................................................................35

Connecting DC Power to the OS-10 System ............................................................................................35

Wiring Procedure for DC Input Power .....................................................................................................35

Checking the OS-10 System Installation .........................................................................................................38

23

Page 24

OnSite Series Getting Started Guide 3 • Installation Overview

Introduction

This chapter provides the procedures for installing the OnSite OS-10 system.

Unpacking and Inspection

Do not unpack the OS-10 system until you are ready to install it. If the final installation site will not be ready

for some time, keep the chassis in its shipping container to prevent accidental damage. When you are ready to

install the unit, proceed with unpacking it.

Note Do not discard the shipping cartons when you unpack the OS-10 sys-

tem. Flatten and store them. You will need the containers if you need

to move or ship the system. Repacking instructions will be provided

in your return material authorization (RMA) paperwork.

To check the contents of the shipping cartons, follow these steps:

1. Check the contents of the shipping container and accessories box or bag against the content list and the

packing slip which were included with your unit.

2. Verify that you received all listed equipment, including the following:

– OS-10 Series documentation (if ordered)

– Optional equipment that you ordered, such as network interface cables, or special connectors

3. Inspect all items for shipping damage.

Note If anything appears to be damaged or you encounter problems install-

ing or configuring your OS-10 Series chassis, contact customer service.

4. Check the expansion modules that may be located in each slot. Ensure that the configuration matches the

packing list and that all specified interfaces are included.

Site Preparation

This section describes the requirements your site must meet for safe installation and operation of your OnSite

OS-10 Series equipment. Ensure that the site is properly prepared before beginning installation.

The requirements described in this chapter are intended for the personnel responsible for installing and managing the network hardware. A working knowledge of telecommunications and local area network (LAN)

operations and a familiarity with communications protocols that are used on interconnected networks are

assumed. Installation, maintenance, and removal of a chassis, or its components must be done by qualified service personnel only. Qualified personnel have had appropriate technical training and experience that is necessary to be aware of the hazards to which they are exposed when performing a task and of measures to minimize

the danger to themselves and other people. By carefully planning your site, you can maximize the performance

of your existing network and ensure that it is ready to migrate to future service and capacity upgrades.

Introduction 24

Page 25

OnSite Series Getting Started Guide 3 • Installation Overview

Site Environment

The OS-10 system can be mounted in a rack or on a wall. The location of the chassis and layout of your equipment rack or wiring room are extremely important for proper system operation. Equipment that is too close

together, ventilation that is inadequate, and panels that are inaccessible can make system maintenance difficult

or cause system malfunctions and possible shutdowns.

The following precautions help you plan an acceptable operating environment for your OS-10 system and

avoid environmentally caused equipment failures:

• Ensure that the room in which you operate your system has adequate air circulation. Electrical equipment

generates heat. Ambient air temperature might not be able to cool equipment to acceptable operating temperatures without adequate circulation.

• Always follow the proper ESD-prevention procedures described in §3.2 (Electrostatic Discharge Damage)

to avoid damage to equipment. Damage from static discharge can cause immediate or intermittent equipment failure.

• Ensure that the chassis cover and all expansion slot covers are secure. The chassis is designed to allow cool-

ing air to flow effectively inside it. An open chassis allows air leaks, which might interrupt the flow of cooling air from internal components.

When planning your site layout and equipment location, remember the following precautions to help avoid

equipment failures and reduce the possibility of environmentally caused equipment problems.

Maximum recommended operating temperature – The maximum recommended operating temperature for

the OS-10 is 50°C (122°F). Determine a suitable operating environment based on this recommendation.

Elevated operating ambient temperature – If the unit is installed in a closed or multiunit rack assembly, the

operating temperature of the rack environment may be greater than the ambient temperature of the room.

Keep this in mind when you install the unit.

Reduced airflow – Install the OS-10 system chassis in the rack so that the amount of airflow required for safe

operation of the equipment is not compromised.

Mechanical load – Mount the OS-10 system chassis in the rack to avoid a potentially hazardous condition due

to uneven mechanical loading.

Circuit overload – When you connect the OS-10 system chassis to the supply circuit, consider the effect that

overloading of the circuits might have on over-current protection and supply wiring.

Reliable Ground – Maintain reliable grounding for the OS-10 system and all rack-mounted equipment, giving

particular attention to supply circuits.

Planning Your Site

Site Requirements

To install your OS-10 equipment successfully, you should plan your site carefully. The site planning process

has three major areas for consideration to ensure that your physical installation meets the requirements for a

safe and successful installation:

• Environmental, safety, and thermal requirements for the OS-10 system

• Power and local building and electrical code requirements

Site Environment 25

Page 26

OnSite Series Getting Started Guide 3 • Installation Overview

• Distribution rack requirements

The following sections provide further details for each area.

Operating Environment Requirements

You need to verify that your site meets all environmental and safety requirements. During the early planning

stages of installing or modifying your network, it is important that you develop a thorough understanding of

the regulations that pertain to your location and industry.

Temperature – The OS-10 system generates a specified amount of heat as indicated on the data sheet. It is

essential that you provide a temperature-controlled environment for both proper performance and safety.

Install the equipment only in a temperature- and humidity-controlled indoor area that is free of airborne materials that can conduct electricity.

The following are some general thermal recommendations for your wiring closet or equipment room:

• Ensure that the ventilation in the area is adequate to maintain a temperature below 50°C (122°F).

• Install a reliable air conditioning and ventilation system.

• Keep the ventilation in the wiring closet running during nonbusiness hours; otherwise, the equipment can

overheat.

• Maintain the following ambient operating temperature: 0° to 50° C (32° to 122°F)

• Maintain the following storage temperature: –40° to 70°C (–40° to 158°F)

Airflow requirements – To ensure proper airflow through the OS-10 equipment, follow these recommendations when you are installing your chassis:

• Leave 7.62 cm (3 inches) of minimum clearance on both the left and right sides of the chassis.

• Leave a half-rack unit (RU) of minimum clearance above and below the chassis for properairflow.

Note The OS-10 is a convection-cooled system, and adherence to these

clearance requirements is required for proper operation of the system.

Humidity – Keep the operating humidity between 5 and 95 percent relative humidity (noncondensing).

Table 4 summarizes the acceptable operational conditions for the OS-10 system.

Table 4. Environmental Conditions for Operating the OS-10 System

Environment Minimum Maximum

Temperature Ambient operating 5°C +40°C

Short-term (96 hours) 0°C +50°C

Humidity Short-term (96 hours) 5% 80%

Short-term (96 hours) 5% 95%

Altitude Ambient operating –60 m 1800 m

Planning Your Site 26

Page 27

OnSite Series Getting Started Guide 3 • Installation Overview

Power Supply Requirements

To operate your OS-10 equipment safely, follow these requirements:

• Ensure that your power supply meets the site power requirements of the equipment to be installed.

• Check the power at your site to ensure that you are receiving “clean” power (free of spikes and noise). Install

a power conditioner, if necessary.

• Ensure that DC connections are made by an on-site electrician.

• When connecting power to installed equipment, avoid connecting through an extension cord or apower

strip.

Table 5 summarizes the power requirements for the OS-10 system chassis.

Table 5. Power Requirements for the OS-10 System

Power Source

AC 110 or 220 VAC 1.0 A at 50 to 60 Hz 100 to 245 VAC

DC –48 VDC 2.0 A –36 to –72 VDC

Note If you system is shipped with the AC power option, use an AC power

Nominal Input

Voltage

Nominal Input

Current

cable appropriate for your country. Check your local electrical codes

and regulatory agencies for power cable requirements.

Note The system uses a universal AC power supply with an autoselection

function for operation with either 110 V (60 Hz) or 220 V (50 Hz).

Distribution Rack Requirements

The OS-10 can be installed in either a 19-inch EIA/TIA or ETSI 300-mm rack.

Note The 19-inch EIA/TIA rack should comply with the specification in

EIA-310-D.

Note The ETSI 300-mm rack should comply with the specification in

ETSI EN 300 119-3 V2.1.0 (2004-05).

Tolerance Limits

Planning Your Site 27

Page 28

OnSite Series Getting Started Guide 3 • Installation Overview

Mechanical Recommendations for the Rack

The following information will help you plan your equipment rack configuration:

• Use a rack made of steel or aluminum.

• Install equipment in the lower half of the rack first to avoid making the rack top heavy.

• The rack should be able to support the full weight of the final installed chassis.

• Enclosed racks must have adequate ventilation. Ensure that the rack is not overly congested because each

unit generates heat. An enclosed rack should have louvered sides and a fan to provide cooling air.

• When mounting a chassis in an open rack, ensure that the rack frame does not block the cooling holes. If

the chassis is installed on slides, check the position of the chassis when it is seated all the way into the rack.

• In an enclosed rack with a ventilation fan in the top, excessive heat generated by equipment near the bot-

tom of the rack can be drawn upward and into the intake ports of the equipment above it in the rack. In

addition, ensure that you provide adequate ventilation for equipment at the bottom of the rack.

• Baffles can help isolate exhaust air from intake air, which also helps draw cooling air through the chassis.

The best placement of the baffles depends on the airflow patterns in the rack, which can be found by experimenting with different arrangements.

Protective Grounding for the Rack and Chassis

Use a rack grounding kit and a ground conductor that is carried back to earth or another suitable building

ground. The OS-10 chassis is designed with mounting brackets that provide solid metal-to-metal connection

to the rack. If you do not use equipment racks, you can attach a wiring terminal directly to the chassis at the

position indicated for appropriate grounding. Figure 9 shows the location of the grounding terminal location

for the OS-10 chassis.

Figure 9. Grounding Terminal Location for the OS-10 System Chassis

Note

Because building codes vary worldwide, OnSite Systems strongly recommends that you consult an electrical contractor to ensure that

proper equipment grounding is in place for your specific installation.

Space Requirements for the Rack

Provide enough space in front of and behind the OS-10 system chassis so that you can service it easily. Typically, allow a minimum of 122 cm (48 inches) in front of the rack and 61 cm (24 inches) behind the rack.

Securing the Rack

The rack should be attached to the equipment room floor with 9.5-mm (3/8-inch) lag screws or equivalent

hardware. The floor under the rack should be level within 5 mm (3/16 inch). Use a floor-leveling cement compound if necessary or bolt the racks to the floor.

Planning Your Site 28

Page 29

OnSite Series Getting Started Guide 3 • Installation Overview

Tools and Equipment for Installation and Maintenance

You need the following tools and equipment to install or upgrade the OS-10 system and its components:

• ESD-preventive cord and wrist strap (when working with modular components or expansion cards)

• Number 1 or number 2 Phillips screwdriver

• Mounting brackets (provided); two are required for rack mounting or for wall mounting

• 8 screws (provided) to secure the L mounting brackets to the OS-10 system chassis (four screws for each

bracket)

• A minimum of four 12-24 x 3/4-inch screws (not provided) to secure the OS-10 system chassis to the rack

• Suitable screws and wall anchors to install an OS-10 system on a wall

• Cable ties, if required, for organizing cables

In addition, depending on the type of modules you plan to use, you might need the following equipment to

connect the OS-10 system to an external network:

• Cables for connection to the fiber-optic and client signal ports (depending on configuration)

• Ethernet hub or PC with a network interface card for connection to Ethernet LAN ports

• Console terminal (an ASCII terminal or a PC running terminal emulation software) configured for 9,600

baud, 8 data bits, no parity, and 1 stop bit

OnSite System Installation

Note Read the information in this section thoroughly and completely

before you attempt to install or remove an OS-10 Series system chassis.

Only trained and qualified personnel should be allowed to install, replace, or

service this equipment.

WARNING

Mounting the Chassis to an EIA/TIA 19-Inch Rack

To install the OS-10 system chassis in an EIA/TIA 19-inch rack, see Figure 10 and follow these steps:

1. Install the two L mounting brackets in the orientation shown in Figure 10. Insert and fully tighten the

screws to secure the brackets to the chassis (four screws for each bracket).

Note For this rack configuration, the L mounting bracket holes are flush

with the front panel of the OS-10 system, as shown in Figure 4.

2. Position the chassis in the rack and align the mounting holes in the L bracket with the mounting holes in

the equipment rack.

Note The mounting-hole pitch for the 19-inch rack has the following

repetitive pattern: 5/8”- 5/8”-1/2”.

Tools and Equipment for Installation and Maintenance 29

Page 30

OnSite Series Getting Started Guide 3 • Installation Overview

Note Take care to load the rack so that it is not top heavy.

Note Do not cover vents that would restrict airflow. Leave a minimum of a

half-rack space above and below the OS-10 system for adequate ventilation.

3. Secure the chassis using four 12-24 x 3/4-inch screws (two screws for each side) through the elongated

holes in the L bracket nearest to the chassis and to the threaded holes in the mounting post. Use a suitable

screwdriver for this task.

4. Tighten any loose captive installation screws on the expansion slot front panel covers.

Figure 10. Mounting the OS-10 System Chassis in an EIA/TIA 19-Inch Rack

Mounting the Chassis to an ETSI Rack

To install the OS-10 system chassis in an ETSI 300-mm rack, see Figure 11 and follow these steps:

1. Install the two L mounting brackets in the orientation shown in Figure 11. Insert and fully tighten the

screws to secure the brackets to the chassis (four screws for each bracket). Use a suitable screwdriver for this

task.

Note For this rack configuration, the L mounting bracket holes are posi-

tioned 50 mm back from the front panel of the OS-10 system, as

shown in Figure 11.

2. Position the chassis in the rack and align the mounting holes in the L bracket with the mounting holes in

the equipment rack.

Note The mounting-hole pitch for the ETSI 300 mm rack is 25 mm.

Note Take care to load the rack so that it is not top heavy.

OnSite System Installation 30

Page 31

OnSite Series Getting Started Guide 3 • Installation Overview

Note Do not cover vents that would restrict airflow. Leave a minimum of a

half-rack space above and below the OS-10 system for adequate ventilation.

3. Secure the chassis using four 12-24 x 3/4-inch screws (two screws for each side) through the elongated

holes in the L bracket nearest to the chassis and to the threaded holes in the mounting post. Use a suitable

screwdriver for this task.

4. Tighten any loose captive installation screws on the expansion slot front panel covers.

Figure 11. Mounting the OS-10 System in an ETSI 300-mm Rack

OnSite System Installation 31

Page 32

OnSite Series Getting Started Guide 3 • Installation Overview

Mounting the Chassis on the Wall

Note When choosing a wall-mounting location, consider the cable limita-

tions and the wall structure. Use the four L brackets provided for rack

mounting to mount the chassis on a wall. The brackets provide the

most stable installation for the chassis.

1. Install the two L mounting brackets in the orientation shown in Figure 12. Insert and fully tighten the

screws to secure the brackets to the chassis (four screws for each bracket). Use a suitable screwdriver for this

task.

Note For this rack configuration, the L mounting bracket holes are flush

with the bottom panel of the OS-10 system chassis.

2. Position the chassis against the wall using wall mount option 1 or option 2, as shown in Figure 12.

3. Secure the chassis to the wall using four 12-24 x 3/4-inch screws (two screws for each side) through the

elongated holes in the L bracket nearest to the chassis. Use a suitable screwdriver for this task.

4. Tighten any loose captive installation screws on the expansion slot front panel covers.

Figure 12. Mounting the OS-10 System Chassis on a Wall

OnSite System Installation 32

Page 33

OnSite Series Getting Started Guide 3 • Installation Overview

Installing the Chassis Ground Connection

The OS-10 system chassis requires a reliable earth ground connection. You must connect the chassis to a reliable earth ground. The ground wire must be installed in accordance with local electrical safety standards.

Table 6. Ground Wire Specifications

Grounding Standard Wire

EN/IEC 60950 AWG 18 (1 mm2) or larger wire and an

appropriate user-supplied ring terminal

NEBS AWG 6 (13 mm2) wire and the ground

lug provided in the accessory kit

NEC (National Electric Code) AWG 14 (2 mm2) or larger wire and an

appropriate user-supplied ring terminal

To connect the OS-10 system chassis to a reliable earth ground, follow these steps:

1. Strip one end of the ground wire to the length required for the ground lug or terminal.

Note For the NEBS ground lug, the length is approximately 0.75 inches

(20 mm)

Note For a user-provided ring terminal—as required

2. Crimp the ground wire to the ground lug or ring terminal, using a crimp tool of the appropriate size.

3. Attach the ground lug or ring terminal to the chassis grounding terminal location shown in Figure 3.

4. Connect the other end of the ground wire to a suitable grounding point at your site.

After installation and proper grounding of the OS-10 chassis, you can connect the following:

• Power wiring

• Cables for the fiber-optic interface and Category 5 cables for E1 and Ethernet client signal interfaces

• Category 5 cables for the Ethernet LAN and SERIAL management ports

Connecting Power to the OS-10 System

The system supports AC and DC power options, as listed in Table 7. These options are factory installed.

Table 7. OS-10 Power Options

Power Options Nominal Input Tolerance Limit Feature

AC 110 VAC at 50 Hz and

220 VAC at 60 Hz

DC –48VDC –36 to –72 VAC Auto-switching AC to DC power converter

100 to 245 VAC Auto-switching AC to DC power converter

Note Both AC and DC options provide short-circuit and over-voltage pro-

tection.

Note The DC option provides reverse input polarity protection.

OnSite System Installation 33

Page 34

OnSite Series Getting Started Guide 3 • Installation Overview

Note The DC-to-DC converter has dual power inputs (A and B power).

The system continues to operate normally if either the A or B power

input fails.

The system uses natural convection for heat dissipation (that is, it does not use fans). The absence of fans

increases system reliability and eliminates periodic maintenance visits for fan filter replacement.Table 8 pro-

vides the maximum power consumption figures for the OS-10 system under normal operating conditions.

Table 8. Power Consumption

System Configuration Maximum Power (W)

Base system 40

Base system with a single expansion module 50

Base system with dual expansion modules 60

This section explains how to connect the AC or DC power to the OS-10 system chassis.

Read the installation instructions before connecting the system to the power

source.

WARNING

Do not work on the system or connect or disconnect cables during periods of

lightning activity.

WARNING

The installation must comply with all required electrical codes applicable at the installation site.

Connecting AC Power to the OS-10 System

If your OS-10 system uses AC power, connect it to a 15 A at 120 VAC (or 10 A at 240 VAC) circuit with overcurrent protection.

Note The input voltage tolerance limits for AC power are 100 to 245 VAC.

•AC-connected units must have a permanent ground connection in addition to

the power cable ground wire. NEBS-compliant grounding satisfies this

WARNING

requirement.

•This product relies on the installation of the building for short-circuit (overcurrent) protection. Ensure that the protective device is rated not greater

than: 15A at 120 VAC (or 10 A at 240 VAC).

•The AC power supply for the OS-10 system has Double Pole/Neutral Fusing.

OnSite System Installation 34

Page 35

OnSite Series Getting Started Guide 3 • Installation Overview

Powering On the OS-10 System with AC Power

To power on the OS-10 system using AC power, follow these steps:

1. Connect the AC power cable to the OS-10 system and then to the wall outlet.

2. Turn the power switch on the back panel of the OS-10 system to the ON position.

Note The green PWR (power) LED on the front panel is lit when the sys-

tem receives power from the AC source.

After turning off the AC power switch, wait for at least 3 seconds

before turning it back to the on position.

CAUTION

Connecting DC Power to the OS-10 System

If your OS-10 system has a DC-input power supply terminal block on the front panel, follow the directions in

this section for proper wiring.

This product relies on the installation of the building for short-circuit (overcurrent) protection. Ensure that the protective device is rated not greater than

WARNING

15 A at 60 VDC.

Table 9 summarizes the wiring requirements for the OS-10 system chassis with a DC-input power supply.

Note For installations compliant with the National Electric Code, an AWG

14 (2.0 mm2) wire is required for DC input and safety ground wire.

Table 9. DC Wiring Requirements for the OS-10 System Chassis

DC Nominal Input DC Input Wire Size

–48 VDC at 2.0 A

Note The input voltage tolerance limits for nominal –48 VDC power sup-

AWG 18 (1.0 mm2) AWG 14 (2.0 mm2)

Safety Ground

Wire Size

Over-Current Protection

15 A

plies is –36 to –72 VDC.

Wiring Procedure for DC Input Power

To connect DC power to the OS-10 system, see Figure 13 and follow these steps:

•Connect the DC input wires to the OS-10 system with the following wiring

sequence.

Figure 13 shows the terminal block for the DC power supply on the OS-10

WARNING

•

system. Wire the DC power supply as shown.

OnSite System Installation 35

Page 36

OnSite Series Getting Started Guide 3 • Installation Overview

Figure 13. Wiring the OS-10 System for DC Power

1. Choose an available circuit from a DC power source and identify both the positive and negative leads for

this circuit.

Note The DC power source may be a DC circuit breaker or an AC-to-DC

power rectifier.

•Do not touch the circuit with your hands or with any other instrument until

you make sure that there is no power present on the circuit.

WARNING

•Make sure that power is removed from the DC circuit that will supply power

to the OS-10 system before performing any of the following procedures.

2. Remove power from this circuit.

Note To ensure that power is removed from the DC circuit, locate the cir-

cuit breaker for the DC circuit, switch the circuit breaker to the OFF

position, and tape the circuit-breaker switch in the OFF position.

3. Strip the DC input wires that will connect the circuit to the DC power terminal block on the OS-10 system to the appropriate length.

4. Connect the positive lead of this circuit to ground. See wiring 1-A in Figure 13.

Note As an option, you may choose another common grounding point

other than the one shown in Figure 13. The choice depends on the

grounding practice for your particular location. Figure 13 shows the

grounding point colocated with the DC circuit for “A” power.

OnSite System Installation 36

Page 37

OnSite Series Getting Started Guide 3 • Installation Overview

The ground wire should always be connected first and disconnected last.

CAUTION

5. Connect the positive lead of the circuit to the return direction for “A” power on the OS-10 system terminal block. See wiring 2-A in Figure 7.

Note The terminal block indicates the return direction for “A” power by

the letter R. This lead is second from the top on the OS-10 system

terminal block.

Note Step 4 and Step 5 results in the grounding of the return direction for

“A” power on the OS-10 system terminal block.

6. Connect the negative lead of the circuit to the “A” power input lead on the OS-10 system terminal block.

See wiring 3-A on figure 13 on page 36.

Note The terminal block indicates the “A” power lead by the letter A. This

lead is first from the top on the OS-10 system terminal block.

Continue with the following steps if a second circuit is available for the provision of redundant “A” and

“B” DC power inputs on the system. Otherwise, go directly to Step 10 to complete this task.

7. Connect the positive lead of this circuit to ground. See wiring 1-B on figure 13 on page 36.

Note As an option, you may choose another common grounding point

other than the oneshown in Figure 13. The choice depends on the

grounding practice for your particular location. Figure 13 shows the

grounding point colocated with the DC circuit for “B” power.

The ground wire should always be connected first and disconnected last.

CAUTION

8. Connect the positive lead of the circuit to the return direction for “B” power on the OS-10 Series system

terminal block. See wiring 2-B on Figure 13.

Note The terminal block indicates the return direction for “B” power by

the letter R. This lead is fourth from the top on the OS-10 system

terminal block.

Note Step 7 and Step 8 result in the grounding of the return direction for

“B” power on the OS-10 system terminal block.