Patterson Fan Manual

Operating, Installation & Parts Manual (OIPM)

Patterson Fan Company, Inc

Blythewood, SC 29016

www.pattersonfan.com

800.768.3985

Contents Page

Assembly Instructions 3- 10

Maintenance Instructions 12-14

Trouble Shooting 15

Patterson Fan Company, Inc

Blythewood, SC 29016

www.pattersonfan.com

800.768.3985

YM Yoke Mount Assembly Instructions

Note: There are many acceptable methods

for hanging a Patterson Yoke Mount fan. The

most important things to remember are that

the yoke must be securely connected to a

solid structure and that all materials used to

hang the yoke and fan must be rated for this

type of rigging and workload. Below is what

we consider to be the simplest method of fan

suspension. Feel free to improvise, but please

use caution and good judgment.

1. Secure the “U” Shaped Yoke to the

object from which you intend to mount

the fan. Use a 5/8” bolt, a 5/8” nut and

(2) 5/8” washers. Tighten the nut onto the

bolt using a 5/16” bolt end wrench and

ratchet with 5/16” socket.

2. The factory assembled fan head ts

inside of the “U” shaped yoke, the

threaded studs on each side of the fan

t through the predrilled holes on the “U”

shaped yoke. Secure the factory assembled fan head to the “U” shaped yoke

with the supplied nuts. Mount the factory

assembled fan head so that the motor

capacitor is in up position.

3. If safety cable installation is desired (rec-

ommended), use a length of chain or

cable to secure the fan to a solid surface

and attach to the fan. Make sure cable

or chain is rated for the weight and purpose of securing the fan.

Patterson Fan Company, Inc

Blythewood, SC 29016

www.pattersonfan.com

800.768.3985

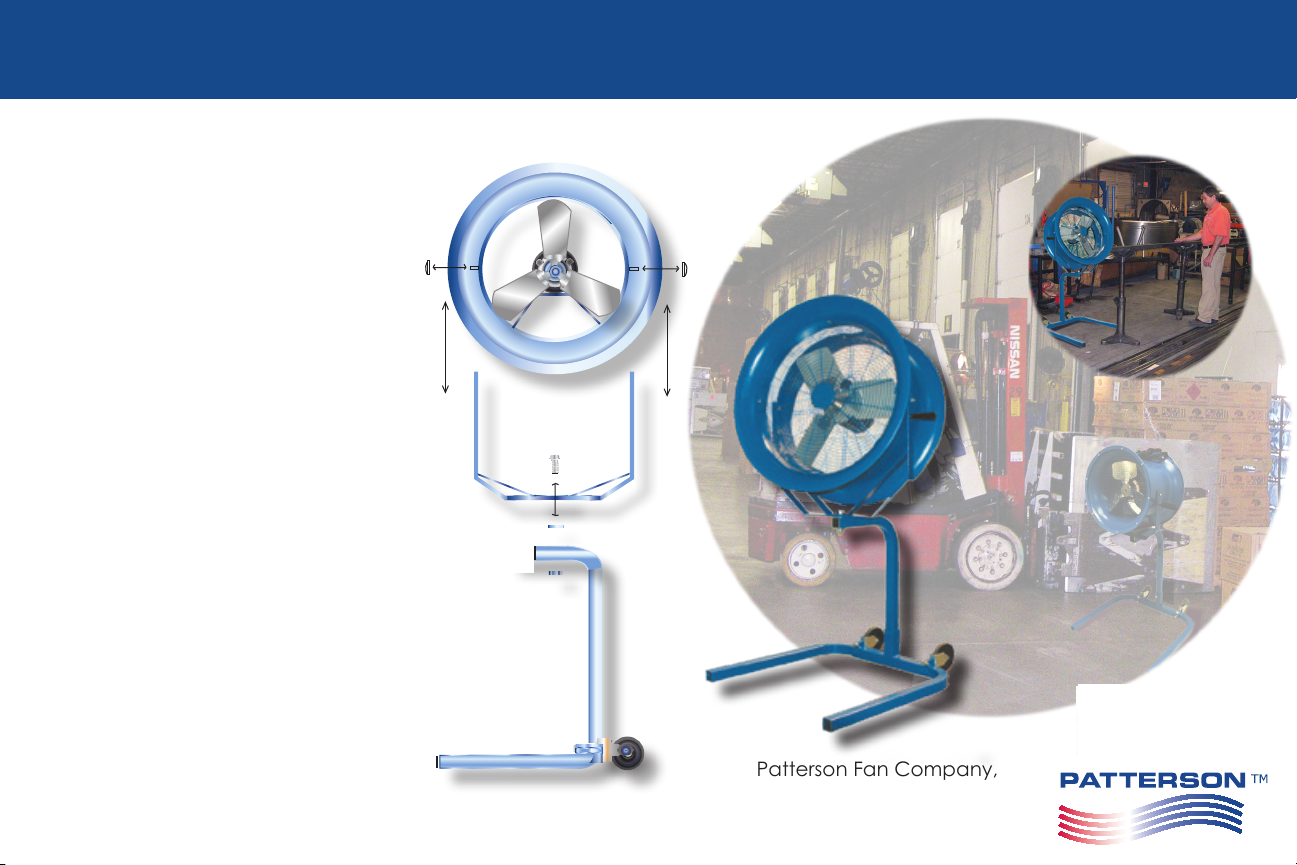

PS Portable Stroller Mount Assembly Instructions

Note: There are many applications for the

Patterson Portable Stroller Fan. Use care

when selecting locations for the fan. Do not

place the fan on a sloped surface. Do not

use if the nger guards are missing or are

damaged or not tting properly. Do not use

if the cord or connector has exposed wires

or is damaged in any way.

1. Place the portable base on a at

surface.

2. Secure the “U” shaped yoke to the

portable base by inserting the 5/8” bolt

through the center hole in the yoke

and through the hole in the pedestal

base arm. Place the 5/8” nut on the

5/8” bolt and tighten securely.

3. Carefully mount the factory assembled

fan with mounting studs through the

holes in the uprights of the “U” shaped

yoke with the motor capacitor is in up

position. Secure the fan to the yoke

with the factory supplied nuts.

Note: Due to continual product improvement,

items are subject to change without notice.

Patterson Fan Company, Inc

Blythewood, SC 29016

www.pattersonfan.com

800.768.3985

PB Portable Base Mount Assembly Instructions 34” Fan Only

Note: There are many applications for the Patterson

Portable Base 34” fan. Use care when selecting locations for the fan. Do not place the fan on a sloped

surface. Do not use if the nger guards are missing

or damaged or not tted properly. Do not use if the

cord or connector has exposed wires or is damaged

in any way.

1. If you ordered the 6ALG2, fan head and the

6ALG9, portable base together on the same pu

chase order they will be shipped assembled

together from the factory.

2. If you ordered these separately begin mounting

the fan head to the probable base by rst

securing the separate PB telescoping upright

arms to the fan head stud bolt on either side of

the fan housing leaving them loose for free

swinging.

3. After attaching the upright arms to the fan head

(loosely) using a fork lift to pickup the fan head

maneuver the fan head directly over the

portable base and slowly lower until the upright

telescoping arms slip into the xed uprights of the

portable base.

4. Inserted arm should measure 33-34” total height

from oor keeping fan level between the two

uprights some tapping with block of wood and

hammer may be necessary.

5. Tighten nuts on stud bolts connecting the upright

arms to the fan head housing.

Note: Due to continual product improvement,

items are subject to change without notice.

Patterson Fan Company, Inc

Blythewood, SC 29016

www.pattersonfan.com

800.768.3985

TC Truck Cooler Assembly Instructions

Note: Important things to remember are that

the wall mount should be a solid structure

able to support the weight of the fan safely

and that the fan should not be at a height

that will cause employees to bump their

heads. Ideally, the fan should be mounted

to blow into the back of the truck down the

top corner of either side of the trailer.

1. Secure the wall bracket and arm to the solid

surface where you will hang the fan. A structurally secure solid wall or beam is best.

2. Secure the “U” shaped yoke to the arm of the

wall bracket. Use the 5/8” bolt and 5/8” nut

supplied. Tighten the nut onto teh bolt using

a 5/16” box end wrench and ratchet with a

5/16” socket. For clearance reasons, the “U”

shaped yoke must open down.

3. The fan head ts inside the “U” shaped yoke,

the threaded studs on each siide of the fan

ts through the predrilled holes on the “U”

shaped yoke. Secure the fan head to the “U”

shaped yoke with the supplied nuts. Mount

the fan head so that the motor capacitor is

in up position.

Note: Due to continual product improvement,

items are subject to change without notice.

Patterson Fan Company, Inc

Blythewood, SC 29016

www.pattersonfan.com

800.768.3985

CW Column Wall Mount Assembly Instructions

Note: The most important thing to remember is that if

the fan is at a level near people, it should be equipped

with OSHA approved Patterson nger guards. Please

contact your factory sales representative to order.

1. Secure Part A of the wall bracket to the solid

surface from which you will hang the fan. There

is a single mounting hole on the short end of the

part. Secure part A using a wall anchor, etc.

(Wall anchor not included.) Place a level on the

part.

2. Position part B under part A as shown and

situate part B in such a way so that part A

becomes level. Mark part B for the hole. Attach

part B using the appropriate wall anchor, (not

included).

3. Secure the “U” shaped yoke to the wall bracket

using the supplied 5/8” bolt and nut. If you plan

to add an oscillator, mount the yoke so that it

opens up. The bolt must go through all three

pieces. Check for level and stability.

4. The factory assembled fan head ts inside of the

“U” shaped yoke. Secure the fan head to the

yoke with the supplied nuts. Mount the fan head

so the motor capacitor is in up position.

Note: Due to continual product improvement,

items are subject to change without notice.

Patterson Fan Company, Inc

Blythewood, SC 29016

www.pattersonfan.com

800.768.3985

CW Column Wall Mount Assembly Instructions 34” Only

Note: The 6ALG2 fan head is equipped with OSHA

compliant nger guards. Mount the fan at desired

height making sure the fan is not in the headway of

personnel preferably out of reach. These fans are powerful and should not be mounted too close to personnel at work stations.

1. See yoke mount instruction for yoke to fan

assembly.

2. Assemble the column wall bracket as follows.

Secure Part A (horizontal bottom strut) to the

solid surface from which you will hang the fan

either a wall or column using appropriate wall

anchor (not included). This Part A has a wall

mount bracket with a 4 hole pattern for mounting

to surface.

3. Secure Part B to the wall allowing the bolt hole

to lineup where the fan yoke will be bolted to the

column wall bracket. The fan head and yoke are

suspended below the column wall bracket

allowing full 360° rotation left and right.

4. Secure the “U” shaped yoke to the end of the

column wall bracket where Part A and Part B

converge using the bolt supplied. The yoke

allows a 30+- degree tilt toward the oor for

directing air throw as desired.

5. Safety cable is mandatory. Use a length of

chain of cable to secure the fan to a solid

surface and attach the fan. Make sure cable

or chain is rated for the weight and purpose.

Patterson Fan Company, Inc

Blythewood, SC 29016

www.pattersonfan.com

800.768.3985

HV Ceiling Suspended Assembly Instructions

90°

X

2 X

1. Facing outlet of fan, drill 2- 5/16” diameter holes (1/2” for 34” fan) one at 10 and one at 2:00 position in front ange. Facing the inlet side of

fan, drill 1- 5/16” diameter hole (1/2” for 24” fans) at the 6:00 position in rear ange. Holes should be drilled just behind the bead of the fan

housing.

2. Attach two eyebolts to holes in top front of fan. Attach third eyebolt to back rear hole in fan.

3. By means of a mechanical lift (cherry picker, scissor lift, etc.) get the factory assembled fan head to the point where you plan to suspend it.

You will need three lengths of chain, three connectors, hardware for chains and bolt cutters.

4. Secure two lengths of chain to the beam or girder number 1 about two times the distance apart that the fan will hang down (see diagram).

The third length of chain should be centered between the two front lengths of chain and attached to beam number 2. Attach the chains to

the beams using your preferred method.

5. Connect the lengths of chain to the eyebolts on the factory assembled fan head using the chain connectors.

6. Rough focus the fan on your target while on the mechanical lift.

7. Get a co-worker to stand at the target mark. Make sure the power is turned off. Have someone plug the fan in.

Let the fan run for approximately 30 seconds (to get up to speed and settle itself down). With someone on

the oor, someone at the fan, and someone at the power, focus the fan. DO NOT ATTEMPT TO ADJUST THE

FAN WHILE IT IS RUNNING!

8. Remove excess chain with bolt cutters.

30°

Note: Due to continual product improvement,

items are subject to change without notice.

Yoke Yoke Mount Assembly Instructions 34” Only

Note: There are many acceptable methods for hanging a Patterson Yoke Mount 34 fan. The most important

things to remember are that the yoke must be securely

connected to a solid structure and that all materials use

to hang the yoke and fan must be rated for this type of

rigging and workload. Below is what we consider to be

the simplest method of fan suspension. Feel free to improvise, but please use caution and good judgment.

1. Assemble the yoke connecting side A with Side B to

the stud bolts of the fan housing. The factory

assembled fan head ts inside the “U” shapped yoke,

the threaded studs on each side of the fan t through

the predrilled holes on the “U” shaped yoke. Secure

the fan head to the yoke with the supplied nuts.

2. Assemble side A and side B of the yoke and connect

with supplied bolt.

3. Safety cable is mandatory. Use a length of chain of

cable to secure the fan to a solid surface and attach

the fan. Make sure cable or chain is rated for the

weight and purpose.

Note: Due to continual product improvement, items are

subject to change without notice.

Patterson Fan Company, Inc

Blythewood, SC 29016

www.pattersonfan.com

800.768.3985

End of Assembly Instructions

Please read carefully before assemble, install, operate or maintain any Patterson Fan Product.

Protect yourself and others by observing all safety information. Failure to comply with assmebly instructions, national electric codes and OSHA codes, could result in personal injury and/or

property damage. Retain instructions for future reference.

Please read carefully before assemble, install, operate or maintain any Patterson Fan

Product. Protect yourself and others by observing all safety information. Failure to

Caution

comply with instructions could result in personal injury and/or property damage. Retain

instructions for future reference.

Disconnect power source before installing or servicing. Failure to

disconnect power source can result in re, shock or serious injury.

1. Patterson products should be installed and serviced by qualied technicians only.

2. Follow all local electrical and safety codes, as well as the National Electric Code (NEC) and the Occupational Safety and Health Act

(OSHA) in the United States.

3. The unit should be installed, protected and fused in accordance with latest issue of the National Electrical Code, MEMA Standard

Publication No. MG2 and local codes.

4. Motor must be securely and adequately grounded. This can be accomplished by wiring with a ground, metal-clad raceway system,

using a separate ground wire connected to the bare metal of the motor frame, or other suitable means.

5. Always disconnect power source before working on or near a motor or its connected load. Lock open position and tag to prevent

unexpected application of power.

6. In accordance with OSHA requirements. Guarding is required if unit is mounted less than 7 feet above oor or where workers have access.

7. Keep hands and clothing away from moving parts.

8. Be careful when touching the exterior of an operating motor; it may be hot enough to cause injury. This condition is normal if operated

at a rated load and voltage and built to operate at higher temperatures.

9. Protect power cable from coming into contact with sharp objects.

10. Do not tangle power cable and never allow cable to come in contact with oil, grease, hot surfaces or chemicals.

11. Make certain that the power source conrms to requirements of your equipment.

Single Phase Motors

The factory assembled fan head is equipped with a 12 foot long cord and connector. To turn on fan, plut it in; to turn off fan, unplug it.

Three Phase Motors

A cord and connector is not supplied with three phase motors. These fans

will need to be tted with an appropriate cord and connector or hard wired directly to a power source. It the fan is supplied with nger

guards, the rear nger guard will need to be partially removed to access the motors internal wiring. Remove all but one of the self-tap-

ping screws and place them in a safe place. You will use them again. Rotate the guards around on the single self-tapping screw. Wire

the fan. Replace the guard using the saved self tapping screws.

When looking at the front of the fan, the blade should be turning clockwise. It it does not, eth electrical connection wires may need to

be reversed. If reversing the wires does not work, contact your factory representative.

Maintenance & Operating Instructions

All Patterson Fans are designed to be virtually maintenance free, but routine cleaning and inspection should be

performed on a regular basis. Clean the fan of all dust, dirt and grease. Regular cleaning will keep the fan

operating safely at optimal performance levels.

Oh an annual basis, we recommend that you inspect the following:

• Tightness of the blade

• Cracking of the blade around rivets, spider, and hub

• Integrity of motor mounts and welds

• Tightness of the safety ner/hand guards

• Tightness of bolts of mounting brackets

• Security of attachment to wall or other structureal member

• Security of the safety chain

If you nd any problems as a result of routine inspection or have any questions about assemly or operating

instructions, consult the trouble shooting guide in the OIPM manual or call factory sales representative at

800-768-3985.

For all parts contact Patterson Fan Company, Inc. direct at 800-768-3985.

Patterson Fan Company, Inc

www.pattersonfan.com

Blythewood, SC 29016

800.768.3985

Trouble Shooting Instructions

Warning: Electrical shock hazard, serious injury or death may occur, disconnect from electrical supply before

servicing these products.

Fan system: The head consist of four major parts: Housing, Guards, Motor and Blade. See trouble shooting array.

PROBLEM CHECK SOLUTION

Fan won’t run and makes no sound.

Fan motor won’t run and makes

humming sound.

Breaker trips or fuse blows when fan

is started.

Motor overheating and shutting off.

Restarting several minutes later.

Power cord, extension cord, circuit breaker.

Connections in motor junction box.

Connections on motor capacitor.

Connections in motor junction box.

Conrm free rotation of the blade.

Connections on motor capacitor.

Connections on motor capacitor.

Blade rotation.

Motor voltage connections match power

source voltage.

Inspect motor barrel for damage.

Extension cord too small.

Inlet air obstructed.

Motor voltage connections match power

source voltage.

Reconnect power, extension cord or reset

breaker.

Verify connections, match motor data plate.

Reattach any loose connections.

Verify connection with motor data plate.

Shift blade on motor shaft.

Reattach any loose connections.

Replace motor.

Reattach any loose connections.

Shift blade on motor shaft.

Check source voltage.

Replace motor.

Replace with heavier cord.

Provide additional inlet clearance.

Check source voltage.

Replace motor.

Please contact your Patterson Sales Representative for further questions. 800-768-3985

Loading...

Loading...