Patterson WWP30E-5-10-208-G-L/R Operation Manual

DOC #

A0000466 / A0000467 Rev1

Patterson Company

870 Riversea Road

Pittsburgh, PA 15233

Phone: 800-322-2018

FAX: 412-322-2785

OPERATIONS/PARTS MANUAL

FOR

PATTERSON'S

WWP30E-5-10-208-G-L/R

ELECTRIC WINCH.

Please fi ll in the following blanks and then keep this manual in a safe and convenient location. When calling with either questions or replacement part needs, always refer to the Winch

Model, Part Number and Serial Number.

WINCH PART #: A0000466/A0000467 WINCH SERIAL #: _____________

MOTOR MFG.: _____________________ MOTOR SERIAL #: __________________

BRAKE SERIAL #: _________________ DATE PURCHASED: ________________

DISTRIBUTOR INFORMATION

NAME: _________________________________________________________________

ADDRESS: ______________________________________________________________

CITY: _____________________________ STATE: ___________ ZIP: ____________

PHONE: ___________________________ FAX: _____________________________

IMPORTANT!

Prior to installing and operating the winch, please read this manual thoroughly

and carefully. Keep this manual and all other instructions accessible at all times.

Although this manual will help you become familiarized with the operating procedures for the winch, it is by no means a substitute for proper training and the

safe use of winches, barge rigging and other marine equipment. Because owners and operators are solely responsible for determining whether a particular

usage is acceptable, only individuals trained in the proper use of winches, barge

rigging and other marine equipment should operate winches.

The typical operational environment of winches includes very high forces, and

the potential hazards associated with these forces should not be underestimated.

Improper installation or misuse of the winch may result in injury to persons or

cause equipment failure or damage.

ALWAYS OBSERVE THESE BASIC SAFETY PRE-

CAUTIONS:

• To reduce potential of electrical shock or other injury, turn off and lock out or tag

out power source before initiating any maintenance or repairs.

• Keep all fi ngers, loose clothing and any foreign objects away from winch while in

operation.

• During operation of the winch, always remain to the side of the winch, slightly behind the gear motor.

• Never operate the winch from the front or when bystanders are in front of it.

• Operators and bystanders should stay clear of any load and the wire rope while the

winch is operating.

• Under no circumstances, should any winch be used to move, raise or lower a

person(s) or equipment.

• Do not operate the winch unless you have a fi rm stance on a non-slippery surface.

• Do not apply tension to the winch unless there are at least four complete wraps of

rope on the drum.

• Inspect the winch carefully at least once a month for worn gears and pawls, cracked

welds, and other damaged parts. If any worn, cracked or damaged parts are found,

stop use immediately and remove the winch from service until all appropriate repairs

are completely made.

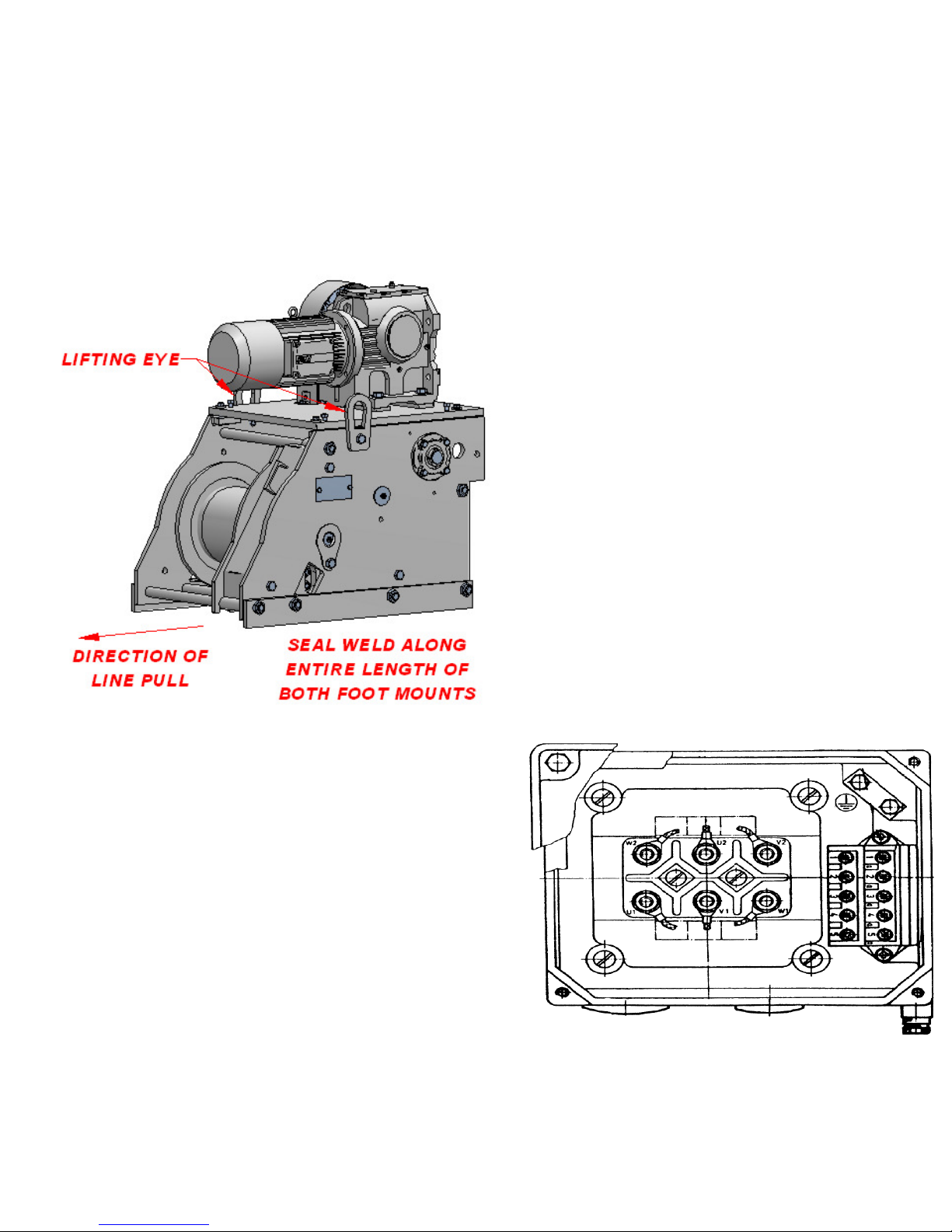

1. INSTALLATION

WINCHES SHOULD ONLY BE LIFTED BY THE

LIFTING EYES ON EACH SIDE OF THE WINCH.

NEVER LIFT THE WINCH BY THE GEARMOTOR

OR DAMAGE WILL OCCUR !

WARNING! ONLY A QUALIFIED ELECTRICIAN SHOULD

WIRE CONTROL BOX AND REMOTE STATION OF A

WINCH. W. W. PATTERSON COMPANY IS NOT LIABLE

FOR DAMAGE CAUSED BY UNAUTHORIZED OR UNQUALIFIED PERSONNEL ATTEMPING TO CONNECT

A WINCH TO A POWER SOURCE.

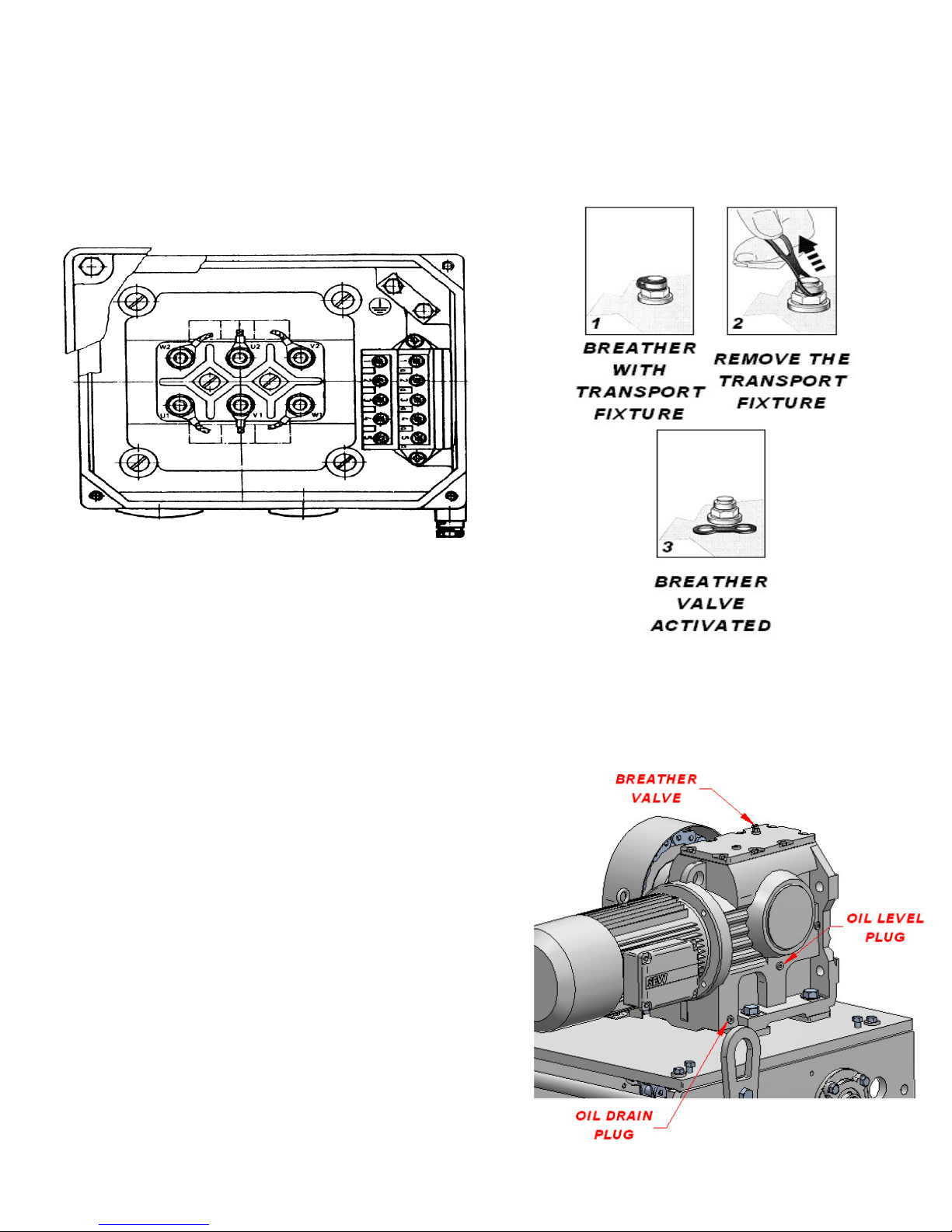

1.4. All winches have been factory wired to the voltage

specifi ed at the time of original purchase. All winches have

been factory tested prior to shipment to insure proper

operation. Assuming the control box and remote station

have been properly installed and wired, no further wiring

is required except to connect the winch to the control box.

1.5. Open the conduit box located on the motor. The

conduit box has been confi gured to the voltage specifi ed

at the time of original purchase.

1.1. All winches must be installed on fl at, rigid and non-

slippery surfaces. Deck and structure must be strong

enough to withstand the weight and holding capacity of

the winch, and the forces likely to occur during operation.

1.2. Place the winch in the mounting area, in line with the

direction of cable pull. Check to make sure there is enough

clearance and Fleet Angle Distance for proper operation.

(Refer to Diagram on Page 8.)

WARNING! EACH WINCH HAS BEEN FACTORY WIRED

TO THE VOLTAGE SPECIFIED AT THE TIME OF ORIGINAL PURCHASE.

1.3. Weld to deck along the complete length of both foot

mounts. Use seal welding to protect the weld against corrosion. Remember, the weld has to be strong enough to

withstand loads equal to, at least, the Ultimate Shock Load

Capacity of the winch.

3

1. INSTALLATION (Cont'd.)

4

1. INSTALLATION (Cont'd.)

1.6. Connect each of the three wires from the control box

to one of the three usable groups of wires in the conduit

box. Please review the label inside the conduit box for the

specifi c wiring schematic. Properly close the cover on the

conduit box.

WARNING! FAILURE TO REMOVEL THE BREATHER

VALVE TRANSPORT FIXTURE MAY RESULT IN DAMAGE

TO THE GEARBOX.

WARNING! ONLY A QUALIFIED ELECTRICIAN SHOULD

PERFORM THIS WIRING. CAUTION MUST BE TAKEN

TO CAREFULLY READ AND UNDERSTAND THE WIRING SCHEMATIC FOUND ON THE INSIDE OF THE

COVER OF THE CONDUIT BOX.

1.7. Disengage the locking dog. Depressing either the

IN or OUT button on either the control box or the remote

station, test to make sure the winch drum turns in the appropriate direction; the rope must reel in from the bot-

tom of the winch drum. Should the winch drum turn in

the opposite direction than desired, open the conduit box

and disconnect two of the wires leading from the control

box. Reverse the position of those two wires in respect to

their original position. Reconnect each of the two wires to

each of the bundle of wires from the winch motor. Close

the conduit box. The winch drum should now turn in the

proper direction.

WARNING! TO REDUCE POTENTIAL OF ELECTRICAL

SHOCK OR OTHER INJURY, TURN OFF AND LOCK OUT

OR TAG OUT POWER SOURCE BEFORE INITIATING

ANY MAINTENANCE OR REPAIRS.

1.8. Coat all gear teeth with heavy-duty gear grease and

lubricate both sprockets and the roller chain.

1.9.Remove the Breather Valve Transport Fixture Shipping Plug

and discard properly. The gearbox must be checked to insure

the gearbox is fi lled to the proper level with oil. When touching

up paint on winches, DO NOT paint over the Breather Valve.

5

Loading...

Loading...