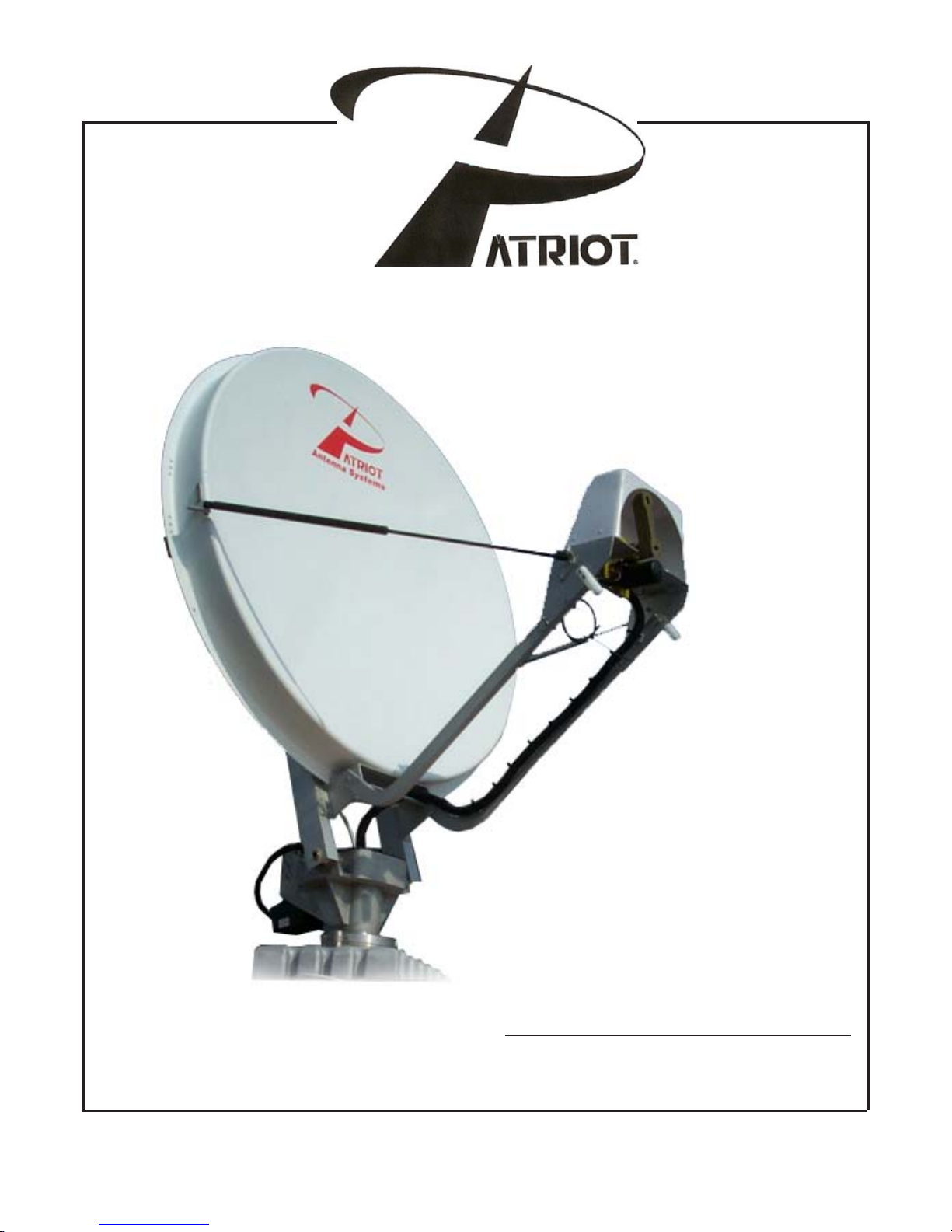

Patriot 1.2M MVSAT Installation & Assembly Instructions Manual

INSTALLATION &

ASSEMBLY INSTRUCTIONS

1.2M MVSAT Antenna

ANTENNA SYSTEMS

2

This PATRIOT ANTENNA equipment is warranted to be free from defects in material and workmanship under

normal use and service. PATRIOT ANTENNA shall repair or replace defective equipment, at no charge, or at its

option, refund the purchase price, if the equipment is returned to PATRIOT ANTENNA not more than twelve (12)

months after shipment. Removal or reinstallation of equipment and its transportation shall not be at cost of PATRIOT ANTENNA except PATRIOT ANTENNA shall return repaired or replaced equipment freight prepaid.

This Warranty shall not apply to equipment which has been repaired or altered in any way so as to affect its

stability or durability, or which has been subject to misuse, negligence or accident. This Warranty does not cover

equipment which has been impaired by severe weather conditions such as excessive wind, ice, storms, lightning,

or other natural occurrences over which PATRIOT ANTENNA has no control, and this Warranty shall not apply to

equipment which has been operated or installed other than in accordance with the instructions furnished by

PATRIOT ANTENNA.

Claimants under this Warranty shall present their claims along with the defective equipment to PATRIOT ANTENNA

immediately upon failure. Non-compliance with any part of this claim procedure may invalidate this warranty in

whole or in part.

THIS WARRANTY IS EXPRESSLY IN LIEU OF ALL OTHER AGREEMENTS AND WARRANTIES, ANY IMPLIED

WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE IS LIMITED IN DURATION

TO THE DURATION OF THIS WARRANTY. PATRIOT ANTENNA DOES NOT AUTHORIZE ANY PERSON TO

ASSUME FOR IT THE OBLIGATIONS CONTAINED IN THIS WARRANTY AND PATRIOT ANTENNA NEITHER

ASSUMES NOR AUTHORIZES ANY REPRESENTATIVE OR OTHER PERSON TO ASSUME FOR IT ANY

OTHER LIABILITY IN CONNECTION WITH THE EQUIPMENT DELIVERED OR PROVIDED.

IN NO EVENT SHALL PATRIOT ANTENNA BE LIABLE FOR ANY LOSS OF PROFITS, LOSS OF USE, INTERRUPTION OF BUSINESS, OR INDIRECT, SPECIAL OR CONSEQUENTIAL DAMAGES OF ANY KIND.

In no event shall PATRIOT ANTENNA be liable for damages in an amount greater than the purchase price of the

equipment.

Some states do not allow limitations on how long an implied warranty lasts, or allow the exclusion or limitation of

incidental or consequential damages, so the above limitations or exclusions may not apply to you.

PATRIOT ANTENNA has the right to void the warranty when the antenna is installed by someone other then a

certified installer.

LIMITED TWELVE (12) MONTH WARRANTY

Patriot Antenna Systems

704 North Clark Street

Albion, MI 49224 USA

Tel: (517)629-5990

Fax: (517)629-6690

E-mail: info@sepatriot.com

Product Serial Number- _________________

Date Purchased- ____________

3

TABLE OF CONTENTS

SECTION 1- Overview

1.1 Technical Description

SECTION 2- Installation and Set-Up

2.1 General

2.2 Installation to Vehicle

2.3 Controller Installation

2.4 Controller/Positioner Verification Tests

2.5 Elevation Stow Switch Setting

2.6 Final Calibration of System

SECTION 3- Azimuth Positioning System

3.1 Azimuth Bearing

3.2 Azimuth Gear Box

3.3 Azimuth Motor

3.4 Azimuth Roto-Lok Cable Drive

3.5 Azimuth Position Feedback

3.6 Azimuth Stow and Limit Switches

SECTION 4- Elevation Positioning System

4.1 Elevation Pivot Assembly

4.2 Elevation Linear Actuator

4.3 Elevation Position Feedback

4.4 Elevation Stow and Limit Switches

SECTION 5- Feed and Polarization System

5.1 General

5.2 Feed

5.3 Polarization Drive

5.4 Polarization Position Potentiometer

5.5 Polarization Limits

5.6 Feed Assembly

SECTION 6- Annual Inspection and Maintenance

6.1 General Maintenance

6.2 Annual Inspection List

6.3 Replacement Parts List

SECTION 7- Interface Drawing

SECTION 8- Specifications

4

4

5

5

5

6

6

6

7

7

7

7

8

8

9

9

10

10

10

11

11

11

11

11

11

12

12

12

13

13

13

13

14

15

4

1.1 TECHNICAL DESCRIPTION

The 1.2M VSAT Antenna System is an elevation over azimuth positioner featuring the simple, rugged Roto-Lok

drive system for the azimuth which produces very low backlash, high stiffness and high reliability and driven by a

low backlash, gear box with a DC motor. The elevation system features a highly reliable linear actuator to control

elevation. All drive components are high strength steel, housed in lubricated for life housings which results in the

most reliable, no maintenance system with the minimum of weight. The reflector is a offset, prime focus, aluminum

illuminated by a corrugated horn. The RF power amplifier may be installed on the feed boom, or inside the truck. A

Handcrank across AZ axis is included allowing easy antenna positioning if the controller malfunction and elevation

actuator my be driven with a battery charger or other 12 volt system. The basic 2-port antenna system weighs

only 150 pounds.

RF SYSTEMS

The offset reflector/feed system produces co-polarization patterns that easily meet the 29-25 log theta requirement.

The .8 f/d optics reduces off axis cross-pol in the asymmetrical plane. The RF power amplifier may be installed on

the feed boom, or inside the truck. Waveguide that run to power amp across each axis can be via twist-flex or

rotary joints. The system can be configured for either 2-port or 4-port

The patented Roto-Lok drive system utilizes highly reliable aircraft control cables in a redundant configuration to

achieve a zero backlash, light weight, very stiff drive system. It achieves this high tech performance using low

tech components by simply wrapping the cable around the driver capstan several times before wrapping the larger

driven drum. The method used to wrap the capstan results a minimum free length of cable. The load in the cable

on the main drum is exponentially reduced as it is wrapped around the drum. Therefore the total elongation of the

cable when under load is minimized. The Roto-Lok system results in stiffness of up to 10 times that of comparable

gear or harmonic drive systems. The cables are pretensioned and spring loaded at the main drum attachment

point which eliminates backlash at installation and from any unexpected cable stretch in the future.

ROTO-LOK DRIVE SYSTEM

The Az Roto-Lok drive system is driven by a low backlash worm gear set with a 40:1 ratio. The factory low back

lash of the worm gear set is reduced further by the Roto-Lok drive ratio resulting in a lash equivalent to only .06 dB

as seen by the RF system. The gear sets are housed in a sealed housing which allows the gear set to be

continuously lubricated in synthetic oil which maximizes gear efficiency and minimizes wear.

SECONDARY DRIVE SYSTEM

Light weight, reliable, servo quality DC motor with integral gear box is used for the Az drive. This motor was

selected because it provides the best torque to weight ratio as well as allowing dual speed operation for slewing

and peaking. These motors produce constant torque over the speed range with no cogging at low speeds which

ensures smooth operation when peaking the antenna. The 24V DC design provides current limiting torque control

and will allow vehicle battery operation if necessary. A linear actuator is used in the elevation drive, a low cost

alternative to a typical roto-lok system. This system offers dependable and continuous constant torque over the full

travel motion of the elevation axis.

MOTOR DRIVES

SECTION 1- OVERVIEW

5

The system will interface with a jog controller which allows remote control of the system. Each axis position is

displayed as well as limit indications. The unit will also interface with a full function controller with features such as

automatic stow, GPS/flux-gate input and automatic satellite pointing and tracking.

CONTROLS

Except for the drive components and bearings, the AZ/EL base plate, AZ/EL casting, feedboom and backing

structure and covers will be all aluminum. The fabrication of parts and assembly will be of world wide quality

standards.

CONSTRUCTION

SECTION 2- INSTALLATION AND SET-UP

The 1.2M VSAT positioner has been fully tested with the controller prior to shipment. All position feedback, limit

sensing, limit switches (except elevation stow) and motor speeds have been calibrated or set. The positioner

should be secured to the vehicle, connecting wave guide or boom mounted HPA cables, connecting coax,

connecting control cables to controller and connecting auxiliary control cable to wave guide switch if applicable.

The vehicle roof should be reinforced with a substructure capable of carrying the wind loads as specified on the

interface drawing to the vehicle frame. The structure should be stiff enough to prevent no more than a 0.5 dB of TX

gain loss in a 30mph gusting to 45mph wind. (850 IN/LB moment @ .25º)

A 3-inch diameter hole should be in the mounting surface. The mounting surface must be flat within .005 inch to

prevent binding the azimuth bearing after torquing the mounting bolts. No obstruction should be above the interface

surface in a 17-inch diameter envelope. Any other roof-mounted equipment such as air conditioners should be

more than 64 inches from center of interface bolt pattern. A hard flat surface is required for the feed bumpers as

shown on the interface drawing.

2.1 GENERAL

Remove the top of the shipping crate. Remove the narrow end at the azimuth

platform end of the crate. Connect controller cable to controller and raise the

antenna in elevation until the backing structure is vertical. (See attached figure.)

2.2 INSTALLATION TO VEHICLE

Adjust the forks on the forklift to just straddle the pallet . Place cardboard

pieces between the pallet and the forks.

Carefully raise positioner out of the crate watching control cables. Safety strap

positioner to forklift truck. Maneuver over to rear of truck. Raise positioner to

clear vehicle roof by about two feet. Lower control cables into center of mounting

hole and place riser tubes in place and install the screws (provided) into holes in

pallet. Use these as guides to position pallet directly over bolt pattern. Note:

Positioner must be installed with azimuth cable termination housing

aligned on centerline of vehicle.

Remove and replace set screws with mounting bolts provided. APPLY

LOCKTITE 242 OR EQUIVALENT TO BOLTS.

TORQUE ALL BOLTS TO 9-10 FT. LBS.

Loading...

Loading...