4

Contents

Operation Manual

Inverter rectifiers PATON VDI 160E | VDI-200E | VDI 250E

- 1 - PATON VDI SERIES ECO DC MMA

TABLE OF CONTENTS

1.

GENERAL INFORMATION ...........................................................................

4

1.1

TECHNICAL CHARACTERISTICS ..............................................................

5

1.2

CONTROLS AND CONNECTORS ................................................................

6

2.

SETTING THE WELDING UNIT INTO OPERATION .................................

7

2.1

PROPER USE ...................................................................................................

7

2.2

REQUIREMENTS FOR INSTALLATION .....................................................

7

2.3

CONNECTION TO A POWER SUPPLY SYSTEM .......................................

8

2.4

REQUIREMENTS FOR AN ELECTRICAL OUTLET ..................................

8

3.

MANUAL COVERED-ELECTRODE ARC WELDING PROCESS (MMA)

8

3.1.

INCREASED – CURRENT ARC STARTING "HOT-START"......................

9

3.2.

REDUCED – WELDING VOLTAGE FUNCTION "ARC-FORCE" .............

9

3.3

PROTECTION AGAINST ELECTRODE STICKING ANTI-STICK ............

10

4.

MAINTENANCE .............................................................................................

10

5.

OPERATION WITH AN ELECTRIC GENERATOR ....................................

11

6.

STORAGE ........................................................................................................

11

7.

TRANSPORTATION .......................................................................................

11

8.

SPECIFICATION DATA .................................................................................

11

9.

DELIVERY SET ..............................................................................................

12

10.

TROUBLESHOOTING ....................................................................................

12

11.

SAFETY INSTRUCTIONS ..............................................................................

13

12.

ELECTRICAL SCHEMATIC DIAGRAM OF THE VDI-MINI UNIT ..........

16

13.

WARRANTY ...................................................................................................

17

14.

INFORMATION CONCERNING DISPOSAL OF EQUIPMENT .................

18

15.

ACCEPTANCE CERTIFICATE ......................................................................

18

PATON VDI SERIES ECO DC MMA - 2 -

EC Declaration of Conformity

Authorised representative:

MASTERWELD Sp. z o.o., Poland

T. Boya-Żeleńskiego 25,

PL35105 Rzeszów

Ust.ID. PL8133751525

Manufacturer Address

Limited Liability Company “Pilot Plant of Welding

Equipment of Electric Welding Institute named after

E.O. Paton”

Ukraine, 03045, Kyiv, 66 Novopyrohivska St.

Product:

INVERTER RECTIFIERS PATON

VDI – 160E, VDI-200E, VDI-250E DC MMA

The statement is based on a single evaluation of one sample of above mentioned products. It

does not imply an assessment of the whole production. The manufacturer should ensure that all

product in series production are in conformity with the product sample detailed in this report.

The applicant should hold the whole technical report at disposal of the competent all the right.

Applied EC Directives:

2014/35/EU (Low Voltage)

2014/30/EU (Electromagnetic Compatibility)

Applied Standards:

EN 60204-1:2006. Safety of machinery - Electrical equipment of

machines – Part 1: General requirements; EN 60974-1:2012 Are

welding equipment – Part 1: Welding power sources; EN 6097410:2014 Are welding equipment – Part 10: Electromagnetic

compatibility (EMC) – requirements.

Issued Date: 12 September 2017

Expiry Date: 11 September 2022

General Manager

We, MASTERWELD Sp z o. o., hereby declare that specified above conforms covering

European Parliament and Council Directives, 2014/35/EC Low Voltage Directive of 26

February 2014 and 2014/30/EU Electromagnetic Compatibility of 26 February 2014.

The CE mark above can be used under the responsibility of manufacturer. After completion of an EC

declaration of conformity and compliance with all relevant EU Directives.

The following products have been tested by us with the listed

standards and found in compliance with the European Community

Low Voltage Directive 2014/35/EU and Electromagnetic

Compatibility Directive 2014/30/EU.

- 3 - PATON VDI SERIES ECO DC MMA

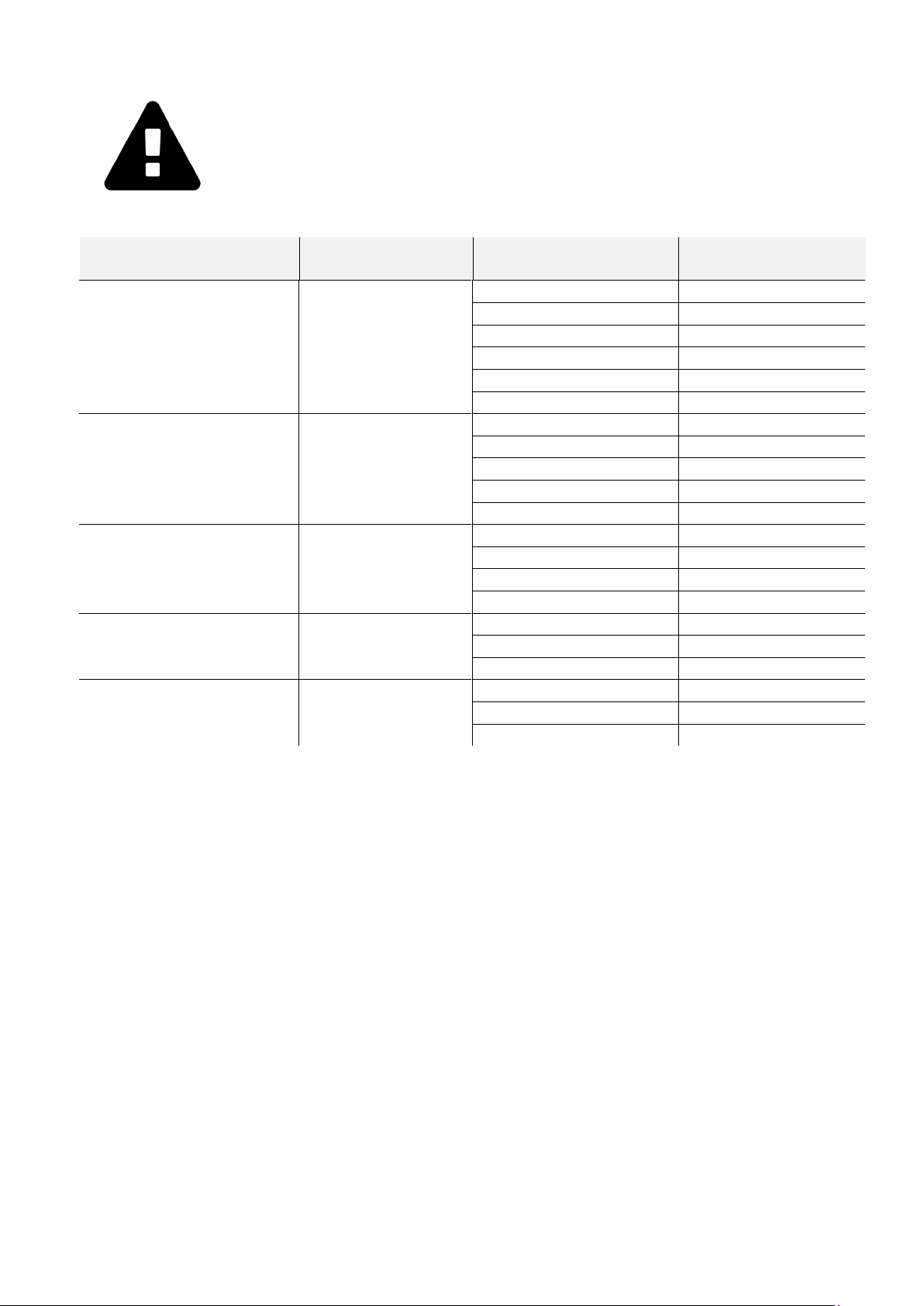

Electrode diameter (mm)

Operating current

(A)

Wire cross-section

(mm2)

Maximum allowable

wire length (m)

Ф2 mm

No more than 80 А

1.0

120

1.5

180

2.0

240

2.5

300

4.0

480

6.0

720

Ф3 mm

No more than

120 А

1.5

120

2.0

160

2.5

200

4.0

320

6.0

480

Ф4 mm

No more than 160 А

2.0

120

2.5

150

4.0

240

6.0

360

Ф5 mm

No more than 200 А

2.5

120

4.0

190

6.0

290

Ф5 mm

refractory

to 250 А

2.5

100

4.0

150

6.0

230

WARNING!!! When connecting the welding unit to an electrical outlet (at a

temperature of 25 ºC) of a power supply system, it is necessary to consider

wall-buried wiring and the lengths of extension cables.

1. GENERAL INFORMATION

Inverter rectifiers PATON™ VDI-160E, VDI-200E, VDI-250E optimized for direct-current

manual arc welding (MMA). This “ECO” series of devices designed for demanding users who wants

the most compact and functional device on its full rated current of 160A / 200A / 250A, respectively. It

is more than enough for most works with electrodes from Ф1,6 mm to Ф5 mm (including refractory),

while operating load factor is not less than 40%, which is more than enough for most works in

household sector (workshops, fleets, etc.).

The block for protection of overvoltage and undervoltage is installed in all Paton™ MMA branded

models.

Due to the increased frequency of the input voltage of the rectifier transformer of the welding unit, the

weight and overall dimensions of the transformer are significantly reduced as compared with other

welding units with similar characteristics.

PATON VDI SERIES ECO DC MMA - 4 -

The basic advantages of the PATON™ welding unit are the following:

PARAMETERS

VDI – 160E

VDI – 200E

VDI – 250E

Rated voltage 50/60 Hz, V

230

230

230

Rated power supply current, A

20

25

32

Rated welding current, A

160

200

250

Maximum operating current, A

190

240

300

Operating load factor, %

40% at 160А

100% at 101A

40% at 200А

100% at 126A

40% at 250А

100% at 158А

Power supply voltage range, V

170 – 260

170 – 260

170 – 260

Welding current control range, A

20 – 160

25 – 200

32 – 250

Function “Hot-Start”

Automatic

Function “Arc-Force”

Automatic

Function “Anti-Stick”

Automatic

Open-circuit voltage, V

to 80

to 80

to 80

Welding arc starting voltage, V

110

110

110

Rated consumed power, kVA

4,4

5,5

7,0

Maximum consumed power, kVA

5,5

6,9

8,8

Efficiency coefficient, %

90

90

90

Cooling

Forced

Operating temperature range

–25 … +45ºС

–25 … +45ºС

–25 … +45ºС

Overall dimensions (length width height),

mm

245 х 100 х

200

270 х 100 х 200

270 х 110 х

200

Weight, kg

3,75

3,95

4,3

Protection class*

IP21

IP21

IP21

1. The welding unit is protected against long-time fluctuations of power supply voltage and

provides arc stabilization when the input voltage of the unit changes in the range of 170 V

through 260 V.

2. The welding unit is rated for operation with the standard power supply system. Due to the higher

efficiency coefficient of the unit, the power consumed by the unit is reduced by 50 percent as

compared with other similar welding units.

3. The rotation frequency of the ventilator motor can be automatically varied depending on the

temperature inside the unit. This feature allows the service life of the ventilator motor to be

increased and, additionally, dust content inside of the unit to be reduced.

4. The welding unit is easy operated due to the optimal operating load factor in operation at the

rated current. In these conditions, it is possible to perform welding by using 4 mm electrodes at

the rated current.

5. The enhanced reliability of the welding unit in operation in dusty environment.

6. All the printed-circuit boards with electronic elements are impregnated with two layers of

high-quality varnish in order to provide the high reliability of the welding unit during its

service life.

7. The possibility to smoothly adjust welding parameters.

8. Enhanced arc stability.

1.1. TECHNICAL CHARACTERISTICS

*The Eco series equipment is protected against ingress of foreign particles more than 5.5 mm in size and against water

drops

- 5 - PATON VDI SERIES ECO DC MMA

The recommended length of the welding cables is indicated below:

The model of device

Cable length (m)

Cable cross

section (mm2)

Cable designation

VDI – 160E

1…4 8 КG 1х8

2…5

10

КG 1х10

3…8

16

КG 1х16

VDI – 200E

1…4

10

КG1х10

2…6,5

16

КG 1х16

3…10

25

КG 1х25

VDI – 250E

1…5

16

КG 1х16

2…8

25

КG 1х25

3…11

35

КG 1х35

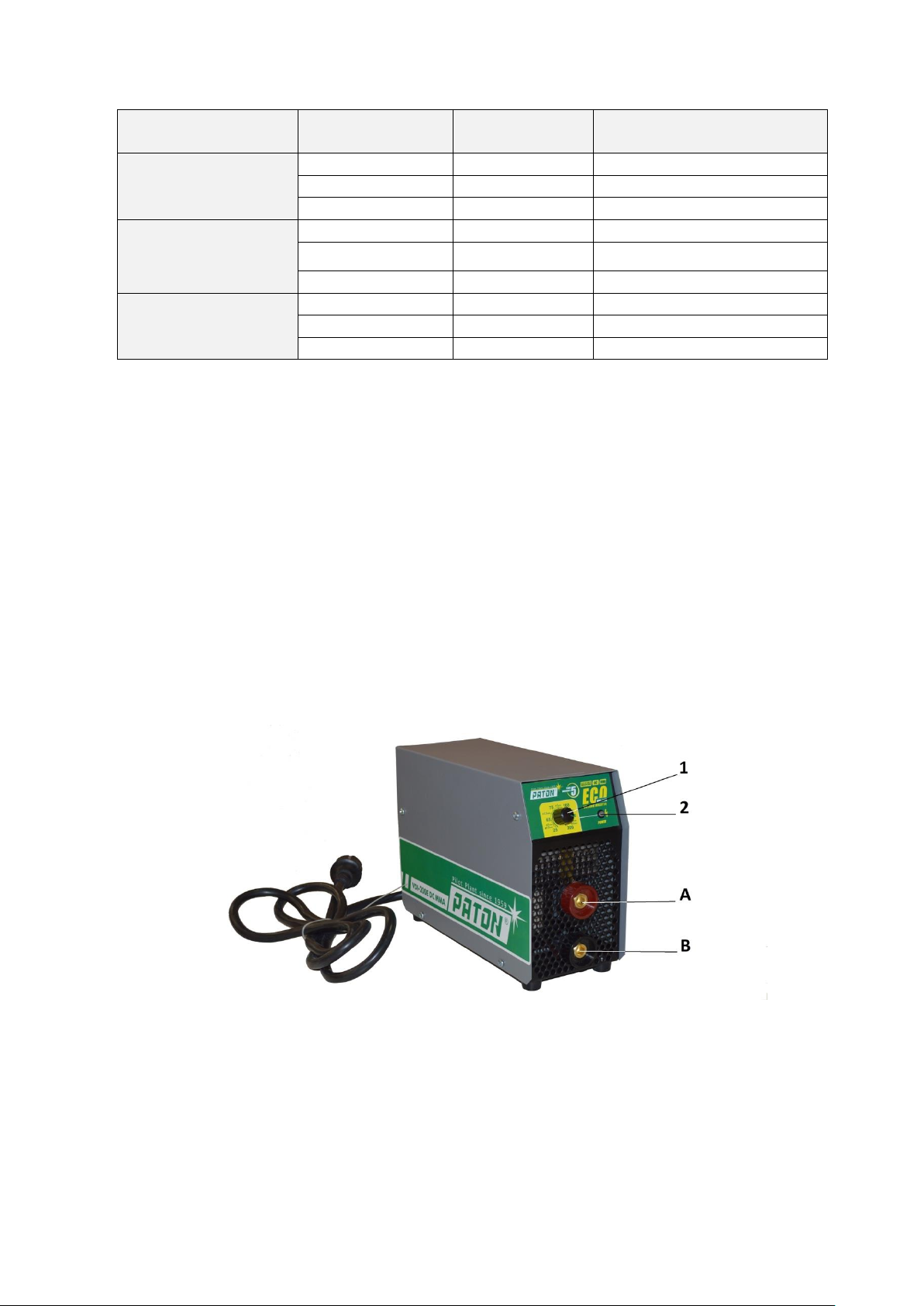

1.2. CONTROLS AND CONNECTORS

1 – Device for regulating the welding current. It allows adjust the welding current.

2 – The status of indicator:

a) constantly lit green - machine is ready to work;

b) blinks green when striking - there is no mains voltage;

c) constantly lit yellow - overheating of the source;

d) does not light up - no power;

3 – The power switch (not light, colour decorative).

A (+) – The bayonet connector socket for connecting:

the electrode cable in the manual arc welding mode (or the earthing cable in some cases when

special welding electrodes are used for welding);

В (-) – The bayonet connector socket for connecting:

the earthing cable in the manual arc welding mode (or the power cable for a welding electrode in

some cases when special welding electrodes are used for welding);

PATON VDI SERIES ECO DC MMA - 6 -

Pic. 1. Control and indication elements

2. SETTING THE WELDING UNIT INTO OPERATION

WARNING!!! Read Section 11, "Safety instructions", before putting the

welding unit into operation.

2.1. PROPER USE

The welding unit is designed for argon shielded tungsten-arc welding and for manual consumableelectrode arc welding.

Any other use of the welding unit is considered as improper. The manufacturer of the welding unit is

not responsible for damages caused by any improper use of the unit.

The use of the welding unit is proper if all the requirements of this Operation Manual are met.

WARNING!!! Do not use the welding unit to unfreeze pipes.

2.2. REQUIREMENTS FOR INSTALLATION

The welding unit is protected against ingress of foreign particles more than 5.5 mm in size, and the

internal elements of the unit are protected against moisture, so the unit is allowed for outdoor

operation.

WARNING!!! When operating the welding unit in cold season, after the unit

was switched off and cooled, condensate may appear inside the unit, so switch

on the welding unit only 3 – 4 hours after the switching off.

For this reason, do not switch off the welding unit if it is anticipated that the unit is to be switched on

not later than 4 hours after switching off.

Install the welding unit so as not to block or cover the ventilation slots on the front and rear panels of

the unit. Prevent ingress of metallic particles (for example, when grinding the weld) sucked by the unit

ventilator.

WARNING!!! After fall from a height, the welding unit might be a source of

electrical shock. Install the unit on a firm stable surface.

- 7 - PATON VDI SERIES ECO DC MMA

2.3. CONNECTION TO A POWER SUPPLY SYSTEM

ELECTRODE HOLDER

GROUNDING CLAMP

WORKPIECE

The commercial welding unit is rated at the input power supply voltage

230 V (- 23/+18 %).

WARNING!!! If the input power supply voltage exceeds 450 V, the warranty

of the manufacturer of the welding unit would be invalid.

The power supply connector, power cable cross-section, and supply-line fuses shall be selected with

consideration for the technical characteristics of the welding unit.

2.4. REQUIREMENTS FOR AN ELECTRICAL OUTLET

WARNING!!! The parameters of an electrical outlet for the power supply of

the welding unit must correspond to the power supply voltage and consumption

current of the welding unit (see Subsection 1.1, "Technical characteristics").

Connect the welding unit to an electrical outlet that is made for three-wire

earthing plugs.

3. MANUAL CONSUMABLE-ELECTRODE ARC WELDING MODE (MMA)

1. Connect the welding electrode cable to connector socket A (+).

2. Connect the earthing cable to connector socket B (-).

3. Connect the earthing cable to the workpiece.

4. Connect the power cable to the electrical outlet of the power supply system.

5. Switch on the welding unit by power on-off switch 6 (set the switch to position "I").

Pic. 2. Diagram of connecting the welding unit for manual covered – electrode welding process

WARNING!!! When power switch 3 is set to position "I", the electrode is

under voltage. Prevent the contact of the electrode with conducting or earthed

parts, for example, the casing of the welding unit.

PATON VDI SERIES ECO DC MMA - 8 -

3.1 INCREASED-CURRENT ARC STARTING HOT-START

t (s)

The advantages ensured by the increased-current arc starting function are the following:

The improved arc starting even when low-quality electrodes are used

The more complete fusion penetration during arc starting period and, as a result, the lower

number of defects associated with incomplete fusion.

Prevention of slag inclusions

What is achieved by:

During a short time, interval of arc starting, the welding current increases

by 33 % of the set welding current (see pic 3).

Example: Electrode diameter is 3 mm.

Set welding current is 90 A.

The current at the increased-current arc starting stage is 90 + 0.3390 = 120 A.

3.2. REDUCED-VOLTAGE WELDING FUNCTION (ARC-FORCE)

The advantages ensured by the reduced-voltage welding function are the following:

The enhanced arc stability in short arc welding mode

The improved transfer of metal drops into the molten pool

Improved arc starting

The reduced probability of electrode sticking

What is achieved by:

When the arc voltage drop is lower then the minimum voltage required for stable arcing, the welding

current increases by 50% relative to the set current (see pic. 4).

This function may be disabled, for example, when welding sheet materials and when the welding unit

is connected to a low-powered voltage source (the welding unit with this function enabled consumes

additional power).

Pic.3. Increased-current arc starting HOT-START

- 9 - PATON VDI SERIES ECO DC MMA

Pic. 4. Forced arcing at reduced welding voltage ARC-FORCE

130

Uoc

Uw

U

min

U (V)

3.3. PROTECTION AGAINST ELECTRODE STICKING (“ANTI-STICK”)

In arc starting, the electrode can stick to the workpiece and, as a result, the electrode can be damaged

due to overheating.

If the electrode has stuck to the workpiece, the welding current decreases in 0.6 … 0.8 s after the

sticking. In this case, the welder can detach the electrode from the workpiece without risk to damage

eyes because of random arc starting. After the detachment of the electrode, the welding can be

continued.

4. MAINTENANCE

WARNING!!! Before maintenance, switch off the welding unit and remove

the plug of the power cable from the electrical outlet of the power supply

system. Wait for about 5 minutes until static charges in the unit circuits are

removed, and then perform the maintenance operations. After completion of

works with the welding unit, apply to the unit a warning plate with a text

prohibiting switching on the unit.

For ensuring the operability of the welding unit for a long-term service life, it is necessary to perform

the following procedures:

Periodically, at specified time intervals, check that the safety requirements in operation of the

welding unit are fulfilled (see Section 11, "Safety instructions").

At half-yearly intervals, purge the welding unit with dry compressed air.

When working in environment with excessive dust content, manually clean the passages for

cooling air.

WARNING! Purging of the unit from a short distance can result in damage

of the electronic elements of the unit.

PATON VDI SERIES ECO DC MMA - 10 -

5. OPERATION WITH AN ELECTRIC GENERATOR

Electrode diameter

(mm)

Set welding current

(A)

Minimum power of the generator

(kVA)

Ф 2

No more than 80А

2.6

Ф 3

No more than 120А

4.1

Ф 4

No more than 160А

5.5

Ф 5

No more than 200А

6.9

Ф 5 refractory

to 250А

8.8

The welding unit can operate with a power supply from an electric generator if the following

conditions are satisfied:

WARNING!!! The output voltage of the electric generator must in the range

of 170 – 260 V.

6. STORAGE

The preserved and packed welding unit can be stored according to State Norm for 5 years.

The welding unit should be stored in a dry closed room at an ambient temperature not lower than 5ºC.

In the room, acid vapors and chemically active substances should not be present.

7. TRANSPORTATION

The packed welding unit can be transported by any means of transport, which ensure the

integrity of the unit if the shipping rules effective for the specified transport means.

8. SPECIFICATION DATA

WARNING! If the welding unit is rated at the special power supply voltage,

the specification data of the unit are indicated on the nameplate on the rear

panel of the unit. In this case, the parameter of an electrical outlet and power

cable should be selected with consideration for the actual power supply

voltage.

- 11 - PATON VDI SERIES ECO DC MMA

Parameters:

VDI-160E

VDI-200E

VDI-250E

Rated power supply voltage 50/60 Hz, V

~230

~230

~230

Power supply voltage range

170 – 260

170 – 260

170 – 260

Efficiency coefficient (at 200A), %

90

90

90

Welding current-control range, A

20 – 160

25 – 200

32 - 250

Welding current at a load factor of 40 %,

for 5 minutes

Welding current at a load factor of 100 %,

for 5 minutes

160 А

101 А

200 А

126 А

250 А

158А

Maximum consumed power, kVA

5,5

6,9

8,8

Normal operating voltage in the manual arc

welding mode

20,4 – 26 V

20,4 – 26,5 V

20,4 – 27,0 V

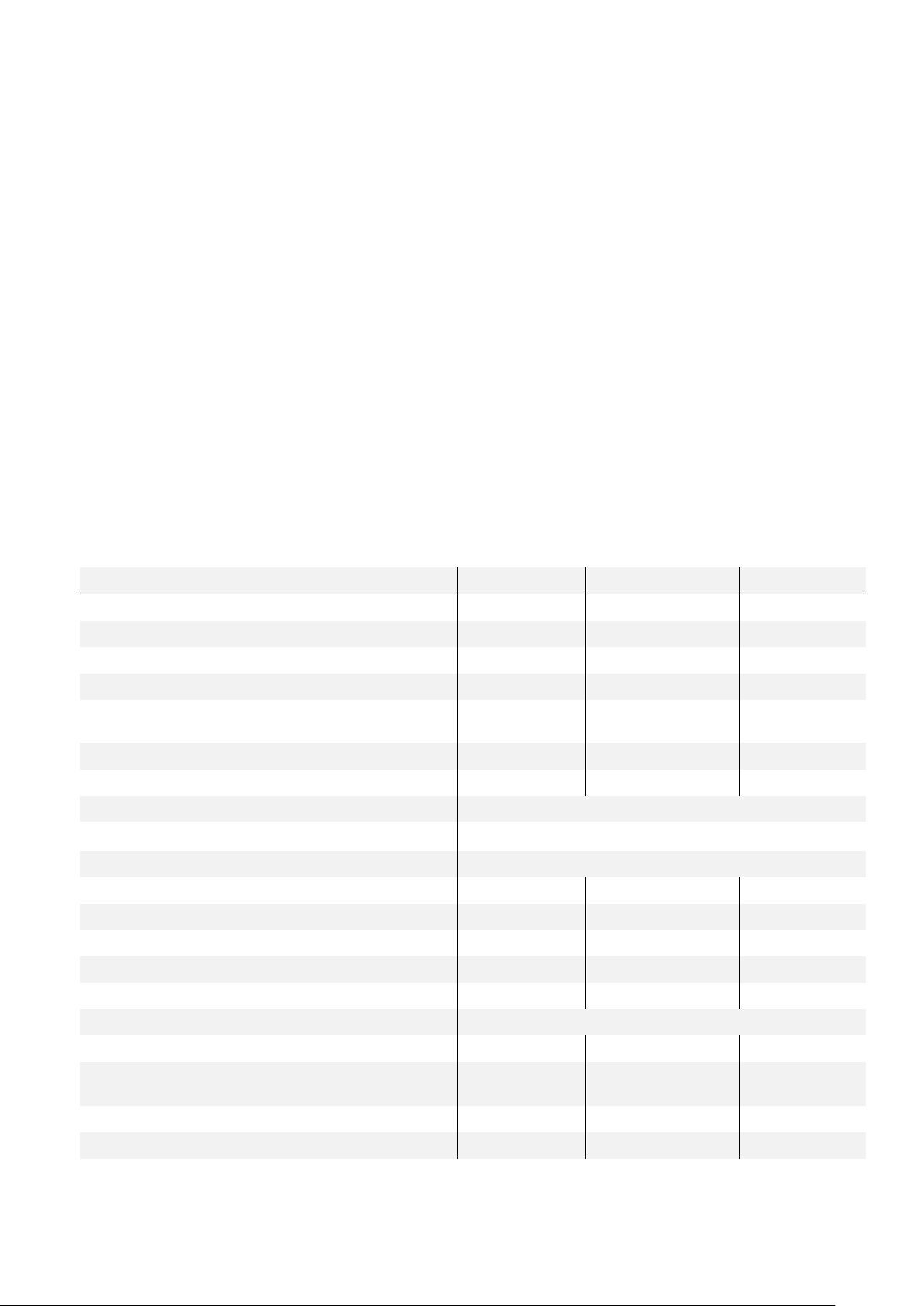

Fault

Fault cause

Fault recovery

No welding currents.

The power is switched on;

the green indicator does not

light.

Power cable breakdown

Check the state of the power

cable.

Power supply voltage is below

155 V.

Connect the welding unit to the

power supply system with

proper voltage.

Power supply voltage exceeds

260 V (the indicator on the rear

panel lights).

Connect the welding unit to the

power supply system with

proper voltage.

Fault of the internal power

supply module of the welding

unit

Apply to the service center.

9. DELIVERY SET

1. Welding unit with a power cable 3 m in length – 1 pcs;

2. Shoulder-carry belt – 1 pcs;

3. Brand corrugated box "PATON™" – 1 pcs;

4. Welding cable with an electrode holder, 3 m in length – 1 pcs;

5. Welding cable with an earthing terminal, 3 m in length – 1 pcs;

6. Operation manual – 1 pcs.

10. TROUBLESHOOTING

PATON VDI SERIES ECO DC MMA - 12 -

No welding currents.

The power is switched on;

the green indicator lights.

Welding cables are not

connected.

Check the state of electric

connectors.

The earthing terminal is not

properly connected or is not

connected to the workpiece.

Properly connect the earthing

terminal to the workpiece.

No welding currents.

The power is switched on;

the yellow indicator lights.

Triggering one of the

temperature sensors

Wait when the machine to cool

down; then it will

automatically switch on again

Insufficient supply of cooling air

To ensure sufficient ventilation

Faulty thermal sensor

Contact your Service Centre

Improper arc starting in the

manual consumableelectrode arc welding; the

green indicator flashes.

The power supply voltage is

close to the minimum allowable

voltage of 165 V.

If it is not possible to increase

the cross-section of the

conductors of the power cable,

decrease the set welding

current to the value which is

sufficient for arc staring.

Select the welding electrode

with consideration for the

welding current.

Random arc extinction

during welding

The arc voltage is too high for

the electrode used.

Use another electrode or a

welding unit rated at higher

power.

The electrode sticks to the

workpiece

The welding current is too low.

Set the proper welding current.

Low quality of the weld

(metal scattering)

The polarity of voltage across

the electrode is improper.

Change the polarity across the

electrode according to the

instructions of the electrode

manufacturer.

11. SAFETY INSTRUCTIONS

GENERAL INFORMATION

This device may only be used for the purposes for which it was created. This appliance is intended for

use by persons with the requisite qualifications. It is the responsibility of the qualified personnel to

install, service and repair. Please read this manual carefully before installing and using this product.

Failure to follow the instructions in this manual may result in serious personal injury, death and

damage to the unit itself. Incorrect installation, maintenance and operation resulting in damage to the

device - the manufacturer is not liable.

- 13 - PATON VDI SERIES ECO DC MMA

INSTRUCTION

Before using this product, please read this manual and use the instructions in

this manual. This instruction manual is a basic piece of equipment.

USER RESPONSIBILITIES: The user agrees to allow only persons who:

have been acquainted with the basic safety rules, have been trained in the use

of welding equipment and have appropriate qualifications. They are familiar

with the chapter "Safety Regulations" and the precautionary guidelines in this

manual.

THREATS

ELECTRIC SHOCK CAN KILL: Welding devices produce high voltage.

While the machine is connected to the power supply, it is not allowed to

touch the welding handle and the workpiece. All of these elements form a

welding current circuit and may cause electric shock, so avoid touching them

with bare hands and wet or damaged protective clothing. Protective clothing

should not restrain movements. If possible, it should not be made of synthetic

materials. Electrocution can be fatal !!!

ARC RAYS CAN BURN: It is not allowed to directly observe the welding

arc with uncovered eyes.

Arc and splinters may cause skin burns or flames, so always wear a

protective mask fitted with a darkened filter (glasses should be equipped with

glass filter grade DIN 9 10)

Any unauthorized persons near your site should protect your eyes with

special protective goggles or with non-flammable, radiation-absorbing

screens.

VAPOUR AND GASES MAY BE DANGEROUS: The resulting smoke and

harmful gases should be removed from the work area by means of specialized

equipment, do not cover the ventilation openings. Welding should be carried

out in well ventilated areas and welding vapors are harmful to health especially when welding materials such as lead, mercury, cadmium, zinc,

beryllium, galvanized or stainless steel. Ensure sufficient fresh air flow in the

room. Do not allow solvent vapors to enter the welding arc area.

ELECTROMAGNETIC POLE MAY BE DANGEROUS:

By inducing a high voltage current, the electromagnetic field flowing through

the welding wires may have a negative effect on the performance of electrical

devices such as the cardio-stimulator. Persons wearing such equipment

should consult a physician before entering the area where welding work is

performed. Welding hoses should be arranged in parallel, as close as possible

to each other.

ELECTRICAL SPARK MAY CAUSE FIRE OR EXPLOSIVES:

Flammable items should be removed from the workplace. Do not perform

welding work on containers that contain gases, fuels, oil products or other

flammable materials. There is a risk of explosion of residue of these products.

When performing welding work in potentially explosive or fire hazards,

special rules must be observed that comply with national and international

standards. Firefighting equipment such as: (powder or snow fire

extinguishers, fire blankets) should be located near the workstation in a

visible, readily accessible place.

PATON VDI SERIES ECO DC MMA - 14 -

BOTTLE CAN EXPLODE: Use only approved bottles and properly

functioning regulators. The cylinder should be transported and positioned

vertically. Protect the cylinder from heat, overturning and mechanical

damage.

WELDED MATERIALS MAY BURN: In no case should you touch the

welded parts with bare hands. Always wear protective gloves when operating

the machine. The arc and splinters that develop during the burn can cause

skin burns. Wear protective gloves and pliers when touching or moving the

welded item.

ELECTRIC POWER SOURCES: It is forbidden to work with damaged

welding wires or on wet substrates. Welding cables should be strong,

undamaged and insulated. Weakened connections and damaged cable must

be replaced immediately. Do not carry the device by pulling it by the power

cord or wires. Do not perform any maintenance work on the unit.

Removing the outside cover of the device while it is connected to the

network and using the device with the lid removed is forbidden.

NOISE ASSOCIATED WITH WELDING CAN BE HARMFUL: The

welding arc formed during welding can emit sounds higher than 85dB for - 8

hours of working time. Welders operating the equipment are obliged to wear

equivalent hearing protectors during work in accordance with the Regulation

of the Minister of Labor and Social Policy of 6 June 2014r. - Dz. U. 2014

pos. 817. Pursuant to the Ordinance of the Minister of Health on Social

Welfare dated 09.07.1996 OJ No. 68 pos. 194 - The employer is required to

carry out research and measurement of factors harmful to health.

CONFORMITY DECISION: This device accomplish the recommendation

of the European CE Committee.

SAFETY MARK: This device is suitable for mains power, for welding work

in an environment of higher standard of electric shock. It is recommended

that the power line be provided with a separate protection against the shock

absorber.

- 15 - PATON VDI SERIES ECO DC MMA

12. ELECTRICAL SCHEMATIC DIAGRAM

230 V

CURRENT

BIS

-0331

BVR

-0331

BPK-0332

PATON VDI SERIES ECO DC MMA - 16 -

13. WARRANTY

The Pilot Plant of Welding Equipment of the E.O PATON Electric Welding Institute guarantees the

correct operation of the power supply if the costumers provided service conditions, storage and

transportation.

ATTENTION!!! Warranty commitments are cancelled in case of mechanical

damage.

Term of the main guarantees for welding inverter series ECO is 5 years. The basic warranty

period is calculated from the date of sale to the end customer of the inverter equipment.

During the main warranty period, the seller covenants charge the inverter equipment of PATON™ to

the owner:

To diagnose and determine the cause of failure,

To ensure the necessary repairs to units and elements,

To carry out work on the replacement of defective components and units,

To test the repaired equipment.

The basic warranty obligations do not include devices:

Mechanical damage affected the availability of the device (deformation body parts and in

consequence of a fall or drop heavy objects on the equipment, loss of pins and connectors)

Traces of corrosion that caused the fault condition,

The failed because of the impact on its power and electronic elements abundant moisture,

The failed due to the accumulation of conductive dust inside (coal dust, metal chips, etc.),

In case of attempting to repair its nodes and / or replacement of electronic components,

Once on six months, clean internal parts and components with compressed air when removing the

protective box in order to avoid exit of the unit system on the equipment. Cleaning should be carried

out carefully, keeping the compressor hose at a sufficient distance to avoid damage to the soldering of

electronic components and mechanical parts.

Also, the basic warranty does not apply to defective external elements of equipment that exposed to

physical contact and the attendant / supplies. Claims on the fallowing items are accepted no later than

two weeks from the date of sale:

Pins on and off,

Knobs of the welding parameters,

Cabling connectors and sleeves,

Connectors management

The power cable and power plug,

Carrying handle, shoulder strap, carrying case,

Electrode holder, earth clamp, burners, bayonet connectors, welding cable, hose.

The Seller reserves the right to refuse to provide warranty repairs, or set as the date for the

commencement of the warranty a month and year of the machine (set by serial number):

In case of loss of the passport holder,

In the absence of a correct or even any passport fill the seller in the sale of the machine,

In the absence of a serial number on the machine manufacturer reserves the full right to

refuse warranty service.

- 17 - PATON VDI SERIES ECO DC MMA

WARNING!!! The warranty period is extended for the period of the warranty

service machine to the service center.

14. INFORMATION CONCERNING DISPOSAL OF EQUIPMENT

(applies to households)

The symbol shown on the product indicates that the appliance can not

be disposed of in the same way as household waste. The device must be

returned to the point of disposal of electrical equipment where it will be

accepted free of charge. Information on such collection points for used

equipment can be found on eg websites.

Proper disposal helps preserve valuable natural resources and avoid

environmental contamination. Failure to comply with the above

recommendations may result in the imposition of fines in accordance

with applicable regulations.

If you would like to return the unit for disposal, please contact your nearest point of sale or contact the

importer of the equipment for further information.

IMPORTER / AUTHORIZED DISTRIBUTOR EU

=

25, Tadeusza Boya – Żeleńskiego Street,

Rzeszów City, Poland zip-code 35105

Tel. +48 (17) 779 00 67

e-mail: biuro@paton.com.pl

www.paton.com.pl

All rights reserved. This document is protected by copyright. Copying or distributing the User Manual

in whole or in excerpts without MasterWeld permission is prohibited.

15. ACCEPTANCE CERTIFICATE

Inverter rectifiers „PATON™ VDI-_________E”

The serial number ______________ECO complies with the harmonized standards and is fit for use.

Date of sale "___" ____________ 20___ year

Stamp here _____________________

(signature of the seller)

================================================================================

PATON VDI SERIES ECO DC MMA - 18 -

Address of the Central PATON™ Service Center

Invertech – Piotr Błaszkowski

9, Ludwika Zamenhofa Street

Sanok City, Poland zip-code 38500

Head of Service Center

Piotr Błaszkowski

Phone: +48 889 226 032

e-mail: serwis@paton.com.pl

ATTENTION!!! DO NOT SEND the welding cables for repair, as these

equipment items are not required for repair.

ATTENTION!!! Delivery of the equipment to the service center "PATON"

is performed at the manufacturer's expense only during the 1st of the year from

the date of purchase! Over 1 year - at the buyer's expense.

Date of reception of the welding unit for repair «_____» __________ 20 ___ year.

_______________________

(signature)

Faults detected:

__________________________________________________________________________________

__________________________________________________________________________________

Faulty-condition cause:

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

Tel. Technical support: +48 889 226 032

Address of the service center: 38500, Poland, Sanok, Zamenhofa 9 Street

=======================================================================

- 19 - PATON VDI SERIES ECO DC MMA

Date of reception of the welding unit for repair «_____» __________ 20 ___ year.

_______________________

(signature)

Faults detected:

__________________________________________________________________________________

__________________________________________________________________________________

Faulty-condition cause:

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

Tel. Technical support: +48 889 226 032

Address of the service center: 38500, Poland, Sanok, Zamenhofa 9 Street

=======================================================================

Date of reception of the welding unit for repair «_____» __________ 20 ___ year.

_______________________

(signature)

Faults detected:

__________________________________________________________________________________

__________________________________________________________________________________

Faulty-condition cause:

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

Tel. Technical support: +48 889 226 032

Address of the service center: 38500, Poland, Sanok, Zamenhofa 9 Street

=======================================================================

PATON VDI SERIES ECO DC MMA - 20 -

Loading...

Loading...