Paton MMA-160P, MMA-200P, MMA-250P Operation Manual

PATON VDI-SERIES PRO DC MMA/TIG/MIG/MAG

-1-

PATON VDI-SERIES PRO DC MMA/TIG/MIG/MAG

-2-

TABLE OF CONTENTS

1.

General information

6

1.1.

Technical characteristics

8

1.2.

Controls and connectors

10

2.

Setting the welding unit into operation

11

2.1.

Proper use

12

2.2.

Requirements for installation

12

2.3.

Connection to a power supply system

13

2.4.

Requirements for an electrical outlet

13

3.

Manual covered-electrode arc welding process (MMA)

13

3.1.

Preparing the welding unit for operation

13

3.2.

Operational cycle of the manual arc welding process

14

3.3.

Increased-current arc starting

15

3.4.

Reduced-voltage welding mode

16

3.5.

Protection against electrode sticking

17

3.6.

Setting the slope of the volt-ampere characteristic of the

welding unit

17

3.7.

Short arc welding mode

17

3.8.

Reduction of open-circuit voltage

17

3.9.

Welding at pulse welding current

18

4.

Argon arc welding process (TIG)

19

4.1.

Preparing the welding unit for operation

19

4.2.

. Operational cycle of the argon arc welding process with

TIG-LIFT function

20

4.3.

TIG-LIFT contact arc starting function

20

4.4.

Linear increase of welding current

21

4.5.

Welding at pulse welding current

21

5.

Semiautomatic arc welding process (MIG/MAG)

22

5.1.

Preparing the welding unit for operation

22

5.2.

Operational cycle of the semiautomatic arc welding process

24

5.3.

Welding at pulse welding voltage

24

6.

Setting the welding unit

25

6.1.

Switching to the required welding function

26

6.2.

Switching to the required welding process

26

6.3.

Return of the values of the functions and parameters of the

welding unit to the default factory values set for the current

welding process.

26

PATON VDI-SERIES PRO DC MMA/TIG/MIG/MAG

-3-

7.

Complete list of the welding unit functions and parameters

27

7.1.

Manual arc welding process (MMA)

27

7.2.

Argon shielded tungsten-arc welding process (TIG)

28

7.3.

Semiautomatic arc welding process (MIG/MAG)

28

8.

Operation with an electric generator

29

9.

Maintenance

29

10.

Storage

30

11.

Transportation

30

12.

Specification data

30

13.

Delivery set

31

14.

Warranty

31

15.

Information concerning disposal of equipment

33

16.

Safety instructions

35

17.

Electrical schematic diagram

36

18.

Acceptance certificate

37

PATON VDI-SERIES PRO DC MMA/TIG/MIG/MAG

-4-

DECLARATION OF CONFORMITY

Manufacturer:

„THE PILOT PLANT OF WELDING

EQUIPMENT OF THE INSTITUTE OF

ELECTRIC WELDING NAMED AFTER E.O.

PATON”

Address:

66 NOVOPIROGOVSKA STREET, KIEV CITY,

UKRAINE, ZIP-CODE 03045

Authorized

manufacturer's

representative:

MASTERWELD SP. Z O.O.

25, TADEUSZA BOYA – ŻELEŃSKIEGO

STREET, RZESZÓW CITY, POLAND, ZIP-CODE

35105

VAT: PL8133751525

I, the undersigned, declare under our sole responsibility that the

product listed below complies with the following Directives:

Product

DIGITAL INVERTER RECTIFIERS

Type:

PATON VDI – 160P, VDI – 200P. VDI – 250P

have been tested and conforms with the following specifications:

Directive

2014/30/EU

Electromagnetic

Compatibility

(EMC)

EN 60974-10: 2014-12

EN 61000-3-2: 2014-10

EN 61000-3-3: 2013-10

Directive

2014/35/EU

Low voltage

(LVD)

EN 60974-1: 2013-04

EN 62233:2008

Date 22/05/2017

Signed on behalf of the manufacturer by:

Vice President M. Olszewski

PATON VDI-SERIES PRO DC MMA/TIG/MIG/MAG

-5-

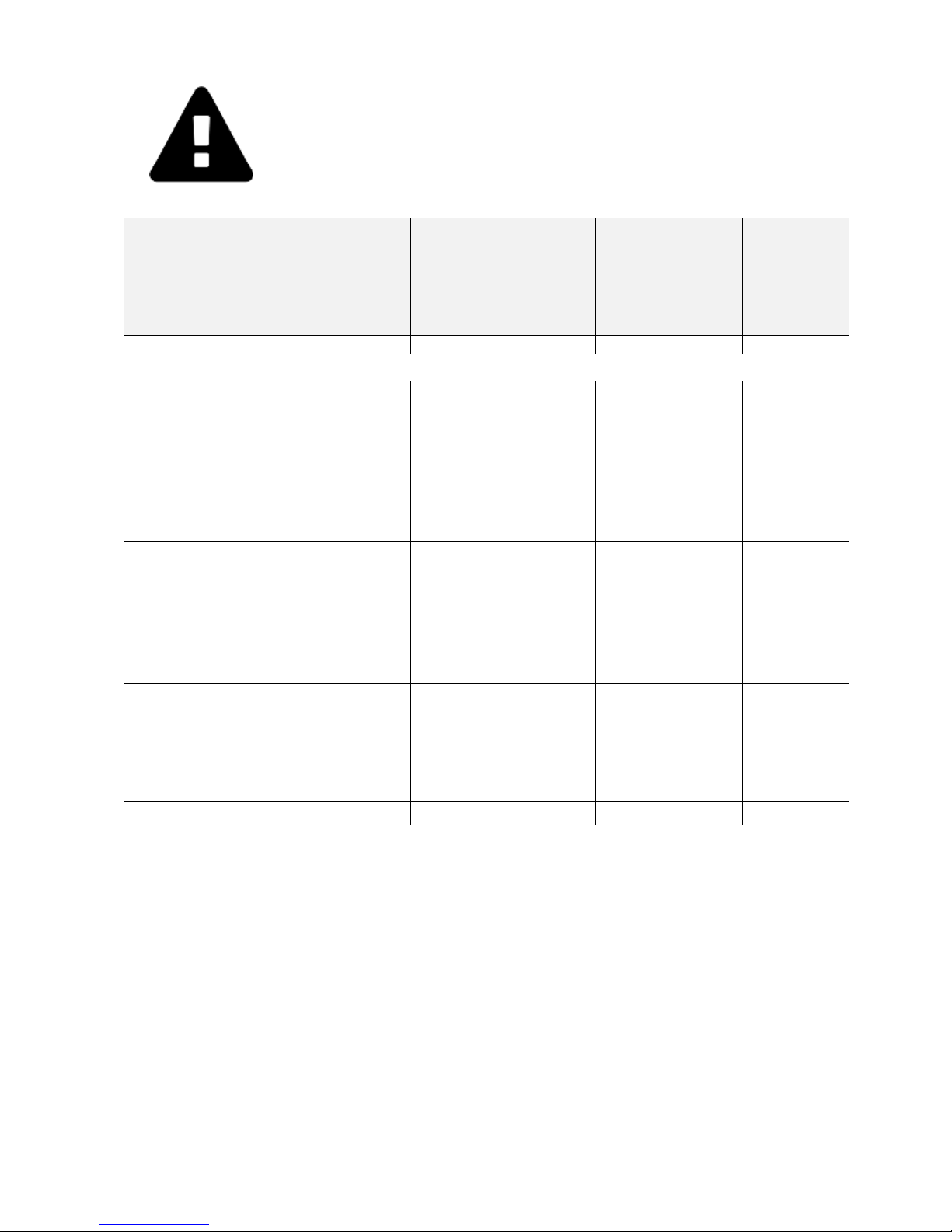

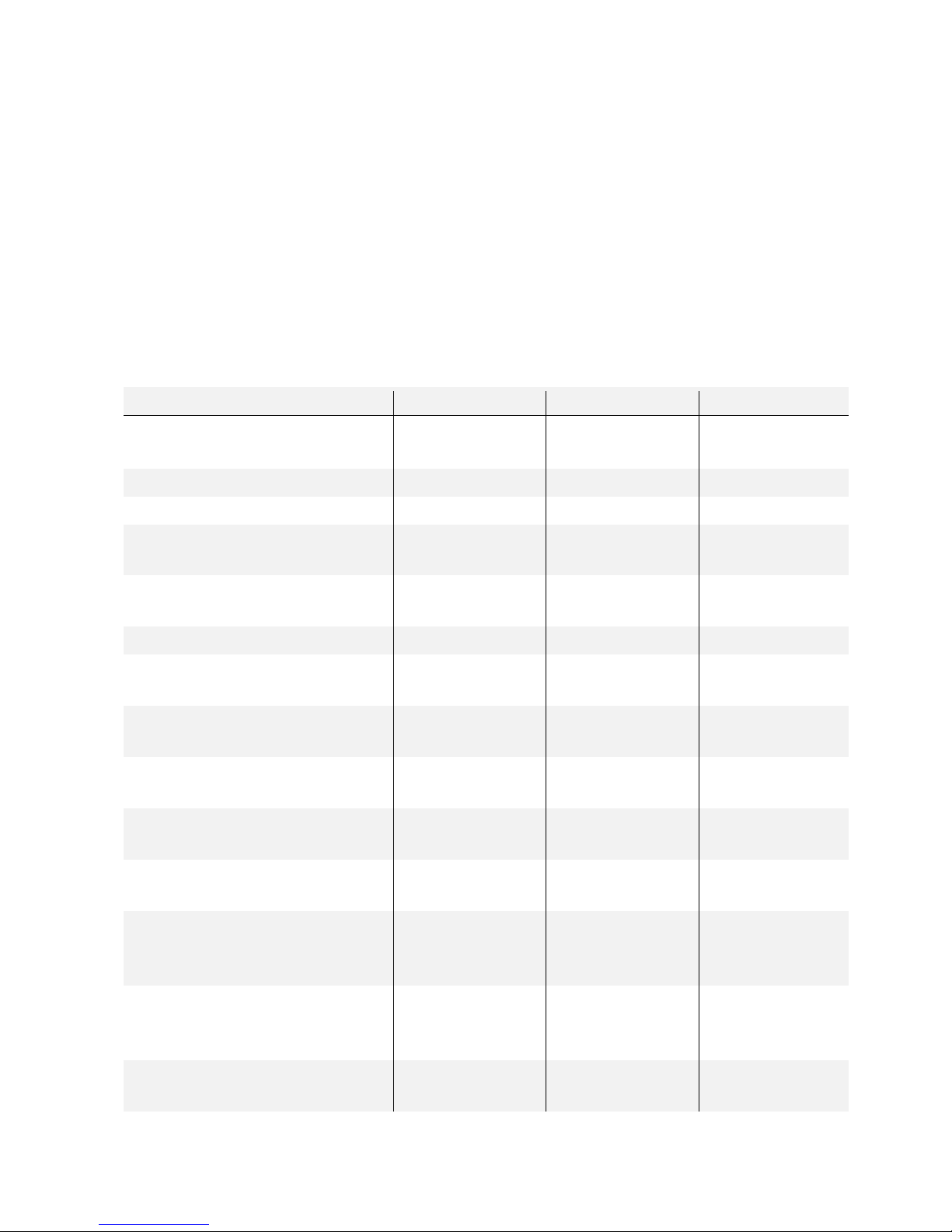

WARNING! When connecting the welding unit to the power

distribution board (at a temperature of 25 ºC), take into account throughthe-wall wiring and the lengths of extension cables.

Electrode

diameter for

a MMA

welding

process (mm)

Set current for

MMA and

TIG welding

processes (A)

Electrode wire

diameter for a

MIG/MAG

welding process

(mm)

Cross-section

area of the

power cable

conductor

(mm2)

Maximum

cable

length (m)

VDI-160P

Ф2 mm

Not more than

80

Not more than 0.6

1.0

75

1.5

115

2.0

155

2.5

195

4.0

310

6.0

465

Ф3 mm

Not more than

120

Not more than 0.8

1.5

75

2.0

105

2.5

130

4.0

205

6.0

310

Ф4 mm

Up to 160

Not more than 1.0

2.0

75

2.5

95

4.0

155

6.0

230

PATON VDI-SERIES PRO DC MMA/TIG/MIG/MAG

-6-

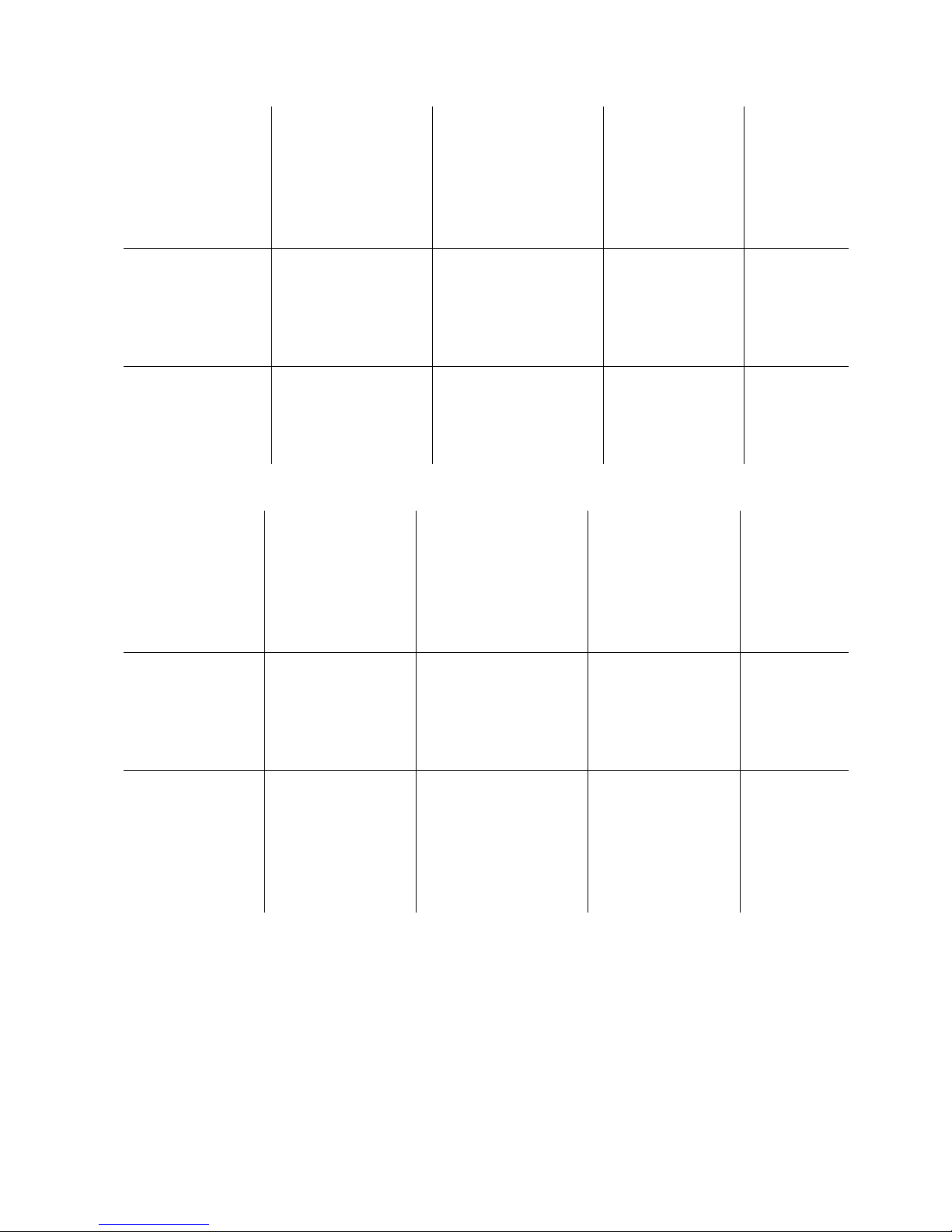

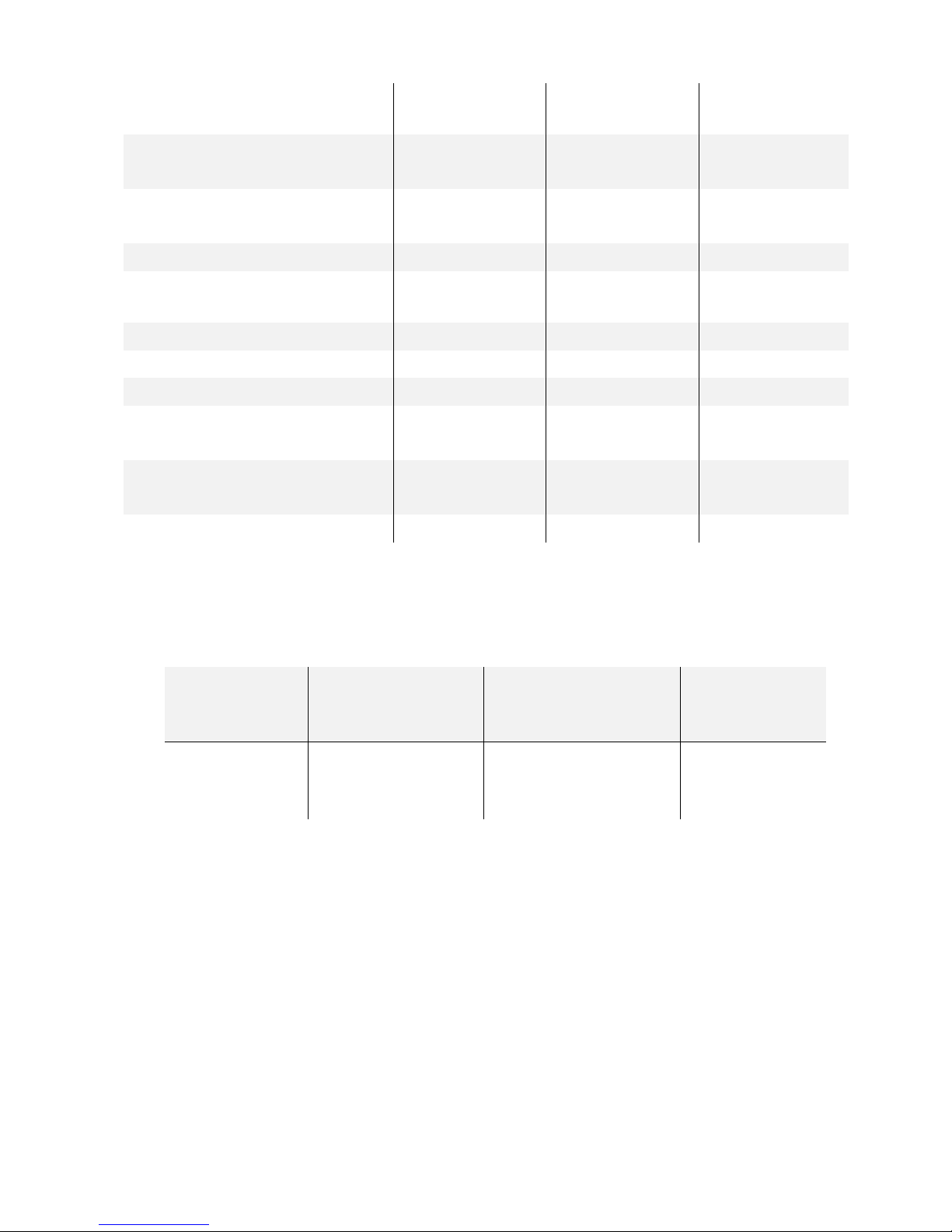

VDI-200P

Ф3 mm

Not more than

120

Not more than 0.8

1.5

75

2.0

105

2.5

130

4.0

205

6.0

310

Ф4 mm

Not more than

160

Not more than 1.0

2.0

75

2.5

95

4.0

155

6.0

230

Ф5 mm

Up to 200

Not more than 1.0

2.5

75

4.0

125

6.0

185

VDI-250P

Ф3 мм

Not more than

120

Not more than 0.8

1.5

75

2.0

105

2.5

130

4.0

205

6.0

310

Ф4 mm

Not more than

160

Not more than 1.0

2

75

2.5

95

4.0

155

6.0

230

Ф5 mm

Up to 250

Not more than 1.2

2.5

60

Ф 6 mm

for a free-

melting

electrode

4.0

100

6.0

150

1. GENERAL INFORMATION

The digitally controlled rectifier welding units PATON™ VDI-160P, VDI-200P,

and VDI-250P are designed for direct-current gas-shielded welding according to such

welding processes as a manual arc welding process (MMA), an argon arc welding process

(TIG), and a semiautomatic arc welding process (MIG/MAG) (with the welding unit

operating together with an external electrode wire feeding unit). The digital controller

used in these welding units ensures significant advantages for the welding unit as

compared with multifunctional analog controllers, as the analog controllers are designed

PATON VDI-SERIES PRO DC MMA/TIG/MIG/MAG

-7-

for the specific operating modes of controlled equipment and are not optimal in all

operating modes. The digital controller of the MMA welding units allows all the

capabilities of the welding unit, up to its capabilities at full power, to be used in all the

operating modes of the unit.

The MMA welding units pertain to the Professional Series equipment and are designed

for industrial use. The additional adjustment operations provided for the welding unit

make it possible to set the optimal values of the operating parameters of the unit in various

operating modes characterized by a high load factor at a rated current of up to 160 A, 200

A, or 250 A. The welding units can be used for manual arc welding with standard

electrodes 1.6 … 5 mm in diameter and free-melting electrodes up to 6.0 mm in diameter

and for semiautomatic arc welding with solid electrode wire 0.6 … 1.2 mm in diameter.

The function of reduction of open-circuit voltage in the manual arc welding process

(MMA), with the possibility for this function to be switched on and off, allows the

welding unit to be operated in unsafe environment.

The welding unit contains a module for protection against excess and low power

supply voltage.

Due to the increased frequency of the input voltage of the rectifier transformer of

the welding unit, the weight and overall dimensions of the transformer are significantly

reduced as compared with other welding units with similar characteristics.

The basic advantages of the PATON™ welding units are the following:

1. The possibility to adjust welding parameters in wide ranges

a) 1 basic parameter + 10 additional parameters for the manual arc welding process

(MMA)

b) 1 basic parameter + 4 additional parameters for the argon arc welding process

(TIG)

c) 1 basic parameter + 3 additional parameters for the semiautomatic arc welding

process (MIG/MAG)

2. The availability of the adjustable pulse welding mode for all the welding

processes.

3. The welding unit is protected against long-time fluctuations of power supply

voltage and ensures welding arc stabilization when the input voltage of the unit

changes in the range of 160 V through 260 V. It should be noted that welding

at a minimum voltage of 160 V is allowed only by using an electrode not more

than 3 mm in diameter for the manual arc welding process, or electrode wire

not more than 0.8 mm in diameter for the semiautomatic arc welding process.

4. The welding unit is rated for operation with a standard power supply system.

Due to the higher efficiency coefficient of the unit, the power consumed by

the unit is reduced by 50 percent as compared with other similar welding

units.

5. The rotation frequency of the driving motor of the ventilator of the welding unit

can be automatically varied depending on the temperature inside the unit.

This feature allows the service life of the ventilator and driving motor to be

increased and, additionally, dust content inside the unit to be reduced.

PATON VDI-SERIES PRO DC MMA/TIG/MIG/MAG

-8-

6. The welding unit is easy operated due to the optimal operating load factor in

operation at the rated current.

7. The enhanced reliability of the welding unit in operation in dusty environment.

8. The welding unit contains an electronic thermal protection system for

protecting all the heat-generating components of the welding unit against

overheating.

9. All the printed-circuit boards with electronic elements are impregnated with

two layers of high-quality varnish in order to provide the high reliability of

the welding unit within its service life.

10. Improved arc stability

1.1. TECHNICAL CHARACTERISTICS

PARAMETERS

VDI-160P

VDI-200P

VDI-250P

Rated power supply voltage

50/60 Hz, V

230

230

230

Rated power supply current, A

18 … 21

25 … 28

32 … 36

Rated welding current, A

160

200

250

Maximum operating current,

A

215

270

335

Operating load factor, %

70 % at 160 A

100 % at 134 A

70 % at 200 A

100 % at 167 A

70 % at 250 A

100 % at 208 A

Power supply voltage range, V

160 … 260

160 … 260

160 … 260

Welding current control range,

V

8 … 160

10 … 200

12 … 250

Welding voltage control

range, V

12 … 28

12 … 28

12 … 28

Diameter of a stick electrode,

mm

1.6 … 4.0

1.6 … 5.0

1.6 … 6.0

Diameter of electrode wire,

mm

0.6 … 1.0

0.6 … 1.0

0.6 … 1.2

Welding processes with a

pulse welding mode

MMA, TIG,

MIG/MAG

MMA, TIG,

MIG/MAG

MMA, TIG,

MIG/MAG

Increased-current arc starting

function of the manual arc

welding process

Adjustable

Adjustable

Adjustable

Reduced-voltage welding

function of the manual arc

welding process

Adjustable

Adjustable

Adjustable

Protection against electrode

sticking

Automatic

Automatic

Automatic

PATON VDI-SERIES PRO DC MMA/TIG/MIG/MAG

-9-

Reduction of open-circuit

voltage

ON/OFF

ON/OFF

ON/OFF

Open-circuit voltage in the

MMA process, V

12/70

12/70

12/70

Welding arc starting voltage,

V

110

110

110

Rated consumed power, kVA

4.0 … 4.6

5.5 … 6.1

6.9 … 7.7

Maximum consumed power,

kVA

5.0 … 6.2

6.6 … 8.0

8.5 … 11.0

Efficiency coefficient, %

92

92

92

Cooling

Forced

Forced

Forced

Operating temperature range

-25 … +45 ºC

-25 … +45 ºC

-25 … +45 ºC

Overall dimensions (length

width height), mm

325 245 250

325 245 250

325 245

250

Weight without the coil and

accessories, kg

5.4

5.6

5.7

Protection class*

IP 33

IP 33

IP 33

*These Professional Series welding units are protected against ingress of foreign particles more than

2.5 mm in size and against rain drops if the rain drops fall at an angle to the vertical surfaces of the

welding unit not more than 60 degrees.

The recommended lengths of the welding cables are indicated below.

Cable length

(m)

Maximum

current (A)

Cross-section area

of the cable

conductor (mm2)

Cable

designation

1 … 5

Not more than 160

16

KG 1 16

2 … 8

Not more than 200

25

KG 1 25

3 … 11

Up to 250

35

KG 1 35

PATON VDI-SERIES PRO DC MMA/TIG/MIG/MAG

-10-

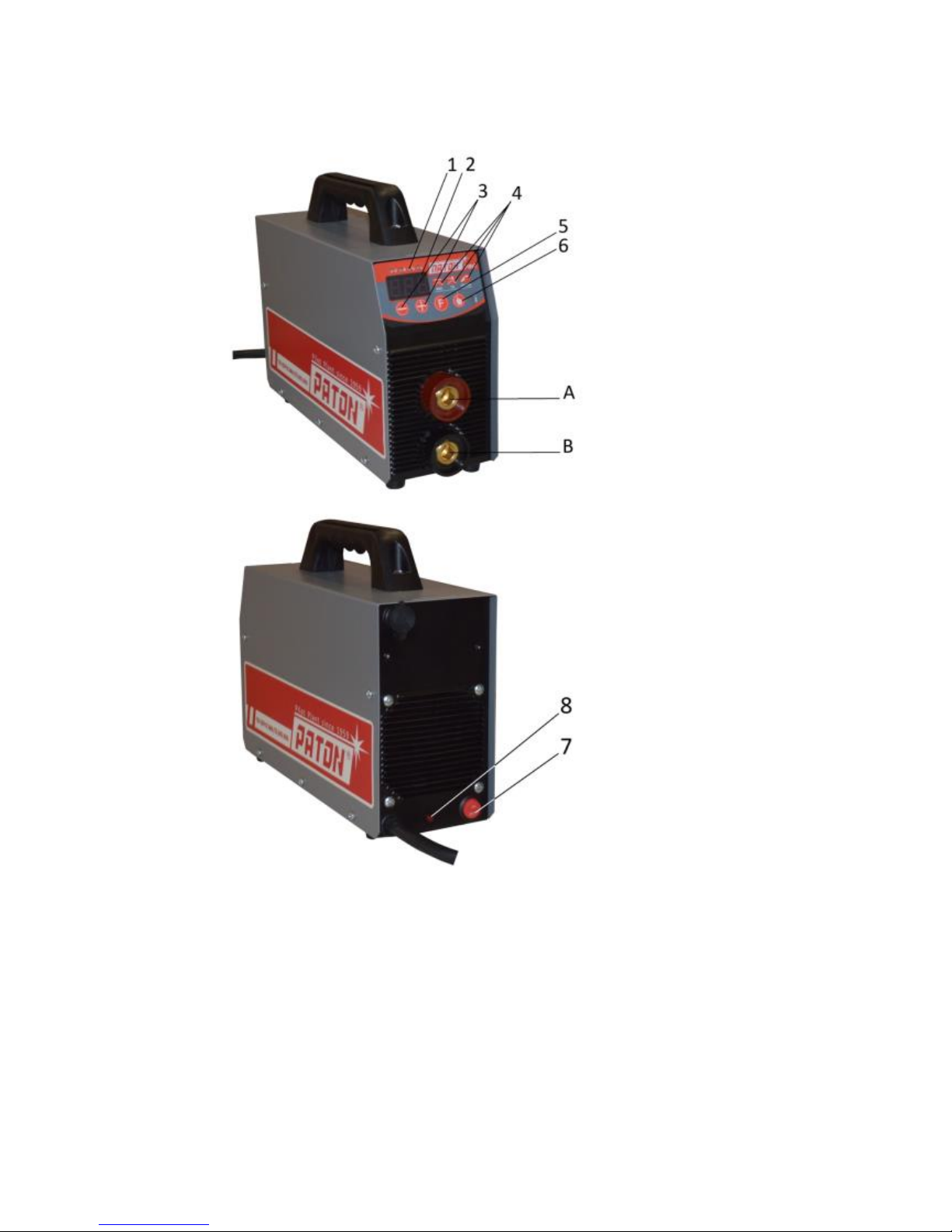

1.2. CONTROLS AND CONNECTORS

1.

Unit of measurement for the current displayed parameter:

a) V - volt

b) A - ampere

c) % - percent

d) s - second

2.

Digital seven-segment display

3.

Buttons for increasing or decreasing the selected parameter value

4.

Indicator of the current or selected welding process

PATON VDI-SERIES PRO DC MMA/TIG/MIG/MAG

-11-

5.

Button for selecting functions for the current welding process and for

switching to the required welding process:

a) Manual covered-electrode arc welding (MMA)

b) Argon arc welding with a no consumable electrode (TIG)

c) Gas-shielded semiautomatic arc welding (MIG/MAG)

6.

Indicator of the operating condition of the welding unit (can blink during

welding):

a) Continuously lights green when the welding unit is in the operating

mode and in the manual arc welding process.

b) Continuously lights yellow when the welding unit is in the standby mode

in the manual arc welding process or semiautomatic arc welding process.

c) Continuously lights red when a fault has occurred or the vending unit is

overheated in any operating mode.

d) Does not light when the power supply voltage is lower or higher than

the rated voltage.

A

(+)

The bayonet connector socket for connecting:

a) The electrode cable (or the grounding cable in some cases when special

electrodes are used for welding) for the manual arc welding process

(MMA)

b) Only the grounding cable for the argon arc welding process (TIG)

This connector socket is not used in the semiautomatic arc welding process

(MIG/MAG)

B (-)

The bayonet connector socket for connecting:

a) The grounding cable (or the electrode cable in some cases when special

electrodes are used for welding) for the manual arc welding process

(MMA)

b) Only the argon gas torch for the argon arc welding process (TIG)

c) The grounding cable for the semiautomatic arc welding process

(MIG/MAG)

7.

Push-button switch for switching on and off the welding unit

8.

Indicator of power supply voltage over 260 V (the indicator lights at the

instant of time when 260 V is exceeded)

2. SETTING THE WELDING UNIT INTO OPERATION

WARNING! Read Section 14, "Safety instructions", before setting the

welding unit into operation.

PATON VDI-SERIES PRO DC MMA/TIG/MIG/MAG

-12-

2.1. PROPER USE

The welding unit is designed for manual covered-electrode arc welding, argon arc

welding, and gas-shielded semiautomatic arc welding. Any other use of the welding unit

is considered as improper. The manufacturer of the welding unit is not responsible for

damages caused by any improper use of the unit.

The use of the welding unit is proper if all the requirements of this Operation Manual are

satisfied.

WARNING!!! Do not use the welding unit to unfreeze pipes.

2.2. REQUIREMENTS FOR INSTALLATION

The welding unit is protected against ingress of foreign particles more than 2.5 mm in

size. The welding unit is allowed for outdoor operation. The internal electrical and

electronic elements of the welding unit are protected against moisture but are not

protected against atmospheric condensate drops.

WARNING! After completing welding works in hot weather, or

completing intensive welding works in any weather, switch off the

welding unit only after at least 5 minutes of time required for the

electronic elements of the unit to be cooled.

WARNING! When operating the welding unit in cold season, after the

unit was switched off and cooled, condensate can be formed inside of the

unit, so switch on the welding unit only 3 … 4 hours after the switching

off.

For this reason, do not switch off the welding unit if it is anticipated that the unit is to be

switched on not later than 4 hours after the switching off.

Install the welding unit so as not to block or cover the ventilation slots on the front and

rear panels of the unit. Prevent ingress of metallic particles (for example, when grinding

the weld) sucked into the welding unit by the unit ventilator.

WARNING! After fall from a height, the welding unit might be a source

of electrical shock. Install the unit on a firm stable surface.

Loading...

Loading...