Patio-Pal® PH Series Patio Heater Installation, Operation, Maintenance and Parts Manual

!

This heater must be installed and serviced by trained gas installation and service personnel only!

WARNING:

Improper installation, adjustment, alteration, service or maintenance can cause property damage, injury or death.

Read the installation, operating and maintenance instructions thoroughly before installing or servicing this equipment.

Protect yourself and others by observing all safety information. Retain instructions for future reference.

PP

P

PP

aa

tio-Ptio-P

a

tio-P

aa

tio-Ptio-P

alal

al

alal

®

PH Series

Gas-Fired High Intensity

Infra-Red Patio Heater

W ARNING!

!

This heater may be used only in outdoor residential

applications or indoor / outdoor commercial (or industrial)

applications. Always observe ventilation requirements as

noted on page 7. This heater is not approved for use in

indoor residential applications (any indoor area attached to

living quarters).

W ARNING!

!

NOT FOR INDOOR RESIDENTIAL USE

This heater is NOT approved for use in any INDOOR

residential application. This includes (but is not limited

to) attached garages, solariums, living quarters, etc.

Consult the local fire marshal and/or insurance provider

if unsure of your application.

For Indoor/Outdoor Commercial Use.

For Outdoor Residential Use.

WARNING!

!

• Children and adults should be alerted to the hazards of

high surface temperatures and should stay away to avoid

burns or clothing ignition.

• Y oung children should be carefully supervised when they

are in the area of the heater.

• Clothing or other flammable materials should not be hung

from the heater, or placed on or near the heater .

• Any guard or other protective device removed for servicing

the heater must be replaced prior to operating the heater .

• Installation and repair should be done by a qualified service

person. The heater should be inspected before use and at

least annually by a qualified service person.

• More frequent cleaning may be required as necessary . It

is imperative that the control compartment, burners and

circulating air passageways of the heater be kept clean.

W ARNING!

!

In locations used for the storage of combustible materials,

signs must be posted to specify the maximum permissible

stacking height to maintain the required clearances from

the heater to the combustibles. Signs must either be

posted adjacent to the heater thermostats or in the

absence of such thermostats in a conspicuous location.

W ARNING!

!

This is NOT an explosion proof heater. Where there is

the possibility of exposure to flammable vapors, consult

the local fire marshal, the fire insurance carrier and other

authorities for approval of the proposed installation.

If you smell gas:

1. Shut off gas to the appliance.

2. Extinguish any open flame.

3. If odor continues, immediately call your gas supplier.

Do not store or use gasoline or other flammable vapors and

liquids in the vincinity of this or any other appliances.

Printed in U.S.A.

© 2006 Detroit Radiant Products Co.

21400 Hoover Rd., Warren, MI 48089

T. (586) 756-0950 F. (586) 756-2626

www.reverberray.com

Form # LIOPH-1M-1/06 (DRP)

Replaces Form#LIOPH-1M-12/05

FOR YOUR SAFETY

FOR YOUR SAFETY

®

Patio-Pal® Installation, Operation, Maintenance and Parts Manual

Patio-PalPatio-Pal

Patio-Pal

Patio-PalPatio-Pal

®

Gas-Fired Infra-Red Patio Heater

Cautions

CAUTION!

The following information should be reviewed

before installing this heater:

• Check the CSA rating label on the heater to verify

model number. Check and maintain the attached

minimum clearance to combustibles label and the

proper gas to be used. Check all labels on the heater

to verify proper mounting.

• The installation of this heater must conform with local

building codes or, in the absence of local codes, with

the National Fuel Gas Code, ANSI Z223.1-1999

(NFP A 54-current edition).

• The installation of this heater in public garages must

conform with the Standard for Parking Structures,

ANSI / NFP A 88A-current edition: or the S tandard for

Repair Garages, ANSI / NFPA 88B-current edition,

and must be at least 8 ft. above the floor while

maintaining all clearances to combustibles.

• The installation of this heater in aircraft hangars must

conform to the Standard for Aircraf t Hangars, ANSI /

NFPA 409-current edition. The heater must be

installed at least 10 ft. above the upper wing surfaces

and engine enclosures of the highest aircraft which

might be stored in the hangar. In areas adjoining the

aircraft storage area, the heaters must be installed

at least 8 ft. above the floor. The heaters must be

located in areas where they will not be subject to

contact by aircraft, cranes, moveable scaffolding or

other objects.

• For installations above 2,000 feet (610 m), the

appliance shall be derated 4 percent for each 1,000

feet (305 m) of elevation above sea level.

• If an external electrical source is utilized, the heater

must be electrically grounded in accordance with

the National Electrical Code, ANSI / NFP A70-current

edition.

• Under no circumstance is either the gas supply line

or the electrical supply line to the heater to provide

any assistance in the suspension of the heater.

• The weight of the heater must be entirely suspended

from a permanent part of the building structure having

adequate load characteristics.

• Neither the gas supply line, electrical supply line nor

sprinkler heads shall be located in or near the path

of the flue products from the heater.

• This heater cannot be used in a building with an

uninsulated roof or condensation problems could

result.

• When installed indoors (

Applications Only), natural or mechanical means

shall be provided to supply and exhaust at least

4.0(Nat.) or 4.5(LP) C.F.M. per 1000 BTU/H of the

heater’s rated input.

• Signs should be posted in storage areas to specify

maximum stacking height allowed in order to

maintain clearance to combustibles. Clearance

safety limit plaques (PLQ), available from Detroit

Radiant Products are recommended for this

purpose.

Commercial/Industrial

2

Patio-Pal® Installation, Operation, Maintenance and Parts Manual

Patio-PalPatio-Pal

Patio-Pal

Patio-PalPatio-Pal

®

Gas-Fired Infra-Red Patio Heater

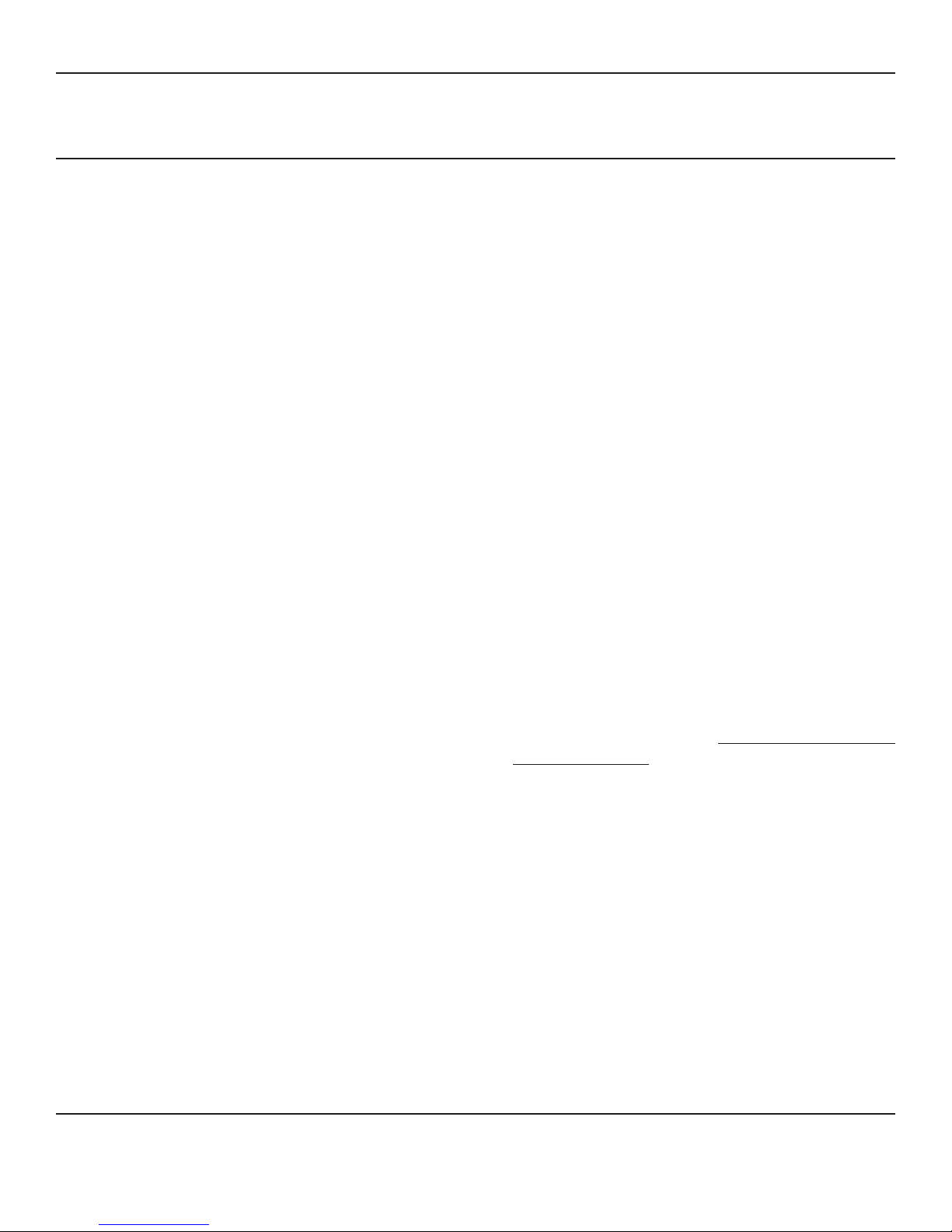

Clearance to Combustibles

W ARNING!

!

Failure to comply with the stated clearance to

combustibles could result in personal injury, death

and/or property damage.

Patio-Pal® Clearance To Combustibles

MODEL NO.

PH 28

28,000

[N,P]

PH 31

31,000

34,000

[N,P]

PH 34

[N,P]

MOUNTING

ANGLE

0° 22 14 46 13 N/A N/A

30° 22 N/A 46 17 8 46

0° 22 14 46 13 N/A N/A

30° 22 N/A 46 17 8 46

0° 22 14 46 13 N/A N/A

30° 22 N/A 46 17 8 46

WARNING!

!

This heater should be installed so that the minimum

clearance to combustibles, as marked on the heater,

will be maintained. If vehicle lifts are present, ensure

that these clearances will be maintained from the

highest raised vehicle.

TOP FRONTSIDE(S) BELOW

BEHINDEND(S)

Figure 1.1 CLEARANCE-TO-COMBUSTIBLES CHART

NOTE: If the heater is mounted beneath a non-combustible surface a 8 in. minimum top clearance

must be maintained from the top of the heater to prevent overheating the controls.

SIDE

TOP

BELOW

END VIEW

0° MOUNTING ANGLE

BEHIND

SIDE

BELOW

END VIEW

30° MOUNTING ANGLE

TOP

FRONT

SIDE VIEW

3

ENDEND

®

Patio-Pal® Installation, Operation, Maintenance and Parts Manual

(

)

Patio-PalPatio-Pal

Patio-Pal

Patio-PalPatio-Pal

®

Gas-Fired Infra-Red Patio Heater

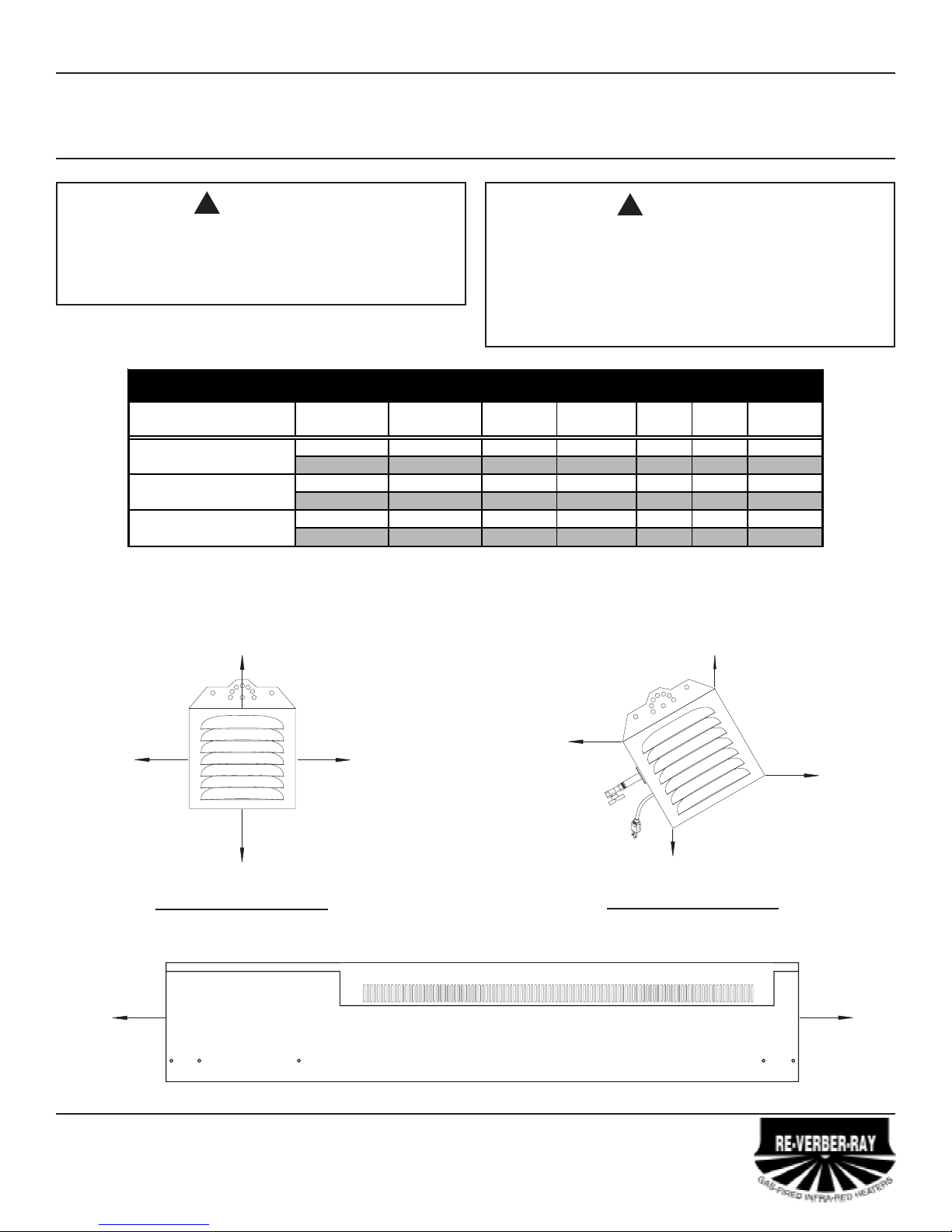

Design

1.1 DESIGN

When positioning heater, keep in mind the clearance to combustibles with materials such as, lights, sprinkler

heads, overhead doors, storage areas with stacked materials, gas and electrical lines, parked vehicles,

cranes, etc. Refer to Figure 1.1 on page 3 for minimum clearance to verify that a safe installation condition

exists. PH Series heaters should never be installed in a recessed ceiling or inside a soffit.

IMPORTANT: In locations used for the storage of combustible materials, signs shall be posted to specify

the maximum permissible stacking height to maintain required clearances from the heater to the

combustibles. Also note that fire sprinkler heads must be located at an appropriate distance from the

heater and that this distance may exceed the published clearance to combustibles. Certain applications

will require the use of high temperature sprinkler heads or the relocation of the heaters. Potentially flammable

substances, such as Propylene Glycol or antifreeze solutions, should not be used in conjunction with our

heaters. For further information consult NFPA 13.

Always observe applicable State and local codes.

NOTE: The effective infrared surface temperature

of a person or object may be diminished with wind

above 5 mph. The use of adequate wind barrier(s)

may be required.

PATIO-PAL® SPOT HEATER LOCATION CHART

APPROX.

MODEL &

INPUT

PH-28

28,000

BTU/H

PH-31

31,000

BTU/H

PH-34

34,000

BTU/H

DIMENSIONS OF

AREA COVERED

7' X 7'

8' X 8'

9' X 9'

APPROX. SQ. FT.

Figure 1.2

COVERED

49 SQ. FT.

64 SQ. FT.

81 SQ. FT.

RECOMMENDED MOUNTING

HEIGHT

"A" DIMENSION

8'-0" to 8'-6"

8'-0" to 9'-0"

8'-6" to 10'-0"

4

Patio-Pal® Installation, Operation, Maintenance and Parts Manual

Patio-PalPatio-Pal

Patio-Pal

Patio-PalPatio-Pal

®

Gas-Fired Infra-Red Patio Heater

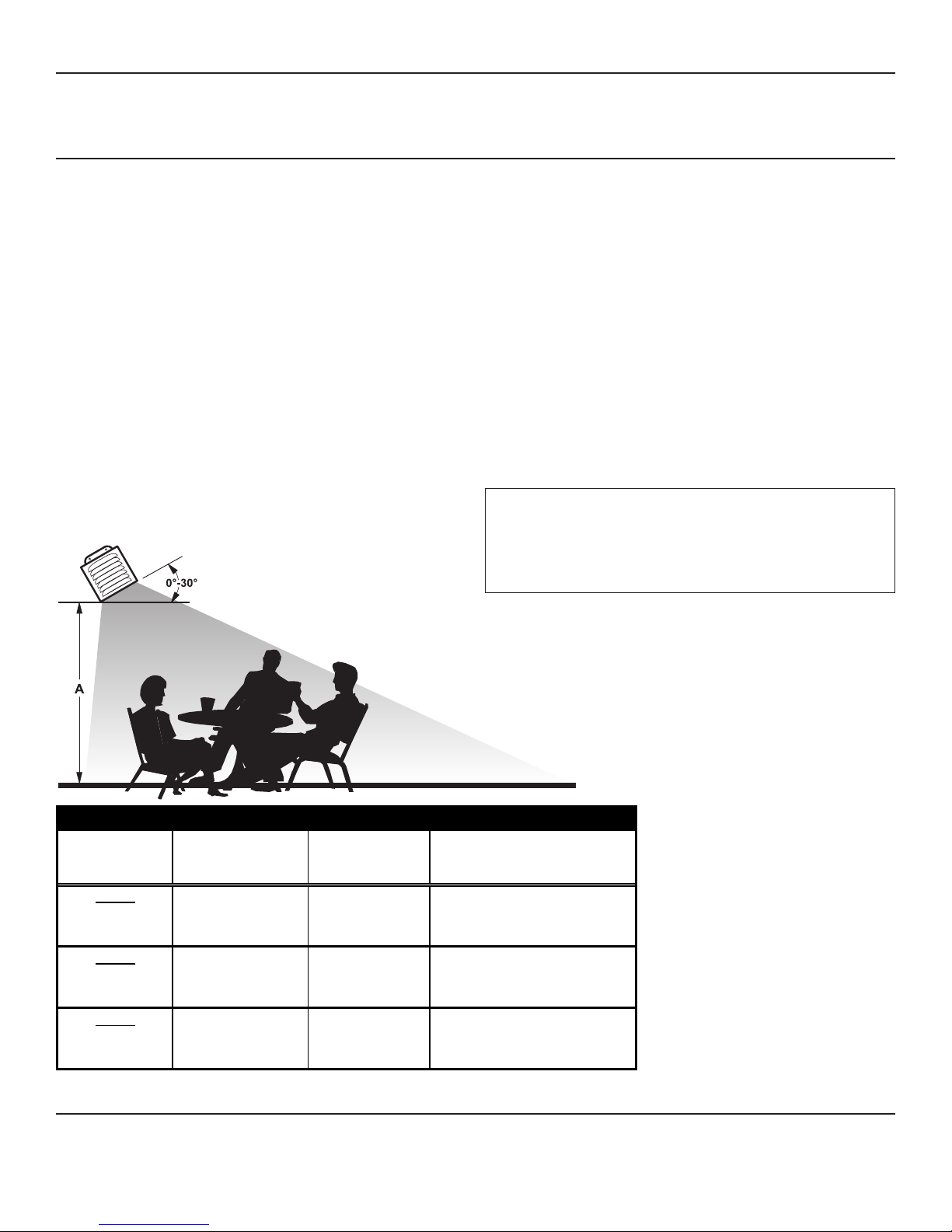

Mounting & Dimensional Data

2.1 HEATER MOUNTING

Figures 2.1 and 2.2 illustrate the more commonly

used methods for heater mounting. Figure 2.1 shows

the fastest and most economical method. Some local

codes or application conditions (where heater

movement or vibration is a possibility and a flex

connector is used) stipulate that the heaters must be

rigidly mounted (Figure 2.2).

• Heater must be level from side to side and the

units must be mounted at a 0° to 30° angle

from horizontal. Gas and electrical lines must

not be located above the path of exhaust.

• When installing heater on an angle (0-30°) place

the gas & electric inlet side down (Figure 2.2)

Threaded

Rod

This

Side

Up

Figure 2.1 TYPICAL HEATER MOUNTING

HEATER DIMENSIONS

9”

8.5”

This

Side

Down

This

Side

Up

This

Side

Down

Figure 2.2 RIGID HEATER MOUNTING

8.5”

45.25”

SIDE VIEW

9”

END VIEW

45.25”

BOTTOM VIEW

5

®

Patio-Pal® Installation, Operation, Maintenance and Parts Manual

Patio-PalPatio-Pal

Patio-Pal

Patio-PalPatio-Pal

®

Gas-Fired Infra-Red Patio Heater

Gas Supply & Connections

3.1 GAS SUPPL Y

CAUTION!

CORRECT INLET PRESSURES ARE VITAL FOR

EFFICIENT OPERATION OF HEATER. REFER TO

AGA/CGA RATING PLATE AND, IF NECESSARY,

CONSUL T GAS COMPANY.

If all or a portion of the gas supply line consists of used

pipe, it must be cleaned and then inspected to determine

its equivalency to new pipe. Test all main supply lines

according to local codes. (Isolate heater gas valve and

supplied gas cock during test.)

Excessive torque on the manifold may misalign the

orifice(s). Always use two wrenches when tightening

mating pipe connections.

W ARNING!

Never use a match or any other flame to test for

gas leaks. Use a soap and water solution to check

for leaks.

If any portion of the gas supply line is located in an area

that could cause an abnormal amount of condensate to

occur in the pipe, a sediment trap should be installed.

NOTE: For high pressure gas above 14 in. W.C.P.

(Water Column), a high pressure regulator and gas cock

must be used. If compressed air is used to detect leaks

in the gas supply line, disconnect and cap shutoff cock

to avoid damage to regulator and gas valve.

A sediment trap in the gas line will decrease the possibility

of any loose scale or dirt in the supply line entering the

heater’s control system and causing a malfunction.

Provide a 1/8 in. (3.2mm) NPT, plugged tapping

accessible for test gauge connection immediately up

stream of gas connection to heater. Consult gas

company for the proper pipe sizing. The gas supply line

must be of sufficient size to provide the required capacity

and inlet pressure to the heater .

NOTE: Manifold pressure should be checked at the tap

on the gas valve. Readings will be above atmospheric

pressure (during operation). Use only a pipe joint

compound that is resistant to liquified petroleum gasses.

The following guidelines must be observed to ensure

proper system performance and safety:

MANIFOLD PRESSURE CHART

Required Manifold

Pressure (WCP)

Natural Gas 5.0 in. 6.0 in. 14.0 in.

Liquified Petroleum

Gas

10.0 in. 11.0 in. 14.0 in.

Figure 3.1

Minimum

Inlet Pressure

(WCP)

Maximum

Inlet Pressure

(WCP)

Allowance for Expansion

• Allowances must be made for the system to expand.

The use of a stainless steel, flexible gas connector

is recommended. If, however, local codes require

rigid piping to the heater, a swing joint can be used.

Gas Line Connection

• The gas outlet shall be in the same room as the

appliance and the connector must not be concealed

within or run through any wall, floor or partition.

• The connector shall be of adequate length.

• The final assembly shall be tested for leaks.

CAUTION: Matches, candles, open flame or other

sources of ignition shall not be used for this purpose.

Leak test solutions may cause corrosion-water rinse

after test.

• Contact with foreign objects or substances should

be avoided.

• The connector should not be kinked, twisted or

torqued.

• Connectors are for use only on piping systems

having fuel gas pressures not in excess of ½ pound

per square inch or 14.0 in. W.C.P.

• Bending, flexing and vibration to the gas connections

should be avoided.

• The appliance and it’s individual shutoff valve must

be disconnected from the gas supply piping system

during any pressure testing of that system at test

pressures in excess of 1/2 psig (3.5 kPa).

• The appliance must be isolated from the gas supply

piping system by closing its individual manual shutoff

valve during any pressure testing of the gas supply

piping system at test pressures equal to or less than

1/2 psig (3.5 kPa).

CAUTION!

CONNECTOR NUTS MUST NOT BE CONNECTED DIRECTL Y

TO PIPE THREADS. THIS CONNECTOR MUST BE

INST ALLED WITH ADAPTORS PROVIDED. DO NOT REUSE.

6

Patio-Pal® Installation, Operation, Maintenance and Parts Manual

Patio-PalPatio-Pal

Patio-Pal

Patio-PalPatio-Pal

®

Gas-Fired Infra-Red Patio Heater

Ventilation & Field Wiring

4.1 V entilation

It is required that the upper levels of the space to be

heated are properly ventilated to supply combustion

air to the heaters and to sufficiently dilute the products

of combustion. This also prevents excessive humidity

buildup. With heaters mounted overhead and a

properly designed ventilation system, products of

combustion and excessive drafts will never be present

at occupancy levels.

For proper ventilation, a positive air displacement

of 4.0 CFM per 1000 BTU/H of natural gas consumed

must be provided. If propane is used, a positive air

displacement of 4.5 CFM per 1000 BTU/H of

propane gas consumed must be provided. Many large

industrial buildings have sufficient air movement to

satisfy these dilution requirements. This air

displacement may be accomplished by either gravity

or mechanical means. Provisions must be made to

provide sufficient fresh air intake area and exhaust air

outlet area.

Mechanical exhausters are preferred and

typically mounted at high points of the building

on areas of the roof where stagnant air can

accumulate under the deck. For a flat roof,

considerations of prevailing winds, high and low

pressure areas, and distribution of air movement

must be taken into consideration when locating

exhausters.

Best air distribution is accomplished by using a

number of small exhausters versus one large

exhauster . Provide a minimum of one square

inch of net free inlet area per 1000 BTU/H for

combustion air supply. Inlet opening in the

building should be well distributed high in the

sidewalls and should direct incoming air upward

to dilute products of combustion while preventing

drafts at lower levels. Inlets are typically 1 to 3

sq. ft.

Local codes may require that mechanical exhaust

systems be interlocked with heaters to enable

both to function simultaneously .

PH Series

L1

L2

PH Series

ThermostatThermostat

L1

L2

Figure 4.1 TYPICAL FIELD WIRING

7

PH Series

Exhaust Fan

®

Patio-Pal® Installation, Operation, Maintenance and Parts Manual

Patio-PalPatio-Pal

Patio-Pal

Patio-PalPatio-Pal

®

Gas-Fired Infra-Red Patio Heater

Operation & Wiring Diagrams

5.1 Operation

· Starting Circuit (see internal wiring diagrams)

When voltage is applied to L1 and L2, a circuit is

completed from L1 via the blower motor to L2. The

blower fan is mounted in the control box and rated to

supply sufficient air for combustion.

Air pressure generated by the blower will cause the

normally open pressure switch to close. Another circuit

is completed from L1 to the spark ignition module and

back to L2. After a seven (7) second pre-purge, the

spark electrode and gas valve are energized

simultaneously . The trial for ignition is fifteen seconds.

Internal Wiring Diagrams

· Running Circuit

After ignition, the flame rod monitors the flame. As long

as a flame is present, the valve is held open. If the

flame is lost, the control acts to close the valve within

one second, and a new trial sequence identical to that

at start-up is initiated. If proof of flame is not established

within the 15 second trial for ignition, the unit will retry

two additional times before entering lockout mode. If

lockout occurs, the control can be reset by briefly

interrupting the power source.

L1

PRESSURE SWITCH

O

ELECTRICAL DIAGRAM

DSI MODULE (120V)

G

BK

WW

ELECTRODE

ASSEMBLY

120V

S ENSE

N EUTRAL

Fan

HV

T STAT

V ALVE

N EUTRAL

GAS VALVE

BK

L2

PICKER

RELAY

24V

T-STAT

TERMINAL

G ROUND

W

L1

THERMAL

NC

NO

G

SWITCH

COM

PRESSURE

SWITCH

O

ELECTRODE

ELECTRICAL DIAGRAM

DSI MODULE (120V)

G

BK

ASSEMBLY

120V

Fan

HV

T STAT

N EUTRAL

V ALVE

N EUTRAL

BK

GAS VALVE

S ENSE

WW

G ROUND

L2

W

Figure 5.1 PH SERIES 120V Figure 5.2 PH SERIES 120V WITH 24V CONTROL

8

Patio-Pal® Installation, Operation, Maintenance and Parts Manual

g

gh g

Patio-PalPatio-Pal

Patio-Pal

Patio-PalPatio-Pal

®

Gas-Fired Infra-Red Patio Heater

Maintenance & Troubleshooting

6.1 MAINTENANCE

WARNING!WARNING!

WARNING!

WARNING!WARNING!

!

Disconnect all power sources related to the

installation before servicing any component.

Use protective glasses when cleaning the heater.

If the control assembly is not completely

disconnected from the manifold, the high air

pressure will cause the controls to become

defective.

It is recommended that the following become a

standard yearly procedure to obtain maximum

operating efficiency and trouble free operation.

7.1 TROUBLESHOOTING

SYMPTOM POSSIBLE CAUSE CORRECTIVE ACTION

Burning of gas-air mixture inside

plenum (flashback).

Delayed ignition.

Low ceramic surface temperature,

excessive rollout or soot on

rods.

Control system overheating.

Gas odor. 1. Loose pipe connection. 1. Check all connections. Ti

Heater cycles repeatedly.

No spark; no ignition.

Heater lights, and "locks out" after

approximately 10 seconds.

Spark is present. No main gas

operation. Unit "locks out".

Heater will not shut off.

1. Heater mounted at incorrect angle. 1. Mounting angle 0º-30º.

2. Excessive drafts. 2. Relocate or shield from draft.

3. Gas leaking at orifice, spud, pilot tube. 3. Check with leak detector solution.

4. Separation of ceramic grids. 4. Replace burner.

5. Ceramic grids cracked. 5. Replace burner.

1. Electrode out of specification. 1. See Ignition System insert.

2. Low gas pressure. 2. See Section 3.1, Gas Supply.

3. Partially blocked orifice. 3. Clean or replace.

4. Improper orifice size. 4. Consult dealer.

5. Incorrect gas. 5. See unit nameplate.

1. Dirty or plugged burner ceramics. 1. See perodic maintenance instructions.

2. Partially blocked orifice. 2. Remove and clean.

3. Low inlet gas pressure. 3. See Section 3.1, Gas Supply.

4. High or Low manifold gas pressure. 4. Adjust main valve regulator as specified.

5. Foreign matter in venturi tube. 5. See periodic maintenance instructions.

6. Excessive dark spots on burner. 6. See periodic maintenance instructions.

7. Gas supply piping too small. 7. Increase inlet pressure or replace undersized piping.

8. Incorrect gas. 8. See unit nameplate.

1. Heater not mounted correctly. 1. Mounting angle 0º-30º. Level heater left to right.

2. Heater mounted too close to ceiling. 2. Observe clearance to combustibles

1. Heater located in drafty area. 1. Relocate or shield from draft.

2. Low gas pressure. 2. See Section 3.1, Gas Supply.

3. Thermostat located in drafty area. 3. Relocate thermostat.

5. Defective flame electrode or circuit board. 5. Replace.

1. Lack of 120V or 24V incoming voltage. 1. Check power supply.

2. Open high voltage wire. 2. Isolate and ohm for resistance, replace if 0.

3. Improper electrode gap. 3. See Ignition System specifications.

4. Loose or open wire connection. 4. Check all wires, tighten or replace.

5. Pressure switch not satisfied. 5. Verify fan operation. Remove obstructions.

6. Poor or no equipment ground. 6. Check all connections, provide positive earth ground.

7. Unit in "safety lockout" mode. 7. Interrupt power source, repeat trial for ignition.

8. Defective "Gaslighter" control. 8. Replace.

1. Poor or no equipment ground. 1. Check all connections, provide positive earth ground.

2. Polarity is reversed. 2. 120V to black, neutral to white.

3. Low gas pressure. 3. See Section 3.1, Gas Supply.

4. Electrode not sensing. 4. Relocate or replace if defective.

5. Heater mounted at incorrect angle. 5. Mounting angle 0º-30º.

6. Defective "Gaslighter" control. 6. Replace.

1. Gas valve in "OFF" position. 1. Turn to "ON" position.

2. Defective gas valve. 2. Isolate and check for resistance. Replace if 0.

3. Defective "Gaslighter" control. 3. Replace.

1. Defective thermostat or wiring. 1. Replace or repair.

2. Gas valve stuck open. 2. Replace.

as pressure. 3. See Section 3.1, Gas Supply.

3. Hi

During long periods of non-usage, remove or cover heater

with a polyethylene bag and shut off gas supply . If further

service to the heater is desired, contact your

representative or the factory .

Main Burner

1. Use an air hose to blow any accumulated dust and/

or dirt off the heater . Air hose pressure should

not exceed 30 psig.

2. Pass the air hose over the entire exposed area of

the ceramic. A distance of 2’ to 4’ from the unit is

recommended.

3. Place the air hose outlet into each venturi tube and

allow the air to flow for approximately one minute.

hten as necessary.

9

®

Patio-Pal® Installation, Operation, Maintenance and Parts Manual

Patio-PalPatio-Pal

Patio-Pal

Patio-PalPatio-Pal

Parts Breakdown

®

Gas-Fired Infra-Red Patio Heater

10

Patio-Pal® Installation, Operation, Maintenance and Parts Manual

Patio-PalPatio-Pal

Patio-Pal

Patio-PalPatio-Pal

Parts List

®

Gas-Fired Infra-Red Patio Heater

PARTS LIST

®

Patio-Pal

PART# DESCRIPTION PART# DESCRIPTION

PH-101 TOP PANEL PH-147 3/8" INCOMING PIPE NIPPLE

PH-102 LEFT FRAME SIDE PANEL (GAS & ELECTRIC) PH-148 3/8" GAS COCK

PH-103 RIGHT FRAME SIDE PANEL PH-149 RUBBER INLET GROMMET

PH-104 CONTROL END PANEL W/ LOUVERS PH-150 IGNITOR ELECTRODE

PH-105 CONTROL BOX COVER W/HINGE PH-151 CIRCUIT BOARD (MARK 10DX-117)

PH-106 END PANEL PH-152 100-900 HARNESS (DRWH-120)

PH-107 HANGING BRACKETS PH-153 CONTROLS MOUNTING PANEL

PH-108 BURNER END MOUNTING PANEL PH-155 ORANGE WIRE W/BOOT

PH-110 RAIN GUARD PH-156 ORANGE CONNECTOR (WIRE NUT)

PH-111 EGG CRATE PH-157 THERMAL FUSE

PH-112 EGG CRATE FRAME PH-160 PRESSURE SWITCH MOUNTING BRACKET

PH-113 EGG CRATE HOLD DOWN PH-161 PRESSURE SWITCH (TP-264B)

PH-115 FAN PH-162 SHORT HOSE

PH-116 FAN MOUNTING PANEL PH-163 LONG HOSE

PH-117 AIR DISTRIBUTION CHANNEL PH-168 BRASS FITTING

PH-125 PICKER RELAY PH-169 "THREADED" BARB FITTING

PH-133 120 VOLT CORD PH-170 INTERNAL BURNER ASSEMBLY W/ HOLDDOWNS & FOOTINGS

PH-134 24 VOLT CORD PH-171 VALVE MOUNTING BRACKET

PH-137 STRAIN RELIEF PH-172 VALVE MOUNTING PANEL

PH-140 GAS VALVE - NATURAL GAS PH-173 CONTROLS FLASHSHIELD

PH-141 GAS VALVE - PROPANE PH-174 BURNER & ELECTRODE MOUNTING PANEL

PH-142 CLOSE PIPE NIPPLE PH-196 3/8" SCREWS

PH-143 3/8" REDUCER FITTING PH-197 3/8" BOLTS

PH-144 GAS ORIFICE PH-198 3/8" NUTS

PH-145 LOCK WASHER PH-199 "TENSION" CLIPS

PH-146 NUT

11

®

Patio-Pal® Installation, Operation, Maintenance and Parts Manual

Patio-PalPatio-Pal

Patio-Pal

Patio-PalPatio-Pal

®

Gas-Fired Infra-Red Patio Heater

Limited Warranty

Limited Warranty

One-Year Limited W arranty. Patio Heaters covered in this manual, are warranted by Detroit Radiant Products Company to

the original user against defects in workmanship or materials under normal use for one year after date of purchase. Any part

which is determined to be defective in material or workmanship and returned to an authorized service location, as Detroit Radiant

Products Company designates, shipping costs prepaid, will be, as the exclusive remedy , repaired or replaced at Detroit Radiant

Products Company’s option. For limited warranty claim procedures, see PROMPT DISPOSITION below . This limited warranty

gives purchasers specific legal rights which vary from jurisdiction to jurisdiction.

Additional Limited Warranty. In addition to the above mentioned one-year warranty, Detroit Radiant Products Company

warrants the original purchaser an additional two-year extension on the ceramic burner . This extension excludes electrical/

purchased components.

Limitation of Liability. To the extent allowable under applicable law, Detroit Radiant Products Company’s liability for

consequential and incidental damages is expressly disclaimed. Detroit Radiant Products Company’s liability in all events is

limited to and shall not exceed the purchase price paid.

Warranty Disclaimer. Detroit Radiant Products Company has made a diligent effort to provide product information and

illustrate the products in this literature accurately; however, such information and illustrations are for the sole purpose of

identification, and do not express or imply a warranty that the products are merchantable, or fit for a particular purpose, or that

the products will necessarily conform to the illustrations or descriptions. Except as provided below , no warranty or affirmation

of fact, expressed or implied, other than as stated in the “LIMITED WARRANTY” above is made or authorized by Detroit Radiant

Products Company .

Product Suitability . Many jurisdictions have codes and regulations governing sales, construction, installation, and/or use of

products for certain purposes, which may vary from those in neighboring areas. While Detroit Radiant Products Company

attempts to assure that its products comply with as many codes, it cannot guarantee compliance, and cannot be responsible

for how the product is installed or used. Before purchase and use of a product, review the product applications, and all

applicable national and local codes and regulations, and be sure that the product, installation, and use will comply with them.

Certain aspects of disclaimers are not applicable to consumer products: e.g., (a) some jurisdictions do not allow the exclusion

or limitation of incidental or consequential damages, so the above limitation or exclusion may not apply to you: (b) also, some

jurisdictions do not allow a limitation on how long an implied warranty lasts, consequently the above limitation may not apply to

you: and (c) by law, during the period of this limited warranty , any implied warranties of implied merchant ability or fitness for a

particular purpose applicable to consumer products purchased by consumers, may not be excluded or otherwise disclaimed.

Prompt Disposition. Detroit Radiant Products Company will make a good faith effort for prompt correction or other adjustment

with respect to any product which proves to be defective within limited warranty . For any product believed to be defective within

limited warranty, first write or call dealer from whom the product was purchased. Dealer will give additional directions. If unable

to resolve satisfactorily , write to Detroit Radiant Products Company at address below , giving dealer’s name, address, date and

number of dealer’s invoice, and describe the nature of the defect. Title and risk of loss pass to buyer on delivery to common

carrier. If product was damaged in transit to you, file claim with carrier .

Registration. Register on-line at www .reverberray.com/warranty.

Detroit Radiant Products Company

21400 Hoover Road Warren, MI 48089 U.S.A.

Voice: (586) 756-0950

Fax: (586) 756-2626

Website: www .reverberray.com

12

Loading...

Loading...