Page 1

Installer’s Guide

This installation guide describes the requirements

for and the steps involved in the permanent

installation of Pathway C-series, D-series and Rseries two-port Pathport® nodes, and Uno single-port

nodes. Some familiarity with DMX512 and Ethernet

lighting networks is assumed.

PRE-CONFIGURATION

Pathport nodes hold their IP and patch configuration in

non-volatile memory. Significant on-site time savings can

be attained by configuring the node name and network

information in the shop. To do so, use the network requirements below to create a mock-up installation. Configure the nodes using Pathport Manager software. Put

temporary labels on the nodes showing their fit-up location, then repackage them for shipping.

ON-SITE CONFIGURATION

If nodes are not pre-configured, configuration can done

after installation, on-site. The configuration process will

involve recording the IP address of each node, and then

using Pathport Manager software.

NETWORK REQUIREMENTS - WIRING & LAYOUT

All network wiring should follow standard Ethernet wiring rules and be installed by a qualified person. Category

5 wiring or better is required. Pathway recommends following the Entertainment Services and Technology Association (ESTA) publication Recommended Practice for

Ethernet Cabling Systems in Entertainment Lighting Applications and its supplement. Both documents are avail-

able on-line at www.esta.org.

As part of the installation, all Ethernet wiring should be

certified under the TIA/EIA-568 standard. Pathway may

limit the technical support provided to nodes installed on

non-certified systems.

Good wiring practice does not allow terminating building

wire with a male RJ45 plug or the hard-wiring of data lines

to end devices. To facilitate proper practice, Pathport 2port nodes ship with an in-line female RJ45 mini-jack,

similar to a punchdown connector, as well as a short

male-to-male RJ45 jumper to connect the jack to the

node. The in-line jack can be installed by finger-pressure

alone, although pliers are recommended. A crimping tool

is not needed. The jumper and jack are available as an

accessory package for the Pathport Uno.

To install the in-line connector, first determine if the installation is using TIA568A or TIA568B wiring scheme.

Strip back the outer insulation jacket no more than ¾”.

Untwist the pairs, trim them to the same length but do not

remove insulation from the individual wire. Following the

applicable color coding scheme on the sticker, slip the

individual wires into the clear plastic guide piece. Position

the guide piece onto the connector half of the jack, and

press down or gently apply pressure with a pair of pliers

until the two pieces click together. The mini-inline connector is removable, if necessary.

NETWORK REQUIREMENTS - POE

Pathport nodes are designed to take advantage of the

IEEE 802.3af standard, commonly called Power-overEthernet (PoE). PoE-enabled switches are readily available, and their use is strongly recommended to simplify

installation and prevent the need for separate power cabling. Please note that the Pathport Uno can only by

powered using PoE and cannot be hooked up to an auxiliary supply.

NETWORK REQUIREMENTS - ETHERNET SWITCHES

For entertainment lighting networks, unmanaged or

plug-and-play switches are preferable to managed or enterprise switches. However with larger networks, sometimes the only switches available with the number of ports

required will be managed. There are two issues commonly encountered with managed switches. First is

broadcast storm control.

DMX-over-Ethernet protocols are multi-cast or broadcast protocols where one source (the console) sends all

the information to all the nodes and each node determines what part of the data stream to use. However the

management features of most switches are intended for

the unicast or one-to-one environment of an office. A

continual broadcast transmission looks like an error – a

broadcast storm – which the switch will try to block. In a

show situation, this would be disastrous. Broadcast storm

features must be disabled.

The other issue is multi-cast filtering. Managed

switches attempt to direct traffic in an intelligent manner

by learning what devices are on what port. Although useful in the unicast environment of an office, this feature can

bog down the lighting network and lead to lost packets.

The ‘snooping’ done to facilitate multi-cast filtering is

known to cause issues with broadcast protocols and so

Page 2

this feature, often called Inter Group Management Protocol (IGMP) should be turned off.

Other security features of the managed switch should

be examined. Most will not be necessary on a lighting

network and should be disabled. At the very least, this

will help keep the through-put speeds of the switch as

high as possible.

One feature that managed switches can provide that

unmanaged switches cannot is redundancy. Managed

switches can be configured to work around a problem or

even to activate a redundant leg of the network. In some

applications, this feature may be sufficiently desirable to

offset the added configuration time and expense.

For unmanaged and plug-and-play switches, the feature

sheets must be carefully examined to ensure broadcast

storm and IGMP filtering are not permanently turned on.

Switches should be connected to an uninterruptible

power supply (UPS) with power conditioning. A UPS allows for orderly shutdown in case of power failure, and

protects against spikes and brown-outs, which can cause

memory corruption or physical damage to the nodes.

OPERATING ENVIRONMENT

All Pathport nodes are designed for indoor use in a dry

location. To maximize equipment life and minimize unreliability and sudden failure, the following environment

should be maintained:

• ambient temperature extremes: -10 to +50 degrees C

• operating temperature: 0 to +40 degrees C

• relative humidity: 10 – 95%, non-condensing

• general conditions: clean, dust-free

Installer’s Guide

connector, use the male-to-male jumper (included) to connect it to the node. Otherwise, plug the male RJ45 pigtail

directly into the connector on the back of the node. Attach the green ground wire to the ground screw in the

backbox.

If local power is required for the node, see the note on

local power at the end of this guide.

Gently insert the node straight into the backbox, lifting it

slightly so that is high in the backbox. Once all the way in,

lower it slightly until the tabs at the top of the trim ring

take hold of the face plate. Once the top of the node’s

faceplate is retained, swing the bottom in tight to the wall.

Make sure no wiring or connectors are pinched or excessively bent or stressed. Using a #0 Phillips driver (not

included), tighten the two setscrews provided, one on

each side of the node’s face, to complete installation. If

the nodes have shipped with hex-head set screws, instead use a 1/16” Allen key (not provided)

The node is ready to be powered up.

C-SERIES NODE INSTALLATION

Disconnect all power before proceeding with the instal-

lation.

C-series nodes are designed to be installed in recessed, standard two-gang masonry deep backboxes

(ears in) for flush-mounting or, for surface mounting, in

Pathport surface mount backboxes, part number 6901.

Use of other surface mount backboxes is not recommended.

If the node has been pre-configured, check the temporary label to ensure the node is being installed in the correct location.

Check the installed backbox for obstructions or any foreign material. The backbox should be clean and empty.

Make sure there is a RJ45 female punchdown connector

in the box (preferred) or a male RJ45 pigtail. Install the

in-line jack provided, if necessary.

Attach the Pathport trim ring to the backbox with the 4

screws provided. Do not over-tighten or do anything that

will distort the shape of the trim ring.

Inspect the node and make sure all components are

secure and that the printed circuit boards are secure.

Note that it is normal to see exposed metal on the mating

connectors.

If the backbox contains an RJ45 female punchdown

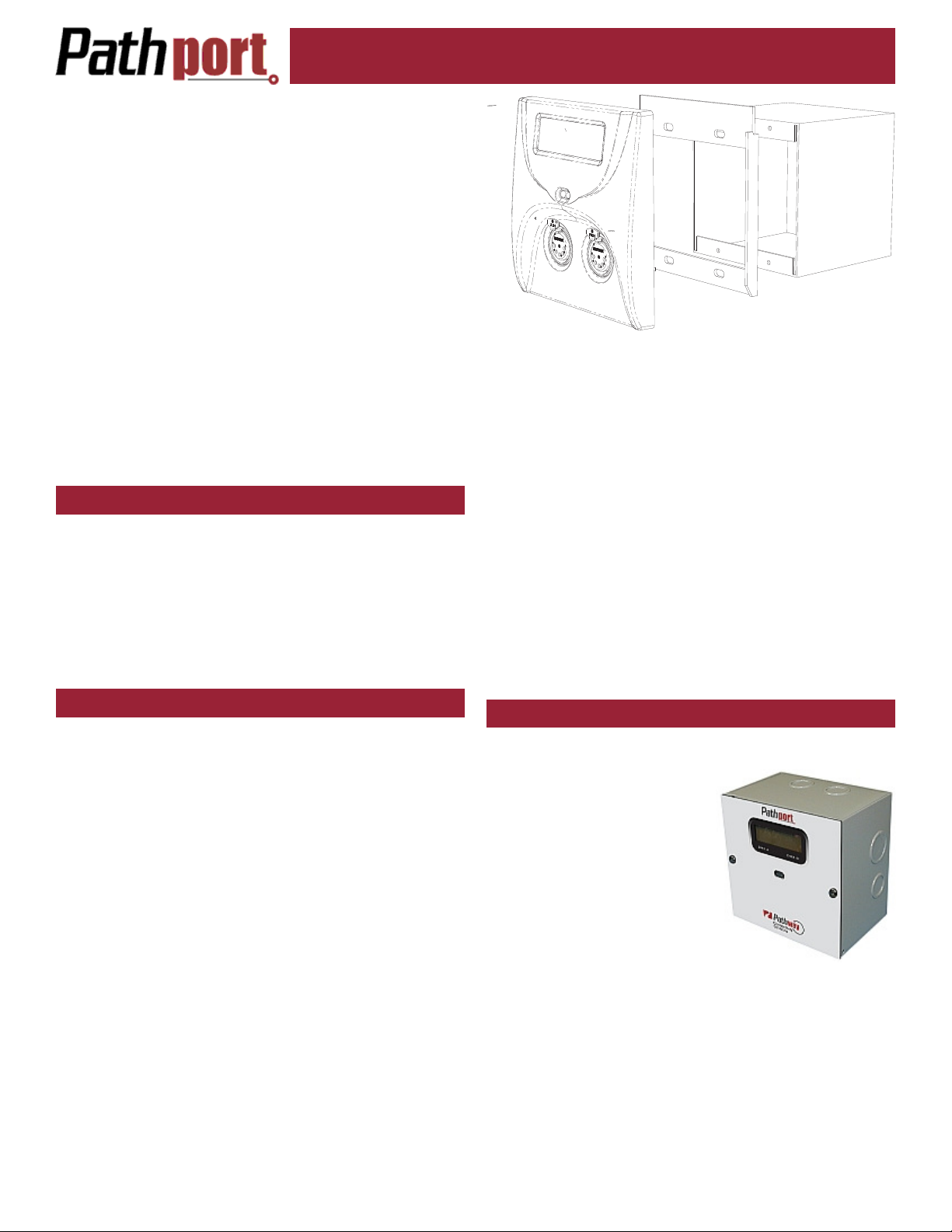

D-SERIES NODE INSTALLATION

Disconnect all power before proceeding with installa-

tion.

D-series nodes are surfacemount enclosures designed for

conduit-enclosed cabling connection to permanently installed

equipment such as dimmers

and relay cabinets. D-series

nodes are shipped attached to

their backboxes.

First, remove the two screws

holding the faceplate to the

backbox. Keep the screws for

later use. Gently remove the faceplate and attached

printed circuit boards. Put the faceplate in a safe and

clean location, such as back into its shipping container.

Determine the location of the backbox in relation to the

incoming and outgoing conduit lines. Remove the appropriate knockouts then securely mount the backbox to the

wall using appropriate fasteners. If the backbox must be

installed prior to the completion of the conduit and wiring

runs, then label the backbox and the container holding the

removed faceplate and store the container in a safe location. Make sure the two faceplate screws are stored in

2

Page 3

Installer’s Guide

the same box.

Attach the conduit runs to the enclosure using standard

connectors (not supplied). The backbox should be clean

and free of obstructions or foreign materials. Inside, there

should be one Cat5 wire with a female RJ45 punchdown

connector (if necessary, install the mini-jack included) and

one or two cables for the DMX connections, ending in

bare wires. Identify which cable is for DMX Universe A

and which is for DMX Universe B.

Retrieve the faceplate from the storage container. Inspect it for damage and to ensure the printed circuit

boards are securely fastened.

Using the XLR pin-out chart at the end of this guide,

attach the cable for DMX Universe A to the terminal block

marked DMX Port A. Repeat, if necessary, for DMX Port

B. If Cat5 cable is being used to complete the DMX run,

use the Cat5 pin-out guide instead.

Using the male-to-male jumper, connect the female

RJ45 connector to the connector on the back of the circuit

board of the node. If the Ethernet wiring has been terminated with a male RJ45 connector (not recommended),

plug it directly into the circuit board connector.

If local power is required, see the note at end of this

guide.

Gently position the faceplate on the backbox until the

screw holes line up, while taking care that no wiring is

pinched or excessively bent or stressed inside the box.

Using the original two screws, reattach the faceplate. Do

not over tighten.

The node is ready to be powered up.

R-SERIES INSTALLATION

Disconnect all

power before

proceeding with

installation.

R-series nodes are designed for installation in

standard EIA 19” racks, at least 18” deep. Up to two Rseries nodes may be installed in one RU of space, using

the included rack-mount ears. Nodes may be mounted

with the display or the connectors toward the front of the

rack. The side walls of the node have an identical screw

pattern at the front and rear. Rack ears can be mounted

on either side of the node.

Determine which direction the node is to face and remove the appropriate four 4-40 Phillips screws from each

side of the enclosure. Attach the 3 inch rack ear to one

side of the node with the pan-head screws included, reusing the 4-40 screw holes. If only one node is being

mounted in the rack space, attach the 10 inch rack ear to

the opposite side of the node, again using the pan-head

screws included. Attach the assembled unit to the rack

using standard rack screws (not included).

If two nodes are to be mounted side-by-side in the rack

space, attach the 3 inch ear to the opposite side of the

second node, again using the pan-head screws provided

into the empty 4-40 screw holes. Then attach the 1-inch

link-ears to the sides of the nodes facing each other using

the pan-head screws provided. Attach the two 1-inch linkears together using four of the Phillips 4-40 screws removed earlier. Do not tighten down completely. Attach

the assembled unit into the rack using standard rack

screws. Now tighten the 4-40 screws to finish the link-ear

assembly.

Plug in the appropriate XLR connectors to the node to

complete the DMX lines. If the node has terminal blocks,

use the XLR pin-out chart at the end of this guide. Attach

the cable for DMX Universe A to the terminal block

marked DMX Port A. Repeat for DMX Port B. If Cat5 cable is being used to complete the DMX run, use the Cat5

pin-out chart instead.

For most installations, the Ethernet switch is located in

the same rack as the nodes. Using a male-to-male RJ45

patch cable (not included), connect the female RJ45 jack

on the node to the switch. If the switch is located elsewhere, consult the appropriate drawings for the Ethernet

jack location.

The node is ready to be powered up. If auxiliary power

is required, see the note on local power at the end of this

guide.

PATHPORT UNO INSTALLATION

Disconnect all power before proceeding with installation. Pathport Unos can only be powered using Powerover-Ethernet.

Pathport Uno single-port nodes are

designed to be installed in recessed,

standard masonry deep backboxes

(ears in) for flush mounting, or deep

(minimum 58mm or 2.25”) surface

mount backboxes. Unos may also be

installed in multi-gang backboxes with

other low voltage devices or Pathway

modular receptacles. In this instance,

the single gang faceplate provided will

need to be replaced with a multi-gang

faceplate. Cover plates ranging from

double-gang up to 6-way, in brushed

stainless steel or black, are available from Pathway.

If the node has been pre-configured, check the temporary label to ensure the node is being installed in the correct location.

Two important things must be done prior to installing

the Uno. Uno nodes can be permanently set to a specific

DMX universe, 1 through 4, by use of a jumper on the

back edge of the circuit board. If the system designer has

not given specific instructions about the setting, then

leave the jumper in the NET position. This position will

allow the universe the node operates on to be set remotely at a later time.

Second, each Uno node ships with additional serial

number stickers. Do not lose these stickers. Because

Unos do not have a faceplate screen, serial numbers and

their locations are necessary to configure the system.

Losing track of this information will add considerable time

to commissioning.

3

Page 4

Installer’s Guide

As each node is installed, remove one of the additional

serial number stickers and place it on the Installation Record Sheet included with each Uno. Write down the location, jumper settings and any other comments. A second

sticker can be placed on the face of the Uno for identification during commissioning. This sticker can be easily removed and discarded when no longer needed.

Once this information is recorded, check the backbox

for obstructions or foreign material. The backbox should

be clean and empty. Make sure there is a RJ45 female

punchdown connector (preferred) in the box or a male

RJ45 pigtail.

Inspect the Uno and make sure all components are securely fastened and that the printed circuit boards are intact.

If the back backbox contains an RJ45 female punchdown connector, use a male-to-male jumper to connect it

to the node. Otherwise, plug the male RJ45 pigtail directly into the connector on the back of the node. Attach

the green ground wire to the ground screw in the backbox.

Gently insert the Uno straight into the backbox and

screw it into place with the long mounting screws provided. Place the cover plate over the installed Uno and

use the two short screws to fasten the cover plate. Do

not over-tighten these screws.

When the network switch or in-line injector is turned on,

the Uno will power up. Remember, the Uno will only operate on Power-over-Ethernet.

TESTING THE INSTALLATION

Once all connections are made and inspected for errors, power up the Ethernet switches on the network. The

Pathports should boot up and, except for the Uno, display

their IP address or node name, if configured. The NET

LED will illuminate on the Uno, showing that it has power.

The appropriate lights on the Ethernet switches should

also light up.

At this point, refer to the Pathport Manager Software

User Manual for system configuration and protocol selection.

LOCAL POWER

All C-series, D-series and R-series nodes can be connected to an external power supply, for situations where

Power-over-Ethernet is not available. Each node will require a supply between 18 and 50VDC and consume 4

watts of power.

With the power supply turned off, connect the bare wire

ends to the 2-wire terminal block (included). Slip the

block over the pins marked V+ and V-, observing polarity.

On C- and D-series nodes, these pins are mounted on the

circuit board. On R-series nodes, the connector is on the

back face of the unit. Check all wiring, then connect the

power supply to the mains power. The node should boot

up.

DMX XLR CONNECTOR WIRE TERMINATION

Wire color is manufacturer-specific. Use the connector

to determine pin number for each wire.

XLR Pin Standard RS422/485 Wire Conductor

Pin 1 Shield

Pin 2 Data – (pair 1 complement)

Pin 3 Data + (pair 1 true)

Pin 4 Optional Data – (pair 2 complement)

Pin 5 Optional Data + (pair 2 true)

The following is the termination for Cat5 cable, when

used for DMX.

Wire

Colour

and #

White/

orange

(1)

Orange

(2)

White/

green (3)

Green

(6)

Blue

(4)

White/

blue (5)

White/

brown

(7)

Brown

(8)

This chart is based on the current ESTA draft standard

BSR E1.27-2 and is intended for DMX cabling - NOT

DMX-over-Ethernet cabling. This pinout chart should NOT

be used for wires carrying Ethernet signals or DMX-overEthernet protocols.

Great care must be taken to prevent the accidental connection to non-DMX equipment.

The connection of DMX equipment to non-DMX equipment such as Ethernet switches may result in serious

equipment damage.

To help prevent this possibility, unless the wires have

another known usage in the existing installation, wires 4

and 5 should be capped and turned back rather than connected.

The use of RJ45 connectors for DMX equipment should

be restricted to patch bays in access controlled rooms

and should not be used for the direct connection of portable equipment.

Data + (pair 1 true)

Data –

(pair 1 complement)

Optional Data +

(pair 2 true)

Optional Data –

(pair 2 complement)

Unassigned

Unassigned

Data signal common for

Pair 1 1

Data signal common for

Pair 2

Function

XLR Pin

Number

3

2

5

4

1

4

Page 5

ESTA

ENTERTAINMENT SERVICES &

TECHNOLOGY ASSOCIATION

PATHPORT SYSTEM COMPONENTS

Model Number Model Description

6001 Single node inline power supply

6010 Pathport Manager Configuration Software on CD

6101 Pathport Uno, Single DMX input node with cover

6102 Pathport Uno, Single DMX output node with cover

6151 Pathport Uno, Single DMX input with Portable Enclosure and bracket

6152 Pathport Uno, Single DMX output with Portable Enclosure and bracket

6201 Pathport C-series node with 2 DMX inputs (XLR5M)

6202 Pathport C-series node with 2 DMX outputs (XLR5F)

6203 Pathport C-series node with 1 DMX input and 1 DMX output (XLR5M/F)

6225 Pathport D-series node with 2 DMX ports (terminals) and backbox

6235 Pathport R-series node with 2 DMX ports (terminal strips)

6241 Pathport R-series node with 2 DMX inputs (XLR5M)

6242 Pathport R-series node with 2 DMX outputs (XLR5F)

6243 Pathport R-series node with 1 DMX input and 1 DMX output (XLR5M/F)

6301 Pathway DMX Manager Plus 4-port node (XLR5)

6302 Pathway DMX Manager Plus 4-port node (terminal strips)

6901 C-series Surface Mount Enclosure

6911 C-series Portable Enclosure with hanging bracket

6913 R-series Truss mount kit

6931 R-series front connectors adaptor kit – inputs (XLR5M)

6932 R-series front connectors adaptor kit – outputs (XLR5F)

6933 R-series front connectors adaptor kit – input/output (XLR5M/F)

6950 RJ45 female in-line mini-jack and M-M RJ45 jumper kit

Installer’s Guide

rev.2, ver.1

Pathway Connectivity Inc.,

1439 17Avenue SE, #103 Calgary AB Canada T2G 1J9

tel (403) 243-8110 fax (403) 287-1281

support@pathwayconnect.com

www.pathwayconnect.com

Printed in Canada

11/07

Loading...

Loading...