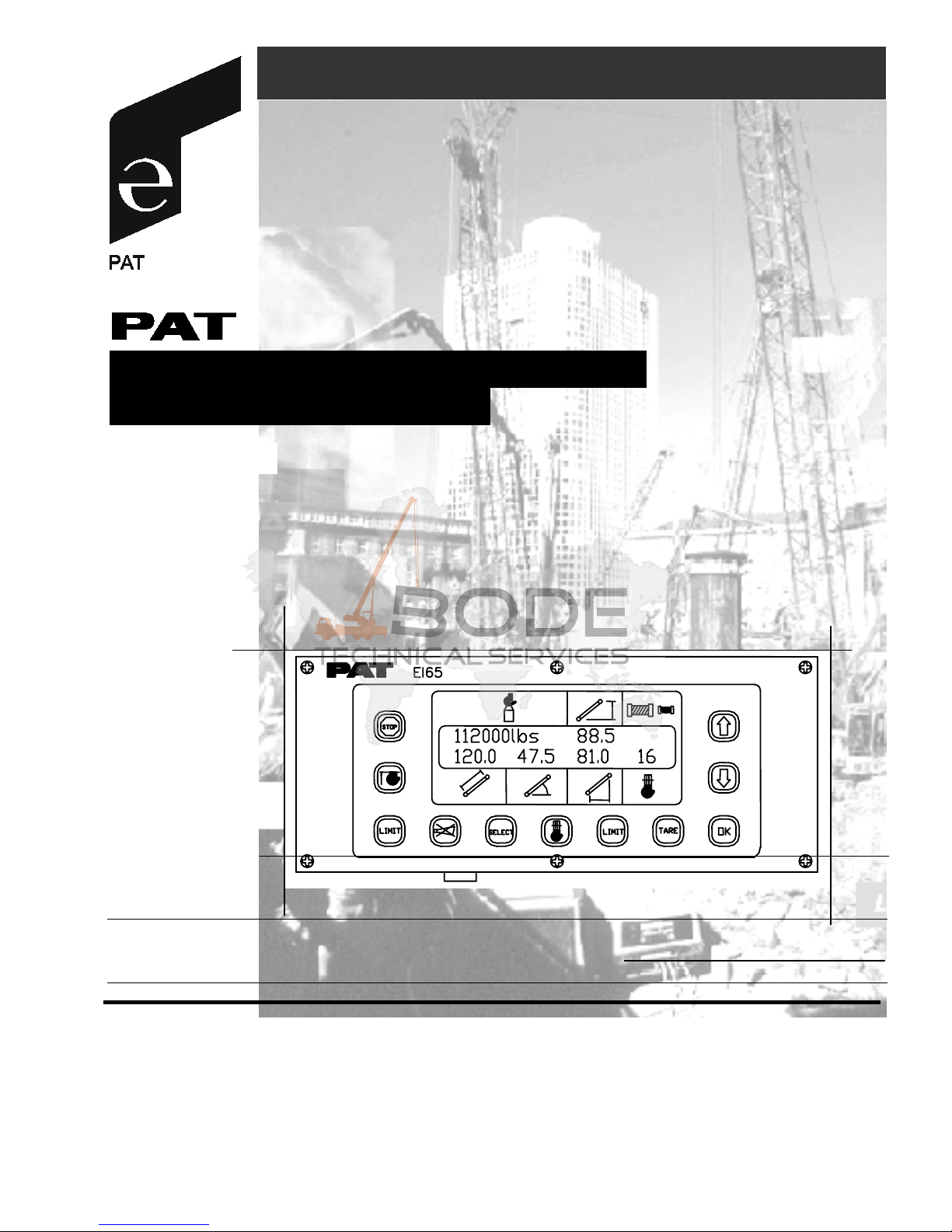

PAT America EI65 Service Manual

www.patamerica.com

PAT America,

!!

!

LENGTH-ANGLE-RADIUS-LOAD

INDICATING SYSTEM

!

EI65/0005

!

!

!

!

!

!

!

SERVICE MANUAL

P/N 031-300-190-007, Rev.B, 03/8/02

!"#$%!&"'(#)"!*+,-+.!

NOTICE

The information in this document is

subject to change without notice.

PAT makes no warranty of any kind with

regard to this material, including, but

not limited to the implied warranties

of merchantability and fitness for a

particular purpose.

PAT shall not be liable for errors

contained herein or for incidental or

consequential damages in connection

with the furnishing, performance or use

of this manual.

This document contains proprietary

information, which is protected by

copyright. All rights are reserved. No

part of this document may be

photocopied, reproduced, or translated

to another language without prior

consent of PAT.

© 1999 PAT America, Chambersburg, PA 17201, USA

'234!5!!6786986:!88!).)! 67;<766!8!;=666>?@4AB)

/!0+1!

!

!"#$%!&"'(#)"!*+,-+.!

Table of Contents

1 GENERAL INFORMATION ............................................1

REFERENCE: ............................................................1

SYSTEM MALFUNCTION: ...................................................1

SYSTEM DESCRIPTION: ...................................................1

2 WARNINGS .......................................................2

3 TROUBLESHOOOTING USING THE ANALOG VALUES SCREEN ................3

4 TROUBLESHOOTING FLOW CHARTS ....................................4

4.1 GENERAL FLOW CHART ................................................... 4

4.2 NO DISPLAY ........................................................... 5

4.3 ANTI TWO BLOCK PROBLEM................................................ 6

4.4 ANGLE READING PROBLEM ................................................ 8

4.5 LENGTH READING PROBLEM ............................................... 9

4.6 LOAD READING PROBLEM ................................................ 11

5 ERROR CODE TABLE ..............................................13

6 SYSTEM DRAWINGS ...............................................14

Connection Board 056-065-300-002 Designations: .......................14

6.1 DRAWING 1. SYSTEM WIRING DIAGRAM (REFER TO INSTALLLATION

MANUAL 031-300-190-008) ............................................. 14

6.2 DRAWING 2. CONNECTION BOARD LAYOUT ................................... 15

6.3 DRAWING 3. MAIN BOARD LAYOUT ......................................... 15

6.4 DRAWING 4, ANGLE SENSOR CIRCUIT ...................................... 16

6.5 DRAWING 5, LENGTH SENSOR CIRCUIT ..................................... 17

6.6 DRAWING 6, LINERIDER CIRCUIT......................................... 18

6.7 DRAWING 7, LINERIDER SUPPLY VOLTAGES ................................. 19

6.8 DRAWING 8, CONSOLE PARTS LIST ........................................ 20

'234!5!!6786986:!88!).)! 67;<766!8!;=666>?@4AB)

/!0+1!

!

C","'+.!#,DB'*+1#B,!

1 GENERAL INFORMATION

The purpose of this service manual is to provide additional information to

assist a service or maintenance person in identifying malfunctions or

system problems with the PAT System. A digital voltmeter and regular

maintenance and service tools will be required to troubleshoot the system.

Note: Knowledge of how to use a digital voltmeter is assumed.

REFERENCE:

Operator’s Manual 056-065-190-005

Calibration Manual 031-300-190-009

Installation Manual 031-300-190-008

SYSTEM MALFUNCTION:

MB 115.0 J1 85.0

J2 50.0 0J 15.0

E71

the EI65, explain each fault, and describe the action, which shall be taken

to correct the fault.

Faults within the electronic microprocessor shall be repaired by factory

trained service personnel. When these faults occur, contact your authorized

dealer or service organization.

If the operator identifies a possible problem in the system, perform the

pre-operation inspection Section 5 in the Operator’s Manual 056-065-190-005

to define the problem.

SYSTEM DESCRIPTION:

The PAT Length-Angle-Radius-Load Indicator System EI65 has been designed to

provide the crane operator with the essential information required to

enable the machine to be used within its design parameters. The EI65 System

indicates the length and angle of the boom, tip height, working radius and

the total weight being lifted by the crane. Using the various sensors and

the limits set by the operator, the EI65 System warns the crane operator of

certain approaching hazardous conditions which could occur during the

operation of his crane.

In case of a malfunction of the system, an error code

which identifies the system malfunction will be

displayed in the reeving portion of the display. The

error codes are listed in Section 4, Error Codes. The

table identifies various faults that can occur with

;!

Always refer to operational instructions and load charts provided by the crane

manufacturer for specific crane operation and load limits.

'234!5!!6786986:!88!).)! 67;<766!8!;=666>?@4AB)

/!0+1!

WARNING

!

:!

! !"#$%!&"'(#)"*+,-+.!

2 WARNINGS

x! The EI65 is an operational aid, which warns a crane operator of certain

approaching hazardous conditions, which could cause damage to equipment

and personnel.

x! The device is not, and shall not be, a substitute for good operator

judgment, experience and use of accepted safe crane operating

procedures.

x! The responsibility for the safe operation of the crane shall remain with

the crane operator who shall ensure that all warnings and instructions

supplied are fully understood and observed.

x! Prior to operating the crane, the operator must carefully and thoroughly

read and understand the information in the operator’s manual to ensure

that he/she knows the operation and limitations of the indicating system

and crane.

'234!5!!6786986:!88!).)! 67;<766!8!;=666>?@4AB)

/!0+1!

!

1EFG@H2IJFFFKLMN!-ILMN!1J2!+MOHFN!(OHG2I!&PE22M!

7!

3 TROUBLESHOOOTING USING THE ANALOG VALUES SCREEN

For a sensor error or problem with a sensor, look at the output voltage of

the linerider and angle sensors and compare the reading with the following:

Angle sensor 1.875 at 0q, 2.5 at 45q, or 3.125 at 90q

Linerider under no load is 0 to 15mV not to exceed 2500 mV.

To access the analog output screen use the following procedure.

1. Power up the system. The screen will display EI 65/10 software version

and date.

2. To start calibration, within 5 seconds of powering up, simultaneously

press the ‘‘OK’’ and ‘‘SELECT’’ buttons. Hold these buttons (approximately

15 seconds) until the screen changes to ‘‘CALIB. PASSWORD’’. If these

buttons are not pressed and held, the screen changes to the existing

operating configuration. Refer to Operator’s section in this manual.

3. Enter the calibration password ‘‘0815’’. Use the ‘‘UP’’ and ‘‘DOWN’’

buttons to select the number and the ‘‘OK’’ button to confirm each entry.

Enter 0 -- OK, 8 -- OK, 1 -- OK, 5 - OK

4. Scrole to the ANALOG VALUES screen by pressing the ‘‘UP’’ or ‘‘DOWN’’

arrows, pressing ‘‘OK’’ to select and show the following screen.

All Analog input voltages (shown in millivolts), received from the sensors

will be displayed here as described below. The minimum values are show in

the screen pictured.

1950 15 VOLT *1000

0 3125 3125

LENGTH!!W[\TEOGHLP!*OPJLM2I!BMH\Y

E2OTLMN!IJFGHT!@2!6!RLKJ!MF!I2MIFE!

LMIKOHH2T4

FORCE 1 and FORCE 2

QLKJ!MF!ILNMOH!FE!R2LNJK!OSSHL2T!KJLI!IJFGHT!

E2OT!;%!U3!FE!@2HFR4!!+K!UOVLUGU!HFOT!KJ2!

E2OTLMN!IJFGHT!MFK!2VP22T!:%66!U3!WX8<:%U3Y4

ANGLE 1 and ANGLE 2

QLKJ!KJ2!@FFU!OK!Z2EF!T2NE22I!KJLI!IJFGHT!E2OT!

7;:%!U3!4!!+K!UOVLUGU!FE!=6!T2NE22I!KJ2!

E2OTLMN!IJFGHT!@2!;9>%!U3!WX8<:%U3Y4

'234!5!!6786986:!88!).)! 67;<766!8!;=666>?@4AB)

/!0+1!

!

Loading...

Loading...