Page 1

User Manual IK 150 / 0031 e

© 1997 PAT GmbH · D-76275 Ettlingen · Hertzstr. 32 - 34 · ) ++49 (0) 7243 709-0 · FAX ++49 (0) 7243 709-222 · Email: pat.ettlingen@pat-gmbh.de 1

50 / 150 / 19_0031E.DOC / 19.03.1997 / Rev. C / rk.

The information in this document is subject to change without notice. PAT makes no warranty of any kind

with regard to this material, including, but not limeted to, the implied warranties of merchantability and fitness

for a particular purpose. PAT shall not be liable for errors contained herein or for identical or consequential

damages in connection with the furnishing, performance, or use of this manual. This document contains

proprietary information which is protected by copyright. All rights reserved. No part of this document may be

photocopied, reproduced, or translated to another language without the prior written consent of PAT.

USER MANUAL

IK 150 / 0031

doc. no. 50 150 19 0031 e

Page 2

User Manual IK 150 / 0031 e

© 1997 PAT GmbH · D-76275 Ettlingen · Hertzstr. 32 - 34 · ) ++49 (0) 7243 709-0 · FAX ++49 (0) 7243 709-222 · Email: pat.ettlingen@pat-gmbh.de 2

50 / 150 / 19_0031E.DOC / 19.03.1997 / Rev. C / rk.

TABLE OF CONTENTS

1 General Information .................................................................................................. 3

2 Warnings..................................................................................................................... 3

3 System Description................................................................................................... 4

3.1 Operating Console ...................................................................................................... 6

4 Control Identification................................................................................................ 7

5 Pre- Operation Inspection and Calibration Verification................................... 12

6 Service and Maintenance....................................................................................... 14

7 Troubleshooting ...................................................................................................... 15

Appendix: Important Notes

Page 3

User Manual IK 150 / 0031 e

© 1997 PAT GmbH · D-76275 Ettlingen · Hertzstr. 32 - 34 · ) ++49 (0) 7243 709-0 · FAX ++49 (0) 7243 709-222 · Email: pat.ettlingen@pat-gmbh.de 3

50 / 150 / 19_0031E.DOC / 19.03.1997 / Rev. C / rk.

1. GENERAL INFORMATION

The PAT DS 150 Load Moment Indicator (LMI) complements the operator's know-how by

providing the information, right in the cab, needed to make the demanding lifts required of

modern cranes.

Using various sensing devices, the PAT DS 150 Load Moment Indicator monitors all crane

functions and provides the operator with a continuous reading of the crane's rated capacity.

The readings continuously change as the crane moves through the motions needed to make

the lift.

The PAT DS 150 Load Moment Indicator also provides the operator with information regarding the length of the boom, angle of the boom and jib, working radius, rated load and the total

calculated weight being lifted by the crane.

If non permitted conditions are approached, the PAT DS 150 Load Moment Indicator will warn

the operator by sounding an audible alarm, lighting a warning light and locking out those functions that may aggravate the crane´s condition.

2. WARNINGS

The PAT DS 150 Load Moment Indicator (LMI) is an operational aid which warns a crane operator of an approaching two blocking condition as well as approaching overload conditions

which could cause damage to equipment and property, and injury to the operator or bystanders. This device is not, and should not, be a substitute for good judgement, experience and

accepted safe crane operating procedures. The operator is solely responsible for the safe

operation of the crane and must observe and obey all warnings and instructions supplied by

PAT and the crane manufacturer. Prior to operating a crane equipped with a PAT operational

aid, the operator must carefully and thoroughly read and understand the information in this

manual and the crane manufacturer's manual to insure that the operator knows the operation

and limitations of the operational aid and crane. Proper functioning is dependent on proper

daily inspection and observance of the operating instructions set forth in this manual. We

draw your attention to section 5 of this handbook.

WARNING

The display (1) will only aid the operator when the LMI is properly programmed and the

proper load capacity chart and operating code are selected for the crane configuration

being utilized.

To prevent property damage or serious bodily injury or death to personnel, ensure the

LMI is properly programmed before operating the crane.

Page 4

User Manual IK 150 / 0031 e

© 1997 PAT GmbH · D-76275 Ettlingen · Hertzstr. 32 - 34 · ) ++49 (0) 7243 709-0 · FAX ++49 (0) 7243 709-222 · Email: pat.ettlingen@pat-gmbh.de 4

50 / 150 / 19_0031E.DOC / 19.03.1997 / Rev. C / rk.

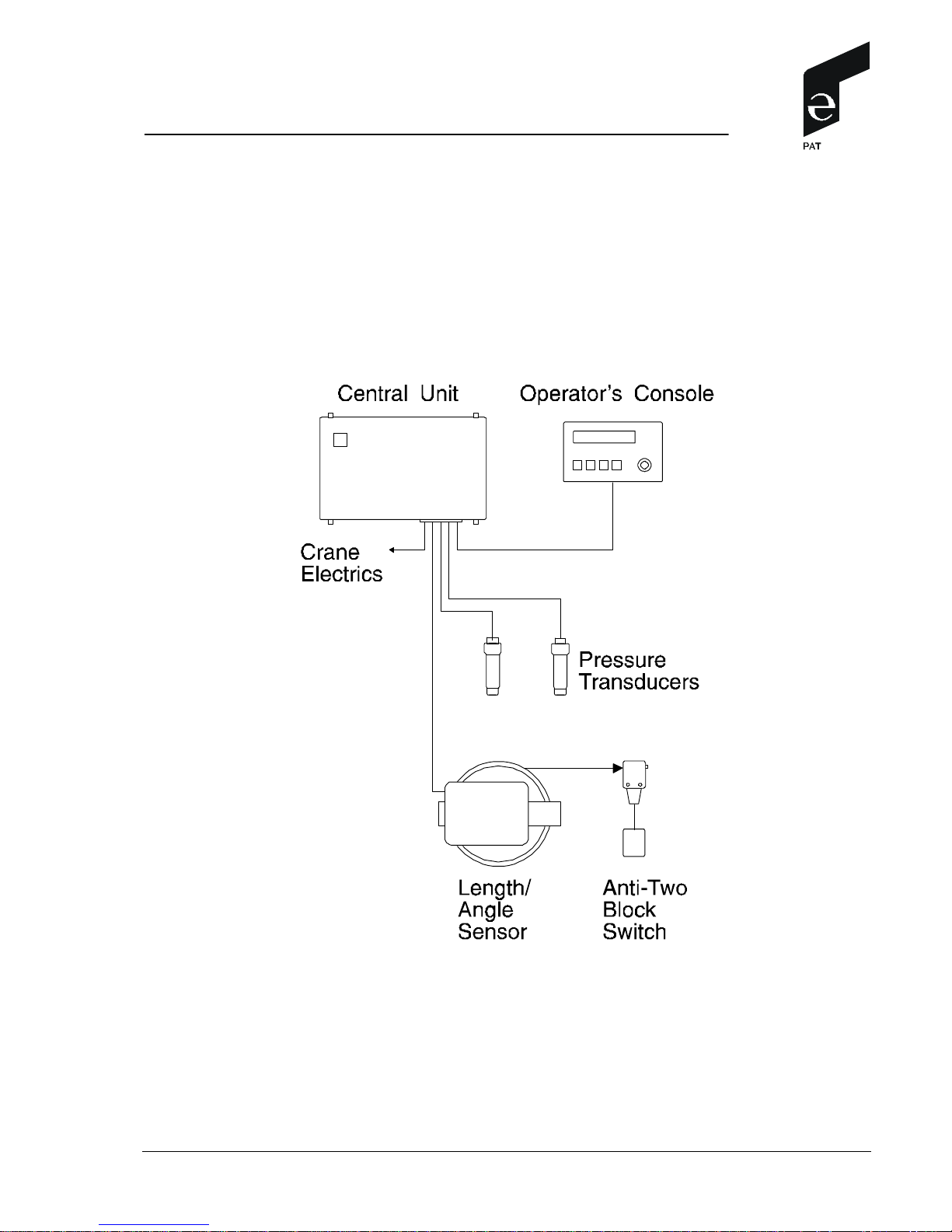

3. SYSTEM DESCRIPTION

The PAT DS 150 load moment indicator consists of a central microprocessor unit, operator's

console and peripheral equipment to register the angles, pressures and hoist limit. The system operates on the principle of reference/real comparison. The real values resulting from the

force or pressure measurement is compared with the reference data stored in the central

processor memory and evaluated in the microprocessor. When limits are exceeded, an

overload warning signal is generated at the operator's console. At the same time, the dangerous crane movements, such as hoist up, telescope out and boom down will be stopped.

The fixed data regarding the crane, such as capacity charts, boom weights, centers of gravity

and dimensions are stored in memory chips in the central processor unit. This data is the reference information used to calculate the overload conditions.

Boom length and boom angle are registerd by the length/angle sensor, mounted indide the

cable reel which is mounted on the boom. The boom length is measured by the cabel reel cable which also serves as electrical conductor for the anti-two-block switch.

The crane load is measured by pressure transducers attached to the piston and rod side of

the lift cylinders.

Page 5

User Manual IK 150 / 0031 e

© 1997 PAT GmbH · D-76275 Ettlingen · Hertzstr. 32 - 34 · ) ++49 (0) 7243 709-0 · FAX ++49 (0) 7243 709-222 · Email: pat.ettlingen@pat-gmbh.de 5

50 / 150 / 19_0031E.DOC / 19.03.1997 / Rev. C / rk.

SYSTEM COMPONENTS

Page 6

User Manual IK 150 / 0031 e

© 1997 PAT GmbH · D-76275 Ettlingen · Hertzstr. 32 - 34 · ) ++49 (0) 7243 709-0 · FAX ++49 (0) 7243 709-222 · Email: pat.ettlingen@pat-gmbh.de 6

50 / 150 / 19_0031E.DOC / 19.03.1997 / Rev. C / rk.

3.1 OPERATING CONSOLE

The console has 2 functions:

• terminal for input of instructions to the system by the crane operator

• display of important data and information

Page 7

User Manual IK 150 / 0031 e

© 1997 PAT GmbH · D-76275 Ettlingen · Hertzstr. 32 - 34 · ) ++49 (0) 7243 709-0 · FAX ++49 (0) 7243 709-222 · Email: pat.ettlingen@pat-gmbh.de 7

50 / 150 / 19_0031E.DOC / 19.03.1997 / Rev. C / rk.

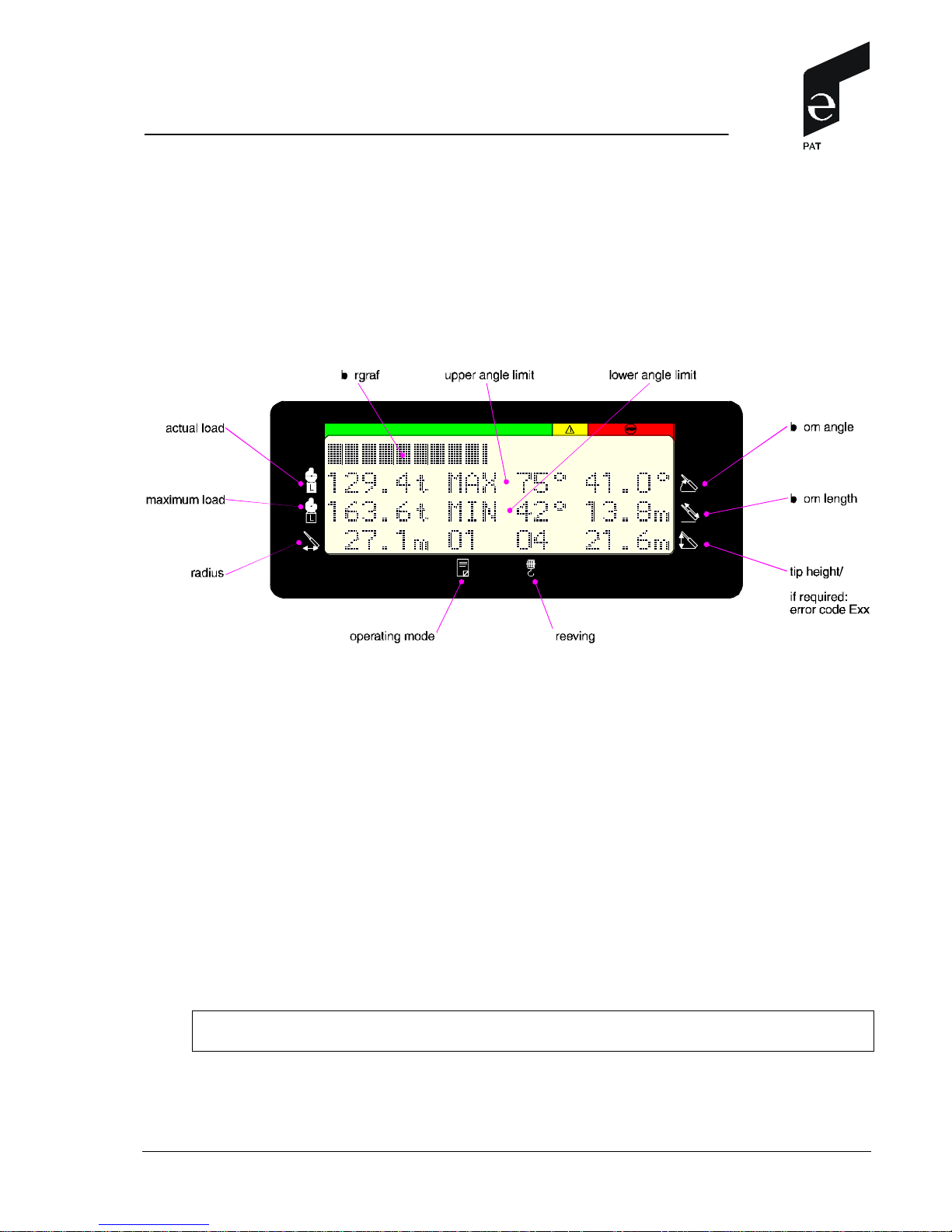

4. CONTROL IDENTIFICATION

The following list will describe the controls and displays of the DS 150 safe load indicator. The numbers of

the illustration (on page 6) correspond to the numbers in the following list:

(1) LC DISPLAY

The LC DISPLAY will show technical information as well as operating information to the operator.

During crane operation the readout will display radius, boom length, boom angle, height of boom tip,

actual and maximum load. The load moment will also be indicated at the display in form of a bargraph. In case of system malfunctions the various faults will be indicated via an error code instead of

the tip height display (Described in chapter 7).

(2) BARGRAPH

This indicator displays how much of the crane rated capacity is being used. As the crane is moved

through its various motions, the bargraph will constantly change on the display.

The range is divided into 3 areas:

A green area is the normal working area, the yellow prewarning area shows the remaining portion of

the rated load capacity and the bargraph indicates the approach to the overload condition and the

red area shows that the maximum rated load capacity is exceeded.

NOTE

Operating within the red area is not permitted.

Page 8

User Manual IK 150 / 0031 e

© 1997 PAT GmbH · D-76275 Ettlingen · Hertzstr. 32 - 34 · ) ++49 (0) 7243 709-0 · FAX ++49 (0) 7243 709-222 · Email: pat.ettlingen@pat-gmbh.de 8

50 / 150 / 19_0031E.DOC / 19.03.1997 / Rev. C / rk.

(3) OPERATING CODE SWITCH

The operating code switch is used to set the load moment indicator (LMI) to the operating configuration of the crane.

Caution

The correct setting is of utmost importance for the proper function of the system and the

crane. Therefore only operators who are thoroughly familiar with crane load capacity charts

and the use and operation of the system shall set the operating code switch. To set the operating mode, the operator has to adjust the operating code switch to a code number which

is printed in the load chart in accordance with the actual crane configuration.

(4) REEVING SWITCH

The REEVING SWITCH (4) provides the load moment indicator with information regarding the number of falls (parts of line) used to reeve the hook block. The switch has 16 positions which are shown

under the window of the control knob when it is turned. The operator has to set the reeving switch to

the actual number of falls (parts of line) being used.

Caution

The correct setting is of utmost importance for the proper function of the system and the

crane.

(5) ANTI-TWO-BLOCK WARNING LIGHT

The red ANTI-TWO-BLOCK WARNING LIGHT (5) will light up when the anti-two-block limit switch

contacts open, indicating that a two-blocking condition is approaching. At the same time the audible

alarm will sound. The following crane movements will be stopped subsequently: hoist up, telescope

out, boom down.

The term "two block" is a crane term which refers to a condition when the load handling device

comes into contact with the boom head. This condition, if not prevented, may cause the wire rope to

break, allowing the load to fall. Two blocking can be caused by raising the load into the boom head

or lowering the boom without paying out hoist line.

(6) PREWARNING LIGHT

Page 9

User Manual IK 150 / 0031 e

© 1997 PAT GmbH · D-76275 Ettlingen · Hertzstr. 32 - 34 · ) ++49 (0) 7243 709-0 · FAX ++49 (0) 7243 709-222 · Email: pat.ettlingen@pat-gmbh.de 9

50 / 150 / 19_0031E.DOC / 19.03.1997 / Rev. C / rk.

The yellow LOAD MOMENT PREWARNING LIGHT (6) will light up when the load on the crane is

between 90 and 100 % of the crane rating, indicating that an overload condition is approaching. This

means for the operator to continue his crane operation with extreme caution.

(7) OVERLOAD LIGHT / ALARM SWITCH

This control serves a dual purpose:

• the red warning lamp lights up when the load on the crane is in excess of 100% of the crane rat-

ing, indicating that an overload condition has been reached.

• this button allows the audible alarm to be silenced for 15 seconds.

(8) TARE BUTTON

The TARE BUTTON is used to indicate the net load on the load display (ref. #1). Net load is the actual load, less lifting tackle and hook block. The tare button has to be activated before lifting.

After pushing the TARE BUTTON the display of actual load will be set to zero (taring). and the display shows max. load and net load. Net load display is blinking and set to zero. After lifting a load

the net load display shows the net load (pay load).

The net load display will change to the normal working display when the radius is changed (either by

boom angle or jib angle).

Display errors can be caused by reason of environmental factors such as wind acting upon the

crane and the load.

BOOM ANGLE LIMITS

This system is equipped with presets for boom angle range selection. There are limits for maximum

and minimum boom angle which can be set by the operator as allowed by crane geometry. After restart the system the limits have to be set new.

(9) SETTING OF BOOM ANGLE LIMIT: MAXIMUM

After pressing this button, the actual boom angle will be stored as maximum boom angle limit. The

LC Display shows the value "MAX xx °". To indicate that the maximum angle limit is activated, the

lamp in the button will light up. Once this angle is reached, the lamp flashes and the buzzer will

sound until the boom is moved back into a permissible angle range.

(10) SETTING OF BOOM ANGLE LIMIT: MINIMUM

After pressing this button, the actual boom angle will be stored as minimum boom angle limit. The LC

Display shows the value "MIN xx °". To indicate that the minimum angle limit is activated, the lamp in

the button will light up. Once this angle is reached, the lamp flashes and the buzzer will sound until

the boom is moved back into a permissible angle range.

Page 10

User Manual IK 150 / 0031 e

© 1997 PAT GmbH · D-76275 Ettlingen · Hertzstr. 32 - 34 · ) ++49 (0) 7243 709-0 · FAX ++49 (0) 7243 709-222 · Email: pat.ettlingen@pat-gmbh.de 10

50 / 150 / 19_0031E.DOC / 19.03.1997 / Rev. C / rk.

RESET ANGLE LIMITS

To reset the boom angle limits press button (9) and (10) simultaneously. The values for angle limitation on the LC Display will be cleared.

(11) ENTER BUTTON "E"

This control has no function.

(12) BY-PASS KEY SWITCH

WARNING

Since this switch deactivates the cut-off function of the LMI system and the anti-two-block

system, the following instructions shall be adhered to:

• the by-pass key should be used with discretion, as unwarranted use of it to override the

control lever lockout system can result in harm to the crane and danger to property and

persons

• never use the by-pass key to either overload or operate the crane in a range not permissi-

ble

The BY-PASS KEY SWITCH (12) can deactivate the cut-off of the LMI or anti-two-block momentarily

to allow the crane operator to override the control lever lockout. It can be operated only by using the

matching key. The spring-loaded by-pass switch has 3 positions which are further described as follows:

Page 11

User Manual IK 150 / 0031 e

© 1997 PAT GmbH · D-76275 Ettlingen · Hertzstr. 32 - 34 · ) ++49 (0) 7243 709-0 · FAX ++49 (0) 7243 709-222 · Email: pat.ettlingen@pat-gmbh.de 11

50 / 150 / 19_0031E.DOC / 19.03.1997 / Rev. C / rk.

This position by-passes the anti-two-block control lever lockout which does not influence the LMI system. The red warning light (5) and the audible alarm (13) for

approaching two-block condition will also come on at all times. The By-Pass Key

Switch is springloaded in order to return the switch to the neutral position. To activate the switch, it therefore has to be held manually during it's operation.

This is the neutral position to which the switch returns because of it's springloaded mechanism. In this position, the by-pass switch is without influence to the

LMI and anti-two-block control lever lockout.

In this position, the by-pass key switch deactivates the control lever lockout function of the LMI. All other display, indicating and alarm functions, as well as the

control lever lockout function of the anti-two-block system will continue to work.

The by-pass switch is springloaded in order to return the switch to the neutral position. Therefore to activate the switch, it has to be held manually during it's opera-

tion.

(13) AUDIBLE ALARM

This element is the AUDIBLE ALARM, which sounds during the following conditions:

overload situation, approaching two-block condition, boom angle preset limits are reached, in case

of a malfunction of the LMI system and in case of an recognised operating error. The alarm can be

turned off temporarily by pushing the button (7).

Page 12

User Manual IK 150 / 0031 e

© 1997 PAT GmbH · D-76275 Ettlingen · Hertzstr. 32 - 34 · ) ++49 (0) 7243 709-0 · FAX ++49 (0) 7243 709-222 · Email: pat.ettlingen@pat-gmbh.de 12

50 / 150 / 19_0031E.DOC / 19.03.1997 / Rev. C / rk.

5. PRE-OPERATION INSPECTION AND CALIBRATION VERIFICATION

Prior to operating the crane, the following electrical connections must be checked to ensure that the

system is properly connected for the crane configuration.

Machines with only a Main Hoist

If the crane works only with the boom and without boom extension or jib, no additional connections

are necessary. However, be sure the weight of the anti-two-block switch is properly installed on the

main hoist load line. With even parts of hoisting line, the weight shall be attached to the dead-end

line. With odd parts of hoisting line, the weight shall be attached to the line of lowest speed.

If the crane works with boom extension or jib, the connecting cable shall be installed between the

junction box on the boom extension or jib and the boom junction box. The weight attached to the

main hoist anti-two-block switch shall be removed. Then the weight shall be reattached to the boom

extension or jib anti-two-block switch.

WARNING

Failure to re-position the anti-two-block switch weight will prevent the overhoist system from functioning properly. No weight shall be on the main hoist anti-two-block switch when the boom extension or jib is being used.

Machines with Main and Auxiliary Hoists

If the boom extension or jib is not in the operating position, the by-pass plug shall be installed in the

main boom junction box. The weight of the main hoist anti-two-block switch shall be installed.

If the boom extension or jib is in the operating position, the connecting cable shall be installed between the junction boxes on the boom extension or jib and the main boom. Weights shall also be

attached to the anti-two-block switches on both the main boom and boom extension or jib.

If the boom extension or jib is in the operating position and no load line is being used on main boom,

to prevent injury or damage to equipment, the weight shall be removed from main boom switch.

Page 13

User Manual IK 150 / 0031 e

© 1997 PAT GmbH · D-76275 Ettlingen · Hertzstr. 32 - 34 · ) ++49 (0) 7243 709-0 · FAX ++49 (0) 7243 709-222 · Email: pat.ettlingen@pat-gmbh.de 13

50 / 150 / 19_0031E.DOC / 19.03.1997 / Rev. C / rk.

After the electrical connections have been checked to insure that the system is properly connected

for the crane configuration, the following checks shall be made:

1. Check the electrical wiring connecting the various parts of the system for physical damage.

2. Check the anti-two-block switches and weights for free movement.

3. Check the spring-loaded cable reel to be sure it is free to rotate, has tension and the cable is

reeled properly.

4. Check mechanical installation and electrical connection of the force transducer(s) on jibs where

applicable.

WARNING

The following tests shall be performed with care to prevent damage to the machine or injury to personnel. Proper functioning of the system requires successful completion of these tests before operating the machine.

If the operator cannot see the load handling device approaching the boom nose, he shall have an

assistant (signal person) watch the load handling device. The operator shall be prepared to stop the

machine immediately should the LMI system not function properly as indicated by lighting the red

warning light (7), sounding the audible alarm (13) and locking the crane movements, hoist up, telescope out and boom down.

Check the anti-two-block alarm light (5) and the audible alarm (13) by performing one of the following

tests:

1. By manually lifting the weight attached to the anti-two-block switches. When the weight is lifted,

the audible alarm (16) should sound, the anti-two-block alarm light (5) should light.

2. Slowly raise the main boom load handling device to create a potential two-block condition.

When the load handling device lifts the weight, the audible alarm (13) should sound, the antitwo- block alarm light (5) should light and the motion of the load handling device should be

stopped. Lower the load handling device slightly to eliminate this condition.

3. Slowly lower the boom to create a potential two-block condition. When the load handling device

lifts the weight, the audible alarm (11) should sound, the anti-two-block alarm light (5) should

light and the boom lowering function should be stopped. Lower the load handling device slightly

to eliminate this condition.

4. Slowly extend (telesope) the boom to create a potential two-block condition. When the load

handling device lifts the weight, the audible alarm (13) should sound, the anti-two-block alarm

light (5) should light and the boom telescope out function should be stopped. Lower the load

handling device slightly to eliminate this condition.

WARNING

If the light and audible alarm do not function as described and the crane movements are not

stopped, the system is not working properly. The malfunction shall be corrected before operating the

crane.

5. If the crane is equipped with a boom extension or jib, repeat the test procedure for the boom

extension or jib anti-two-block switch.

6. Check that the display of the main boom length agrees with the actual boom length.

7. Check that the display of the main boom angle agrees with the actual boom angles.

8. Check that the display of the operating radius of the crane agrees with the actual radius.

9. Check the load display by lifting a load of known weight. The accuracy of the load indication

shall be within the tolerance of SAE J159.

Page 14

User Manual IK 150 / 0031 e

© 1997 PAT GmbH · D-76275 Ettlingen · Hertzstr. 32 - 34 · ) ++49 (0) 7243 709-0 · FAX ++49 (0) 7243 709-222 · Email: pat.ettlingen@pat-gmbh.de 14

50 / 150 / 19_0031E.DOC / 19.03.1997 / Rev. C / rk.

OPERATION

After being properly programmed, the LMI is operational. Therefore, the operator shall be thoroughly

familiar with all controls of the LMI and he shall properly set each switch before operating the crane.

All settings shall be checked by lifting a load of known weight and comparing the load to the information displayed on the LMI.

Rated loads include the weight of the hook block, slings, and auxiliary load handling devices. Their

combined weights shall be subtracted from the listed load capacities as stated on the load capacity

chart to obtain the net load to be lifted.

WARNING

If any of the displays reflect a deviation between displayed and actual values an authorized PAT

service representative shall be called for repair of the system or reverification of the crane's LMI

calibration.

WARNING

Any structural modifications or changes to the crane shall require reverification of the crane's LMI

calibration.

6. SERVICE AND MAINTENANCE

Page 15

User Manual IK 150 / 0031 e

© 1997 PAT GmbH · D-76275 Ettlingen · Hertzstr. 32 - 34 · ) ++49 (0) 7243 709-0 · FAX ++49 (0) 7243 709-222 · Email: pat.ettlingen@pat-gmbh.de 15

50 / 150 / 19_0031E.DOC / 19.03.1997 / Rev. C / rk.

Daily maintenance of the load moment indicator consists of inspecting:

1. The electrical wiring connecting the various parts of the system. If electrical wiring is damaged,

it shall be replaced immediately.

2. If the insulation is worn on the length sensor cable or cable guides are damaged, these parts

shall be replaced.

3. Check the anti-two-block limit switches for freedom of movement.

4. The cable reel shall be under tension to operate properly.

5. Check the pressure transducers at the lift cylinder(s) and the connecting hoses for oil leakage.

6. Check mechanical installation and electrical connection of force transducer(s) on jibs where applicable.

Other than correcting the problems identified in the Malfunctions Table and replacing faulty mechanical parts and cables, no other repairs shall be performed by unauthorized or untrained personnel.

Page 16

User Manual IK 150 / 0031 e

© 1997 PAT GmbH · D-76275 Ettlingen · Hertzstr. 32 - 34 · ) ++49 (0) 7243 709-0 · FAX ++49 (0) 7243 709-222 · Email: pat.ettlingen@pat-gmbh.de 16

50 / 150 / 19_0031E.DOC / 19.03.1997 / Rev. C / rk.

7. TROUBLESHOOTING

GENERAL

In case of a malfunction of the system, the display (1) will indicate a code which identifies the system malfunction.

The error codes listed in the Malfunction Table will identify various faults which can occur with the

LMI. Following the Malfunction Table are pages which explain each fault and describes the action

which should be taken to correct the fault.

Faults within the electronic microprocessor must be repaired by factory trained service personnel.

When these faults occur, the competent service organization must be contacted.

Malfunctions Table

Error Code Error

E01 Fallen below the radius or above angle range

E02 Radius range exceeded or fallen below angle range

E03 Boom position is out of the permissible working area

E04 Operating mode not existing

E05 Prohibit length range

NOTE:

If there is any Error Code displayed on the console which is not listed in the Malfunctions Table you

should call the Local Distributor.

Page 17

User Manual IK 150 / 0031 e

© 1997 PAT GmbH · D-76275 Ettlingen · Hertzstr. 32 - 34 · ) ++49 (0) 7243 709-0 · FAX ++49 (0) 7243 709-222 · Email: pat.ettlingen@pat-gmbh.de 17

50 / 150 / 19_0031E.DOC / 19.03.1997 / Rev. C / rk.

ERROR CODE DESCRIPTION

OPERATING ERRORS

Malfunctions in the system which are caused by range exceedings or operating errors by the crane

operator himself are indicated on the display together with an explanation. These error codes are

E01, E02, E03, E04 and E05 and they can normally be eliminated by the crane operator himself.

Page 18

User Manual IK 150 / 0031 e

© 1997 PAT GmbH · D-76275 Ettlingen · Hertzstr. 32 - 34 · ) ++49 (0) 7243 709-0 · FAX ++49 (0) 7243 709-222 · Email: pat.ettlingen@pat-gmbh.de 18

50 / 150 / 19_0031E.DOC / 19.03.1997 / Rev. C / rk.

ERROR CODE TABLE

Error Code Error Cause Elimination

E01

Fallen below radius

range or angle range

exceeded

• Fallen below the minimum

radius or gone past the

maximum angle specified in

the respective load chart

due to luffing up the boom

too far

• Luff down the boom to a radius or angle specified in the

load chart.

E02

Radius range exceeded or fallen below angle range

• Gone past the maximum radius or fallen below the

minimum angle specified in

the respective load chart

due to luffing down the boom

too far

• Luff up the boom to a radius

or angle specified in the load

chart.

E04

Operating mode not

acknowledged

• A non existing operating

mode has been selected

• Set the correct operating

mode for the operating state

in question

E05

Prohibited length

range

• Boom has been extended

either too far or not far

enough, e.g. if it is prohibited to go beyond a certain

maximum boom length or

with load curves for jibs

where the main boom has to

be extended to a certain

length

• Extend/retract boom to the

correct length

• Length sensor adjustment

has changed, e.g. the cable

slid off the length sensor

reel.

• Retract boom. Check the

prestress of the cable reel

(cable must be taut). Open

the length sensor and carefully turn the length sensor

pot counterclockwise until

the detent by means of a

screw driver

• Clutch between length sensor pot and drive is defective

• Replace the complete clutch

including drive wheel and

adjust length sensor pot as

described above

• Failure of +5V supply of

analog part of analog board

• Check +5 V supply. Exchange main board in case

of voltage failure or breakdown when loaded with 50

ohms approx.

• Cable between central unit

and length sensor is defective or disconnected.

• Check cable and plugs, replace, if need be.

Page 19

User Manual IK 150 / 0031 e

© 1997 PAT GmbH · D-76275 Ettlingen · Hertzstr. 32 - 34 · ) ++49 (0) 7243 709-0 · FAX ++49 (0) 7243 709-222 · Email: pat.ettlingen@pat-gmbh.de 19

50 / 150 / 19_0031E.DOC / 19.03.1997 / Rev. C / rk.

Error Code Error Cause Elimination

• Defective length potentometer

• Replace length potentiometer.

E06

Radius range exceeded or fallen below angle range with

luffing jib operation

• Maximum radius as specified in the load chart exceeded or fallen below

minimum angle due to luffing

down the luffing jib too far

• Luff the jib to a radius or angle specified in the load

chart.

E07

Faulty acknowledgment of the overload

relay on the connection board.

The relay should be

energized, the 2nd

contact however is

indicated to be off, or

the 2nd contact is indicated to be on

while the relay

should be deenergized.

• Overload relay or connection board are defective

• Processor board defective

• Replace connection board

• Replace processor board.

E08

No acknowledgment

from the anti-twoblock relay

• refer to E07 • refer to E07

E10

Error in the length

measurement

• With the boom retracted, the

signal "main boom length"

differs by more than 2 %

from the programmed value

for the basic length

• Check length sensor of the

main boom

• With the boom retracted, the

signal "length Tele I (+II)"

differs by more than 2 %

from the reference value 0

• Check length sensor 2.

E11

Fallen below lower

limit value for measuring channel "length

main boom"

• Cable between central unit

and length sensor is defective or disconnected. Water

inside the plug of the

length/angle sensor

• Check cable as well as

plugs, replace, if need be.

• Length potentiometer is

defective

• Replace length potentiometer

• Electronic component in the

measuring channel is defective

• Replace LMI main board or

processor board.

E12

Fallen below the

lower limit value in

the measuring channel "pressure piston

side"

• Cable between the central

unit and pressure transducers defective or water inside

the plugs

• Check cable as well as

plugs, replace, if need be.

Page 20

User Manual IK 150 / 0031 e

© 1997 PAT GmbH · D-76275 Ettlingen · Hertzstr. 32 - 34 · ) ++49 (0) 7243 709-0 · FAX ++49 (0) 7243 709-222 · Email: pat.ettlingen@pat-gmbh.de 20

50 / 150 / 19_0031E.DOC / 19.03.1997 / Rev. C / rk.

Error Code Error Cause Elimination

• Pressure transducer is defective.

• Replace pressure transducer

• Electronic component in the

measuring channel is defective.

• Replace LMI main board or

processor board.

E13

Fallen below lower

limit value in the

measuring channel

"pressure rod side"

• refer to E12 • refer to E12

E15

Fallen below lower

limit value in measuring channel "angle

main boom"

• Cable between central unit

and the length/angle sensor

defective or loose. Water

inside the plug of the

length/angle sensor.

• Check cable as well as

plugs, replace, if need be.

• Angle potentiometer defective

• Replace angle sensor

• Electronic component in the

measuring channel defective.

• Replace LMI main board or

processor board.

E16

Fallen below lower

limit value in measuring channel "angle

2"

• Cable between the central

unit and the angle sensor

defective or loose. Water

inside the plug of the angle

sensor.

• Check cable as well as

plugs, replace, if need be.

• Angle potentiometer defective

• Replace angle sensor

• Electronic component in the

measuring channel defective.

• Replace LMI main board or

processor board.

E17

Fallen below lower

limit value "length

telescope I (+II)"

• Cable between the central

unit to the length sensor

defective or loose. Water

inside the length sensor

plug.

• Check cable as well as

plugs, replace, if need be.

• Length potentiometer defective

• Replace length sensor.

• Electronic component in the

measuring channel defective

• Replace LMI main board or

processor board.

E19

Reference and/or

supply voltage defective

• The supply voltage is falsified by one of the sensors

(DAV, LWG)

• Check the voltages on the

LMI main board (AGND =

MP0). Check sensors, plugs

and cable, replace, if need

be.

• Electronic component is

defective

• Replace LMI main board

• A/D converter defective. • Replace LMI main board

Page 21

User Manual IK 150 / 0031 e

© 1997 PAT GmbH · D-76275 Ettlingen · Hertzstr. 32 - 34 · ) ++49 (0) 7243 709-0 · FAX ++49 (0) 7243 709-222 · Email: pat.ettlingen@pat-gmbh.de 21

50 / 150 / 19_0031E.DOC / 19.03.1997 / Rev. C / rk.

Error Code Error Cause Elimination

E21

Upper limit value in

measuring channel

"main boom length"

has been exceeded.

• refer to E11 • refer to E11

E22

Upper limit value in

measuring channel

"pressure piston

side" has been exceeded

• refer to E12 • refer to E12

E23

Upper limit value in

measuring channel

"pressure rod side"

has been exceeded.

• refer to E12 • refer to E12

E25

Upper limit value in

measuring channel

"main boom angle"

has been exceeded.

• refer to E15 • refer to E15

E26

Upper limit value in

measuring channel

"angle 2" has been

exceeded.

• refer to E16 • refer to E16

E29

Reference and/or

supply voltage defective.

• refer to E19 • refer to E19

E31

Error in the system

program

• The system program PROM

is defective.

• Replace system program

PROM (PROM No. 0)

E38

System program and

data EPROM do not

match.

• The system program in the

LMI does not match to the

programming in the data

EPROM

• Replace the system program

PROM or the data EPROM

(PROM No. 1)

E39

System program and

TLK EPROM do not

match

• The system program in the

LMI and the programming in

the TLK EPROM do not

match.

• Replace system program

PROM or TLK EPROM

(PROM No. 2).

E41

Error in the internal

write/read memory

(RAM) of the computer component

80C537

• Computer component

80C537 defective

• CPU module defective

• Processor board defective.

• Replace computer compo-

nent 80C537.

• Replace CPU module.

• Replace processor board

with CPU module.

E42

Error in the external

write/read memory,

1st part (RAM)

• Write/read memory (CMOS

RAM) or processor board

defective.

• Replace processor board

with CPU module.

E43

Error in the external

write/read memory,

2nd part (RAM)

• refer to E42 • refer to E42

Page 22

User Manual IK 150 / 0031 e

© 1997 PAT GmbH · D-76275 Ettlingen · Hertzstr. 32 - 34 · ) ++49 (0) 7243 709-0 · FAX ++49 (0) 7243 709-222 · Email: pat.ettlingen@pat-gmbh.de 22

50 / 150 / 19_0031E.DOC / 19.03.1997 / Rev. C / rk.

Error Code Error Cause Elimination

E45

Redundancy error in

the A/D conversion

• The A/D converter on the

processing board and the

redundant A/D converter in

the CPU 80C537 provide

different results.

• Replace processor board.

E46

Error in the A/D converter uPD 7004 of

the processor board.

• No acknowledgment of the

A/D converter uPD 7004

• Replace processor board.

E47

Error in the monitored

write/ read memory.

The CRC verification

of the monitored

write/read memory

provides an incoherent result

• The CRC sign of the monitored write/read memory is

wrong

• The buffer battery is decharged (< 2V at 1kOhm).

• Processor board defective.

• Restart the LMI

• Replace buffer battery on

the LMI main board

• Replace processor board.

E48

Cyclic RAM test: error in the internal

write/read memory

(RAM) of the computer component

80C537

• Computer component

80C537 defective

• CPU module defective

• Processor board defective.

• Replace computer compo-

nent 80C537.

• Replace CPU module

• Replace processor board

with CPU module.

E51

Error in the crane

data EPROM or

EEPROM.

• No valid data in the crane

data EEPROM.

• Memory module wrongly

bridged.

• Crane data EPROM defective

• Load crane data EEPROM

containing valid data.

• Bridge memory module acc.

to memory type

• Replace crane data EPROM

E52

Error in load chart

PROM.

• Memory module wrongly

bridged.

• Load chart EPROM defective.

• Bridge memory module acc.

to memory type.

• Replace load chart EPROM

E56

Error in crane data

EEPROM.

• Memory module wrongly

bridged.

• Crane data EEPROM defective

• Bridge memory module acc.

to memory type

• Replace crane data

EEPROM

Page 23

User Manual IK 150 / 0031 e

© 1997 PAT GmbH · D-76275 Ettlingen · Hertzstr. 32 - 34 · ) ++49 (0) 7243 709-0 · FAX ++49 (0) 7243 709-222 · Email: pat.ettlingen@pat-gmbh.de 23

50 / 150 / 19_0031E.DOC / 19.03.1997 / Rev. C / rk.

Error Code Error Cause Elimination

E57

Error in serial crane

data EEPROM.

• Serial crane data EEPROM

does not contain valid data.

• Memory module defective

• Write data on the serial

crane data EEPROM (by

means of test program or

on-line function), then restart

the LMI

• Replace memory module.

E58

Error in the serial

analog data

EEPROM.

• No valid data in the serial

analog data EEPROM.

• LMI main board defective.

• Write data on the serial

analog data EEPROM by

means of the test program,

then, restart the LMI

• Replace LMI main board.

E69

Error in the load chart

EPROM

• Memory module wrongly

bridged

• Bridge memory module acc.

to memory type

The number of the

selected EPROM

base and the programmed value are

not identical

• Load chart EPROM defective

• Replace load chart EPROM

• Base number not pro-

grammed

• Program the correct base

number (1 for base 1, 2 for

base 2)

• Load chart EPROM wrongly

programmed

• Check base programming in

the load chart EPROM.

E71

Faulty acknowledgment of relay K1 on

the connection board

• Relay K1 or connection

board defective.

• Replace connection board.

Relay should be energized but the 2nd

contact is signaled to

be off or the 2nd

contact is signaled to

be on whereas the

relay should be deenergized.

• LMI main board is defective • Replace LMI main board.

E72

...

E77

Faulty acknowledgment of relays

K2...K7 on the connection board.

• refer to E71 • refer to E71

E85

Error in the radius

determination

• The computed radius is too

small (negative deflection)

• Check the programming in

the data EPROM.

E89

Operating mode

switchover with load.

• The operating mode on the

console has been switched

over with the boom loaded.

• Select operating mode without load on the boom

E91

No data transmission

form the console to

the central unit

• 24 V supply of the console

is interrupted

• Check 24 V at terminal X1 of

the console electronics

Page 24

User Manual IK 150 / 0031 e

© 1997 PAT GmbH · D-76275 Ettlingen · Hertzstr. 32 - 34 · ) ++49 (0) 7243 709-0 · FAX ++49 (0) 7243 709-222 · Email: pat.ettlingen@pat-gmbh.de 24

50 / 150 / 19_0031E.DOC / 19.03.1997 / Rev. C / rk.

Error Code Error Cause Elimination

• Interruption or accidental

ground in the line between

console electronics and

central unit

• Check the connection console electronics - central

unit. In case of an accidental ground, the transmitter

module of the console electronics might be damaged.

Therefore, replaces the

console electronics.

• Transmitter/receiver module

is defective

• Exchange console electronics or LMI main board

resp.

E92

Error in the data

transmission from

console to central

unit

• Loose connection in the line

between console electronics

and central unit

• Transmitter/receiver module

is defective

• Check the connection between console electronics

and central unit

• Exchange console electronics or LMI main board

resp.

E93

Error in the data

transmission from the

central unit to the

console

• refer to E92 • refer to E92

E94

No data transmission

from the central unit

to the console

• Interruption or accidental

ground in the line central unit

- console

• Check line to the console (in

case of accidental ground,

replace console electronics,

too).

• 5 V supply of the computer

in the central unit is missing

• Check connection to the

power unit

• 5 V supply is too low • Exchange the LMI main

board

• Transmitter/receiver module

is defective

• Replace console electronics

or LMI main board

• Computer module is defective

• Replace processor board.

• Electro-magnetic interfer-

ences (e.g. when switching

contactors or valves)

• Eliminate the source of interferences by inverse diodes or varistors.

E95

Error in the console

EPROM

• The console EPROM is defective.

• Replace the console

EPROM

E96

Error in the internal

RAM of the console.

• The CPU of the console is

defective.

• The console main board is

defective.

• Replace the CPU of the

console

• Replace the console main

board.

Page 25

User Manual IK 150 / 0031 e

© 1997 PAT GmbH · D-76275 Ettlingen · Hertzstr. 32 - 34 · ) ++49 (0) 7243 709-0 · FAX ++49 (0) 7243 709-222 · Email: pat.ettlingen@pat-gmbh.de 25

50 / 150 / 19_0031E.DOC / 19.03.1997 / Rev. C / rk.

Error Code Error Cause Elimination

E97

Error in the external

RAM of the console

• The external RAM of the

console is defective.

• The console main board is

defective.

• Replace the external RAM of

the console.

• Replace the console main

board.

Page 26

User Manual IK 150 / 0031 e

© 1997 PAT GmbH · D-76275 Ettlingen · Hertzstr. 32 - 34 · ) ++49 (0) 7243 709-0 · FAX ++49 (0) 7243 709-222 · Email: pat.ettlingen@pat-gmbh.de 26

50 / 150 / 19_0031E.DOC / 19.03.1997 / Rev. C / rk.

PAMPHLET 1 Cut-off Values for Boom Cranes with Variable Capacity depending

on Variable Radius

The crane cut-off values are calculated by us on the basis of the load charts and construction drawings

supplies by the crane manufacturers.

These theoretical cut-off values must be checked by testing the crane with weighed test loads in all operating modes and at least in the following equipment conditions depending on the crane type.

• Cranes with fixed boom length during operation:

Minimum, medium and maximum radius with shortest, medium and longest boom length as well as with

shortest, medium and longest jib length with these boom lengths.

• Cranes with variable boom length during operation:

Minimum, medium and maximum radius at each length step as well as with all jibs.

PAMPHLET 2 Important notes for crane operators

The LMI is an operational aid which warns a crane operator of approaching overload conditions and also

warns of overhoist conditions which could cause damage to equipment and personnel.

The device is not, and shall not, be a substitute for good operator judgement, experience and use of accepted safe crane operating procedures. The responsibility for the safe operation of the crane shall remain

with the crane operator who shall ensure that all warnings and instructions supplied are fully understood and

observed. Prior to operating the crane, the operator must carefully and thoroughly read and understand the

information in the crane/SLI manual to ensure that he knows the operation and limitations of the indicator

and crane.

Proper functioning is dependent upon proper daily inspection and observations of the operating instructions

set forth in the manual.

WARNING

This system can be equipped with an override key on the central micro-processor unit. This

key switch bypasses cut-off functions of the load moment indicator device. The switch may

only be used by authorized personnel during emergency situations. Failure to follow this

instruction may result in property damage and/or personal injury.

Page 27

User Manual IK 150 / 0031 e

© 1997 PAT GmbH · D-76275 Ettlingen · Hertzstr. 32 - 34 · ) ++49 (0) 7243 709-0 · FAX ++49 (0) 7243 709-222 · Email: pat.ettlingen@pat-gmbh.de 27

50 / 150 / 19_0031E.DOC / 19.03.1997 / Rev. C / rk.

PAMPHLET 3 Important notes for crane users

In the Federal Republic of Germany, the directives of the Union of German Engineers VDI (Verein Deutscher

Ingenieure) 3570 are effective for the construction of safe load indicators. There, too, it is directed to the significant and the limits of the safe load indicator.

"Safe load indicators shall, during crane operation, hinder accidents, endangering of persons, things, the load, the crane due to overload within the limits possible. User and crane operator must take into account that

a safe load indicator cannot realize all dangers in time and that a malfunction by nonperceptible influences

indeed is possible. Therefore they are not dispensed from circumspection and the responsibility to the observance of the operating instructions and the load of the crane. Safe load indicators are not intended for

regular operation. They shall only respond in emergency cases. The capacity of the hoisting appliance shall

not be reduced by safe load indicator".

Instructional Pamphlet VDMA

for safe load indicators (load moment limiting devices) on boom cranes

The boom crane delivered to you has a safe load indicator (overload cut-off device) according to §24 of the accident prevention regulation UVV "boom cranes" which will cut off the hoist and boom hoist unit of the crane when exceeding the

admissible safe load. The opposite movement must remain possible in order to be able to relieve the crane of the load

after the safe load indicator has reacted, e.g. it must be possible to lower the load when the hoist was cut off.

Installation of a safe load indicator (overload cut-off device) has the purpose to prevent the crane from lifting a load which

would endanger its stability. Hence the safe load indicator (overload cut-off device) is an emergency switch which, in the

event of overload, cuts off all movements increasing the load moment thus avoiding a possible damage or accident.The

following must be observed for the safe load indicator to comply with its function as a safety device.

1. Safe load indicators (overload cut-off devices) must not be used operationally to cut off the hoist or boom hoist unit.

The crane operator must in any case previously make sure that the load to be lifted will not exceed the lifting capacity

of the crane. Superheavy loads exceeding the lifting capacity of the crane must not be lifted even with a safe load indicator installed. The unit must not be loaded beyond the respectively admissible load.

2. Freeing loads which are stuck may only be effected in agreement with the crane manufacturer and with cranes especially equipped for this purpose. During these jobs it is not allowed to use the safe load indicator (overload cut-off device) as an operational unit for force measurements.

3. The built-in safe load indicator must be regularly serviced and checked as to its functional safety before starting operation. According to the accident prevention regulation UVV "boom cranes" §35 maintenance of the crane also includes regular checks of the safe load indicator.

4. Generally, the safe load indicator does not adjust automatically to the various operating conditions of the crane.

When changing the operating condition of the crane, the operator is therefore responsible of changing the safe load

indicator over to the new load or load moment range as well. For this purpose, observe the manufacturers operating

instructions for the safe load indicator installed. Safe operation of the device and accident-free operation of the crane

depend to a high extent on careful observance of this instruction. Maladjusted safe load indicators, e.g. set to a high

load moment with retracted outriggers, are much more dangerous than cranes without a safe load indicator since the

crane operator is given a wrong feeling of safety which might be the cause of serious accidents.

5. When changing the crane over to various operating conditions, the safe load indicator installed must be changed

over to the new load or safe load ranges resp. by the crane operator, e.g.:

Page 28

User Manual IK 150 / 0031 e

© 1997 PAT GmbH · D-76275 Ettlingen · Hertzstr. 32 - 34 · ) ++49 (0) 7243 709-0 · FAX ++49 (0) 7243 709-222 · Email: pat.ettlingen@pat-gmbh.de 28

50 / 150 / 19_0031E.DOC / 19.03.1997 / Rev. C / rk.

a) when extending or retracting the outriggers (changing over to high or little load moment);

b) when changing the boom length by:

- extending or retracting (telescoping) manually;

- mounting or dismounting intermediary parts;

c) when slewing or pivoting the crane to the range of greater or smaller stability moment (changing over to high or lit-

tle load moment);

d) when passing into another load capacity range by several parts of line in the cables of the hoist or boom hoist unit.

6. It must be strictly pointed out that due to wrong operation of the crane it might not be possible for the safe load indicator to respond or resp. that the engine might not be cut off quickly enough. In this case you cannot exclude an accident inspite of a safe load indicator installed.

In particular, this applies to:

- underhooking the load or the load handling accessories;

- excessive retardation forces,

- loads falling into the line,

- diagonal pull,

- moving the crane to an area of higher gradient,

- yielding ground,

- wind pressure.

7. If there is a device available to switch off or bridge the safe load indicator (load moment limiting system), it must only

be used with regard to special measures of precaution and in presence of the crane superintendence, for instance

when testing the crane and for special applications provided for by the crane manufacturer. The safe load indicator

must not be switched off or bridged operationally under no circumstances in order to lift loads which exceed the respectively admissible loading capacity of the crane.

Careful observance of the regulations contained in this instructional pamphlet and in the operating

instructions of the crane manufacturer is the precondition for the safe function of the safe load indicator (overload cut-off device).

In all cases of doubt consult the operating instructions of the manufacturer. Should this be not sufficient, it is necessary to inquire at the company concerned.

Unauthorized interventions in the mechanism of the safe load indicator will void the warranty.

Publisher: VDMA Fachgemeinschaft für Hebezeuge und Fördermittel

im Verein Deutscher Maschinenbau Anstalten e.V.

Düsseldorf - Oberkassel

Page 29

User Manual IK 150 / 0031 e

© 1997 PAT GmbH · D-76275 Ettlingen · Hertzstr. 32 - 34 · ) ++49 (0) 7243 709-0 · FAX ++49 (0) 7243 709-222 · Email: pat.ettlingen@pat-gmbh.de 29

50 / 150 / 19_0031E.DOC / 19.03.1997 / Rev. C / rk.

PAMPHLET 4 Instructions to ensure the electromagnetical compatibility (EMC)

with electronic systems under the effect of electromagnetic fields

Electromagnetic fields increasingly affect electronic systems and can thus cause malfunctions for whose

elimination we shall indicate some preventive measures according to today's state of engineering below:

1. The preventive measures are mainly based upon the idea to shield the electronic circuits from irradiated

high frequency interferences:

- All components will have metal housings outside with grounding possibility;

- The cables used will have braided shields. The shield applied must be highly conductive as to the

surface of all junction areas;

- Coupling of crane ground and electronic ground at only one point of the system.

2. The general measures listed in item 1, however, cannot ensure complete protection against electromagnetic fields in individual cases because the size and the type of the effect depends on the local

conditions.

The influencing factors, inter alia, are as follows:

- Particularly unfavourable arrangement of the antenna as to the system;

- Very high transmitter powers;

- Impossible to observe the measures of item 1 consistently by reason of local conditions;

- Long cables;

- Interferences coupling into the supply lines.

With unfavourable conditions you can therefore not do without taking any measures exceeding the preventive ones experimentally on site, taking into account the principles mentioned in item 1, e.g.:

• Adding filters or short-circuiting the interfering frequencies by means of capacitors;

• Making or removing ground connections;

• Using double shielded cables (guarded shield system).

Page 30

User Manual IK 150 / 0031 e

© 1997 PAT GmbH · D-76275 Ettlingen · Hertzstr. 32 - 34 · ) ++49 (0) 7243 709-0 · FAX ++49 (0) 7243 709-222 · Email: pat.ettlingen@pat-gmbh.de 30

50 / 150 / 19_0031E.DOC / 19.03.1997 / Rev. C / rk.

PAMPHLET 5 Notes for Protection of Labour During Repair of Display and Oper-

ating Consoles

Caution: LCD displays contain fluid chemicals.

Therefore, you have to proceed carefully when:

• operating devices with LCD displays

• storing or carrying them (risk of fracture)

• clearing spare or unusable LCD displays

Possible risks are chemical reactions because of skin contact with broken LCD displays. In

case of contact with chemicals, carefully clean the parts of body affected with soap. Caution in case of open wounds.

PAMPHLET 6 Installation instructions for display and operator's console without

closed metal housing

In order to avoid radio interferences, high frequency devices and systems subject to the general approval

the Federal Minister of the Post Office and Telecommunication published in the gazette no. 163/1984 as order no. 1045/1984 and no. 1046/1984 have to observe the limits and requirements stipulated.

In case of display and operator's console without closed metal housing (panel-mounted) type, the cable

shield must be applied via a bare clamp on the panel directly in front of the console.

Page 31

User Manual IK 150 / 0031 e

© 1997 PAT GmbH · D-76275 Ettlingen · Hertzstr. 32 - 34 · ) ++49 (0) 7243 709-0 · FAX ++49 (0) 7243 709-222 · Email: pat.ettlingen@pat-gmbh.de 31

50 / 150 / 19_0031E.DOC / 19.03.1997 / Rev. C / rk.

MANUFACTURER'S CERTIFICATE

This is to certify that

Unit: Electronic Measuring System

Type: DS 150

Description: Load Moment Indicator

is radio shielded according to the provisions of Decree No. 1046/1984, General Approval in

accordance with the Law on Operation of High Frequency Equipment, Gazette of the Federal

Minister of Post and Communications, Edition 1984, No. 163 dated December 14, 1984 and

DIN VDE 0871/6.78 "Interference Suppression of High Frequency Equipment for Industrial,

Scientific, Medial (ISM) and Similar Purposes", limit class B.

The German Federal Post has been informed that this unit is put into service and is entitled

to inspect the series for compliance with the regulations.

PAT GmbH

Loading...

Loading...