Pasqualicchio Cantinola Touch Series, Cantinola Touch 24, Cantinola Touch 29 Use And Maintenance Manual

1

Manual use and maintenance _2016

Cantinola Touch boiler

Manual use and maintenance

2

Manual use and maintenance _2016

Table of contents

3

Manual use and maintenance _2016

Declaration of Compliance

We, Pasqualicchio srl, located in Via Vannara – Paolisi (BN),

D E C L E A R E

That the all the boilers manufactured by Pasqualicchio are in compliance with the

following European standards:

2014/30 UE (ex 2004/108/ CE), (EMCD)

2014/35 UE (ex 2006/95 CE), (LVD)

2006/42/CE, (MD)

2011/65/UE, RoHS

and that all the technical and specifications standard listed down below have

been applied:

EN61000-6-2

EN61000-6-3

EN50581

EN60335-1

EN60335-2-102

EN62233

EN303-5

Pasqualicchio s.r.l.

4

Manual use and maintenance _2016

INTRODUCTION

1.1. GENERAL WARNINGS FOR THE USER

The instruction booklet is an integral part of the product: make sure it is always in the same place as

the boiler, also in case of sale, transfer to another owner, or relocation, so that it can be read by the

user, the installer and the authorized personnel.

The installation of the Boiler and any other assistance and maintenance intervention must be carried

out by qualified personnel, in compliance with Law 37/08 (ex 46/90).

Keep the receipt/invoice of the technician who performed the test and the first product ignition. In the

absence of the above, the user will lose the warranty right on the product itself.

When the boiler is being installed, all local regulations, included those referring to national and

European rules, must be respected.

The Boiler and its equipment must not, for the whole life of the system, undergo modifications by

people other than the manufacturer and the supplier. All unauthorized modifications are forbidden and

can cause the warranty to be invalidated.

If the boiler is not used for a long time, is it recommendable to turn off the power supply general

switch.

The manufacturer is not to be held liable for injuries and damages to animals or objects caused by a

wrong installation or wrong use. During the installation and use, the installer and/or designer and user

must always respect the safety regulations.

For any option or kit (electrical items included), it is recommendable to use only original accessories.

Wrong installation can cause injuries and damages to animals or objects, for which the manufacturer

is not to be held liable.

The Pasqualicchio srl boilers cannot be used as incinerator.

Fuels other than those specified in this manual cannot be used.

During the warranty period, even in case of defects or faults, NEVER disassemble the appliance from

its installation site, but report the problems to the Assistance Centre or Dealer. No component can be

modified or replaced with another non-original, penalty the immediate voiding of the warranty right.

The Pasqualicchio boiler is a boiler for use in domestic environment, it is not suitable for use in medial

environments: it CANNOT be installed in bedrooms but only in suitable premises (boiler room)

Product warranty

For warranty terms, refer to the "warranty activation" document, available on the company website.

Safety warnings

Warnings for the installer

Follow the instructions indicated in this manual.

The stove assembly and disassembly instructions are reserved to qualified technicians only.

It is always advisable for users to contact our assistance service to request for qualified

technicians. In case of intervention by other technicians, we recommend to be sure of their

real abilities.

The responsibility of the work performed in the stove's area is, and remains, of the user; the

latter is also responsible for executing verifications relating on the proposed installation

solutions.

The user must comply with all local, national and European safety regulations.

The appliance must be installed on floors with adequate bearing capacity.

Verify that the predispositions of the flue and of the air intake conform to the type of

installation.

Do not make loose electrical connections with provisional or non-insulated cables.

Verify the earthing of the electrical system is efficient.

Before starting to assemble and/or disassemble the boiler, the installer must comply with the

legal safety precautions, in particular:

not operate in adverse conditions;

5

Manual use and maintenance _2016

operate in perfect physical conditions and verify that the personal accident-prevention

devices are intact and perfectly functional;

must wear accident-prevention gloves;

must wear accident-prevention shoes;

must use tools fitted with electrical insulation;

must make sure that the assembly and disassembly area is free from obstacles.

Warnings for the maintenance technician

Follow the instructions indicated in this manual.

Always use personal protective equipment and other protective means.

Make sure that the boiler, if it has been used, has cooled before starting any maintenance operation.

When even only one of the safety devices is not calibrated or malfunctioning, the boiler is to be

considered non-functional.

Disconnect the electrical power supply before intervening on electric, electronic parts and connectors.

Warnings for the user

Prepare the place of installation of the stove according to local, national and European standards.

As it is a heating product, the product has particularly hot external surfaces. For this reason we

recommend extreme caution during operation, in particular:

Do not touch or near the glass door, it may cause burns;

Do not touch the fumes discharge;

Do not perform any kind of cleaning;

Do not unload the ashes;

Do not open the glass door;

Do not open the ash drawer;

Make sure children do not go near.

Follow the instructions indicated in this manual.

Only use fuel conform with the instructions in the chapter relating to the features of the fuel itself.

Strictly follow the routine and extraordinary maintenance program.

Do not use the boiler without having first performed the daily inspection as prescribed in this manual's

"Maintenance" chapter.

Do not use the boiler in case of abnormal operation, suspected break or unusual noises.

Do not throw water on the stove in operation or to extinguish the fire in the brazier.

Do not switch-off the stove by disconnecting the mains electrical connection.

Do not lean on the open door, it may jeopardize the stability.

Do not use the stove as support or anchorage of any type.

Do not clean the stove until the structure and ashes have completely cooled.

Only touch the door with the stove cold.

Carry out all operations with maximum safety and calm.

Do not touch painted parts during operation to avoid damaging the paint.

We recommend keeping children and inexperienced people away from hot parts (doors, glass, etc.)

which could cause burns.

We also recommend respecting all national, local and European laws when using the appliance.

Residues inside the stove's combustion chamber is exclusively due to the try-out performed in the factory.

All our boilers are tested and put into operation for about 20/30 minutes, in order to verify the correct

functioning before shipping them.

6

Manual use and maintenance _2016

HANDLING AND TRANSPORT

The boiler is delivered complete with all its provided parts.

Pay attention to the tendency to imbalance of the boiler.

IMPORTANT WARNING

The Boiler must always be moved in vertical position and using

trolleys, AND LIFTED HOLDING IT FROM THE BOTTOM.

Be careful with the control panel, which must be protected from

both mechanical stress (impacts) and weather conditions (rain,

humidity). These would jeopardise its correct functioning.

Make sure that children do not play with the packaging

components (e.g.: film, polystyrene).

CHOKING HAZARD.

Pasqualicchio srl boilers are a good alternative to traditional

gas (methane, lpg) or liquid (gas oil) fueled boilers, since

they are cheap to operate, thanks to the low market price of

the fuels used.

CHARACTERISTICS

II.1 FUELS USED

II.1.1 Pellet

The pellet used must be of good quality, since the efficiency and heat capacity of the

stove can vary depending on the type and quality of the used pellet

Therefore, for correct operation, the pellet must have the following minimum requirements:

Compressed virgin wood chips without additional binders

Max size: 6 mm diameter and 2 cm length

Heating Value: from 19 MJ/kg = 4.538 kcal/kg = 5.28 kWh/kg

to 17,20 MJ/kg = 4.100 Kcal/kg = 4.77 kWh/kg

Density: from 1,25 to 1,4 kg/dm3

Humidity content: less than 10%

Ash: from 0,19% to 1,0%

BASIC OPERATINGS

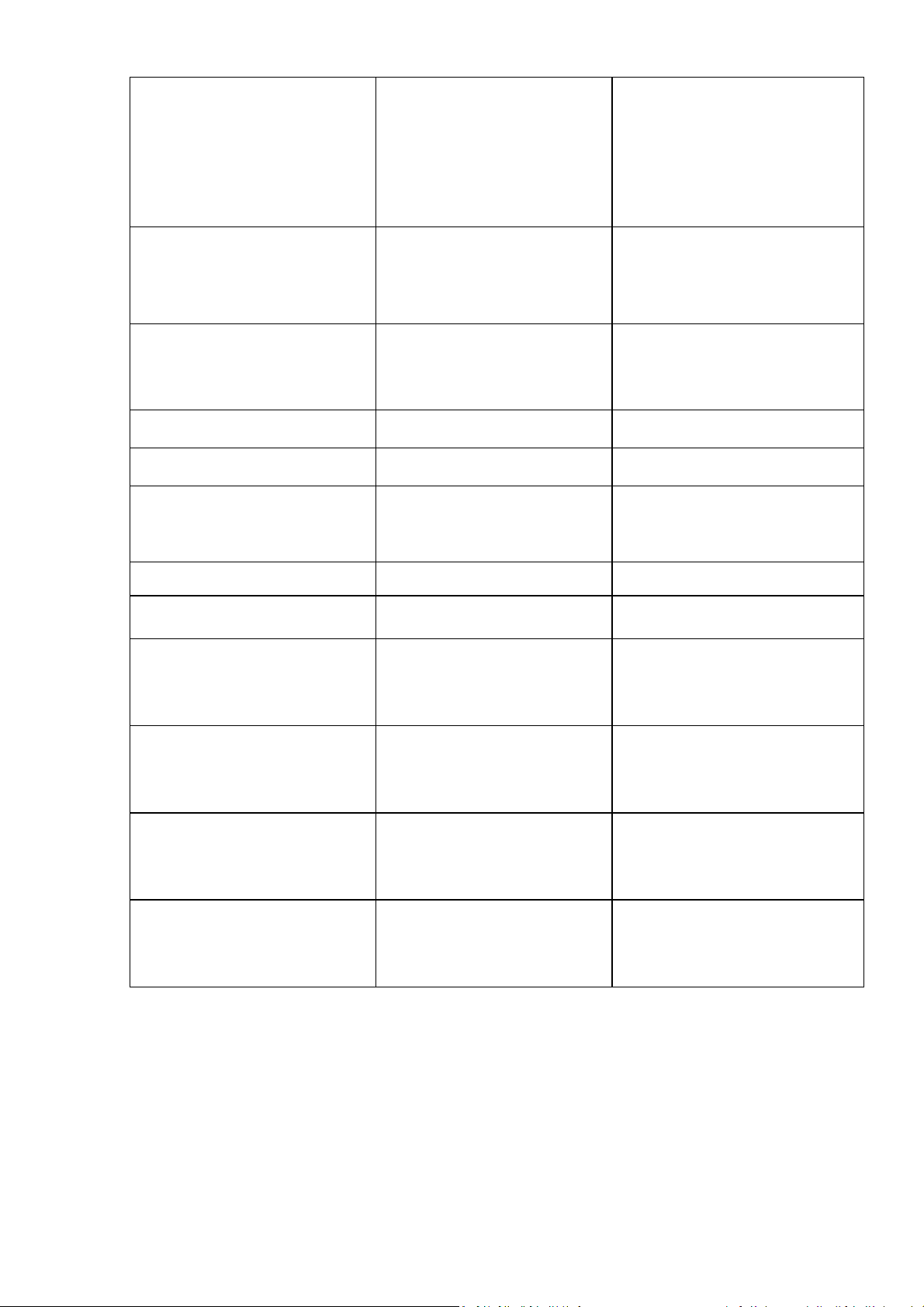

Below a brief description of the boiler functioning.

The pellet, stored in special tank, is picked up by a rotary valve, driven by a geared motor then

let it fall through a conduit, into the burner placed in the combustion chamber. In here, through

an electrical resistance of ignition (glow plug) the combustion get started.

The combustion takes place thanks to the combustion air brought inside the chamber with the

aid of an extractor fan fixed at the smoke outlet.

7

Manual use and maintenance _2016

The combustion chamber is surrounded by water within a cavity; during the combustion

Pressure transmitter

Valve with manual reset

Smoke temperature probe

Pressure switch

Water temperature

probe

process, the heat is divided into two types: a first one, which is provided by conduction and

radiation from flames to the water; a second one, which is provided by the hot exhaust gases by

convection on their way towards the chimney. In fact, in the boiler there is a forced draught so

that an extractor fan creates a depression inside the combustion chamber, letting the smoke be

evacuated through the shell and tube system.

Once the water gets hot, it will flow into the system by the standard circulator and letting the

radiators be on in the rooms to warm.

The boiler is fully managed by the electronic unit control, which regulates the flow of combustion

air and the quantity of pellets into the burner. The air-fuel mix makes it possible to determine the

heating capacity of the machine.

The functioning of this product is based on 3 different levels of combustion, which are specified

as "powers". The combustion levels of our boilers are 3 and shift down when approaching to the

temperature you set on the display of the electronic unit control. Once you have reached the

temperature value set on the display, the boiler runs in the so called ' MODULTAION ' mode.

For safety reasons it is essential to indicate the correct locations of control and security sensors.

The figure shows a cross-section of the boiler in order to identify the components:

Down below the top section of the boiler with the location of the temperature probe water.

PRODUCTION FEATURES

All the boilers are equipped with:

8

Manual use and maintenance _2016

-

Model

Cantinola Touch 24

Cantinola Touch 29

Power heart

Min / Max [kW]

6,76 / 23,21

6,76 / 29,00

Water efficiency

Power Min / Max [%]

89,51 /90,38

89,51 / 90,05

Nominal heat power

Min /Max heating [kW]

6,1 / 21,0

6,1 / 26,1

Combustible

Type

Pellet

Pellet

Tank Capacity

[Lit / Kg-Pellet]

59/34

59/34

Extension capacity

[Lit / Kg-Pellet]

56/32

56/32

Info

Water capacity[lit.]

47

47

Option

Hot sanitary water

production

Hot sanitary water production

Circulator

-

Membrane expansion vessel

-

Electronic unit control, complete of panel and 3 temperature probes.

Smoke temperature

Water boiler temperature

-

Safety valve (3 bar)

-

Smoke Draught Pressure sensor

-

Manometer for checking the loading pressure (not more than 1,5 bar)

-

Water pressure sensor

-

Smoke extractor

-

Automatic cleaning system of smoke pipes

-

Ash collecting box

As an option, the boiler can be equipped with a circuit for the production of hot sanitary water

complete of the following additional parts:

- Hall effect flow switch

- Three-way diverter valve

- 16 heat-exchanger plates for the production of hot sanitary domestic water

- Tank and feeding system for a bigger autonomy

- GSM system for a remote control

- Remote display

Technical features

9

Manual use and maintenance _2016

Standard

Expansion vessel,

Circulater, Brush, Semi-

automatic shel and tube

cleaning system.

Expansion vessel,

Circulater, Brush, Semi-

automatic shel and tube

cleaning system.

Electric Power [W]

Ignition

Nominal

Min. Power

Stand-by

480 W

110 W

40 W

6 W

480 W

115 W

40 W

6 W

Output smoke [°C]

Nominal power/min.

power

110/57

127/57

Combustible consumption

[kg / h]*

Min 1,4

Max 4,8

Min 1,4

Max 6,0

Heatable Volume

[m3]**

490

680

Smoke speed

Nominal

power/min. power

[kg/h]

0,014/0,006

0,0169/0,006

Boiler Class

5

5

Min. Draught

[mbar]

0,1

0,1

Range at

nominal power

/min. power [h]

7/25

5/25

Water resistence

at 10 K and 20 K

[mbar]

533/133

827/206

Min. return water

temperature [°C]

50

50

Noise level

Pmax/Pmin

[dB(A)]

(EN15036-1)

45,1/35,2

48/35,2

Notes: * referred to the pellet consumption with calorific value of 5 kWh/kg; ** The heated volume, should be understood in

a rough line, for buildings with heat requirement of 34.8 W/M3 ÷ 30 (kcal/h)/mc, built under the law 10/91.

10

Manual use and maintenance _2016

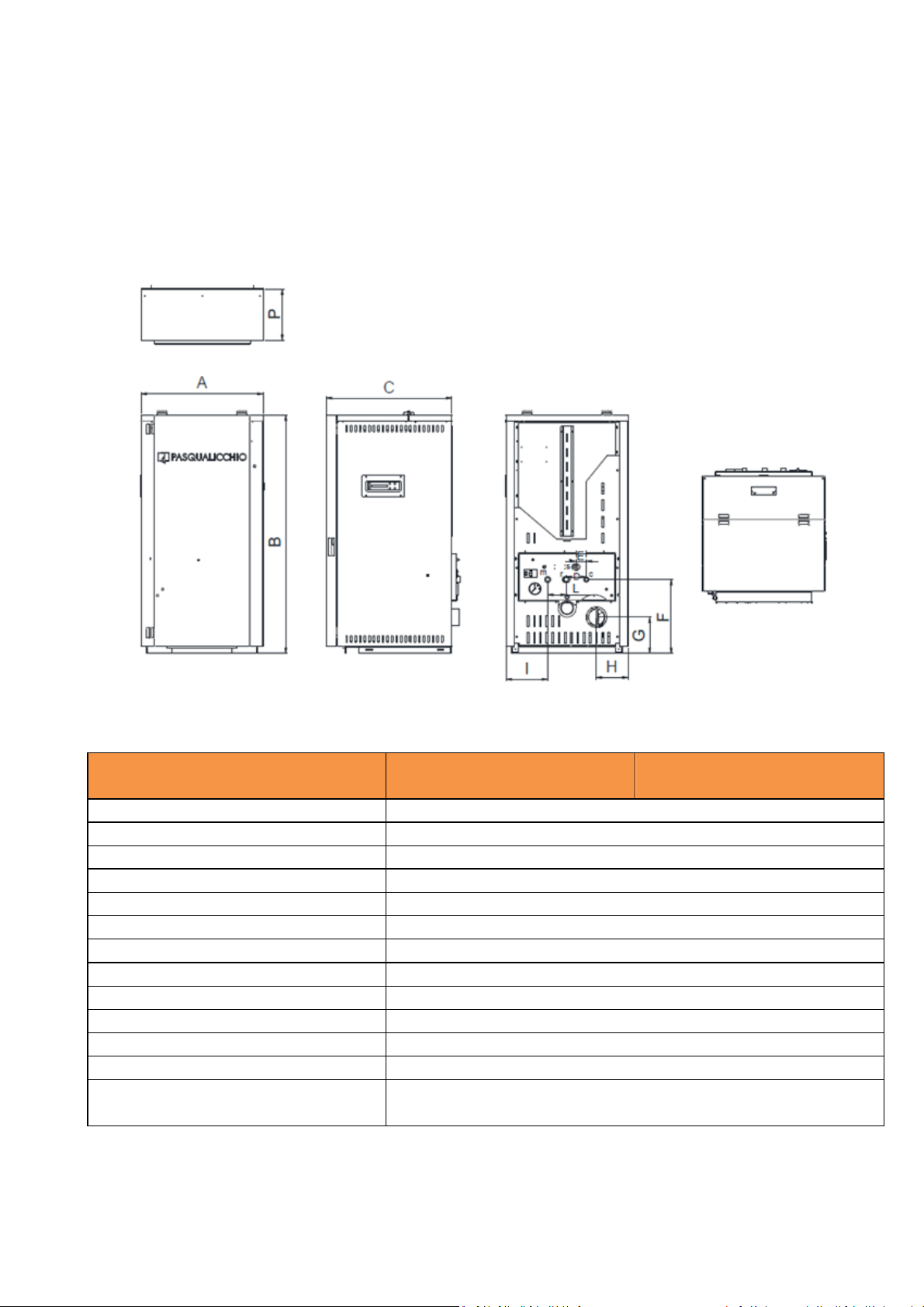

Dimensions [mm]

Cantinola

Touch 24

Cantinola

Touch 29

A

590

B

1305

C

665

D

105

E

50

F

425

G

225

H

180

I

135

L

110

P

250

B+P

1556

Smoke output diameter

100

Scheme and measurements

Any reproduction, even partially, is not permitted without authorization. The manufacturer reserves the right to

make changes or improvements to the products without this can be disputed.

11

Manual use and maintenance _2016

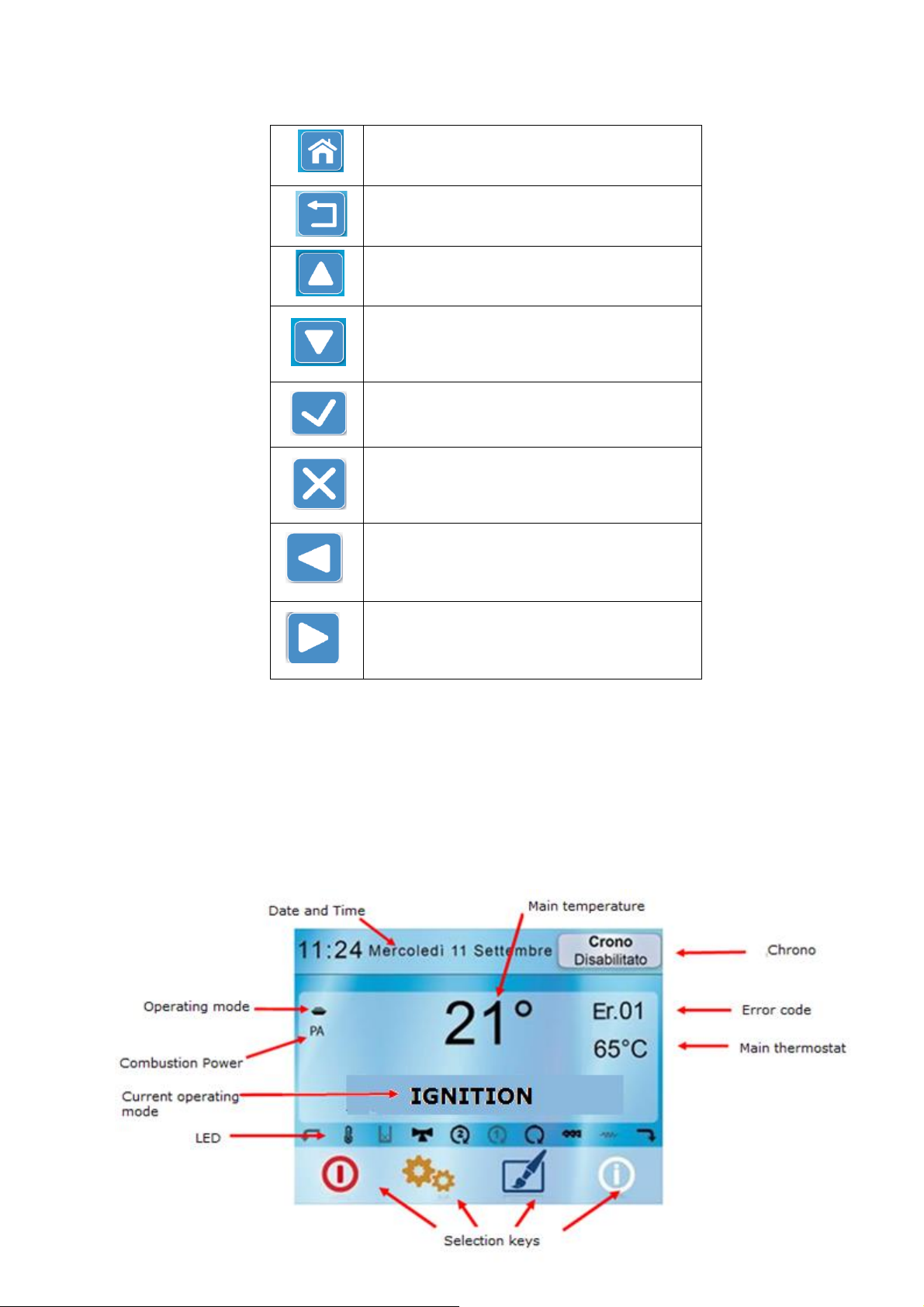

Ignition after 3 seconds pressure

Alarm reset after 3 seconds pressure

Set up Menu Access

Custom Menu Access

Information Menu Access

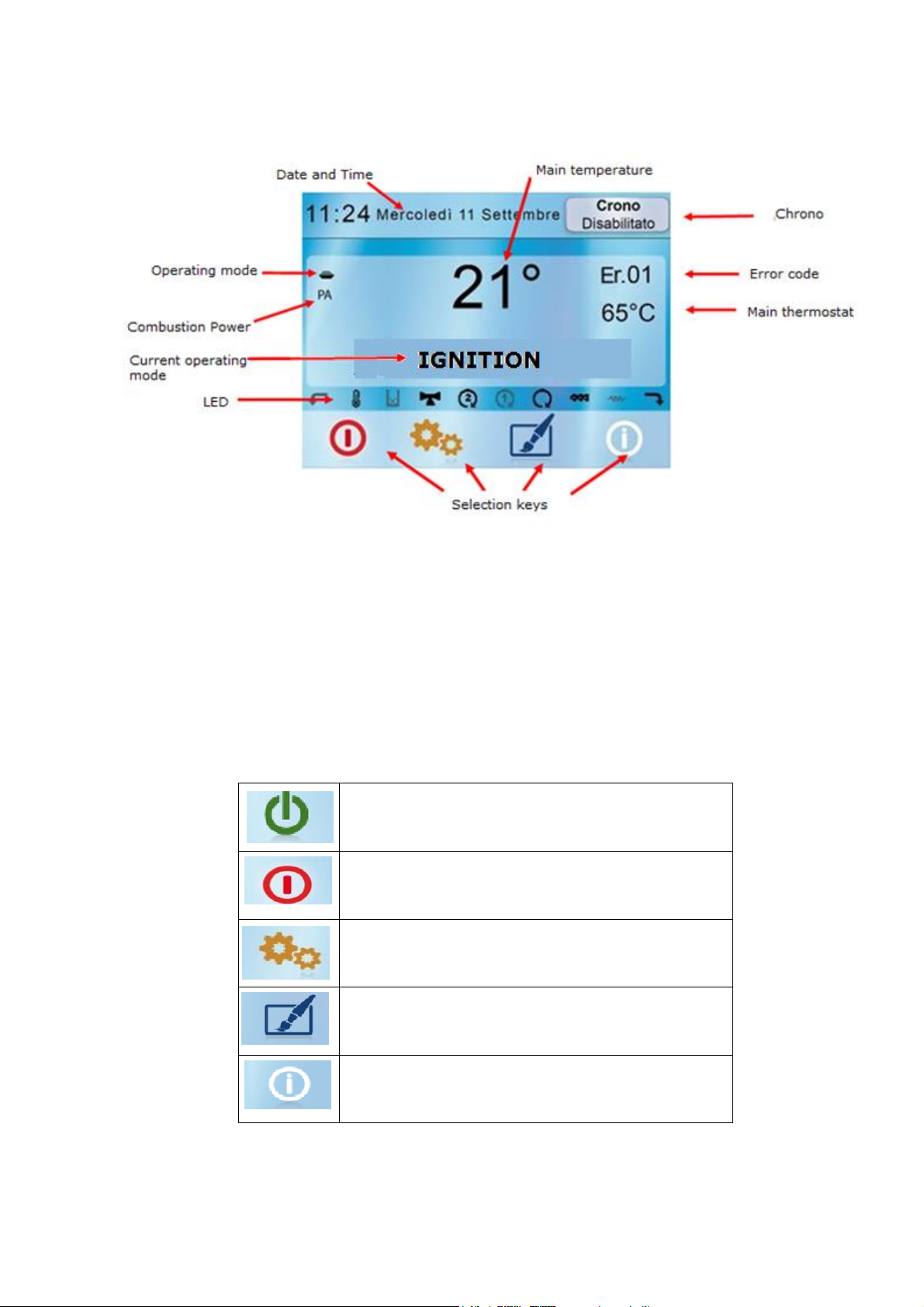

THE ELECTRONIC CONTROL UNIT

The electronic temperature controller allows to manage both the fuel and combustion air supply

through a “subsequence stages” logic of operation, showing the operating parameters on the

display, such as the boiler temperature and the combustion power, as well as the time and

displaying with special led the smoke extractor, pump and spark plug functions. The logic control

can be programmed by using two menu, one already set up and shielded by the manufacturer,

and a second “user” one, where you can change some parameters, as follows.

Control panel key functions

Key selection from the Menù:

12

Manual use and maintenance _2016

Back to Home page

Upper level

Scrolling / Increasing Value

Scrolling / Decreasing Value

Exit and save data

Menu exit – not saving data

Moving to the left

Moving to the right

Navigation buttons:

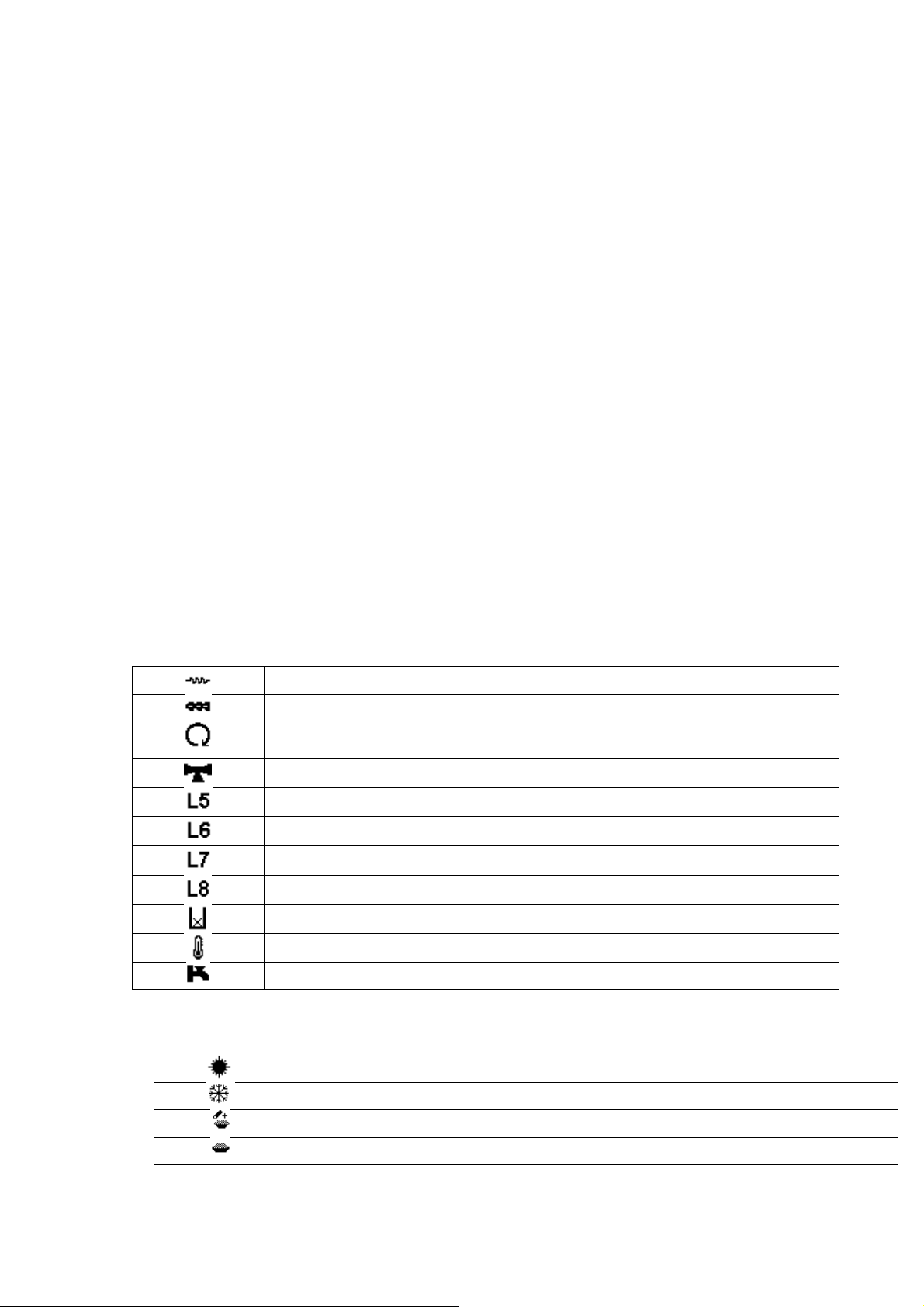

The display

Below the picture of the Touch Screen keyboard with the legend of the key functions:

-Main screen:

13

Manual use and maintenance _2016

Led On: Igniter Operating

Led On: Coclea Operating

Led On: Pump Operating

Led On: Sanitary valve Operating

Led On: Aux1 Operating

Led On: Aux2 Operating

Led On: Aux3 Operating

Led On: Aux4 Operating

Led On: Pellet sensor warning no fuel

Led On: Room thermostat Local/Remote operating

Led On: Flow switch sanitary water needed

Led On: Summer Function

Led On: Winter Function

Led On: Combi Mode Operating

Led On: Pellet Function

-

Date and time;

-

Chrono Mode (D–Daily, W–Weekly, WE–Week end);

-

Power, Selected recipe of combustion (Pellet 1);

-

Function phase of the system;

-

Error that may occur;

-

Boiler Thermostat value

-

Boiler temperature detected by the boiler probe

System Functions :

-

-

-

-

-

-

-

-

Warning lights

Checkup;

Ignition;

Stabilization;

Normal;

Modulation;

Switch off

Power Recovery;

Block.

The Led field is not always visible on the main screen of the display. To make it appear or disappear,

press in the area of the display that contains the main temperature or operating status. The LEDs

visible are:

There are also special LEDs always visible on the left side of the main screen:

Loading...

Loading...