Pasontech.com Present

E-Evolution

E-Power F3A Areobatics Airplane

For Intermediate & Advanced Fliers.

SAFETY PRECAUTIONS

This radio control model is not a toy!

Fist-time builders should seek advice from people having building

Experience in order to assemble the model correctly and to produce

Its performance to full extent.

Assemble this kit only in places out of children’s reach!

Take enough safety precautions prior to operating this model.

You are responsible for this model’s assembly and safe operation!

Always keep this instruction manual ready at hand for quick

Reference, even after completing the assembly.

Notice:

By the time the Yak arrives in your shop, it will have endured several climate changes.

As a result you may find some wrinkles in the covering and wing or Fus. Part maybe

have some twisted. This is not a manufacturing defect. Please take a few moments

with your iron or heat gun to remove any wrinkles and correct all twisted parts. Iron

over all the edges to ensure they are sealed.

This Products Produce by Pasontech Hobby Company

Room J, Floor 22 Baiheyindu building Buji town Longgang district Shenzhen China

E-mail: sales@pasontech.com http://www.pasontech.com

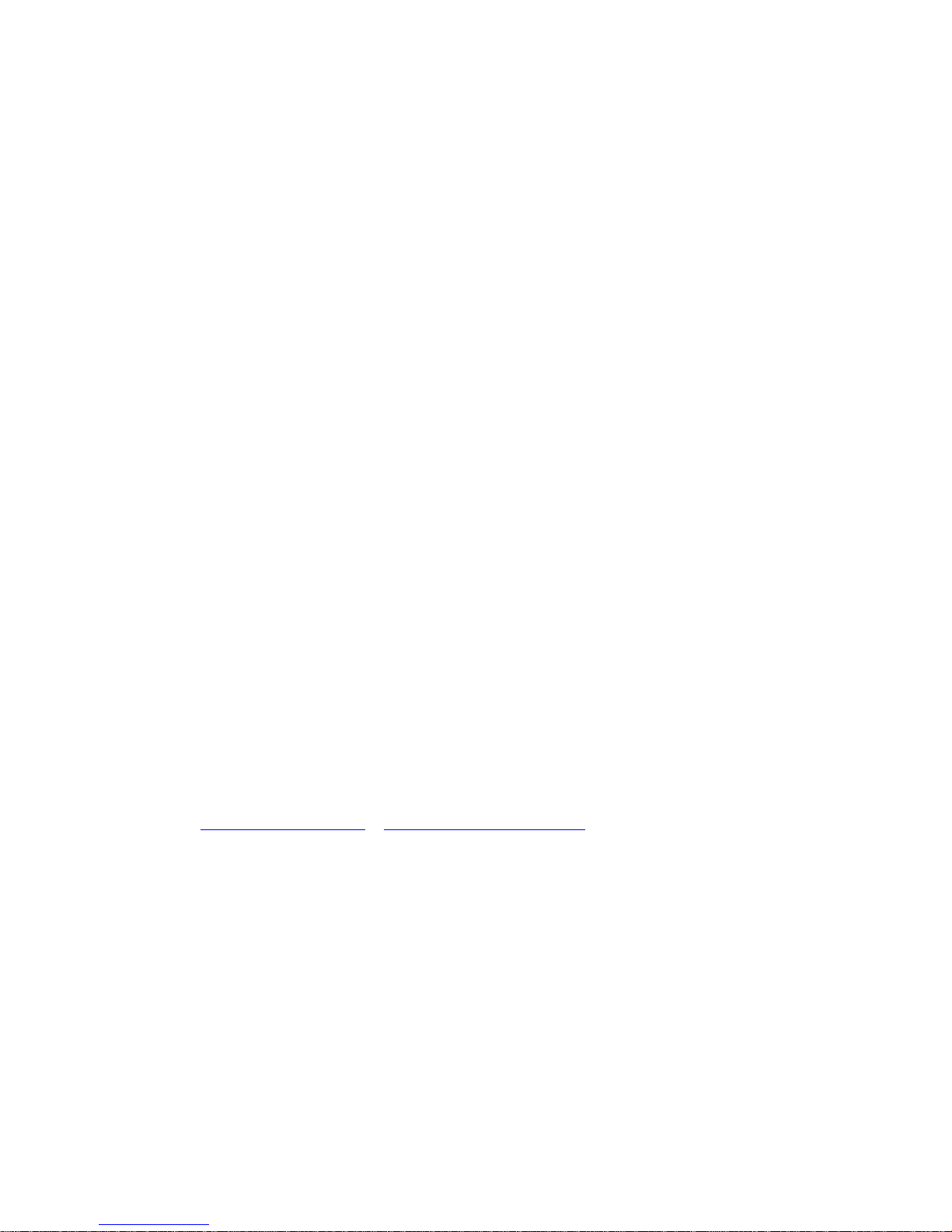

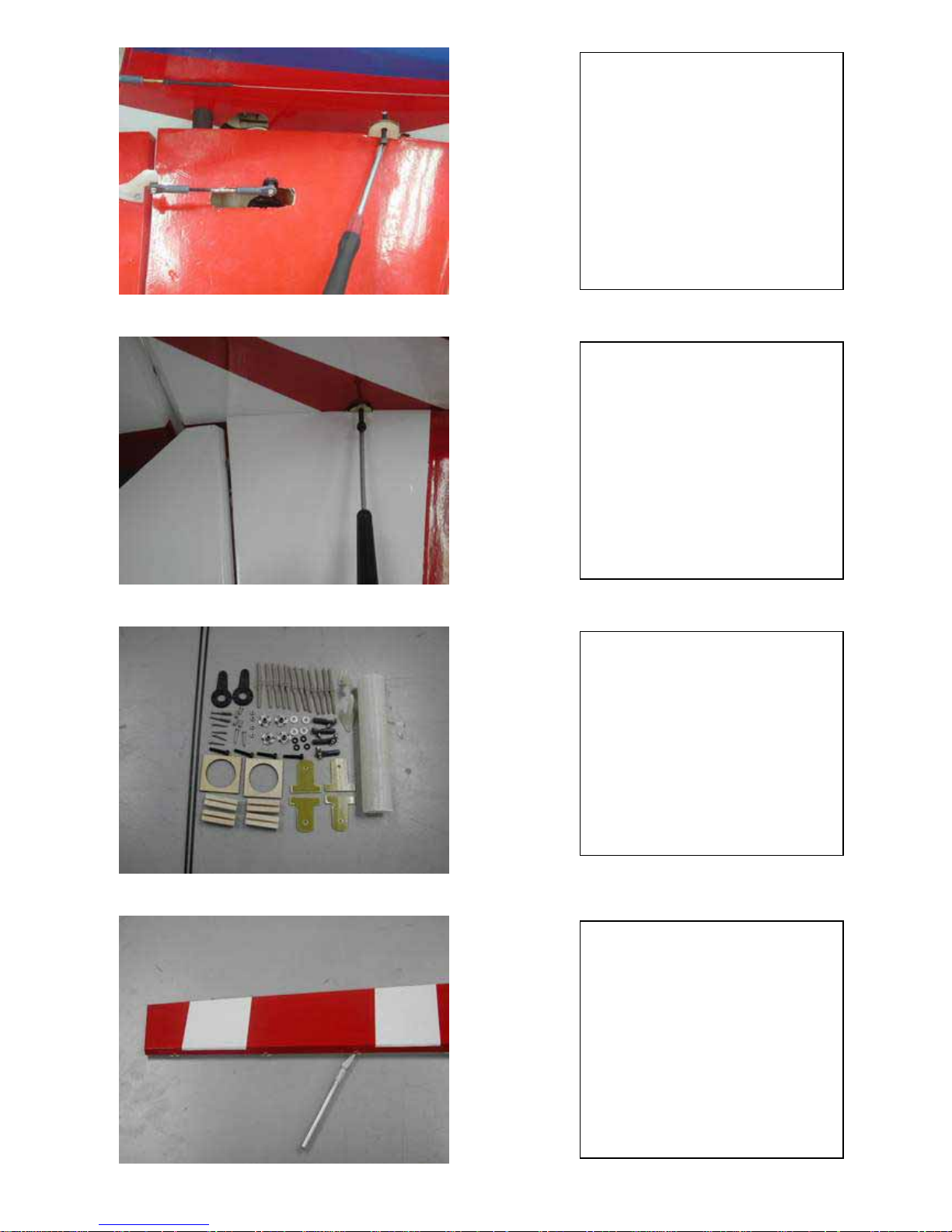

Find the Tail gear assemble parts as

show.

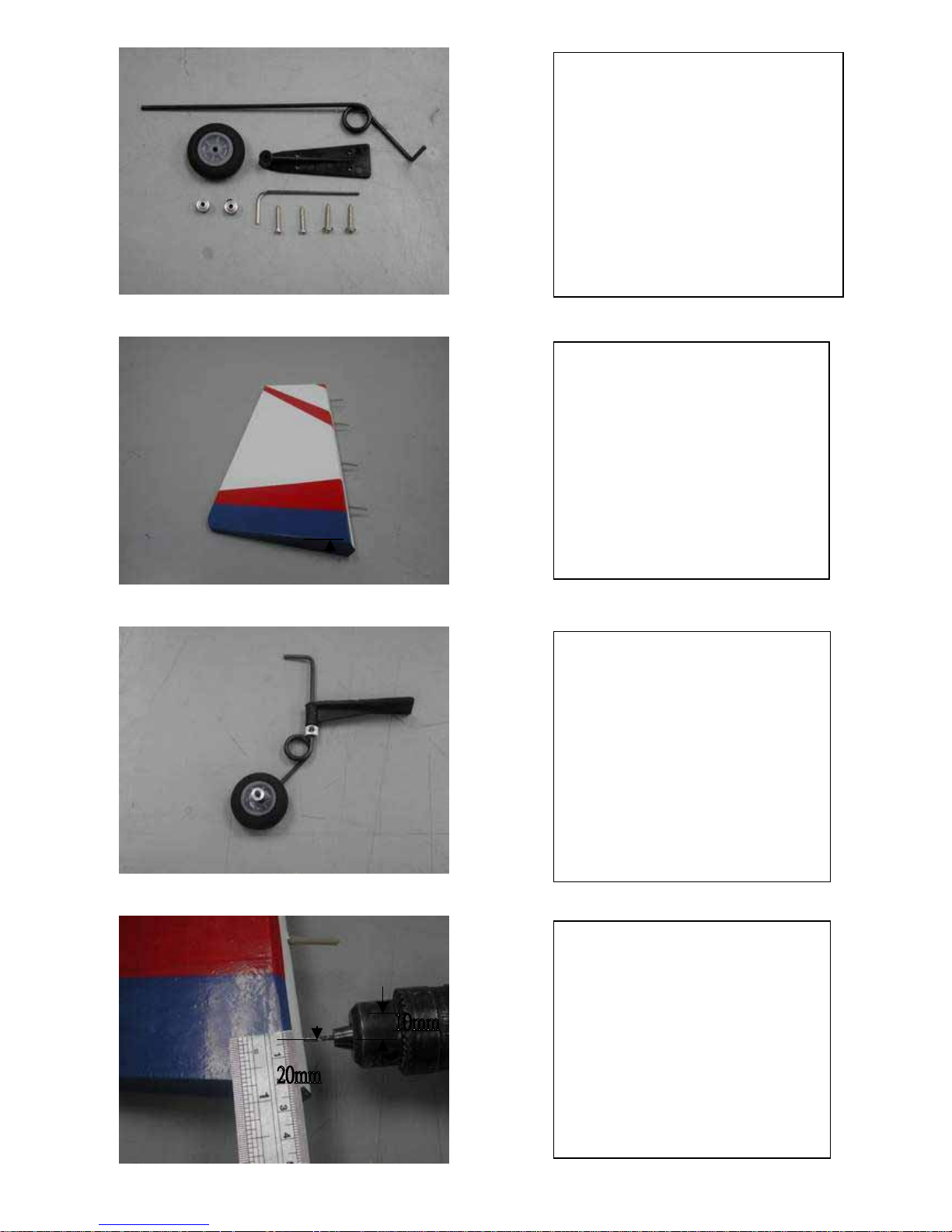

Cut out film as hole

Glue the four pin hinges with

Epoxy.

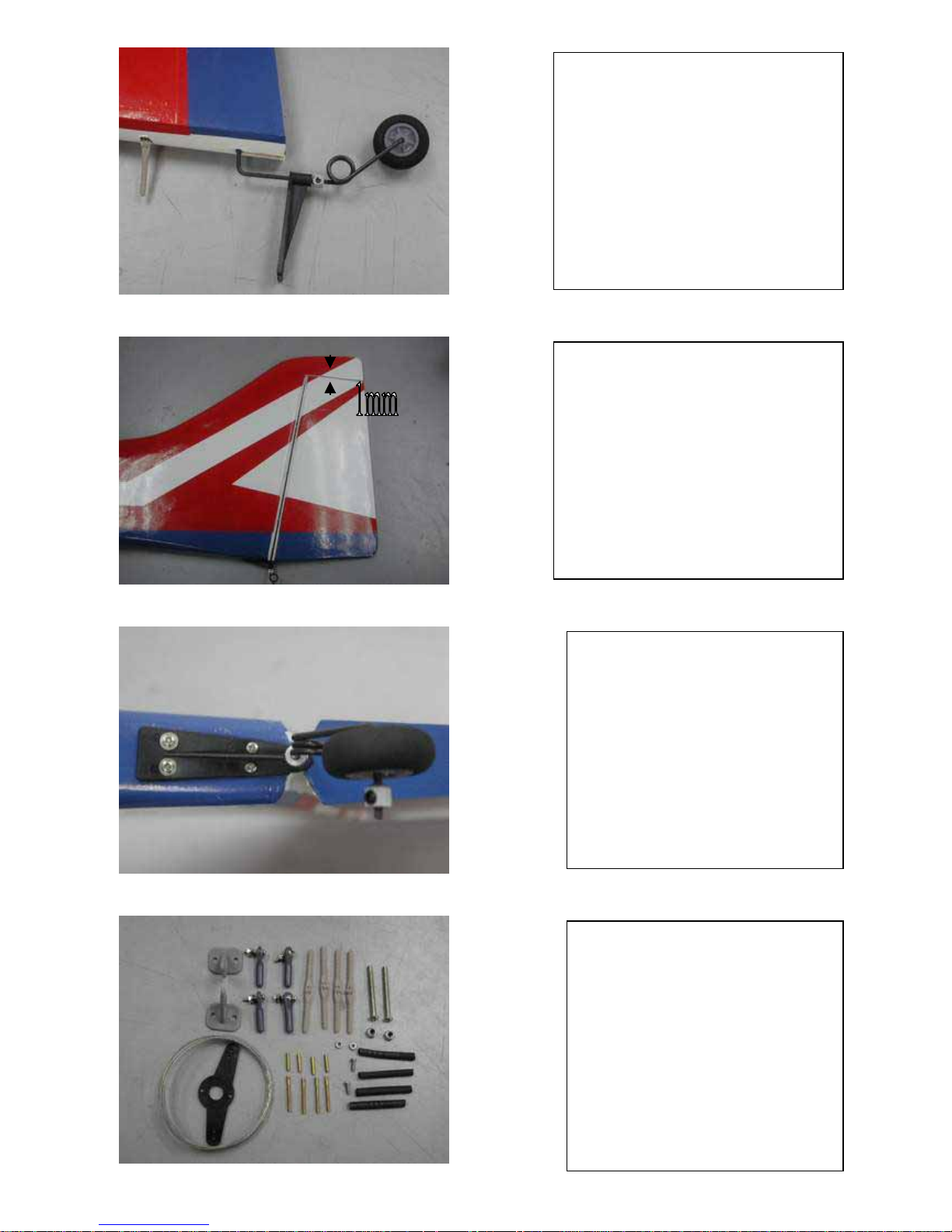

Install the tail gear wire in to the

gear mount.

Then bending the wire as the show.

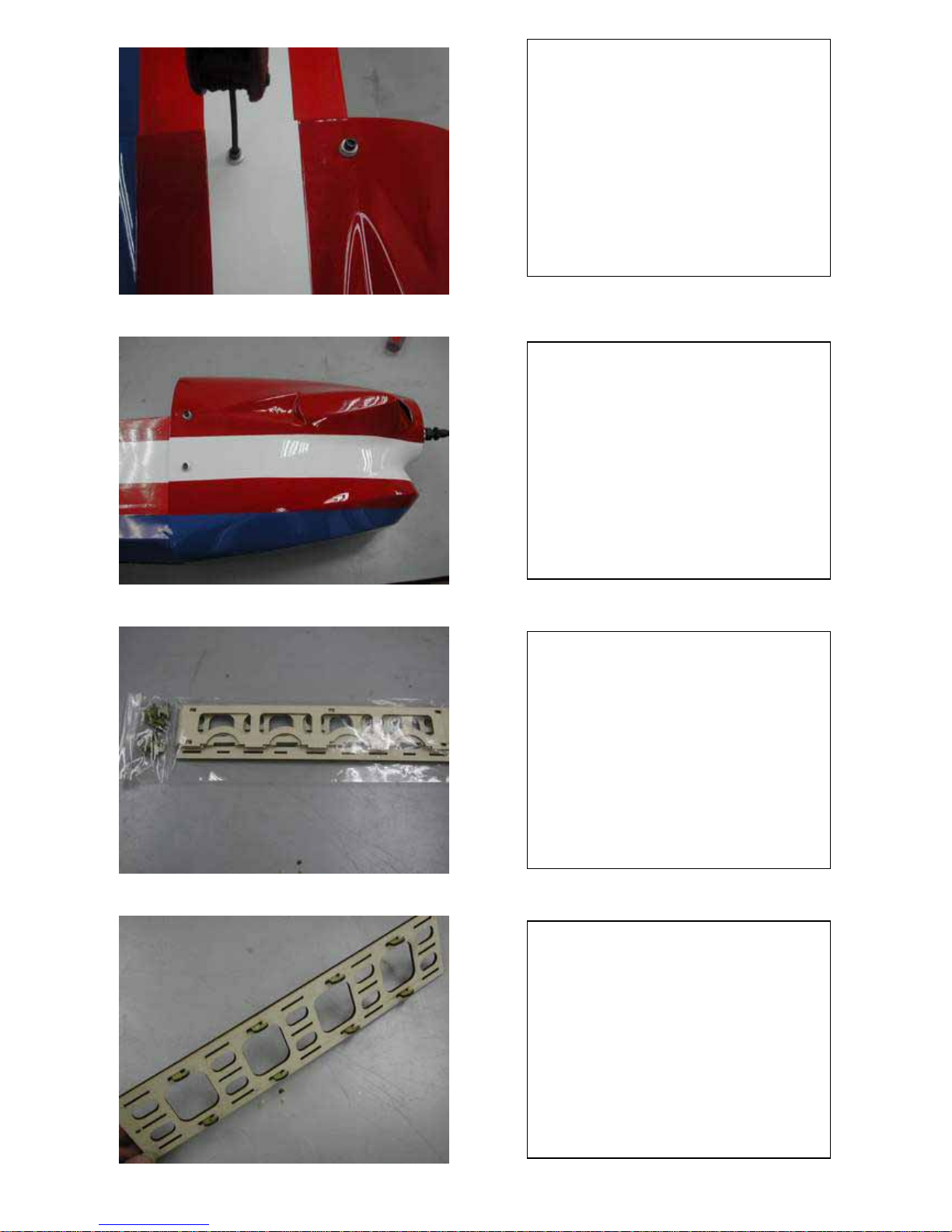

Install the tail wheel and wheel

stopper as show.

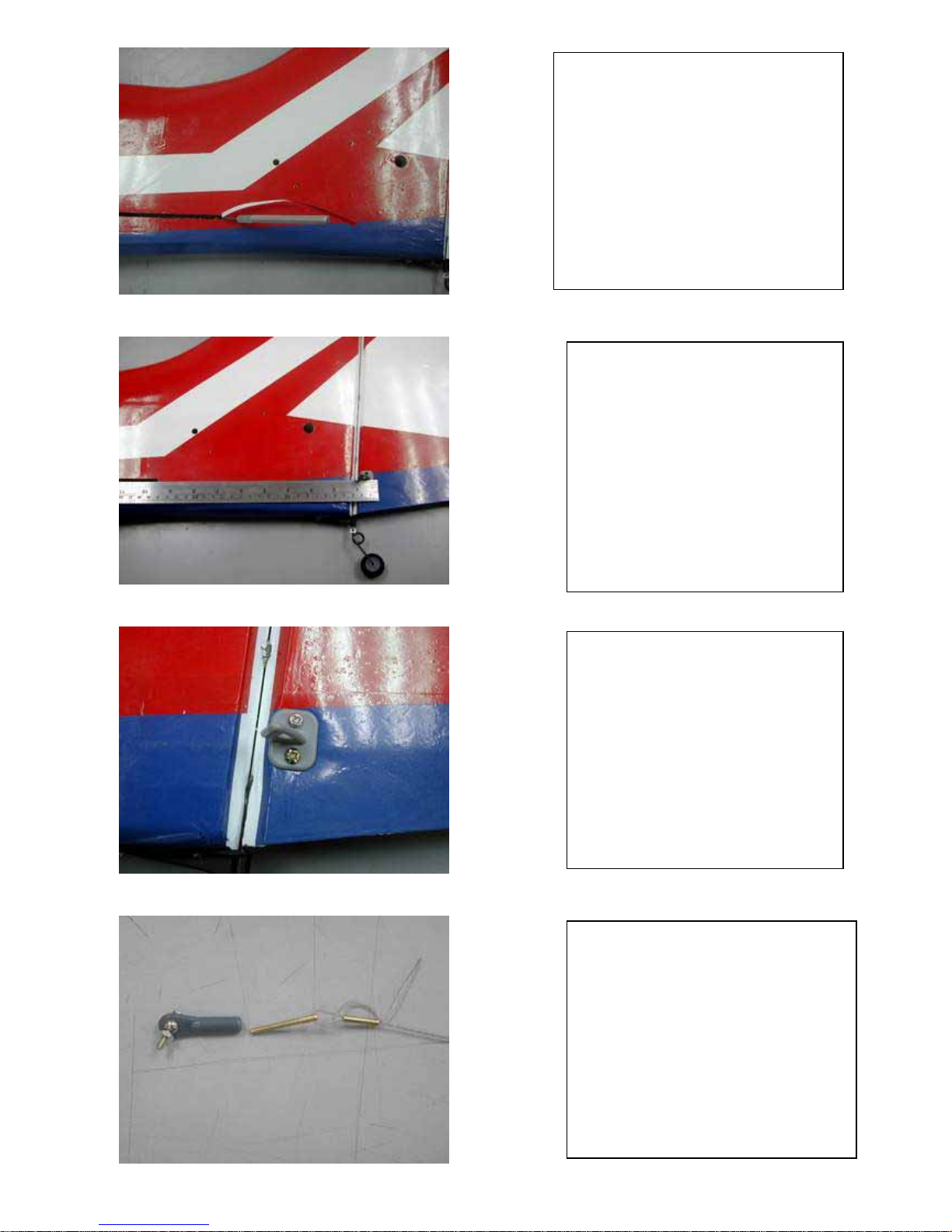

Drill a 2mm hole into the exact

center of the rudder as marked to

accept the tail wheel wire.

Install the tail wheel wire to the

Rudder and

Glue the with Epoxy.

Install the Rudder to Fin and Fus.

Keep the Rudder and Fin top have

1mm grip .

Glue them in piece.

Drill four 1.0mm hole

Fix the tail gear with four 2X13mm

TP. Screw.

TP. Screw 2X13MM X4

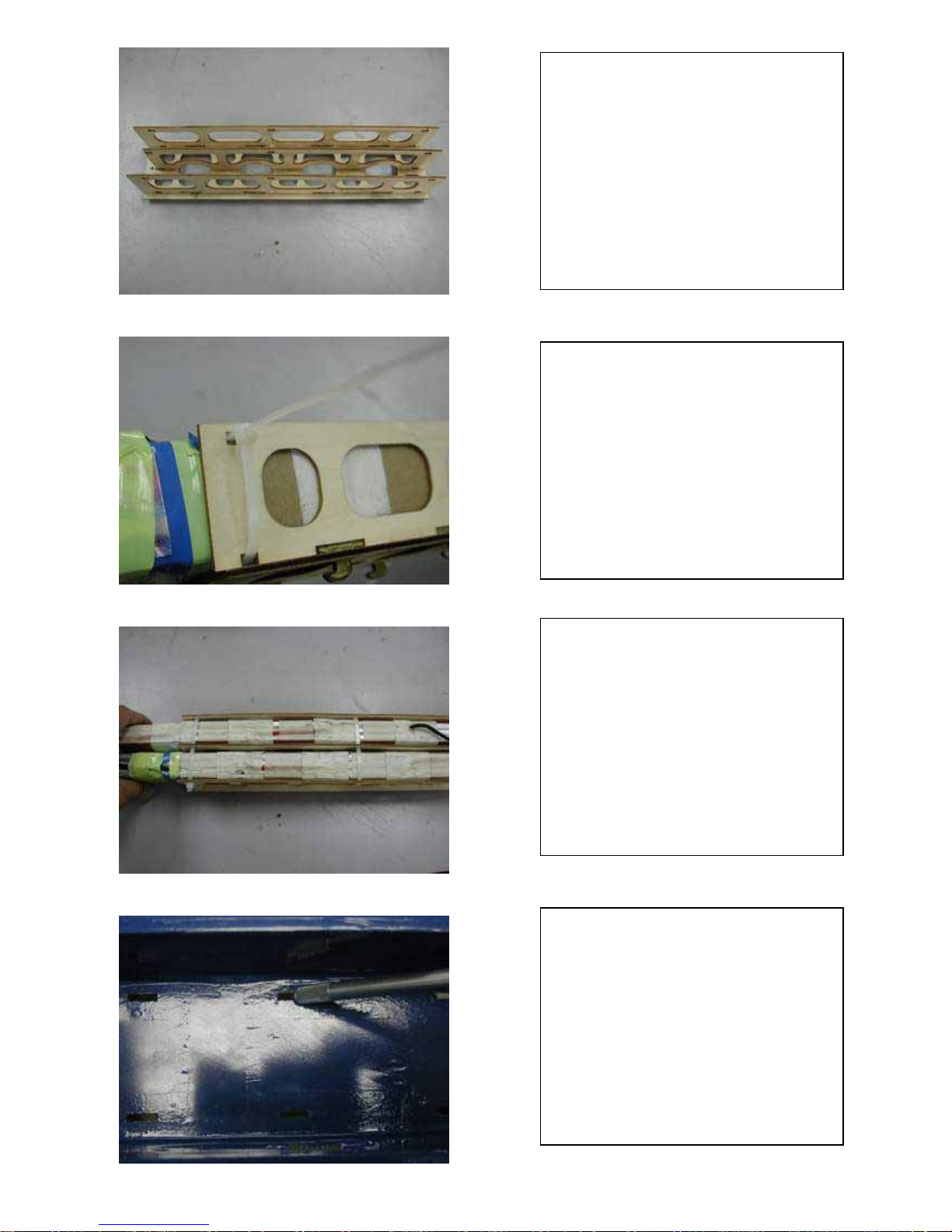

find the Rudder control parts as

show.

Trim off covering film as show.

.Check the Rudder control horn in

line as the wire outlet.

Install Rudder control as show

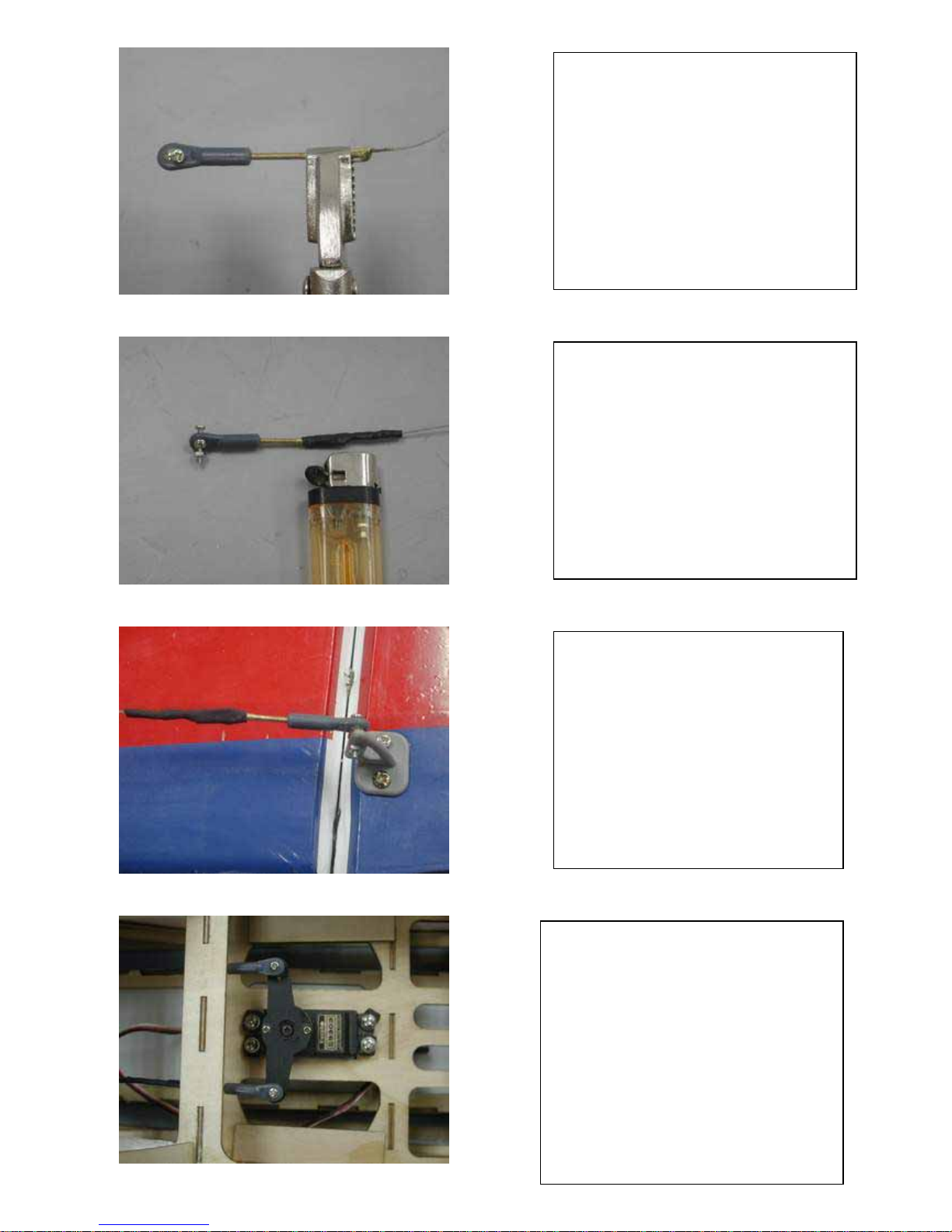

Assemble ball link end and wire as

show

Use any tool to made the wire stopper

p

ipe tight as show.

Use some heat to made the heat sink

tube to cover wire stopper pipe as

show.

Install the ball link end with two M2

screw as show.

Use same way as Rudder Horn to

assemble Rudder servo horn as horn.

PIN hinges X8

After check the last hinges will not

stop Stab. Join. Glue Stabilizer and

Elevator together with epoxy.

Cut the last two hinges 3mm shorter

So the last hinge will not stop the

Stab. Join inside the Stab.

glue four hinges to each Elevator.

.

glue four hinges to each Elevator to

each side Stabilizer.

At the Stabilizer bottom trim off the

film servo horn slot as show.

Elevator servo bay was inside

Stabilizer and it size was stander size

servo.

Install the carbon anti roll pin as

show to each Stabilizer and glue it

together with thick CA. or epoxy.

.

Check Elevator servo horn

And Elevator horn was inline.

Install the Elevator control horn as

show.

Cut the push rob to 35mm.

Use iron to solid the push rod

connector as show .

After the push rod cool down install

the ball link end as show.

Install the Elevator control push rob

as show.

Install the carbon join to Fus. as

show .

Install each Stabilizer on lower

side of the Fus. With four M3 X

15mm screw and washer.

Important notice: Please apply

“thread locker” before you install

Stab. Screw.

Connecting the servo lead before

you install the Stabilizer.

Install each Stabilizer on upper

side of the Fus. With four M3 X

15mm screw and washer.

Important notice: Please apply

“thread locker” before you install

Stab. Screw.

Connecting the servo lead before

you install the Stabilizer.

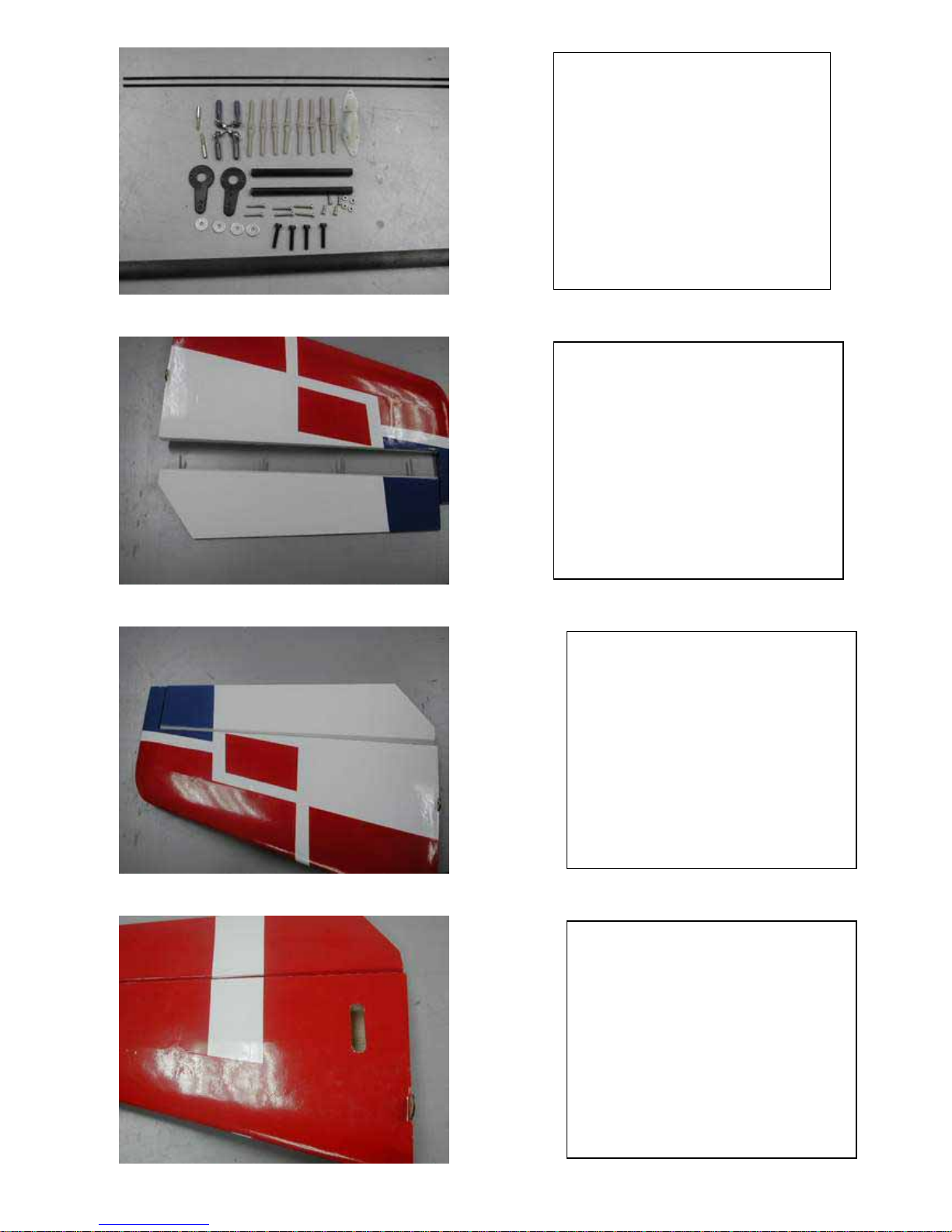

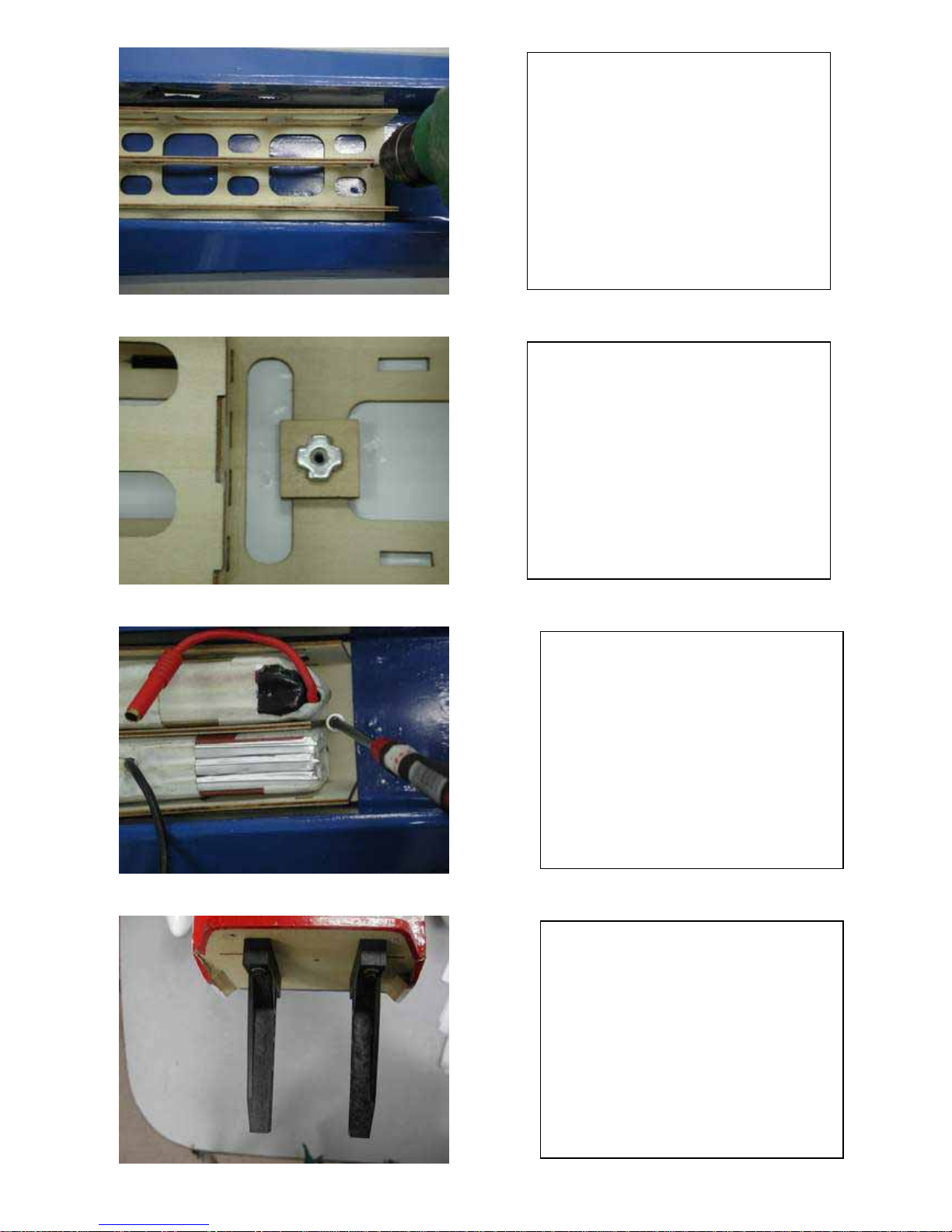

Find the Aileron linkage set as

show.

Install aileron linkage as the

show.

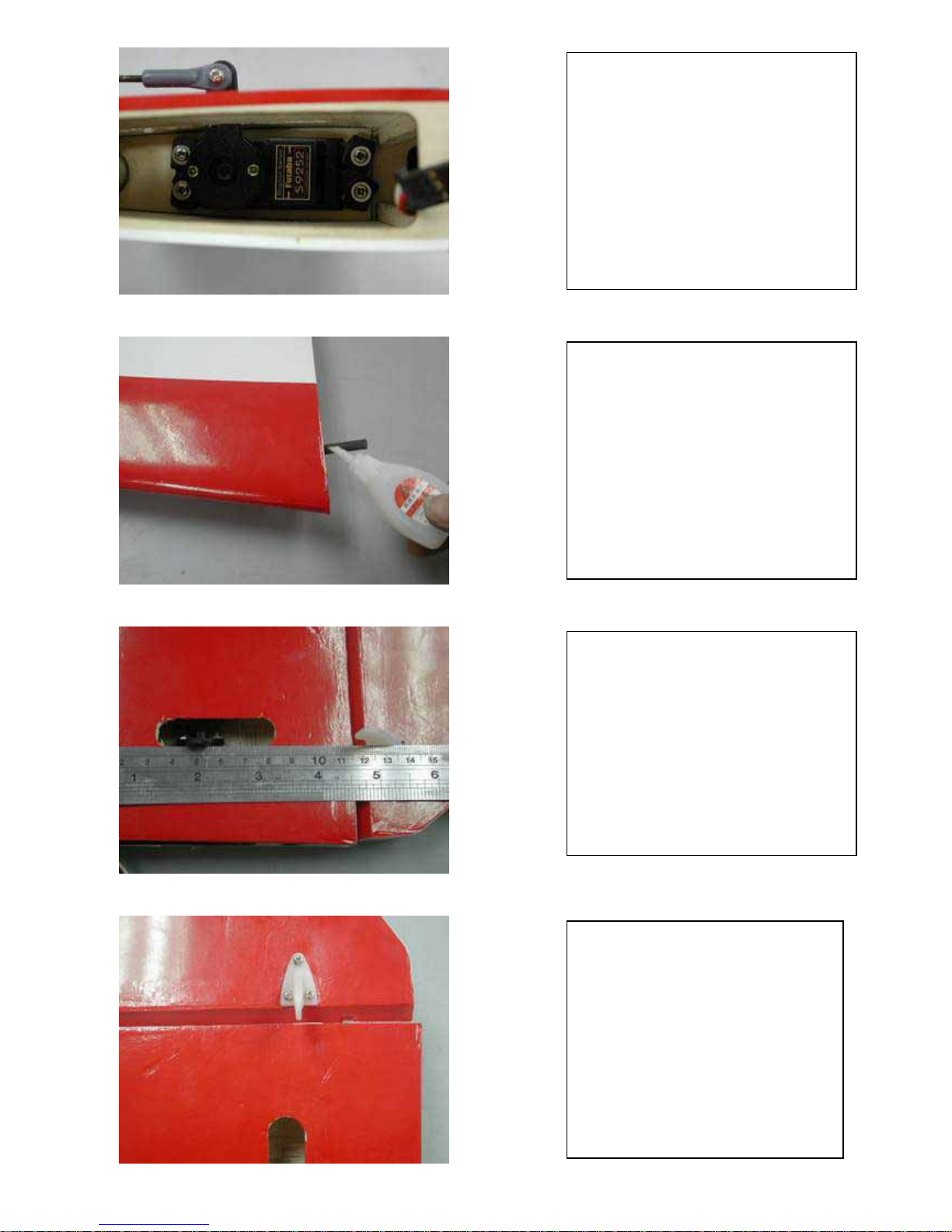

Trim off the covering film as

show.

Install and Glue seven pin hinge in

to each side Aileron.

Glue them in piece with epoxy.

PIN hinge X 7

Install each side Aileron. To each

side wing panel.

Glue them in piece with epoxy

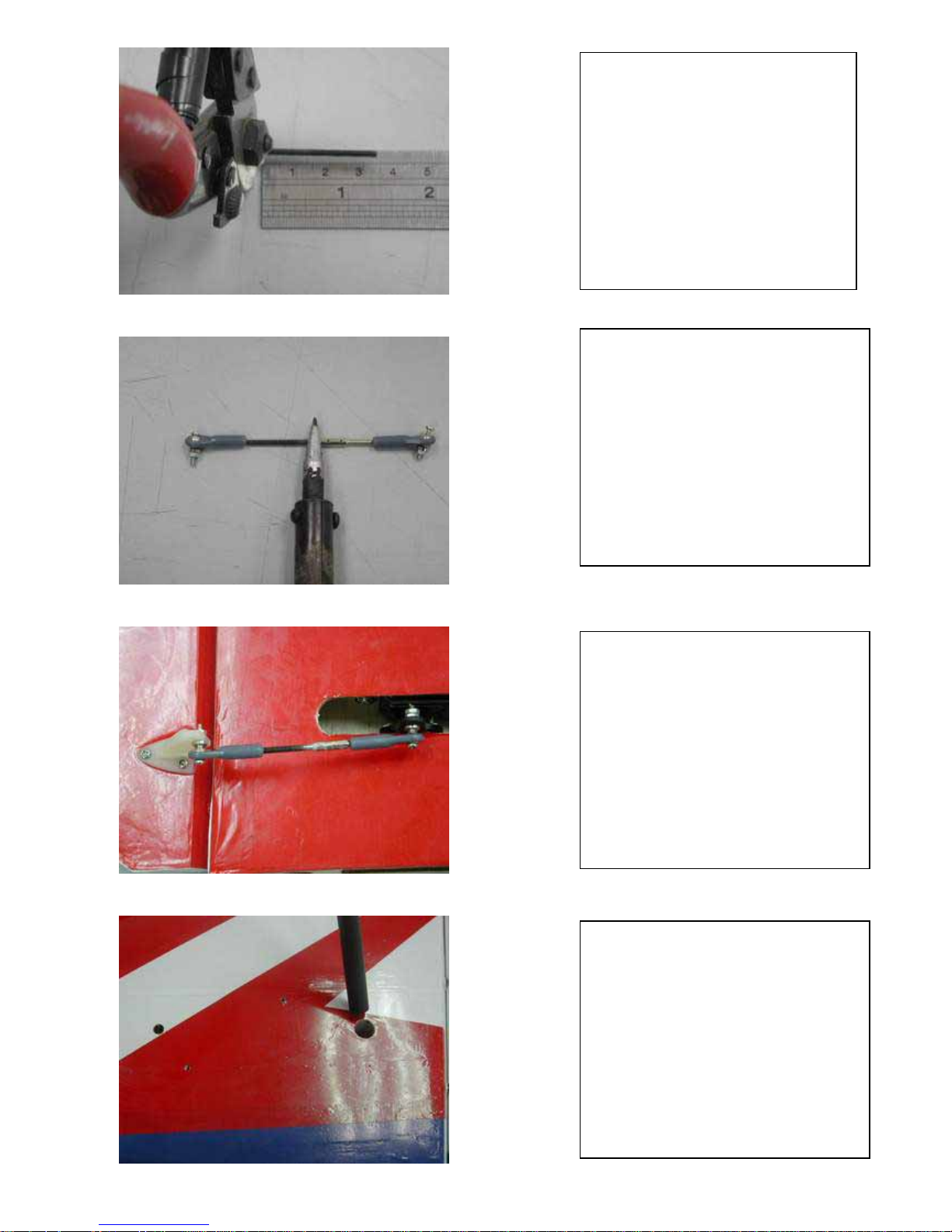

Trim off the cover film at servo bay

area under each wing panel.

Check the aileron Control horn and

servo horn in line as show.

Install aileron Control horn the show.

Cut the push rob to 45mm.

Use iron to solid the push rod

connector as show .

After the push rod cool down

install the ball link end as show.

Install aileron Control push rob as

show.

find two wing hookup plate as

show.

Install the wing mount plate from

inside wing root at both LE. And

TE.

Gluethe wing mount plate from

inside wing root at both LE. And

TE. With Epoxy.

Use M3X 15mm screw to fix the

canopy.

N

otice: please use the “O” ring and

washer to made the canopy screw

not easy to loosing .

Before you install wing panel to

fus. Trim off the cover at wing

mount slot as show.

Follow the mount plate hole to drill

a 3mm hole then remove the wing

and made hold bigger for blind nut

as show.

Install blind nut on wing mount and

use screw to made the blind nut tight

as show.

We stronger recommended After

you find out the good CG. Point

for your flying style.

Reinforce your airplane with FRP.

Wing join tube and ply support.

Find the canopy and wire lock parts

as show.

Follow the slot to trim off covering

film for Fus. Side as show.

Install wire and glue wire and the

wood block in place as show.

Install the wire end cover as

show.

Important notice:

Please glue the wire end cover

before you use it. If you not

install wire cover it will cause

injury.

Find the engine mount and

template as show.

Placing engine mount template as

show.

Follow engine mount template to drill

the hole the engine or motor that you

use on the fire wall.

N

otice: “M” mark was for

YS140-160 or OS.160 .

“E” mark was for “Hacker C50 XL

motor.

After drill the engine mount hole the

engine or motor that you use on the fire

wall.

Install four blind nuts from back side o

f

fire wall.

as show.

Follow the mark to drill eight

3mm hole.

Install the motor as show.

Install the motor mount as show.

Find cowl fix parts.

Install the cowl and and made sure the

drive hub have distance for cowl end

3mm.

If you find the motor mount will touch

the cowl.

Please cut the cooling vent shorter as

shorter as show.

After you trim fit the motor mount with

the cowl drill two 4mm hole at each

side of cowl and fus. Side .

Then install two blind nut at each Fus.

Side.

Install two “O” ring at each side of

cowl as show.

Fix the cowl with four M3 screw.

Find the battery tay as show.

Assemble FRP. Teeth as show.

N

otice: the teeth direction was forward.

Assemble battery tray as show.

Install the battery in side the battery

tray, if the are differ size you can

choice not use the center plywood.

Fix the battery with wire tight.

Trim off the film at slot area.

Install the battery under pipe tunnel

then follow the hole at end of battery

tray to drill a 3mm hole.

Follow the hole to install a blind nut for

battery tray fix.

Lockup the battery tray with a M3

screw.

If you choice use Glow power. Follow

engine mount template to drill the hole

the engine or motor that you use on the

fire wall.

N

otice: “M” mark was for YS140-160

or OS.160 .

“E” mark was for “Hacker C50 XL

motor.

We recommend you if you use high

vibration engine such “YS” 4T engine ,

you should use a good soft mount,

unless will cause airplane damage.

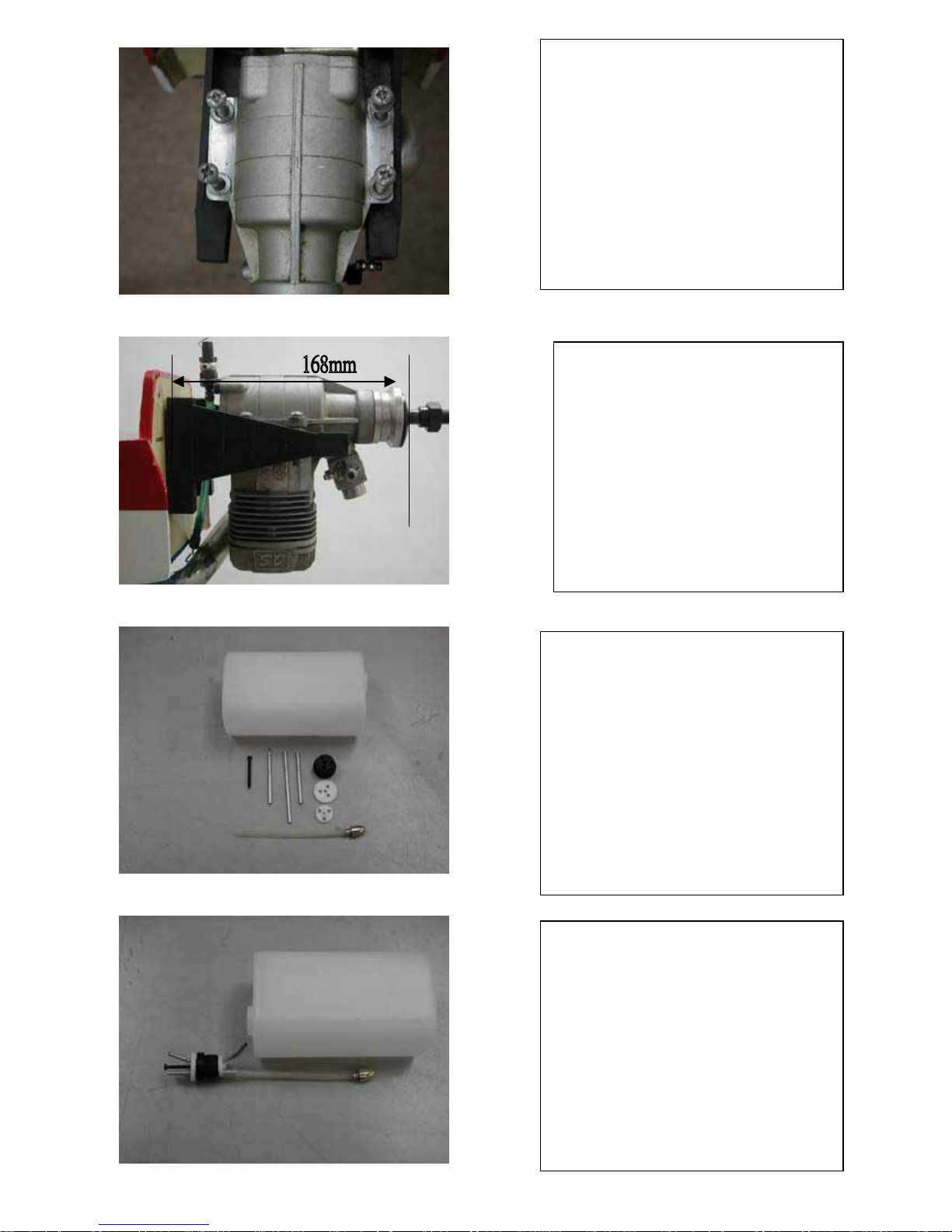

The motor drive hub distance from

fire wall 168 mm

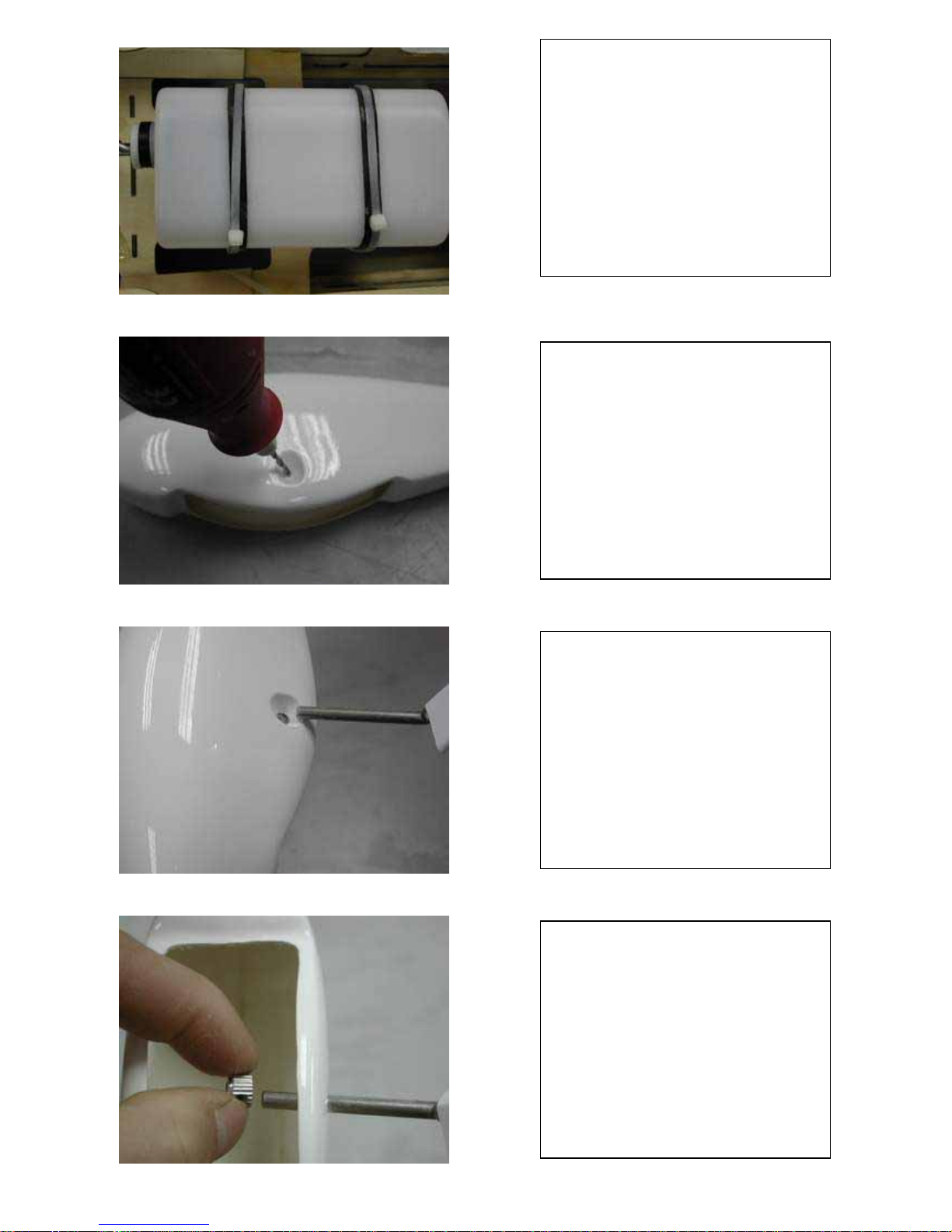

Find the fuel tank as show.

Assembling the Fuel line in fuel tank as

the show.

If use use glow engine with a pump

or Gas engine you can use the fuel

tank mount made fuel tank on CG.

Point. If your engine with no pump,

you must install engine near by

engine or add a fuel pump.

If you use E-power, you don’t need to

install this fuel tank mount at all.

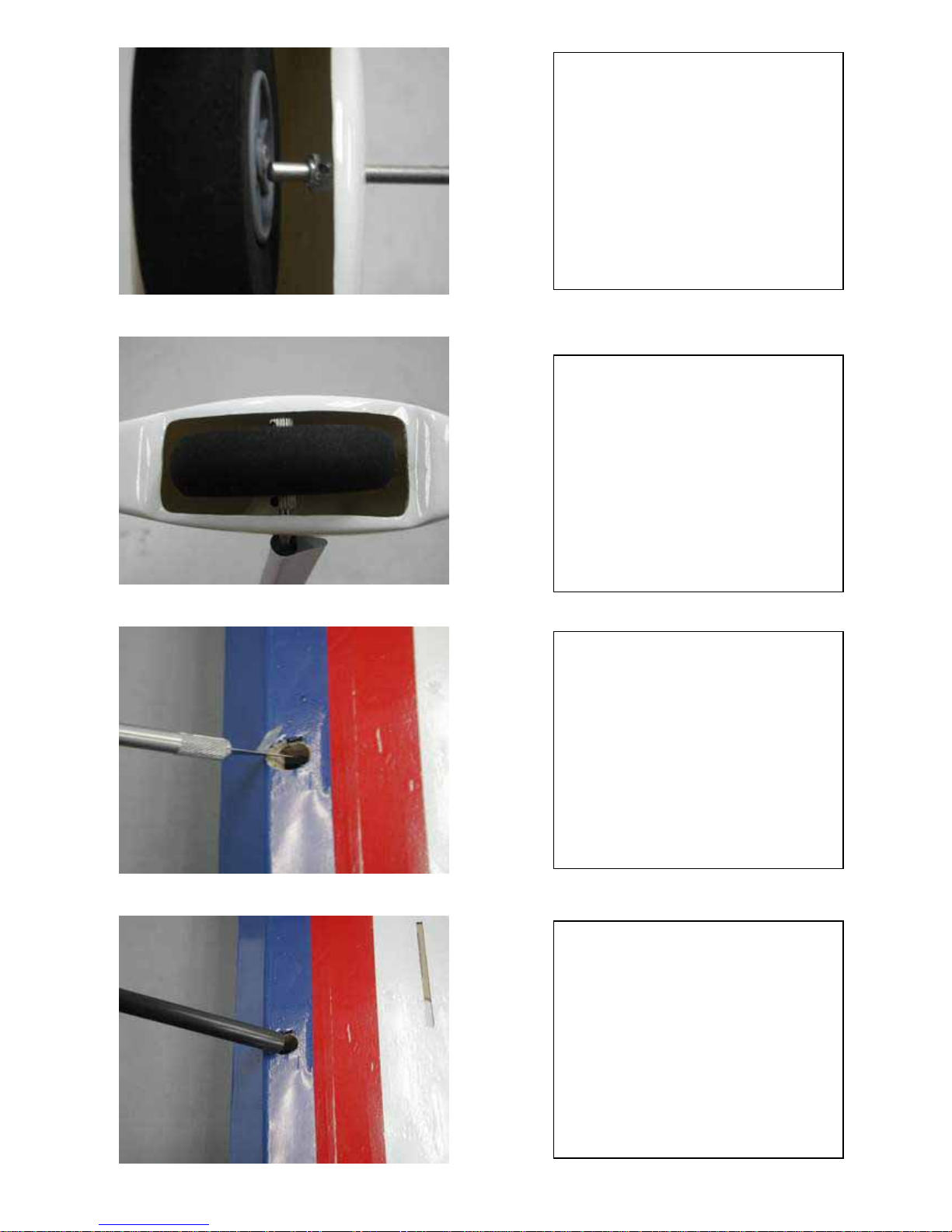

Drill a 40mm hole at each wheel

p

ants.

Inset the wheel Axle inside the wheel

p

ants.

Install the wheel shopper at wheel

axle.

Install the wheel shopper at wheel

axle between wheel and wheel pants.

Install the wheel second shopper at

wheel axle to hole wheel.

Then fix shopper with set screw.

Trim off the cover film as show.

Install the landing gear sleeve inside

fus. If there have some thing made

you can not inset the sleeve, please

use sanding paper or file made that

sleeve more easy to inset to Fus.

But don’t made it too loosing.

Inset landing inside the sleeve as

show.

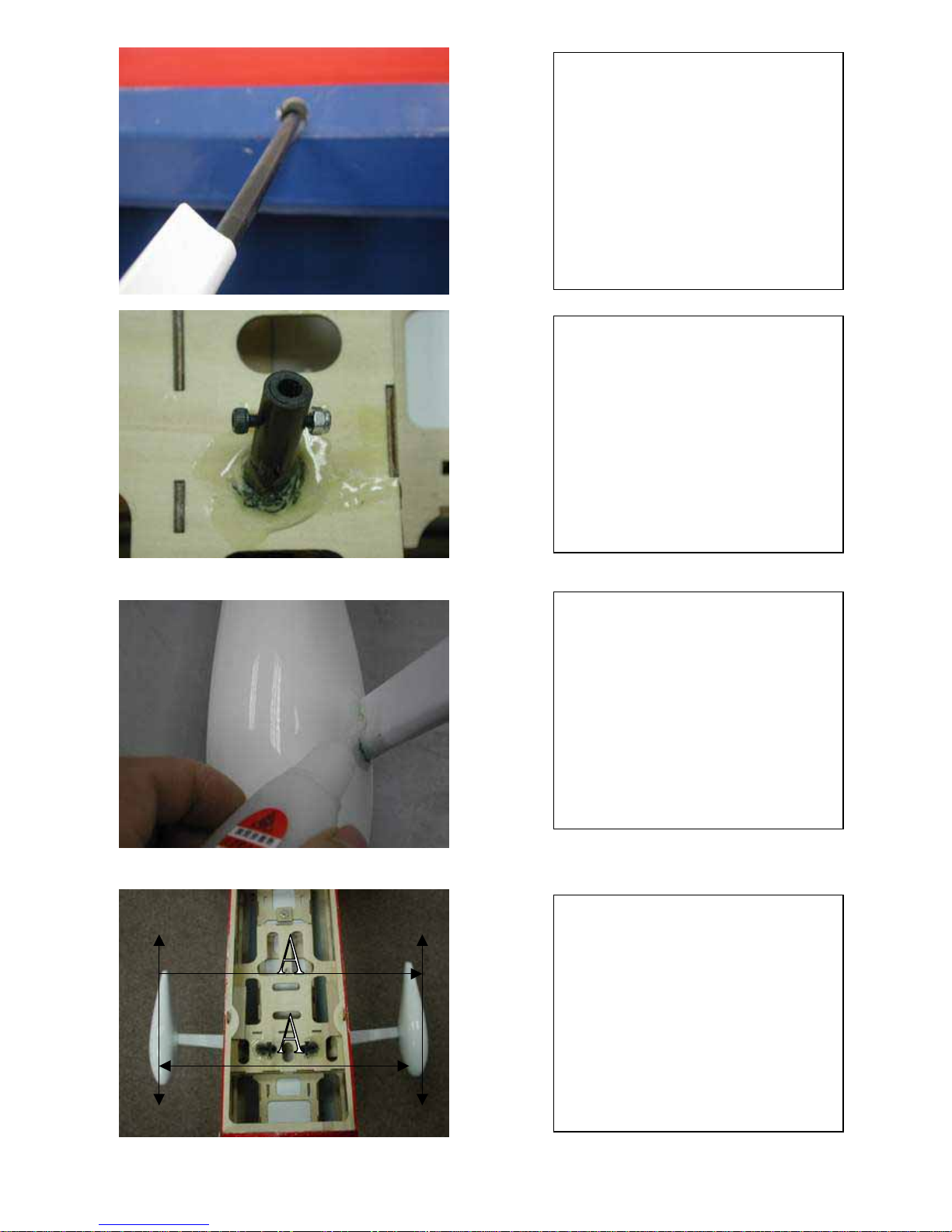

Install the landing gear in sleeve then

use a M3 screw and look nut fix it

together.

And use Epoxy to glue it with fus.

Together.

Important notice: before you glue

landing you must made sure a pair

wheel must straight with center of fus

Glue the wheel pants and landing

gear with Epoxy.

Before you glue the landing gear ,

p

lease check and made sure the main

wheel are straight with center line of

Fus.

If you choice a tuned pipe for your

Exhaust .

Please follow your tuned pipe.manual

to install the tuned or you can follow

here. Drill two 3mm hole at top of

p

ipe tunnel as show.

Then use two M3 screw to fix the

p

ipe as show.

The pipe after install as show.

***Check the all Alignment as the show before you install wing and tail plane.****

Cod

e

NO. Description DIM. QUT'Y

A ME030 TAIL LANDING GEAR Φ6X50 1PC

PI012

WH014 TAIL WHELL Φ25X 13 1pc

ME001 COLLAR M2 2pcs

ME029 SET SCREW Ø3x3 2pcs

WINCH KEY for SET SCREW Φ1.5X30 1PC

TP. SCREW Ø2X12 2pcs

TP. SCREW Ø2X12 2pcs

B PI003 PIN HINGES FOR RUDDER Ø2.5X48 4pcs

RO005 RUDDER CONTROL HORN 2.5X28.6 2pcs

HORN SCREW FOR RUDDER 3X30 2pcs

HORN NUTS FOR RUDDER M3 2pcs

LK03S

BALL LINK END 4set

ME015 BALL LINK CONNENTOR Ø2X20 4PCS

ME033 RUDDER CONTROL WIRE 0.6X1150 2PCS

SINK TUBE FOR CONTROL WIRE 3x30 4PCS

ME023 RUDDER CONTROL WIRE PIPE 1.8X10 4PCS

RO002 RUDDER SERVO EXTEND HORN 1PCS

RUDDER SERVO EXTEND HORN SC

R

Ø2X6 2PCS

SERVO EXTEND HORN NUTS M2 2pcs

C PI003 PIN HINGES FOR ELEVATOR Φ2.5X48 8PCS

RO006 ELEVATOR CONTROL HORN 20X28.5 2pcs

TP. SCREW ELE. CONTROL HORN Φ2X15 6PCS

LK03S

BALL LINK END 4SET

ME013 BALL LINK CONNENTOR Φ2X20 2PCS

ME031 WIRE PUSH ROD Φ2X280 2PCS

CARBON PIPE FOR STAB. Ø12.7X316 1PC

CARBON ANTI ROLL PIN OF STAB. Ø6X80 2PCS

STAB. FIX SCREW Φ3X15 4PCS

STAB. FIX SCREW WASHER Φ3X10 4PCS

RO001 ELEVATOR SERVO EXTEND HORN 2PCS

BALL LINK SCREW Φ2x13 4PCS

BALL LINK NUTS M2 4PCS

D1 PI003 PIN HINGES FOR AILERON Φ2.5X48 12PCS

RO006 AILERON CONTROL HORN 20X28.5 2PCS

AILERON CONTROL HORN SCREW Ø2X15 6PCS

LK03S

BALL LINK END 4SET

p.01

Parts list E-EVOLUTION

第 1 页

Cod

e

NO. Description DIM. QUT'Y

ME031 WIRE PUSH ROD Φ2X280 2PCS

ME013 BALL LINK CONNENTOR Φ2X20 2PCS

RO001 AILERON SERVO EXTEND HORN 2PCS

SCREW FOR SERVO EXTEND HOR

N

Ø2X6 4PCS

NUTS M2 4PCS

D2 CARBON WING JOIN Ø25.4X497 1PC

FRP. WING LOOK 4PCS

WOOD SUPPORT FOR WING LOOK 4PCS

WING BOLT Φ3X15 4PCS

WASHER FOR WING BOLT Φ3X8 4PCS

"O" RING FOR WING BOLT Φ3X6 4PCS

BLIND NUTS FOR WING BOLT M3 4PCS

PLY SUPPORT FOR WING TUBE 25.4X35 2PCS

FRP. WING TUBE SLEEVE 25.4x130 1PC

E CANOPY LOCK WIRE Ø1.8x155 1PC

CANOPY LOCK WIRE END COVER 2PCS

F HX.SCREW FOR COWL Ø3X10 4PCS

BLIND NUTS FOR COWL SCREW M3 4PCS

WASHER FOR SCREW FOR COWL Ø3X8 4PCS

"O" RING FOR COWL SCREW 4PCS

G GA005 FUEL TANK 448CC 1SET

FUEL TANK TIGHTED TAPE 5x350mm 3PCS

H BOLTS FOR LANDING GEA

R

Φ3x15 2PCS

LOCK NUT FOR LANDING GEA

R

M3 2PCS

A119-LG CARBON LANDING GEAR 1SET

ME006 WHEEL COLLAR M4 4PCS

ME029 SET SCREW WHEEL COLLAR Ø3x3 4PCS

WH001 MAIN WHEELS Φ4X75 2PCS

A119-WP

WHEEL PANTS 1PAIR

J1 KI001 ENGINE MOUNTS 68X105 1SET

BLIND NUTS FOR ENGINE MOU M4 4PCS

J2 A119-WS MOTOR MOUNT 1PC

MOTOR MOUNT TEMPLATE 1PC

HX.SCREW FOR MOTOR MOUNT M3X20 4PCS

WASHER MOTOR MOUNT BOTLS M3X8 4PCS

BATTERY TRAY LOCK THEETH 8PCS

A119-BS BATTERY TRAY 1 SET

SCREW FOR BATTERY TRAY M3X15 1PC

WASHER FOR BATTERY TRAY SCR

E

M3X8 1个

BLIND NUT FOR BATTERY TRAY 1个

PLY SUPPORT FOR BLIND NUT 18x25x3mm 1PC

p.02

Parts list E-EVOLUTION

第 2 页

SPECIFICATION

CODE A119 ITEM E-EVOLUTION

WING SPAN

WING AERA

TOTAL LENGTH

ROOT AIRFOIL

TIP AIRFOIL

1950.6mm

62.4dm

1980mm

11.80%

11.80%

2

MOTOR Haker C50 XLMotor

RTF. WEIGHT 4.3-5kg

Recommented Battery Lipo5000MA 10S 37V 1.3 KG

WING LOADING

CENTER OF GRAVITY 200mm from LE

WING INCIDENCE 0 °

WING DIHEDRAL

1°

STAB. INCIDENCE 0 °

RIGHT THRUST 2-3 °

DOWN THRUST 0 °

Loading...

Loading...