Page 1

Pit Volume Totalizer (PVT) User Guide

Canadian Version

Revised February 11, 2013

Revision 5 of DOCU006

Page 2

Revised February 11, 2013

Revision 5 of DOCU006, © Copyright

Page 2 of 28

This document contains proprietary information and is not intended for public distribution. Pason

Systems and all other trademarks and trade names used in this document, unless otherwise

specified, are the property of Pason Systems Corp.

No part of this document may be reproduced by any means, nor transmitted, nor translated, nor

translated into computer language, in whole or in part, without written permission from Pason

Systems Corp.

As updates and modifications occur, a new document will be made available as appropriate.

The revision date on the title page determines the most current version of the document.

Documents with the latest date replace any and all previous versions of the same document.

The most current is definitive in case of contradictions, errors, omissions, or misstatements.

While all reasonable care has been taken in the preparation of this document, no liability is

accepted by the author(s) for any errors, omissions or misstatements it may contain, or for any

loss or damage, howsoever occasioned, to any person relying on any statement or omission in

this document.

Copyright © 2013 Pason Systems Corp.

Any questions regarding this document or others should be forwarded to the following:

Pason Systems Corp.

6130 – 3rd Street S.E.

Calgary, Alberta T2H 1K4

Canada

Phone: 1-403-301-3400

Fax: 1-403-301-3499

Email: info@pason.com

Website: www.pason.com

For 24-hour support, phone Pason Technical Support toll free: 1-877-255-3158

Page 3

Revised February 11, 2013

Revision 5 of DOCU006, © Copyright

Page 3 of 28

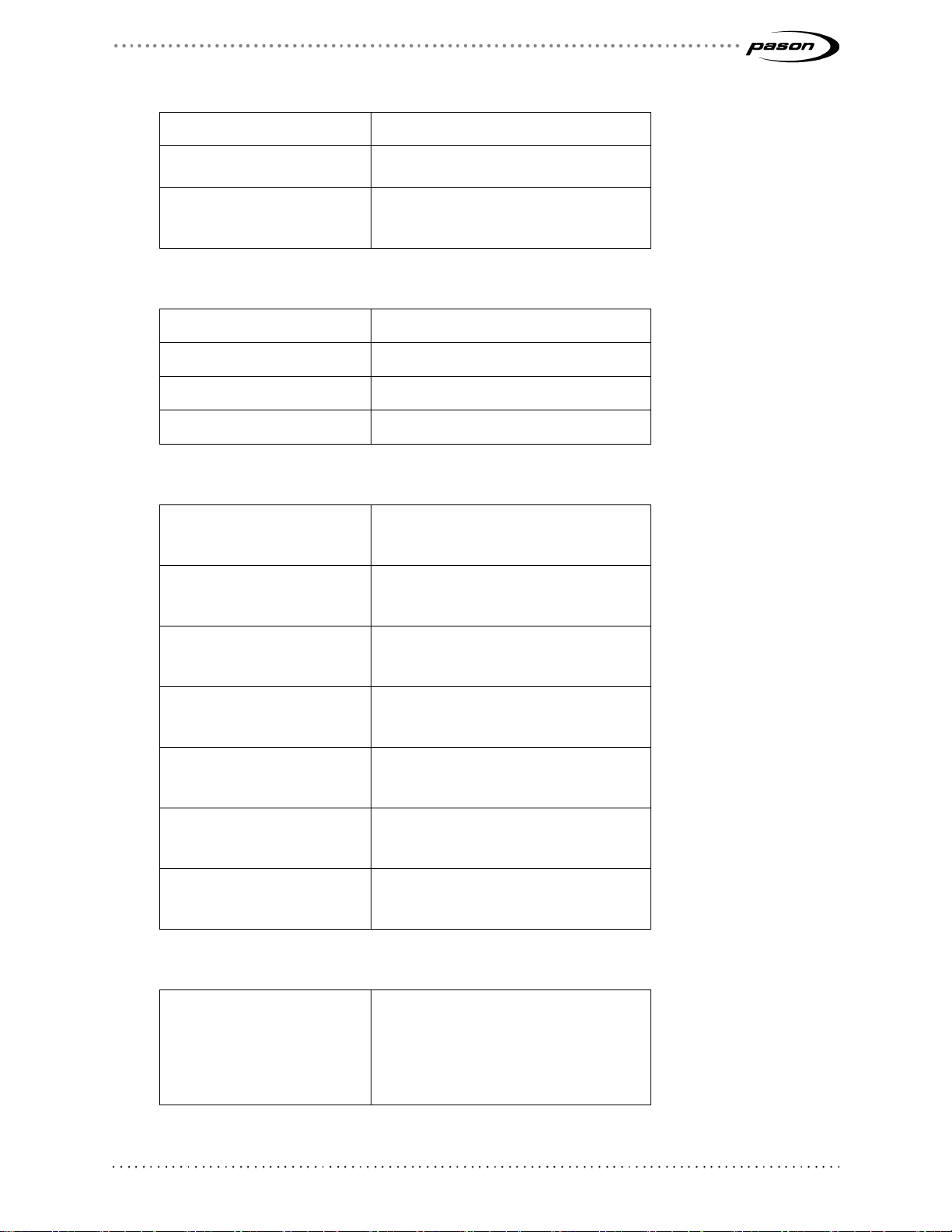

Table of Contents

1 Specifications .................................................................................... 7

1.1 Display Unit Specifications ............................................................................. 7

Input Power Requirements ...................................................................................... 7

Environmental Specifications ................................................................................... 7

Physical Specifications ............................................................................................ 7

Technical Specifications .......................................................................................... 7

Functional Specifications ......................................................................................... 8

1.2 J Box Specifications ....................................................................................... 8

Input Power Requirements ...................................................................................... 8

Environmental Specifications ................................................................................... 8

Physical Specifications ............................................................................................ 9

Technical Specifications .......................................................................................... 9

Functional Specifications ......................................................................................... 9

2 Installation ....................................................................................... 10

2.1 Installing in Hazardous (Class 1, Div. 2) Locations ...................................... 10

Non-Incendive Field Wiring for Class 1, Div. 2, Groups B, C, & D ...........................10

Equipment Suitable for use in Class 1, Div. 2, Groups B, C, & D ............................10

Suitability of Associated Equipment ........................................................................10

2.2 Mounting the Equipment .............................................................................. 10

Mounting the Display Unit .......................................................................................10

Mounting the J Box .................................................................................................11

Mounting the Tank Sensor ......................................................................................11

Mounting the Flow Paddle ......................................................................................11

Installing Wiring and Cabling ..................................................................................11

3 System Calibration .......................................................................... 13

3.1 Calibration Mode .......................................................................................... 13

3.2 Calibrating the Volume System .................................................................... 14

3.3 Calibrating the Flow System ........................................................................ 14

3.4 Calibrating the Tr ip S y s tem .......................................................................... 16

Calibration Channels ..............................................................................................17

Calibration Switches ...............................................................................................17

Page 4

Revised February 11, 2013

Revision 5 of DOCU006, © Copyright

Page 4 of 28

4 System Operation ............................................................................ 18

4.1 Operating the Volume Sy st em ..................................................................... 18

4.2 Operating the Flow System .......................................................................... 20

4.3 Operating the Trip Tank Sys tem .................................................................. 22

4.4 Operating the Mud Pump System ................................................................ 23

5 System Maintenance ....................................................................... 24

5.1 Maintenance Warnings ................................................................................ 24

5.2 Troubleshooting ........................................................................................... 24

Troubleshooting the Volume System ......................................................................24

Troubleshooting the Flow System ...........................................................................26

Troubleshooting the Mud Pumps System ...............................................................26

General Troubleshooting ........................................................................................26

Troubleshooting Summary ......................................................................................27

Page 5

Revised February 11, 2013

Revision 5 of DOCU006, © Copyright

Page 5 of 28

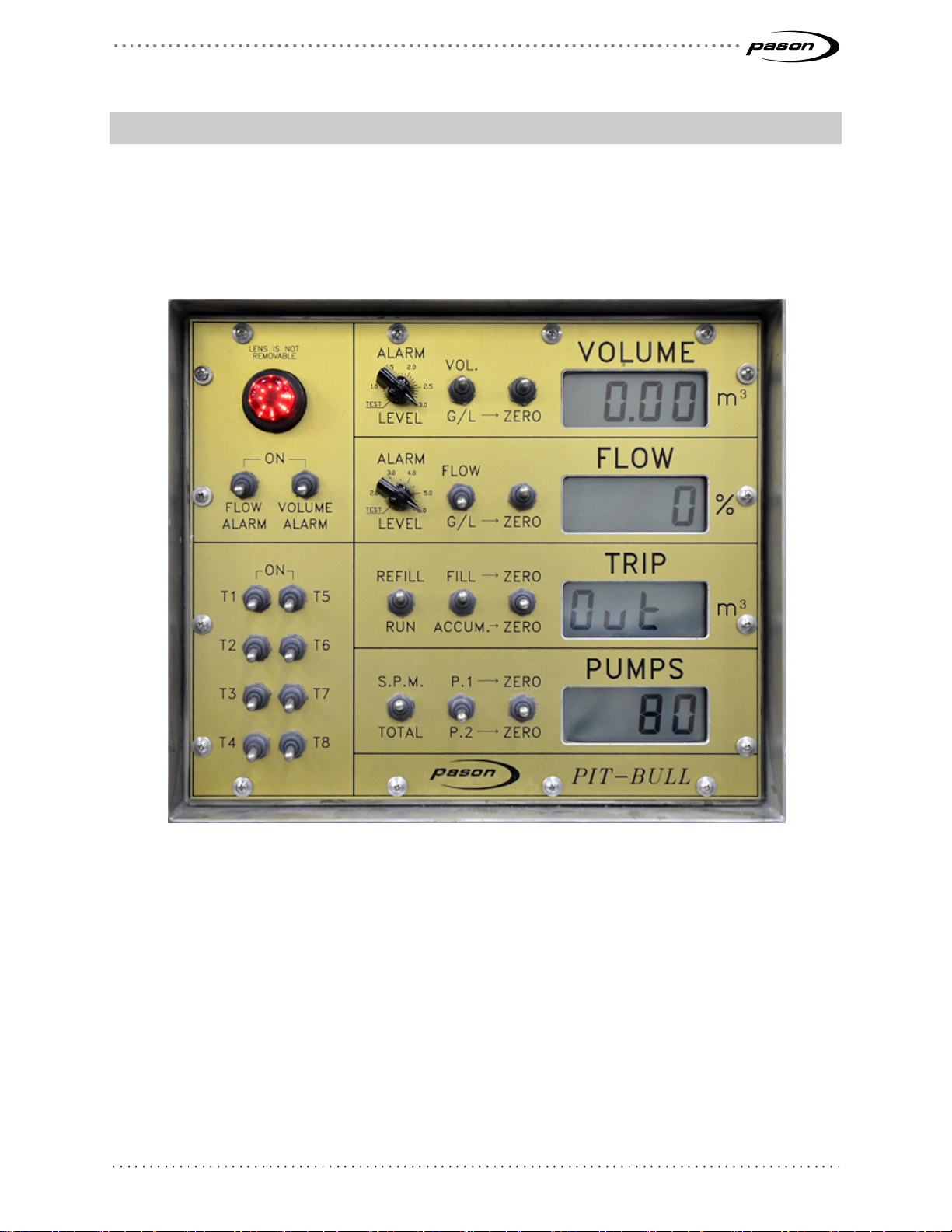

General Description

The Pason Pit Volume Totalizer (PVT) system is a high-quality microprocessor-based

instrumentation package, comprised of four main functions. The system measures,

calculates, and displays signals from the main mud system, the trip tank system, the

return flow system, and both main mud pumps.

Figure 1 PVT face plate

The Pason PVT system is specifically designed to withstand the harsh environmental

extremes encountered in the Canadian drilling industry. The main display unit is

equipped with a 100-watt thermostatically controlled heater. This allows for operation in

ambient temperatures down to -45°C without any degradation in performance.

The unit is water-resistant and is designed to operate reliably under the adverse

conditions found on drilling rigs. All panel switches are environmentally sealed and have

a water-tight panel seal installed to provide protection from the elements. The system is

fully protected from input noise and over-voltage.

Page 6

Revised February 11, 2013

Revision 5 of DOCU006, © Copyright

Page 6 of 28

The Pason PVT system consists of two main units: the display unit and the junction box

(J Box). The J Box is provided so that field wiring connections can be made in a safe,

convenient location. The J Box also provides an excellent location for field personnel to

troubleshoot the system.

The display unit is the heart of the system, containing all the controls, switches, and

alarms. A 1” backlit Liquid Cryst al Dis play (LCD) is provided for each main function

monitored. A variety of information can be displayed about each function by using the

panel switches on the unit. The volume and flow sections monitor either gain/loss

readings or absolute values. The pump section monitors either strokes per minute or

total strokes for both pumps. The trip tank section monitors trip tank volume, individual

fill volume, or total accumulated fill volume.

An alarm is provided for both volume and flow gain/loss deviations. The alarms are fully

independent of each other and are adjustable. If one or both of the alarms are disabled,

a red warning light (LED) will flash to remind the operator to turn the alarm back on as

soon as possible. In addition to the volume and flow alarms, the trip tank system is

provided with both a high and low alarm to assist the operator in filling or draining the trip

tank.

Page 7

Revised February 11, 2013

Revision 5 of DOCU006, © Copyright

Page 7 of 28

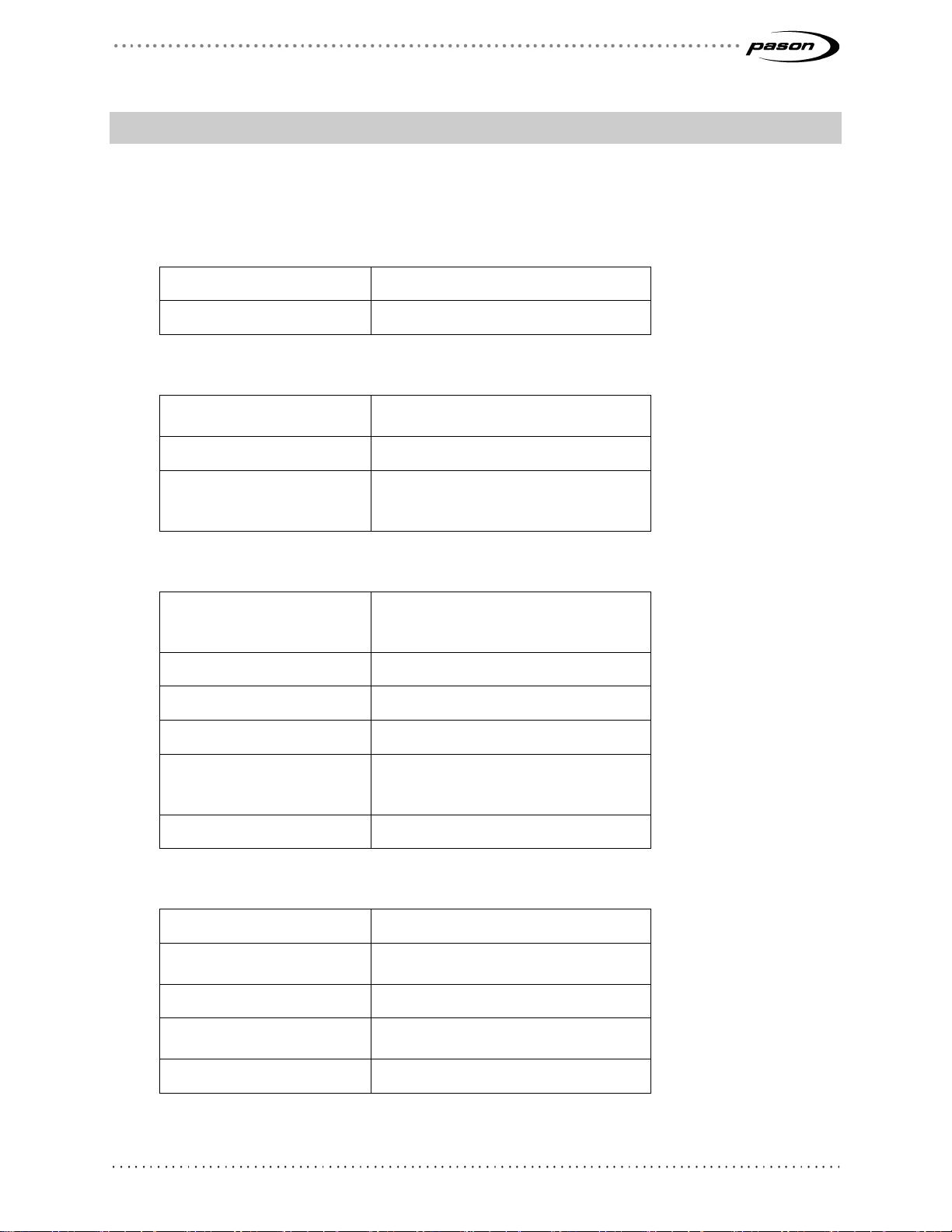

1 Specifications

1.1 Display Unit Specifications

Input Power Requirements

Voltage 110 VAC, 50/60 HZ

Current 1.5 Amps

Environmental Specifications

Ambient Temperature

Relative Humidity 100% (Outdoor Use)

Hazardous Area

Classification

Physical Specifications

Dimensions (W-H-D) 14¾” x 123/8” x 7¼”

Weight 35 lbs.

Mounting Pipe Bracket

Box Material 1/16” Stainless Steel

Face plate Material 1/8” Aluminum

Viewing Windows Material 5 mil Safety Glass

–40 to 45

Class 1, Div. 2 (CSA)

(Excluding Mounting Brack et)

(Reverse Silk-Screened)

°C

Technical Specifications

Displays 4 Digit, 1” LCD (Backlit)

Display Accuracy

Volume Resolution 0.1 m3

Pit Accuracy

Flow Resolution 1%

± ½” of Fluid Level

± ½” of Fluid Level

Page 8

Revised February 11, 2013

Revision 5 of DOCU006, © Copyright

Page 8 of 28

Trip Resolution 0.01 m3

Pumps Resolution 1 Stroke/Minute

Chart Output

Chart Output Resolution 8 Bit (0.4%)

Functional Specifications

Displayed Functions Total Pit Volume

Main Pits Monitored Up To 8 Pits Plus Trip Tank

Volume Alarm Range 0.5 to 2.75 m3

0 to

± 20 mA (Programmable)

Volume Per Tank

Volume Gain/Loss

Return Flow Percent

Return Flow Gain/Loss

Trip Tank Volume

Individual Fill (Trip)

Accumulated Fill (Trip)

Strokes/Min. (Pump 1 & 2)

Total Strokes (Pump 1 & 2)

Flow Alarm Range 2.0 to 5.5%

Chart Recorder Output Volume, Flow and Trip (20 mA)

Alarm Horn 120 VAC Klaxon Type

1.2 J Box Specifications

Input Power Requirements

Input Voltage 14 VDC

Input Current 70 mA Typical

Environmental Specifications

Ambient Temperature

(Supplied Via Signal Cable)

(Limited to 100 mA)

–40 to 45

°C

Page 9

Revised February 11, 2013

Revision 5 of DOCU006, © Copyright

Page 9 of 28

Relative Humidity 100% (Outdoor Use)

Max. Internal Temperature

Hazardous Area

Classification

Physical Specifications

Dimensions (W-H-D) 155/8” x 12¾” x 8”

Weight 13 lbs.

Mounting Lugs (2)

Box Material PolyGlass

Technical Specifications

Reference Voltage

(Red to Black)

Short Circuit Current

(Red to Black)

Ambient + 2

°C

Class 1, Div. 2 (CSA)

6.2 VDC

(All Tanks–Open or Closed Circuit)

12 mA (All Tanks)

Signal Input Impedance

(White)

Open Circuit Voltage

(Red To Black)

Short Circuit Current

(Red to Black)

Open Circuit Voltage

(Red To Black)

Short Circuit Current

(Red To Black)

Functional Specifications

Field Inputs Main Pits (8)

100k ohm (All Tanks)

12 volts (Flow)

50 mA (Flow)

8.2 VDC (Pumps 1 & 2)

8.2 mA (Pumps 1 & 2)

Trip Tank

Flow

Pumps (2)

Page 10

Revised February 11, 2013

Revision 5 of DOCU006, © Copyright

Page 10 of 28

2 Installation

2.1 Installing in Hazardous (Class 1, Div. 2) Locations

Non-Incendive Field Wiring for Class 1, Div. 2, Groups B, C, & D

All field wiring connections provided in the Pason PVT system J Box are classified as

non-incendive and can be installed while the system is powered up or in the presence of

hazardous gases, providing that the field sensors/wiring are approved for that purpose.

Equipment Suitable for use in Class 1, Div. 2, Groups B, C, & D

All equipment provided with the Pason PVT system is suitable for use in Class 1, Div. 2,

Groups B, C, & D locations with the exception of the main power connector, which must

be installed in a safe (non-hazardous) area (e.g., the doghouse).

Suitability of Associated Equipment

The following associated equipment may be connected to the non-incendive field wiring

terminals without any further approval.

1. GEMS level switch or STI RPM series

(for Main Tanks (8) and Trip Tank Sensors).

2. Micro-Switch LSX Type Enclosed Waterproof Limit Switches or Equivalent

(Any Device With Only Switch Contacts For Pump 1 and 2 Sensors).

3. A 1 to 2k ohm Non-Inductive Type Potentiometer Suitably Housed

(for Return Flow Sensor).

2.2 Mounting the Equipment

Mounting the Display Unit

The display unit is equipped with a bracket for mounting on a 2” pipe. The unit should be

mounted somewhere near the driller’s console, slightly above eye level. Select a location

that provides maximum protection from any physical damage due to drilling activities.

Also, there must be a suitable route for the system cables to feed through the driller’s

console wireway. For maximum safety and reliability, run the cables in a manner that

prevents damage during normal rig operation or rig moves.

Page 11

Revised February 11, 2013

Revision 5 of DOCU006, © Copyright

Page 11 of 28

Mounting the J Box

The preferred location for the J Box is in the pump house. However it can also be

mounted under the sub-structure or on the tanks, if necessary. The location should also

be selected so that there is access to wireways.

Mounting the Tank Sensor

Tank sensors should be mounted in mud tanks as far away from any agitator blades as

possible. Short pieces of pipe may be welded to the bottoms of the tanks to prevent the

bottom of the probe from moving around. Regardless, install suitable brackets at the top

of the probe, so any lateral motion of the probe is prevented. Place probes clear of

skimmers, tank walls, and fill p ip es .

Mounting the Flow Paddle

The flow paddle is mounted to a saddle that is welded to the flow line during rig setup.

Note:

Proper flow paddle operation requires that the flow paddle be mounted above the level of the mud

in the shaker tank. If this is not done, reliable readings are virtually impossible. Generally, the

further up the pipe the flow paddle is mounted, the better it operates. On smaller rigs, it may not

be necessary to install the flow paddle at all due to insufficient fill.

Installing Wiring and Cabling

Instructions for installing sensor wiring and interconnecting cables are given below.

Sensor Wiring

Sensors should be wired using a 3-conductor, 20 AWG, overall foil-shielded (with shield

drain wire) type cable. The color combination of the cable is red, white, and black

(CBL038). This color-coding should match the labeling in the J Box, as well as the colorcoding used in the tank probes. The pump strokes, probes, and return flow sensor

should have lead wires installed that correspond to this color code, thereby simplifying

field installation. Lead wires inside the sensor housings can be connected using junction

blocks.

Important:

When wiring the sensors ensure that the shield does not touch the housing of the sensor, as this

will result in a ground loop and may cause noise problems in the system. Also, run tank wiring

underneath tank gratings and neatly tie the wiring to the bottom railings around the tanks. Sensor

wires must not be run in the same cable trays used for high voltage because this can lead to

abnormal voltages being induced into the signal cables (due to magnetic coupling), and a

reduced level of safety for rig personnel.

Page 12

Revised February 11, 2013

Revision 5 of DOCU006, © Copyright

Page 12 of 28

Note:

Connect the wiring according to the color and sensor definitions as outlined on the J Box circuit

board.

Once all connections have been made, any strain relief must be tightened so that a firm

tug on the wire does not cause it to slip through the strain relief.

At this point, the J Box lid may be secured, as no further

installation is required.

Unused tanks must be shorted out ("jumpered") with a small wire

between the white (W) and black (B) connections on the terminal

J Box. If a flow sensor is not being used, the "flow" channel in the

PVT J Box should also be "jumpered". A red PVT J Box plug (part

#CON237) should be used for each unused tank and the flow, to preserve the integrity of

the J Box seal.

Cable Installation

Interconnecting cables provided with the system are equipped with high-quality, militarystyle connectors. These connectors can provide many years of trouble-free

performance, if properly installed and cared for. When running cables between system

components, it is important that the free end of the cable be protected from mechanical

abuse that can occur from being dropped, etc. It is also critical to protect the connector

from water, dirt, oil, etc., so use cap protectors. It should reach its destination in a clean,

dry, and undamaged state.

Note:

When running the system cables, do not use excessive force to pull the cables through openings

in the rig: this can destroy the outer jacket of the cable.

Cables should be run in dry, out-of-the way locations. The cables are high-quality

products with good resistance to oil, chemicals, sunlight, water, and temperature

extremes; however, it is recommended that the cables be thoroughly cleaned between

jobs to extend their lifespan. If connector ends get dirty during installation, wash them

with an electrical cleaner before they are assembled. The cleaner is available in aerosol

cans (with a nozzle) and should be included as part of the field service equipment. Use

an electrical contact cleaner that is safe for plastics.

Note:

Prior to assembling the connector, apply a small amount of dielectric grease to one half of the

connector. This will help seal the connector and prevent the pins from corroding.

Page 13

Revised February 11, 2013

Revision 5 of DOCU006, © Copyright

Page 13 of 28

3 System Calibrati on

The Pason PVT is designed so that calibration is straightforward. No tools or meters are

required. All span and zero adjustments are made at the display unit, using panel

switches. Calibration factors are stored in non-volatile memory within the system, so if

the unit is powered down, you do not have to recalibrate.

3.1 Calibration Mode

Note:

Calibration should only be perf orm ed by a Pason field tec hnic ian.

To calibrate the Pason PVT, install the dummy 4-pin military connector into the terminal

marked Calibrate System on the underside of the PVT monitor.

Note:

The dummy connector can be thought of as a key, as it prevents unauthorized access to the

system calibration routines.

If the dummy connector is lost, take a short piece of wire with the ends bared to the

conductor and bend it into a “U”. Insert the ends into the two pins on the right-side of the

calibration connector’s plug, achieving a calibration mode signal of 8888.

Once in calibration mode, the panel switches and displays tak e on different functions.

The PUMPS display indicates the channel being calibrated. To change the channel, use

the PUMPS

ZERO switch to increase or decrease the channel shown on the PUMPS

display.

Once you select the proper channel, use the TRIP

ZERO switch to increase or decrease

the reading for that particular channel. The speed at which the reading changes can be

controlled by the FILL/ACCUM switch (this can be thought of as a fast or slow control).

When this switch is in the FILL position, the display changes quite quickly; while in the

ACCUM position, the display slows down considerably, thereby allowing the reading to

be stopped at the exact desired location.

To further simplify calibration, the system is programmed so that the channel being

calibrated shows up on the display that corresponds to that channel, while non-related

displays are blank. The channel number that corresponds to the trip tank span is shown

on the PUMPS display. In addition to the switches described above the flow, the ZERO

switch is used to set the flow zero point.

Page 14

Revised February 11, 2013

Revision 5 of DOCU006, © Copyright

Page 14 of 28

3.2 Calibrating the Volume System

Calibration of the volume system is done on a tank-by-tank basis. The basic procedure

is as follows:

1. Multiply the length, width, and height of the tank together to arrive at the tank

volume.

2. Pull the probe float all the way to the top of the tank and secure it.

3. Set the corresponding reading on the PVT monitor to match the calculated

tank volume.

Note:

The height measurement is obtained by measuring the distance from the bottom of

the tank to the center of the float; therefore, if the tank grating has been used as the

“top” of the tank, it is necessary to subtract half the thickness of the float from this

measurement to arrive at the true tank height. It is not necessary to compensate for

the probe zero offset error when calculating tank volumes, because the Pason PVT

software automatically adds the correct amount to the tank volume to compensate

for this.

3.3 Calibrating the Flow S ystem

To calibrate the flow system follow this procedure:

1. Set the system to calibrate mode (see Calibration Mode on page 13).

2. Use the PUMP ZERO switch to select channel 10 (Flow).

3. Place the flow paddle arm in the bottom position.

Figure 2: Flow paddle arm in the bottom position (zero flow)

4. Press down the FLOW G/L ZERO switch. The flow zero point has now been

established.

Page 15

Revised February 11, 2013

Revision 5 of DOCU006, © Copyright

Page 15 of 28

5. Set the flow span by holding the flow paddle arm in the top position

(maximum flow).

Figure 3: Flow paddle arm in the top position (maximum flow)

6. Use the FILL/ACCUM. ZERO switch to set the span to the desired value. The

flow span is usually set to read from 0 to 100, however, this may vary

depending on the application.

Note:

The flow zero point must be set before the flow span is set.

Page 16

Revised February 11, 2013

Revision 5 of DOCU006, © Copyright

Page 16 of 28

3.4 Calibrating the Trip System

Calibrating the trip tank is identical to calibrating the main mud tanks.

1. Select channel 9 on the PUMPS display.

2. Pull the probe float up to the top of the tank and secure it in this position.

3. Measure from the bottom of the tank to the middle of the float to find the tank

height.

4. Calculate the tank volume (L*W*H).

5. Use the FILL/ACCUM. ZERO switch to set the trip tank reading to the

calculated volume.

Note:

It is not necessary to compensate for the probe zero offset error (0.17 m) when

calculating trip tank volume. The system automatically calculates and compensates

for this.

At this point, set the trip high alarm level.

1. Use the PUMP ZERO switch to select channel 11.

2. Use the FILL/ACCUM. ZERO switch to adjust the setting until it reads about

0.5 m3 less than the trip tank volume (full). This will allow the operator a few

seconds to reach the fill pump switch.

3. Remove the dummy connector from the Calibrate System terminal, thus

returning the system to Run mode. This completes the calibration process.

Note:

You may have to reset the string weight in the Weight on Bit Trace on the DHC.

Page 17

Revised February 11, 2013

Revision 5 of DOCU006, © Copyright

Page 17 of 28

Calibration Channels

Switch

Setting Channel on PVT 1.03 and

lower

Channel on PVT 2.0 and

higher

Tanks 1-8 Span Setting 1-8 1-8

Trip Tank Span Setting 9 9

Flow Zero and Span Setting

10 10

(see note below)

Trip Tank High Alarm

11 13

Setting

Decimal Places (CDN) 12 14

Horn Sleep Feature (On,

11

Off)

Horn Sleep Delay 12

Table 1 Calibration Channels

Note:

Set the Flow Zero before Flow Span; Use the FLOW G/L ZERO switch to set the flow zero point.

Calibration Switches

P1/P2 - Zero Switch

Fill / Accum. Zero Switch

Flow G/L Zero Switch

Fill / Accum. Switch

Table 2 Calibration Switches

Note:

The selected channel is displayed on the PUMPS display.

Function in calibration mode

Select the channel to be calibrated

Increase/decrease settings

Set the Flow Zero Point (Channel 10)

Adjust the rate of change (fast/slow)

Page 18

Revised February 11, 2013

Revision 5 of DOCU006, © Copyright

Page 18 of 28

4 System Operation

4.1 Operating the Volume System

The volume system consists of:

• Eight tank switches

• A volume alarm switch (to enable/disable the alarm)

• An alarm level setting control

• A volume/gain-loss switch (to select which function to display)

• A gain-loss zeroing switch

• A warning light to indicate that the alarm is disabled

• A flow and volume alarm “snooze” feature (PVT versions 2.0 and higher)

The eight tank switches are used to sum up the active tanks in th e system. They are

also used to isolate individual tanks or to remove a tank from the active system, if

required.

The volume alarm is set to indicate gain/loss readings that exceed the limit. The alarm

level setting should reflect the maximum allowable gain. Fluid gains are usually

exponential in nature (as a result of gas rising in the wellbore), while fluid losses are

generally linear in nature and therefore not nearly as critical. For example, on a 4,000 m.

hole, if 1 m

3

of gas is forced into the wellbore (at the bottom), an alarm setting of 2 m3 will

detect a problem when the gas bubble reaches about 2,000 m. However, if the alarm is

set at 4 m

3

, the gas bubble will rise to a depth of 1,000 m. before an alarm is triggered.

This represents a 50% difference in warning time and clearly demonstrates how critical

the gain setting can be.

Analysis of fluid losses shows that alarm settings are far less critical. For example, if a

rig’s mud system contains a total of 100 m

3

of mud, an alarm setting of 0.5 m3 triggers

the alarm to go off when 0.5% of the total fluid has been lost. And an alarm setting of

3

1 m

triggers an alarm when 1% of the total fluid has been lost. Clearly, the difference

between these two figures is not very significant.

The VOLUME/GAIN-LOSS switch is provided to allow the operator to display either total

mud volume or volume gain-loss. The volume alarm is active regardless of which

position this switch is in. During normal operation, this switch should be in the gain-loss

position, as this provides the most critical information.

Page 19

Revised February 11, 2013

Revision 5 of DOCU006, © Copyright

Page 19 of 28

The GAIN-LOSS ZERO switches are used to periodically zero the gain-loss reading.

This is necessary if mud is added to the system, or if the reading has drifted down to the

alarm level due to normal drilling operation.

Note:

The GAIN-LOSS ZERO switches only operate when the switch is set to the GAIN-LOSS position.

This allows you to observe the gain-loss reading before zeroing it out.

The volume alarm switch on the left side of the panel allows the alarm to be disabled

when the mud volume is not stable enough for proper operation. When the volume (or

flow) alarm is disabled, the panel warning light blinks to remind you to turn the alarm

back on as soon as possible.

The volume/gain-loss readings are displayed on a 1”, 4-digit LCD (Liquid Crystal

Display). The maximum volume that can be

displayed is 800 m

loss that can be displayed is

3

, while the maximum gain-

±99.9 m

3

.

If an alarm condition is present (volume), the horn sounds to indicate an alarm has

occurred (volume or flow).

Note:

The red LED blinks when one or both alarms are set to OFF (VOLUME or FLOW).

The volume alarm “snooze” feature is available for RigComm compatible PVTs running

firmware version 2.0 and higher. This feature allows you to temporarily mute the volume

alarm. The PVT can be set to snooze the alarm for between 1 and 10 minutes. When the

alarm is snoozed, “SLEEP” is displayed on the VOLUME LCD. For more information on

the snooze feature, see DOCU196 PVT Alarm Snooze Quick Tips at help.pason.com.

Note:

The channel configuration was changed for PVT firmware versions 2.0 and higher. See Table 1

Calibration Channels on page 17.

Page 20

Revised February 11, 2013

Revision 5 of DOCU006, © Copyright

Page 20 of 28

4.2 Operating the Flow System

The flow system operates in a manner very similar to the volume system. Flow is

displayed as a percentage of full rather than as a volume.

Proper operation of the flow system requires some knowledge of the flow sensor

(paddle) as well as some of the conditions encountered in the return flow system. The

flow paddle consists of a paddle that rides on the surface of the mud and is attached to a

shaft, which rotates a potentiometetop r, thereby producing a signal corresponding to

shaft position. The purpose of the flow paddle is to produce a signal that is related to the

amount of mud flowing in the return line. For example, if the pump rate is doubled, the

reading on the monitor roughly doubles. The flow system doesn’t give an exact value for

the return flow system (affected by slope, temperature, viscosity, obstructions, etc.), but

it establishes a relative number (benchmark) for normal flow conditions. This number

may increase or decrease depending on variables such as viscosity or temperature, but

if you are aware of these factors, you gradually get used to interpreting the data supplied

by the flow system.

Table 3: Pason flow paddle

The flow paddle is calibrated so that the output varies from 0 to 100% as the flow paddle

moves from its bottom position through to its top position. The alarm level setting is a

percentage of the full flow line as opposed to a

percentage of the actual flow reading. For

example, if a flow line is calibrated to read from 0

Page 21

Revised February 11, 2013

Revision 5 of DOCU006, © Copyright

Page 21 of 28

to 100% and the normal reading is 20%, then an alarm level of 5% will cause an alarm to

occur at 15% or 25%, depending on whether an increase or decrease has occurred.

Setting the alarm level varies from rig to rig, as some rigs have very smooth flow lines,

while others are quite turbulent. The alarm level should be set as low as possible without

causing alarms due to normal turbulence. The flow alarm can be disabled so that

operations such as tripping or adding pipe can be performed without causing the alarm

to go off. When the flow alarm is disabled, the panel warning light blinks to remind the

operator to turn it back on as soon as possible.

Note:

On some rigs with very flat flow lines or obstructions that cause “shaling”, it may not be possible

to achieve a reliable flow reading. In cases like this, it may be better not to install the flow paddle

at all.

The flow alarm “snooze” feature is available for RigComm compatible PVTs running

firmware version 2.0 and higher. This feature allows you to temporarily mute the volume

alarm. The PVT can be set to snooze the alarm for between 1 and 10 minutes. When the

alarm is snoozed, “SLEEP” is displayed on the VOLUME LCD. For more information on

the snooze feature, see DOCU196 PVT Alarm Snooze Quick Tips at help.pason.com.

Note:

The channel configuration was changed for PVT firmware versions 2.0 and higher. See Table 1

Calibration Channels on page 17.

Page 22

Revised February 11, 2013

Revision 5 of DOCU006, © Copyright

Page 22 of 28

4.3 Operating the Tr i p Tank System

The Pason PVT trip tank instrumentation allows you to monitor three separate aspects of

the trip operation: the trip tank volume, individual fills volume, and the total accumulated

fill volume. First fill the trip tank to the specified level. Then you can monitor the actual

trip tank volume by placing the REFILL/RUN switch in the REFILL position.

Once the trip tank has been filled, initialize the trip monitor. Assuming that this tank is the

first tank of the trip operation, the initialization procedure is outlined in the following

steps:

1. Place the REFILL/RUN switch in the RUN pos ition.

2. Place the FILL/ACCUM. switch in the ACCUM. position.

3. Use the ACCUM. ZERO switch to initialize (zero) the ACCUM. reading.

4. Place the FILL/ACCUM. switch in the FILL position.

5. Use the FILL ZERO switch to initialize (zero) the FILL reading.

When the stands have been removed from the hole and a hole fill is required, the trip

display shows the amount of mud being pumped into the hole. When the display shows

that the required amount of mud has been

pumped into the hole, the pump is shut off

and the FILL ZERO switch is used to zero the

FILL reading again. The quantity of mud that was pumped into the hole is retained by the

system for addition to subsequent fill operations. The FILL/ACCUM switch can be

switched over to ACCUM. at any time to see the total amount of mud that has been

pumped down the hole.

If you wish to see the actual volume of the trip tank, you may place the REFILL/RUN

switch in the REFILL position. However, don’t do this while mud is being pumped down

the hole. When the REFILL/ RUN switch is in the REFILL position, any change in the trip

tank volume is not reflected in the total accumulated reading. This allows you to refill the

trip tank during multiple tank trips.

Important:

During multiple tank trips it is important that the REFILL/RUN switch be placed in the REFILL

position when refilling the tank. If this is not done, the amount of mud pumped from the main

system into the trip tank will be subtracted from the total accumulated reading.

Forgetting to switch from RUN to REFILL during multiple tank trips should not be a

problem because the only way to see the actual trip tank volume (when filling the tank) is

Page 23

Revised February 11, 2013

Revision 5 of DOCU006, © Copyright

Page 23 of 28

to place the switch in the REFILL position. Conversely, forgetting to switch back to RUN

when the tank has been refilled should not be a problem, as the only way to get a zero

reading on the fill display is to have the switch in the RUN position.

In addition to the above features, the trip tank system is also equipped with high and low

alarms. The low alarm is used to warn you that the trip tank level has decreased to

approximately 0.44 m in height (not adjustable). If the alarm is triggered during a fill

operation, this allows the fill to be safely completed without running the tank dry. The

high alarm is used to warn the operator to shut the fill pump off to prevent overflowing

the trip tank. The high alarm is based on volume and should be set during system setup

by a Pason field technician. The high alarm is normally set to go off at about 0.5 m

before the tank is full, to allow the operator a few seconds to disable the fill pump.

4.4 Operating the Mud Pump System

3

Select the function to be monitored by using the SPM/TOTAL switch to select either

strokes per minute or total strokes. Next, select the pump to be observed by using the

P.1/P.2 switch.

The system monitors and keeps track of total strokes for both pumps, even when both

pumps are running simultaneously. If it is necessary to zero a total stroke reading, select

the total stroke function, and then select the desired pump. Use the corresponding

ZERO switches to clear the reading.

The number of strokes per minute is continuously monitored for both pumps, and

therefore no waiting period is necessary when

switching from one pump to the other. The

number of strokes per minute is calculated on

a on a stroke-by-stroke basis. This means that the update time for strokes per minute

(spm) is tied directly to pump speed. For example, a pump running at 30 spm will be

updated every 2 seconds.

Page 24

Revised February 11, 2013

Revision 5 of DOCU006, © Copyright

Page 24 of 28

5 System Maintenance

5.1 Maintenance Warnings

This equipment has been approved for use Class 1, Division 2 areas.

Important:

Substituting components may impair suitability for Class 1, Division 2, thereby resulting in an

explosion hazard. If you are not absolutely certain about the suitability of replacement parts,

contact the manufacturer before proceeding.

Caution:

If the main display unit has to be opened for service, first disconnect the power and ensure the

area is known to be non-hazardous. Failure to observe this precaution can result in an explosion

hazard.

The main display unit of the system operates at line voltage (120 VAC), which constitutes a shock

hazard. If it is necessary to troubleshoot the system with the power on, use extreme caution.

Once the problem has been identified, remove the power. Do not attempt to replace or disconnect

any parts while the power is on.

5.2 Troubleshooting

The majority of problems encountered in the field are related to damaged field sensor

wiring or improperly installed/maintained cables and connectors. Sensors can also

become faulty due to their placement and environment.

Troubleshooting the Volume System

If the volume reading on the display unit is erratic or reading too high/low and the rest of

the system appears to be functioning properly, the problem is likely a broken or shorted

sensor wire. Use the traces on the DHC to determine where any historical spikes

occurred.

Important:

Always check the data cable connection from the PVT to the J Box first. You should only see 3-4

threads.

Note:

The VOL/G/L switch should be set to the VOL function. If the display reads zero, start turning the

tank switches on one at a time, and check to see if the readings are abnormal. This quick check

often isolates the faulty tank circuit, thereby eliminating the need to check all the tank sensors

and wiring. If one tank circuit gives abnormal readings, you can determine if the problem is in the

sensor wiring, the probe, or is an internal system problem.

Page 25

Revised February 11, 2013

Revision 5 of DOCU006, © Copyright

Page 25 of 28

A quick way to determine if the problem is internal is to disconnect the faulty circuit

(inside the J Box) and replace it with a known good circuit. For instance, if Tank #5 is

giving problems, disconnect the wiring to Tank #5 and replace it with the sensor wiring

from a tank that is working properly. Then return to the PVT monitor and see if the

problem still exists. If this fixed the problem, check the wiring, sensor, and J Box.

If the problem still exists, check the sensor wiring. Following the wire from the probe to

the J Box usually uncovers a damaged area on the wire. If no problem is apparent, try

replacing the wire, since it may be faulty inside. If this procedure indicates an internal

system problem, check the main signal cable and its connectors. If the connectors

appear to be installed correctly (not loose), remove them, and check for any sign of

moisture, corrosion, dirt, etc. If evidence of contamination is found, clean and lubricate

the connectors. Replace the connectors and try the system again. If the problem

persists, follow the cable from the PVT monitor to the J Box while looking for any signs

of damage.

If only one tank circuit is acting up, the problem is probably due to probe/wiring troubles.

If more than one tank circuit is acting up, the problem is probably the module, data

cable, or PCB board. If readings differ between the DHC and the PVT, the problem is

probably a faulty cable or module.

To replace the electronics module:

1. Disconnect the power.

2. Remove the 16 face plate screws.

3. Remove the face place using Tool 132 (PVT Face plate pry bar).

4. Locate the module in the upper left corner of the box, and then remove it by

disconnecting the three d-sub connectors using a small screwdriver. Also

remove the screws holding the module in place.

5. Switch out the module, ensuring all screws are tightened.

6. Replace the leads.

7. Turn on the power and try the unit.

If the unit still doesn’t work, return it to Pason for inspection.

Page 26

Revised February 11, 2013

Revision 5 of DOCU006, © Copyright

Page 26 of 28

Troubleshooting the Flow System

If the flow display reading is abnormal and the rest of the system seems to be working

properly, the problem is likely in the sensor wiring or sensor. A quick way to test the

complete flow system from the J Box to the sensor is to connect the flow wiring to one of

the tank input connectors (in the J Box). The trip tank is the best choice as the FILL

ZERO switch can be used to establish a zero point.

After hooking up the wiring, check the PVT monitor to see if the display shows a

reasonable figure. If not, the problem lies in the field wiring, sensor, or the J Box. As a

last resort, return to the PVT monitor and ensure the display is functioning properly.

Abnormal readings may require adjustment of the FLOW LED at the potentiometer. If

not, the problem is in the sensor wiring. Check the wiring from the flow sensor to the

JBox and repair or replace it. The system should work. If the problem is found to be an

internal one, go to Troubleshooting the Volume System on page 24 to determine the

next course of action.

Troubleshooting the Mud Pumps System

Pump strokes are sent from the EDR (if the pump stroke sensors are connected to the

EDR). If strokes are present on the DHC but not on the PVT monitor, check the 4-pin

connecting cable (CBLASS002).

Note:

Pump strokes can come from either the PVT or the EDR. If the strokes are coming from the EDR

and are not showing up on the PVT, there could be a communications problem between the two

systems. If the strokes are coming from the PVT (mechanical switches) the problem could be the

wiring, J Box, or PVT.

If the problem is found to be an internal system problem, use a mechanical stroke

counter to verify that strokes are being recorded correctly.

General Troubleshooting

If the system is acting up, follow these steps to isolate the problem:

1. Ensure that the unit is plugged in and that the power outlet is working.

2. Inspect the AC plug for loose wiring or corrosion.

3. Check the power to the J Box by hooking up a voltmeter between the circuit

board mounting plate and the binding post on the circuit board (marked V+).

The voltmeter should read approximately 14.3 volts. If the reading doesn’t

Page 27

Revised February 11, 2013

Revision 5 of DOCU006, © Copyright

Page 27 of 28

match, the main signal cable should be inspected for damage. If any

problems are found with the cable it should be repaired or replaced, even if

no visual damage is evident. Also check for loose or dirty connectors.

4. Return to the J Box and repeat the power test (if the results are still not

correct, the problem is likely with the power supply in the main display unit).

5. If the system does nothing when plugged in, the problem is most likely a

blown fuse. There are two fuses in the system. The first (½ amp slo-blo)

protects the transformer supply, and the second (2 amps) protects the horn

and the heater. If the system is completely dead, then the ½ amp fuse is most

likely blown. To replace the fuse, DISCONNECT THE POWER to the system

and remove the face plate. If the new fuse blows after the power is turned

back on, then the cause must be isolated. DO NOT SUBSTITUTE A

LARGER FUSE, as doing so leads to larger problems.

6. Test the power outlet. The voltage measured at the outlet should be between

110 and 125 VAC. If this isn’t the case, corrective action must be taken. If the

power outlet is functioning properly, the problem is likely in the power supply.

Disconnect the main power and remove the display unit face plate. Replace

the power supply. Temporarily replace the face plate, using 2 or 3 screws and

try the system again.

7. If the problem is still present, remove the face plate and replace the

electronics module.

8. If the system is still not working, return it to Pason for further testing.

Troubleshooting Summary

The best place to start troubleshooting is at the J Box, where the problem can be

isolated to either the field side or the system side of the J Box. Problems on the field side

of the J Box are easily narrowed down by substitution of known good parts or simulators.

Problems on the system side can usually be broken down into three problem areas:

power supply, electronics module, or data cables. If only one function is acting

improperly, the problem is likely an electronics or cable problem. If the whole system is

acting up, the problem is likely a power supply problem. If in doubt as to what

component is at fault when servicing the PVT monitor, replace the power supply first. If

this does not fix the problem, leave the new power supply in place and replace the

Page 28

Revised February 11, 2013

Revision 5 of DOCU006, © Copyright

Page 28 of 28

electronics module. This is the safest method to use, as it prevents new parts from being

damaged by old parts that are malfunctioning.

Note:

Problems with the display board are usually self-evident (e.g., missing display segments etc.)

Remember that the majority of problems are on the field side of the J Box, so ensure

that this part of the system is tested before opening the PVT monitor. It is also important

to eliminate any possibility that the power cord, power connector, or power outlet is

causing the problem before opening the PVT monitor.

Note:

Take proper precautions when opening the PVT monitor, as there is sufficient voltage (120 VAC)

to constitute a shock hazard.

When replacing the face plate, be sure to tighten the screws down evenly and in a

random pattern. Failure to do this could cause damage to the gasket or the face plate,

resulting in a box that leaks.

If the general procedures outlined in this section are followed, troubleshooting the

system should be a relatively straightforward task. It has been shown that an intimate

knowledge of the internal electronics is not necessary for field servicing. The most

common problems with the PVT are as follows:

• The 4-pin cable is screwed into the 5-pin connector (P1/P2) on the PVT.

• The data cable is not screwed in all the way, or it’s cross-threaded.

• The Woodhead connector is missing the ground pin.

• There’s electrical interference between the PVT and DC cables strung too

closely to the PVT.

Loading...

Loading...