Page 1

P

P

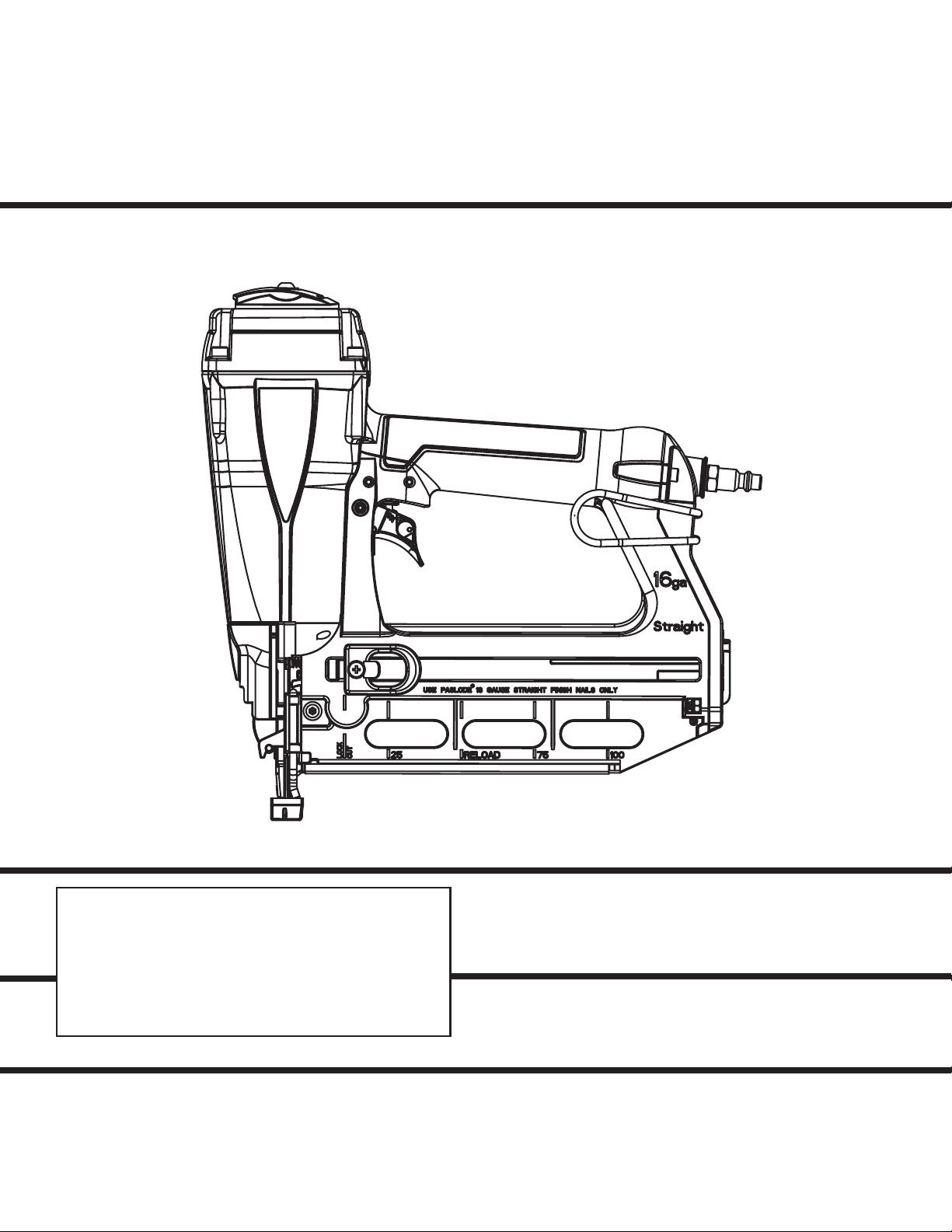

MODEL T250S-F16

16 Gauge Straight

Finish Nailer

IMPORTANT!

DO NOT DESTROY

It is the customer’s responsibility to have all

operators and service personnel read and

understand this manual.

OPERATING MANUAL AND

TOOL SCHEMATIC

Page 2

INTRODUCTION

The PASLODE® T250S-F16 finish nailer is a quality-built tool designed for use in residential

trim applications. This tool will deliver efficient, dependable performance when used according

to the manufactures guidelines. Please study this manual including the safety instructions to

fully understand the operation of this tool.

TOOL AND FASTENER SPECIFICATIONS ....................................................... 3

SAFETY INSTRUCTIONS ...................................................................................4

TOOL OPERATION .............................................................................................. 5

EXPLODED VIEW AND SPARE PARTS LIST .............................................10-11

ACCESSORIES ..................................................................................................12

TOOL WARRANTY AND LIMITATIONS

2

Page 3

TOOL AND FASTENER SPECIFICATIONS

TOOL SPECIFICATIONS

MODEL NO. T250S-F16 (Part# 501680)

HEIGHT 11.3"

WIDTH 3.1"

LENGTH 11.5"

WEIGHT 3.9lbs.

OPERATING PRESSURE 80 to 120 p.s.i. (5.5 to 8.3 bars)

ASSEMBLY HARDWARE SYSTEM Metric

FASTENER SPECIFICATIONS

NAIL LENGTH 3/4" - 2-1/2"

SHANK DIAMETER 16 gauge

TOOL AIR FITTINGS:

This tool uses a 1/4” N.P.T. male plug. The inside diameter should be .28” (7mm)

or larger. The fitting must be capable of discharging tool air pressure when

disconnected from the air supply.

OPERATING AIR PRESSURE:

80 to 120 p.s.i. (5.5 to 8.3 bars). Select the operating air pressure within this range

for best tool performance.

DO NOT EXCEED THIS RECOMMENDED OPERATING PRESSURE.

3

Page 4

SAFETY INSTRUCTIONS

SAFETY FIRST

These safety instructions provide information necessary

for safe operation of Paslode

TO OPERATE THE TOOL UNTIL YOU READ AND

UNDERSTAND ALL SAFETY PRECAUTIONS AND

MANUAL INSTRUCTIONS.

WEAR EYE AND HEARING PROTECTION

Always wear hearing and eye protection devices, that

conform to ANZI Z87.1 requirements, when operating or

working in the vicinity of a tool. As an employer you are

responsible for enforcing the use of eye protection.

Wear hard hats in environments that require their use.

THE TOOL MUST BE USED ONLY FOR THE PURPOSE FOR WHICH IT WAS DESIGNED

Do not throw the tool on the floor, strike the housing in

any way or use the tool as a hammer to knock

material into place.

NEVER ENGAGE IN HORSEPLAY WITH THE TOOL

The tool is not a toy so do not use it like one. Never

engage in horseplay with the tool or point it at yourself

or any other person, even if you think it is not loaded.

NEVER ASSUME THE TOOL IS EMPTY

Check the magazine for fasteners that may be left in the

tool. Even if you think the tool is empty or disconnected,

never point it at anyone or yourself. Unseen fasteners

could fire from the tool.

NEVER CLAMP THE TRIGGER IN A LOCKED OR

OPERATING POSITION

The trigger of the tool must never be tampered with,

disabled or clamped in a locked or operating position

since this will cause the tool to drive a fastener any time

the work contacting element depressed.

DO NOT LOAD FASTENERS WITH THE AIR LINE

CONNECTED, OR WITH THE TOOL TRIGGER OR

WORK CONTACTING ELEMENT DEPRESSED

When loading fasteners into the tool be sure you

disconnect the air line and that you do not depress the

trigger or work contacting element.

OPERATE THE TOOL ONLY ON A WORKPIECE

The tool should be operated only when it is in contact

with the workpiece. Even then you should be careful

when fastening thin material or working near the edges

and corners of the workpiece since the fasteners may

drive through or away from the workpiece.

DO NOT DISABLE OR REMOVE THE WORK CONTACTING ELEMENT

This tool is equipped with a safety mechanism, called a

work contacting element, to help prevent

accidental firing. Never tamper with, disable or remove

the work contacting element. Do not use the tool unless

the work contacting element is working properly. The

tool could fire unexpectedly.

®

tools. DO NOT ATTEMPT

DISCONNECT THE TOOL WHEN NOT IN USE

Always disconnect the tool from the air line when it is

not in use, when you leave the work area or when

moving the tool to a new location. The tool must

never be left unattended because people who are not

familiar with the tool might handle it and injure

themselves or others.

CARRY THE TOOL ONLY BY THE HANDLE

Always carry the tool by the handle only. Never carry

the tool by the air hose or with the trigger depressed

since you could drive a fastener unintentionally and

injure yourself or someone else.

DO NOT WEAKEN THE TOOL HOUSING

The tool housing is a pressure vessel and should never

be weakened by having your company’s name, area

of work or anything else stamped or engraved into its

surface.

DISCONNECT THE TOOL WHEN PERFORMING

REPAIRS AND CLEARING JAMS

Never attempt to clear a jam or repair a tool unless you

have disconnected the tool from the air line and

removed all remaining fasteners from the tool.

ALWAYS USE THE PROPER FITTING FOR THE

TOOL

Only MALE pneumatic type air connectors should be

fitted to the tool, so that high pressure air in the tool is

vented to atmosphere as soon as the air line is

disconnected.

NEVER install FEMALE quick disconnect couplings on

the tool. Female couplings will trap high pressure air

in the tool when the air line is disconnected, leaving

the tool charged and able to drive at least one fastener.

DO NOT EXCEED THE MAXIMUM RECOMMENDED

AIR PRESSURE

Operate the tool only at the recommended air pressure. Do not exceed the maximum air pressure marked

on the tool. Be sure the air pressure gauge is

operating properly and check it at least twice a day.

Never use any bottled air or gases such as oxygen to

operate the tool since they could cause the tool to

explode.

INSPECT TOOL FOR PROPER OPERATION

Clean the tool at least daily and lubricate as required.

Never operate a dirty or malfunctioning tool.

USE ONLY PASLODE RECOMMENDED PARTS AND

FASTENERS

Use only parts and fasteners specifically designed and

recommended by Paslode for use in the tool and for

work to be done. Using unauthorized parts and

fasteners or modifying the tool in any way creates

dangerous situations. Replace all missing warning

labels---refer to tool schematic for correct placement

and part number.

WARNING

Failure to follow any of the above instructions could result in severe personal

injury to tool user and bystanders or cause damage to tool and property.

Contact your local Paslode Representative for presentation of Paslode’s Safety Awareness Program

4

Page 5

TOOL OPERATION

Fasteners

The Paslode T250S-F16 Finish Nailer drives

Paslode® 16 gauge fasteners designed to be used

with the tool. The use of fasteners that do not meet

Paslode standards could cause tool damage and will

void all warranty claims.

Loading Fasteners

STEP 1: Align the heads of the Paslode 16 ga.Finish

nails to the brad channel in the rear of the magazine

and insert one or two strips. Push the nails strips

forward.

STEP 2: Next, while applying pressure to the release

lever, pull the follower toward the rear of the

magazine until the follower passes the last strip of

fasteners. Release the lever on the follower and let

the follower push the nails forward into the nose of

the tool.

Depth of Drive Adjustment

Disconnect the air supply.

The depth of drive adjustment is done by turning the

adjustment wheel as shown by the arrows on the side of

the tool.

Turn

adjustment

wheel in

either

direction

Clearing a Jam

An occasional problem you may encounter is a jammed

fastener. Because of the unique design of the Paslode

Finish Nailer, clearing a jammed fastener is easy:

1. Disconnect the air supply.

2. Pull the latch, releasing front guide. Pivot front guide

forward.

3. Clear jam, and push driver blade back up to its normal

position.

4. Close front guide and latch it. Check that work

contacting element moves freely.

When the follower reaches the reload area, marked

on the side of the magazine, you may insert a new

strip of nails. When the follower arrow reaches the

lockout area the tool automatically locks the tool to

prevent the tool from operating. To unlock the tool,

simply reload another strip of nails.

Lockout Feature

The purpose of this feature is to prevent needless

blank cycling, which could mar woods and damage tool components. Ten (10) nails will be left in

the magazine when the follower reaches the

lockout area. When changing fastener length or

loading at the beginning of the work day, you

should inspect the magazine and nose for any

fasteners left in the tool. These nails will not be

visible unless you open the nose of the tool.

5

Page 6

TOOL OPERATION

Trigger Methods:

The Paslode T250S-F16 Finish Nailer has a triggering

system than can be switched from sequential to contact

trip. To switch the trigger, press in the round orange

button on the right side of the trigger and rotate the left

side of the button to the desired triggering method. The

TTT indicates contact trip and the T indicates sequential

operation.

Successive (Bounce) Driving -

Grasp the handle firmly.

Squeeze the trigger and move the tool along the

workpiece with a bouncing motion, depressing the work

contacting element at the points where you want to drive

a fastener.

Keep the trigger depressed and continue to bounce the

work contacing element against the workpiece, positioning the tool above as carefully as possible.

When the desired number of fasteners have been

driven, release the tool trigger to avoid unintentional

fastener discharge.

Reversible Belt Hook:

The belt hook can be changed from the left hand side of

the tool to the right hand side. To change the position,

squeeze the base of the belt hook and remove it from the

tool and position it on the desired side.

➔

➔

➔

➔

Adjustable Exhaust:

The direction of the exhaust air can be changed by

rotating the orange air deflector on the cap of the tool.

Sequential Operation -

The sequential setting T prevents succesive or "bounce"

driving.

Depress the work contacting element and hold it

against the work surface before pulling the trigger.

After each fastener is driven, completely release the

trigger and lift the tool from the work surface.

6

Page 7

MAINTENANCE

Paslode® tools are built for ease of maintenance. A few

simple details will assure trouble-free operation and long

tool life. Anyone who uses or maintains the tool must read

the safety and maintenance instructions. Study the schematic drawing before starting any repairs on the tool.

Air-operated tools must be inspected periodically, and worn

or broken parts must be replaced to keep the tool operating

safely and efficiently. Also the items on the maintenance

chart must be checked often.

Cold Weather Care

❑ Open the drain on the air compressor tank to drain any

moisture at least daily in extremely cold or humid weather.

A few ounces of anti-freeze in the tank will keep the air

free of frost.

Testing the Tool After Servicing

After replacing any part or parts, it is important to check

the tool for proper operation. This ensures that the tool

was put together correctly, is safe to use, and will perform

the job properly.

❑ Ensure that all hardware is tight.

❑ Ensure that the work contacting element is installed

correctly in relation to the trigger, and that both parts

move freely.

When temperatures are below freezing, tools should be

kept warm by any convenient, safe method. If this is not

possible, the following procedure should be used to warm

up the tools.

❑ Reduce the regulated air pressure to 30 psi.

❑ Remove all fasteners from the tool.

❑ Collect an air line and blank fire the tool. The reduced

air pressure will be enough to free-fire the tool. Slow speed

operation tends to warm up the moving parts. Slowing up

the piston helps the bumper and the O-rings to become

pliable.

❑ Once the tool is warmed up, readjust the regulator to

the proper working pressure and reload the tool.

❑ Tool operators working outdoors or in unheated areas in

extremely cold temperatures should also:

❑ Ensure that the magazine is properly attached.

❑ Ensure that the required safety information on the tool

is legible.

❑ Use only Paslode approved fasteners in the tool, and

ensure that they are correct for the application.

❑ Ensure that a male air fitting is securely connected to

the tool.

❑ Test the tool by driving fasteners into a workpiece

identical to the tool's application.

❑ Check the tool for air leaks during testing and for the

proper sequence of operation.

❑ Ensure that all fasteners are driven to the same depth

and that the crown of the fastener is flush with the

workpiece.

Tool Lubrication

It is most important that the tool be properly lubricated by

keeping the air line lubricator filled and correctly adjusted.

Without proper lubrication the tool will not work properly

and parts will wear prematurely.

Use Paslode pneumatic oil with antifreeze in the

lubricator, Part No. 219090 (8oz.)

Once a week, depending on the amount of tool use,

take the tool apart and wash away any sludge with

degreaser cleaner (Paslode Part No. 219086) to

keep the tool operating efficiently.

Cleaning the air-operated tools with solvents removes the

thin coating of grease applied to the cylinder wall and

O-rings at the factory. To replace this coating of grease,

use Chemplex grease (Paslode Part No. 403734).

Use the proper lubricant in the air line lubricator. The

lubricator should be of low air flow or changing air flow

type, and should be kept filled to the correct level. Use

only Paslode recommended lubricants. Substitutes may

harm the rubber compounds in the tools O-rings and other

rubber parts. Paslode Part No. 403720 is a pneumatic

lubricating oil specially made for pneumatic applications.

If a filter/regulator/lubricator is not installed on the air

system, air operated tools should be lubricated at least

once a day with 6 to 20 drops of oil, depending on the

work environment, directly through the male fitting in the

tool housing.

Most minor problems can be resolved quickly and easily

using the maintenance table that follows. If problems

persist, contact your Paslode dealer for assistance.

7

Page 8

MAINTENANCE

ACTION WHY HOW

Drain air line filter (daily).

Keep lubricator filled.

Clean filter element, then blow

air through filter in direction

opposite to normal flow.

Check that all screws on tool

are tight.

Keep work contacting elelment

working properly.

Keep magazine and feeder

mechanism clean.

Prevent accumulation of

moisture and dirt.

Keep tool lubricated.

Prevent clogging of filter with

dirt.

Prevent air leakage and promote efficient operation.

Promote operator safety and

efficient tool operation.

Prevent jamming of fasteners.

Open manual petcock (most

air supply systems have such

a valve).

Fill with Paslode pneumatic

tool lubricant. Part No.

219026.

Wash with soap and water or

follow manufacturers instructions.

Check screws daily.

Blow clean daily.

Blow clean daily.

Lubricate "O" rings that are

replaced.

Use only Paslode replacement

parts.

Assure long life and proper

operation of tool.

Keep tool operating efficiently

and maintain Paslode tool

warranty.

8

Use Chemplex grease, Part

No. 403734.

Order any replacement parts

needed from Paslode Dealer.

Page 9

OPERATOR TROUBLESHOOTING

PROBLEM CORRECTIVE ACTION

Fasteners will not drive completely into wood.

Fasteners penetrate properly during normal

operation, but won't drive fully at faster speeds.

Fasteners drive too deeply into wood.

Fastener jams in nose of tool.

Tool skips during operation - no fasteners are driven

from time to time.

Adjust the

Increase air pressure (do not exceed 120 psi).

Increase air flow to tool -- use larger air lines

(3/8 inch ID minimum).

Adjust the

Reduce air pressure.

Open front guide latch, release jammed fastener,

and close latch securely.

Check magazine for proper fasteners. Magazine

follower should slide freely. Clean as needed to

remove debris.

depth of drive adjustment (retract length).

depth of drive adjustment (extend length).

Tool operates, but no fasteners are driven.

Air leaks at cap when tool is connected to air.

Make sure correct fasteners are being used.

Use fasteners that meet Paslode® specifications only.

Increase air flow to tool -- use larger air lines

(3/8 ID minimum).

Adjust work contacting element where available.

Check magazine for proper fasteners. Fasteners

should slide freely with no follower pressure.

Open front guide latch or loosen magazine knob and

check for jams or debris in the nose area. Clear as

necessary.

Increase air pressure (do not exceed 120psi).

Tighten cap screws.

9

Page 10

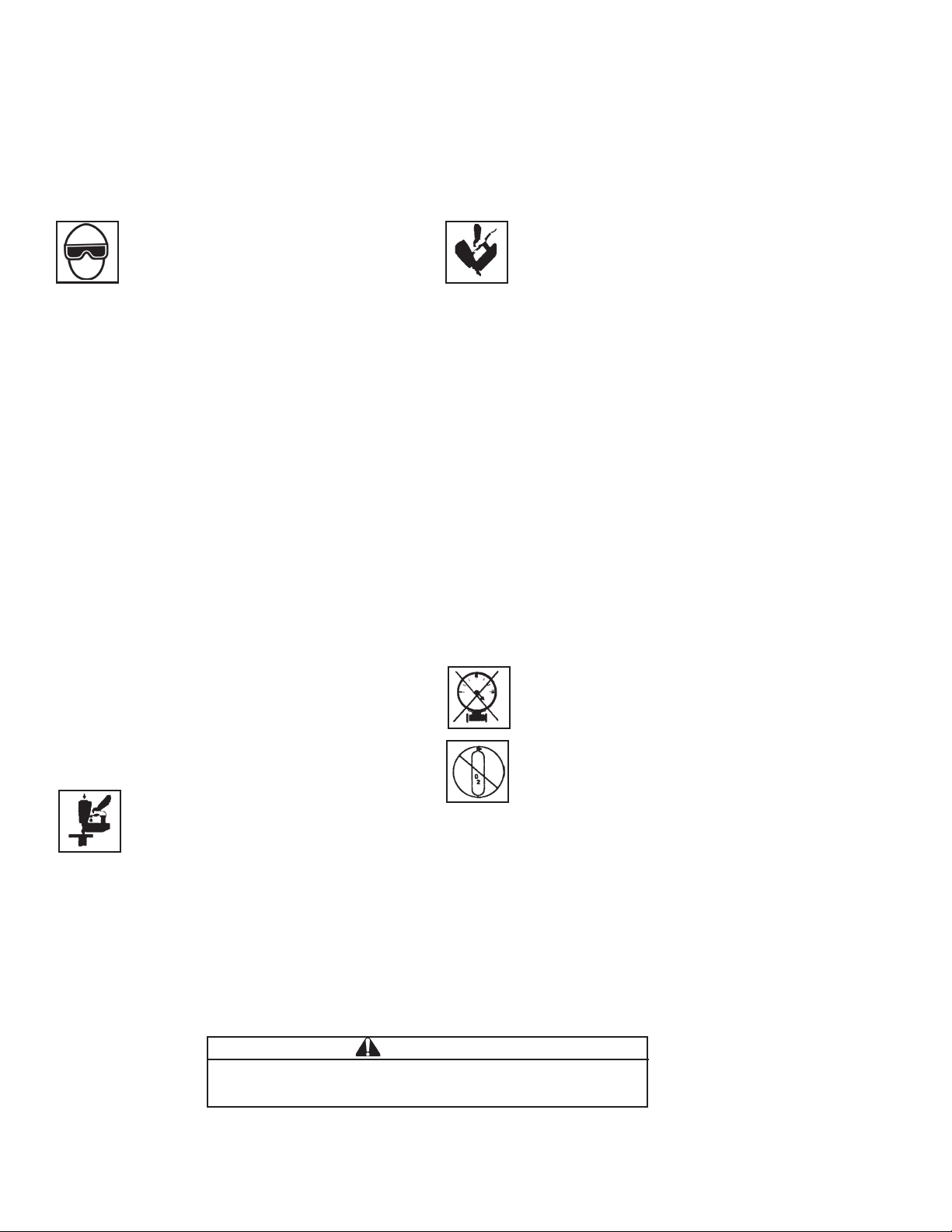

PARTS LEGEND T250S-F16, 501680

1 501885 1 T.H.S.C.S. 1/4-20 x 1/2

2 501896 1 Flat Washer

3 501899 1 Deflector

4 501901 1 Bolt

5 501902 1 Cap

6 501903 1 Seal

7 501904 1 Spring, Main Valve

*8 501905 2 O-Ring

9 501906 1 Head Valve Piston

10 501907 1 O-Ring

*

11 501908 1 Collar

*

12 501909 1 Packing

13 501910 1 Piston Ring

*

*

14 501911 1 O-Ring

15 501912 1 Driver Blade

*

16 501920 1 Cylinder Press Ring

17 501913 1 O-Ring

18 501914 1 Cylinder

19 501915 1 Cylinder Ring

20 501916 1 Cylinder Spacer

21 501917 1 O-Ring

*

22 501918 1 Bumper

23 501919 1 Driver Guide

*

24 501921 1 O-Ring

*

25 501922 1 O-Ring

26 501923 1 Plunger Cap

27 501930 2 Spring Pin

28 501924 1 Valve Plunger

*

29 501925 2 O-Ring

*

30 501926 1 O-Ring

31 501927 1 Spring

32 501928 1 Plunger

33 500999 2 O-Ring

34 501929 1 Trigger Valve Head

35 501932 1 Spring

36 501933 1 Trigger Unit

37 501965 2 Tap Bolt

38 501962 1 Lock Nut

39 501964 1 Magazine B

40 501961 1 Counter Sunk Screw

41 501934 1 Trigger Pivot Pin

42 501935 1 Housing

43 501936 1 O-Ring

44 501937 1 End Cap

45 501092 1 Dust Cover

46 501972 2 Bolt

47 501091 1 Air Plug

48 501939 1 Belt Hook

49 501938 2 Hex S.H.C.S.

50 501998 1 Spring Pin

51 501931 1 Spring Pin

52 501089 1 Urethane Retainer

53 501963 1 Steel Channel

54 501966 1 Safety B

55 501967 1 Safety Spring

56 501968 1 E-Ring

57 501969 1 Adjust Shaft

58 501387 1 Spring

59 501970 1 Safety A

60 501971 1 No Mar Tip

61 501951 1 Latch Cover

62 501950 2 Spiral Pin

63 501949 1 Front Latch Handle

64 501948 1 Front Latch

65 501947 1 Driver Guide Cover

66 501946 1 Spiral Pin

67 501940 2 Hex Soc.Hd.Bolt

68 501941 1 Driver Guide Cover B

69 501942 1 Driver Guide

70 501943 1 Stopper Finger Spring

71 501944 1 Stopper

72 501945 1 Fixed Pin

73 501953 1 Pusher Spring

74 501954 1 Pusher

75 501955 1 Spring Pin

76 501952 1 Anchor Block

77 501956 1 Negator Spring

*

78 501960 1 Magazine Steel Cover

79 501961 1 Counter Sunk Screw

80 501959 1 Tap Bolt

81 501958 1 Protecting Hood Cover

82 501962 1 Lock Nut

83 501957 1 Magazine A

84 501973 1 Nameplate

85 501302 1 Warning Label

**

86 501140 1 Housing Label-left

87 501141 1 Housing Label-right

88 501995 1 Tap Bolt

* Denotes Normal Wear Items.

** Make sure Warning Label (501302) is properly affixed.

Replace if necessary.

Label available at no charge through the Service Parts Dept.

10

SAFETY INSTRUCTIONS

WEAR EYE AND HEARING PROTECTION

Always wear hearing protection and eye protection devices,

including side shields when operating or working in the vicinity

of a tool.

DO NOT EXCEED MAXIMUM

RECOMMENDED AIR PRESSURE

60

120

0

60

120

0

Operate the tool using only the recommended air pressure. Do

not exceed the maximum air pressure marked on the tool. Be

sure the air pressure gauge is operating properly and check it

at least twice a day.

Never use any bottled air or gases such as

oxygen to operate the tool since they could cause

the tool to explode.

Page 11

T250S-F16

37

1

84

85

38

501680

30

31

28

34

24

26

25

37

40

57

58

59

39

60

56

55

67

87

66

63

54

68

88

41

74

69

65

75

73

70

86

72

52

76

71

42

77

43

50

51

45

44

53

79

78

81

80

46

47

46

48

49

83

82

2

3

4

5

6

7

8

9

10

11

12

16

23

Trigger

Valve

Assembly

#501988

15

13

14

17

18

19

20

21

22

27

29

33

Driver Blade

Assembly

#501987

32

35

36

Assembly Hardware System - Metric

WARNING

All parts must be periodically inspected and

replaced if worn or broken. Failure to do this can

affect the tool’s operation and present a safety

hazard.

61

64

62

11

Page 12

ACCESSORIES

.

L

ubricants

Tool Cleaner

Safety Glasses

027304 .oN traP.zo 61 liO gnitacirbuL

090912 .oN traP.zo 8 ezeerftinA htiw liO gniacirbuL

437304 .oN traP.bl1 tnacirbuL 017 xelpmehC

483912 .oN traP.sloot edolsaP lla rof renaelc laedI

382104 .oN traPraelC

Tool Case

Handy carrying case that conveniently stores your tool

879105 .oN traP .seirossecca lanoitidda rof moor htiw

© 2010, Illinois Tool Works, Inc.

P

An Illinois Tool Works Company

888 Forest Edge Drive

Vernon Hills, Illinois 60061-8117

501977-3

04/10

Loading...

Loading...