Page 1

P

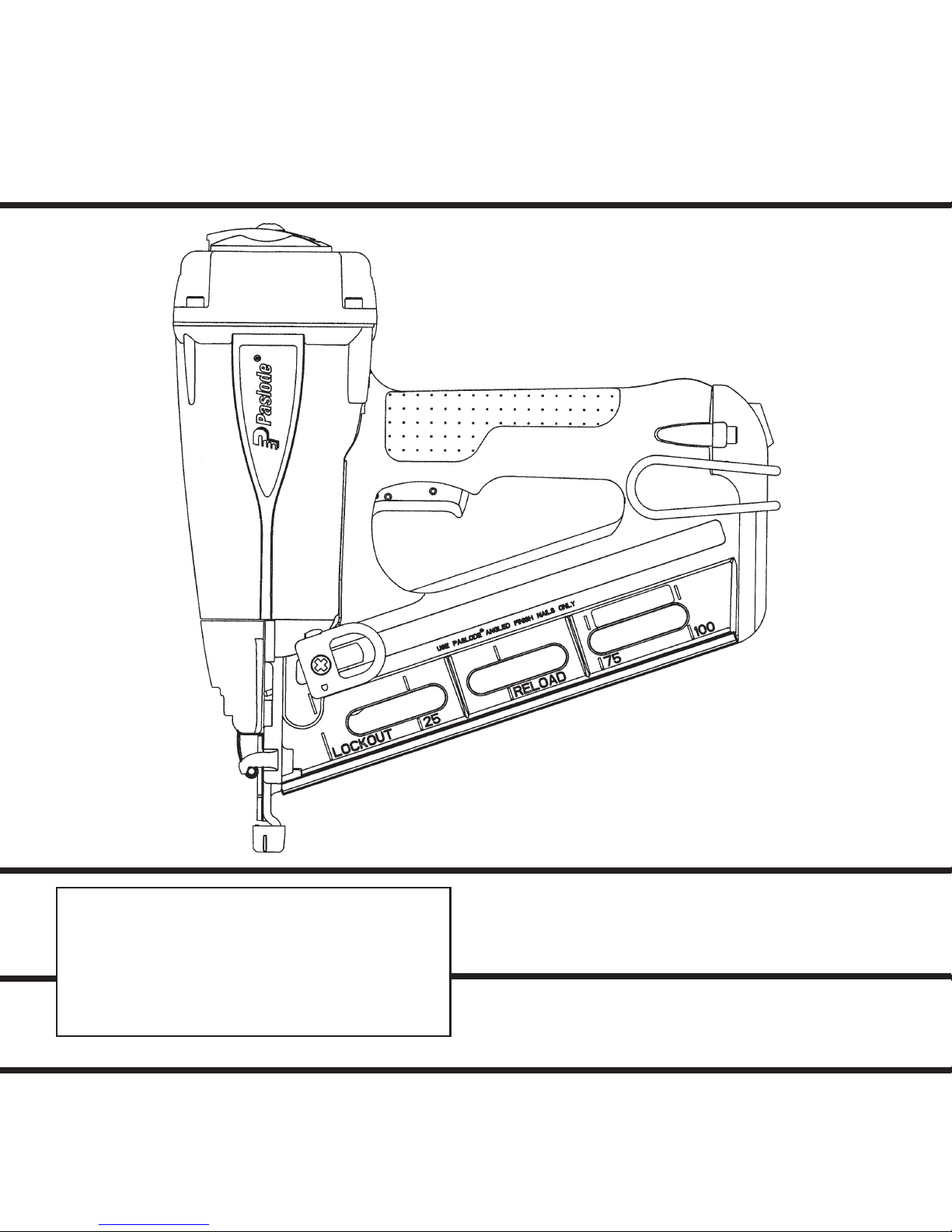

MODEL T250A-F16

16 Gauge Angled

Finish Nailer

IMPORTANT!

DO NOT DESTROY

It is the customer’s responsibility to have all

operators and service personnel read and

understand this manual.

OPERATING MANUAL AND

SCHEMATIC

Page 2

PARTS LEGEND T250A-F16, 500910

1 501043 1 T.H.S.C.S. 1/4-20 x 1/2

2 500921 1 Deflector

3 501332 4 S.H.C.S. 10x24 x 7/8

4 500909 1 Cap

➔

*5 500927 1 Gasket

6 500913 1 Piston Stop

7 501288 1 Spring, Main Valve

*8 091023 2 O -Ring

*9 095406 1 O -Ring

10 501277 1 Main Valve Assembly

*

11 405430 1 O -Ring

12 500911 1 Piston

13 401130 1 Driv Lok Pin

14 500920 1 Driver Blade

*

15 091863 1 O -Ring

*

*

16 500369 1 O -Ring

17 500907 1 Sleeve

18 500917 1 Bumper

*

➔

*

19 501404 1 Blade Seal

20 500908 1 Housing

21 501141 1 Label, Logo R

22 501140 1 Label, Logo L

23 026133 2 Roll Pin

24 501757 1 Spring

25 097748 1 Spring

26 097746 1 Pin Valve

27 092174 1 O -Ring

*

28 401958 1 Valve Body

29 501755 1 Adjustment Knob

30 500937 1 Brad Chanel

31 501039 1 Sequential Trigger

* Denotes Normal Wear Items.

** Make sure Warning Label (501302) is properly affixed.

Replace if necessary.

Label available at no charge through the Service Parts Dept.

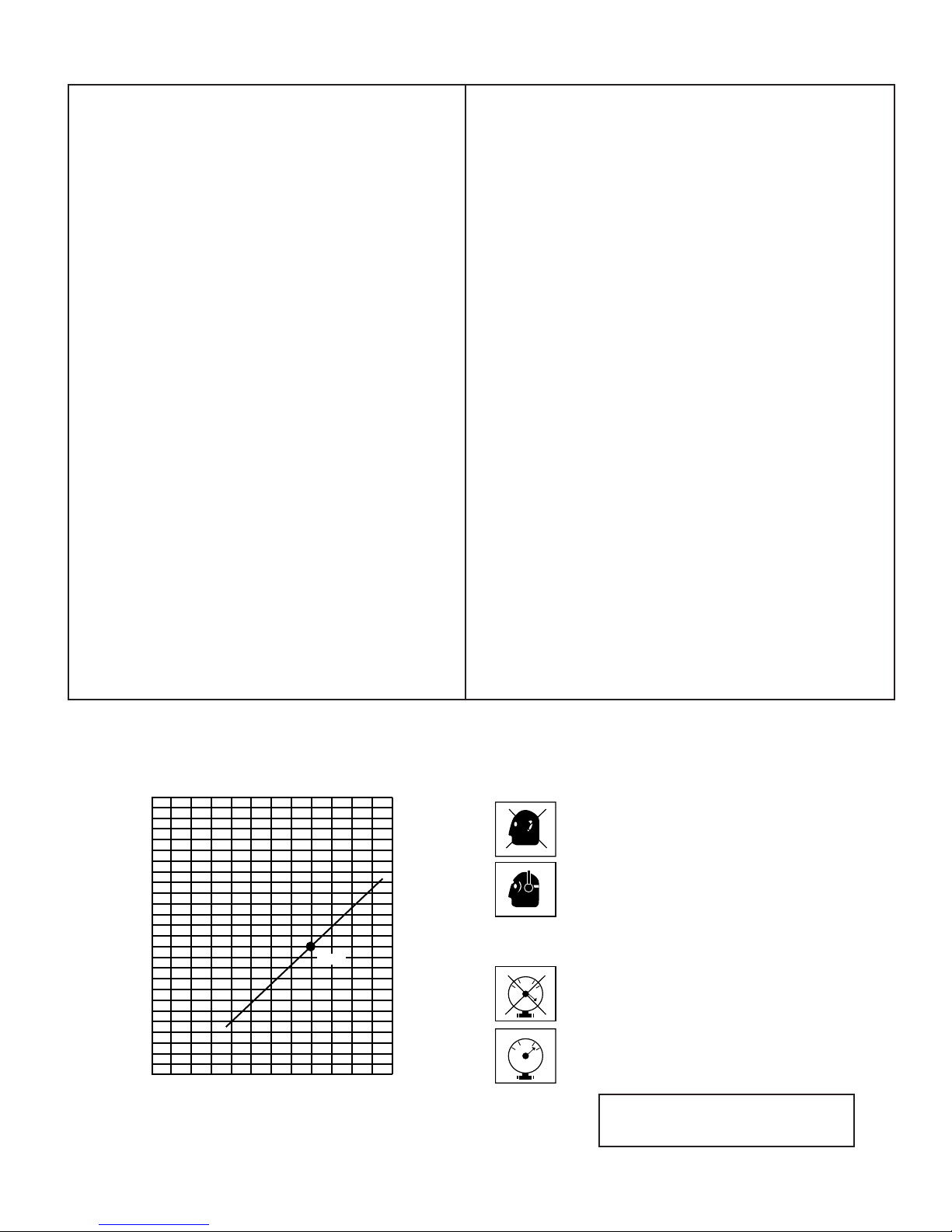

AIR CONSUMPTION CHART

.050

.045

32 500940 1 Wire Belt Hook

33 501324 4 S.H.C.S. 10-24 x 3/4

34 501316 1 Pin Dowel

35 501301 1 Nose

36 500918 1 Front Plate

37 500924 1 Latch Clamp Spring

38 500923 1 Clamp Spring

39 404659 2 Roll Pin

40 402730 1 Pin

41 500939 1 Quick Clear Cover

42 501754 1 Upper W.C.E.

43 501753 1 Lower W.C.E.

44 500936 1 No-Mar Tip

*

45 501414 1 Spring, W.C.E.

*

46 402963 1 O -Ring

*

47 500928 1 End Plug

48 501756 1 Pin

49 501362 1 Rail, Magazine

50 500933 1 Follower

51 501150 1 Pull Back Lever

52 500944 1 Negator Spring

*

53 501148 1 Follower Core Assembly

54 501225 1 Follower Pin

55 500934 1 Spring, Follower

56 501224 1 Screw, #8-16 x 5/8 Plastite

57 501458 1 Right & Left Handle Kit

58 501223 2 Screw, #8-16 x 7/8 Plastite

59 501311 1 Nameplate

**

60 501302 1 Warning Label

61 501398 1 Torsion Spring, Quick Clear

62 402669 1 Trigger Pin

63 402668 1 Retaining Ring

SAFETY INSTRUCTIONS

WEAR EYE AND HEARING PROTECTION

Always wear hearing protection and eye protection

devices, including side shields when operating or

working in the vicinity of a tool.

.040

.035

AIR CONSUMPTION - SCFM/FASTENER

.030

70 80 90 100 110 120

AIR PRESSURE - PSIG

.040

DO NOT EXCEED MAXIMUM

RECOMMENDED AIR PRESSURE

60

120

0

60

120

0

6

Operate the tool using only the recommended air

pressure. Do not exceed the maximum air pressure

marked on the tool. Be sure the air pressure gauge is

operating properly and check it at least twice a day.

Never use any bottled air or gases such as

oxygen to operate the tool since they could cause

the tool to explode.

Page 3

T250A-F16

1

2

59

500910

4

Valve Assembly

#501459

8

11

Piston Assembly

#501460

14

3

57

60

58

30

5

6

7

46

33

21 20

9

32

10

23

25

47

12

26

13

41

22

27

28

57

61

34

33

35

62

63

31

37

38

17

15

Latch

Assembly

#501461

16

18

19

43

WARNING

All parts must be periodically inspected and

replaced if worn or broken. Failure to do this can

affect the tool’s operation and present a safety

hazard.

40

48

39

42

36

44

OPTIONAL:

Bump

Trigger

Assembly

#501048

45

49

29

24

Follower

Assembly

#501457

55

50

54

51

53

52

7

56

Page 4

ACCESSORIES

Contact Trip Trigger Kit

The T250A-F16 comes with a Sequential Fire Trigger installed on the

tool. Using the Sequential Trigger, the user must fully depress the

work contact element (w.c.e) before squeezing the trigger and

successfully firing the tool. An optional Contact Trip Trigger,

designed for "bump" or "bounce" firing, is an included accessory.

Using the Contact Trip Trigger, the user is able to successively fire

fasteners by squeezing and holding the trigger and then "bumping" the

w.c.e. along the workpiece. Instructions for changing to the contact

trip trigger are included. Part No. 501048

Lubricants

Lubricating Oil 16 oz. Part No. 403720

Lubricaing Oil with Anitfreeze 8 oz. Part No. 219090

Chemplex 710 Lubricant 1lb. Part No. 403734

Degreaser Cleaner

Ideal cleaner for all Paslode tools. Part No. 219086

Safety Glasses

Clear Part No. 402510

Tinted Part No. 402512

Tool Case

Handy carrying case that conveniently stores your tool

with room for additional accessories. Part No. 501304

P

PRINTED IN U.S.A.

© 2006, Illinois Tool Works, Inc.

An Illinois Tool Works Company

888 Forest Edge Drive

Vernon Hills, Illinois 60061-3105

405653-2

03/06

Loading...

Loading...