Page 1

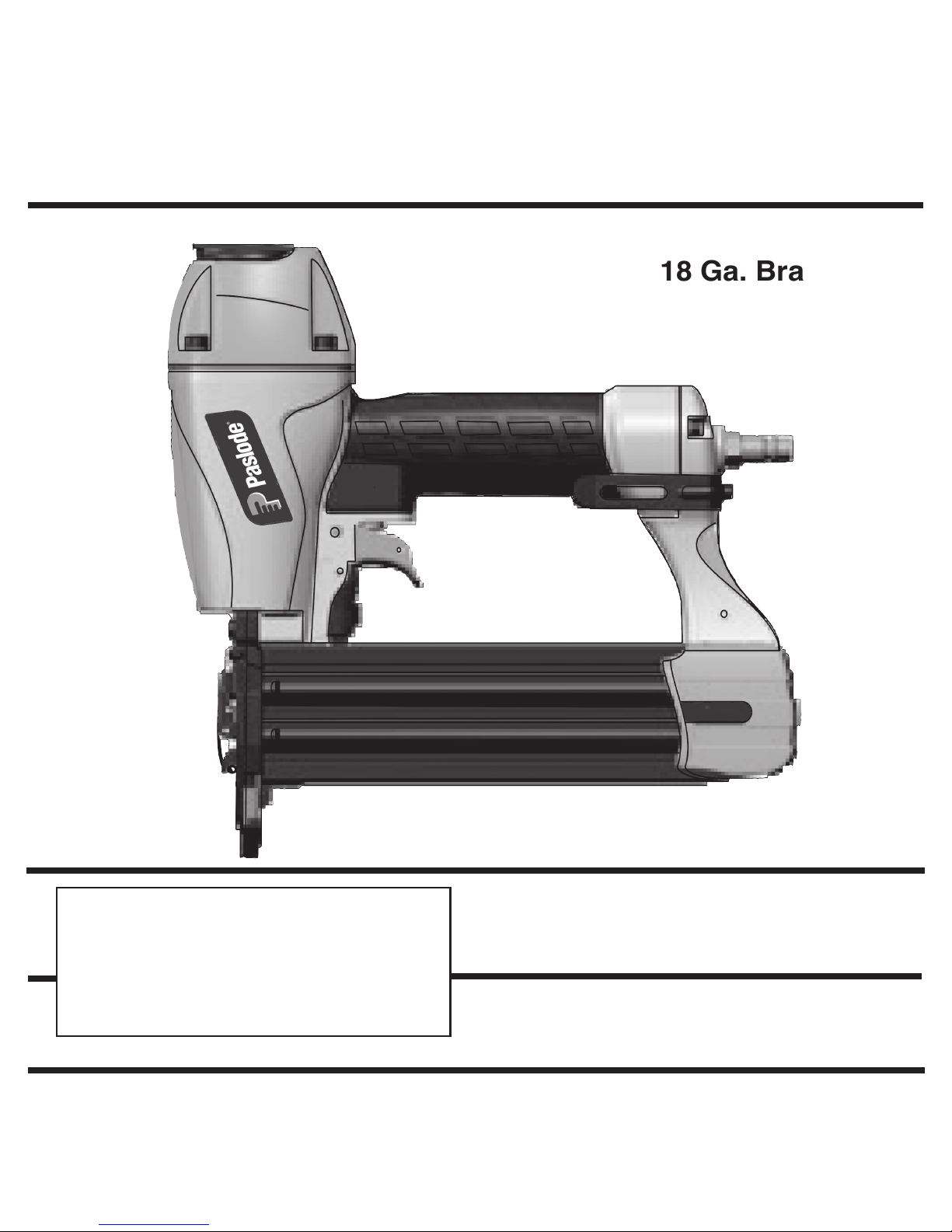

P

Part# 515600

MODEL T200-F18P

18 Ga. Brad Nailer

IMPORTANT!

DO NOT DESTROY

It is the customerʼs responsibility to have all

operators and service personnel read and

understand this manual.

PRINTED IN U.S.A.

© 2017, Illinois Tool Works Inc.

515610-2

08/17

OPERATING MANUAL AND

SCHEMATIC

Page 2

INTRODUCTION

The PASLODE® T200-F18P

Brad Nailer is a quality-built tool designed for use in residential

trim applications. This tool will deliver efficient, dependable performance when used according

to the manufactures guidelines. Please study this manual including the safety instructions to

fully understand the operation of this tool.

TOOL AND FASTENER SPECIFICATIONS ....................................................... 3

SAFETY INSTRUCTIONS ...................................................................................

TOOL OPERATION .............................................................................................. 5

EXPLODED VIEW AND SPARE PARTS LIST ............................................. 10- 1 1

ACCESSORIES .................................................................................................. 412..

TOOL WARRANTY AND LIMITATIONS

Paslode warrants that newly purchased power

fastening tools, parts and accessories will be free

from defects in material and workmanship for the

period shown below, after the date of delivery to

the original user.

90 DAY LIMITED WARRANTY

A 90-day warranty will apply to all parts, except

those which are specifically covered by an extended

warranty.

EXTENDED LIMITED WARRANTY FOR ONSITE

CONSTRUCTION APPLICATIONS

one year warranty will apply to all housing and cap

A

assembly castings. A six month warranty will apply

to all magazine parts.

NORMAL WEARING PARTS

WARRANTY STATEMENT

This warranty is limited to tools sold and service requested

in the United States. To obtain information on warranty

service in the United States, refer to the Service Center

listing that was provided with your tool.

Paslode's sole liability hereunder will be to replace any part

or accessory which proves to be defective within the specific

time period. Any replacement part or accessory provided in

accordance with this warranty will carry a warranty for the

balance of the period of warranty applicable to the part it

replaces. This warranty does not apply to part replacement

required due to normal wear.

This warranty is void as to any tool which has been subjected

to misuse, abuse, accidental or intentional damage, use with

fasteners,not meeting

improperly maintained,

Paslode replacement parts,

which, in Paslode's opinion,

way that affects or detracts

Paslode specification, size, or quality,

repaired with other than genuine

damaged in transit or handling, or

has been altered or repaired in a

from the performance of the tool.

The following parts are considered normal wearing

parts and are not under warranty:

•

Bumper

•

Driver Blade

•

”O” Rings

•

Piston Rings

Paslode reserves the right to change specifications, equipment, or

designs at any time without notice and without incurring obligation.

PASLODE MAKES NO WARRANTY, EXPRESSED OR

IMPLIED, RELATING TO MERCHANTABILITY, FITNESS, OR

OTHERWISE, EXCEPT AS STATED ABOVE, and Paslode's

liability AS STATED ABOVE AND AS ASSUMED ABOVE is

in lieu of all other warranties arising out of, or in connection

with, the use and performance of the tool, except to the extent

other wise provided by applicable law. PASLODE SHALL IN

NO EVENT BE LIABLE FOR ANY DIRECT, INDIRECT, OR

CONSEQUENTIAL DAMAGES, INCLUDING, BUT NOT

LIMITED TO, DAMAGES WHICH MAY ARISE FROM LOSS

OF ANTICIPATED PROFITS OR PRODUCTION, SPOILAGE

OF MATERIALS, INCREASED COST OF OPERATION, OR

OTHERWISE.

2

Page 3

TOOL AND FASTENER SPECIFICATIONS

MODEL NO.

HEIGHT 10.63"

WIDTH 2.56"

LENGTH 10.04"

WEIGHT 2.9lbs.

NAIL LENGTH "2 - "8/5

SHANK DIAMETER

OPERATING PRESSURE 80 to 120 psi

18 gauge

T200-F18P (Part # 515600)

TOOL AIR FITTINGS:

This tool uses a 1/4” N.P.T. male plug. The inside diameter should be .28” (7mm)

or larger. The fitting must be capable of discharging tool air pressure when

disconnected from the air supply.

OPERATING AIR PRESSURE:

80 to120 psi. Select the operating air pressure within this range for best tool

performance.

DO NOT EXCEED THIS RECOMMENDED OPERATING PRESSURE.

3

Page 4

SAFETY INSTRUCTIONS

SAFETY FIRST

These safety instructions provide information necessary

for safe operation of Paslode

TO OPERATE THE TOOL UNTIL YOU READ AND

UNDERSTAND ALL SAFETY PRECAUTIONS AND

MANUAL INSTRUCTIONS.

WEAR EYE AND HEARING PROTECTION

Always wear hearing and eye protection devices, that

conform to ANSI Z87.1 requirements, when operating

or working in the vicinity of a tool. As an employer you

are responsible for enforcing the use of eye protection.

Wear hard hats in environments that require their use.

THE TOOL MUST BE USED ONLY FOR THE PURPOSE FOR WHICH IT WAS DESIGNED

Do not throw the tool on the floor, strike the housing in

any way or use the tool as a hammer to knock material

into place.

NEVER ENGAGE IN HORSEPLAY WITH THE TOOL

The tool is not a toy so do not use it like one. Never

engage in horseplay with the tool or point it at yourself

or any other person, even if you think it is not loaded.

NEVER ASSUME THE TOOL IS EMPTY

Check the magazine for fasteners that may be left in the

tool. Even if you think the tool is empty or disconnected,

never point it at anyone or yourself. Unseen fasteners

could fire from the tool.

NEVER CLAMP THE TRIGGER IN A LOCKED OR

OPERATING POSITION

The trigger of the tool must never be tampered with,

disabled or clamped in a locked or operating position

since this will cause the tool to drive a fastener any

time

the work contacting element depressed.

DO NOT LOAD FASTENERS WITH THE AIR LINE

CONNECTED, OR WITH THE TOOL TRIGGER OR

WORK CONTACTING ELEMENT DEPRESSED

When loading fasteners into the tool be sure you

disconnect the air line and that you do not depress

the trigger or work contacting element.

OPERATE THE TOOL ONLY ON A WORKPIECE

The tool should be operated only when it is in contact

with the workpiece. Even then you should be careful

when fastening thin material or working near the edges

and corners of the workpiece since the fasteners may

drive through or away from the workpiece.

DO NOT DISABLE OR REMOVE THE WORK

CONTACTING ELEMENT

This tool is equipped with a safety mechanism, called a

a work contacting element, to help prevent accidental

firing. Never tamper with, disable or remove the work

contacting element. Do not use the tool unless the work

contacting element is working properly.The tool could

fire unexpectedly.

®

tools. DO NOT

ATTEMPT

DISCONNECT THE TOOL WHEN NOT IN USE

Always disconnect the tool from the air line when it

is not in use, when you leave the work area or when

moving the tool to a new location. The tool must

never be left unattended because people who are

not familiar with the tool might handle it and injure

themselves or others.

CARRY THE TOOL ONLY BY THE HANDLE

Always carry the tool by the handle only. Never carry

the tool by the air hose or with the trigger depressed

since you could drive a fastener unintentionally and

injure yourself or someone else.

DO NOT WEAKEN THE TOOL HOUSING

The tool housing is a pressure vessel and should never

be weakened by having your companyʼs name, area of

work or anything else stamped or engraved into its

surface.

DISCONNECT THE TOOL WHEN PERFORMING

REPAIRS AND CLEARING JAMS

Never attempt to clear a jam or repair a tool unless you

have disconnected the tool from the air line and

removed all remaining fasteners from the tool.

ALWAYS USE THE PROPER FITTING FOR THE

TOOL

Only MALE pneumatic type air connectors should be

fitted to the tool, so that high pressure air in the tool is

vented to atmosphere as soon as the air line is disconnected.

NEVER install FEMALE quick disconnect couplings on

the tool. Female couplings will trap high pressure air in

the tool when the air line is disconnected, leaving the

tool charged and able to drive at least one fastener.

DO NOT EXCEED THE MAXIMUM RECOMMENDED

AIR PRESSURE

Do not exceed the maximum air pressure marked on

the tool. Be sure the air pressure gauge is operating

properly and check it at least twice a day.

Never use any bottled air or gases such as oxygen to

operate the tool since they could cause the tool to

explode. Do not operate in explosive atmospheres such

as in the presents of flammable liquids, gases, or combustible dust.

INSPECT TOOL FOR PROPER OPERATION

Never operate a dirty or malfunctioning tool.

USE ONLY PASLODE RECOMMENDED PARTS AND

FASTENERS

Use only parts and fasteners specifically designed and

recommended by Paslode

work to be done. Using unauthorized parts and fasteners

or modifying the tool in any way creates dangerous

situations. Replace all missing warning labels---refer

to tool schematic for correct placement and part Number.

ta ylno loot eht etarepO

®

®

for use in the tool and for

.erusserp ria dednemmocer eht

.deriuqer sa etacirbul dna yliad tsael ta loot eht naelC

Failure to follow any of the above instructions could result in severe personal

injury to tool user and bystanders or cause damage to tool and property.

WARNING

4

Page 5

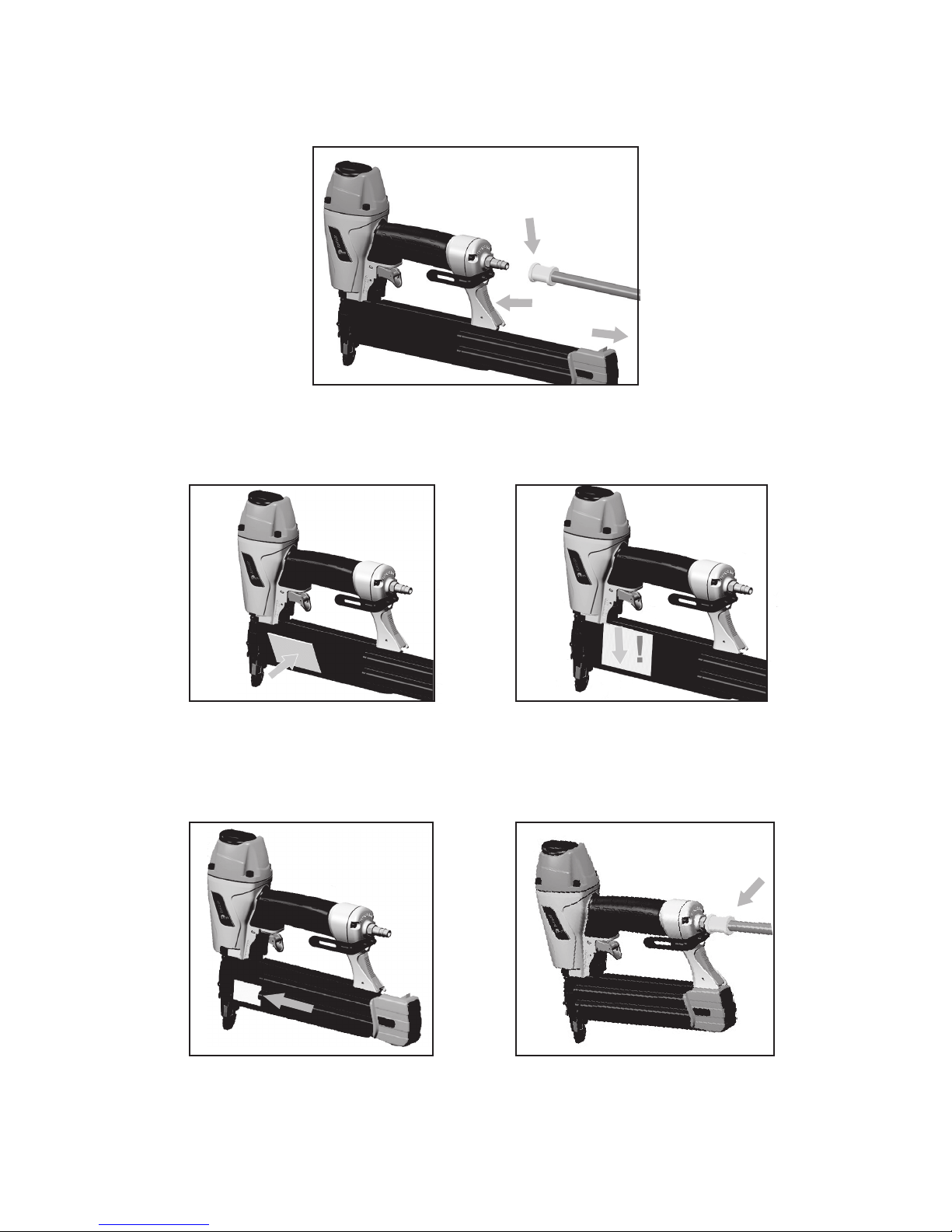

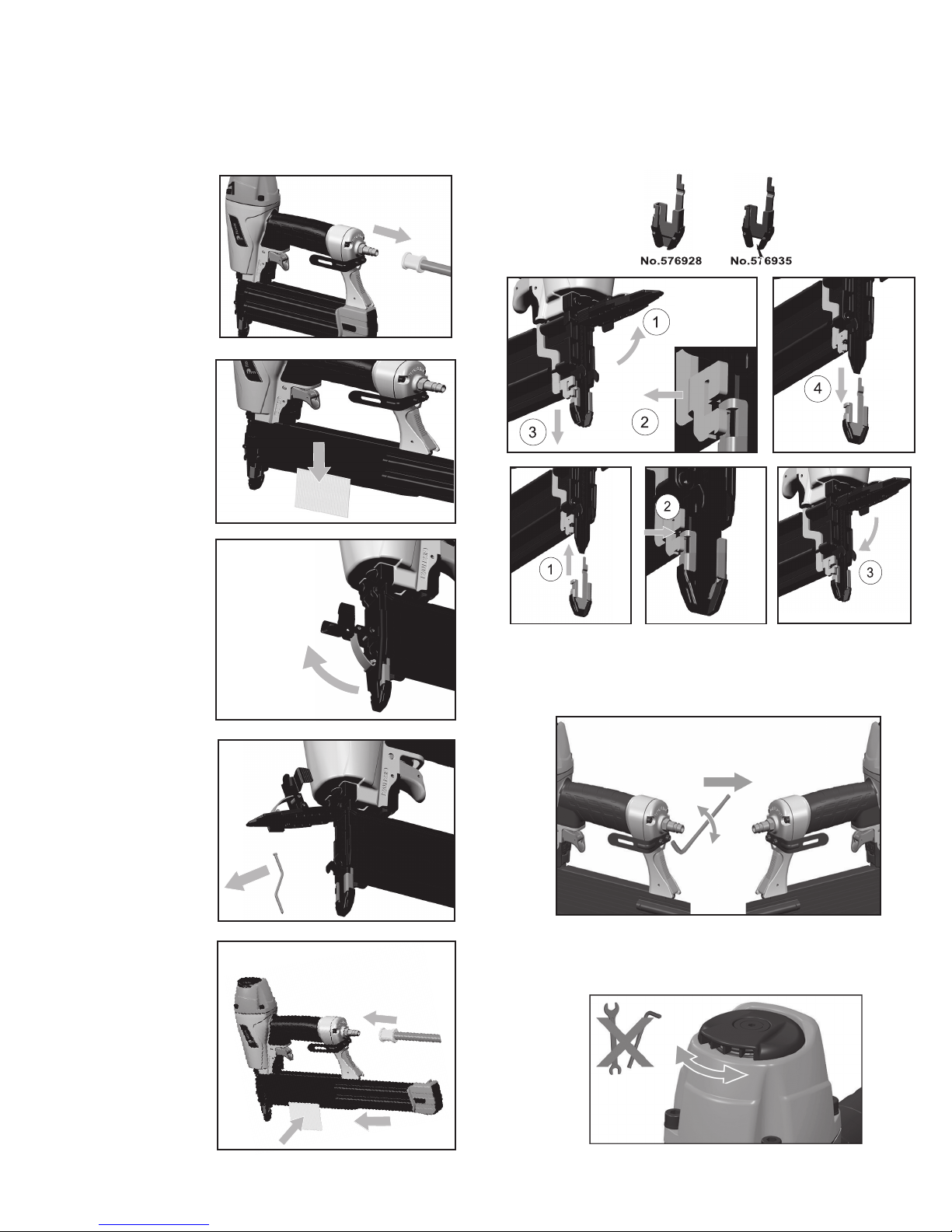

INSTRUCTIONS FOR LOADING

Step No. 1

orange magazine release button at the

– Disconnect the tool from its air source.Grasp the finish nailer firmly with one hand and press the

rear of the

handle and slide the magazine cover back towards you.

Disconnect air

Press release.

Slide cover

Step No. 2 – Insert the strip of 18 gauge brad nails with the point of the fastener facing down and place the point

of the fastener into the bottom of the magazine channel. Placing fasteners on the top of the magazine will cause

jamming.

Step No. 3 – Push the magazine firmly towards the front of the tool until it locks in place.

The tool is now ready to use..

5

Connect the air supply.

Page 6

TOOL OPERATION continued

WARNING

Use only fasteners that meet Paslode specifications.

Use of fasteners that do not meet Paslode specifications can result in damage to the tool or injury to the

operator or bystanders.

®

®

Successive (Bounce) Driving

(Orange Trigger)

■

Grasp the handle firmly.

■

Squeeze the trigger and move the tool along the work-

piece with a bouncing motion, depressing the work con-

tacting element at the points where you want to insert a

fastener.

■

Keep the trigger depressed and continue to bounce the

work contacing element against the workpiece, positioning

the tool above as carefully as possible.

Driving of Nails

Sequential Operation - (Gray Trigger)

The sequential operating kit prevents successive or

“bounce” driving.

■

Depress the work contacting element and hold it against

the work surface before pulling the trigger.

■

After each fastener is driven, completely release the trig-

ger and lift the tool from the work surface.

CHANGING THE TRIGGER

1. Disconnect the tool from air source.

2. Remove trigger step pin rubber retaining ring ( A ).

3. Remove trigger step pin (

4. Remove sequential trigger assembly

C (Gray, part # 576918) and spring.

5. Install contact trigger

with spring and align hole and reinsert Trigger

step pin.

).

B

D (part# 576917,

Orange)

■

When the desired number of fasteners have been driven,

release the tool trigger to avoid unintentional fastener discharge.

Precision Placement Driving

(Orange Trigger)

■

■

Grasp the tool handle firmly and hold the bottom of the

work contacting element firmly against the workpiece until

it is completely depressed.

■

Squeeze the trigger to drive the fastener.

■

Lift the tool from the workpiece.

■

Repeat the procedure for the next fastener.

Adjust the Depth of Drive

6. Reinstall rubber retaining ring and

check for correct operation.

B

C

A

D

6

Page 7

MAINTENANCE

Paslode® tools are built for ease of maintenance. A few

simple details will assure trouble-free operation and long

tool life. Anyone who uses or maintains the tool must read

the safety and maintenance instructions. Study the schematic drawing before starting any repairs on the tool.

Air-operated tools must be inspected periodically, and worn

or broken parts must be replaced to keep the tool operating

safely and efficiently. Also the items on the maintenance

chart must be checked often.

Cold Weather Care

Open the drain on the air compressor tank to drain any

moisture at least daily in extremely cold or humid weather.

A few ounces of anti-freeze in the tank will keep the air

free of frost.

Testing the Tool After Servicing

After replacing any part or parts, it is important to check

the tool for proper operation. This ensures that the tool

was put together correctly, is safe to use, and will perform

the job properly.

Ensure that all hardware is tight.

Ensure that the work contacting element is installed

correctly in relation to the trigger, and that both parts

move freely.

When temperatures are below freezing, tools should be

kept warm by any convenient, safe method. If this is not

possible, the following procedure should be used to warm

up the tools.

Reduce the regulated air pressure to 30 psi.

Remove all fasteners from the tool.

Collect an air line and blank fire the tool. The reduced

air pressure will be enough to free-fire the tool. Slow speed

operation tends to warm up the moving parts. Slowing up

the piston helps the bumper and the O-rings to become

pliable.

Once the tool is warmed up, readjust the regulator to

the proper working pressure and reload the tool.

Tool operators working outdoors or in unheated areas in

extremely cold temperatures should also:

Ensure that the magazine is properly attached.

Ensure that the required safety information on the tool

is legible.

Use only Paslode approved fasteners in the tool, and

ensure that they are correct for the application.

Ensure that a male air fitting is securely connected to

the tool.

Test the tool by driving fasteners into a workpiece

identical to the tool's application.

Check the tool for air leaks during testing and for the

proper sequence of operation.

Ensure that all fasteners are driven to the same depth

and that the crown of the fastener is flush with the

workpiece.

Tool Lubrication

It is most important that the tool be properly lubricated by

keeping the air line lubricator filled and correctly adjusted.

Without proper lubrication the tool will not work properly

and parts will wear prematurely.

Use Paslode pneumatic oil with antifreeze in the

lubricator, Part No. 219090 (8oz.)

Once a week, depending on the amount of tool use,

take the tool apart and wash away any sludge with

degreaser cleaner (Paslode Part No. 219086) to

keep the tool operating efficiently.

Cleaning the air-operated tools with solvents removes the

thin coating of grease applied to the cylinder wall and

O-rings at the factory. To replace this coating of grease,

use Chemplex grease (Paslode Part No. 403734).

Use the proper lubricant in the air line lubricator. The

lubricator should be of low air flow or changing air flow

type, and should be kept filled to the correct level. Use

only Paslode recommended lubricants. Substitutes may

harm the rubber compounds in the tools O-rings and other

rubber parts. Paslode Part No. 403720 is a pneumatic

lubricating oil specially made for pneumatic applications.

If a filter/regulator/lubricator is not installed on the air

system, air operated tools should be lubricated at least

once a day with 6 to 20 drops of oil, depending on the

work environment, directly through the male fitting in the

tool housing.

Most minor problems can be resolved quickly and easily

using the maintenance table that follows. If problems

persist, contact your Paslode dealer for assistance.

7

Page 8

Operation Continued:

Clearing a Jam

Disconnect tool

from

its air source.

Remove all

fasteners.

Unlatch the

front guide and

lift open.

Changing the work contact element.

Disconnect tool from its air source.

Remove jammed

fastener and

relatch

front guide.

Reload fasteners,

close and latch

the magazine.

Reconnect

the air.

Reversable belt hook

Tooless Ajustable Exhaust

8

Page 9

MAINTENANCE

WOHYHWNOITCA

Add several drops of pneumatic

oil into the air fitting.

Check that all screws on tool

are tight.

Keep work contacting elelment

working properly.

Keep magazine and feeder

mechanism clean.

Lubricate "O" rings that are

replaced.

Use only Paslode replacement

parts.

Keep tool lubricated.

Prevent air leakage and promote efficient operation.

Promote operator safety and

efficient tool operation.

Prevent jamming of fasteners.

Assure long life and proper

operation of tool.

Keep tool operating efficiently

and maintain Paslode tool

warranty.

Use Paslode pneumatic

tool lubricant. Part No.

403720.

Check screws daily.

Inspect and blow clean daily

and check for proper operation.

Blow clean daily.

Use Chemplex grease, Part

No. 403734.

Order any replacement parts

needed from Paslode Dealer.

OPERATOR TROUBLESHOOTING

CAUTION

Disconnect the tool when performing

repairs or clearing jams.

PROBLEM CORRECTIVE ACTION

Fasteners will not drive completely into wood.

Fasteners drive too deeply into wood.

Fastener jams in nose of tool.

Tool skips during operation - no fasteners are driven

from time to time.

Adjust the

Increase air pressure (do not exceed 120 psi).

Adjust the

Reduce air pressure.

Open front guide latch, release jammed fastener,

and close latch securely.

Check magazine for proper fasteners. Magazine

follower should slide freely. Clean as needed to

remove debris.

depth of drive adjustment (retract length).

depth of drive adjustment (extend length).

Make sure correct fasteners are being used.

Use fasteners that meet Paslode

9

®

specifications only.

Page 10

Washer

Label, Safety Warning

PARTS LEGEND

1 617539 1 Screw

2 617558 1 Bushing

3 617504 1 Air Deflector

4 576913 1

5

6

8

* 9

10

*

*11

12

*

13

*

14

15

16

*

17

*

18

*

19

*20

*21

22

*

23

*

24

25

*

26

27

28

29

30

34

32

33

35

36

37

38

617533

617535 4 Washer

7

617489 1 Cap

617550 1 Gasket, Cap

617548 1 Seal

617519 1 Spring

617521 1 O-Ring

617510 1 Valve

617527 1 O-Ring

617507 1 Piston Stop

617552 1 Restrict Washer

617551 1 Cylinder Seal

617523 1

576914

617505 1 Cylinder Sleeve

617524 1

617525 1 O-Ring

617503 1 Collar

617522 1 O-Ring

4

Piston Assembly

1

617506 1 Bumper

617508

617526 1 O-Ring

617545 1 Logo-1

617488 1

576915 1

576916 1 Spring

576918 131

617537

617553

576919

576920

617544

617549

617529

1 Joint Guide

1

1 Safety Bracket

1 Spring

1 Safety Lever Unit

1

1

1

Pin

Spring

Screw

O-Ring

O-Ring

Housing

Trigger Valve Assembly

Trigger, Sequential

Spring Pin

Logo-2

Gasket

39 576921

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

**

617513 4

576922 1

576923 1

576966

576924

617547 1

576925 1

617530 1

576926 1 Lock Lever Unit

576927 1 Pin

576928 1 Work Contact A

576929 1 Pusher

617520 1

576967 2 Spring

617538 2 Screw

617511 1 Rear Plate

617536 2

617556 1

617512 1

576930 1

617496 1

576931 1 Label, Trigger Sequential

576934 1 Magazine Unit Sequential

576935 1 Work Contact B

576936 1 Support

617540 1 Screw

617541 1 Pin

617555

576937 1

576938 1

576939 1

576940 1

617534 1

617509 1

576979 1

515620 1

T200-F18P

1 Driver Guide

Screw

Screw

Plate

2

2

Rail

1

Spring Washer

Screw

Washer

Front Plate

PIN

Guide, Spring

Nut

Cover

Cover

Movable Magazine Unit

Lock

Spring

End Cap

Belt Hook

Screw

Air Plug

Guide, Spring

515600

Denotes Normal Wear Items

*

Make sure Warning Label (Part No.515620)

**

is properly affixed. Replace if necessary.

▲

➔

Apply Loctite 242 (Blue) Part N o. 093500

Denotes New Change

®

All parts must be periodically inspected and replaced if

worn or broken. Failure to do this can affect the toolʼs

operation and present a safety hazard.

WARNING

AIR CONSUMPTION-CFM FASTENER

10

AIR CONSUMPTION CHART

.040

.035

.030

.025

.020

.015

.010

AIR PRESSURE-PSIG

.

.034

11010090807060

120

Page 11

10

11

12

13

14

15

16

1

2

3

4

5

6

7

8

9

37

39

40

18

17

26

27

28

36

38

29

30

69

70

71

62

40

72

61

T200-F18P

BRAD NAILER

515600

73

68

67

66

65

40

64

63

19

20

21

22

23

24

25

31

32

33

34

35

A

B

41

42

44 43

45

46

47

48

49

51 52

60

50

59

54 55 56 57

53

58

74

11

Page 12

ACCESSORIES

L

ubricants

.zo 8 ezeerftinA htiw liO gniacirbuL

Tool Cleaner

.sloot edolsaP lla rof renaelc laedI

Safety Glasses

raelC

Tool Case

Handy carrying case that conveniently stores

your tool

027304 .oN traP.zo 61 liO gnitacirbuL

090912 .oN traP

437304 .oN traP.bl1 tnacirbuL 017 xelpmehC

680912 .oN traP

382104 .oN traP

.seirossecca lanoitidda rof moor htiw

515615 .oN traP

Tool Case Latch

Work Contact Element A B

Contact Trigger (Orange)

A

B

617559 .oN traP

576928 .oN traP

576935 .oN traP

576917 .oN traP

P

© 2017, Illinois Tool Works Inc.

An Illinois Tool Works Company

155 Harlem Avenue

Glenview, IL 60025

Page 13

12

Glenview, IL 60025

155 Harlem Avenue

An Illinois Tool Works Company

© 2017, Illinois Tool Works, Inc.

PRINTED IN U.S.A.

P

576917

576935 Pieza No.

576928 Pieza No.

617559 Pieza No.

515615

Pieza No.

B

A

Pieza No.

Contacto Trigger (anaranjado)

A B

Elemento de Contacto de Trabajo

Pestillo de Reemplazo

Maletín de Herramientas

su herramienta con espacio para accesorios adicionales.

Práctico estuche que almacena convenientemente

Maleta de Transporte para Herramientas

Pieza No. 401382

Pieza No. 219348

Pieza No. 403734

Pieza No. 219090

Pieza No. 403720

Claros

Lentes de Seguridad

®

El limpiador ideal para todas las herramientas Paslode.

Desengrasador

Lubricante Chemplex® 710 1lb.

Aceite Lubricante con Anticongelante 8 oz.

Aceite Lubricante 16 oz.

L

ubricantes

ACCESORIOS

Page 14

74

11

60

58

25

53

54 55 56 57

59

50

62

61

63

51 52

49

48

47

46

45

44 43

42

41

40

39

38

36

35

34

33

32

B

31

A

30

29

28

27

24

23

22

21

20

19

18

17

16

15

14

64

40

65

66

67

68

73

40

515600

BRAD NAILER

T200-F18P

72

71

70

69

37

26

13

12

11

10

9

8

7

6

5

4

3

2

1

Page 15

10

Washer

Label, Safety Warning

120

11010090807060

.034

.

PRESIÓN DE AIRE

CONSUMO DE AIRE -SCFM SUJETADOR

.010

.015

.020

.025

.030

Guide, Spring

Air Plug

Screw

Belt Hook

End Cap

Spring

Lock

.035

.040

TABLA DE CONSUMO DE AIRE

515620 1

576979 1

617509 1

617534 1

576940 1

576939 1

576938 1

576937 1

1

617555

617541 1 Pin

617540 1 Screw

576936 1 Support

576935 1 Work Contact B

576934 1 Magazine Unit Sequential

1 Label, Trigger Sequential

Rail

Movable Magazine Unit

Cover

Cover

2

Nut

576931

617496 1

576930 1

617512 1

617556 1

617536

617511 1 Rear Plate

617538 2 Screw

576967 2 Spring

Guide, Spring

617520 1

576929 1 Pusher

576928 1 Work Contact A

576927 1 Pin

576926 1 Lock Lever Unit

PIN

Front Plate

Washer

Screw

2

Spring Washer

2

Plate

1

Screw

1

Screw

1 Driver Guide

617530 1

576925 1

617547 1

576924

576966

576923

576922

617513 4

presentar un riesgo de seguridad.

esto puede afectar el funcionamiento de la herramienta y

y ser reemplazadas si estan gastadas o rotas. Falta de hacer

Todas las piezas deben ser inspeccionadas periódicamente

ADVERTENCIA

este bien pegada. Reemplaze si es necesario.

Pin

**

75

74

73

72

1

Gasket

1

1

Logo-2

1 Safety Lever Unit

71

70

69

68

67

66

65

64

63

62

61

60

59

58

57

56

55

54

53

52

51

50

49

48

47

46

45

44

43

42

41

40

39 576921

Spring Pin

Trigger, Sequential

Trigger Valve Assembly

Housing

O-Ring

Piston Assembly

O-Ring

Screw

Spring

1 Spring

1 Safety Bracket

1

1 Spring

1 Joint Guide

1

1

4

617529

617549

617544

576920

576919

617553

617537

576918 131

576916

576915 1

617488 1

617545 1 Logo-1

617526 1 O-Ring

617508

617506 1 Bumper

617522 1 O-Ring

617503 1 Collar

617525 1 O-Ring

617524 1

617505 1 Cylinder Sleeve

576914

617523

617551 1 Cylinder Seal

617552 1 Restrict Washer

617507 1 Piston Stop

617527 1 O-Ring

617510 1 Valve

617521 1 O-Ring

617519 1 Spring

617548 1 Seal

617550 1 Gasket, Cap

617489 1 Cap

617535 4 Washer

617533

38

37

36

35

33

32

30

29

28

27

26

*

25

24

23

*

*

22

*21

*20

19

*

18

*

17

*

16

15

14

*

13

*

12

*11

*

10

* 9

8

7

6

5

4 576913 1

3 617504 1 Air Deflector

1 617539 1 Screw

**

Asegure que la Etiqueta de Advertencia (515620)

*

Indica piezas de desgaste normal.

34

2 617558 1 Bushing

515600

T200-F18P

LISTA DE PIEZAS,

Page 16

9

®

ciones de Paslode.

Use solamente sujetadores que reúnan las especificaVerifique que se usen los sujetadores apropiados.

Límpielo para quitar cualquier suciedad.

piados. El transportador debe deslizarse sin dificultad.

Compruebe si el cargador tiene los sujetadores apro-

segura.

sujetador atascado, Y cierre el seguro de forma

Abra el pestillo de la guía delantera, suelte el

Reduzca la presión de aire.

(alargar la longitud).

Ajuste la profundidad del ajuste del accionamiento

Aumente la presión de aire (no debe exceder 120 psi).

(longitud de retracción).

Ajuste la profundidad de ajuste del accionamiento

vez en cuando no impulsa sujetadores.

La herramienta “salta” mientras está funcionando; de

ramienta.

Los sujetadores se acumulan en la punta de la her

Los sujetadores penetran demasiado en la madera.

madera.

Los sujetadores no penetran completamente en la

PROBLEMA SOLUCIÓN

reparación o eliminar cualquier obstrucción.

Desconecte la herramienta al hacer cualquier

PRECAUCIÓN

DETECCION Y CORRECCION DE FALLAS

®

Paslode.

Use solamente piezas de repuesto

repuesto que necesite.

Paslode cualquier pieza de

Solicite al representante de

Paslode.

mantener vigente la garantía de

funcionando eficientemente y

Para que la herramienta continúe

adecuado.

N° 403734.

®

Use grasa lubricante Chemplex

herramienta y su funcionamiento

Para prolongar la vida de la

sujetadores.

Límpielos con aire a diario.

Par prevenir que se obstruyan los

hayan reemplazado.

Lubrique los anillos-o que se

del cargador y del alimentador.

Mantenga limpios los mecanismos

de la herramienta.

funciona correctamente.

Revise si el elemento de contacto

Límpielo con aire a diario.

operador y el buen funcionamiento

Para promover la seguridad del

de la herramienta.

Revise los tornillos a diario.

N° 403720 (474 ml).

Llene con lubricante neumático

asegurar el buen funcionamiento

Para evitar pérdidas de aire y

herramienta.

Para mantener lubricada la

la herramienta estén apretados.

Verifique que todos los tornillos de

Mantenga lleno el lubricador.

ACTIVIDAD POR QUE COMO

TABLA DE MANTENIMIENTO

MANTENIMIENTO

Page 17

8

el aire.

Vuelva a conectar

la revista.

cerrar y bloquear

Escape sin herramientas de Ajustable

sujetadores,

Recargar

delantera.

y bloquee la guía

atascado y cierre

Retire el sujetador

Gancho de cinturón reversible

Desconecte la herramienta de su fuente de aire.

levante abierto

guía delantera y

Desenganchar la

sujetadores.

Quite todos los

su fuente de aire.

herramienta de

Desconecte la

de trabajo.

Cambiar el elemento de contacto

Limpiar un Atasco

Operación Continuada:

Page 18

7

®

-

-

-

®

®

-

comuniquese con el representante de Paslode.

28

queños problemas. Si un determinado problema persiste,

resolver rápidamente y fácilmente la mayoría de los pe

Usando la siguiente tabla de mantenimiento es posible

realice, directamente a través del adaptador macho.

y 20 gotas de aceite, según sea el tipo de trabajo que se

lubricadas, por lo menos, diariamente, poniendo entre 6

ma neumático, las herramientas neumáticas deben ser

Si no se instala un filtro/regulador/lubricador en el siste-

cialmente diseñado para aplicaciones neumáticas.

cante N° 403720 (474 ml) es un aceite lubricante espe

caucho de los anillos-o y otras piezas de caucho. El lubri

por Paslode porque otros lubricantes podrian dañar el

variable, y tiene que estar lleno hasta el nivel apropiado

aire. El lubricador debe ser para corriente de aire baja o

Use el lubricante apropiado en el lubricador de la línea de

se gastarán prematuramente.

herramienta no funcionará como es debido y sus piezas

correctamente regulado. Sin la lubricación apropiada, la

manteniendo lleno el lubricador de la línea de aire y

Es muy importante lubricar la herramienta correctamente,

®

PRECAUCIÓN

Lubricación de la Herramienta

dor esté al ras con el material de trabajo.

a la misma profundidad y que la cabeza del sujta-

■

Asegure que todos los sujetadores sean impulsados

apropiada de funcionamiento.

ramienta durante las pruebas y revise la secuencia

■ Verifique que no haya pérdidas de aire en la her-

unmaterial de trabajo idéntico al de la aplicación.

■ Pruebe la herramienta impulsando sujetadores en

adaptador macho a la herramienta.

■

Verifique que se haya conectado firmemente un

aplicación.

y compruebe que sean los apropiados para su

■

Use solamente sujetadores aprobados por Paslode

está en la herramienta, sea legible.

■

Verifique que la información sobre seguridad, que

correctamente.

■ Verifique que el cargador esté colocado

que ambas piezas se muevan libremente.

correctamente instalado en relación con el gatillo y

■

Compruebe que el elemento de contacto haya sido

■ Verifique que ninguna pieza esté floja.

cione correctamente.

rectamente, que la herramienta esté segura y que fun

Esto asegura que todas las piezas estén puestas corcomprobar si la herramienta funciona como es debido.

Después de reemplazar una o más piezas, es importante

Servicio

-

PRECAUCIÓN

la capa de grasa lubricante.

los-o. Use grasa Chemplex N° 403734 para reemplazar

aplica en la fábrica, de la pared del cilindro y de los anilse destruye la delgada capa de grasa lubricante, que se

Al usar solventes para limpiar herramientas neumáticas

inflamable par limpiar la herramienta.

Nunca use queroseno ni ningún solvente

que la herramienta siga funcionando bien.

219348, para eliminar cualquier suciedad y asegurar

herramienta, desármela y lávela con el solvente N°

■

Una vez por semana, según el uso que le dé a su

(8 oz.).

aceite neumático con anticongelante N° 219090

frías también tienen que usar en el lubricador el

sin calefacción con temperaturas extremadamente

■ Los operadores que trabajen al aire libre o en áreas

trabajar y cargue de nuevo la herramienta.

nuevamente el regulador a la presión apropiada para

■

Una vez que la herramienta se haya calentado, ajuste

alta presión.

Nunca dispare la herramienta sin clavos a

elasticidad al amortiguador y los anillos-o.

Disminuyendo la velocidad del pistón le da cierta

tiene la tendencia de calentar las partes movibles.

para lograrlo. El funionamiento a poca velocidad

sin clavos. La presión reducida del aire será suficiente

■

Conecte una línea de aire y dispare la herramienta

■ Quite todos los sujetadores de la herramienta.

■ Disminuya la presión regulada del aire a 30 psi.

para calentar las piezas de la herramienta.

contrario, aconsejamos seguir el siguiente procedimiento

ambiente por el método más seguro y conveniente. De lo

las herramientas deben mantenerse a la temperatura

Cuando la temperatura es inferior a la de congelamiento,

Cuando Hace Mucho Frio

de mantenimiento frecuentemente.

eficiencia y sin peligro. Además, se debe revisar la tabla

rioradas para que la herramienta siga funcionando con

mente, y se deben cambiar las piezas gastadas o dete

Las herramientas neumáticas deben revisarse periódica-

Probar la Herramienta Después de Darle

de hacer cualquier reparación.

la humedad se congele.

cantidad de descongelante en el tanque evitará que

humedad sea muy alto. Poniendo una pequeña

humedad, cuando haga mucho frío o el grado de

que del compresor del aire para eliminar cualquier

■ Abra, por lo menos diariamente, el drenaje del tan-

®

seguridad y mantenemiento. Estudie los diagramas antes

mantener la herramienta deben leer las instrucciones de

lo procedimiento. Las personas encargadas de usar y

de la vida de la herramienta se logran siguiendo un sencilsimple. Su funcionamiento sin problemas y la prolongación

El mantenimiento de cualquier herramienta Paslode es

MANTENIMIENTO

Page 19

6

D

A

C

B

de clavado

Ajustar la profundidad

y compruebe su correcto funcionamiento.

próximo sujetador.

■

Repita el mismo procedimiento con el

trabajo.

■

Separe la herramienta del material de

■

Apriete el gatillo para disparar el sujetador.

insertar el pasador de paso del gatillo.

el material de trabajo.

elemento de contacto quede bien apoyada en

mango y sosténgala de modo que el base del

■

Tome firmamente la herramienta por el

Colocación precisa

ninguna otra cosa que no sea la mano.

No sujete ni sostenga el gatillo con

6. Vuelva a instalar el anillo de retención de caucho

vuelva a

#576917)con resorte y alinee el orificio y

5. Instalar Contacto gatillo (D),naranja, parte

(Gris, Parte # 576918) y resorte.

4.Retire el conjunto de gatillo secuencial (C)

3.

Retire el pasador del gatillo (B)

2. Retirar el anillo de retención

1. Desconecte la herramienta de la fuente de aire.

CAMBIANDO EL DISPARADOR

PELIGRO

trabajo.

y levante la herramienta del material de

evitar que salgan más.

gatillo para

sujetadores necesarios, deje de oprimir el

Una vez que haya colocado todos los

■

colocando cuidadosamente la herramienta.

de contacto contra el material de trabajo,

continúe haciendo rebotar el elemento

Manteniendo apretado el gatillo,

■

un sujetador.

en los lugares donde quiera colocar

oprimiendo el elemento de contacto

trabajo con un movimiento de rebote,

herramienta a lo largo del material de

■ Apriete el gatillo y mueva la

el mango.

■ Tome la herramienta firmemente por

(Gatillo de color Naranja)

Impulsos sucesivos (de rebote)

sujetador, suelte completamente el gatillo

■

Después de haber impulsado cada

de trabajo antes de apreter el gatillo.

manténgalo apoyado contra el material

■

Oprima el elemento de contacto y

evita los impulsos sucesivos o "de rebote".

El juego de funcionamiento en secuencia

Funcionamiento en secuencia

(Gatillo de Color Gris)

La conducción de clavos

(continuación)

HERRAMIENTA

FUNCIONAMIENTO DE LA

Page 20

5

lugar. Conecte el suministro de aire. La herramienta está lista para usar.

Paso No. 3 - Empuje el cargador firmemente hacia la parte delantera de la herramienta hasta que encaje en su

deslizante

Tapa

Presione soltar.

el aire

Desconectar

revista causará atascos.

punto del sujetador en la parte inferior del canal del cargador. Colocar sujetadores en la parte superior de la

Paso No. 2 - Inserte la tira de clavos de calibre 18 con el punto de los sujetadores hacia abajo y coloque el

cubierta del cargador hacia usted.

una mano y presione el botón de liberación del cargador naranja en la parte posterior de la manija y deslice la

Paso No. 1 - Desconecte la herramienta de su fuente de aire. Sujete firmemente la clavadora de acabado con

INSTRUCCIONES DE CARGA

Page 21

4

Seguridad.

Comuníquese con el representante de Paslode sobre la presentación de Programa de Alerta sobre

.

ella o de daños materiales o a la herramienta

lesiones personales, tanto al operador de la herramienta comoa quienes estén cerca de

La falta de observación de cualquiera de estas instrucciones puede ser causa de graves

PELIGRO

producirse un disparo imprevisto.

gación correcta.

de la herramienta sobre el número de cada parte y su ublilas etiquetas de precaucíon que flaten. Consulte el diagrama

pueden crear situaciones peligrosas. Vuelva a colocar todas

autorizados o se modifica de alguna forma la herramienta, se

y para la tarea requerida. Si se usan piezas o sujetadores no

recomendados por Paslode para usar con esa herramienta

Use sólo piezas y sujetadores específicamente diseñados y

MENDADOS POR PASLODE

USE SOLAMENTE PIEZAS Y SUJETADORES RECO-

sucia o defectuosa.

una herramienta

comienda. Nunca trate de hacer funcionar

Limpie diariamente la herramienta y lubríquela como se re-

CION APROPIADA

INSPECCIONE LA HERRAMIENTA PARA LA OPERA-

No haga funcionar en atmósferas explosivas.

funcionar la herramienta porque podrían hacer que explotara.

Nuna use aire o gases envasado, como el oxígeno, para hacer

el calibre de la presíon neumática funcione correctamente.

en la herramienta. Verifique por lo menos dos veces al día que

comendada. No exceda la presíon neumática máxima marcada

La herramienta debe funcionar sólo con la presíon neumática re-

RECOMENDADA

NO EXCEDA LA PRESION NEUMATICA MAXIMA

lista para disparar por lo menos un sujetador.

desconectar la línea de aire comprimido, dejándola cargada y

en la herramienta, porque atrapan el aire a alta presíon al

NUNCA coloque enlaces HEMBRAS de desconexíon rápida

comprimido.

síon salga tan pronto como se desconecte la línea de aire

neumáticos MACHOS, para permitir que el aire de alta preSe debe conectar a la herramienta solamente conectores

PARA SU HERRAMIENTA

USE SIEMPRE LOS ADAPTADORES APROPIADOS

y quitado todos los sujetadores.

mienta sin haberla desconectado de la línea de aire compromido

Nunca trate de eliminar obstrucciones o reparar una herra-

REPARACIONES O ELIMINAR OBSTRUCCIONES

DESCONECTE LA HERRAMIENTA PARA HACER

del área de trabajo, ni ningún otro detalle.

se debe grabar en su superficie el nombre de su compañia, el

El armazón de la herramienta es un recipiente a presión y nunca

NO ALTERE EL ARMAZON DE LA HERRAMIENTA

podría disparar un sujetador y herirlo o herir a otra persona.

tome por la manguera o con el gatillo oprimido, porque se

Siempre tome la herramienta sólo por el mango. Nunca la

MANGO

TOME LA HERRAMIENTA SOLAMENTE POR EL

que dicho elemento funcione correctamente, porque podría

ni quite el elemento de contacto. No use la herramienta a menos

aro accidental. Nunca manipule indebidamente, deje inoperante,

dad, llamado elemento de contacto, para prevenir cualquier dispEsta herramienta está equipada con un mecanismo de seguri-

CONTACTO

NO DEJE INOPERANTE NI QUITE EL ELEMENTO DE

porque los sujetadores podrían atravesar o salirse del material.

material sea delagado o trabaje cerca de las aristas del mismo,

con el material de trabajo. Debe tener mucho cuidado cuando el

La herramienta debe funcionar sólo cuando esté en contacto

MATERIAL DE TRABAJO

USE LA HERRAMIENTA SOLAMENTE SOBRE UN

el elemento de contacto estén oprimidos.

línea de aire comprimido esté desconectada y que ni el gatillo ni

Antes de cargar sujetadores en la herramienta, verifique que la

OPRIMIDO.

EL GATILLO O EL ELEMENTO DE CONTACTO ESTE

AIRE COMPRIMIDO ESTE CONECTADA, O CUANDO

NO CARGUE SUJETADORES CUANDO LA LINEA DE

de contacto.

porque se podría disparar un sujetador al oprimirse el elemento

gatillo, o sujetarlo en la posición de cierre o defuncionamiento,

Nunca se debe manipular indebidamente o dejar inoperante el

CIERRE O DE FUNCIONAMIENTO

NUNCA SUJETE EL GATILLO EN LA POSICION DE

sujetador que no esté a la vista.

a otra persona con la herramienta, porque podría dispararse un

crea que está vacía o desconectada, nunca se apunte ni apunte

Verfique que ho haya sujetadores en elcargador. Aun cuando

NUNCA ASUMAQUE LA HERRAMIENTA ESTA VACIA

otra persona, aun cuando crea que no está cargada.

tal. Nunca juguetee con ella, ni se apunte a usted mismo ni a

Esta herramienta no es un juguete; por lo tanto no la trate como

NUNCA USE LA HERRAMIENTA PARA JUGUETEAR

como un martillo.

No arroje la herramienta al suelo; no golpee el armazón ni la use

PROPOSITO CON QUE FUE DISEÑADA

USE SU HERRAMIENTA SOLAMENTE PARA EL

uso.

sombreros duros en los ambientes que requieren su

able de imponer el usp del la porteccion de ojo. Lleve

herramienta en uso. Como empleador usted es responsmeintras usa una herramienta o trabaja cerca de una

los ojos y los oídos que sea conforme con ANZI Z87,

Use siempre el equipo adecuado para protegerse

PROTEJASE LOS OJOS Y LOS OIDOS

esté familiarizada con ella podría lastimarse o lastimar otros.

trabajo. Nunca la descuide, porque cualquier persona que no

comprimido cuando no la esté usando o al dejar su lugar de

Siempre desconecte la herramienta de la línea de aire

LA ESTE USANDO

DESCONECTE LA HERRAMIENTA CUANDO NO

ciones de este manual.

tendido todas las precauciones de seguridad y las instruc-

trate de usar su herramienta hasta que no haya léido y en-

el funcionamiento sin peligrode las herramientas Paslode. NO

Estas instrucciones proporcionan la información necesatia para

LA SEGURIDAD ESTA PRIMERO

INSTRUCCIONES DE SEGURIDAD

Page 22

3

19

NO EXCEDA LA PRESIÓN DE AIRE RECOMENDADA.

esta gama para obtener el mejor rendimiento.

70 hasta120 p.s.i. Seleccione una presión de aire dentro de

OPERACION de PRESIÓN de AIRE:

del suministro de aire.

capaz de descargar la presión de aire en la herramienta cuando sea desconectada

Esta herramienta utiliza un tapón macho de 1/4" N.P.T. El acoplamiento debe ser

ACOPLAMIENTO DE AIRE:

DIAMETRO DEL TALLO 18 gauge

LONGITUD DEL CLAVO 5/8" to 2”

ESPECIFICACIONES de los SUJETADORES

PRESIÓN de OPERACIÓN 70 hasta 120 p.s.i. (6.2 hasta 8.3 bar)

PESO 2.9 lbs.

LONGITUD 10.04"

ANCHO 2.56"

ALTURA 10.63”

NO. de MODELO T2OO-F18P (Pieza# 515600)

ESPECIFICACIONES DE LA HERRAMIENTA

ESPECIFICACIONES DE LA HERRAMIENTA Y LOS SUJETADORES

Page 23

2

18

®

OPERACIÓN O CUALQUIER OTRO.

RIORO DE MATERIALES, AUMENTOS EN EL COSTO DE

PRODUCCIÓN O GANANCIAS ANTICIPADAS, EL DETECUALQUIER DAÑO RESULTADO DE LA PÉRDIDA DE

CONSECUENTE INCLUYENDO, PERO SIN LIMITARSE,

CASO POR NINGÚN DAÑO DIRECTO, INDIRECTO O

lo estipulen las leyes pertinen-

mienta.

que afecte o sea

Paslode hayan

piezas que no

®

Paslode,

que no reúnan

ía por

®

®

®

®

®

tes. PASLODE NO SERÁ RESPONSABLE EN NINGÚN

herramienta, excepto según

o estén relacionadas con el uso y funcionamiento de la

ARRIBA reemplaza a todas las otras garantías que resulten

de Paslode TAL COMO SE INDICA Y SE ASUME MÁS

LO DECLARADO ANTERIORMENTE, y la responsabilidad

CUALQUIER OTRA NATURALEZA, CON EXCEPCIÓN DE

CIALIZACIÓN O ADAPTACIÓN AL USO PREVISTO, O DE

PLÍCITA O IMPLÍCITA CON RESPECTO A LA COMERPASLODE NO OTORGA NINGUNA GARANTÍA EX -

contraria al funcionamiento de la herra

sido modificadas o reparadas de manera

sean marca Paslode, o que en opinión de

adecuado, o que haya sido reparada con

o a la que no se le haya dado el mantenimiento o el uso

especificaciones, el tamaño o la calidad de

las

intencionalmente,usada con sujetadores

haya sido usada incorrectamente, dañada accidental o

Se cancelará esta garantía a cualquier herramienta que

desgaste normal.

que necesitan ser repuestas como consecuencia de su

al accesorio originales. Esta garantía no cubre las piezas

el período restante de la garantía que cubría a la pieza o

conformidad con esta garantía, gozará de la garant

Cualquier pieza o accesorio de repuesto, entregado de

como defectuoso dentro del período especificado.

poner cualquier pieza o accesorio que se compruebe

Paslode asume únicamente la responsabilidad de re-

que fue proporcionada con su herramienta.

Estados Unidos, véa la lista de Centros de Servicio

más información sobre el servicio de garantía en los

das y revisadas en los Estados Unidos. Para obtener

Esta garantía esta limitada a las herramientas vendi-

DECLARACIÓN DE LA GARANTÍA

90

DÍAS

diseños en cualaquier momento, sin aviso previo y sin incurrir en obligación alguna.

Paslode se reserva el derecho de cambiar las especificacionnes, el equipo o los

• Anillos del pistón

• “O rings”

• Hojas del impulsor

• Amortiguador

por ninguna garantía.

que sufren desgaste normal y no están cubiertas

Las siguientes piezas se consideran como piezas

PIEZAS DE DESGASTE NORMAL

una garantía de seis meses.

Todas las piezas del cargador están cubiertas por

tapa están cubiertas por una garantía de un año.

Todas las piezas fundididas del armazón y de la

CIONES EN EL LUGAR DE CONSTRUCCION.

GARANTIA LIMITADA ADICIONAL PARA APLICA-

mente cubiertas por una garantía extendida.

piezas, con excepción de las que estén especifica-

La garantia limitada de 90 días cubre todas las

GARANTIA LIMITADA DE

la fecha de compra del comprador original.

cación por el período indicado más abajo, a partir de

nuevos, están libres de defectos de material y fabri-

sus piezas y accesorios, que hayan sido comprados

Paslode garantiza que sus herramientas mecánicas,

®

TERMINOS DE LA GARANTÍA

CONTENIDO

le herramienta correctamente.

Lea cuidadosamente este manual y las instrucciones

es una herramienta de calidad, diseñada para uso en

T200-F18P

®

reglas del fabricante.

residenciales. Esta herramienta le provera confiabilidad y eficiencia cuando sea

ACCESORIOS....................................................................................................................12

VISTA EXPANDIDA CON LISTADO DE PIEZAS...........................................................10-11

INSTALACIÓN Y OPERACIÓN DE LA HERRAMIENTA.....................................................5

INSTRUCCIONES DE SEGURIDAD................................................................................... 4

ESPECIFICACIONES DE LA HERRAMIENTA Y SUS SUJETADORES............................3

de seguridad para comprender como usar

usada acorde con las

aplicaciones

La herramienta Paslode

INTRODUCCIÓN

Page 24

17

Esquema

Manual de Funcionamiento y

¡IMPORTANTE!

entienda este manual.

el personal de operaciones y servicio lea y

El cliente tiene la responsibilidad de que todo

NO DESTRUYE ESTE MANUAL

Calibre 18 Clavadora Brad

T200-F18P

Pieza# 515600

MODELO

Loading...

Loading...