Page 1

P

Part No. 515500

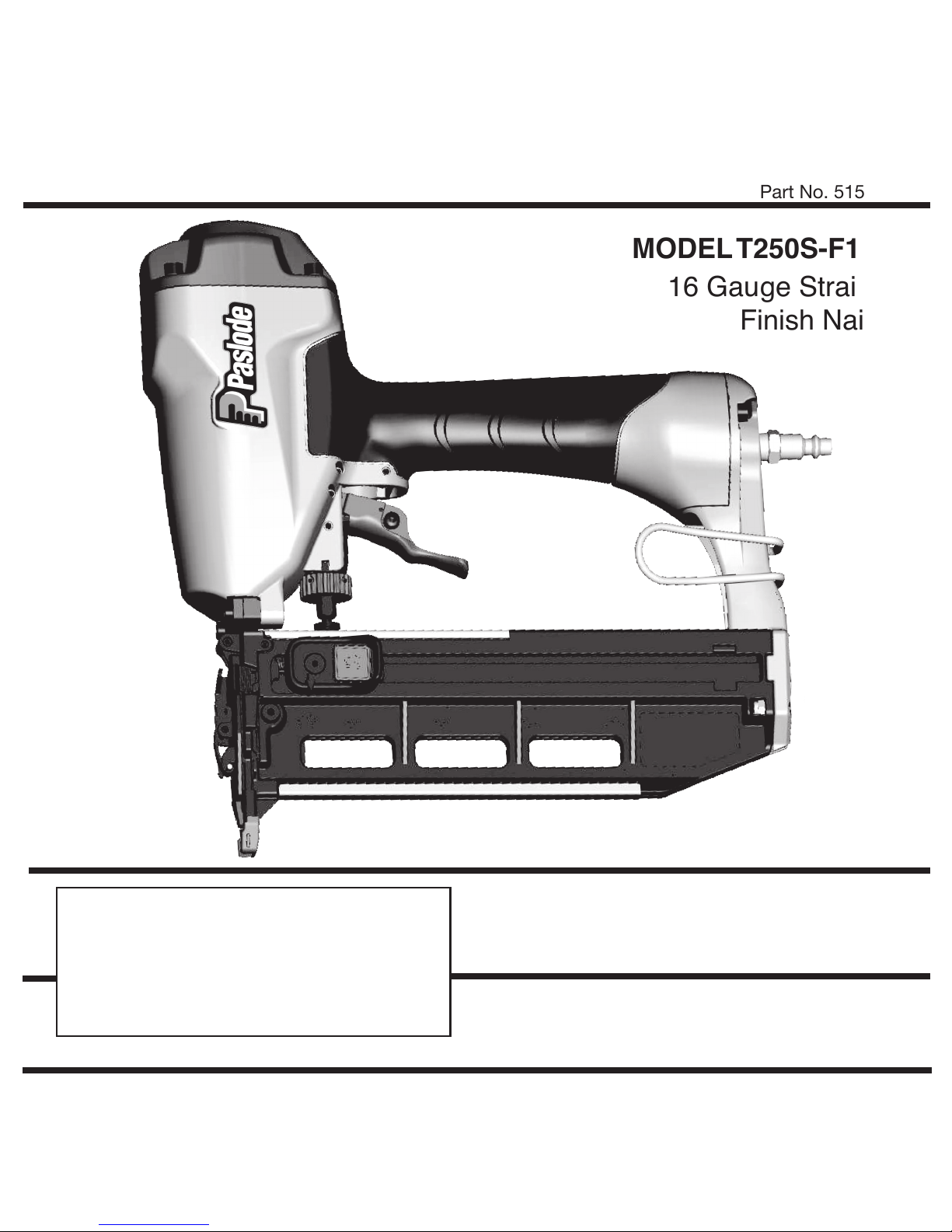

MODEL

T250S-F16P

16 Gauge Straight

Finish Nailer

IMPORTANT!

DO NOT DESTROY

It is the customerʼs responsibility to have all

operators and service personnel read and

understand this manual.

P

RINTED IN TAIWAN

© 2018, Illinois Tool Works Inc.

219495-2

08/18

OPERATING MANUAL AND

TOOL SCHEMATIC

Page 2

INTRODUCTION

The PASLODE® T250S-F16P

finish nailer is a quality-built tool designed for use in residential

trim applications. This tool will deliver efficient, dependable performance when used according

to the manufactures guidelines. Please study this manual including the safety instructions to

fully understand the operation of this tool.

TOOL AND FASTENER SPECIFICATIONS ....................................................... 3

SAFETY INSTRUCTIONS ...................................................................................4

TOOL OPERATION ..............................................................................................5

EXPLODED VIEW AND SPARE PARTS LIST ..............................................10-11

ACCESSORIES ..................................................................................................12

TOOL WARRANTY AND LIMITATIONS

Paslode warrants that newly purchased power

fastening tools, parts and accessories will be free

from defects in material and workmanship for the

period shown below, after the date of delivery to

the original user.

ONE-YEAR FULL WARRANTY

A one-year warranty will apply to all parts, except

those which are specifically covered by an extended

warranty.

FIVE-YEAR EXTENDED LIMITED WARRANTY

A

five-year warranty will apply to all housing and cap

assembly castings.

WARRANTY STATEMENT

This warranty is limited to tools sold and service requested

in the United States. To obtain information on warranty

service in the United States, refer to the Service Center

listing that was provided with your tool.

Paslode's sole liability hereunder will be to replace any part

or accessory which proves to be defective within the specific

time period. Any replacement part or accessory provided in

accordance with this warranty will carry a warranty for the

balance of the period of warranty applicable to the part it

replaces. This warranty does not apply to part replacement

required due to normal wear.

This warranty is void as to any tool which has been subjected

to misuse, abuse, accidental or intentional damage, use with

fasteners,not meeting

improperly maintained,

Paslode replacement parts,

which, in Paslode's opinion,

way that affects or detracts

Paslode specification, size, or quality,

repaired with other than genuine

damaged in transit or handling, or

has been altered or repaired in a

from the performance of the tool.

Paslode reserves the right to change specifications, equipment, or

designs at any time without notice and without incurring obligation.

PASLODE MAKES NO WARRANTY, EXPRESSED OR

IMPLIED, RELATING TO MERCHANTABILITY, FITNESS, OR

OTHERWISE, EXCEPT AS STATED ABOVE, and Paslode's

liability AS STATED ABOVE AND AS ASSUMED ABOVE is

in lieu of all other warranties arising out of, or in connection

with, the use and performance of the tool, except to the extent

other wise provided by applicable law. PASLODE SHALL IN

NO EVENT BE LIABLE FOR ANY DIRECT, INDIRECT, OR

CONSEQUENTIAL DAMAGES, INCLUDING, BUT NOT

LIMITED TO, DAMAGES WHICH MAY ARISE FROM LOSS

OF ANTICIPATED PROFITS OR PRODUCTION, SPOILAGE

OF MATERIALS, INCREASED COST OF OPERATION, OR

OTHERWISE.

2

Page 3

TOOL AND FASTENER SPECIFICATIONS

TOOL SPECIFICATIONS

MODEL NO. T250S-F16P (Part# 515500)

HEIGHT 11.6"

WIDTH 2.9"

LENGTH 12.3"

WEIGHT 3.9lbs.

OPERATING PRESSURE 80 to 120 p.s.i. (5.5 to 8.3 bars)

FASTENER SPECIFICATIONS

NAIL LENGTH 1" - 2-½"

SHANK DIAMETER 16 gauge

TOOL AIR FITTINGS:

This tool uses a 1/4” N.P.T. male plug. The inside diameter should be .28” (7mm)

or larger. The fitting must be capable of discharging tool air pressure when

disconnected from the air supply.

OPERATING AIR PRESSURE:

80 to 120 p.s.i. (5.5 to 8.3 bars). Select the operating air pressure within this range

for best tool performance.

DO NOT EXCEED THIS RECOMMENDED OPERATING PRESSURE.

3

Page 4

SAFETY INSTRUCTIONS

SAFETY FIRST

These safety instructions provide information necessary

for safe operation of Paslode

TO OPERATE THE TOOL UNTIL YOU READ AND

UNDERSTAND ALL SAFETY PRECAUTIONS AND

MANUAL INSTRUCTIONS.

WEAR EYE AND HEARING PROTECTION

Always wear hearing and eye protection devices, that

conform to ANSI Z87.1 requirements, when operating

or working in the vicinity of a tool. As an employer you

are responsible for enforcing the use of eye protection.

Wear hard hats in environments that require their use.

THE TOOL MUST BE USED ONLY FOR THE PURPOSE FOR WHICH IT WAS DESIGNED

Do not throw the tool on the floor, strike the housing in

any way or use the tool as a hammer to knock material

into place.

NEVER ENGAGE IN HORSEPLAY WITH THE TOOL

The tool is not a toy so do not use it like one. Never

engage in horseplay with the tool or point it at yourself

or any other person, even if you think it is not loaded.

NEVER ASSUME THE TOOL IS EMPTY

Check the magazine for fasteners that may be left in the

tool. Even if you think the tool is empty or disconnected,

never point it at anyone or yourself. Unseen fasteners

could fire from the tool.

NEVER CLAMP THE TRIGGER IN A LOCKED OR

OPERATING POSITION

The trigger of the tool must never be tampered with,

disabled or clamped in a locked or operating position

since this will cause the tool to drive a fastener any time

the work contacting element depressed.

DO NOT LOAD FASTENERS WITH THE AIR LINE

CONNECTED, OR WITH THE TOOL TRIGGER OR

WORK CONTACTING ELEMENT DEPRESSED

When loading fasteners into the tool be sure you

disconnect the air line and that you do not depress

the trigger or work contacting element.

OPERATE THE TOOL ONLY ON A WORKPIECE

The tool should be operated only when it is in contact

with the workpiece. Even then you should be careful

when fastening thin material or working near the edges

and corners of the workpiece since the fasteners may

drive through or away from the workpiece.

DO NOT DISABLE OR REMOVE THE WORK

CONTACTING ELEMENT

This tool is equipped with a safety mechanism, called a

work contacting element, to help prevent accidental

firing. Never tamper with, disable or remove the work

contacting element. Do not use the tool unless the work

contacting element is working properly. The tool could

fire unexpectedly.

®

tools.

DO NOT ATTEMPT

DISCONNECT THE TOOL WHEN NOT IN USE

Always disconnect the tool from the air line when it

is not in use, when you leave the work area or when

moving the tool to a new location. The tool must

never be left unattended because people who are

not familiar with the tool might handle it and injure

themselves or others.

CARRY THE TOOL ONLY BY THE HANDLE

Always carry the tool by the handle only. Never carry

the tool by the air hose or with the trigger depressed

since you could drive a fastener unintentionally and

injure yourself or someone else.

DO NOT WEAKEN THE TOOL HOUSING

The tool housing is a pressure vessel and should never

be weakened by having your companyʼs name, area of

work or anything else stamped or engraved into its

surface.

DISCONNECT THE TOOL WHEN PERFORMING

REPAIRS AND CLEARING JAMS

Never attempt to clear a jam or repair a tool unless you

have disconnected the tool from the air line and removed

all remaining fasteners from the tool.

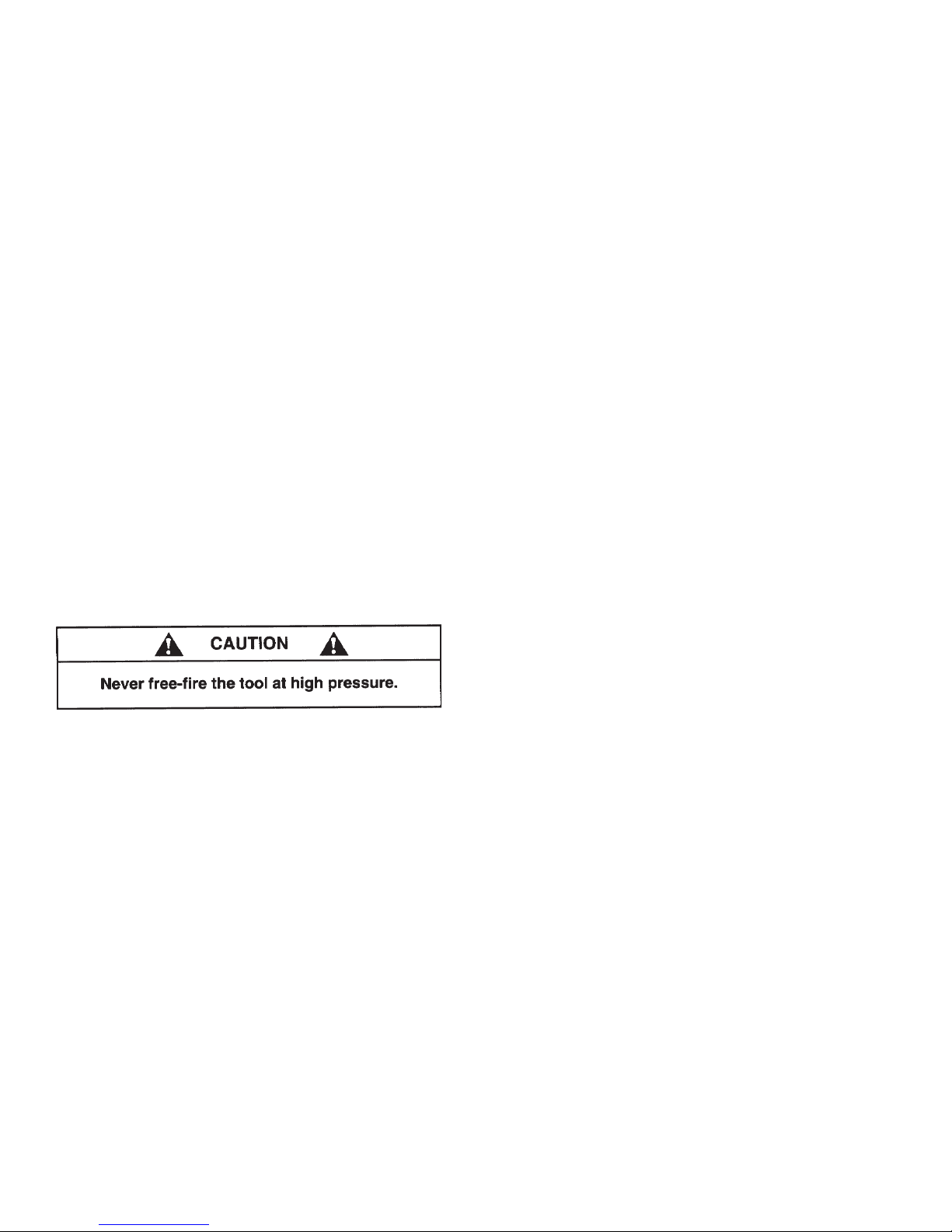

ALWAYS USE THE PROPER FITTING FOR THE

TOOL

Only MALE pneumatic type air connectors should be

fitted to the tool, so that high pressure air in the tool is

vented to atmosphere as soon as the air line is disconnected.

NEVER install FEMALE quick disconnect couplings on

the tool. Female couplings will trap high pressure air in

the tool when the air line is disconnected, leaving the

tool charged and able to drive at least one fastener.

DO NOT EXCEED THE MAXIMUM RECOMMENDED

AIR PRESSURE

Do not exceed the maximum air

the tool. Be sure the air pressure gauge is operating

properly and check it at least twice a day.

Never use any bottled air or gases such as oxygen to

operate the tool since they could cause the tool to

explode. Do not operate in explosive atmospheres.

INSPECT TOOL FOR PROPER OPERATION

USE ONLY PASLODE RECOMMENDED PARTS AND

FASTENERS

Use only parts and fasteners specifically designed and

recommended by Paslode for use in the tool and for

work to be done. Using unauthorized parts and fasteners

or modifying the tool in any way creates dangerous

situations. Replace all missing warning labels. Refer

to tool schematic for correct placement and part number.

pressure marked on

.erusserp ria dednemmocer eht ta ylno loot eht etarepO

Failure to follow any of the above instructions could result in severe personal

injury to tool user and bystanders or cause damage to tool and property.

Contact your local Paslode Representative for presentation of Paslodeʼs Safety Awareness Program

WARNING

4

Page 5

TOOL OPERATION

–

Fasteners

T

he Paslode T250S-F16P Finish Nailer drives

Paslode® 16 gauge fasteners designed to be used

with the tool. The use of fasteners that do not meet

Paslode standards could cause tool damage and

will void all warranty claims.

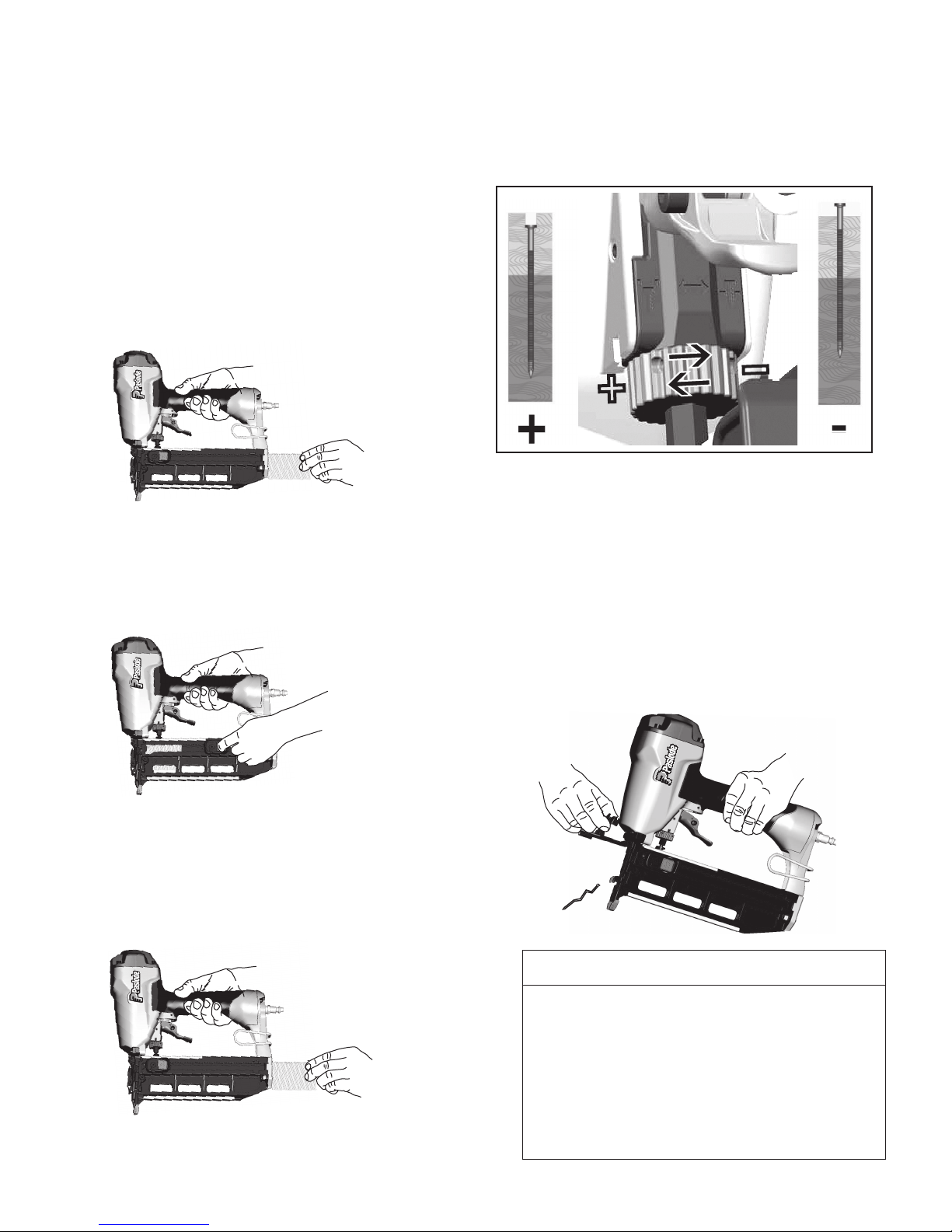

Loading Fasteners

STEP 1: Align the heads of the Paslode 16 ga.Finish

nails to the brad channel in the rear of the magazine

and insert one or two strips. Push the nails strips

forward.

STEP 2: Next,

magazine

fasteners.

push the nails forward into the nose of the tool.

pull the follower toward the rear of the

until the follower passes the last strip of

Release the follower and let the follower

Depth of Drive Adjustment

Disconnect the air supply.

The depth of drive adjustment is done by turning the

adjustment wheel located below the trigger.

–

Clearing a Jam

An occasional problem you may encounter is a jammed

fastener. Because of the unique design of the Paslode

Finish Nailer, clearing a jammed fastener is easy:

1. Disconnect the air supply.

2. Pull the latch, releasing front guide. Pivot front guide

forward.

3. Clear jam, and push driver blade back up to its normal

position.

4. Close front guide and latch it. Check that work

contacting element moves freely.

+

When the follower reaches the reload area, marked

on the side of the magazine, you may insert a new

strip of nails. When the follower arrow reaches the

lockout area the tool automatically locks the tool to

prevent the tool from operating. To unlock the tool,

simply reload another strip of nails.

Lockout Feature

The purpose of this feature is to prevent needless

blank cycling, which could mar woods and damage

tool components.

magazine when the follower reaches the lockout

area. When changing fastener length or loading

at the beginning of the work day, you should inspect

the magazine and nose for any fasteners left in the

These nails will not be

tool.

the nose of the tool.

5

Ten (10) nails will be left in the

visible unless you open

Page 6

TOOL OPERATION

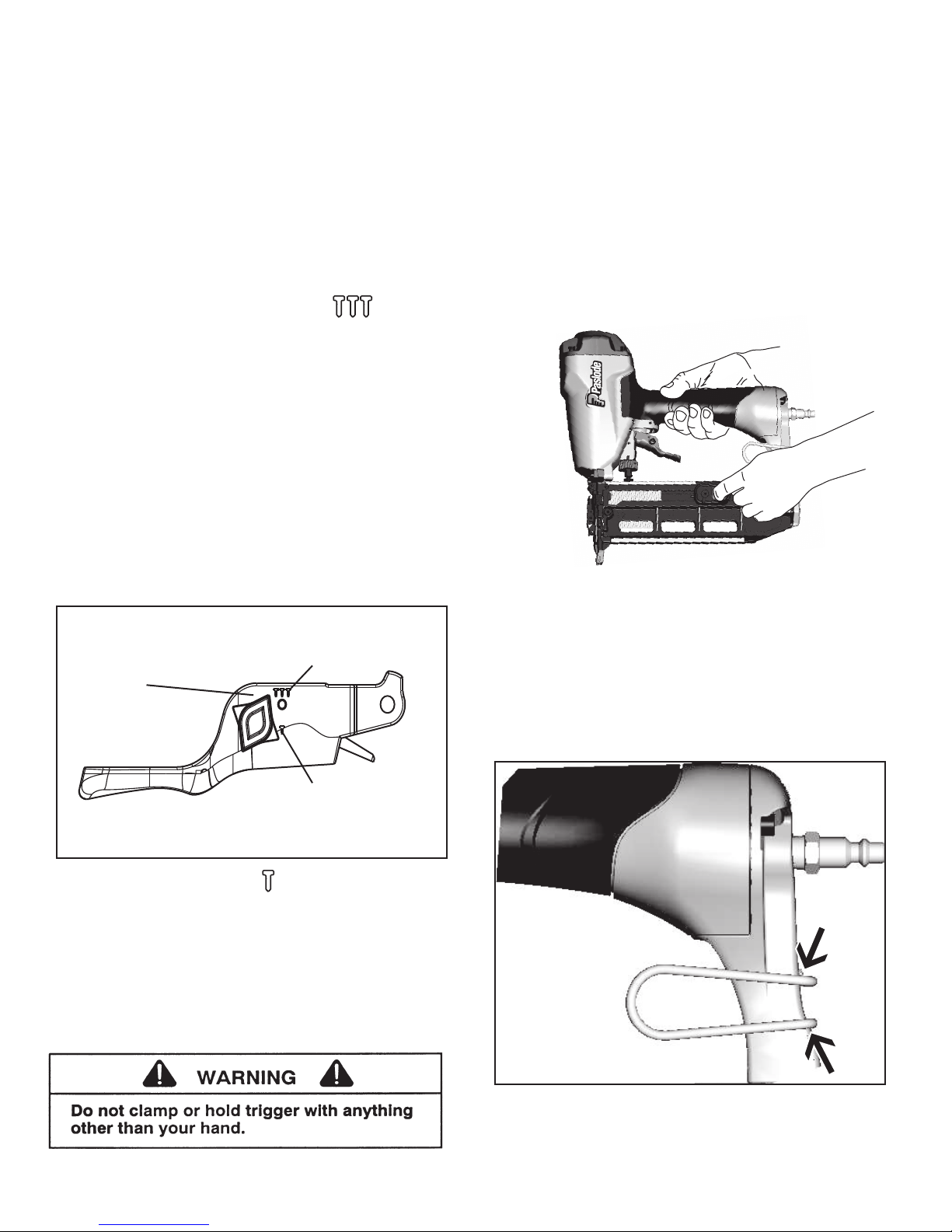

Trigger Methods:

The Paslode T250S-F16P Finish Nailer has a triggering

system than can be switched from sequential to contact

trip. To switch the trigger, press in the round button

on the left side of the trigger and rotate the right side

of the button to the desired triggering method. The TTT

indicates contact trip and the T indicates sequential

operation.

Successive (Bounce) Driving -

Grasp the handle firmly.

Squeeze the trigger and move the tool along the workpiece with a bouncing motion, depressing the work contacting element at the points where you want to drive a

fastener.

Keep the trigger depressed and continue to bounce the

work contacing element against the workpiece, positioning the tool above as carefully as possible.

When the desired number of fasteners have been

driven, release the tool trigger to avoid unintentional

fastener discharge.

Unload Nails:

To unload nails, simply pull the follower to the rear of the

magazine and press the center lock button on the follower.

The lock will move the follower out of the way and allow

nails to slide past the follower and out of the rear of the

magazine. To release the lock simply pull the follower back

and the lock button will release and allow the follower to

move forward.

Successive (Bounce)

Driving

Trigger select

indicator

Sequential

Operation

Sequential Operation -

The sequential setting T prevents succesive or "bounce"

driving.

Depress the work contacting element and hold it

against the work surface before pulling the trigger.

After each fastener is driven, completely release the

trigger and lift the tool from the work surface.

Reversible Belt Hook:

The belt hook can be changed from the left hand side of the

tool to the right hand side. To change the position, squeeze

the base of the belt hook and remove it from the tool and tool

and position it on the desired side.

6

Page 7

MAINTENANCE

Paslode® tools are built for ease of maintenance. A few

simple details will assure trouble-free operation and long

tool life. Anyone who uses or maintains the tool must read

the safety and maintenance instructions. Study the schematic drawing before starting any repairs on the tool.

Air-operated tools must be inspected periodically, and worn

or broken parts must be replaced to keep the tool operating

safely and efficiently. Also the items on the maintenance

chart must be checked often.

Cold Weather Care

When temperatures are below freezing, tools should be

kept warm by any convenient, safe method. If this is not

possible, the following procedure should be used to warm

up the tools.

❑ Reduce the regulated air pressure to 30 psi.

❑ Remove all fasteners from the tool.

❑

Collect an air line and blank fire the tool. The reduced

air pressure will be enough to free-fire the tool. Slow speed

operation tends to warm up the moving parts. Slowing up

the piston helps the bumper and the O-rings to become

springy.

Testing the Tool After Servicing

After replacing any part or parts, it is important to check

the tool for proper operation. This ensures that the tool

was put together correctly, is safe to use, and will perform

the job properly.

❑ Ensure that all hardware is tight.

❑

Ensure that the work contacting element is installed

correctly in relation to the trigger, and that both parts move

freely.

❑ Ensure that the magazine is properly attached.

❑

Ensure that the required safety information on the tool

is legible.

❑

Use only Paslode approved fasteners in the tool, and

ensure that they are correct for the application.

❑

Ensure that a male air fitting is securely connected to

the tool.

❑

Test the tool by driving fasteners into a workpiece identical to the tool's application.

❑

Check the tool for air leaks during testing and for the

proper sequence of operation.

❑ Once the tool is warmed up, readjust the regulator to

the proper working pressure and reload the tool.

❑

Open the drain on the air compressor tank to drain any

moisture at least daily in extremely cold or humid weather.

A few ounces of anti-freeze in the tank will keep the air

free of frost.

❑

Ensure that all fasteners are driven to the same depth

and that the crown of the fastener is flush with the workpiece.

Most minor problems can be resolved quickly and easily

using the maintenance table that follows. If problems persist, contact your Paslode dealer for assistance.

7

Page 8

MAINTENANCE

WOHYHWNOITCA

Drain air line filter (daily).

Clean filter element, then blow

air through filter in direction

opposite to normal flow.

Check that all screws on tool

are tight.

Keep work contacting element

working properly.

Keep magazine and feeder

mechanism clean.

Use only Paslode replacement

parts.

Prevent accumulation of

moisture and dirt.

Prevent clogging of filter with

dirt.

Prevent air leakage and promote efficient operation.

Promote operator safety and

efficient tool operation.

Prevent jamming of fasteners.

Keep tool operating efficiently

and maintain Paslode tool

warranty.

Open manual petcock (most

air supply systems have such

a valve).

Wash with soap and water or

follow manufacturers instructions.

Check screws daily.

Blow clean daily.

Blow clean daily.

Order any replacement parts

needed from Paslode Dealer.

8

Page 9

OPERATOR TROUBLESHOOTING

PROBLEM CORRECTIVE ACTION

CAUTION

Disconnect the tool when performing

repairs or clearing jams.

Fasteners will not drive completely into wood.

Fasteners penetrate properly during normal

operation, but won't drive fully at faster speeds.

Fasteners drive too deeply into wood.

Fastener jams in nose of tool.

Tool skips during operation - no fasteners are driven

from time to time.

Adjust the depth of drive adjustment (retract length).

Increase air pressure (do not exceed 120 psi).

Increase air flow to tool — use larger air lines

(3/8 inch ID minimum).

Adjust the depth of drive adjustment (extend length).

Reduce air pressure.

Open front guide latch, release jammed fastener,

and close latch securely.

Check magazine for proper fasteners. Magazine

follower should slide freely. Clean as needed to

remove debris.

Tool operates, but no fasteners are driven.

Air leaks at cap when tool is connected to air.

Make sure correct fasteners are being used. Use

fasteners that meet Paslode

®

specifications only.

Increase air flow to tool -- use larger air lines

(3/8 ID minimum).

Adjust work contacting element where available.

Check magazine for proper fasteners. Fasteners

should slide freely with no follower pressure.

Open front guide latch and check for jams or

debris in the nose area. Clear as necessary

Increase air pressure (do not exceed 120psi).

Tighten cap screws.

9

Page 10

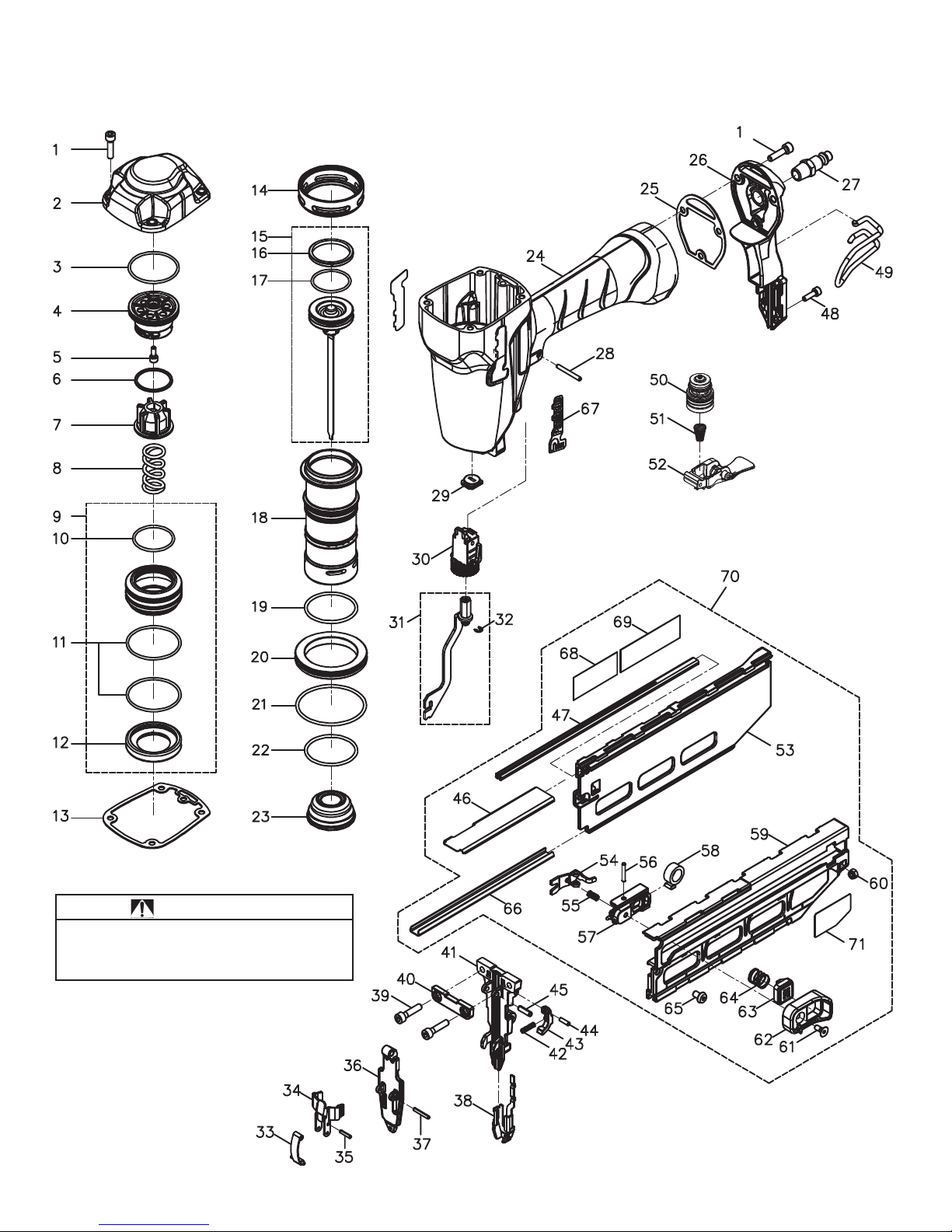

PARTS LEGEND T250S-F16P Part #515500

1 515501 7 Hex. Soc. Hd. Bolt

2 515502 1 Cap

3

*

515503 1 O-Ring

4 515504 1 Top Cap Ring

5 515505 1 Hex. Soc. Hd. Bolt

6 515506 1 Spacer

7 515507 1 Piston Stopper

8 515508 1 Spring

*

9 515509 1 Head Valve Assembly

10 515510 1 O-Ring

*

*

11 515511 O-Ring

*

12 515512 1 Seal

13

*

*

14 515514 1 Collar

15 515515 1 Driver Blade Assembly

*

*

16 515516 1 Wear-Ring

*

17 515517 1 O-Ring

515513 1 Top Cap Seal

2

18 515518 1 Cylinder

19 515519 1 O-Ring

*

20 515520 1 Cylinder-Ring

*

*

21 515521 1 O-Ring

*

22 515522 1 O-Ring

23 515523 1 Bumper

*

24 515524 1 Housing

*

25 515525 1 End Cap Seal

26 515526 1 End Cap

27 615920 1 Air Plug

28 515528 4 Spring Pin

29 515529 1 Bumper Seal

30 515530 1 Depth of Drive A

31 515531 1 WCE Connector

32 403713 1 E-Ring

33 515533 1 Latch Spring Assembly

34 515534 1 Latch

35 515535 1 Spring Pin

36 515536 1 Door

37 515537 1 Spring Pin

38 515538 1 WCE

39 515539 2 Hex. Soc.Hd. Bolt

40 515540 1 Set Plate

41 515541 1 Nose

42 617456 1 Spring

43 515543 1 Lock-out Lever

44 515544 1 Spring Pin

45 515545 1 Spring Pin

46 515546 1 Upper Plate

47 515547 1 Nail Guide

48 515548 2 Hex. Soc.Hd. Bolt

49 515549 1 Belt Hook

50 515550 1 Trigger Valve Assembly

51 617780 1 Spring

52 515552 1 Selectable Trigger

53 515553 1 Magazine (Right)

54 515554 1 Pusher

55 515555 1 Spring

56 515556 1 Spring Pin

57 515557 1 Pusher Seat Assembly

58 515558 1 Roll Spring

59 515559 1 Magazine (Left)

60 515560 2 Lock Nut

61 515561 1 Flat self-tapping Bolt

62 515562 1 Pusher Upper seat

63 515563 1 Push Button

64 515564 1 Spring

65 515565 2 UM. HD. Bolt

66 515566 1 Lower Plate

67 515567 2 Logo Label

68

**

515568 1 Warning Label

69 515569 1 Model Label

70 515570 1 Magazine Assembly

71 515571 1 Lock Label

* Denotes Normal Wear Items.

** Make sure Warning Label (515568) is properly affixed.

Replace if necessary.

AIR CONSUMPTION CHART

.040

.035

.030

.025

.020

.015

AIR CONSUMPTION-CFM FASTENER

.010

AIR PRESSURE-PSIG

.

.034

11010090807060

120

10

SAFETY INSTRUCTIONS

WEAR EYE AND HEARING PROTECTION

Always wear hearing protection and eye protection devices,

including side shields when operating or working in the vicinity

of a tool.

DO NOT EXCEED MAXIMUM

RECOMMENDED AIR PRESSURE

60

120

0

60

120

0

Operate the tool using only the recommended air pressure. Do

not exceed the maximum air pressure marked on the tool. Be

sure the air pressure gauge is operating properly and check it

at least twice a day.

Never use any bottled air or gases such as

oxygen to operate the tool since they could cause

the tool to explode.

Page 11

T250S-F16P

515500

WARNING

All parts must be periodically inspected and

replaced if worn or broken.

affect the toolʼs operation and present a safety

hazard.

Failure to do this can

11

Page 12

ACCESSORIES

Safety Glasses

raelC

382104 .oN traP

P

© 2018, Illinois Tool Works, Inc.

An Illinois Tool Works Company

155 Harlem Avenue

Glenview, IL 60025

12

Page 13

Pieza# 515500

MODELO

T250-F16P

Clavadora de Acabado

Recto de Calibre 16

¡IMPORTANTE!

NO DESTRUYE ESTE MANUAL

El cliente tiene la responsibilidad de que todo

el personal de operaciones y servicio lea y

entienda este manual.

Manual de Funcionamiento y

Esquema

17

Page 14

INTRODUCCIÓN

La herramienta Paslode

aplicaciones

usada acorde con las

residenciales. Esta herramienta le provera confiabilidad y eficiencia cuando sea

reglas del fabricante.

de seguridad para comprender como usar

®

T250-F16P

es una herramienta de calidad, diseñada para uso en

Lea cuidadosamente este manual y las instrucciones

le herramienta correctamente.

CONTENIDO

ESPECIFICACIONES DE LA HERRAMIENTA Y SUS SUJETADORES............................3

INSTRUCCIONES DE SEGURIDAD................................................................................... 4

INSTALACIÓN Y OPERACIÓN DE LA HERRAMIENTA.....................................................5

VISTA EXPANDIDA CON LISTADO DE PIEZAS...........................................................10-11

ACCESORIOS....................................................................................................................12

TERMINOS DE LA GARANTIA

Paslode garantiza que sus herramientas mecánicas,

sus piezas y accesorios, que hayan sido comprados

nuevos, están libres de defectos de material y fabricación por el período indicado más abajo, a partir de

la fecha de compra del comprador original.

GARANTÍA DE UN AÑO

La garantía

excepción de aquellas cubiertas por la extención

de garantía.

GARANTÍA LIMITADA ADICIONAL DE CINCO AÑOS

La garantía de cinco años cubre todos los armazones

y ensambles de las tapas.

DECLARACIÓN DE LA GARANTÍA

Esta garantía esta limitada a las herramientas vendidas y revisadas en los Estados Unidos. Para obtener

mas información sobre el servicio de garantía en los

Estados Unido, véa la lista de Centros de Servicio

que fue proporcionada con su herramienta.

de un año cubre todas las

piezas, con

Paslode asume únicamente la responsabilidad de re-

poner cualquier pieza o accesorio que se compruebe

como defectuoso dentro del período especificado.

Cualquier pieza o accesorio de repuesto, entregado de

conformidad con esta garantía, gozará de la garantía por

el período restante de la garantía que cubría a la pieza o

al accesorio originales. Esta garantía no cubre las piezas

que necesitan ser repuestas como consecuencia de su

desgaste normal.

Se cancelará esta garantía a cualquier herramienta

haya sido usada incorrectamente, dañada accidental o

intencionalmente,usada con sujetadores

las

especificaciones, el tamaño o la calidad de

o a la que no se le haya dado el mantenimiento o el uso

adecuado, o que haya sido reparada con

sean marca Paslode, o que en opinión de

sido modificadas o reparadas de manera

contraria al funcionamiento de la herra

PASLODE NO OTORGA NINGUNA GARANTÍA EXPLÍCITA O IMPLÍCITA CON RESPECTO A LA COMER-

CIALIZACIÓN O ADAPTACIÓN AL USO PREVISTO, O

DE CUALQUIER OTRA NATURALEZA, CON EXCEP-

CIÓN DE LO DECLARADO ANTERIORMENTE, y la

responsabilidad de Paslode TAL COMO SE INDICA Y

SE ASUME MÁS ARRIBA reemplaza a todas las otras

garantías que resulten o estén relacionadas con el uso

y funcionamiento de la herramienta, excepto según lo

estipulen las leyes pertinentes. PASLODE NO SERÁ

RESPONSABLE EN NINGÚN CASO POR NINGÚN

DAÑO DIRECTO, INDIRECTO O CONSECUENTE

LUYENDO, PERO SIN LIMITARSE, CUALQUIER

INC

DAÑO RESULTADO DE LA PÉRDIDA DE PRODUC-

CIÓN O GANANCIAS ANTICIPADAS, EL DETERIORO

DE MATERIALES, AUMENTOS EN EL COSTO DE OP-

ERACIÓN O CUALQUIER OTRO.

que no reúnan

Paslode,

piezas que no

Paslode hayan

que afecte o sea

mienta.

que

Paslode se reserva el derecho de cambiar las especificacionnes, el equipo o los

diseños en cualaquier momento, sin aviso previo y sin incurrir en obligación alguna.

2

Page 15

ESPECIFICACIONES DE LA HERRAMIENTA Y LOS SUJETADORES

ESPECIFICACIONES DE LA HERRAMIENTA

NO. de MODELO T25O-F16P (Pieza# 515500)

ALTURA 295mm

ANCHO 74mm

LONGITUD 313mm

PESO 1.8kg

PRESIÓN de OPERACIÓN 80 hasta 120 p.s.i. (5,5 hasta 8,3 bar)

ESPECIFICACIONES de los SUJETADORES

LONGITUD DEL CLAVO 25mm-63mm

DIAMETRO DEL TALLO 16 Calibre

ACOPLAMIENTO DE AIRE:

Esta herramienta utiliza un tapón macho de 1/4" N.P.T. El acoplamiento debe ser

capaz de descargar la presión de aire en la herramienta cuando sea desconectada

del suministro de aire.

OPERACION de PRESIÓN de AIRE:

80 hasta120 p.s.i. Seleccione una presión de aire dentro de

esta gama para obtener el mejor rendimiento.

NO EXCEDA LA PRESIÓN DE AIRE RECOMENDADA.

19

3

Page 16

INSTRUCCIONES DE SEGURIDAD

LA SEGURIDAD ESTA PRIMERO

Estas instrucciones proporcionan la información necesatia para

el funcionamiento sin peligrode las herramientas Paslode. NO

trate de usar su herramienta hasta que no haya léido y entendido todas las precauciones de seguridad y las instrucciones de este manual.

PROTEJASE LOS OJOS Y LOS OIDOS

Use siempre el equipo adecuado para protegerse

los ojos y los oídos que sea conforme con ANZI Z87,

meintras usa una herramienta o trabaja cerca de una

herramienta en uso. Como empleador usted es responsable de imponer el usp del la porteccion de ojo. Lleve

sombreros duros en los ambientes que requieren su uso.

USE SU HERRAMIENTA SOLAMENTE PARA EL

PROPOSITO CON QUE FUE DISEÑADA

No arroje la herramienta al suelo; no golpee el armazón ni la use

como un martillo.

NUNCA USE LA HERRAMIENTA PARA JUGUETEAR

Esta herramienta no es un juguete; por lo tanto no la trate como

tal. Nunca juguetee con ella, ni se apunte a usted mismo ni a

otra persona, aun cuando crea que no está cargada.

NUNCA ASUMAQUE LA HERRAMIENTA ESTA VACIA

Verfique que ho haya sujetadores en elcargador. Aun cuando

crea que está vacía o desconectada, nunca se apunte ni apunte

a otra persona con la herramienta, porque podría dispararse un

sujetador que no esté a la vista.

NUNCA SUJETE EL GATILLO EN LA POSICION DE

CIERRE O DE FUNCIONAMIENTO

Nunca se debe manipular indebidamente o dejar inoperante el

gatillo, o sujetarlo en la posición de cierre o defuncionamiento,

porque se podría disparar un sujetador al oprimirse el elemento

de contacto.

NO CARGUE SUJETADORES CUANDO LA LINEA DE

AIRE COMPRIMIDO ESTE CONECTADA, O CUANDO

EL GATILLO O EL ELEMENTO DE CONTACTO ESTE

OPRIMIDO.

Antes de cargar sujetadores en la herramienta, verifique que la

línea de aire comprimido esté desconectada y que ni el gatillo ni

el elemento de contacto estén oprimidos.

DESCONECTE LA HERRAMIENTA CUANDO NO

LA ESTE USANDO

Siempre desconecte la herramienta de la línea de aire

comprimido cuando no la esté usando o al dejar su lugar de

trabajo. Nunca la descuide, porque cualquier persona que no

esté familiarizada con ella podría lastimarse o lastimar otros.

TOME LA HERRAMIENTA SOLAMENTE POR EL

MANGO

Siempre tome la herramienta sólo por el mango. Nunca la

tome por la manguera o con el gatillo oprimido, porque se

podría disparar un sujetador y herirlo o herir a otra persona.

NO ALTERE EL ARMAZON DE LA HERRAMIENTA

El armazón de la herramienta es un recipiente a presión y nunca

se debe grabar en su superficie el nombre de su compañia, el

del área de trabajo, ni ningún otro detalle.

DESCONECTE LA HERRAMIENTA PARA HACER

REPARACIONES O ELIMINAR OBSTRUCCIONES

Nunca trate de eliminar obstrucciones o reparar una herramienta sin haberla desconectado de la línea de aire compromido

y quitado todos los sujetadores.

USE SIEMPRE LOS ADAPTADORES APROPIADOS

PARA SU HERRAMIENTA

Se debe conectar a la herramienta solamente conectores

neumáticos MACHOS, para permitir que el aire de alta presíon salga tan pronto como se desconecte la línea de aire

comprimido.

NUNCA coloque enlaces HEMBRAS

en la herramienta, porque atrapan el aire a alta presíon al

desconectar la línea de aire comprimido, dejándola cargada y

lista para disparar por lo menos un sujetador.

de desconexíon rápida

NO EXCEDA LA PRESION NEUMATICA MAXIMA

RECOMENDADA

La herramienta debe funcionar sólo con la presíon neumática recomendada. No exceda la presíon neumática máxima marcada

en la herramienta. Verifique por lo menos dos veces al día que

el calibre de la presíon neumática funcione correctamente.

Nuna use aire o gases envasado, como el oxígeno, para hacer

funcionar la herramienta porque podrían hacer que explotara.

No haga funcionar en atmósferas explosivas.

USE LA HERRAMIENTA SOLAMENTE SOBRE UN

MATERIAL DE TRABAJO

La herramienta debe funcionar sólo cuando esté en contacto

con el material de trabajo. Debe tener mucho cuidado cuando el

material sea delagado o trabaje cerca de las aristas del mismo,

porque los sujetadores podrían atravesar o salirse del material.

NO DEJE INOPERANTE NI QUITE EL ELEMENTO DE

CONTACTO

Esta herramienta está equipada con un mecanismo de seguridad, llamado elemento de contacto, para prevenir cualquier disp

aro accidental. Nunca manipule indebidamente, deje inoperante,

ni quite el elemento de contacto. No use la herramienta a menos

que dicho elemento funcione correctamente, porque podría

producirse un disparo imprevisto.

La falta de observación de cualquiera de estas instrucciones puede ser causa de graves

lesiones personales, tanto al operador de la herramienta comoa quienes estén cerca de

ella o de daños materiales o a la herramienta

Comuníquese con el representante de Paslode sobre la presentación de Programa de Alerta sobre

Seguridad.

-

PELIGRO

.

4

INSPECCIONE LA HERRAMIENTA PARA LA OPERACION APROPIADA

USE SOLAMENTE PIEZAS Y SUJETADORES RECOMENDADOS POR PASLODE

Use sólo piezas y sujetadores específicamente diseñados y

recomendados por Paslode para usar con esa herramienta

y para la tarea requerida. Si se usan piezas o sujetadores no

autorizados o se modifica de alguna forma la herramienta, se

pueden crear situaciones peligrosas. Vuelva a colocar todas

las etiquetas de precaucíon que flaten. Consulte el diagrama

de la herramienta sobre el número de cada parte y su ubligación correcta.

Page 17

Característica de bloqueo del proceso

FUNCIONAMIENTO DE LA

–

HERRAMIENTA

Sujetadores

El pasador de acabado Paslode T250S-F16P

acciona pasadores Paslode de calibre 16

diseñados para usarse con la herramienta. El uso

de sujetadores que no cumplan los estándares de

Paslode podría causar daños en las herramientas

y anulará todas las reclamaciones de garantía.

Cargando sujetadores

Paso 1:

bado Paslode con el canal de clavitos plateado en

la parte posterior del cargador e intro

dos tiras. Empuje las tiras de clavos hacia adelante.

Alinee las cabezas del los clavos de aca

®

®

duzca una o

Ajuste de profundidad de Drive

Desconectar el suministro de aire.

La profundidad de ajuste de accionamiento se hace

girando la rueda de ajuste situado debajo del gatillo.

-

–

Para desatorar la clavadora

Un problema típico que puede encontrar es una

clavadora con clavos atorados. Debido al diseño

único de la clavadora Paslode, es muy sencillo sacar

los clavos atorados:

Paso 2:

del cargador hasta que el seguidor haya pasado la

última tira de clavos. Suelte la palanca del seguidor

y deje que el mismo mueve los clavos hacia adelan

te dentro de la boca de la herramienta.

Paso 3:

recarga, marcada en el lado del cargador, usted

puede introducir una nueva tira de clavos. Cuando

la flecha de seguidor alcance al área de bloqueo,

la herramienta se bloquea automáticamente para

evitar su funcionamiento. Para desenganchar la her

ramienta, recargue simplemente otra tira de clavos.

Tire del seguidor hacia la parte posterior

Cuando la flecha aparezca en el área de

-

1. Disconecte el aire.

2. Deslice el seguro para soltar la quía delantera

y hágala pivotear hacia adelante.

3. Quite las clavos atorados y empuje la hoja del

impulsador hacia atrás hasta la posición normal

de retorno.

4. Cierre la guía delantera y asegúrela. Verifique

que el elmento de contacto no esté obstruido.

El propósito de esta característica es evitar ciclos

en blanco innecesarios, lo que podría dañar las

maderas y dañar los componentes de la herramienta.

Se colocarán 10 clavos en el cargador cuando el

seguidor alcance el área de bloqueo. Cuando

cambie la longitud o la carga del sujetador al

del día de trabajo, debe inspeccionar el cargador y

principio

la nariz para los sujetadores que queden en el visible

a menos que abra la nariz de la herramienta.

5

Page 18

OPERACIÓN DE LA HERRAMIENTA

Métodos de disparo:

El clavador de acabado Paslode T250S-F16P tiene un

Sistema que se puede cambiar de secuencial a con-

tacto viaje. Para activar el gatillo, pulse el botón redon-

do en el lado izquierdo del gatillo y gire el lado derecho.

Del botón al método de activación deseado. El TTT

Indica disparo de contacto y el T indica secuencia

operación.

Sucesiva (Bounce) de conducción -

Agarre firmemente el mango.

Apriete el gatillo y mueva la herramienta a lo largo de

la pieza con un movimiento de rebote, deprimiendo el

contacto de trabajo elemento en los puntos en los que

desea abrochador.

Apriete el gatillo y mueva la herramienta a lo largo de

la pieza

PELIGRO

No sujete ni sostenga el gatillo con ninguna

otra cosa que no sea la mano.

Quitar las Uñas

Para descargar los clavos, simplemente tire del seguidor

hacia la parte posterior del cargador y presione el botón

de bloqueo central en el seguidor. La moverá el seguidor

hacia afuera y permitirá que los clavos pasen por delante

del seguidor y por la parte posterior del cargador.

Para liberar la cerradura, simplemente tire del seguidor

hacia atrás y el botón de bloqueo se liberará y permitir

que el

seguidor se mueva hacia adelante.

Cuando el número deseado de sujetadores ha sido

dispare el gatillo de la herramienta para evitar descarga del sujetador.

Posición de impulso

Indicador

por salto

de posición

Operación

Secuencial

Operación Secuencial -

El ajuste secuencial T evita sucesivas o "rebote"

conducción.

Presione el elemento de contacto de trabajo y manténgalo contra la superficie de trabajo antes de tirar del

gatillo.

Gancho reversible de la correa:

El gancho de la correa se puede cambiar desde el lado

izquierdo de la herramienta a la derecha. Para cambiar

la posición, apretar la base del gancho de cinturón y

sacarlo de la herramienta y la herramienta de y posicionarlo en el lado deseado.

Después de accionar cada sujetador, libere completamente el dispare y levante la herramienta de la superficie de trabajo.

6

Page 19

MANTENIMIENTO

El mantenimiento de cualquier herramienta Paslode es

simple. Su funcionamiento sin problemas y la prolongación

de la vida de la herramienta se logran siguiendo un sencillo procedimiento. Las personas encargadas de usar y

mantener la herramienta deben leer las instrucciones de

seguridad y mantenemiento. Estudie los diagramas antes

de hacer cualquier reparación.

Las herramientas neumáticas deben revisarse periódicamente, y se deben cambiar las piezas gastadas o dete

rioradas para que la herramienta siga funcionando con

eficiencia y sin peligro. Además, se debe revisar la tabla

de mantenimiento frecuentemente.

Cuando Hace Mucho Frio

Cuando la temperatura es inferior a la de congelamiento,

las herramientas deben mantenerse a la temperatura

ambiente por el método más seguro y conveniente. De lo

contrario, aconsejamos seguir el siguiente procedimiento

para calentar las piezas de la herramienta.

■ Disminuya la presión regulada del aire a 30 psi.

■ Quite todos los sujetadores de la herramienta.

■

Conecte una línea de aire y dispare la herramienta

sin clavos. La presión reducida del aire será suficiente

para lograrlo. El funionamiento a poca velocidad

tiene la tendencia de calentar las partes movibles.

Disminuyendo la velocidad del pistón le da cierta

elasticidad al amortiguador y los anillos-o.

PRECAUCIÓN

®

-

Probar la Herramienta Después de Darle

Servicio

Después de reemplazar una o más piezas, es importante

comprobar si la herramienta funciona como es debido.

Esto asegura que todas las piezas estén puestas correctamente, que la herramienta esté segura y que fun

cione correctamente.

■ Verifique que ninguna pieza esté floja.

■

■ Verifique que el cargador esté colocado

■

■

■

■ Pruebe la herramienta impulsando sujetadores en

■ Verifique que no haya pérdidas de aire en la her-

■

dor esté al ras con el material de trabajo.

Compruebe que el elemento de contacto haya sido

correctamente instalado en relación con el gatillo y

que ambas piezas se muevan libremente.

correctamente.

Verifique que la información sobre seguridad, que

está en la herramienta, sea legible.

Use solamente sujetadores aprobados por Paslode

y compruebe que sean los apropiados para su

aplicación.

Verifique que se haya conectado firmemente un

adaptador macho a la herramienta.

unmaterial de trabajo idéntico al de la aplicación.

ramienta durante las pruebas y revise la secuencia

apropiada de funcionamiento.

Asegure que todos los sujetadores sean impulsados

a la misma profundidad y que la cabeza del sujta-

®

-

Nunca dispare la herramienta sin clavos a

alta presión.

■

Una vez que la herramienta se haya calentado, ajuste

nuevamente el regulador a la presión apropiada para

trabajar y cargue de nuevo la herramienta.

■ Abra, por lo menos diariamente, el drenaje del tan-

que del compresor del aire para eliminar cualquier

humedad, cuando haga mucho frío o el grado de

humedad sea muy alto. Poniendo una pequeña

cantidad de descongelante en el tanque evitará que

la humedad se congele.

Usando la siguiente tabla de mantenimiento es posible

resolver rápidamente y fácilmente la mayoría de los pe

queños problemas. Si un determinado problema persiste,

comuniquese con el representante de Paslode.

®

-

-

-

28

7

Page 20

MANTENIMIENTO (continuación)

Desconecte la herramienta al hacer cualquier

reparación o eliminar cualquier obstrucción.

TABLA DE MANTENIMIENTO

ACTIVIDAD POR QUE COMO

PRECAUCIÓN

Drene el filtro de la línea de aire a

diario.

Limpie el elemento del filtro;

luego, sople aire a través del filtro

en la dirección opuesta a la

corriente normal.

Verifique que todos los tornillos de

la herramienta estén apretados.

Revise si el elemento de contacto

funciona correctamente.

Mantenga limpios los mecanismos

del cargador y del alimentador.

Para evitar que se acumulen la

humedad y la suciedad.

Para evitar que la suciedad obstruya el filtro.

Para evitar pérdidas de aire y

asegurar el buen funcionamiento

de la herramienta.

Para promover la seguridad del

operador y el buen funcionamiento

de la herramienta.

Par prevenir que se obstruyan los

sujetadores.

Abra la llave de escape.

(La mayoría de los sistemas

neumáticos la tienen.)

Lave con agua y jabón, o siga las

instrucciones del fabricante.

Revise los tornillos a diario.

Límpielo con aire a diario.

Límpielos con aire a diario.

Use solamente piezas de repuesto

Paslode.

Para que la herramienta continúe

funcionando eficientemente y

mantener vigente la garantía de

Paslode.

8

Solicite al representante de

Paslode cualquier pieza de

repuesto que necesite.

Page 21

GUÍA PARA SOLUCIONAR

PROBLEMAS

PROBLEMA CORRECCIÓN

PRECAUCIÓN

Desconecte la herramienta al repararla

o desatascarla.

Las sujeciones no entran por completo en la madera.

Las sujeciones entran bien durante la operación

normal, pero no entran por completo cuando

aumento la velocidad.

Las sujeciones penetran demasiado profundo

en la madera.

La sujeción se atasca en la punta de la herramienta.

La herramienta salta durante la operación –

a veces no salen las sujeciones.

Ajuste la profundidad de penetración (retraiga

la longitud).

Aumente la presión del aire (sin exceder los 120 psi).

Aumente el caudal de aire a la herramienta –use

líneas de aire más grandes (con un DI de 3/8"

como mínimo)

Ajuste la profundidad de penetración (extienda

la longitud)

Reduzca la presión del aire.

Abra la traba de la guía frontal, libere la sujeción

atascada y cierre bien la traba.

Verifique que el cargador tenga las sujeciones

correctas. El seguidor del cargador debe deslizarse

libremente. Límpielo si está sucio.

Asegúrese de usar las sujeciones correctas.

Use solo sujeciones que cumplan con las

especificaciones de Paslode

®

.

La herramienta funciona pero no salen

las sujeciones.

Pierde aire por la tapa cuando la herramienta está

conectada al aire.

Aumente el caudal de aire a la herramienta – use

líneas de aire más grandes (con un DI de 3/8"

como mínimo).

Ajuste el elemento de contacto, si puede.

Verifique que el cargador tenga las sujeciones

correctas. Las sujeciones deben deslizarse

libremente sin presión del seguidor.

Abra la traba de la guía frontal y verifique que no

haya sujeciones atascadas ni suciedad en la punta.

Despeje cualquier obstrucción.

Aumente la presión del aire (sin exceder los 120 psi).

Ajuste los tornillos allen.

9

Page 22

LISTA DE PIEZAS,

T250S-F16P Part #515500

1 515501 7 Hex. Soc. Hd. Bolt

2 515502 1 Cap

3

*

515503 1 O-Ring

4 515504 1 Top Cap Ring

5 515505 1 Hex. Soc. Hd. Bolt

6 515506 1 Spacer

7 515507 1 Piston Stopper

8 515508 1 Spring

*

9 515509 1 Head Valve Assembly

10 515510 1 O-Ring

*

*

11 515511 O-Ring

*

12 515512 1 Seal

13

*

*

14 515514 1 Collar

15 515515 1 Driver Blade Assembly

*

*

16 515516 1 Wear-Ring

*

17 515517 1 O-Ring

515513 1 Top Cap Seal

2

18 515518 1 Cylinder

19 515519 1 O-Ring

*

20 515520 1 Cylinder-Ring

*

*

21 515521 1 O-Ring

*

22 515522 1 O-Ring

23 515523 1 Bumper

*

24 515524 1 Housing

*

25 515525 1 End Cap Seal

26 515526 1 End Cap

27 615920 1 Air Plug

28 515528 4 Spring Pin

29 515529 1 Bumper Seal

30 515530 1 Depth of Drive A

31 515531 1 WCE Connector

32 403713 1 E-Ring

33 515533 1 Latch Spring Assembly

34 515534 1 Latch

35 515535 1 Spring Pin

36 515536 1 Door

37 515537 1 Spring Pin

38 515538 1 WCE

39 515539 2 Hex. Soc.Hd. Bolt

40 515540 1 Set Plate

41 515541 1 Nose

42 617456 1 Spring

43 515543 1 Lock-out Lever

44 515544 1 Spring Pin

45 515545 1 Spring Pin

46 515546 1 Upper Plate

47 515547 1 Nail Guide

48 515548 2 Hex. Soc.Hd. Bolt

49 515549 1 Belt Hook

50 515550 1 Trigger Valve Assembly

51 617780 1 Spring

52 515552 1 Selectable Trigger

53 515553 1 Magazine (Right)

54 515554 1 Pusher

55 515555 1 Spring

56 515556 1 Spring Pin

57 515557 1 Pusher Seat Assembly

58 515558 1 Roll Spring

59 515559 1 Magazine (Left)

60 515560 2 Lock Nut

61 515561 1 Flat self-tapping Bolt

62 515562 1 Pusher Upper seat

63 515563 1 Push Button

64 515564 1 Spring

65 515565 2 UM. HD. Bolt

66 515566 1 Lower Plate

67 515567 2 Logo Label

68

**

515568 1 Warning Label

69 515569 1 Model Label

70 515570 1 Magazine Assembly

71 515571 1 Lock Label

*

**

Indica piezas de desgaste normal.

Asegure que la Etiqueta de Advertencia (515568)

este bien pegada. Reemplaze si es necesario.

TABLA DE CONSUMO DE AIRE

.040

.035

.030

.025

.020

.015

.010

CONSUMO DE AIRE -SCFM SUJETADOR

PRESIÓN DE AIRE

.

.034

11010090807060

120

10

INSTRUCCIONES DE SEGURIDAD

USE PROTECCIÓN PARA OJOS Y OÍDOS.

Siempre use protección para oídos y equipo de seguridad para los ojos, incluyendo protectores laterales

cuando este manejando o trabajando en los alred-

edores de una herramienta.

NO SOBRE P

AIRE RECOMEND

Solo opere la herramienta usando la presión de aire

recomendada. No sobre pase la maxima presión de

aire marcada sobre la herramienta. Asegure que el

indicador de presi

reviselo por lo menos dos veces al día.

Nunca use algún aire o gas embotellado tal como el

oxígeno para funcionar la herramienta ya que pueden

causar que la herramienta explote.

ASE LA MAXIMA PRESIÓN DE

ADA

ón

de aire este trabajando bien y

Page 23

T250S-F16P

515500

ADVERTENCIA

Todas las piezas deben ser inspeccionadas

periódicamente y reemplazadas si están gastadas o rotas. Si no lo hace, puede afectar el

funcionamiento de la herramienta y representar un peligro para la seguridad.

11

Page 24

ACCESORIOS

Lentes de Seguridad

Claros

Pieza No. 401382

P

PRINTED IN U.S.A.

© 2018, Illinois Tool Works, Inc.

An Illinois Tool Works Company

155 Harlem Avenue

Glenview, IL 60025

12

Page 25

12

Glenview, IL 60025

155 Harlem Avenue

Une compagnie d'Illinois Tool Works

®

/MD

Pièce n° 401382

Transparentes

Lunettes de sécurité

ACCESSOIRES

Page 26

11

la sécurité.

fonctionnement de l'outil, et cela peut créer un risque pour

à les remplacer au moment opportun peut affecter le

doivent être remplacées si usées ou brisées. Tout manquement

Toutes les pièces doivent être inspectées périodiquement, et

Avertissement

515500

T250S-F16P

Page 27

10

10

MAXIMALE RECOMMANDÉE

NE DÉPASSEZ PAS LA PRESSION D'AIR

CONSIGNES DE SÉCURITÉ

Étiquette de blocage

Jeu du magasin

Étiquette du modèle

Étiquette d’avertissement

Étiquette de logo

Plaque inférieure

Boulon hex.

Ressort

Bouton poussoir

Siège supérieur du poussoir

Boulon plat auto-taraudeur

Contre-écrou

Magasin (gauche)

Ressort en rouleau

Jeu de siège du poussoir

Tige du ressort

Ressort

Poussoir

Magasin (droite)

Gâchette sélectionnable

Ressort

Jeu de vanne de déclenchement

Crochet de ceinture

Boulon à tête hex.

Guide d’attache

Plaque supérieure

Tige du ressort

Tige du ressort

Levier de blocage

Ressort

Nez

Plaque de retenue

Boulon à tête hex.

WCE

Tige du ressort

gaz en bouteille peuvent faire exploser l’outil.

de l’oxygène, pour faire fonctionner cet outil, puisque ces

N’utilisez jamais d’air ou de gaz en bouteille, tel que

fois par jour.

d’air fonctionne correctement, et vérifiez-le au moins deux

indiquée sur l’outil. Assurez-vous que l’indicateur de pression

recommandée. Ne dépassez pas la pression d’air maximale

Utilisez l’outil uniquement avec la pression d’air qui est

.034

.

ou travaillez à proximité d’un outil.

des yeux, y compris des écrans latéraux, lorsque vous utilisez

Portez toujours des équipements de protection de l’ouïe et

PORTEZ UNE PROTECTION POUR LES YEUX ET POUR L’OUÏE

71 515571 1

515570 1

70

515569 1

69

68

67

66

65

64

63

62

61

60

59

58

57

56

55

54

53

52

51

50

49

48

47

46

45

44

43

42

41

40

39

38

**

515568 1

515567 2

515566 1

515565 2

515564 1

515563 1

515562 1

515561 1

515560 2

515559 1

515558 1

515557 1

515556 1

515555 1

515554 1

515553 1

515552 1

617780 1

515550 1

515549 1

515548 2

515547 1

515546 1

515545 1

515544 1

515543 1

617456 1

515541 1

515540 1

515539 2

515538 1

37 515537 1

Porte

Tige du ressort

Loquet

Jeu de ressort de loquet

Anneau en E

Connecteur WCE

Profondeur d’entraînement A

Sceau du pare-chocs

Tige du ressort

Prise d’air

Bouchon du bout

Scellement du bout

Bâti

Pare-chocs

Joint Torique

Joint Torique

Collet de cylindre

Joint Torique

Cylindre

Joint Torique

Bague d’usure

Jeu de tête d’entraînement

Collet

Sceau supérieur

Scellement

Joint Torique

2

Joint Torique

Ensemble de vanne de tête

Ressort

Butée du piston

Espaceur

Boulon à tête hex.

Anneau-bouchon supérieur

Joint Torique

Capuchon

Boulon à tête hex.

CONSOMMATION D’AIR - PIEDS CUBE/MINUTE / ATTACHE

.010

.015

.020

.025

.030

.035

.040

TABLEAU DE CONSOMMATION D’AIR

515513 1

515503 1

2 515502 1

1 515501 7

soit apposée correctement. Remplacez-la au besoin.

** Assurez-vous que l’étiquette d’avertissement (515568)

* Indique les articles qui présenteront une usure normale.

36 515536 1

35 515535 1

34 515534 1

33 515533 1

32 403713 1

31 515531 1

30 515530 1

29 515529 1

28 515528 4

27 615920 1

26 515526 1

25 515525 1

*

24 515524 1

23 515523 1

*

22 515522 1

*

21 515521 1

*

20 515520 1

*

19 515519 1

*

18 515518 1

17 515517 1

*

16 515516 1

*

*

15 515515 1

14 515514 1

*

*

13

12 515512 1

*

11 515511

*

*

10 515510 1

9 515509 1

*

8 515508 1

7 515507 1

6 515506 1

5 515505 1

4 515504 1

3

*

T250S-F16P Pièce no 515500

LÉGENDE DES PIÉCES

Page 28

9

Les attaches ne s’enfoncent pas complètement

vitesses plus élevées.

alimenté en air.

Serrer les vis du capuchon.

Augmenter la pression d’air (ne pas dépasser 120 psi).

de bourrages ou de débris, le cas échéant.

Ouvrir le loquet du guide frontal et vérifier la présence

sans pression du pourvoyeur.

appropriées. Les attaches doivent glisser librement

Vérifier que le magasin contient des attaches

Ajuster l’élément de contact lorsque cela est possible.

d’air plus gros (diamètre intérieur d’au moins 3/8 po).

Augmenter le flux d’air vers l’outil; utiliser des tuyaux

spécifications de Paslode®.

Utiliser uniquement des attaches qui répondent aux

S’assurer que des attaches appropriées sont utilisées.

librement. Si nécessaire, retirer les débris présents.

appropriées. Le pourvoyeur du magasin doit glisser

Vérifier que le magasin contient des attaches

Des fuites d’air au capuchon lorsque l’outil est

attache n’est éjectée.

L’outil semble fonctionner, mais aucune

temps, aucune attache n’est éjectée.

L’outil saute durant l’utilisation; de temps en

coincée, et refermer le loquet de façon sécuritaire.

Ouvrir le loquet du guide frontal, retirer l’attache

Réduire la pression d’air.

(augmenter la longueur).

Ajuster le réglage de profondeur d’entraînement

moins 3/8 po).

tuyaux d’air plus gros (diamètre intérieur d’au

Augmenter le flux d’air vers l’outil; utiliser des

Augm

enter la pression d’air (ne pas dépasser 120 psi).

la longueur).

Ajuster le réglage de profondeur d’entraînement (diminuer

Les attaches se coincent dans le nez de l’outil.

dans le bois.

Les attaches s’enfoncent trop profondément

s’enfoncent pas complètement à des

d’une utilisation normale, mais elles ne

Les attaches pénètrent correctement lors

dans le bois.

PROBLÈME MESURE CORRECTIVE

ATTENTION

du dégagement de bourrages.

Débrancher l’outil lors d es réparati ons ou

DÉPANNAGE PAR L’UTILISATEUR

Page 29

Purgez le filtre de la conduite

Pour prévenir l’accumulation

Ouvrez le robinet de purge

8

local.

MD

Paslode

auprès de votre détaillant

rechange dont vous avez besoin

Commandez toute pièce de

soufflant.

Nettoyez quotidiennement en

soufflant.

Ne

ttoyez quotidiennement en

quotidiennement.

Vérifiez le bon serrage des vis,

les instructions du fabricant.

Lavez à l’eau savonneuse ou selon

ce type de robinet).

d’alimentation en air comportent

manuelle (la plupart des systèmes

.

MD

l’outil Paslode

de l’outil, et maintenir la garantie de

Pour préserver le bon fonctionnement

Pour prévenir le blocage des attaches.

efficace de l’outil.

l’utilisateur, et un fonctionnement

Pour favoriser la sécurité de

plus efficace.

favoriser un fonctionnement

Pour prévenir les fuites d’air, et pour

par la saleté

Pour prévenir l’obstruction du filtre

d’humidité et de saleté.

.

MD

rechange Paslode

Utilisez uniquement des pièces de

d’alimentation propres.

Gardez le magasin et le dispositif

correctement.

pointe de contact fonctionne

Assurez-vous que l’élément de

soient bien serrées.

Vérifiez que toutes les vis de l’outil

en direction opposée du débit normal.

soufflez de l’air à travers le filtre,

Nettoyez l’élément du filtre, puis

d’air (quotidiennement).

MESURE À PRENDRE POURQUOI COMMENT

TABLEAU D’ENTRETIEN

une réparation ou un déblocage

Débranchez l’outil avant d’effectuer

MISE EN GARDE

ENTRETIEN - suite

Page 30

dans

MD

7

détaillant Paslode pour de l’assistance.

ci-dessous. Si le problème persiste, communiquez avec votre

ment et facilement, en vous référant au tableau d’entretien

La plupart des problèmes mineurs peuvent être réglés rapide-

MISE EN GARDE

affleurement avec la pièce à travailler.

même profondeur, et que la couronne des attaches soit à

❑

Assurez-vous que toutes les attaches soient enfoncées à la

correcte.

testez aussi que la séquence de son fonctionnement soit

❑

Vérifiez la présence de fuite d’air sur l’outil pendant le test,

sera utilisé.

travailler qui soit identique à l’application pour laquelle l’outil

❑

Testez l’outil en enfonçant des attaches dans une pièce à

ment sur l’outil, et de manière sécuritaire.

❑

Assurez-vous qu’un raccord d’air mâle soit connecté solidel’application.

l’outil, et vérifiez qu’elles soient bien appropriées pour

❑

N’utilisez que des attaches approuvées par Paslode

soient bien lisibles.

❑

Assurez-vous que les consignes de sécurité requises sur l’outil

❑

Assurez-vous que le magasin soit fixé correctement.

pièces puissent bouger librement.

correctement relativement à la gâchette, et que les deux

❑

Assurez-vous que l’élément de pointe de contact soit installé

❑

Assurez-vous que toutes les pièces soient bien serrées.

manière appropriée.

réassemblé correctement, est sûr et exécutera les tâches de

vérifier que l’outil fonctionne bien. Ceci assure que l’outil a été

Après avoir remplacé une ou plusieurs pièces, il est important de

Tester L’outil Après une Réparation

sont conçus pour faciliter leur entretien.

MD

ou de givre.

le réservoir peut aussi contribuer à garder l’air libre de gel

au moins une fois par jour. Une petite quantité d’antigel dans

réservoir du compresseur d’air pour purger toute humidité,

❑

Par temps très froid ou humide, ouvrez le purgeur du

rechargez l’outil.

régulateur à la bonne pression de fonctionnement, et

❑

Une fois que l’outil sera réchauffé, réglez à nouveau le

à la haute pression.

Ne jamais tirer à blanc avec l'outil, en recourant

niveau voulu de rebond.

le piston aidera la butée et les joints toriques à atteindre leur

lente aura tendance à réchauffer les pièces mobiles. Ralentir

déclenchement librement. Un fonctionnement à vitesse

La pression d’air réduite sera suffisante pour activer un

❑

Raccordez une conduite d’air et tirez à blanc avec l’outil.

❑

Retirez toutes les attaches de l’outil.

❑ Réduisez la pression d’air régulé à 2,06 bars (30 psi).

sécuritaire. Si cela n’est pas possible, il faut suivre les procédures

être gardés au chaud par tout moyen qui soit pratique et

Si les températures tombent en dessous de zéro, les outils doivent

Entretien par temps froid

Les outils pneumatiques doivent être inspectés régulièrement, et

schémas avant d’entamer toute réparation sur cet outil.

comprendre les consignes de sécurité et d’entretien. Examinez les

utile. Toute personne qui utilise ou répare l’outil doit lire et

fonctionnement sans souci, et d’en tirer une longue durée de vie

Quelques détails simples vous permettront d’en assurer le

Les outils Paslode

ENTRETIEN

Page 31

6

moyen que votre main.

MISE EN GARDE

Ne pas coincer ni retenir la gâchette par un autre

la gâchette, et soulevez l'outil de la surface de travail.

Après avoir enfoncé chaque attache, relâchez complètement

sur la gâchette.

maintenez-la contre la surface de travail, avant de presser

Appuyez sur l’élément de pointe de contact de travail et

le déclenchement successif ou « à rebond. »

Le réglage de déclenchement séquentiel (sigle T) empêche

Opération Séquentielle -

séquentielle

Opération

de l'outil, puis, positionnez-le sur le côté voulu.

compressez la base du crochet de ceinture et enlevez-le

au côté droit de l’outil. Pour changer la position,

Le crochet de ceinture peut être changé du côté gauche

Crochet Réversible de Ceinture :

successif (au rebond)

du déclenchement

Indicateur de sélection

Déclenchement

des attaches.

gâchette de l'outil pour éviter tout déclenchement involontaire

Lorsque le nombre souhaité d'attaches a été atteint, relâchez la

possible l'outil au-dessus du point à clouer.

travailler, tout en positionnant aussi soigneusement que

rebonds de l’élément de pointe de contact contre la pièce à

Maintenez la gâchette enfoncée, et continuez à faire des

enfoncer une attache.

ant l’élément de pointe de contact aux points où vous voulez

travailler, dans un mouvement ponctué de rebonds, en appuyPressez la gâchette et déplacez l'outil le long de la pièce à

Saisissez fermement la poignée.

Déclenchement Successif (au Rebond) -

libéré, et permettra au pourvoyeur de bouger vers l’avant.

l'arrière du magasin, le bouton de verrouillage sera alors

relâcher le verrou, tirez simplement le pourvoyeur vers

plus loin que le pourvoyeur, et à l'arrière du magasin. Pour

dégager le pourvoyeur, et permettra aux attaches de glisser

central de verrouillage sur le pourvoyeur. Le verrou va

pourvoyeur à l'arrière du magasin, et appuyez sur le bouton

Pour décharger les attaches, tirez simplement sur le

Décharger les Attaches :

que le sigle T indique un déclenchement séquentiel.

Le sigle T T T indique un déclenchement au contact, alors

déclenchement voulue.

le côté droit du bouton pour choisir la méthode de

bouton rond sur le côté gauche de la gâchette, et tournez

contact. Pour commuter le déclenchement, appuyez sur le

déclenchement séquentiel à un déclenchement au

système de déclenchement qui peut être commuté d’un

Méthodes de déclenchement :

FONCTIONNEMENT DE L'OUTIL

Page 32

nez de l'outil.

Ces attaches ne seront visibles que si vous ouvrez le

présence d’attaches laissées dans l’outil.

devez inspecter le magasin et le nez pour détecter la

chargement au début de la journée de travail, vous

changement de la longueur des attaches, ou du

pourvoyeur atteint la zone de verrouillage. Lors du

attaches sont laissées dans le magasin lorsque le

endommager les composantes de l'outil. Dix (10)

vide, ce qui pourrait gâcher les planches en bois, et

Le but de cette fonction est d'empêcher un cycle à

5

t à sa

ez le

Fonction de Verrouillage

de pointe de contact puisse bouger librement.

rmale.

rontal vers l'avant.

position no

Dégagez le blocage, puis pousser la lame d’entraînemen

3.

guide f

2. Tirez le loquet, pour dégager le guide frontal, puis pivot

Débranchez l'alimentation en air.

1.

facilite grandement le déblocage d’une attache bloquée :

recharger simplement une autre bande d’attaches.

fonctionnement de l'outil. Pour débloquer l'outil,

verrouille automatiquement, pour prévenir tout

pourvoyeur atteint la zone de verrouillage, l'outil se

marquée sur le côté du magasin, vous pouvez insérer

Lorsque le pourvoyeur atteint la zone de recharge,

l'avant, dans le nez de l'outil.

laissez le pourvoyeur pousser les attaches vers

dernière bande d’attaches. Relâchez le pourvoyeur et

magasin, jusqu'à ce que le pourvoyeur dépasse la

ÉTAPE 2 : Ensuite, tirez le pourvoyeur vers l'arrière du

–

Vous pourriez à l’occasion rencontrer le problème d’une attache

Dégager un Bourrage

gâchette.

tournant la roue de réglage, située au-dessous de la

Le réglage de la profondeur d'entraînement se fait en

Débrancher l'alimentation en air.

T250S-F16P permet

MD

d'entraînement

Réglage de la Profondeur

d’attaches. Poussez les bandes d’attaches vers l’avant.

l'arrière du magasin, et insérez une ou deux bandes

Paslode de calibre 16 avec le guide des attaches, à

Chargement des Attaches

réclamation sous garantie.

l’outil, et cela entraînera l’annulation de toute

les normes de Paslode peut causer des dommages à

outil. L'utilisation des attaches qui ne rencontrent pas

lesquelles sont conçues pour être utilisées avec cet

d’enfoncer des attaches Paslode de calibre 16,

Attaches

FONCTIONNEMENT DE L'OUTIL

Page 33

É

É

Ne pas

Assurez-vous que la

PRESSION D'AIR

PASSER LA

4

MISE EN GARDE

de l'outil pour l'emplacement et le numéro de pièce.

POUR SON BON FONCTIONNEMENT

faire fonctionner dans des atmosphères explosives.

l'outil, ceci pourrait faire exploser l'outil.

bouteille tel que de l'oxygène pour faire fonctionner

Ne jamais utiliser de l'air comprimé ou autre gaz en

pression fonctionne adéquatement et en

indiquée sur l'outil.

bon fonctionnement au moins deux fois par jour.r.

jauge de

maximale

recommandées. Ne pas dépasser la pression d'air

N'opérer l'outil que dans les limites de pressions

MAXIMALE RECOMMANDÉE

NE JAMAIS DÉ

au schéma

Remplacez toutes les étiquettes de mise en garde – reportez vous

toute modification de l'outil créent des situations dangereuses.

accomplir. L'utilisation de pièces et attaches non autorisées ou

et recommandées par Paslode pour l'outil et pour le travail à

N'utiliser que les pièces et les attaches spécifiquement conçues

RECOMMANDÉES

N'UTILISER QUE LES PIÈCES ET ATTACHES PASLODE

opérer un outil sale ou qui ne fonctionne pas bien.

Nettoyer l'outil tous les jours et le lubrifier au besoin. Ne jamais

INSPECTER L'OUTIL

vérifier le

laissant ainsi l'outil chargé et capable d'enfoncer une attache.

pression d'air dans l'outil lorsque la source d'air est désaccouplée,

rapide sur l'outil. Les raccords femelles retiennent la haute

Ne JAMAIS installer des raccords FEMELLES à désaccouplement

dans l'atmosphère dès que la ligne à air est désaccouplée.

l'outil, afin que la haute pression d'air dans l'outil puisse se dissiper

N'utiliser que les raccords MÂLES de type pneumatique pour

T

OUJOURS UTILISER LE BON RACCORD POUR L'OUTIL

r

.

blessures sérieuses à l'utilisateur et tierces personnes et pourrait endommager l'outil et autres biens.

Le manque à suivre n'importe laquelle des instructions ci-haut mentionnées pourrait résulter en des

R

VICE L'ÉLÉMENT

T

ACT TOUCHE LA PIÈCE

ACHES LORSQUE LA SOURCE

Communiquez avec votre représentant Paslode pour une présentation du Programme de Sensibilisation sur la Sécurité de Paslode.

accidentellement.

contact ne fonctionne proprement. L'outil pourrait se décharger

contact. Ne pas utiliser l'outil à moins que l'élément de pointe de

modifier

, enlever ou mettre hors service l'élément de pointe de

de contact, afin de prévenir la décharge accidentelle. Ne jamais

L'outil est équipé d'un mécanisme de sécurité, l'élément de pointe

DE POINTE DE CONTACT

NE PAS ENLEVER OU METTRE HORS SE

travail.

minces, ou près des bords et dans les coins, puisque

doublez de précaution avec les pièces de travail

avec la pièce de travail. Même dans cette situation,

L'outil ne devrait être opéré que lorsqu'il est en contact

PIÈCE DE TRAVAIL

FONCTIONNER L'OUTIL SEULEMENT SUR UNE

ATT

r

, mettre hors service ou pincer la gâchette de

les attaches pourraient traverser ou faire ricochet de la pièce de

rechargez l'outil.

et la pointe de contact ne sont pas pressées lorsque vous

Assurez-vous d'avoir désaccouplé l'entrée d'air et que la gâchette

DE TRAVAIL.

L'ÉLÉMENT DE POINTE DE CON

D'AIR EST ACCOUPLÉE, LA GÂCHETTE EST PRESSÉE OU

NE P

AS CHARGER LES

l'élément de pointe de contact touche la pièce de travail.

trait à l'outil d'enfoncer une attache, n'importe quand, lorsque

l'outil en position barrée ou opérationnelle, puisque ceci permetNe jamais modifie

OU OPÉRATIONNELLE.

NE JAMAIS PINCER LA GÂCHETTE EN POSITION BARRÉE

pourrait décharger des attaches non remarquées.

jamais le pointer vers vous ou vers une autre personne. L'outil

Même si vous croyez que l'outil est vide ou est désaccouplé, ne

Vérifiez le magasin pour des attaches qui pourraient y reste

NE JAMAIS PRÉSUMER QUE L'OUTIL EST VIDE

de l'outil.

désaccoupler l'outil de la source d'air et d'enlever toutes attaches

Ne jamais tenter de débloquer ou de réparer l'outil avant de

DÉBLOCAGES

L

LORS DE L'ENTRETIEN OU DES

pourriez décharger l'outil accidentellement et vous

d'air ou avec la gâchette pressée puisque vous

poignée. Ne jamais transporter l'outil par le tuyau

T

oujours transporter l'outil uniquement pas sa

POIGNÉE

NE TRANSPORTER L'OUTIL QUE PAR SA

DÉSACCOUPLER L'OUTI

entreprise, lieu de travail ou toute autre information sur sa surface.

être af

faibli en faisant graver ou poinçonner le nom de votre

Le boitier de l'outil est un conduit de pression et ne devrait jamais

NE PAS AFFAIBLIR LE BOITIER DE L'OUTIL

blesser ou blesser une autre personne.

sures.

son fonctionnement pourraient le manipuler et causer des blessurveillance, puisque de tierces personnes, non familières avec

l'outil vers un autre endroit. L'outil ne doit jamais être laissé sans

lorsque vous quittez le chantier de travail ou que vous transportez

T

oujours désaccoupler l'outil de la source d'air lorsqu'il est remisé,

DÉSACCOUPLER L'OUTIL QUAND IL N'EST PAS UTILISÉ

pas chargé.

ou toute autre personne, même si vous croyez que l'outil n'est

jamais initier des jeux brutaux avec l'outil ou le pointer vers vous

Cet outil n'est pas un jouet donc ne pas l'utiliser comme tel. Ne

NE JAMAIS INITIER DES JEUX BRUTAUX AVEC L'OUTIL

en place.

ce soit ou utiliser l'outil comme marteau pour enfoncer la pièce

Ne pas jeter l'outil à terre, frapper le boîtier de quelque façon que

PRÉVU.

L'OUTIL NE DOIT ÊTRE UTILISÉ QUE POUR SON USAGE

vous assurer du port de l'équipement de protection.

, il en est de votre responsabilité de

ANSI

VOIR LU ET

tant qu'employeur

Z87.1 lors de l'opération de l'outil ou à proximité. En

les yeux et l'ouïe qui se conforment aux normes

Toujours porter de l'équipement de protection pour

POUR LES YEUX ET L'OUÏE.

PORTER DE L'ÉQUIPEMENT DE PROTECTION

OUTES LES PRÉCAUTIONS À PRENDRE ET LES

Porter des casques de sécurité lorsque nécessaire.

INSTRUCTIONS DU MANUEL.

COMPRIS T

NE PAS ESSAYER D'OPÉRER L'OUTIL AVANT D'A

nécessaire pour manipuler les outils Paslode en toute sécurité.

Ces instructions se rapportant à la sécurité donnent l'information

LA SÉCURITÉ AVANT TOUT

CURIT

INSTRUCTIONS SUR LA S

Page 34

3

NE DÉPASSEZ PAS CETTE PRESSION DE FONCTIONNEMENT RECOMMANDÉE

comprise dans cette plage pour obtenir le meilleur rendement de l’outil.

5,5 à 8,3 bars (80 à 120 p.s.i.). Choisissez une pression d’air de fonctionnement

PRESSION D’AIR DE FONCTIONNEMENT :

débranché de l’alimentation en air.

7 mm (0,28 po) ou plus. Le raccord doit pouvoir libérer la pression d’air de l’outil lorsqu’il est

Cet outil utilise un raccord mâle de 1/4 po N.P.T. Le diamètre intérieur doit être de

RACCORDS À AIR DE L’OUTIL

5,5 à 8,3 bars (80 à 120 p.s.i.)

kg

Calibre 16

25 mm à 63 mm (1 po à 2½ po)

1,8

313 mm

74 mm

295 mm

DIAMÈTRE DE L A TIGE

DES CLOUS

LONGUEUR

CARACTÉRISTIQUES DES ATTACHES

PRESSION DE FONCTIONNEMENT

POIDS

LONGUEUR

LARGEUR

HAUTEUR

MODÈLE N° T250S-F16P (Pièce n° 515500)

CARACTÉRISTIQUES DE L’OUTIL

CARACTÉRISTIQUES DE L’OUTIL ET ATTACHES

Page 35

2

D'OPÉRATIONS OU AUTRES.

PRODUCTION, PERTE DE MATERIAUX, COÛTS MAJORÉS

DÉCOULER PAR LA PERTE DE PROFITS ANTICIPÉS, DE

INCLUANT MAIS NON LIMITÉ AUX DOMMAGES POUVANT

DE DOMMAGES DIRECTS, INDIRECTS OU CONSÉQUENTS À,

POURRAIT ÊTRE TENUE RESPONSABLE, EN AUCUN CAS,

l'exception des modalités légales applicables. PASLODE NE

être connexes à l'utilisation et la performance de l'outil, à

qui a trait à toutes autres garanties pouvant provenir de ou

, prime en ce

et la responsabilité de Paslode,

TELLE QUE CITÉE ET CONVENUE CI-DESSUS

CLARATION CI-DESSUS,

CONVENANCE, OU AUTRE, À L'EXCEPTION DE LA DÉIMPLICITE, EN CE QUI À TRAIT À LA COMMERCIALITÉ

PASLODE NE DONNE AUCUNE GARANTIE, EXPRESSE OU

l'outil.

manière telle qu'elle affecte ou amoindrit la performance de

d'après l'expertise de Paslode, a été modifié ou réparé de

endommagé durant le transport ou la manutention, ou bien,

des composantes autres que les pièces originales Paslode,

leur grandeur ou qualité, ayant été mal entretenu, réparé avec

des attaches qui ne rencontrent pas les normes de Paslode,

accidentels ou intentionnels, ou bien utilisé de concert avec

sujetti à de l'abus, une mauvaise utilisation, des dommages

Cette garantie est nulle dans le cas d'un outil qui a été as-

couvercle.

moulées du boîtier et ensemble de

s'applique sur toutes les pièces

Une garantie limitée de cinq ans