Page 1

Instruction Sheet

®

temp hot - temp cold

temp hot

------------------------------------------------- -

% efficiency=

Flywheel

Crankshaft

Graphite

power piston

Foam

displacer

Connecting

rod

Connecting

rod

IMPORTANT:

Do Not Oil

Low Delta T Stirling Engine

SE-8576A

012-06870B

Introduction

The PASCO SE-8576A Low Delta T Stirling Engine is a

jewel-like engine. Because of its precision components and

careful construction, it can operate on temperature differences as small as four degrees celsius (4 °C).

For example, when the room temperature is 22.2 °C (72 °F)

or cooler, the heat from a warm hand is enough to power the

engine.

Stirling engines can be very efficient with some designs

attaining efficiencies up to 50% of the Carnot Cycle efficiency . The Carnot Cycle determines the maximum theoretical efficiency of a heat engine according to the formula:

where the temperature is measured in absolute degrees

(kelvin (K) or rankine).

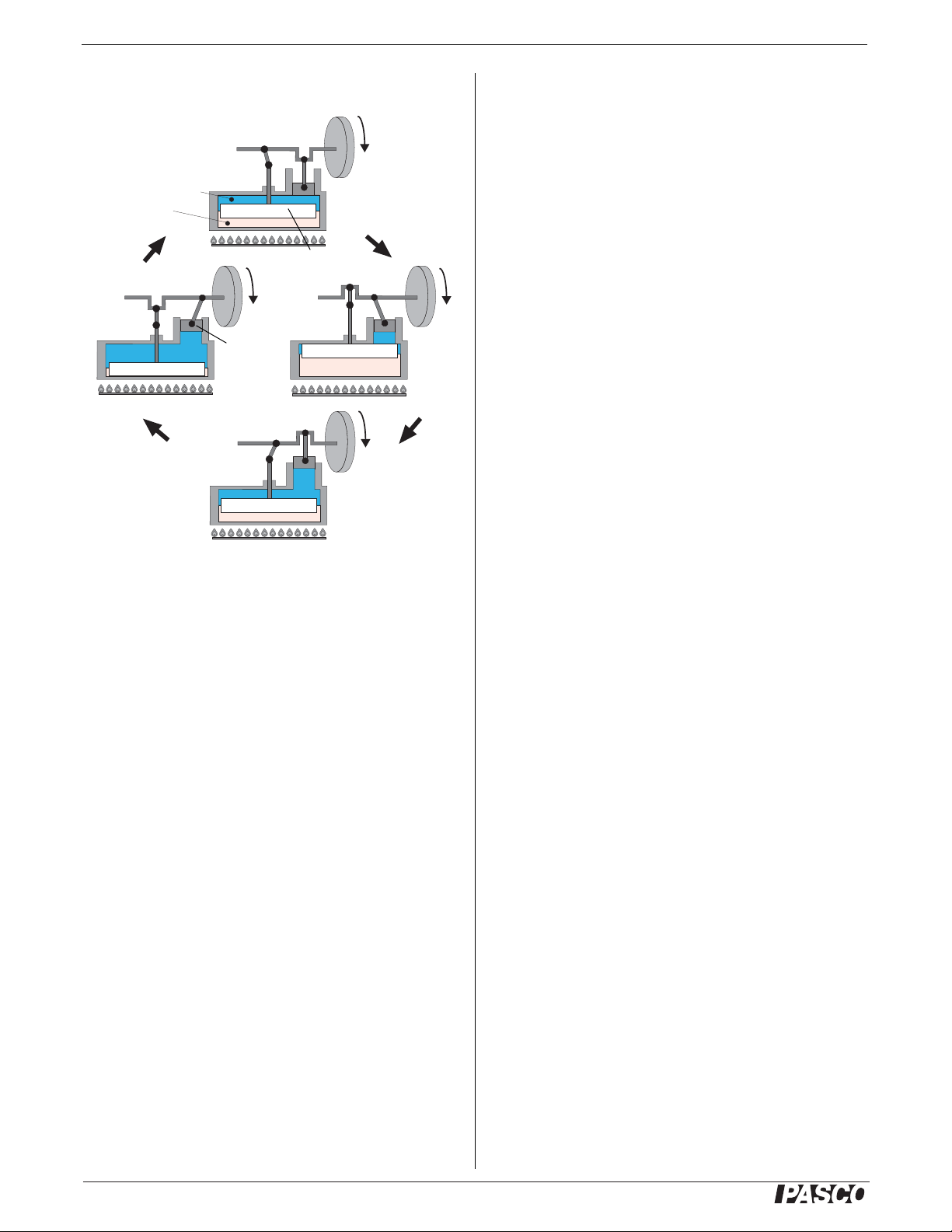

Operation

The Low Delta T Stirling Engine operates as follows:

Next, the energy stored in the flywheel moves the displacer

closer to the warm side of the engine, and the air once again

flows around the edge of the displacer toward the cool side

of the engine.

When the air is cooled, it contracts, and the pressure drops

throughout the engine. The pressure inside the engine

becomes less than the pressure outside, and the graphite

power piston is pushed down. The displacer moves back

toward the cool side, the air is displaced toward the warm

side, and the cycle starts all over again.

The bottom plate of the engine along with the clear acrylic

cylinder, the top plate, and the graphite power piston make

up a sealed system. When the air inside this system changes

temperature, so does the pressure.

Inside the clear acrylic cylinder is a large white foam dis-

placer. This displacer looks like a piston, but it has a

3.125 mm (1/8” inch) gap around its outer edge. Air never

pushes on the displacer; it flows around the displacer.

The engine can begin working when either the bottom plate

or the top plate is heated or cooled to a temperature at least

4 °C warmer or cooler than the other plate. A gentle spin on

the flywheel is needed to start the engine.

As the foam displacer moves away from the warm side of the

engine, air flows around the edge of the displacer toward the

warm side and is heated. When the air is heated, it expands,

which increases the pressure inside the entire engine. This

increase in air pressure pushes up on the graphite power piston.

800-772-8700 techsupp@pasco.com www.pasco.com

The foam displacer only moves the air back and forth from

the warm side to the cool side of the engine. It does not do

any work on the crankshaft. In other words, the connecting

Page 2

®

Low Delta T Stirling Engine SE-8576A

HEATING

EXPANSION

COOLING

CONTRACTION

REVOLUTION

COLD AIR

HOT AIR

Foam displacer

Graphite

power

piston

Operation of a displacer type Stirling Engine

rod to the displacer could be a string and the engine would

still work.

Troubleshooting

Generally there are three reasons why Stirling engines fail to

run: too much friction, air leaks, or inadequate thermal transfer. The most likely reason for the Low Delta T Stirling

Engine to fail to run is inadequate thermal transfer.

If the engine will not run, try the following:

Put 2.5 cm (1 inch) of water in the bottom of a coffee mug.

Heat the water until the water is boiling vigorously. Carefully remove the mug from the heat source, and place the

engine on top of the mug. Wait for 15 seconds, and then gently spin the flywheel. Try spinning the flywheel in both

directions if it fails to start in a minute or so.

If the engine will not run when you try this test, it needs to be

returned for maintenance.

A Brief History of the Stirling Engine

The Reverend Robert Stirling, a minister of the Church of

Scotland, was troubled by some of the dangerous engines

that were used at the beginning of the industrial revolution.

Steam engines would often explode with tragic effects to

anyone unfortunate enough to be standing nearby. So in 1816

he invented and patented “A New Type of Air Engine with

Economizer”.

Usage

Place the Low Delta T Stirling Engine on the palm of your

ward hand with the label toward you. After the engine has

warmed up for a couple of minutes, gently spin the flywheel

in a clockwise direction to get it started.

NOTE: Hand temperatures vary widely. Not everyone has

warm enough hands to make this engine run. If your hands

are cool, find someone with warm hands to try this.

You can also run the engine in the opposite direction by placing the bottom plate on a cold object, letting it cool down,

and then gently spinning the flywheel in the counterclockwise direction.

Maintenance

• Dust is the number one enemy of this engine. Cover it

when it is not in use.

• It is a good idea to store it in a plastic case.

• Never oil the engine.

• Do not store the engine where it will be exposed to

bright sunlight or the colors will fade.

• Handle with care. The Low Delta T Stirling Engine is a

delicately balanced precision engine and it is very fragile.

2

Robert Stirling realized that the engines he built would be

more efficient if some of the heat that was used to warm the

air for one cycle was saved and used again in the next cycle.

He called the device that saved the heat an “economizer”.

T oday, this is usually called a “regenerator”, and is probably

Robert Stirling’s most important invention.

“Hot air engines”, as they were initially called, couldn’t

explode and often produced more power than the steam

engines of their day. The problem was that the only readily

available metal in the early 1800s was cast iron, which oxidizes rapidly when left in a very hot flame.

Despite this difficulty, Stirling engines were widely used as

water pumping engines at the turn of the century. They

required little service, never exploded, were fairly quiet, and

the water provided a good cooling source for the cool side of

the engine. Thousands of these engines were sold

The Low Delta T Stirling Engine

.In 1983, Ivo Kolin, a professor at the University of Zagreb

(in what was then Y ugoslavia) demonstrated the first Stirling

engine that would run on small temperature differences.

After he published his work, Dr. James Senft, a mathematics

professor at the University of Wisconsin - River Falls

(United States), built the first engines similar to the PASCO

Low Delta T Stirling Engine.

The Carnot Energy Cycle

In the mid 1800s, a Frenchman named Sadi Carnot figured

out the maximum limits of efficiency. His formula is an

accepted standard for determining the maximum possible

Page 3

®

Low Delta T Stirling Engine SE-8576A

efficiency of an engine. No engine can exceed the Carnot

efficiency. (The second law of thermodynamics says you

can’t get out more than you put in; you can only break even.)

It takes good engineering and complex machines to achieve

a significant fraction of the Carnot efficiency. Real Stirling

engines can reach 50 percent of the maximum theoretical

value, which is a very high percentage.

Stirling Engines Today

The modern uses of Stirling engines are invisible to almost

everyone. There have been many research engines built in

recent years, but there are only three areas where Stirling

engines have made a dramatic impact. These are Stirling

engines in submarines, in cryocoolers, and in science classrooms.

Cryogenics is the science of things that are very cold, and

Stirling engines can be used to produce extremely cold temperatures. It’s not obvious, but a Stirling engine is reversible.

If you warm one side and cool the other, you get mechanical

work out. However, if you mechanical work in, by connecting an electric motor, for example, one side will get hot and

the other will get cold. In a correctly designed Stirling

engine, the cold side will get extremely cold. In fact, Stirling

engines used as cryocoolers have been made that will cool

below 10 kelvin (K). Micro-sized Stirling engines have been

produced in large numbers for cooling infrared chips down

to 80 K for use in night vision goggles and infrared cameras.

Since Stirling engines are so efficient, an obvious question

is: Why doesn’t my car have one?

Technical Support

For assistance with any PASCO product, contact PASCO at:

Address: PASCO scientific

10101 Foothills Blvd.

Roseville, CA 95747-7100

Phone: +1 916 786 3800 (worldwide)

800-772-8700 (U.S.)

Web: www.pasco.com

Email: techsupp@pasco.com

For more information about the Low Delta T Stirling Engine

and the latest revision of this Instruction Sheet, go to the

PASCO web site at www.pasco.com and enter SE-8576A in

the Search window.

Limited Warranty For a description of the product warranty, see

the PASCO catalog. Copyright The PASCO scientific

012-06870B Low Delta T Stirling Engine Instruction Sheet is copyrighted with all rights reserved. Permission is granted to non-profit

educational institutions for reproduction of any part of this manual,

providing the reproductions are used only in their laboratories and

classrooms, and are not sold for profit. Reproduction under any other

circumstances, without the written consent of PASCO scientific, is

prohibited. Trademarks PASCO and PASCO scientific are trademarks or registered trademarks of PASCO scientific, in the United

States and/or in other countries. All other brands, products, or service names are or may be trademarks or service marks of, and are

used to identify, products or services of, their respective owners. For

more information visit www.pasco.com/legal.

Although a variety of prototype Stirling engine powered cars

have been developed, they have not gained popularity

because that have to warm up for 30 seconds to a minute

before they will move. Most consumers have not been willing to wait that long to get started. The low gas prices of the

1980s and 1990s did not provide an economic incentive for

consumers to switch to Stirling engines, and automobile

companies have not had the incentive to research and

develop more saleable engine designs.

Stirling Engines in the Future

Future uses of Stirling engines could include applications in

the maritime and aviation industries. Stirling engines would

work exceptionally well for auxiliary power generators on

pleasure boats, where their silence and efficiency would be

value, and cooling water is plentiful. Some research has

already been done in this area: the French research submarine “Saga” is Stirling engine powered. Stirling engines

would also work very well in airplanes where the air gets

cooler as the plane climbs to altitude. Stirling engines would

not lose as much power as they climb as conventional piston

engines or jet engines. Stirling engines would operate with

very low levels of vibration and noise.

3

Loading...

Loading...