Page 1

Instruction Manual and

Experiment Guide for

the PASCO scientific

Model SE-8575

THE VISIBLE

STIRLING ENGINE

012-06055A

2/96

© 1995 PASCO scientific $5.00

Page 2

Page 3

012-06055A The Visible Stirling Engine

T able of Contents

Section Page

Copyright, Warranty, and Equipment Return .....................................................ii

Introduction ......................................................................................................1

History and Theory of Operation .......................................................................2

Operation

Operating on Ice .........................................................................................3

Power from your Fingertips.........................................................................3

Operating with Hot Water ...........................................................................4

Operating on Maximum Power ...................................................................4

Experiment .......................................................................................................5

Demonstration: An Engine that Runs on Ice ......................................................7

Maintenace .......................................................................................................8

Troubleshooting ................................................................................................9

Credits ............................................................................................................10

Technical Support ...........................................................................inside back cover

®

i

Page 4

The Visible Stirling Engine 012-06055A

Copyright, Warranty and Equipment Return

Please—Feel free to duplicate this manual

subject to the copyright restrictions below.

Copyright Notice

The PASCO scientific Model SE-8575 The Visible

Stirling Engine manual is copyrighted and all rights

reserved. However, permission is granted to non-profit

educational institutions for reproduction of any part of

this manual providing the reproductions are used only for

their laboratories and are not sold for profit. Reproduction under any other circumstances, without the written

consent of PASCO scientific, is prohibited.

Limited Warranty

PASCO scientific warrants this product to be free from

defects in materials and workmanship for a period of one

year from the date of shipment to the customer. PASCO

will repair or replace, at its option, any part of the product

which is deemed to be defective in material or workmanship. This warranty does not cover damage to the product

caused by abuse or improper use. Determination of

whether a product failure is the result of a manufacturing

defect or improper use by the customer shall be made

solely by PASCO scientific. Responsibility for the return

of equipment for warranty repair belongs to the customer.

Equipment must be properly packed to prevent damage

and shipped postage or freight prepaid. (Damage caused

by improper packing of the equipment for return shipment will not be covered by the warranty.) Shipping

costs for returning the equipment, after repair, will be

paid by PASCO scientific.

Equipment Return

Should the product have to be returned to PASCO

scientific for any reason, notify PASCO scientific by

letter, phone, or fax BEFORE returning the product.

Upon notification, the return authorization and

shipping instructions will be promptly issued.

ä

NOTE: NO EQUIPMENT WILL BE

ACCEPTED FOR RETURN WITHOUT AN

AUTHORIZATION FROM PASCO.

When returning equipment for repair, the units

must be packed properly. Carriers will not accept

responsibility for damage caused by improper

packing. To be certain the unit will not be

damaged in shipment, observe the following rules:

➀ The packing carton must be strong enough for the

item shipped.

➁ Make certain there are at least two inches of

packing material between any point on the

apparatus and the inside walls of the carton.

➂ Make certain that the packing material cannot shift

in the box or become compressed, allowing the

instrument come in contact with the packing

carton.

Credits

This manual authored by: Brent Van Arsdell

This manual edited by: Mary Ellen Niedzielski

Address: PASCO scientific

10101 Foothills Blvd.

Roseville, CA 95747-7100

Phone: (916) 786-3800

FAX: (916) 786-3292

email: techsupp@pasco.com

web: www.pasco.com

®

ii

Page 5

012-06055A The Visible Stirling Engine

ld

Introduction

The PASCO Visible Stirling Engine is a tool to teach

students how engines work and to excite them about

physics.

Stirling engines have the most efficient cycle in the

world. Does that mean the Model SE-8575 engine is the

most efficient engine in the world? No. It means that

Stirling engines with regenerators have a cycle that

matches the Carnot cycle. The Carnot cycle determines

the maximum theoretical efficiency of a heat engine.

temphot – temp co

temp hot

The temperatures must be measured in absolute degrees

(Kelvin or Rankine) for this formula to work.

No real engine (one that could be built in a machine shop)

can achieve the Carnot theoretical efficiency. But real

Stirling engines come closer to the Carnot cycle than any

other engine! Some research Stirling engines have

attained 50 percent of the theoretical Carnot efficiency!*

The efficiency of the SE-8575 is calculated in the experiments section of this manual.

× 100 = % efficiency

If Stirling engines are so efficient, why don’t we have

them in automobiles? The best answer to this question is

an easy demonstration. Start the SE-8575 on nearly

boiling water and wait for it to get up to full speed. Then

remove the engine from the heat source and notice that it

keeps running for a few minutes.

It is very easy to do an engineering trick to make the

engine stop instantly, but there is nothing in the world that

can be done to make a Stirling engine start instantly.

Today’s drivers want to be able to start their cars instantly

(if not sooner) and some of them want to burn rubber

across the parking lot. Stirling engines can’t do that.

Research automobile Stirling engines generally take

about 30 seconds before the car can be driven away.

Modern drivers do not want to wait.

Computer Compatibility

Photogates may be used to measure the engine rpm.

Additional Equipment Recommended

You may also find it convenient to use:

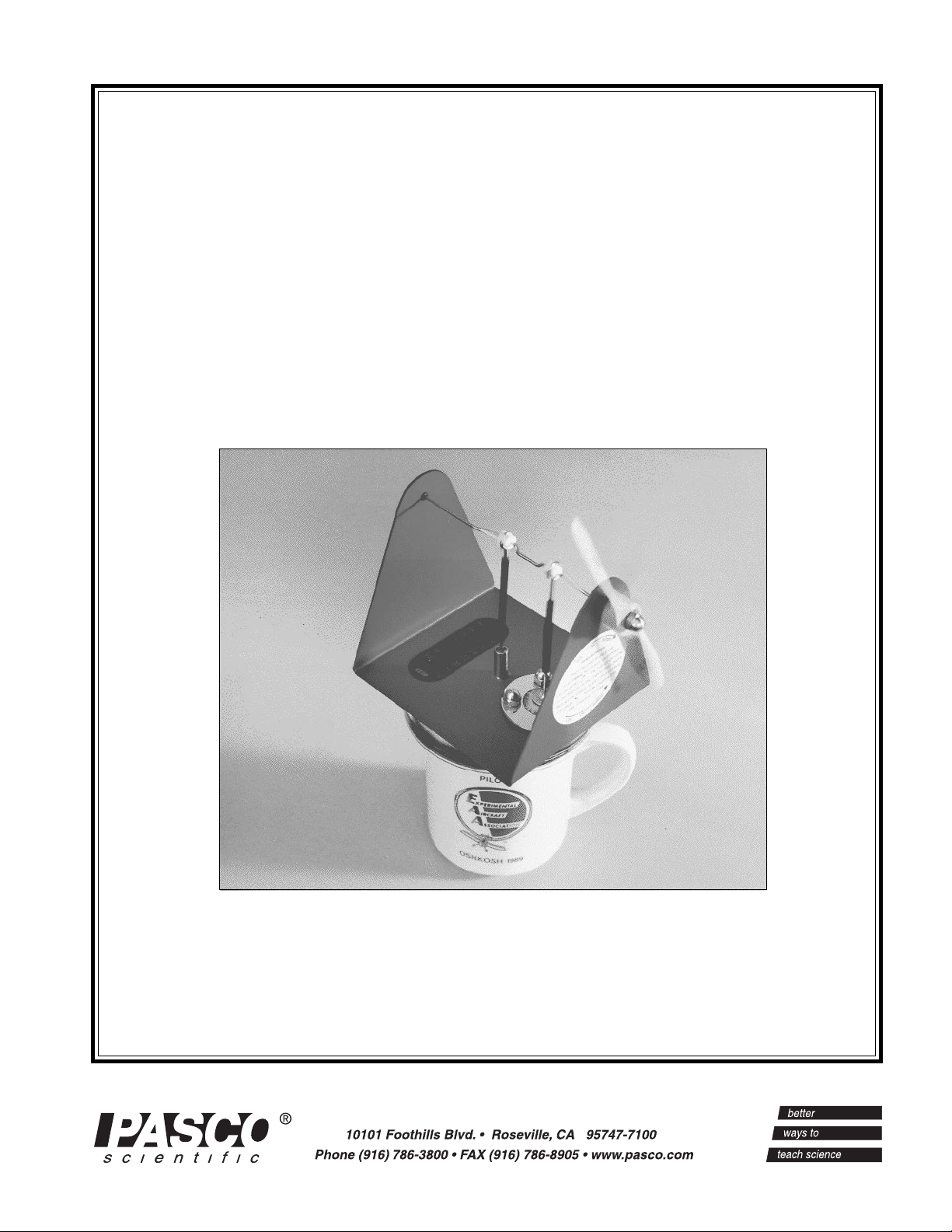

• A coffee cup.

*

“Stirling Machines: An Emerging Technology Paradigm”

by B. Ross and L.B. Penswick, page 8.

®

• A clear water glass

• A Styrofoam dinner plate or a Styrofoam bowl.

1

Page 6

The Visible Stirling Engine 012-06055A

History and Theory of Operation

Why STIRLING Engines are important

Every practical engine ever built compresses a gas then

expands it and moves it through a cycle.

The Reverend Robert Stirling, a minister of the Church of

Scotland, was troubled by some of the dangerous engines

that were used at the beginning of the industrial revolution. Steam engines would often explode with tragic

effects to anyone unfortunate enough to be standing

nearby. So in 1816 he invented and patented “A New

Type of Air Engine With Economizer.”

Hot air engines, as they were initially called, couldn’t

explode and often put out more power than the steam

engines of their day. The only trouble was that the readily

available metal of the early 1800’s was cast iron, and cast

iron oxidizes rapidly when you leave it in a very hot flame.

In spite of these difficulties, Stirling engines were widely

used as water pumping engines at the turn of the century.

They required little service, never exploded, were fairly

quiet and the water provided a good cooling source for

the cold side of the engine. Thousands of these engines

were sold .

In the mid 1800’s a bright Frenchman named Sadi Carnot

figured out the maximum limits on efficiency. His

formula is an accepted standard for determining the

maximum possible efficiency of an engine. No engine

can exceed the Carnot efficiency. [The first law of

Thermodynamics says you can’t get out more than you

put in. You can only break even.] In fact no real engine

can achieve carnot efficiency. [The second law of thermodynamics says you can’t break even.]

It takes good engineering and complex machines to

achieve a significant fraction of the Carnot efficiency.

On the simplest level, a Stirling engine operates as

follows. When a gas in a closed cylinder is heated it

expands and pushes up on a piston. When the same gas is

cooled, it contracts and pulls down on the piston.

The next level of understanding is to realize how regeneration works. Robert Stirling realized that the engines he

built would be much more efficient if some of the heat

that was used to heat the air for one cycle was saved and

used again in the next cycle. Robert Stirling called the

device that saved heat in his engines an economizer.

Today, these are usually called regenerators and probably

are Robert Stirling’s most important invention.

In the model SE-8575, regeneration works as follows.

When the yellow foam inside the engine is near the top of

the cylinder (and the engine is running on a cup of hot

water) most of the air is on the bottom side (the hot side)

where it is heated. When the air gets hot it expands and

pushes up on the piston. When the foam moves to the

bottom of the engine it moves most of the air (it displaces

the air) to the top of the engine. The top of the engine is

cool, allowing the air inside the engine to cool off (reject

heat to the environment) and the piston receives a downward push. This engine would run even if the “displacer”

(the yellow foam) was made of solid Styrofoam. It runs

much better because it is made of a special air filter foam.

When the air is flowing from the hot side of the engine to

the cold side it flows through and around the yellow foam

(the displacer). Since the air is hotter than the foam, some

of the heat from the air will flow into the foam. The air

cools off and the foam heats up. This is called regeneration and is very important in many industrial processes.

When the air makes the return trip to the hot side of the

engine it once again flows through and around the foam.

This time the air heats up and the foam cools off. The

heat that would have been wasted in an engine without

regeneration is saved and a much more efficient engine is

the result.

A Stirling engine with a regenerator has a cycle that

matches the Carnot cycle. It has the same theoretical

maximums and the same theoretical efficiencies.

2

®

Page 7

012-06055A The Visible Stirling Engine

Operation

Operating On Ice

Running the engine on ice is a quick and interesting way

to start the engine. Pick up the engine and rub an ice cube

vigorously around the bottom (the blue part) of the

engine. Then place the engine on a pile of ice cubes (ice

chips work best) and flip the prop in the direction indicated on the label.

Ice cream or frozen yogurt also work well as ice substitutes. Ice cream provides a good heat sink, (when compared to ice cubes) because it makes such good thermal

contact with the bottom of the engine. Ice cubes tend to

provide only limited points of contact on the top edges of

the cubes.

If you run the engine on ice cream or frozen yogurt, take

extra care to clean it after you are done. Carefully run the

bottom of the engine under some warm water to clean it.

Stirling Engine on a Bowl Filled with Ice

Stirling Engine on an Ice Cream Cone

Power From Your Fingertips!

When running the engine on ice in a room that is 72° to

75°F the temperature of the top of the engine will drop to

about 68°F. When this occurs an interesting demonstration can be performed.

®

Palm over LCD Thermometer

Place a warm hand (as many fingers as fit) over the LCD

thermometer and the surrounding area. Within 20 seconds

you will observe a significant increase in the operating

speed of the engine. Engines run on heat, and in this case

body heat can be used to increase the output power of the

SE-8575.

3

Page 8

The Visible Stirling Engine 012-06055A

Operating with Hot Water

Water is a very good thermal transfer medium. The

visible Stirling engine will run well on a cup of hot water.

Does the water have to be in contact with the bottom of

the engine? No. Steam rising off the water and then

condensing on the bottom of the engine moves the heat

to the hot side of the engine. Here’s how to start the

engine in a hurry.

Fill a coffee mug about 1/3 full of hot tap water then

microwave it until the water is boiling vigorously. Place

the engine on the top of the coffee mug, wait 20 seconds,

and flip the prop in the direction indicated on the label.

This also works well with a clear water glass. Using a

clear glass has the added benefit of letting students see the

steam rise and the water condense on the bottom of the

engine. Make sure to use a glass that is safe for the

temperature of water you will be putting in it.

The engine should start immediately and run at a high

rate of speed.

Operating On Maximum Power

The way to get the most power out of the model SE-8575

is to increase the temperature difference between the top

and bottom plates. The maximum operating temperature

is 212°F and the minimum operating temperature is -40°F.

➤ NOTE: Do not apply direct flame to the unit!

The best way to achieve maximum power is to put boiling

water on the bottom (do not use a Bunsen burner) and ice

cubes on the top. Be careful not to get water down inside the

engine or on top of the piston. Water on the top of the LCD

thermometer is okay.

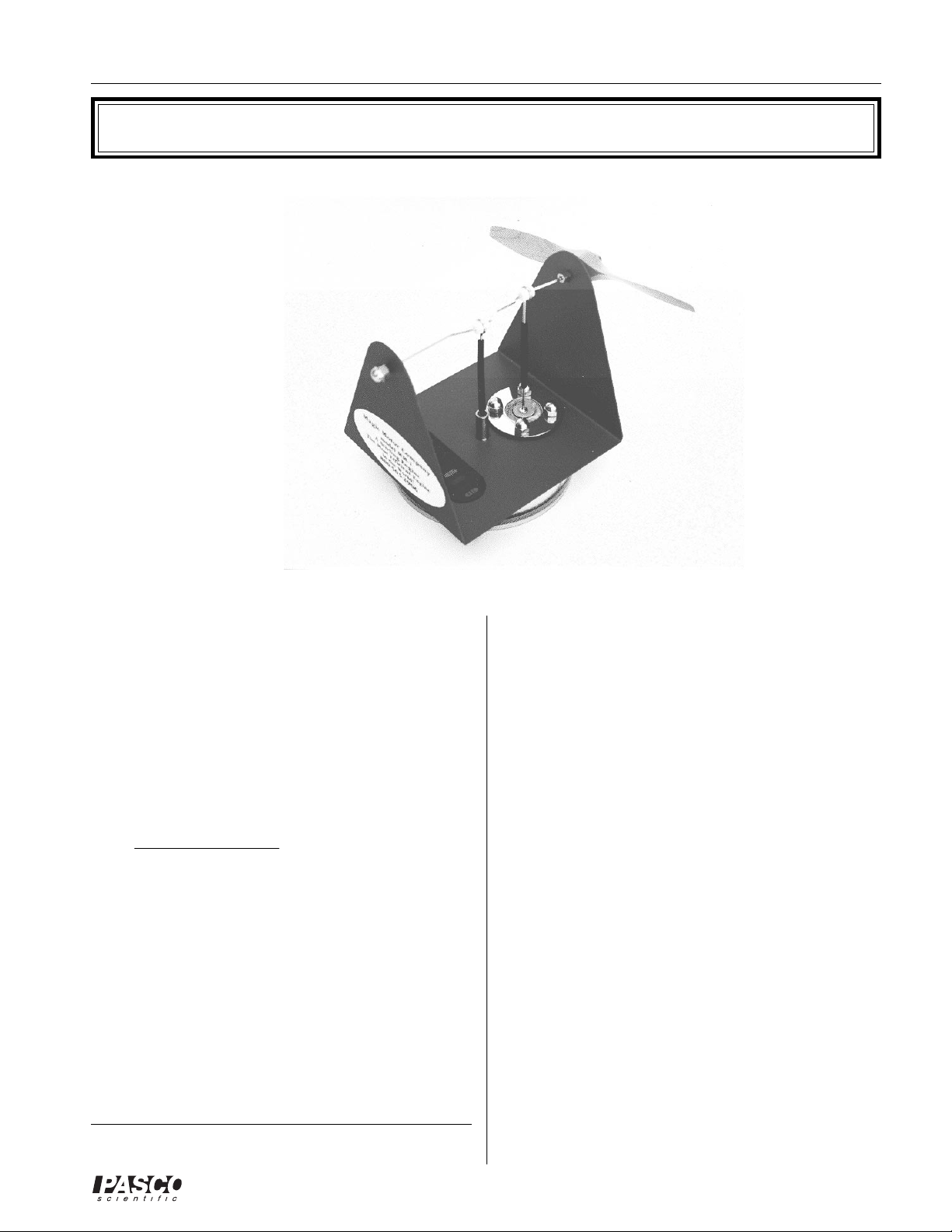

Air Displacer

(90° out of phase from

the piston)

Propeller

Piston

Yellow Foam

Air Displacer

Stirling Engine on a Cup of Hot Water

Liquid Crystal Thermometer

®

4

Page 9

012-06055A The Visible Stirling Engine

ld

y

Experiment

Equipment needed

– Model SE-8575 Visible Stirling Engine

– (2) Styrofoam cups

– Thermometer

– Hot water (boiling is preferred )

– Paper towels to wipe up water

– Optional: Basic Calorimetry Set (TD-8557)

Purpose

The purpose of this experiment is to get a physical feel for the loss mechanisms in any engine.

Theory

Engines are made to do something. They take in energy from a source, they reject waste heat to a

reservoir, and they do useful work. Every engine has losses. The purpose of this experiment is to

identify the loss mechanisms and determine what could be done to reduce those losses.

Setup

➀ Nest one Styrofoam cup inside the other to make a two cup calorimeter. Weigh the cups.

➤ NOTE: The TD-8557 styrofoam Calorimeter works well to replace the cups.

➁ Fill the cups half full with very hot water. Put a lid over the assembly and weigh it again.

➂ Measure the temperature of the water. Convert the temperature to Kelvin or Rankine.

➃ Measure the temperature of the air in the room. Convert this temperature to Kelvin or Rankine.

➄ Place the engine on top of the hot water and start it. After it gets up to speed stop the engine and

turn it slowly by hand. Watch what happens to the piston when the air shifts from the hot side to

the cold side.

Calculation

Calculate the theoretical efficiency of the engine operating between these two temperatures using

temphot – temp co

the following formula.

What is the theoretical efficiency of a Carnot engine operating between these temperatures?

temp hot

× 100 = % efficienc

Questions

➀ Which would do more for efficiency of the engine, raising the temperature hot by 50°, or

lowering the temperature cold by 50°?

➁ The hot water in the cups is a form of stored energy available to do work. Would it be possible

to run a car on very hot water?

➂ How much energy is stored in the hot water?

®

5

Page 10

The Visible Stirling Engine 012-06055A

➃ When you buy gasoline to run your car, what is it that you are really buying?

➄ If hot water could be used to run a car, why do we buy gasoline instead of hot water? Hot water

would be a zero pollution engine.

➆ How much stored energy is there in a gallon of gasoline?

➇Some of the air makes the piston bulge up around the edges when the air moves to the hot side.

Does this air do any useful work?

➈ Would the engine put out more power if this flexible piston was replaced with a very tight fitting

light weight graphite piston?

6

®

Page 11

012-06055A The Visible Stirling Engine

DEMONSTRATION:

An Engine That Runs On Ice

Setup

Set the SE-8575 up to run on ice chips, ice cream, or frozen yogurt. Detailed instructions are in

the Operation section of this manual. Start it running and ask the following questions.

Questions

➀ What is the source of energy to run this engine?

➁ Since there is no such thing as a free lunch, who paid for the energy to make this engine run and

what company did they pay it to?

➂ After the SE-8575 has been running for some time, do the Power From Your Fingertips demo as

explained in the operations section. Who paid for this energy to make the engine run faster and

who did they pay it to?

➃ Would it be possible to have a full power engine that had zero pollution and used the heat from

the room as a hot source.

➄ Calculate the Carnot efficiency of an engine running with liquid nitrogen as a cold sink and a

72°F (23°C) ambient hot source.

➅ Liquid nitrogen is readily available. What determines whether it would be a good idea to build

an engine like this?

➆ Since the air is roughly 80% nitrogen, would an engine like this cause any pollution?

➇ When an engine is running on a heat source the Carnot formula determines how much of the

heat can become useful work. In this engine as in most engines the majority of the heat that

could become useful work doesn’t become useful work. What happens to this heat? Identify the

specific loss mechanisms.

➈ Internal combustion four stroke engines have one power pulse every other trip of the piston.

Stirling engines have two power pulses per trip of the piston (one going up, and one going

down). All other things being equal (which they never are) how much smoother should a

Stirling engine be than an Otto cycle engine?

➉ Are you likely to see a Stirling engine offered for sale in a car? Why or why not?

Would Stirling engines be good candidates for powering submarines? Stirling engines are quiet

11

and submarines like quiet.

Would Stirling engines be a good source of auxiliary power generation for yachts? Good

12

cooling water is available, and people on yachts like it quiet too.

®

7

Page 12

The Visible Stirling Engine 012-06055A

Maintenance

The PASCO Visible Stirling Engine SE-8575 is a delicate

apparatus. Treat it like a fine piece of laboratory equipment and it will last a very long time.

Maximum Operating Temperature

The engine is made for intermittent use with a maximum

operating temperature of 100°C (212°F).

For Intermittent Use Only

➤ IMPORTANT: The PASCO SE-8575 Stirling

Engine is not made for continuous use.

It may be tempting to find a source of waste heat and let

the engine run continuously. Do NOT do this!

• The piston has a limited life time. While it should

last for years with occasional use, it will only last

for about 6 weeks running 24 hours a day.

• To extend the life of the engine, do not exceed its

maximum operating temperature. Do not run the

engine on heat sources other than hot water.

Non-Acceptable Heat Sources

➤ IMPORTANT: Do NOT heat the engine using

any type of flame!

The SE-8575 will indeed run very fast on the heat from a

candle flame, but you will exceed the maximum temperatures of the materials in the engine and ruin it.

If you use a burner to heat the water, put the engine on

top of the water after the burner is shut off.

Running the engine on top of a lamp or a similar heat

source is likely to raise the temperature of the acrylic

above its yield temperature and ruin the engine.

DO NOT USE LIQUID NITROGEN!

➤ IMPORTANT: Liquid nitrogen is far too cold

for this engine and very likely will break it. Dry ice

would probably be okay but has not been tested.

A good cooling source is “freeze spray”. This is sold in

an aerosol can at Radio Shack and other electronics

supply stores. It’s a lot of fun to make the engine appear

to run on “nothing”.

DO NOT OIL THE BEARINGS!

During the development of this engine, many different

lubricants were tried in an effort to improve performance.

None of them improved performance at all, and most of

them made the engine run less well or not at all.

All the bearing surfaces contain Teflon. It is unlikely that

any lubricant you might use would improve performance.

To Remove Oil:

Oiling the engine will probably degrade performance or

cause the engine to quit. Use a TINY drop of WD-40 (a

very light dispersant petroleum based product) to clean

off the oil. Be careful to keep the oil from running over

the red anodized surface as it will stain the anodizing.

KEEP THE ENGINE DRY!

After running the engine, make sure it is completely dry

before putting it away. The metal ring that holds the blue

plate on the bottom of the engine in place is made of a

stainless steel alloy that contains some iron. It can rust if

not put away dry. Towel dry the engine carefully before

you put it away. Blow drying it is also a good idea.

Most Common Reason for Engine Failure

• The most common reason for the engine failing to run

is inadequate thermal transfer. If the engine won’t run

try putting about an inch of water in a coffee mug and

microwaving it until it is boiling vigorously!

• Remove the mug from the oven and place the engine

on top of the boiling water, wait 15 seconds, and turn

the prop the direction indicated on the instruction label

for “hot on the bottom.” The engine should start

quickly and run rapidly.

➤ NOTE: Boiling water is dangerous. Handle

with care!

If the engine still does not work or runs very slowly, refer

to the Troubleshooting section.

8

®

Page 13

012-06055A The Visible Stirling Engine

Troubleshooting

There are three general reasons why the SE-8575 Stirling

Engine might not run.

➀ Not enough temperature difference between the hot and

cold side of the engine. This Stirling engine needs about a

40°F (23°C) difference in temperature to run. If the room

is at 72°F (23°C) and the ice temperature is 32°F or

cooler the engine should run at 100 rpm or faster.

If ice is used as the “cold” source, it is possible to have

the bottom of the engine rest on only a few high points

on top of the ice cubes. The best solution is to pick up

the engine and rub an ice cube vigorously around its

bottom. Then place the engine on a pile of ice cubes

(ice chips are best). Push down on the LCD thermometer with your warm hand to help establish contact

with the ice. This will simultaneously warm up the top

of the engine and help establish better ice contact with

the cold side of the engine.

➁ The engine may have developed a leak in the system.

The Stirling cycle engine is a sealed system. It can

only tolerate one tiny leak. If there are any obvious

holes in the grey diaphragm (which is the piston) the

engine will not run. Contact the Magic Motor Company 1-800-503-2906 for replacement parts or service.

➂ There might be internal friction in the system. Every

engine ever built has internal friction losses. However

this engine when operating between such small temperature differences does not have room for much

wasted power.

There are two things that have been observed to sometimes cause problems. There must be about slight looseness in the collars where the crankshaft goes through the

aluminum upright near the propeller. In other words, If

the engine is held in one hand and the prop is moved back

and forth along the axis of the crankshaft it should be

possible to hear the collars make a clicking sound, and

see the bushings which hold the crankshaft in place move

back and forth about the distance of 2 to 4 sheets of

notebook paper.

Also, the piston must move freely without binding at the

top or bottom of its travel. This should never need

adjustment, but it can be adjusted if someone accidentally

moves it out of its range. The piston (grey rubber diaphragm) should, at the bottom of its travel, be almost (but

not quite) tight. At the top of its travel it should also be

almost but not quite tight. If the piston is tight at either

end of its travel it can be adjusted slightly by hand.

The black tubing that covers the rod connecting the piston

and the crankshaft is a slip adjustment mechanism. If the

piston is too tight at the bottom of its travel, shorten the

connecting rod by pushing in (ever so slightly) on the

piston end and the crankshaft end. Hold one hand at the

crankshaft end of the connecting rod and the other at the

piston end and push these ends together. If the piston is

too tight at the top end of its travel then lengthen the

connecting rod (very slightly) by pulling down the piston

and pulling up on the crankshaft end of the connecting

rod. In other words, reverse the previous process.

Adjusting the Regenerator

The regenerator is the yellow piece of foam inside the

engine that moves the air from the hot side to the cold

side. In normal use this should never need adjusting.

However if someone grabs it and pulls on it, the regenerator can be moved out of adjustment. Ideally the displacer

should just barely touch (or not quite touch) the top side

of the engine when it is at the top end of its travel. It also

should not quite touch (or barely touch) the blue plate

when it is at the bottom end of its travel.

Turn the propeller slowly through by hand and watch the

regenerator. If it is adjusted as indicated in the above

paragraph then don’t do anything with it. If it hits the

bottom enough so that the flexible rubber linkage tubing

bows out when the regenerator is at the bottom of its

travel then push the black tubing slightly down onto the

regenerator shaft. The regenerator shaft is the shiny piece

of wire that goes down into the engine and attaches to the

yellow foam.

This looseness is essential to proper operation of the

engine. If one of the bushings has moved slightly and

becomes a tight fit on the aluminum upright, the engine

will run poorly or not at all. The solution to this problem

is to use a knife blade to move one of the collars slightly

away from the aluminum uprights.

®

If the LCD Thermometer Turns Black

LCD thermometers of this type have specific operating

ranges. When the temperature is within their range they

display colors. When the temperature is out of their range

they turn black.

9

Page 14

The Visible Stirling Engine 012-06055A

If the LCD thermometer is black it means that the

temperature of the thermometer is out of the range of the

thermometer. Either the temperature is above 86°F

(30°C) or below 61°F (16°C). The thermometer is not

damaged by this at all and will again indicate colors when

the temperature returns to its operating range.

Credits

Acknowledgments

This type of Stirling engine is relatively new. The first

Stirling engine ever built to run on small temperature

differences was built in 1983 by Ivo Colin of the University of Zagreb in what was then Yugoslavia.

Jim Senft, a mathematics professor at the University of

Wisconsin River Falls, built engines that substantially

improved on those built by Ivo Colin. This engine is a

follow up design to those built by Jim Senft. The concept

for this engine was created by Darryl Phillips of the

Airsport Corporation, Sallisaw Oklahoma. The detail

design and engineering was done by Brent H. Van

Arsdell of the Magic Motor Company.

The Thermometer Shows 86° But the

Engine Still Does Not Run

Operation of Stirling engines is dependent on a temperature difference. If the engine was running on hot water

and the thermometer now shows a temperature of 86° it is

likely that there is no longer a temperature difference of

40°F or more. This is a normal condition. Reheat the

water (boiling is acceptable) and start the engine again.

How to Get A FREE Book

If you have any experiments that you feel should be

included in the next edition of this manual, we would love

to hear from you. If we use your experiment in the next

edition of the manual we will give you a Free copy of

“Introduction to Stirling Engines” by Jim Senft. Write up

your experiment and mail it to

Magic Motor Company

1945 N. Rock Rd. Suite

1012 Wichita, KS 67206

More STIRLING Information

Additional information on Stirling engines is available

from:

Stirling Machine World [ Brad Ross, Editor]

1823 Hummingbird Court

West Richland, WA 99353 9542

(509)-967-5032

Stirling Machine World publishes a quarterly newsletter.

Additional books and video tapes on Stirling engines are

also available.

10

®

Page 15

012-06055A The Visible Stirling Engine

T echnical Support

Feed-Back

If you have any comments about this product or this

manual please let us know. If you have any suggestions

on alternate experiments or find a problem in the manual

please tell us. PASCO appreciates any customer feedback. Your input helps us evaluate and improve our

product.

To Reach PASCO

For Technical Support call us at 1-800-772-8700 (tollfree within the U.S.) or (916) 786-3800.

email: techsupp@PASCO.com

Tech support fax: (916) 786-3292

Contacting Technical Support

Before you call the PASCO Technical Support staff it

would be helpful to prepare the following information:

• If your problem is with the PASCO apparatus, note:

Title and Model number (usually listed on the label).

Approximate age of apparatus.

A detailed description of the problem/sequence of

events. (In case you can't call PASCO right away, you

won't lose valuable data.)

If possible, have the apparatus within reach when calling. This makes descriptions of individual parts much

easier.

• If your problem relates to the instruction manual, note:

Part number and Revision (listed by month and year on

the front cover).

Have the manual at hand to discuss your questions.

®

11

Page 16

Loading...

Loading...