Page 1

Dual Pressure Sensor

PS-2181

Quick Start

1. Connect the Dual Pressure Sensor to your PASPORT inter-

face.

2. If you are using a computer, connect the PASPORT interface

to it and start DataStudio.

3. Use the included tubing and quick-release connectors to con-

nect a device to one or both or the sensor’s pressure ports.

Instruction Sheet

012-09969A

Included Equipment Part Number

Dual Pressure Sensor

Quick-release Connectors (4 pieces)

Tubing Connectors (4 pieces)

Polyurethane Tubing (length 2.4 m)

Required Equipment

PASPORT Interface

PS-2181

640-021

640-030

640-023

See PASCO catalog

or www.pasco.com

4. Press or click the start button to begin recording data.

Introduction

The Dual Pressure Sensor is capable of reading up to two absolute pressures, one differential pressure, or one gauge pressure.

Dynamic variable over-sampling automatically reduces measurement noise at low sampling rates. Sample rates up to 1000 Hz

make studies of both transient and steady-state pressure possible.

The sensor measures pressure in units of kPa, N/m

per square inch (psi).

2

, and pounds

Setup

Types of Pressure Measurements

To measure pressure in an apparatus, connect one or both of the

pressure ports using the included tubing and connectors. The way

that you connect the Dual Pressure Sensor depends on whether

you will measure absolute pressure, differential pressure, or

gauge pressure.

Absolute Pressure The sensor can measure up to two absolute pressures simultaneously. One connection is required for

each measurement, and either of the pressure ports may be used.

Differential Pressure The sensor measures differential pressure by determining the pressure difference between ports 1

and 2. Differential Pressure is positive when the pressure in port

1 is higher than port 2. (See “DataStudio Setup” on page 2 for

instructions on making this measurement available.)

®

Page 2

Dual Pressure Sensor PS-2181

Gauge Pressure Gauge pressure is a special case of differential pressure in which port 2 is left unconnected. The sensor

measures the pressure difference between port 1 (connected to

the apparatus) and port 2 (left open to the atmosphere).

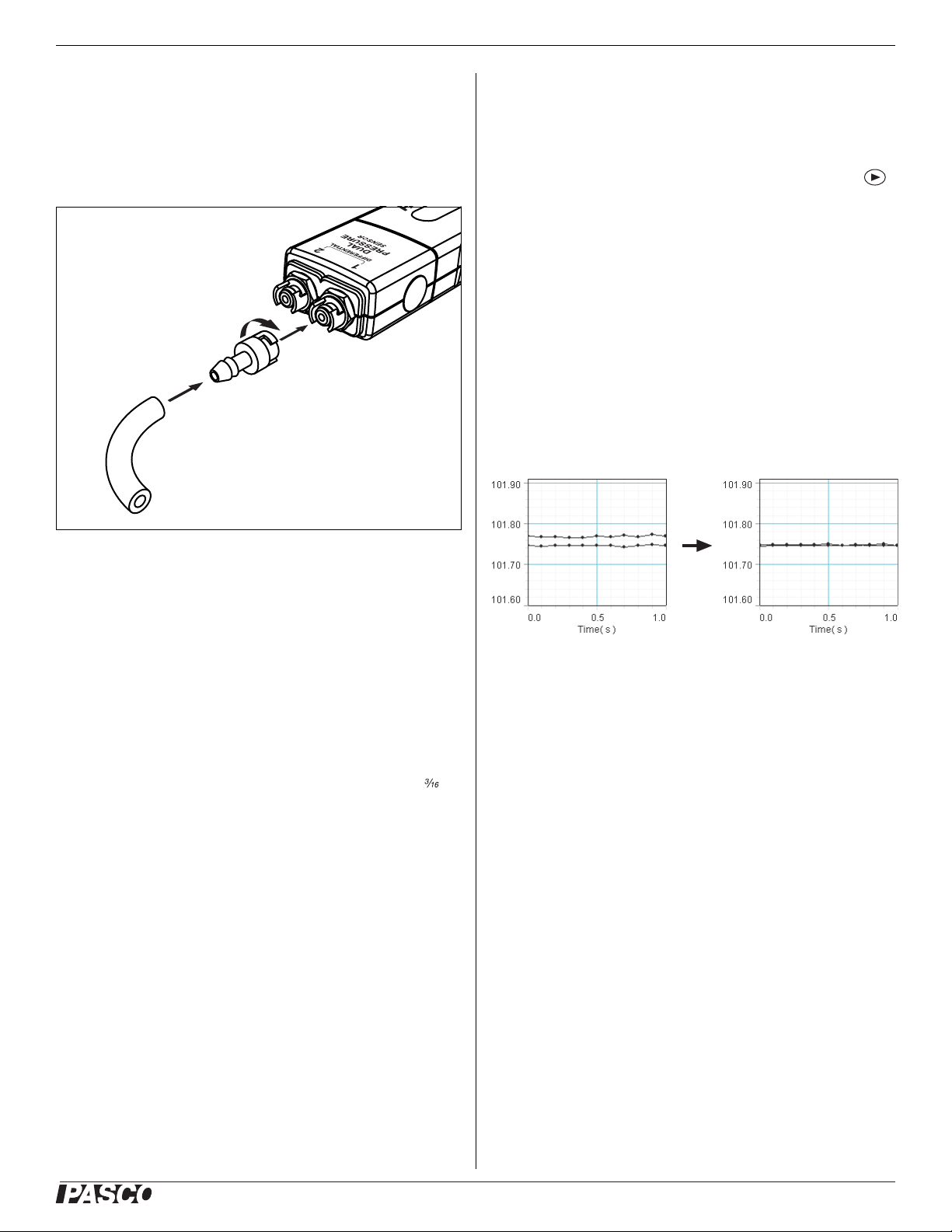

Sensor Setup

measure. For more instructions on using DataStudio, press F1 to

open DataStudio’s on-line help.

Xplorer GLX Setup

If you are using an Xplorer GLX in standalone mode, press

to start data collection. By default, the GLX displays the absolute

pressure from port 1 (“Absolute Pressure 1”) in units of kPa, but

you can select the other absolute measurement or the differential

measurement for display. For more instructions on using the

Xplorer GLX, refer to the GLX Users’ Guide.

Multiple-measurement Alignment

When you are using both pressure ports, you may find that their

readings differ slightly when they are measuring the same thing.

In the example illustrated below, measurements from both ports

open to the atmosphere differ by about 0.02 kPa. The multiple-measurement alignment procedure adjusts the calibrations of

the measurements so they agree more closely.

1. Cut a piece (or pieces) of tubing to the desired length.

2. Insert a quick-release connector into each piece of tubing.

3. Connect each piece of tubing to the sensor by inserting the

quick-release connector into one of the pressure ports and

twisting clockwise.

4. Connect the free ends of the tubing to the apparatus using

connectors supplied with the apparatus or the tubing connectors include with the Dual Pressure Sensor.

You can use the included tubing connectors to connect to a 5 mm (

inch) hole in a rubber stopper.

5. Connect the sensor to your PASPORT interface.

DataStudio Setup

If you are using a computer, connect the PASPORT interface to

the computer and start DataStudio. (Refer to the documentation

that came with your PASPORT interface for instructions on connecting it to your computer.) In DataStudio, click Star t to begin

data collection; click Stop to stop data collection.

By default, DataStudio displays the absolute pressures (in units

of kPa) measured by both ports in a Graph display. To make the

differential measurement available for display, click Setup to

open the Experiment Setup window; in that window, select the

1-2 Differential Pressure check box. There you can also change

the sampling rate (up to 1000 Hz) and select different units of

The procedure described here for DataStudio can also be performed on

the Xplorer GLX. See the Xplorer GLX Users’ Guide for detailed instructions.

1. Click Setup to open the Experiment Setup window. Click

Calibrate Sensors to open the calibration dialog box.

2. From the Sensor field, select the Dual Pressure Sensor.

(See screenshot on page 3.)

3. Select the Calibrate all similar measurements simulta-

neously check box.

4. From the Calibration Type menu, select 1 Point (Adjust

Offset Only).

5. Apply the same pressure to both ports (for instance by open-

ing them to the atmosphere).

6. Click the Read From Sensor button for Point 1.

7. Click OK to accept the new calibration.

®

2

Page 3

Dual Pressure Sensor PS-2181

Specifications

Select Dual Pressure Sensor

Select Calibrate all...

Select 1 Point (Adjust Offset Only)

Click Read From Sensor

Click OK

One-point and Two-point Calibrations

Range Absolute pressure: 0 to 200 kPa

Resolution 0.01 kPa at 10 Hz

Repeatability 1 kPa

Units of Measure kPa, N/m

Max. Sample Rate 1000 Hz

Included tubing Material: polyurethane

Differential pressure: −100 kPa to +100 kPa

2

, psi

Inside diameter: 3.2 mm ( inch)

Length: 2.4 m (8 feet)

Technical Support

For assistance with any PASCO product, contact PASCO at:

Address: PASCO scientific

10101 Foothills Blvd.

Roseville, CA 95747-7100

Phone: 916-786-3800 (worldwide)

800-772-8700 (U.S.)

Fax: (916) 786-7565

Web: www.pasco.com

Email: support@pasco.com

Though it is usually not necessary, a one-point or two-point calibration can be performed on any of the measurements to make

them more accurate. To do so, you must have a very accurate,

independent means of measuring pressure such as a barometer.

For step-by-step instructions refer to the documentation for

DataStudio, the Xplorer, or the Xplorer GLX.

Over-sampling

The Dual Pressure Sensor uses dynamic variable over-sampling

to reduce noise, produce smoother data, and improve the measurement resolution. This effect is especially noticeable when

very small pressure changes or differences are measured. The

degree of dynamic variable over-sampling that takes place within

the sensor depends on the sample rate. To maximize the

over-sampling, set the sample rate as low as possible for a given

application. Maximum over-sampling occurs at sample rates of

1 Hz or slower.

Limited Warranty For a description of the product warranty, see the

PASCO catalog.

Copyright The PASCO scientific 012-09969A

Instruction Sheet

granted to non-profit educational institutions for reproduction of any part of

this manual, providing the reproductions are used only in their laboratories

and classrooms, and are not sold for profit. Reproduction under any other

circumstances, without the written consent of PASCO scientific, is prohibited.

Trademarks PASCO, PASCO scientific, DataStudio, PASPORT, Xplorer,

and Xplorer GLX are trademarks or registered trademarks of PASCO scientific, in the United States and/or in other countries. All other brands,

products, or service names are or may be trademarks or service marks of,

and are used to identify, products or services of, their respective owners.

For more information visit www.pasco.com/legal.

is copyrighted with all rights reserved. Permission is

Dual Pressure Sensor

®

3

Loading...

Loading...