Page 1

®

Oxygen Gas Sensor

sensor amplifier

sampling

bottle

connecting cable

sensing

element

rubber stopper

Included Equipment Part Number

Sensor Amplifier

PS-2126A (includes

sensing element)

Oxygen Sensing Element (with deflector)

699-299

Rubber Stopper

699-08186

Connecting Cable (3.5 millimeter)

514-08583

Sampling Bottle

650-064

Required Equipment

PASPORT Interface

See PASCO catalog

or www.pasco.com

PS-2126A

Oxygen Sensing Element Life:

Galvanic fuel cells have a limited lifetime which is determined

by their age and their exposure to oxygen. This is similar to

the life of a battery in a flashlight. If the flashlight frequently

used, the battery life will not be as long as it would have been

with limited usage. Similarly, the fuel cell’s useful life is

determined by its exposure to oxygen gas.

The fuel cell included with the PS-2126A has a useful life of

900,000 oxygen percent (O

An example: If the sensor is used in a 100% oxygen atmosphere, the life of the sensor may be calculated as

900,000 O

9,000 hours. This is about 1 year.

% hours divided by 100% oxygen which is

2

Instruction Sheet

*012-11736*

%) hours.

2

012-11736B

Introduction

The PS-2126A Oxygen Gas Sensor measures oxygen gas concentration in percent (%) and parts per million (ppm) oxygen.

It can be used to study plant, animal, or cellular respiration; air

quality; and the rate of oxygen (O

reactions (see the experiment on page 2 for one example).

How it works:

The Oxygen Sensing Element is a galvanic fuel cell with a gas

permeable membrane at one end. It is very similar to a battery .

The fuel cell contains an electrolyte, anode and cathode. When

oxygen enters the fuel cell through the membrane, a chemical

reaction between the metallic cathode and anode and the electrolyte occurs. This chemical reaction produces a voltage and

current that is present at the output jack at the other end of the

Oxygen Sensing Element. The current produced is proportional to the concentration of oxygen present.

) production in chemical

2

The life of the sensor in normal air (20.9% oxygen) is

900,000 O

% hours divided by 20.9% oxygen which is

2

43,062 hours. This is about 4.9 years.

The sensor is guaranteed for a minimum of 2 years from the

date of manufacture. This is the absolute guarantee. If it is

used in a 100% oxygen atmosphere its life will be shortened.

If it is used in normal air, its life will be 4 to 5 years. There is

reported evidence of this particular sensing element being in

use for almost 10 years. In the end, the useful life of the sensing element is dependent on the manner in which it is used.

Setup

Connect the Oxygen Gas Sensor to your PASPORT interface.

To prepare the Oxygen Sensing Element for use:

1. Remove the Oxygen Sensing Element and deflector from

the packaging.

2. Remove the pink tape from the Oxygen Sensing Element.

3. Carefully thread the deflector onto the Oxygen Sensing

Element.

4. Slide the rubber stopper over the deflector.

Page 2

®

Model No. PS-2126A Collecting O2 Samples

5. Plug one end of the connecting cable into the Oxygen

Sensing Element.

6. Plug the other end of the connecting cable into the Sensor

Amplifier.

7. Connect the Sensor Amplifier to the PASCO interface.

8. Refer to the documentation that came with the PASCO

interface and software for further instructions for data

collection.

Collecting O2 Samples

To collect an atmospheric sample, hold the bottle upright and

open to the air. Insert the end of the sensing element into the

bottle. Press the rubber stopper into the neck to seal the bottle.

To collect expired air or

other gas samples, place the

sensing element inside a

plastic bag. Press any atmospheric air out of the bag.

Use a tube to fill the bag

with the gas sample. Hold,

tie, or clamp the bag closed

round the tube and sensing

element cable to contain the

gas sample and exclude atmospheric air.

Calibration

The sensor is factory calibrated. However, for greater accuracy, you can follow these steps to calibrate the sensor:

1. With the sensor connected to a powered PASPORT inter-

face, place the sensing element in the empty sampling

bottle. Outside air has an O

2. Press the CAL (20.9%) button on the sensor and hold it

for 3 seconds. The green light will flash on and off for 4

seconds, indicating that calibration is in progress.

3. After 4 seconds, the reading will stabilize at 20.9%. When

calibration is complete, the light will stop flashing.

Note: If the green light flashes rapidly after calibration, the sensing element may be expired and it may need replacement.

concentration 20.9%.

2

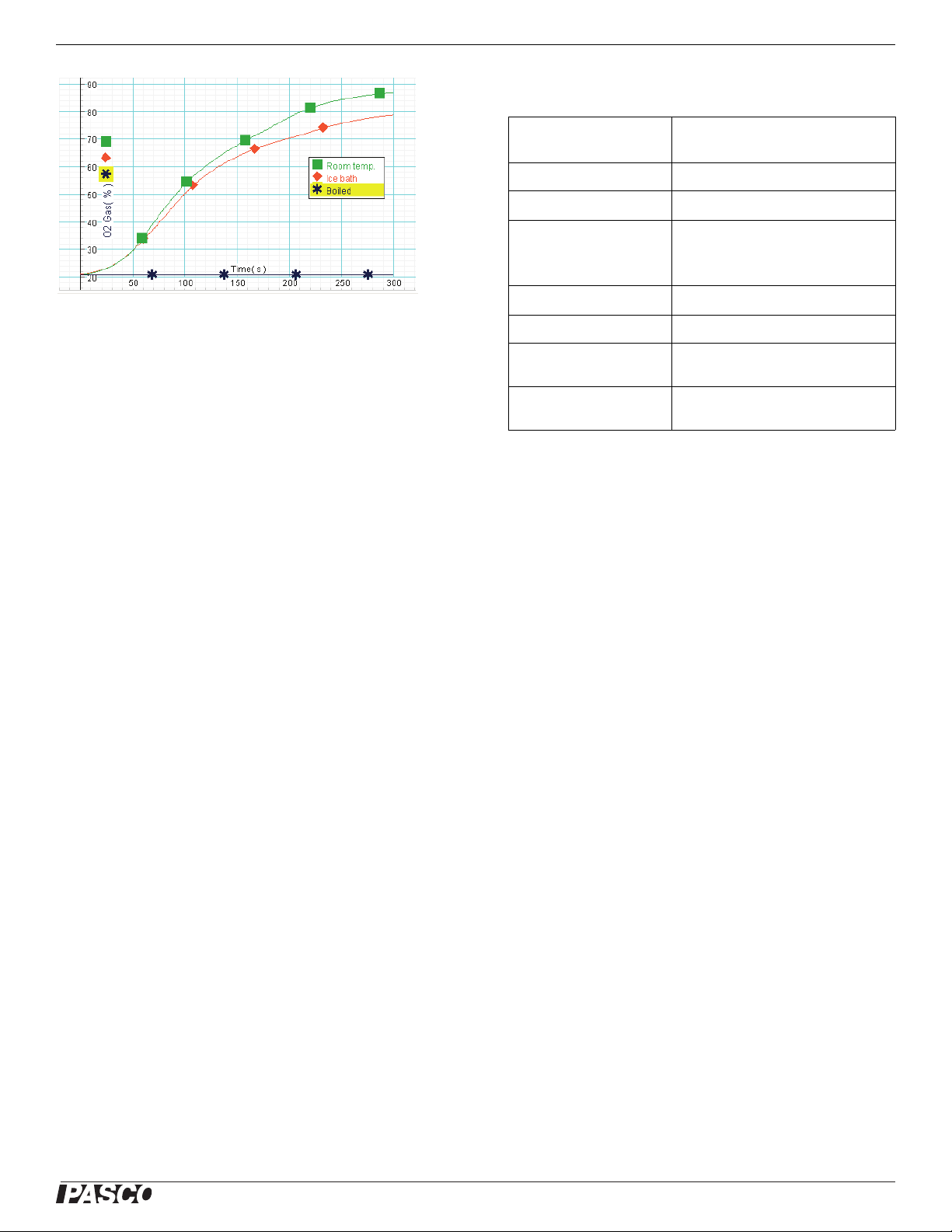

Experiment: Oxygen

Production from Liver Catalase

Equipment required: Oxygen Gas Sensor with sampling bottle, beef

or chicken liver, hydrogen peroxide, pipette, mortar and pestle, ice

bath, boiling water, and safety goggles.

Safety: Always wear safety goggles when performing this experiment.

Do not allow excessive pressure to develop in the sampling bottle.

1. Place the liver in an open container and allow it to warm

to room temperature.

When doing an experiment that requires a faster than usual

response time, the response time of the sensor may be

increased by removing the white deflector and stopper from

the Oxygen Sensing Element. This shortens the path to the

sensor's membrane allowing it to be populated more rapidly

with the sample.

The purpose of the white deflector is to deflect air from an air

stream into the sensing element and provide protection for the

gas permeable membrane. It also holds the rubber stopper.

While the white deflector is removed from the sensing element, be careful not to place sharp objects near the membrane

as puncturing the membrane could lead to damage to the sensing element and electrolyte leaking from the membrane.

Removal of the deflector is not required or recommended during typical operating conditions.

Warning: Do not allow the sensing element to contact liquids.

2. (Optional) Calibrate the Oxygen Gas Sensor (see above).

3. Grind the liver to a mushy consistency.

4. Place 10 mL of hydrogen peroxide into the clean, dry

sampling bottle.

Note: Perform step 5 through 7 carefully and quickly.

5. With a pipette, extract 1 mL of blood/homogenate from

the ground liver and release it into the sampling bottle.

6. Insert the end of the sensing element into the bottle. Press

the rubber stopper into the neck of the bottle just enough

to close the bottle, but not too tightly

7. Start data collection on the computer or interface.

8. After about 300 seconds, stop data collection.

9. Clean and dry the sampling bottle. Repeat steps 4 through

8 with cold liver homogenate that has been chilled in an

ice bath. Repeat again with liver homogenate that has

been boiled in water.

10. Compare your results from the three runs.

2

Page 3

®

Model No. PS-2126A

Specifications

Range 0 to 100% O2 concentration

0 to 1000000 parts per million (ppm)

Resolution 0.025% oxygen

Sensing Element Maintenance

Storage:

The Oxygen Sensing Element may be stored in its package

until its first use.

It is recommended that the sensing element be stored with the

threaded nose piece in the downward position. This insure s

that the electrolyte remains in contact with the membrane for

extended periods of storage. Sensor life may be extended by

storing the sensing element in a refrigerator at 40ºF to 50ºF

(4°C to 10°C). Do not freeze the sensor or sensing element.

Repeatability

Accuracy

Operating temperature

Relative humidity range 0 to 100%, non-condensing

Sensing element

useful life

Sensing element

warranty period

±0.5% oxygen

±1% O

at constant temperature and

2

±5% O

pressure;

temperature range

°C

0 to 40

4+ years

24 months

over operating

2

Technical Support

For assistance with any PASCO product, contact PASCO at:

Address: PASCO scientific

10101 Foothills Blvd.

Roseville, CA 95747-7100

Phone: 916-786-3800 (worldwide)

800-772-8700 (U.S.)

Fax: (916) 786-3292

Web: www.pasco.com

Email: support@pasco.com

Limited Warranty: For a description of the product warranty, see the

PASCO catalog.

Copyright: The P A SCO scientific 012-11736B Oxygen Gas Sensor Instruc-

tion Sheet is copyrighted with all rights reserved . Permission is granted to

non-profit educational institutions for reproduction of any part of this manual,

providing the reproductions are used only in th eir la boratories and classrooms, and are not sold for profit. Reproduction under any other circum stances, without the written consent of PASCO scientific, is prohibited.

Trademarks: PASCO, PASCO scientific, DataStudio, PASPORT, Xplorer

Xplorer GLX, SPARK, and SPARKvue are trademarks or registered trademarks of PASCO scientific, in the United States and/or in other countries.

For more information visit www.pasco.com/legal.

3

Loading...

Loading...