Page 1

Experiment Guide

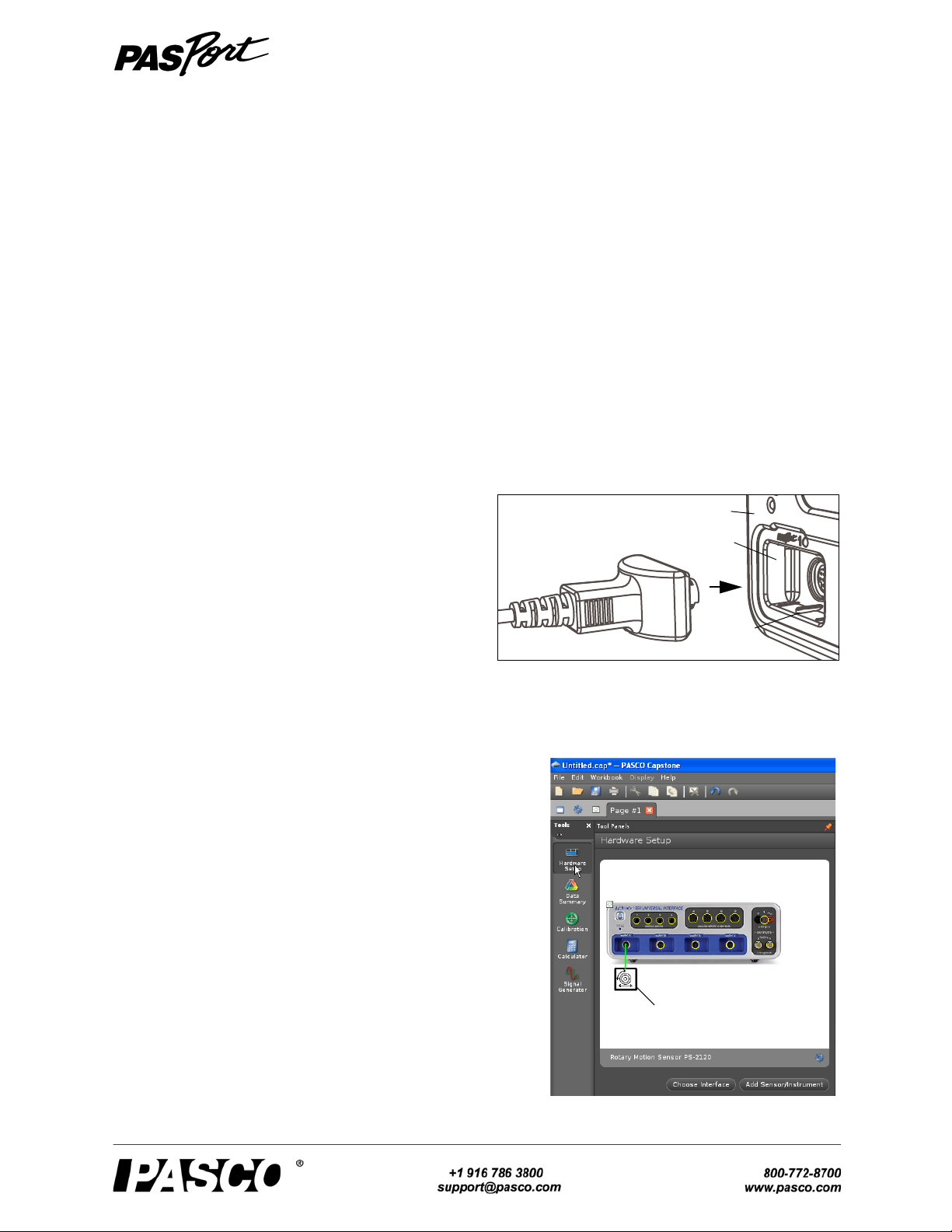

Sensor Plug

Alignment

tab

PASPORT

input port

850 Universal Interface

Capstone Hardware Setup panel

Rotary Motion

Sensor icon

850 Universal

Interface

013-13496A

Rotary Motion Sensor

PS-2120A

Contents

Using the Rotary Motion Sensor with Data Acquisition Software..........................................................................1

Experiment 1: Rotational Inertia of a Point Mass....................................................................................................3

Experiment 2: Rotational Inertia of Disk and Ring .................................................................................................5

Experiment 3: Conservation of Angular Momentum ..............................................................................................7

Using the Rotary Motion Sensor with Data Acquisition Software

• Plug the Sensor Plug into a P ASPORT input port of

a PASPORT-compatible PASCO interface (such as

the 850 Universal Interface, Xplorer GLX, or

SPARK Science Learning System (SLS)).

• Turn on the PASPORT-compatible interface.

• For the PASPORT-compatible interface, start the

PASCO Capstone software.

• For the SPARK SLS, if the sensor is plugged in, the SPARKvue software will start automatically when you

turn on the interface. The SPARKvue software will show the SPARK SLS Home Screen with the Rotary

Motion Sensor.

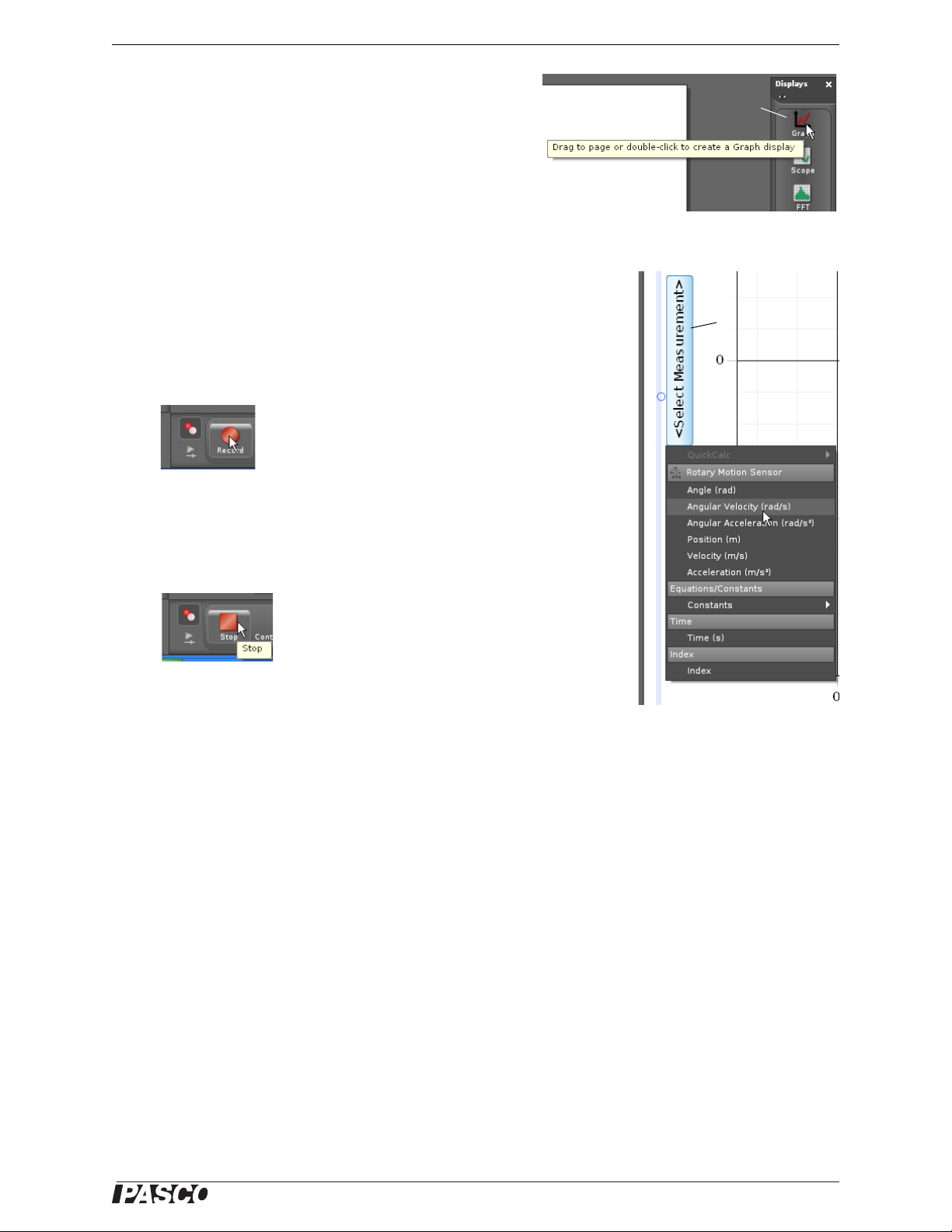

PASCO Capstone Setup

• In PASCO Capstone, click “Hardware Setup” in the Tools

palette to open the Hardware Setup panel. Confirm that the

Hardware Setup panel shows the interface you are using

and the icon of the Rotary Motion Sensor.

Page 2

®

PS-2120A Contents

Create a Graph display

Graph display

icon

Click the “Select

Measurement”

menu button

Select “Angular Velocity”

Click “Record”

Click “Stop”

• Set up a data display. For example, drag the Graph icon

from the Displays palette onto the workbook page, or double-click the icon to create a Graph display..

• Set up the Graph display to show Angular Velocity (rad/s) on the vertical

axis. Click the “Select Measurement” menu button on the vertical axis

and pick Angular Velocity (rad/s) from the menu. Time (s) automatically

shows on the horizontal axis.

• Click ‘Record’ in the lower left corner of the PASCO Capstone window

to begin recording data. (The “Record” button changes to “Stop”.)

• Turn the shaft of the Rotary Motion Sensor back-and-forth. V iew the data

• Click “Stop” to end data recording.

• SETUP: For detailed information on setting up the data acquisition software and recording data,

in the Graph display.

refer to the User’s Guide and the online help for the data acquisition software.

Experiment Guide

2

Page 3

®

PS-2120A Contents

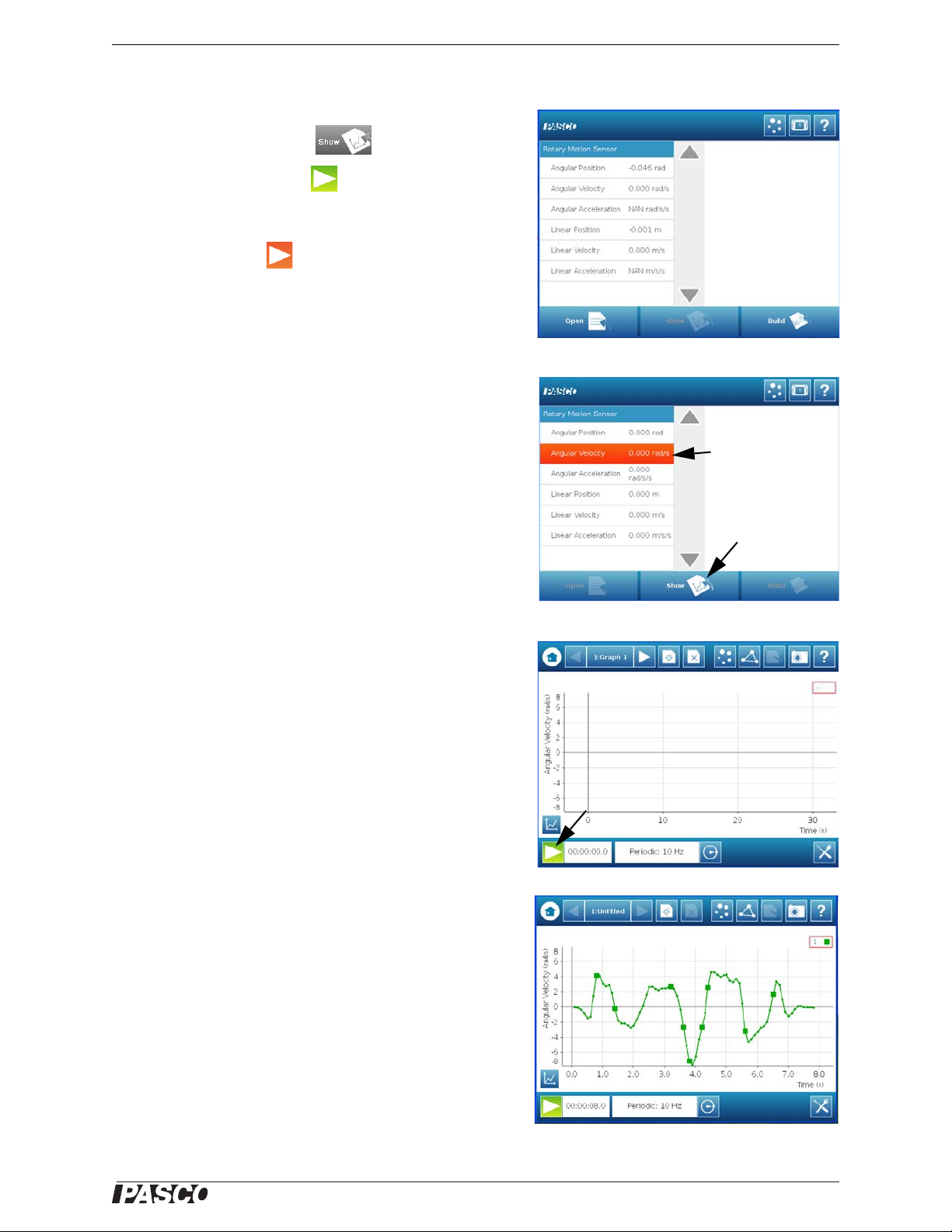

SPARK SLS Home Screen for

the Rotary Motion Sensor

Press

Show

Press “Angular

Velocity”

Press “Angular Velocity” and

then press “Show”

Press “Start”

Press

Start

Turn the Rotary Motion

Sensor shaft

SPARK SLS Setup

• In the Home Screen, press “Angular Velocity” and then

press the Show button ( ) to open a graph display.

• Press the Start button ( ) to begin recording data.

Turn the shaft of the sensor and view the data in the display.

• Press the Stop ( ) button to end data recording.

• SETUP: For detailed information on setting up the

data acquisition software and recording data, refer

to the User’s Guide and the online help for the data

acquisition software.

Technical Support

For assistance, contact PASCO:

Address: PASCO scientific

10101 Foothills Blvd.

Roseville, CA 95747-7100

Phone: +1 916-786-3800 (worldwide)

800-772-8700 (U.S.)

Web: www.pasco.com

Email: support@pasco.com

Experiment Guide

3

Page 4

®

Rotary Motion Sensor Contents

4

Experiment Guide

Page 5

®

PS-2120A Experiment 1: Rotational Inertia of a Point Mass

I

total

M

total

R

2

=

I =

rT=

FmgT– ma==

Tmga–=

Experiment 1: Rotational Inertia of a Point Mass

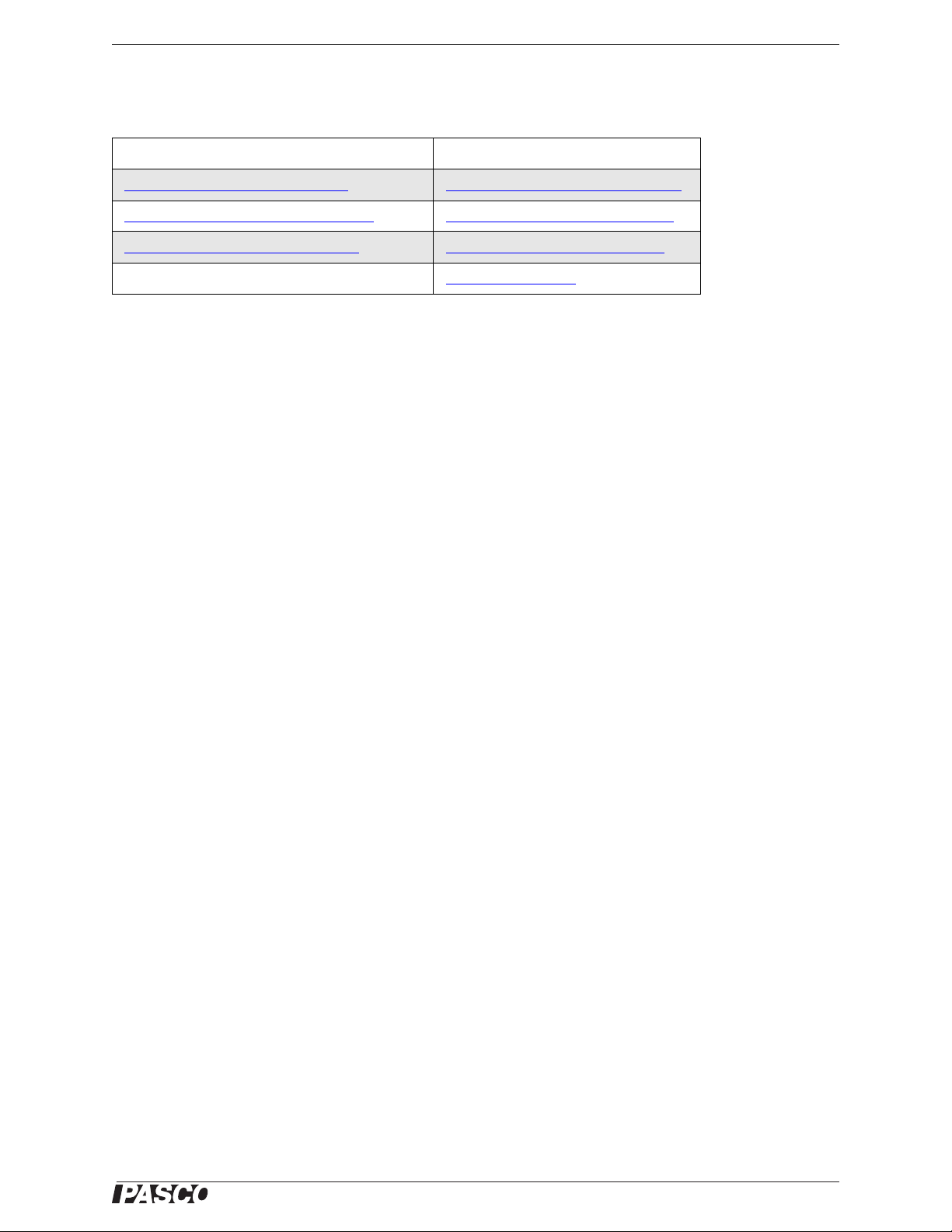

Equipment Required* Equipment Required*

PASPORT-Compatible Interface Rotary Motion Sensor (PS-2120A)

Mini-Rotational Accessory (CI-6691) Mass and Hanger Set (ME-8979)

Base and Support Rod (ME-9355) Triple Beam Balance (SE-8723)

Paper clips (for masses <1 g) Calipers (SF-8711)

*Click the equipment item to go to the PASCO web site.

Purpose

The purpose of this experiment is to find the rotational inertia of a point mass experimentally and to verify that

this value corresponds to the calculated theoretical value.

Theory

Theoretically, the rotational inertia, I, of a point mass is given by I = MR2, where M is the mass, and R is the distance the mass is from the axis of rotation. Since this experiment uses two masses equidistant from the center of

rotation, the total rotational inertia will be

where M

To find the rotational inertia experimentally, a known torque is applied to the object and the resulting angular

acceleration is measured. Since

where

the weight hanging from the thread that is wrapped around the 3-step Pulley.

where r is the radius of the chosen pulley about which the thread is wound, and T is the tension in the thread

when the apparatus is rotating.

Applying Newton’s Second Law for the hanging mass, m, gives

= M1 + M2, the total mass of both point masses.

total

= I,

is the angular acceleration, which is equal to a/r (a = linear acceleration), and is the torque caused by

(see Figure 1.1). Solving for the tension in the thread gives:

After the angular acceleration of the mass (m) is measured, the torque and the linear acceleration can be obtained

for the calculation of the rotational inertia.

Experiment Guide

5

Page 6

®

Rotary Motion Sensor Experiment 1: Rotational Inertia of a Point Mass

T

mg

a

Rod and Masses

3-Step Pulley

Rotary Motion

Sensor

Super Pulley with

Clamp

Hanger

and Mass

Thread

Support

Rod

Rod

Clamp

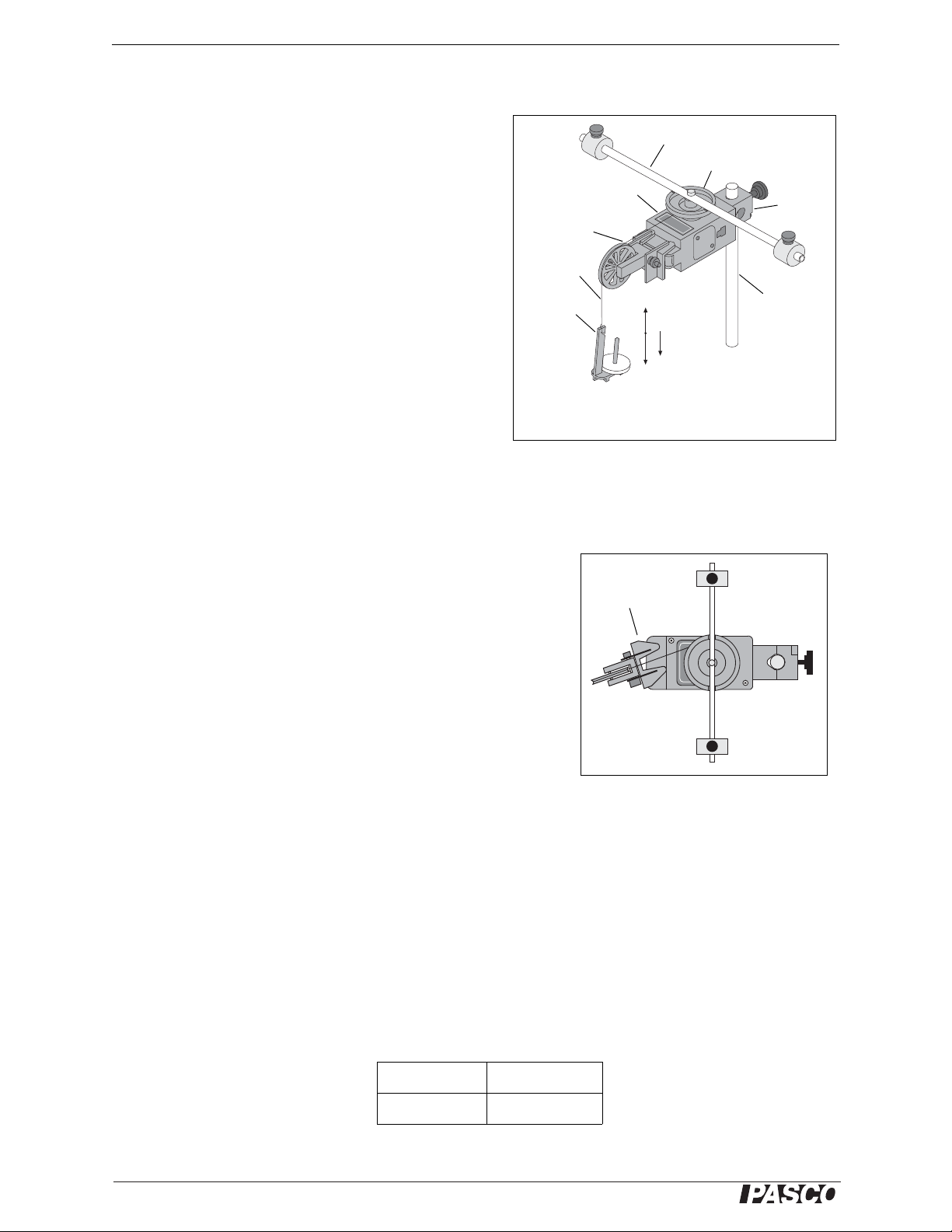

Figure 1.1: Rotary Motion Sensor and

Free Body Diagram

Super

Pulley

Figure 1.2: Super Pulley Position

Equipment Setup

1. Attach a mass on each end of the rod (part of the

Mini-Rotational Accessory) equidistant from the rod

center. You may choose any radius you wish.

2. Tie one end of a thread to a Mass Hanger and tie the

other end to one of the levels of the 3-step Pulley on

the Rotary Motion Sensor (RMS).

3. Mount the rod and masses to the pulley on the Rotary

Motion Sensor. Please note the orientation of the

3-step Pulley.

4. Mount the RMS on a support rod and connect it to a

PASPORT-compatible interface. Make sure that the

support rod does not interfere with the rotation of the

rod and masses. See Figure 1.1.

5. Mount the Super Pulley wish Clamp on the end of the

Rotary Motion Sensor.

6. Drape the thread over the Super Pulley such that the thread is in the groove of the pulley and the Mass

Hanger hangs freely (see Figure 1.1).

Note: The Super Pulley with Clamp must be adjusted at an angle,

so that the thread runs in a line tangent to the point where it leaves

the 3-step Pulley and straight down the middle of the groove on the

clamp-on Super Pulley (Figure 1.2).

7. Adjust the Super Pulley height so that the thread is level with

the 3-step pulley.

8. Connect the Rotary Motion Sensor to the interface and turn the

interface on.

Procedure

Part 1: Measurements for the Theoretical Rotational Inertia

1. Weigh the two ma sses from the ends of the thin rod to find the total mass M

Table 1.

2. Measure the distance from the axis of rotation to the center of the masses and record this radius in Data

Table 1

Data Table 1: Theoretical Rotational Inertia

Total Mass

Radius

and record the value in Data

total

6

Experiment Guide

Page 7

®

PS-2120A Experiment 1: Rotational Inertia of a Point Mass

Select Size of 3-step Pulley

Select “Linear” as the Curve Fit

Part 2: Measurement for the Experimenta l Method

A. Finding the Acceleration of the Point Masses and Apparatus

1. In the data acquisition software, create an experiment to measure the angular velocity (in radians per sec-

ond) versus time (in seconds) of the point masses and apparatus.

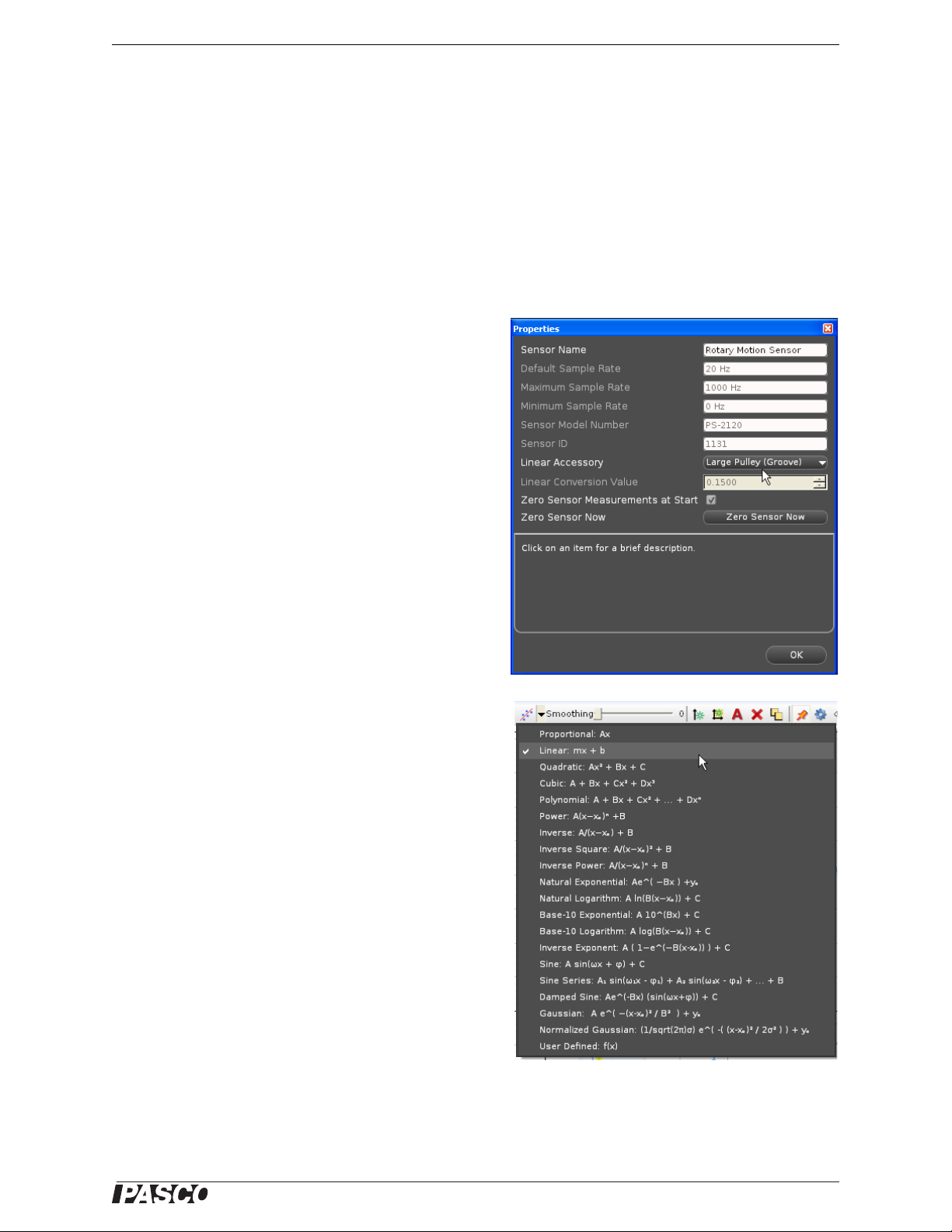

• In PASCO Capstone, for example, drag th e Graph icon from th e Display s pal ette to the workbook. Select

“Angular Velocity (rad/s)” for the vertical axis, and “Time (s)” for the horizontal axis.

• Click the Hardware Setup icon in the Tools palette to open the “Hardware Setup” panel. In the panel, click

the properties button (it looks like a gear wheel in the lower right corner).

• In the Properties window for Linear Accessory , select

the size of the 3-step Pulley you are using. The

default setting is “Large Pulley (Groove)”. Click OK.

2. Put a 50-g mass on the Mass Hanger and turn the

3-step Pulley to wind up the thread so the hanger is

just below the Super Pulley. Hold the 3-step Pulley.

3. Click Record to begin recording data, and release the

3-step Pulley, allowing the hanger to fall.

4. Caution! Click Stop to end data recording BEFORE

the hanger reaches the floor or the thread completely

unwinds from the 3-step Pulley.

5. In the Graph display, select the region of the data that

represents when the Point Masses and Apparatus

were accelerating.

6. In the display, select “Linear” from the curve fit

menu.

The slope, m, of the linear fit represents the angular acceleration () for the Point Mass and Apparatus

7. Record the value of the slope, m, as the angular accel-

eration in Data Table 2.

8. Using calipers, measure the diameter of the pulley

about which the thread is wrapped and calculate the

radius. Record the radius in Data Table 2.

In the previous procedure, the apparatus is rotating and

contributing to the total rotational inertia. The next step is

to find the rotational inertia of the apparatus by itself so

that this rotational inertia can be subtracted from the total.

Experiment Guide

7

Page 8

®

Rotary Motion Sensor Experiment 1: Rotational Inertia of a Point Mass

B. Finding the Acceleration of the Apparatus Alone

1. Take the point masses off the ends of the rod.

2. Repeat the procedure from Part A for finding the angular acceleration of the apparatus alone.

• You may need to decrease the amount of hanging mass so that the apparatus does not accelerate too fast for

smooth data collection.

• Remember that the value of the slope, m, is the angular acceleration.

3. Record the data in Data Table 2.

Data Table 2: Experimental Rotational Inertia Data

Point Mass and

Apparatus Alon e

Apparatus

Hanging Mass

Slope, m

Radius

Calculations

1. Calculate the experimental value of the rotational inertia of the point masses and apparatus together and

record the calculation in Data Table 3.

2. Calculate the experimental value of the rotational inertia of the apparatus alone and record the calculation in

Data Table 3.

3. Subtract the rotational inertia of the apparatus from the total rotational inertia of the point masses and appa-

ratus together. Record this in Data Table 3 as the rotational inertia of the point masses alone.

4. Calculate the theoretical value of the rotational inertia of the point masses and record the calculation in Data

Table 3.

5. Calculate the percent difference to compare the experimental value to the theoretical value, and record the

percent difference in Data Table 3.

Component Rotational Inertia

Point Masses and Apparatus Combined

Apparatus Alone

Point Masses (experimental value)

Point Masses (theoretical value)

Percent Difference

8

Data Table 3: Results

Experiment Guide

Page 9

®

PS-2120A Experiment 2: Rotational Inertia of Disk and Ring

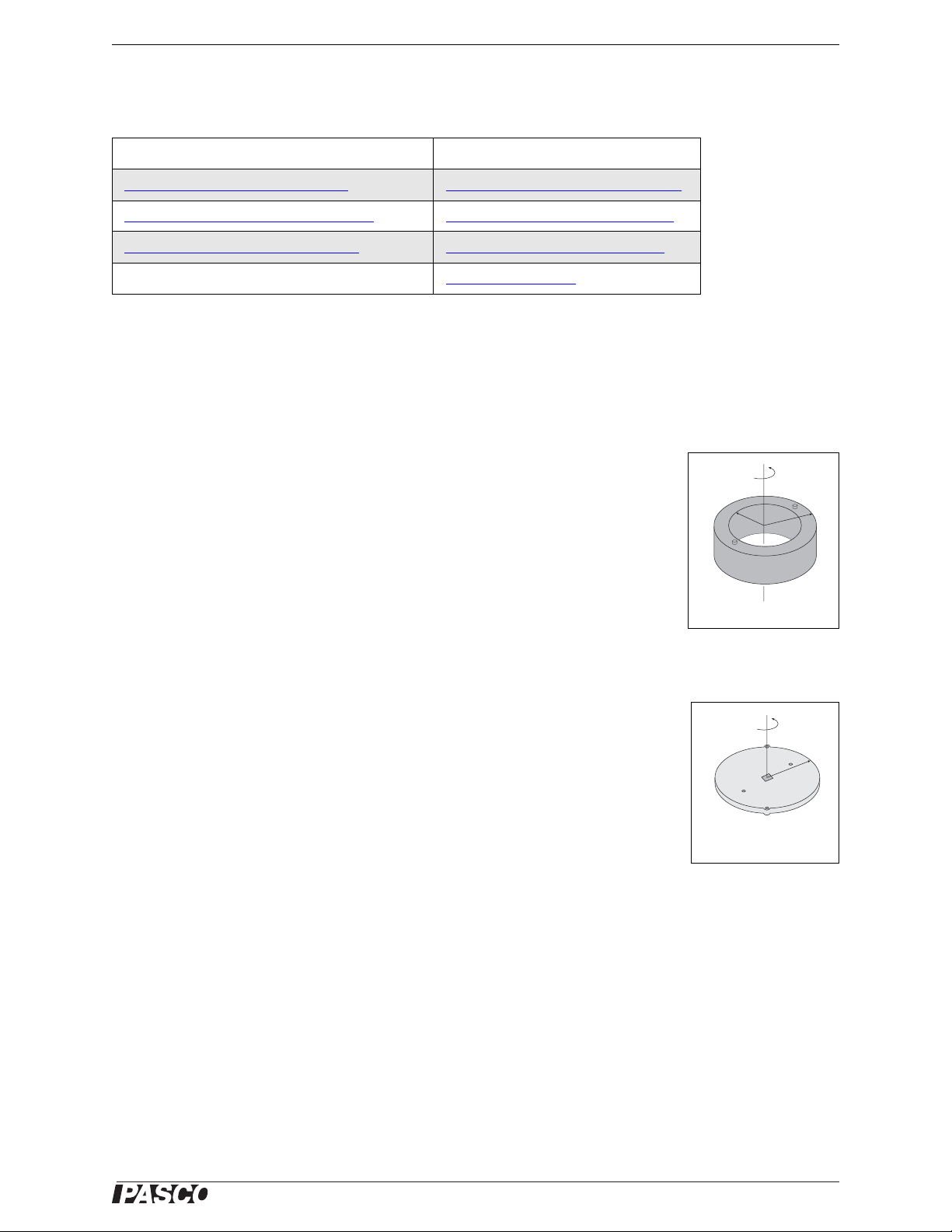

Figure 2.1: Ring

I

1

2

-- -

MR

1

2

R

2

2

+=

I

1

2

-- -

MR

2

=

Figure 2.2: Disk about

center of mass

I

---

=

rT=

FmgT– ma==

Tmga–=

Experiment 2: Rotational Inertia of Disk and Ring

Equipment Required* Equipment Required*

PASPORT-Compatible Interface Rotary Motion Sensor (PS-2120A)

Mini-Rotational Accessory (CI-6691) Mass and Hanger Set (ME-8979)

Base and Support Rod (ME-9355) Triple Beam Balance (SE-8723)

Paper clips (for masses <1 g) Calipers (SF-8711)

*Click the equipment item to go to the PASCO web site.

Purpose

The purpose of this experiment is to experimentally find the rotational inertia of a ring and a disk and verify that

these values correspond to the calculated theoretical values.

Theory

Theoretically, the rotational inertia, I, of a ring about its center of mass is given by:

where M is the mass of the ring, R

is the inner radius of the ring, and R2 is the outer

1

radius of the ring. See Figure 2.1.

The rotational inertia of a disk about its center of mass is given by:

where M is the mass of the disk and R is the radius of the disk. See Figure 2.2. To find

the rotational inertia experimentally, a known torque is applied to the object and the

resulting angular acceleration is measured, Since

= I,

where is the angular acceleration, which is equal to a/r (a = acceleration), and is the

torque caused by the weight hanging from the thread that is wrapped about the 3-step

Pulley on the Rotary Motion Sensor. The torque is given by:

where r is the radius of the pulley step about which the thread is wound, and T is the tension in the thread when

the apparatus is rotating.

Applying Newton’s Second Law for the hanging mass, m, gives:

See Figure 2.3. Solving for the tension in the thread gives:

Once the angular acceleration is measured, the radius and the linear acceleration, a, can be obtained for the calculation of the torque.

Experiment Guide

9

Page 10

®

Rotary Motion Sensor Experiment 2: Rotational Inertia of Disk and Ring

T

mg

a

Figure 2.3: Rotary Motion Sensor

Setup and Free Body Diagram

Mass Hanger

and mass

Support

rod

Thread

Disk

Hole for

Ring Pin

Figure 2.4: Super Pulley Position

Super Pulley

with Clamp

3-step Pulley

Figure 2.5: Setup for Disk and Ring

Rotary Motion

Sensor

Super Pulley

with Clamp

Ring

Setup

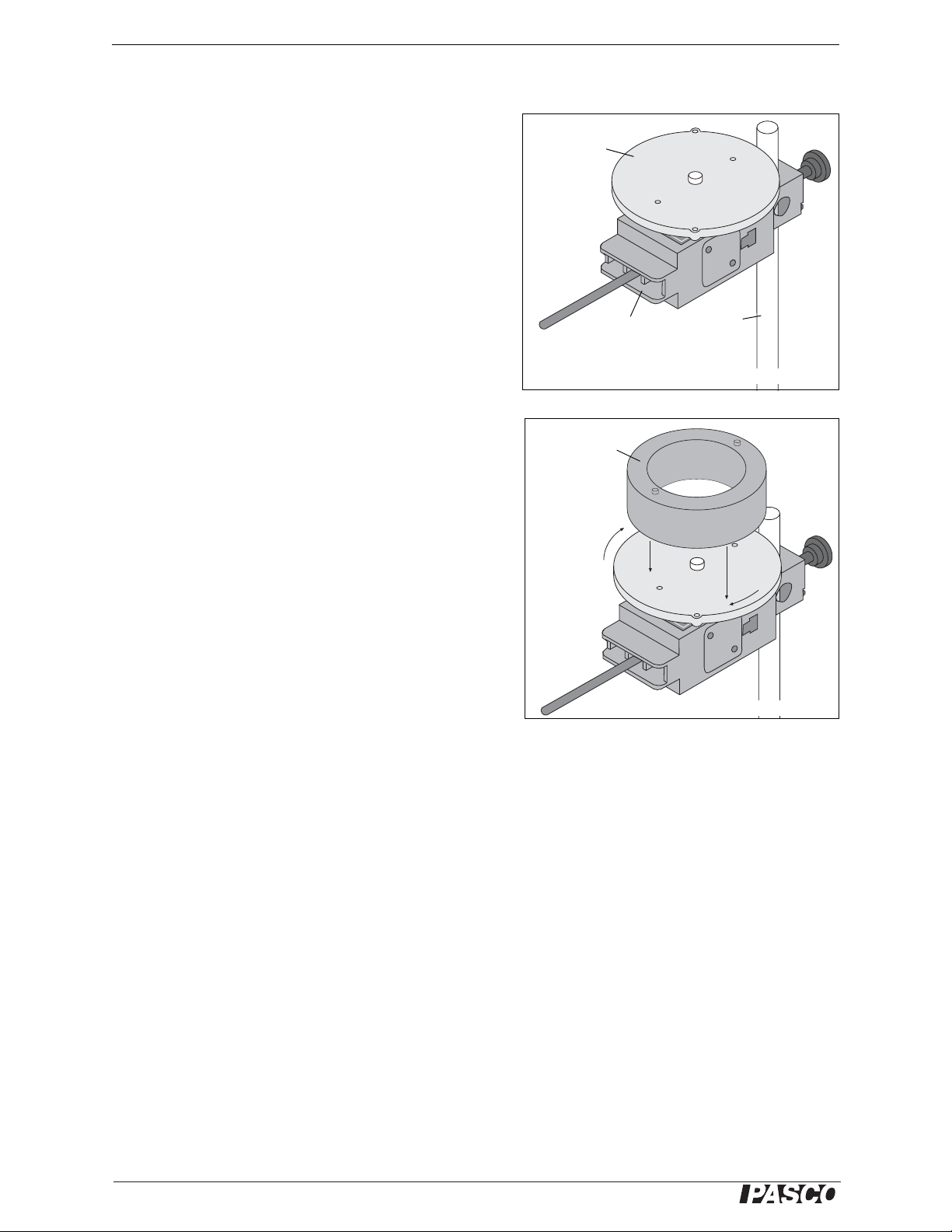

1. Mount the Rotary Motion Sensor (RMS) on a

support rod and connect the sensor to the interface.

2. Mount the Super Pulley with Clamp to the end of

the RMS.

3. Tie one end of a thread to a Mass Hanger and the

other end of the thread to one of the levels of the

3-step Pulley on the RMS.

4. Drape the thread over the Super Pulley such that

the thread is in the groove of the Super Pulley

and the Mass Hanger hangs freely.

5. Adjust the Super Pulley with Clamp to an angle

so that the thread runs in a line tangent to the

point where it leaves the 3-step Pulley and is

straight down the middle of the groove on the

Super Pulley. See Figure 2.4.

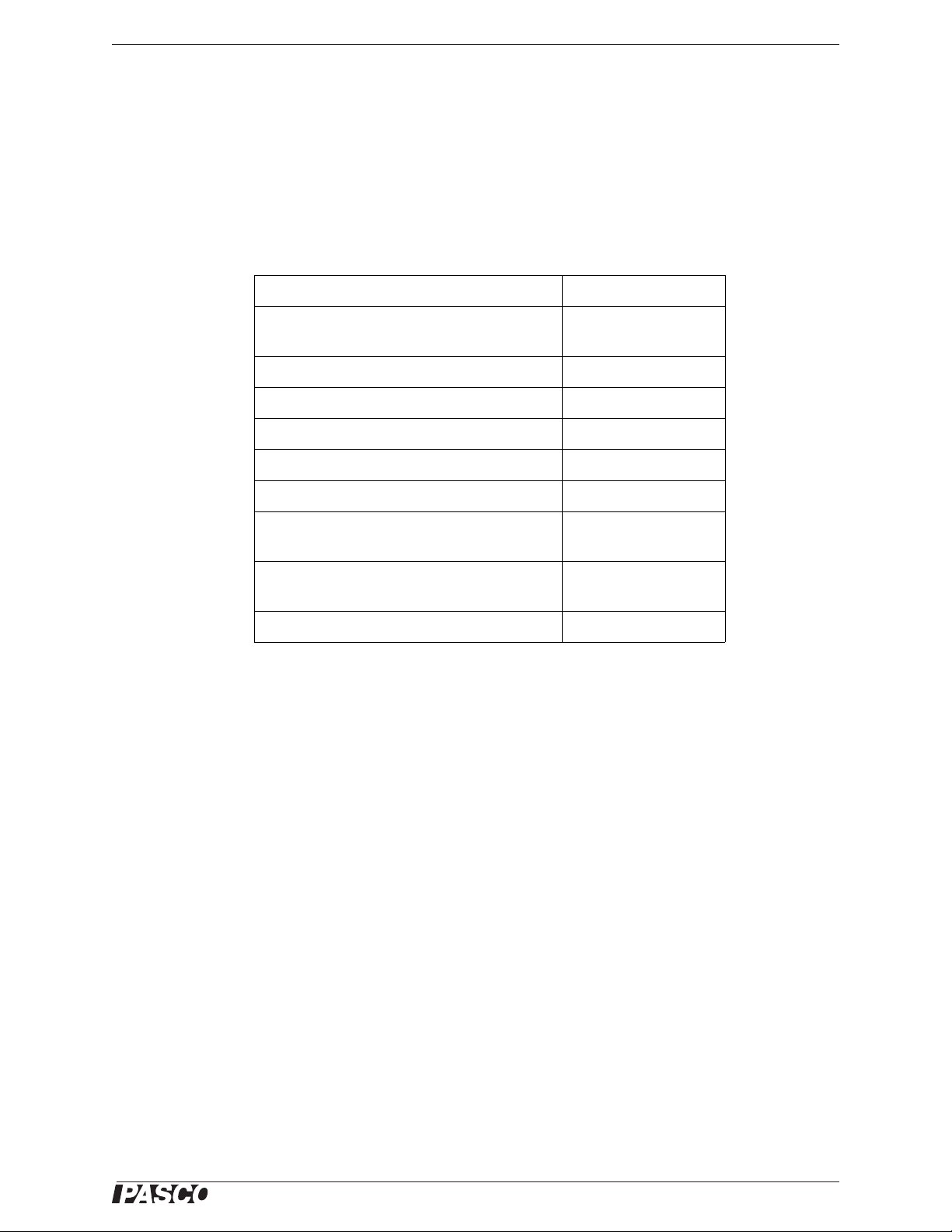

6. Place the disk directly on the 3-step Pulley as shown in

Figure 2.3.

7. Place the ring on the disk, inserting the ring pins on the

bottom edge into the holes in the top of the disk as

shown in figure 2.5.

10

Experiment Guide

Page 11

®

PS-2120A Experiment 2: Rotational Inertia of Disk and Ring

Select Size of 3-step Pulley

Procedure

Measurements for the Theoretical Rotational Inertia

1. Weigh the ring and the disk to find their masses and record these masses in Data Table 1.

2. Measure the inside and outside diameters of the ring and calculate the radii, R

and R2. Record in Data Table

1

1.

3. Measure the diameter of the disk and calculate the radius, R, and record into Data Table 1

Data Table 1: Theoretical Rotational Inertia.

Mass of ring

Mass of disk

Inner radius of ring

Outer radius of ring

Radius of disk

Measurements for the Experimental Method

A. Finding the Acceleration of the Ring and Disk

1. In the data acquisition software, create an experiment to measure the angular velocity (in radians per sec-

ond) versus time (in second) of the ring and disk.

• In PASCO Capstone, for example, drag th e Graph icon from th e Display s pal ette to the workbook. Select

“Angular Velocity (rad/s)” for the vertical axis, and “Time (s)” for the horizontal axis.

• Click the Hardware Setup icon in the Tools palette to open the “Hardware Setup” panel. In the panel, click

the properties button (it looks like a gear wheel in the lower right corner).

• In the Properties window for Linear Accessory , select

the size of the 3-step Pulley you are using. The

default setting is “Large Pulley (Groove)”. Click OK.

2. Put a 50-g mass on the Mass Hanger and turn the

3-step Pulley to wind up the thread so the hanger is

just below the Super Pulley. Hold the 3-step Pulley.

3. Click Record to begin recording data, and release the

3-step Pulley, allowing the hanger to fall.

4. Caution! Click Stop to end data recording BEFORE

the hanger reaches the floor or the thread completely

unwinds from the 3-step Pulley.

5. In the Graph display, select the region of the data that

represents when the ring and disk were accelerating.

Experiment Guide

11

Page 12

®

Rotary Motion Sensor Experiment 2: Rotational Inertia of Disk and Ring

Select “Linear” from the Curve Fit Menu

6. In the Graph display, select “Linear” from the curve

fit menu.

The slope, m, of the linear fit represents the angular acceleration () for the Point Mass and Apparatus

7. Record the value of the slope, m, as the angular acceleration in Data Table 2.

B. Measure the Radius

• Using calipers, measure the diameter of the pulley

about which the thread is wrapped and calculate the

radius. Record the radius in Data Table 2.

Data Table 2: Experimental Rotational Inertia Data

Ring and Disk

Disk Alone

Combined

Hanging Mass

Slope, m

Radius

C. Finding the Acceleration of the Disk Alone

1. In "Finding the Acceleration of Ring and Disk," both the disk and the ring are rotating; therefore, it is necessary to determine the acceleration and the rotational inertia of the disk by itself so this rotational inertia can

be subtracted from the total, leaving only the rotational inertia of the ring.

2. Take the ring off the apparatus and repeat the steps under “Finding the Acceleration of the Ring and Disk”

for the disk alone. Record the results in Data Table 2.

Calculations

1. Calculate the experimental value of the rotational inertia of the ring and disk together, and record the value

in Data Table 3.

2. Calculate the experimental value of the rotational inertia of the disk alone and record the value in Data T able

3.

3. Subtract the rotational inertia of the disk from the total rotational inertia of the ring and disk, and record this

as the rotational inertia of the ring alone.

4. Use a percent difference to compare the experimental values to the theoretical values.

12

Experiment Guide

Page 13

®

PS-2120A Experiment 2: Rotational Inertia of Disk and Ring

Data Table 3: Results

Item Rotational Inertia

Ring and Disk

Disk alone

Ring alone

Percent difference for the disk

Percent difference for the ring

Experiment Guide

13

Page 14

®

Rotary Motion Sensor Experiment 2: Rotational Inertia of Disk and Ring

14

Experiment Guide

Page 15

®

PS-2120A Experiment 3: Conservation of Angular Momentum

LIiiIf

f

==

I

i

1

2

-- -

M

1

R

2

=

I

f

1

2

-- -

M

1

R

2

1

2

-- -

M

2r1

2

r

2

2

++=

f

M1R

2

M1R2M2r

1

2

r

2

2

++

------------------------------------------------------ -

i

=

Experiment 3: Conservation of Angular Momentum

Equipment Required* Equipment Required*

PASPORT-Compatible Interface Rotary Motion Sensor (PS-2120A)

Mini-Rotational Accessory (CI-6691) Mass and Hanger Set (ME-8979)

Base and Support Rod (ME-9355) Triple Beam Balance (SE-8723)

Paper clips (for masses <1 g) Calipers (SF-8711)

*Click the equipment item to go to the PASCO web site.

Purpose

A non-rotating ring is dropped onto a rotating disk, and the final angular speed of the system is compared with

the value predicted using the principle of the conservation of angular momentum.

Theory

When the ring is dropped onto the rotating disk, there is no net torque on the system since the torque on the ring

is equal and opposite to the torque on the disk. Therefore, there is no change in angular momentum; angular

momentum (L) is conserved.

where I

inertia and

is the initial rotational inertia and i is the initial angular speed of the disk and If is the final rotational

i

is the final angular speed of the disk and the ring together.

f

The rotational inertia of a disk is given as:

and the final rotational inertia of a disk and ring together is:

where M

is the mass of the disk, M2 is the mass of the ring, R is the radius of the disk, and r1 and r2 are the inner

1

and outer radii of the ring.

Based on this, the final rotational speed is given by:

Experiment Guide

15

Page 16

®

Rotary Motion Sensor Experiment 3: Conservation of Angular Momentum

Figure 3.1: Setup for Dropping Ring onto Disk

Disk

Support

Rod

RMS with

3-step Pulley

Figure 3.2: Drop Ring onto Disk

Ring

Setup

1. Mount the Rotary Motion Sensor to a support rod and

connect it to the interface. Place the disk directly on the

pulley as shown in Figure 3.1.

2. In the data acquisition software, create an experiment to

measure the angular velocity (in radians per second)

versus time (in second) of the disk before and after the

ring is dropped on top of it.

• In PASCO Capstone, for example, drag the Graph icon

from the Displays palette to the workbook. Select

“Angular Velocity (rad/s)” for the vertical axis, and

“Time (s)” for the horizontal axis.

Procedure

1. Hold the ring with the pins facing up just above the center of the disk.

2. Give the disk a spin with your hand and click Record to

begin recording data.

3. After about 25 data points have been recorded, drop the

ring on the spinning disk. See Figure 3.2.

4. Click Stop to end data recording after the disk and ring

have made a few rotations..

5. In the Graph display, select the region of the data that

represents when the ring was dropped onto the disk.

6. In the Graph display, select the data analysis tool that

shows the coordinates of any point in the plot of data

and move the cursor to the data point that is immediately before the collision. Record the Angular Velocity

at this point as the initial angular velocity in Data Table 1.

7. Move the cursor to the data point immediately after the collision. Record the Angular Velocity at this point

as the final angular velocity in Data Table 1.

8. W eigh the ring and disk and record their masses. Measure the inner and outer radii of the ring, and the radius

of the disk. Record these values in Data Table 1.

Analysis

1. Calculate the theoretical value for the final angular velocity and record this value in the Data Table.

2. Calculate the percent difference between the experimental and theoretical values of the final angular veloc-

ity and record it in the Data Table.

Questions

1. How does the experimental result for the final angular velocity compare with the theoretical value for the

final angular velocity?

16

Experiment Guide

Page 17

®

PS-2120A Experiment 3: Conservation of Angular Momentum

% KE lost =

1

2

-- -

I

ii

2

1

2

-- -

I

ff

2

+

1

2

-- -

I

i

2

i

2

------------------------------------- -

2. What percentage of the rotational kinetic energy was “lost” during the collision? Calculate the energy lost

and record the results in the Data Table.

.Data Table 1: Data and Results

Initial angular velocity

Final angular velocity

(experimental value)

Mass of disk (M1)

Mass of ring (M2)

Inner radius of ring (r1)

Outer radius of ring (r2)

Radius of disk (R)

Final angular velocity

(theoretical value)

Percent difference between

experimental and theoretical values

Percent of kinetic energy lost

Experiment Guide

17

Loading...

Loading...