Page 1

Instruction Manual

Manual No. 012-07688E

PASPort Dissolved Oxygen

Sensor

Model No.

PS-2108

Page 2

Instruction Manual

Manual No. 012-07688E

PASPort Dissolved Oxygen

Sensor

Model No.

PS-2108

Page 3

®

Model No. PS-2108 Dissolved Oxygen Sensor

Table of Contents

Equipment List .......................................................... 1

Introduction ............................................................. 1

DO Sensor Setup and Calibration...................................... 3

Prepare the Sensor for First Use....................................................................................................3

Set up the Dissolved Oxygen Sensor with DataStudio..................................................................3

Equilibrate the Probe in 100% Humidified Air.............................................................................4

Perform a Single-point Calibration (mg/l Dissolved O2)..............................................................4

Setup to Calibrate in Percent (%) Saturation.................................................................................4

General Sampling Procedure ............................................ 6

Measurements in a Controlled Laboratory Setting........................................................................ 6

Using the Dissolved Oxygen Sensor with other PASCO Sensors:................................................6

Maintenance ............................................................. 7

Changing the Electrolyte solution..................................................................................................7

Replacing the Membrane............................................................ .................................. ...... ...........7

Replacing the O-ring........................................................ ..............................................................8

Storage .................................................................. 9

Short-Term Storage (two weeks or less)........................................................................................9

Long-Term Storage (more than two weeks)..................................................................................9

Troubleshooting ......................................................... 9

Theory of Dissolved Oxygen: ......................................... 10

What is the chemical mechanism by which diatomic oxygen dissolves in water?......................10

Citations:......................................................................................................................................14

Experiment 1:

Introduction to the Operation of the Dissolved O2 Sensor ........ 15

Purpose.........................................................................................................................................15

Materials and Equipment Needed................................................................................................15

Optional Equipment Suggested ...................................................................................................15

Procedure .....................................................................................................................................15

Data Analysis/Questions..............................................................................................................16

Experiment 2:

Photosynthesis and Oxygen Generation with Aquatic Plants ........ 17

Purpose.........................................................................................................................................17

Materials and Equipment Needed................................................................................................17

Procedure .....................................................................................................................................18

During the lab time......................................................................................................................18

Collecting Data ............................................................................................................................19

Sample Data.................................................... ...... .......................................................................19

Analysis .......................................................................................................................................19

i

Page 4

®

Model No. PS-2108 Dissolved Oxygen Sensor

Experiment 3:

Effect of Sodium Sulfite on Dissolved O2 Concentrations ......... 20

Materials and Equipment Needed................................................................................................20

Optional Materials .......................................................................................................................20

Purpose.........................................................................................................................................20

Procedure .....................................................................................................................................20

Questions .....................................................................................................................................21

Experiment 4: Biochemical Oxygen Demand * ....................... 22

Background..................................................................................................................................22

Procedure .....................................................................................................................................22

Experiment 5:

The Effect Of Respiration On Dissolved O2 Concentration ........ 23

Purpose.........................................................................................................................................23

Materials required........................................................................................................................23

Optional materials ........................................................................................................................23

Procedure .....................................................................................................................................23

Questions .....................................................................................................................................24

Appendix A: Tables.................................................... 27

Copyright Notice....................................... ...... ...... .................................. ..... ...... ..........................25

Limited Warranty....................................................... ..................................................................25

Equipment Return........................................................................................................................25

Appendix B: Tables .................................................... 27

Specifications ...............................................................................................................................26

Replacement Parts..................................... ...... .............................................................................26

Technical Support........................................................................................................................26

Appendix C: Tables .................................................... 27

Table 1: Concentration of dissolved oxygen (mg/L) in water at

various temperatures and pressures .............................................................................................27

Table 2: Salinity correction factors for dissolved oxygen in water (based on conductivity)......32

ii

Page 5

Model No. PS-2108 Dissolved Oxygen Sensor

®

PASPort Dissolved Oxygen

Sensor

Model No. PS-2108

Equipment List

Included Equipment Replacement

Model Number*

1. Dissolved Oxygen Probe (1)

2. PASPORT Dissolved Oxygen Sensor box (1)

3. Membrane Replacement Kit (1)

4. Soaker Bottle (1)

5. Electrolyte Solution (1)

6. Syringe for filling cartridge housing (1)

699-06320

CI-6541

R001068

*Use Replacement Model Numbers to expedite replacement orders.

Introduction

The PASCO PS-2108 Dissolved Oxygen Sensor can be used to monitor and explore factors

that affect the concentrations of dissolved oxygen molecules (O2) in aqueous solutions,

particularly in applications related to ecological studies of water environments. The

Dissolved Oxygen Sensor is specifically designed for use with a PASPort interface or logger,

®

plus DataStudio

of temperature, water movement, inorganic chemicals, organic matter, and living organisms

on levels of dissolved O

ecological surveys of aqueous habitats, including BOD (Biological Oxygen Demand) studies.

The Dissolved Oxygen Sensor is designed for use in aqueous media at temperatures ranging

from 10 °C to 40 °C. For greatest accuracy, the following requirements should be met:

although the unit is temperature compensated, it should be calibrated at approximately the

same temperature as the test solution; the sensor must equilibrate for a short period when the

temperature of the test solution changes-the greater the temperature change, the longer the

period of equilibration required; the test solution should constantly flow past the membrane

of the probe.

data acquisition software. In the laboratory, students can explore the effects

. They can also monitor dissolved O2 levels in the field as a part of

2

The Dissolved Oxygen Sensor has a polarographic probe composed of a platinum cathode

and a silver (Ag) anode surrounded by a potassium chloride (KCl

*PASPORT sensors require a PASPORT computer interface.

) electrolyte solution.

(aq)

1

Page 6

PASPort Dissolved Oxygen Sensor Model No. PS-2108

®

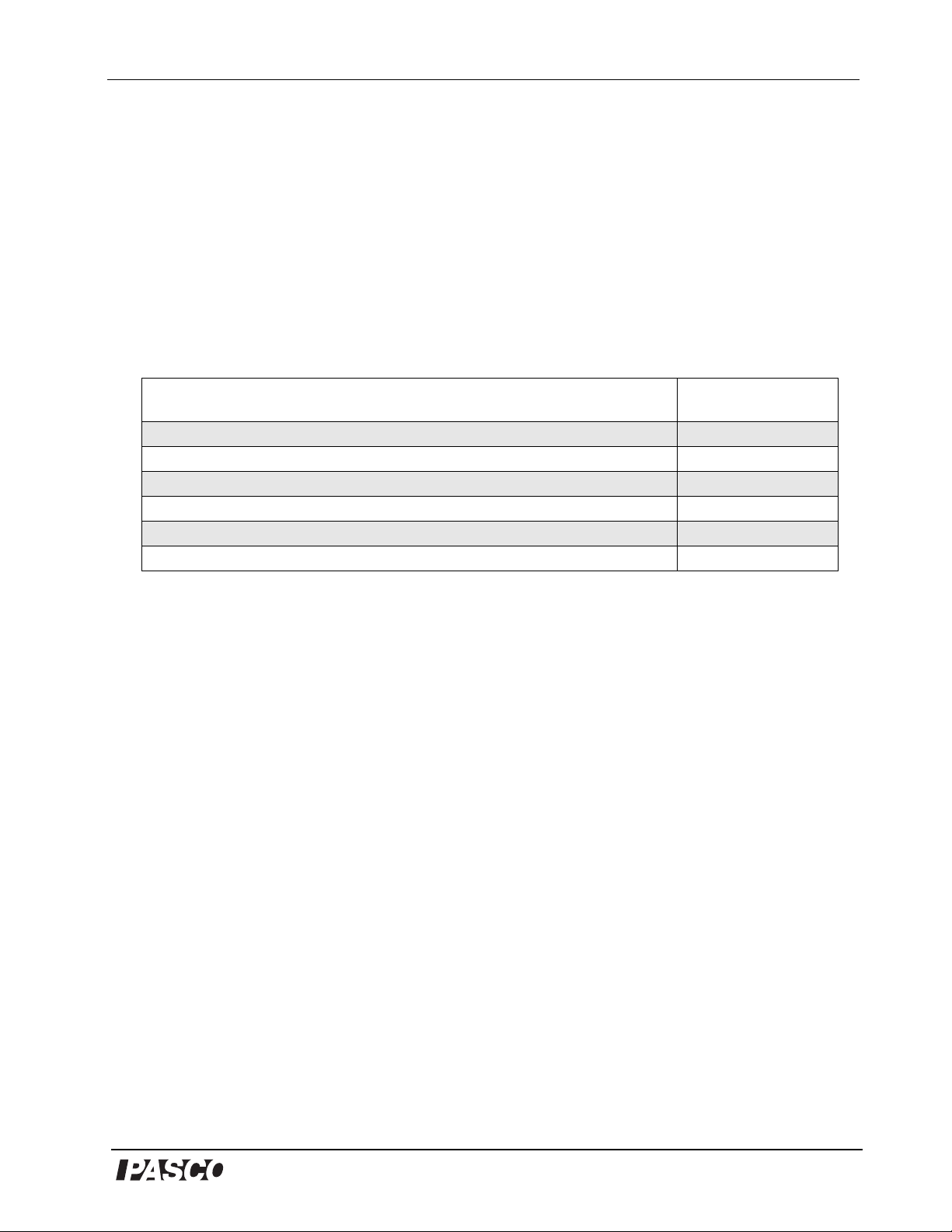

Figure 1

Oxygen molecules pass through the

semipermeable membrane into the

electrolyte surrounding the electrodes

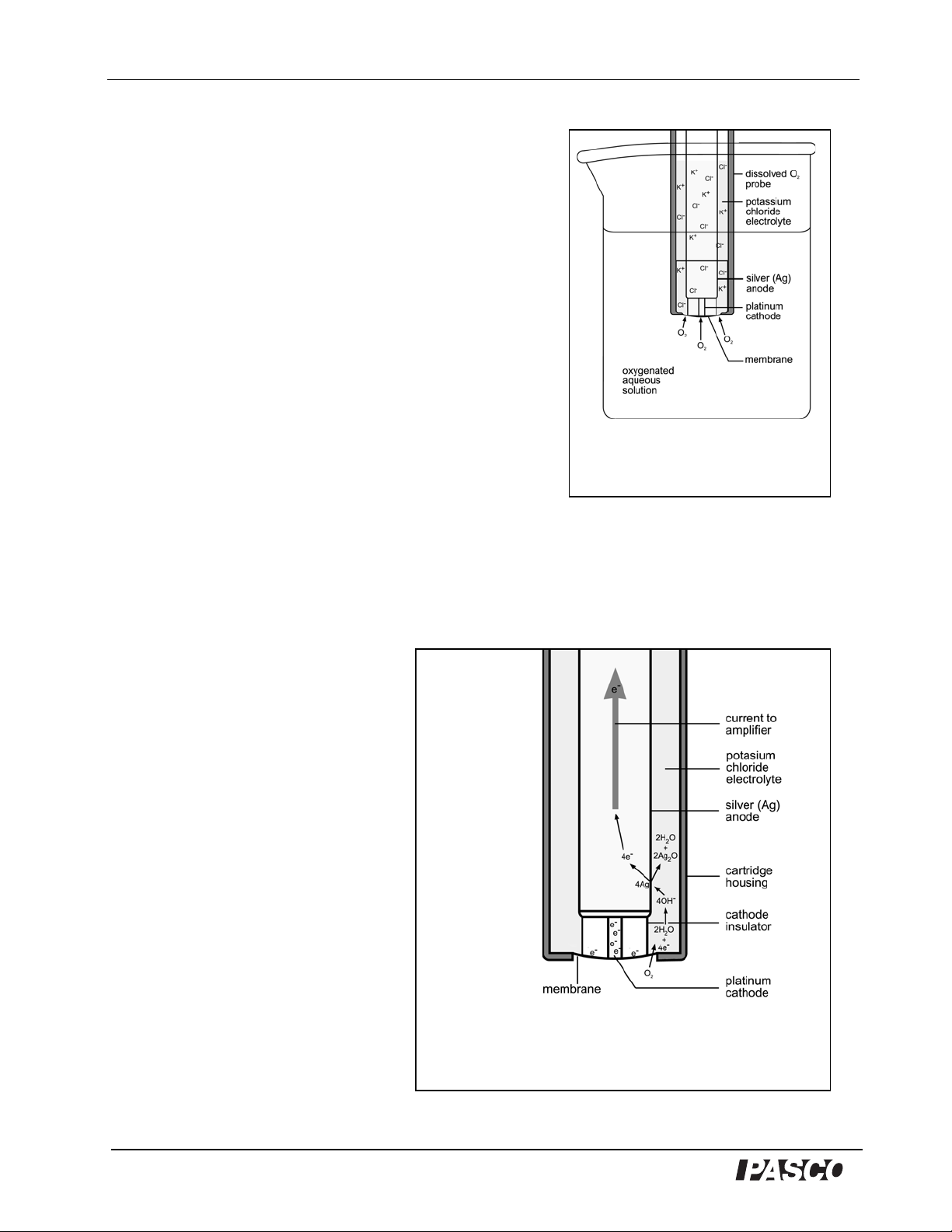

Figure 2

O

2

molecules diffuse across the membrane and react with water

molecules in the presence of electrons from the cathode to form

hydrox ide ions (OH

-

). Hydroxide ions diffuse to the anode and react with

silver (Ag) atoms, forming silver oxide (Ag

2

O), water, and free electrons.

O22H2O4e-4OH

-

Reduction potential = 0.40V

++

The sensor functions by measuring the electric current

produced by a chemical reaction in the probe. The

chemical reaction involves the reduction of oxygen (O2)

molecules and the oxidation of the silver (Ag) atoms of

the anode. A voltage of 0.7 volts is applied across the

electrodes, causing the desired redox reaction (see

below) to be favored. When the dissolved O2 probe is

placed in an aqueous medium, such as deionized water

that contains dissolved O2, the dissolved O2 molecules

diffuse across a thin silicon membrane into the

electrolyte that surrounds the electrodes of the probe

(Figure 1). The membrane is semipermeable, allowing

the dissolved O2 to pass through it, but preventing

passage by most other molecules that might interfere

with the chemical reactions at the elect rodes. The

chemical reactions produce electrons that cause electric

current to flow through the sensor's electric circuit. Since

the rate of diffusion is dependent on the concentration of the dissolved O2, the number of

diffused O2 molecules will vary approximately in direct proportion to the concentration of

dissolved O2 in the test solution. Accordingly, the number of electrons produced by the redox

chemical reactions of the dissolved O2 will be almost directly proportional to the

concentration of dissolved O2 in the test solution.

The following is an overview of the

chemical and electrical processes at

each of the electrodes that are

involved in measuring dissolved O2

with the Dissolved Oxygen Sensor .

As soon as the dissolved O2

molecules pass through the silicon

membrane into the electrolyte

solution, they come into close

proximity to the platinum cathode

(Figure 2). The negative charge

(excess electrons) of the cathode

induces the reduction of the

dissolved O2, forming hydroxide

-

ions (OH

):

1

2

Page 7

Model No. PS-2108 Dissolved Oxygen Sensor

®

4Ag 4OH

-

2Ag2O2H2O4e

-

Reduction potential = 0.343V

+++

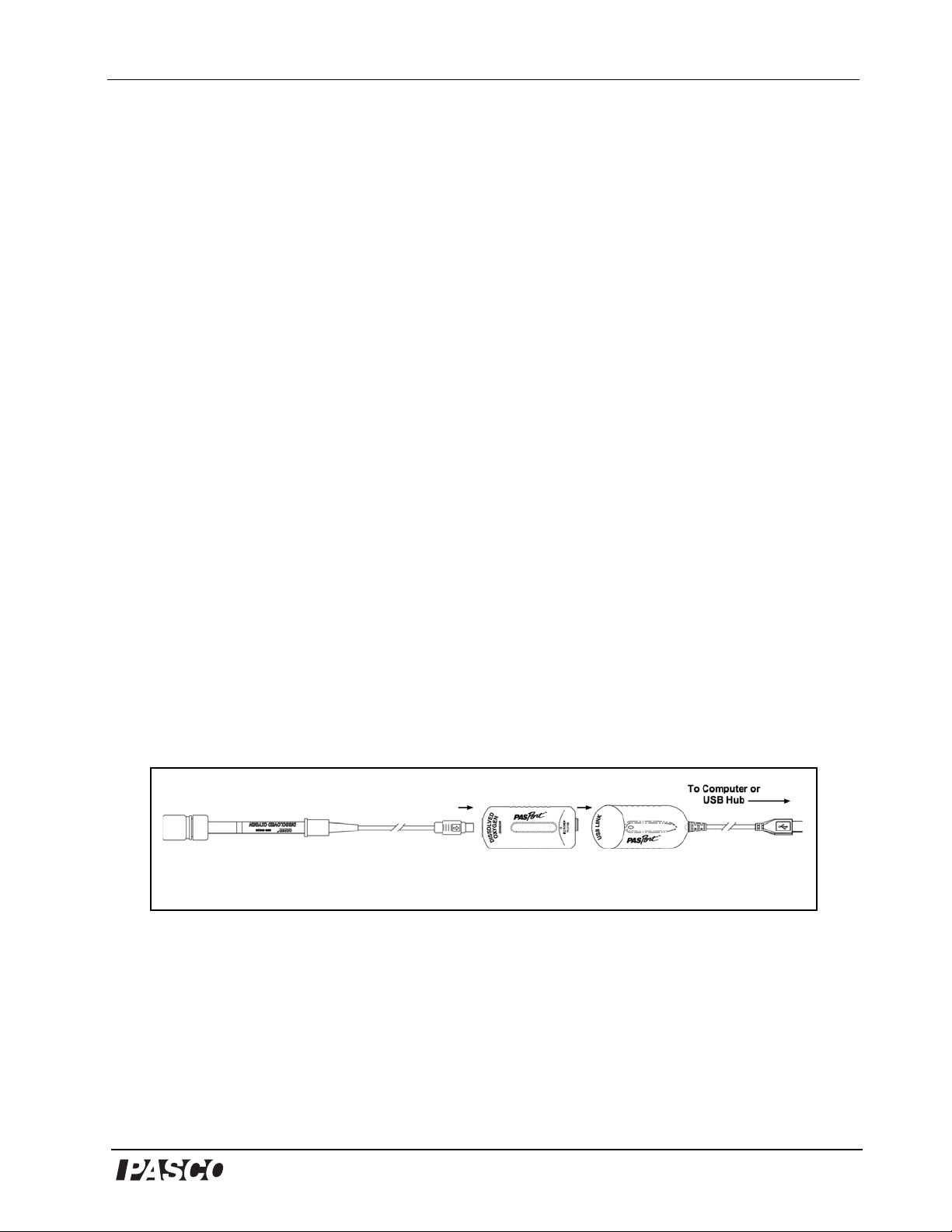

Figure 3

Plug the DO

2

probe into the DO2 sensor box and connect the sensor box to a PASPort USB interface that is

connected to a computer’s USB port or to a USB hub that is connected to the computer.

The negatively charged hydroxide ions diffuse to the silver anode. There they combine with

silver (Ag) atoms from the silver anode, forming silver oxide and releasing electrons that join

the current in the electrode in the following chemical reaction:

The released electrons produce a current that passes from the electrode and is amplified. The

current due to the chemical reactions of the O2 molecules must be corre cted for temperature

variations, since the rate of reaction varies directly with the temperature.

The correction is accomplished through the use of a temperature-sensing thermistor that is

built into the probe. With the temperature sensing thermistor, the temperature of the probe is

monitored, and the gain of the amplifier is automatically adjusted to compensate for the

temperature dependence of the chemical reactions in the probe. A signal representing the

temperature-compensated dissolved O2 concentration of the solution is fed to the computer

interface and displayed by DataStudio in concentration (mg/l) or saturation (%).

DO Sensor Setup and Calibration

Prepare the Sensor for First Use

Prior to the first use of the sensor, you will need to fill the Dissolved Oxygen Sensor electrode

membrane cartridge and cartridge housing with an electrolyte solution. See the maintenance

section for instructions.

Set up the Dissolved Oxygen Sensor with DataStudio.

1. Attach the probe to the sensor box (Figure 3).

2. Plug the sensor box into a PASPort interface or logger connected to a computer.

3. The PASPortal window should open, allowing a choice between DataStudio or EZScreen.

Select DataStudio.

4. The Digits display opens automatically. Open additional or alternate displays as desired.

1

Find a more detailed discussion in Micha el L. Hit ch m an, M e asurement of Dissolved Oxygen, John Wiley and Sons,

New York, 1978, pp. 59-123.

3

Page 8

PASPort Dissolved Oxygen Sensor Model No. PS-2108

®

Water level

Shake

vigorously

Soaker

Bottle

Figure 4

To equilibrate the probe, insert the

end of the probe into a clean soaker

bottle containing ~5 mL of deionized

water. Shake the probe vigorously for

about 10 Sec.

Equilibrate the Probe in 100% Humidified Air

1. Place about 5 mL (to a height of about 1 cm) of deionized

water into a clean soaker bottle. Slip the cap and O-ring of the

soaker bottle over the end of the probe.

2. Insert the probe into the soaker bottle and screw on the lid.

Adjust the height of the end of the probe to about 2 cm above

the top of the water (Figure 4).

3. Shake the soaker bottle vigorously for about 10 seconds.

Shake off any large water drops from the membrane.

Perform a Single-point Calibration (mg/l Dissolved O2)

1. Obtain current barometric pressure and temperature readings

for your location. You can use the PAPSPORT Barometer (PS-

2113) and Temperature Sensor (PS-2131), or the PASPORT Weathe r Sensor (PS-2154) to

take the necessary measurements.

2. Refer to the Solubility table 1 in Appendix C and find the appropriate dissolved oxygen

value for the temperature and barometric pressure at your location.

Example: At a temperature of 25ºC and a barometric pressure of 760 MM. Hg, 8.2 mg of oxygen will

dissolve in one liter of water at 10 0% saturation.

3. In DataStudio, click the Setup button on the toolbar. Make sure mg/L is selected next to

the Calibrate… button in the Dissolved Oxygen Sensor dialog.

4. With the DO2 sensor equilibrated as described above, click the Calibrate… button.

5. Refer to the tables for the value of mg/l dissolved O

in saturated water at the temperature

2

and uncorrected barometric pressure at which you are measuring. (If you do not know the

barometric pressure, assume that it is 760 mm Hg.) Enter the value in the mg/l box. Click

OK.

Setup to Calibrate in Percent (%) Saturation

1. (DataStudio only) Click the Setup button on the DataStudio toolbar. Click the mg/L button

next to the Calibrate… button and select % from the drop-down menu

Note: Always calibrate the probe before measuring absolute (rather than relative) concentratio ns. Calibrate at or

close to the temperature and barometric pressure at which the test solution is to be measured.-

Note: Percent (%) saturation output is valid only at the temperature and barometric pressure at which the probe is

calibrated.

Note: Before taking measurements of dissolved oxygen (DO) concentration (rather than % saturation), change

4

Page 9

Model No. PS-2108 Dissolved Oxygen Sensor

®

Cg=k Pg

your software settings back to mg/L.

DataStudio: Click the Setup button on the DataStudio toolbar. Click the % button next to the Calibrate button and

select mg/L from the drop-down menu.

Note: Calibration is not required for measurements of relative DO content, such as before/during/after

experiment relative changes.

2. Click the Calibrate… button to open the Calibrate dialog.

3. Place the probe in 100% humidified air. When the readings stabilize around a value, click

the Set button. Then click OK. It may take a few minutes for the sensor to equilibrate for

calibration. The readings may not completely stabilize at one specific point.

Calibration in 100% humidified air is equivalent to calibrating in 100% air-saturated

water. This is because the oxygen must first pass through the electrolyte solution in the

Dissolved Oxygen Sensor to get to the cathode. The concentration of oxygen in both the

100% air-saturated water and the electrolyte solution will be equivalently proportional to

the partial pressure of oxygen in air, following Henry's law where

Cg = the solubility of the gas (oxygen)

Pg = the pressure of the gas over the solution

This relationship holds true whether the end of the sensor is immersed in the water or

suspended in air.

4. Before taking measurements of dissolved oxygen concentration, change your unit settings

back to mg/L.

5

Page 10

PASPort Dissolved Oxygen Sensor Model No. PS-2108

®

General Sampling Procedure

1. Immerse the Dissolved Oxygen probe into the test solution until the silver temperature

compensation band is submerged.

2. Click the Start button on the DataStudio tool bar or select Monitor Data from the

Experiment menu.

3. Gently, swirl the probe for a minute or two until the dissolved oxygen readings stabilize

around a value. As an alternative, use a magnetic stirrer to slowly stir the test solution (do

not stir fast enough to entrain air bubbles or form a large vortex.

Measurements in a Controlled Laboratory Setting

In a laboratory setting, you can make long-term measurements of dissolved oxygen levels by

gently and continuously stirring the solution with a magnetic stir plate and stir bar. Minimize

the surface area of the atmosphere/liquid interface to retard gas exchange with the

atmosphere. A vessel such as an Erlenmeyer flask or a large test tube works well.

Note: DO NOT USE MINERAL OIL, as it is difficult to clean from the membrane.

Using the Dissolved Oxygen Sensor with other PASCO Sensors:

Some PASCO sensors, including the Dissolved Oxygen Sensor, emit electrical signals into

the test solution and may interfere with other sensors taking simultaneous measurements. If

you want to take simultaneous measurements with the Dissolved Oxygen Sensor and another

PASCO sensor (such as the Conductivity Sensor or pH Sensor), conduct controlled

experiments and ensure that no intra-sensor interference occurs under your experimental

conditions.

6

Page 11

Model No. PS-2108 Dissolved Oxygen Sensor

®

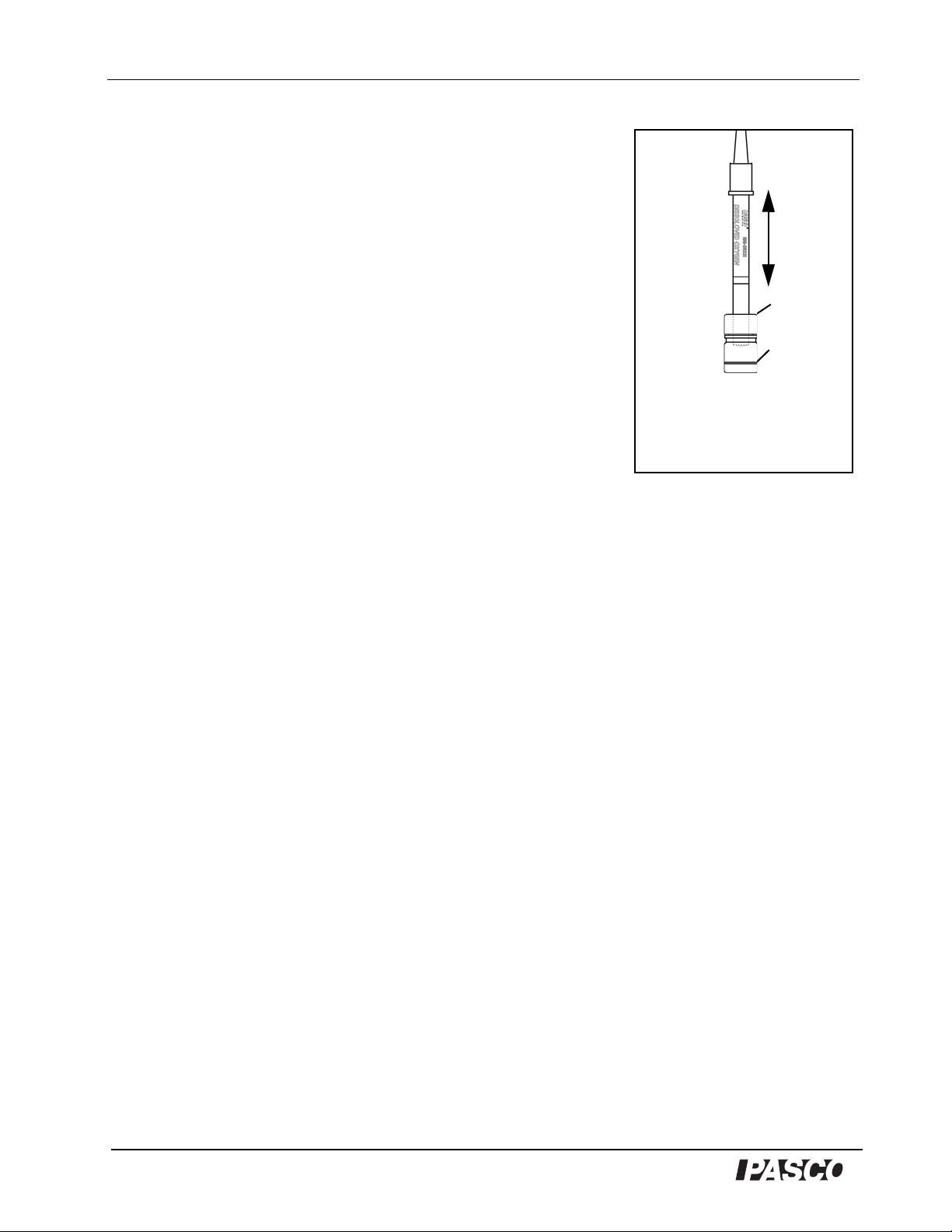

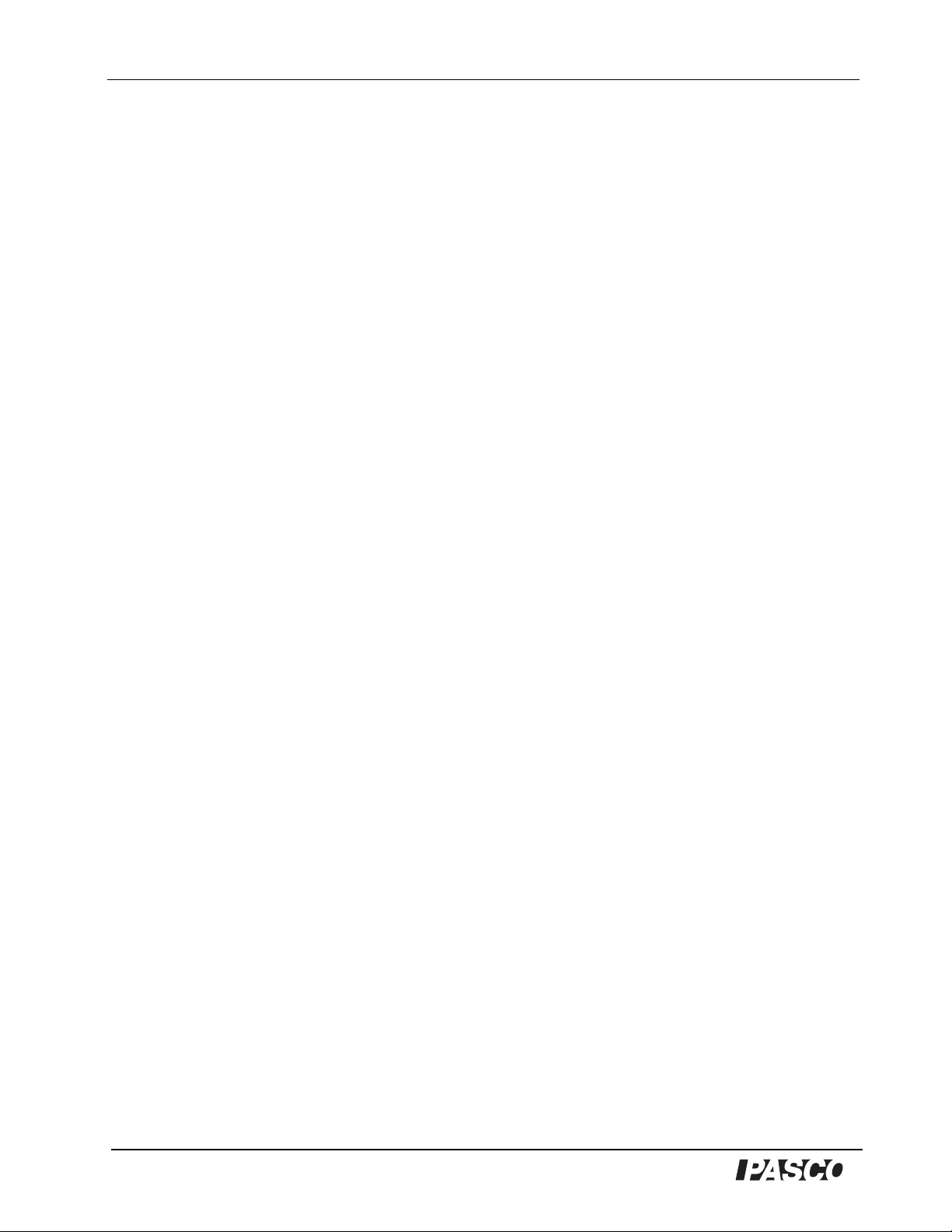

Figure 5

Removing the cartridge

housing and filling with

electrolyte.

Figure 6

Replacing the cartridge

housing.

Maintenance

Changing the Electrolyte solution

The electrolyte solution (probe filling solution) should be

periodically replaced and the silver electrode cleaned to maintain

optimal performance of the probe. If the probe is not performing

optimally, replace the electrolyte solution as follows:

1. Unscrew the end of the probe by turning it to the left, and

remove the cartridge housing (Figure 5).

Always hold the probe below the stainless steel band when

unscrewing the cartridge housing or otherwise applying torque

to the end of the probe.

2. Rinse the electrode with tap water (or deionized water in areas

with hard tap water) and rub it dry with a paper towel, removing

loose silver oxide (Ag2O) from the anode.

3. Rinse and air dry the cartridge housing.

4. Pull about 10 ml of the Polarographic solution into the syringe,

being careful not to introduce air bubbles.

5. Place the tip of the syringe very close to, but not touching the

membrane, and slowly fill the membrane cartridge and cartridge

housing to approximately 5 mm from the top of the housing.

Note: Tap the cartridge housing while filling to avoid introducing air bubbles.

6. Holding the probe in a vertical position, slip the cartridge housing

over the electrode and turn to the right to tighten (Figure 6).

7. Dry with a paper towel or tissue.

Replacing the Membrane

If the silicon membrane becomes torn or otherwise damaged, replace it

as follows:

1. Follow steps 1 through 3 under "Changing the Electrolyte Solution"

above.

7

Page 12

PASPort Dissolved Oxygen Sensor Model No. PS-2108

®

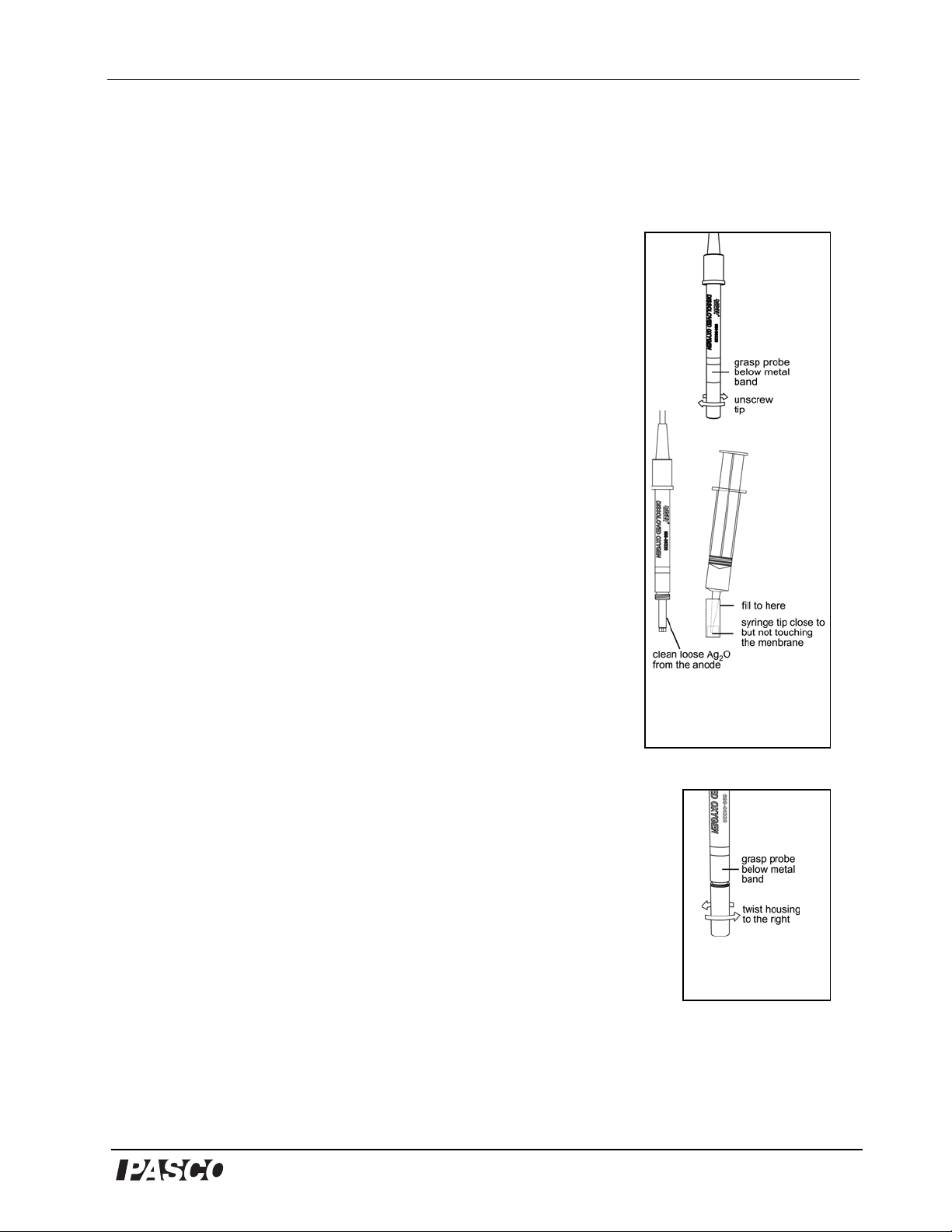

Figure 7

Removing and replacing the

membrane cartridge.

A

B

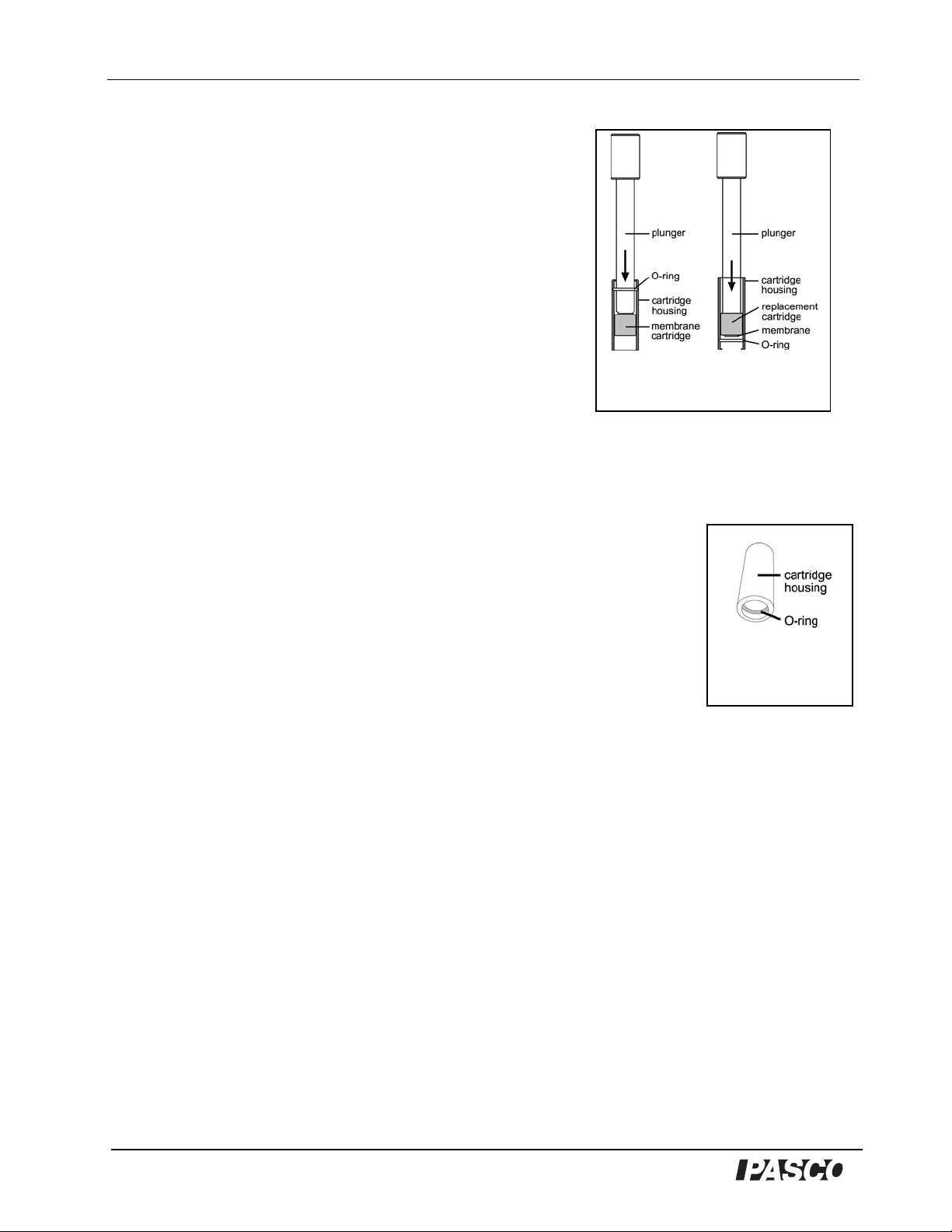

Figure 8

Examine the O-ring for

damage.

2. Use the supplied plunger to push the membrane cartridge

out of the cartridge housing (Figure 7A).

3. Examine the O-ring (Figure 8) and replace it if it is

damaged (See "Replacing the O-ring" below.).

4. Insert a replacement membrane cartridge and use the

plunger to push it down until it is seated at the end of the

housing that has the O-ring (Figure 7B).

5. Fill with ele ctrolyte and reas semble the pr obe as directed

in steps 4 through 7 of "Changing the Electrolyte

Solution."

Replacing the O-ring

The O-ring should rarely if ever require replacing. However, if it develops nicks or splits and

begins to allow leakage of the electrolyte solution from the probe, replace it as follows:

1. Follow steps 1and 2 of the procedure for replacing the membrane

cartridge (above).

2. After removing the membrane cartridge, remove the O-ring with a pair

of fine-tipped tweezers and insert a new O-ring.

3. Insert the membrane cartridge as directed in step 4 of “Replacing the

Membrane”.

4. Fill with electrolyte and reassemble the probe as directed in steps 4

through 7 of "Changing the Electrolyte Solution."

8

Page 13

Model No. PS-2108 Dissolved Oxygen Sensor

®

Storage

Short-Term Storage (two weeks or less)

Store the probe in the plastic storage bag with the tip inserted in the soaker bottle containing

about 10 ml of deionized water.

Long-Term Storage (more than two weeks)

1. Unscrew and remove the cartridge housing by turning it to the left.

Always hold the probe below the stainless steel band when unscrewing the cartridge housing

or otherwise applying torque to the end of the probe.

2. Dispose of the electrolyte and rinse the electrode with tap water (or deionized water in

areas with hard tap water) and dry it with a paper towel, removing loose silver oxide

(Ag2O) from the anode.

3. Rinse the cartridge housing with tap water and allow it to air dry.

4. Rinse the soaker bottle with tap or deionized water and shake dry.

5. Replace the cartridge housing onto the probe and place the dry probe in its storage bag

with the end of the probe in the soaker bottle to protect the membrane from damage.

Troubleshooting

If the Dissolved Oxygen Sensor does not give the expected output, do the following, and

check the function of the sensor after each step until the sensor works properly:

1. Replace the filling solution. See "Changing the Electrolyte Solution."

2. Replace the membrane. See "Replacing the Membrane."

3. Check the O-ring and replace if necessary (See "Replacing the O-ring."

If the Dissolved Oxygen Sensor still does not function properly, contact Technical Support

(See the Technical Support section in the back of this manual.)

9

Page 14

PASPort Dissolved Oxygen Sensor Model No. PS-2108

®

Induced Dipoles

The electron cloud of an isolated Oxygen

molecule is distributed symmetrically

between the bonded O atoms.

As the negative end of the polar water

molecule approaches…

…the O2 electron cloud is moved away to

reduce repulsion between the O2 cloud and

the negative end of the water molecule.

The O2 molecule itself becomes polar.

A dipole has been induced in the otherwise

nonpolar O2 molecule. The H2O and the O2

are now weakly attracted to one another.

Theory of Dissolved Oxygen:

What is the chemical mechanism by which diatomic oxygen dissolves in water?

This is a particularly eloquent description of the mechanism of oxygen solubility in water:

[from Water on the Web1]

Water, as a polar molecule, induces an accumulation of electron density (dipole moment) at one end of nonpolar

gas molecules such as oxygen (O

approaching a nonpolar O

the bonded O

cloud of the O

positive and negative charges sep arated by a di stance) has been induced in the nonpolar O

and H

2

poles of nearby molecules is termed a dipole- indu ced dipole force. Th e creation of th ese forces then explains the

mechanism by which gases dissolve in water.

atoms. As the negative end of the H2O molecule approaches the oxygen molecule, the electron

2

moves away to reduce the negative-to-negative repulsion. As a result, a dipole (a molecule with

2

O to become weakly attracted to each other . This intermolecular attraction between the oppos itely charged

2

Still images from the Water on the Web animation:

) and carbon dioxide (CO2). In animation, observe a polar water molecule

2

molecule. The electron cloud of O2 is normally distributed symm e trically between

molecule, causing O2

2

10

II. What factors influence the amount of dissolved oxygen in water? There are several

factors that can influence the amount of gaseous diatomic oxygen (as well as other gases) that

will dissolve in water. When speaking of gases dissolving in water, discussion is limited to

gases that do not chemically react with the water.

Page 15

Model No. PS-2108 Dissolved Oxygen Sensor

®

1. Water Temperature effects

• Gases usually dissolve in liquids in an exothermic process. This expression represents that

process:

gas + solvent liquid gas saturated solvent + heat (this will reach an equilibrium)

• Le Chatelier's Principle predicts that an added stress to one side of this equilibrium will

cause a shift in equilibrium in order to accommodate that stress, thereby driving the

equilibrium point to the left in the expression below:

GAS + solvent liquid gas saturated solvent +heat

• Experimental results support this theory:

This graph was constructed using DataStudio, drawing on data taken from Table HY-DO-1 in

the GLOBE protocol for Dissolved Oxygen.

2

11

Page 16

PASPort Dissolved Oxygen Sensor Model No. PS-2108

®

P=kC

C1

P1

------ -

C2

P2

------ -=

9mg/L

1012 milibars

--------------------------------------- -

790 milibars 7 mg/L

2. Overlying Gas Pressure Effects

• Henry's Law states that the solubility of a gas in a liquid is affected by the pressure of the

gas above the liquid-gas interface.

P=gas pressure (or partial pressure)

C=concentration of dissolved gas

k = Henry’s Law Constant (differs with temperature, gas, and solvent)

• Changing pressures, while maintaining the same temperature, gas, and solvent allows one

to draw a relationship that excludes Henry's Law Constant:

• If a gas-liquid system starts at equilibrium and the partial pressure of a gas is increased

(with other factors such as temperature remaining unchanged) the amount of gas that is

dissolved in the liquid at the new equilibrium will increase.

For example:

P1 = 1012 millibars (approximately sea level)

C1 = 9 mg / L

P2 = 790 millibars (approximately 6700 ft or 2050 m above sea level)

• The most significant way in which this effect manifests itself is the reduced maximum

possible dissolved oxygen at higher altitudes. This is the reason why barometric pressure

at the sample site is important. Higher altitudes lead to a decrease in atmospheric pressure

(all atmospheric gases), which leads to a decrease in the partial pressure of oxygen (as well

as all of the other atmospheric gases). Please note the weather services often report

barometric pressure for a location, which is normalized for the same local conditions as if

reported at sea level, that is, the values are corrected for altitude.

• The decrease in atmosphere pressure with increase in altitude is not linear. Please see the

altitude correction table in order to compensate for altitude differences.

3. Hydrostatic Pressure

• Water under significant pressure may hold a higher amount of dissolved gas, compared to

water under less pressure. Plumbing systems are commonly under significant pressure.

The gases dissolved in water that is in a plumbing system may be at equilibrium at that

pressure, but when the pressure is released or decreased by an act such as drawing the

water from a tap into a container at atmospheric pressure, the solution may be

supersaturated. This phenomenon is similar to opening a can of carbonated beverage or

soda pop. However, the dissolved gases may take several seconds to several hours to reach

12

Page 17

Model No. PS-2108 Dissolved Oxygen Sensor

®

equilibrium.

A famous, naturally occurring case of supersaturation and subsequent gas release (in this

case it was dissolved carbon dioxide gas) was the Lake Nyos tragedy, which took place in

Cameroon (1986).

4. Salinity.

• Salt and other solids dissolved in water will affect the total amount of gas that a liquid

solvent can dissolve. Given otherwise identical conditions, fresh water can hold more

dissolved oxygen than salt water. When measuring dissolved oxygen in salt water (in

excess of 1000 mg/L dissolved salts), calibrate the probe in a sample of the salt water in

which the DO measurement is desired. For situations in which the salt content is not

constant (such as estuarine environments) one must calibrate the probe using fresh water.

For each DO reading, one must also make an accurate determination of dissolved salt

content in order to account for the change in oxygen solubility in waters of varying salinity.

• To obtain theoretical maximum DO in saline waters, consult the following table for the

theoretical maximum dissolved oxygen at saturation-the low calibration value will remain

at 0 mg/L DO (table from Ambient W ater Quality Criteria, 19973). For values not found in

the table, use the nomogram found on page 28 in Hitchman, 1978.

Solubility of oxygen in water (fresh and sa line) exposed to water-saturated air at sea level

760 mm Hg (101.3 kPa)

Chlorinity (freshwater)

Temp .

(°C)

0.0 14.621 13.728 12.888 12.097 11.355 10.657

1.0 14.216 13.356 12.545 11.783 11.066 10.392

2.0 13.829 13.000 12.218 11.483 10.790 10.139

3.0 13.460 12.660 11.906 11.195 10.526 9.897

4.0 13.107 12.335 11.607 10.920 10.273 9.664

5.0 12.770 12.024 11.320 10.656 10.031 9.441

6.0 12.447 11.727 11.046 10.404 9.799 9.228

7.0 12.139 11.442 11.783 10.162 9.576 9.023

8.0 11.843 11.169 10.531 9.930 9.362 8.826

9.0 11.559 10.907 10.290 9.707 9.156 8.636

10.0 11.288 10.656 10.058 9.493 8.959 8.454

11.0 11.027 10.415 9.835 9.287 8.769 8.279

12.0 10.777 10.183 9.621 9.089 8.586 8.111

13.0 10.537 9.961 9.416 8.899 8.411 7.949

14.0 10.306 9.747 9.218 8.716 8.242 7.792

0 g/L Cl- 5.0 g/L Cl- 10.0 g/L Cl- 15.0 g/L Cl- 20.0 g/L Cl- 25.0 g/L Cl-

4

13

Page 18

PASPort Dissolved Oxygen Sensor Model No. PS-2108

®

Chlorinity (freshwater)

Tem p.

(°C)

15.0 10.084 9.541 9.027 8.540 8.079 7.642

16.0 9.870 9.344 8.844 8.370 7.922 7.496

17.0 9.665 9.153 8.667 8.207 7.770 7.356

0 g/L Cl- 5.0 g/L Cl- 10.0 g/L Cl- 15.0 g/L Cl- 20.0 g/L Cl- 25.0 g/L Cl-

5. Surface Area and Mixing/Turbulence

• The surface area of the water/gas interface may affect the rate at which gas dissolves into

the water, but ultimately, it will not affect the total amount of gas dissolved at static (nonturbulent) equilibrium. Situat ions in whic h t urbulence is constant (such as the outfall from

a dam spillway) can host a dynamic equilibrium in which water remains supersaturated at a

given point in the stream.

• Stirring a water sample in a laboratory setting has a drastic effect on the behavior of the

DO probe. The nature of a Clark-type probe is that it consumes oxygen in its immediate

environment (leading to an apparent localized drop in DO level). Stirring the sample,

while taking data, is highly recommended in order to obtain faithful DO readings. It is

crucial to maintain a sufficient flow rate across the membrane of the sensor . Flow of about

1 cm per second is recommended. Do not stir to the point of causing excessive turbulence

in the water.

• Allow the probe to reach equilibrium in experiments that are not conducive to stirring.

There will be an initial drop (in most cases up to 60 seconds) on apparent readings until a

local equilibrium is established.

Citations:

1. WOW. 2003. Water on the Web - Monitoring Minnesota Lakes on the Internet and Training

Water Science Technicians for the Future - A National On-line Curriculum using Advanced

Technologies and Real-Time Data. (http://wow.nrri.umn.edu). University of MinnesotaDuluth, Duluth, MN 55812

2. Table HY-DO-1 from Globe Dissolved Oxygen Protocol (http://www.globe.gov/tctg/

hydro_prot_do.pdf?sectionId=151)

3. Ambient Water Quality Criteria for Dissolved Oxygen, February, 1997. Water

Management Branch Environment and Lands Headquarters Division, Ministry Of

Environment, Lands and Parks, Canada

4. Hitchman, Michael L.1978. Measurement of Dissolved Oxygen. John Wiley and Sons,

New York. 255 p.

14

Page 19

Model No. PS-2108 Dissolved Oxygen Sensor

®

Figure 1

Gently stir the probe in the

test solution

Experiment 1: Introduction to the Operation of the

Dissolved O

Sensor

2

Purpose

The purpose of the experiment is to explore the basic operation of the Dissolved Oxygen

Sensor: how to set it up, how to calibrate it, and how to obtain the most accurate

measurements with it.

Materials and Equipment Needed

• Dissolved Oxygen Sensor (PS-2108)

• 600 ml beaker

• PASCO ScienceWorkshop

• 400 ml deionized water saturated with air

• PASPort Interface and DataStudio software

• Reference tables for dissolved oxygen

• aquarium pump (optional)

Optional Equipment Suggested

T o s aturate deionized water with air, fill a clean container one-third full wit h deionized water,

seal it, and shake vigorously for 10 seconds. Alternatively, bubble air through the deionized

water for 15 minutes using an aquarium pump.

Procedure

1. Set up and calibrate the Dissolved Oxygen Sensor in DataStudio

according to the calibration procedure detailed in this manual.

2. Place the probe in the test solution and stir it gently for thirty

seconds.

3. Click t he Start button on the DataStudio toolbar to begin recording

data (Data Run #1).

4. Being careful to keep the stainless steel band submerged to at least

1 cm under the surface of the water, gently stir the probe in the test

solution until the dissolved O

readings stabilize.

2

5. Click the Stop button on the DataStudio toolbar to end data

recording.

15

Page 20

PASPort Dissolved Oxygen Sensor Model No. PS-2108

®

Figure 2

Allow the probe to rest

undisturbed in the test solution

6. Click the Start button on the DataStudio toolbar to begin recording data (Data Run #2).

7. Allow the probe to rest undisturbed in the test solution and

observe the sensor reading.

8. After the sensor reading stabilizes at the new level, gently move

the probe back and forth through the test solution and observe

the sensor reading.

9. After the sensor reading stabilizes at the new level, repeat steps

6 and 7 several times.

10. . Click the Stop button to end data recording. Save the recorded

data.

Note: The concentration of dissolved O2 should be about the level of the high

value that you entered dur ing cali brat ion. If not , check to be sure that ther e are no lar ge air bubbles on the b ottom

of the probe. If the value is still significantly (mo re than 10 %) different than the high value, re-calibrate the

sensor.

Data Analysis/Questions

1. Why does the measured dissolved O2 concentration decline when you leave the probe

undisturbed?

2. Why does measured dissolved O2 concentration stop declining while the probe is

undisturbed?

3. Why does the measured dissolved O2 concentration rise when you move the probe

through the test solution?

4. Why does the measured dissolved O

concentration stop rising while the probe is moving

2

through the test solution?

5. Which measurement is the most accurate representation of the dissolved O2 concentration

of the test solution?

6. Explain why it is important to move a steady flow of the test solution by the membrane of

the Dissolved Oxygen Sensor while taking dissolved O2 concentration measurements.

16

Page 21

Model No. PS-2108 Dissolved Oxygen Sensor

®

Experiment 2: Photosynthesis and Oxygen Generation

with Aquatic Plants

Purpose

Explore the change in level of dissolved oxygen in water associated with photosynthesis of

aquatic plants.

Materials and Equipment Needed

• 2-PASPort DO sensors PS-2108

• 2-PASPort USB Links PS-2100

• USB equipped computer running DataStudio software

• 100 watt incandescent lamp (or equivalent)

• Lab stand(s)

• Masking Tape

• Paper

• 2-Test Tubes (25mm x 150mm)

• 1-1000 mL beaker

• 1 healthy sprig of Elodea

• Deionized or clean fresh water

1

Background

Plants carry out the process of photosynthesis when conditions are appropriate. Plants take in

reactants including carbon dioxide, water, and energy in the form of light. A waste product

from the photosynthetic process is gaseous oxygen, which is released to the environment.

For aquatic plants, this gas is released into the water, increasing the amount of dissolved

oxygen present in the water.

The dissolved oxygen sensor is well-suited to monitor changing levels of molecular oxygen

in the aqueous environment of the Elodea plant.

Tips for success:

• Set up and run the experiment far ahead of time, so that the procedure is familiar.

• Use fresh Elodea (the growing tip will give the best results).

• Allow water to reach equilibrium, in terms of the dissolved gases (this may take up to 24

hours)

• Submerge the DO sensor so that the metallic band is below the surface of the water.

• Use a full beaker of water for the water bath to control thermal fluctuations.

• Set up: (Complete steps 1-4 in advance)

1. or other PASPort interface

17

Page 22

PASPort Dissolved Oxygen Sensor Model No. PS-2108

®

Figure 1

Equipment setup.

Procedure

1. Perform a test run on the DO sensor(s) to ensure that the

membrane is intact.

2. Arrange equipment so that the two large test tubes are

nearly full of water.

3. Clamp test tubes in place vertically, with the beaker as a

water bath (to minimize temperature fluctuations).

4. With no plants in place, allow the entire system to reach

equilibrium for about three to four hours (it is not harmful

to exceed this time).

During the lab time

1. Insert each DO sensor into its respective test tube. Perform a virtual calibration in

DataStudio so that the DO mg/L value is set at the same level for each sensor (7 mg/L is a

good starting point). Absolute calibration is less important in this particular situation, since

the goal is to measure relative change, instead of absolute dissolved oxygen.

2. Conduct a test run for approximately 30 seconds to ensure that the DO probes are reading

values that are reasonably close to each other.

3. Remove the DO sensors. Do not allow the probe tip to contact other surfaces (it helps to

clamp the probes to a rack, and then lif t the entir e rac k until the probes ar e clear of the test

tubes).

4. Gently and carefully insert a sprig (about 2-3 cm long) of the healthy green tip of the

Elodea plant in one test tube (experiment). Insert a control, such as a plastic Elodea plant,

in the other test tube (optional). Ta ke care to avoid stirring or agitating the water in the

test tubes more than necessary.

5. Reinsert the DO sensors until the tip of the sensor is close to, but not touching the plant.

6. Use tape and a folded piece of paper to form a light mask around the upper part of the

beaker, such that it's lower edge is even with the bottom of the DO sensor probe tip.

7. Position the light about one meter away from the beaker, so that it can illuminate the

plants through the side of the beaker (horizontally). Turn the light on for a momentary

check of positioning then turn it off.

18

Page 23

Model No. PS-2108 Dissolved Oxygen Sensor

®

Collecting Data

8. Begin collecting data. Allow the system to take in ambient light for 60 seconds, and then

cover the entire set up with an opaque cloth, such as a rubberized lab apron. After fifteen

minutes, remove the cover and turn on the light. Continue to collect data for another

fifteen minutes. Stop data collection.

9. If desired, conduct additional data runs in a similar manner.

Sample Data

Analysis

1. Discuss the reasons for use of a control in this experiment.

2. Why was it not necessary to calibrate the sensors to an absolute standard?

19

Page 24

PASPort Dissolved Oxygen Sensor Model No. PS-2108

®

Figure 3

Stir test solution with probe

while adding sodium sulfite.

Experiment 3: Effect of Sodium Sulfite on Dissolved

O

Concentrations

2

Materials and Equipment Needed

• Dissolved Oxygen Sensor

• PASPort interface or logger

• 2 M sodium sulfite (25.2 g Na2SO3/100 ml)

• aquarium pump or large bottle

• PASPort USB Interface and DataStudio software

• 600 ml beaker

• 400 ml deionized water

• pipet

Optional Materials

• hot plate/stir plate and magnetic stir bar

CAUTION: Sodium sulfite is a potential skin irritant. Use safety glasses and avoid s kin contact. Skin that

contacts the solution should be rinsed liberally with water.

Purpose

The purpose of the experiment is to explore the effect of the inorganic chemical, sodium

sulfite on dissolved O2 concentrations. Sodium sulfite (Na2SO3) is a commonly used

chemical in photographic developers, paper making, dyeing, bleaching, and engraving.

Procedure

1. Set up and calibrate the Dissolved Oxygen Sensor.

2. Saturate the deionized water with air by vigorously shaking the

water in a bottle or by bubbling with the aquarium pump.

3. Monitor the dissolved O

concentrations of the deionized water

2

while stirring gently with the dissolved O2 probe.

4. When the meter reading stabilizes, record for 30 seconds.

5. After 30 seconds, add 1 ml of the 2 M Na

solution into the

2SO3

water.

6. Continue stirring the solution and recording until the reaction stops.

7. Stop recording and save your data.

20

Page 25

Model No. PS-2108 Dissolved Oxygen Sensor

®

Questions

1. Describe the effect of sodium sulfite on dissolved O2 concentrations.

2. Discuss some potential environmental effects of untreated effluent from industries or

businesses such as paper mills and photo labs that may use sodium sulfite.

21

Page 26

PASPort Dissolved Oxygen Sensor Model No. PS-2108

®

Experiment 4: Biochemical Oxygen Demand

1

Background

Biochemical oxygen demand (BOD) is an important measure of water quality. BOD is a

measurement of the quantity of oxygen used by microorganisms in the aerobic oxidation of

organic matter. In rivers and streams with high BOD levels, much of the available dissolved

oxygen is consumed by aerobic bacteria, robbing other aquatic organisms of the oxygen they

need to live. This is a condition that may be exacerbated by excessive nitrogenous wastes in

runoff water.

Procedure

1. Measure the dissolved O2 concentration and water temperature in a waterway, preferably on

site using the PASPort logger of choice, with the dissolved oxygen sensor.

2. Colle ct a sample of the water in an airtight, black bottle, and incubate the water sam p le at

room temperature for 5 days.

3. Bring the water sample to approximately the same temperature as the first sample and

measure the dissolved O2 concentration.

4. Calculate the BOD level: mg/l dissolved O2 (original sample) - mg/l dissolved O2 (5-day

old sample).

5. Score the BOD as follows:

4 (excellent): less than 2 mg/l

3 (good): 2- 4mg/l

2 (fair): 4.1-10 mg/l

1 (poor): greater than 10 mg/l

1.Adapted from a 1996 publication by Stevens Institute of Technology

22

Page 27

Model No. PS-2108 Dissolved Oxygen Sensor

®

Figure 1

Transfer activated yeast solution to the

test beaker.

Experiment 5: The Effect Of Respiration On Dissolved

O

Concentration

2

Purpose

The purpose of the experiment is to explore the effect of respiration on dissolved O2

concentrations.

Materials required

• Dissolved Oxygen Sensor (PS-2108)

• 400 ml deionized water

• PASPort interface ha rdware and DataStudio software

• aquarium pump or large bottle

• 1 package rapid active yeast

• 600 ml beaker (2)

• table sugar

Optional materials

• hot plate/stir plate and magnetic stir bar

Procedure

1. Follow the dir ections on the yeast package to activate the

yeast in a beaker using tap water and sugar.

2. Set up and calibrate the Dissolved Oxygen Sensor.

3. Stir 1 teaspoon sugar into the deionized water and

saturate it with air.

4. Monitor the dissolved O

concentrations of the

2

deionized sugar water while stirring gently with the

dissolved O

probe.

2

5. When the reading stabilizes, click the Start button in

DataStudio and record data for 30 seconds.

6. After 30 seconds, transfer about 1 teaspoon of the activated yeast solution into the water.

7. Continue stirring with the probe and recording data for about 10 minutes or until the

oxygen level stabilizes.

23

Page 28

PASPort Dissolved Oxygen Sensor Model No. PS-2108

®

8. Stop recording and save the data.

Questions

1. What is the evidence that the yeast cells are alive and respiring during the experiment?

2. What happens to the yeast cells when the dissolved O2 concentration reaches zero? (Hint:

Look carefully at the beaker that contains the concentrated yeast solution and think about

how yeast is used in industry.)

24

Page 29

Model No. PS-2108 Dissolved Oxygen Sensor

®

Appendix A: Copyright and Warranty Information

Copyright Notice

The PASCO scientific 012-07688D manual is copyrighted and all rights are reserved.

However, permission is granted to non-profit educational institutions for reproduction of any

part of the Dissolved Oxygen Sensor manual providing the reproductions are used only for

their laboratories and are not sold for profit. Reproduction under any other circumstances,

without the written consent of PASCO scientific, is prohibited.

Limited Warranty

PASCO scientific warrants the product to be free from defects in materials and workmanship

for a period of one year from the date of shipment to the customer. PASCO will repair or

replace at its option any part of the product which is deemed to be defective in material or

workmanship. The warranty does not cover damage to the product caused by abuse or

improper use. Determination of whether a product failure is the result of a manufacturing

defect or improper use by the customer shall be made solely by PASCO scientific.

Responsibility for the return of equipment for warranty repair belongs to the customer.

Equipment must be properly packed to prevent damage and shipped postage or freight

prepaid. (Damage caused by improper packing of the equipment for return shipment will not

be covered by the warranty.) Shipping costs for returning the equipment after repair will be

paid by PASCO scientific.

Equipment Return

Should the product have to be returned to PASCO scientific for any reason, notify PASCO

scientific by email, letter, phone, or fax BEFORE returning the product. Upon notification,

the return authorization and shipping instructions will be promptly issued.

NOTE: NO EQUIPMENT WILL BE ACCEP TE D FOR RETURN WITHOUT AN AUTHORIZATION FROM

PASCO.

When returning equipment for repair, the units must be packed properly. Carriers will not

accept responsibility for damage caused by improper packing. To be certain the unit will not

be damaged in shipment, observe the following rules:

1. The packing carton must be strong enough for the item shipped.

2. Make certain there are at least two inches of packing material between any point on the

apparatus and the inside walls of the carton.

3. Make certain that the packing material cannot shift in the box or become compressed,

allowing the instrument come in contact with the packing carton.

25

Page 30

PASPort Dissolved Oxygen Sensor Model No. PS-2108

®

Appendix B: Specifications, Replacement Parts,

Technical Support

Specifications

• Cathode: platinum

• Anode: silver/silver chloride

• Response: 98% in 60 seconds

• Stability: Better than 2%

• Fully temperature compensated: 10 °C - 40 °C

• Temperature range: 0 °C - 60 °C

• Output (medium saturated with air): 240 -320 nA

• Membrane: 1 ml silicon

• Probe body: PVC

Replacement Parts

Order from PASCO (1-800-772-8700)

Replacement kit (part number CI-6541) includes:

• Three dissolved O2 probe membrane cartridge

• three O-rings

• bottle of dissolved O2 probe filling solution (contains enough solution to refill the probe

about ten times)

• 10 ml syringe

• Plunger tool

Technical Support

For assistance with the PS-2108 Dissolved Oxygen Sensor or any other PASCO products,

contact PASCO as follows:

Address: PASCO scientific

10101 Foothills Blvd.

Roseville, CA 95747-7100

Phone: (800) 772-8700 (toll-free within U.S.)

Phone: (916) 786-3800

FAX: (916) 786-3292

Web: www.pasco.com

Email: support@pasco.com

26

Page 31

Model No. PS-2108 Dissolved Oxygen Sensor

®

Appendix C: Tables

Table 1: Concentration of dissolved oxygen (mg/L) in water at various temperatures

and pressures

From R. F. Weiss (1970). Temp ° C, temperature in degrees Celsius;

atmospheric pressures from 695-600 millimeters mercury (27.36-23.62 “Hg) begin after 40° C

Conversion Factors: 1.0 “Hg = 25.4 mmHg = 33.86 mb or hPa

Temp. Atmospheric pressure, in millimeters of mercury and (in ch e s of mercury)

795

790

785

780

775

770

765

760

755

750

745

740

735

730

725

720

715

710

°C

(31.30

(31.10

(30.91

(30.71

(30.51

(30.31

(30.12

(29.92

(29.72

(29.53

(29.33

(29.13

(28.94

(28.74

(28.54

(28.35

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

0.0 15.3 15.2 15.1 15.0 14.9 14.8 14.7 14.6 14.5 14.4 14.3 14.2 14.1 14.0 13.9 13.8 13.7 13.6 13.5 13.4

0.5 15.1 15.0 14.9 14.8 14.7 14.6 14.5 14.4 14.3 14.2 14.1 14.0 13.9 13.8 13.7 13.6 13.5 13.4 13.3 13.2

1.0 14.8 14.7 14.7 14.6 14.5 14.4 14.3 14.2 14.1 14.0 13.9 13.8 13.7 13.6 13.5 13.4 13.3 13.2 13.2 13.1

1.5 14.6 14.5 14.5 14.4 14.3 14.2 14.1 14.0 13.9 13.8 13.7 13.6 13.5 13.4 13.3 13.2 13.2 13.1 13.0 12.9

2.0 14.4 14.3 14.3 14.2 14.1 14.0 13.9 13.8 13.7 13.6 13.5 13.4 13.3 13.3 13.2 13.1 13.0 12.9 12.8 12.7

(28.15

)

)

(27.95

)

705

(27.76

)

(27.56

700

)

2.5 14.2 14.2 14.1 14.0 13.9 13.8 13.7 13.6 13.5 13.4 13.3 13.3 13.2 13.1 13.0 12.9 12.8 12.7 12.6 12.5

3.0 14.1 14.0 13.9 13.8 13.7 13.6 13.5 13.4 13.3 13.3 13.2 13.1 13.0 12.9 12.8 12.7 12.6 12.5 12.5 12.4

3.5 13.9 13.8 13.7 13.6 13.5 13.4 13.3 13.3 13.2 13.1 13.0 12.9 12.8 12.7 12.6 12.6 12.5 12.4 12.3 12.2

4.0 13.7 13.6 13.5 13.4 13.3 13.3 13.2 13.1 13.0 12.9 12.8 12.7 12.6 12.6 12.5 12.4 12.3 12.2 12.1 12.0

4.5 13.5 13.4 13.3 13.3 13.2 13.1 13.0 12.9 12.8 12.7 12.7 12.6 12.5 12.4 12.3 12.2 12.1 12.1 12.0 11.9

5.0 13.3 13.3 13.2 13.1 13.0 12.9 12.8 12.7 12.7 12.6 12.5 12.4 12.3 12.2 12.2 12.1 12.0 11.9 11.8 11.7

5.5 13.2 13.1 13.0 12.9 12.8 12.7 12.7 12.6 12.5 12.4 12.3 12.2 12.2 12.1 12.0 11.9 11.8 11.7 11.7 11.6

6.0 13.0 12.9 12.8 12.8 12.7 12.6 12.5 12.4 12.3 12.3 12.2 12.1 12.0 11.9 11.8 11.8 11.7 11.6 11.5 11.4

6.5 12.8 12.8 12.7 12.6 12.5 12.4 12.3 12.3 12.2 12.1 12.0 11.9 11.9 11.8 11.7 11.6 11.5 11.5 11.4 11.3

7.0 12.7 12.6 12.5 12.4 12.4 12.3 12.2 12.1 12.0 12.0 11.9 11.8 11.7 11.6 11.6 11.5 11.4 11.3 11.2 11.1

7.5 12.5 12.4 12.4 12.3 12.2 12.1 12.0 12.0 11.9 11.8 11.7 11.6 11.6 11.5 11.4 11.3 11.3 11.2 11.1 11.0

8.0 12.4 12.3 12.2 12.1 12.1 12.0 11.9 11.8 11.7 11.7 11.6 11.5 11.4 11.3 11.3 11.2 11.1 11.0 11.0 10.9

8.5 12.2 12.1 12.1 12.0 11.9 11.8 11.8 11.7 11.6 11.5 11.4 11.4 11.3 11.2 11.1 11.1 11.0 10.9 10.8 10.7

9.0 12.1 12.0 11.9 11.8 11.8 11.7 11.6 11.5 11.5 11.4 11.3 11.2 11.2 11.1 11.0 10.9 10.8 10.8 10.7 10.6

9.5 11.9 11.9 11.8 11.7 11.6 11.6 11.5 11.4 11.3 11.2 11.2 11.1 11.0 10.9 10.9 10.8 10.7 10.6 10.6 10.5

10.0 11.8 11.7 11.6 11.6 11.5 11.4 11.3 11.3 11.2 11.1 11.0 11.0 10.9 10.8 10.7 10.7 10.6 10.5 10.4 10.4

10.5 11.7 11.6 11.5 11.4 11.4 11.3 11.2 11.1 11.1 11.0 10.9 10.8 10.8 10.7 10.6 10.5 10.5 10.4 10.3 10.2

11.0 11.5 11.4 11.4 11.3 11.2 11.2 11.1 11.0 10.9 10.9 10.8 10.7 10.6 10.6 10.5 10.4 10.3 10.3 10.2 10.1

11.5 11.4 11.3 11.2 11.2 11.1 11.0 11.0 10.9 10.8 10.7 10.7 10.6 10.5 10.4 10.4 10.3 10.2 10.2 10.1 10.0

12.0 11.3 11.2 11.1 11.0 11.0 10.9 10.8 10.8 10.7 10.6 10.5 10.5 10.4 10.3 10.3 10.2 10.1 10.0 10.0 9.9

12.5 11.1 11.1 11.0 10.9 10.8 10.8 10.7 10.6 10.6 10.5 10.4 10.4 10.3 10.2 10.1 10.1 10.0 9.9 9.9 9.8

13.0 11.0 10.9 10.9 10.8 10.7 10.7 10.6 10.5 10.4 10.4 10.3 10.2 10.2 10.1 10.0 10.0 9.9 9.8 9.7 9.7

13.5 10.9 10.8 10.7 10.7 10.6 10.5 10.5 10.4 10.3 10.3 10.2 10.1 10.1 10.0 9.9 9.8 9.8 9.7 9.6 9.6

14.0 10.8 10.7 10.6 10.6 10.5 10.4 10.4 10.3 10.2 10.1 10.1 10.0 9.9 9.9 9.8 9.7 9.7 9.6 9.5 9.5

27

Page 32

PASPort Dissolved Oxygen Sensor Model No. PS-2108

®

Temp. Atmospheric pressure, in millim e ter s of m ercury and (inc hes of mercury)

795

790

785

780

775

770

765

760

755

750

745

740

735

730

725

720

715

710

705

°C

(31.30

(31.10

(30.91

(30.71

(30.51

(30.31

(30.12

(29.92

(29.72

(29.53

(29.33

(29.13

(28.94

(28.74

(28.54

(28.35

(28.15

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

14.5 10.6 10.6 10.5 10.4 10.4 10.3 10.2 10.2 10.1 10.0 10.0 9.9 9.8 9.8 9.7 9.6 9.6 9.5 9.4 9.4

15.0 10.5 10.5 10.4 10.3 10.3 10.2 10.1 10.1 10.0 9.9 9.9 9.8 9.7 9.7 9.6 9.5 9.5 9.4 9.3 9.3

15.5 10.4 10.4 10.3 10.2 10.2 10.1 10.0 10.0 9.9 9.8 9.8 9.7 9.6 9.6 9.5 9.4 9.4 9.3 9.2 9.2

16.0 10.3 10.2 10.2 10.1 10.0 10.0 9.9 9.8 9.8 9.7 9.7 9.6 9.5 9.5 9 .4 9.3 9.3 9.2 9.1 9.1

16.5 10.2 10.1 10.1 10.0 9.9 9.9 9.8 9.7 9.7 9.6 9.5 9.5 9.4 9.4 9.3 9.2 9.2 9.1 9.0 9.0

17.0 10.1 10.0 10.0 9.9 9.8 9.8 9.7 9.6 9.6 9.5 9.4 9.4 9.3 9.3 9.2 9.1 9.1 9.0 8.9 8.9

17.5 10.0 9.9 9.9 9.8 9.7 9.7 9.6 9.5 9.5 9.4 9.3 9.3 9.2 9.2 9.1 9.0 9.0 8.9 8.8 8.8

18.0 9.9 9.8 9.8 9.7 9.6 9.6 9.5 9.4 9.4 9.3 9.3 9.2 9.1 9.1 9.0 8.9 8.9 8.8 8.7 8.7

18.5 9.8 9.7 9.7 9.6 9.5 9.5 9.4 9.3 9.3 9.2 9.2 9.1 9.0 9.0 8.9 8.8 8.8 8.7 8.7 8.6

19.0 9.7 9.6 9.6 9.5 9.4 9.4 9.3 9.3 9.2 9.1 9.1 9.0 8.9 8.9 8.8 8.8 8.7 8.6 8.6 8.5

19.5 9.6 9.5 9.5 9.4 9.3 9.3 9.2 9.2 9.1 9.0 9.0 8.9 8.9 8.8 8.7 8.7 8.6 8.5 8.5 8.4

20.0 9.5 9.4 9.4 9.3 9.3 9.2 9.1 9.1 9.0 8.9 8.9 8.8 8.8 8.7 8.6 8.6 8.5 8.5 8.4 8.3

20.5 9.4 9.3 9.3 9.2 9.2 9.1 9.0 9.0 8.9 8.9 8.8 8.7 8.7 8.6 8.6 8.5 8.4 8.4 8.3 8.3

21.0 9.3 9.2 9.2 9.1 9.1 9.0 8.9 8.9 8.8 8.8 8.7 8.6 8.6 8.5 8.5 8.4 8.4 8.3 8.2 8.2

(27.95

)

)

(27.76

)

700

(27.56

)

21.5 9.2 9.2 9.1 9.0 9.0 8.9 8.9 8.8 8.7 8.7 8.6 8.6 8.5 8.4 8.4 8.3 8.3 8.2 8.1 8.1

22.0 9.1 9.1 9.0 9.0 8.9 8.8 8.8 8.7 8.7 8.6 8.5 8.5 8.4 8.4 8.3 8.2 8.2 8.1 8.1 8.0

22.5 9.0 9.0 8.9 8.9 8.8 8.8 8.7 8.6 8.6 8.5 8.5 8.4 8.3 8.3 8.2 8.2 8.1 8.0 8.0 7.9

23.0 9.0 8.9 8.8 8.8 8.7 8.7 8.6 8.6 8.5 8.4 8.4 8.3 8.3 8.2 8.1 8.1 8.0 8.0 7.9 7.9

23.5 8.9 8.8 8.8 8.7 8.6 8.6 8.5 8.5 8.4 8.4 8.3 8.2 8.2 8.1 8.1 8.0 8.0 7.9 7.8 7.8

24.0 8.8 8.7 8.7 8.6 8.6 8.5 8.4 8.4 8.3 8.3 8.2 8.2 8.1 8.0 8.0 7.9 7.9 7.8 7.8 7.7

24.5 8.7 8.7 8.6 8.5 8.5 8.4 8.4 8.3 8.3 8.2 8.1 8.1 8.0 8.0 7.9 7.9 7.8 7.7 7.7 7.6

25.0 8.6 8.6 8.5 8.5 8.4 8.3 8.3 8.2 8.2 8.1 8.1 8.0 8.0 7.9 7.8 7.8 7.7 7.7 7.6 7.6

25.5 8.5 8.5 8.4 8.4 8.3 8.3 8.2 8.2 8.1 8.0 8.0 7.9 7.9 7.8 7.8 7.7 7.7 7.6 7.6 7.5

26.0 8.5 8.4 8.4 8.3 8.3 8.2 8.1 8.1 8.0 8.0 7.9 7.9 7.8 7.8 7.7 7.6 7.6 7.5 7.5 7.4

26.5 8.4 8.3 8.3 8.2 8.2 8.1 8.1 8.0 8.0 7.9 7.8 7.8 7.7 7.7 7.6 7.6 7.5 7.5 7.4 7.4

27.0 8.3 8.3 8.2 8.2 8.1 8.0 8.0 7.9 7.9 7.8 7.8 7.7 7.7 7.6 7.6 7.5 7.5 7.4 7.3 7.3

27.5 8.2 8.2 8.1 8.1 8.0 8.0 7.9 7.9 7.8 7.8 7.7 7.7 7.6 7.5 7.5 7.4 7.4 7.3 7.3 7.2

28.0 8.2 8.1 8.1 8.0 8.0 7.9 7.9 7.8 7.7 7.7 7.6 7.6 7.5 7.5 7.4 7.4 7.3 7.3 7.2 7.2

28.5 8.1 8.0 8.0 7.9 7.9 7.8 7.8 7.7 7.7 7.6 7.6 7.5 7.5 7.4 7.4 7.3 7.3 7.2 7.1 7.1

29.0 8.0 8.0 7.9 7.9 7.8 7.8 7.7 7.7 7.6 7.6 7.5 7.5 7.4 7.3 7.3 7.2 7.2 7.1 7.1 7.0

29.5 8.0 7.9 7.9 7.8 7.8 7.7 7.6 7.6 7.5 7.5 7.4 7.4 7.3 7.3 7.2 7.2 7.1 7.1 7.0 7.0

30.0 7.9 7.8 7.8 7.7 7.7 7.6 7.6 7.5 7.5 7.4 7.4 7.3 7.3 7.2 7.2 7.1 7.1 7.0 7.0 6.9

30.5 7.8 7.8 7.7 7.7 7.6 7.6 7.5 7.5 7.4 7.4 7.3 7.3 7.2 7.2 7.1 7.1 7.0 7.0 6.9 6.9

31.0 7.8 7.7 7.7 7.6 7.6 7.5 7.5 7.4 7.4 7.3 7.3 7.2 7.1 7.1 7.0 7.0 6.9 6.9 6.8 6.8

31.5 7.7 7.6 7.6 7.5 7.5 7.4 7.4 7.3 7.3 7.2 7.2 7.1 7.1 7.0 7.0 6.9 6.9 6.8 6.8 6.7

32.0 7.6 7.6 7.5 7.5 7.4 7.4 7.3 7.3 7.2 7.2 7.1 7.1 7.0 7.0 6.9 6.9 6.8 6.8 6.7 6.7

32.5 7.6 7.5 7.5 7.4 7.4 7.3 7.3 7.2 7.2 7.1 7.1 7.0 7.0 6.9 6.9 6.8 6.8 6.7 6.7 6.6

33.0 7.5 7.5 7.4 7.4 7.3 7.3 7.2 7.2 7.1 7.1 7.0 7.0 6.9 6.9 6.8 6.8 6.7 6.7 6.6 6.6

28

Page 33

Model No. PS-2108 Dissolved Oxygen Sensor

®

Temp. Atmospheric pressure, in millimeters of mercury and (in ch e s of mercury)

770

765

760

755

750

745

740

735

730

725

720

715

710

705

795

790

785

780

775

(30.51

(30.31

(30.12

(29.92

(29.72

(29.53

(29.33

(29.13

(28.94

(28.74

(28.54

(28.35

(28.15

°C

(31.30

(31.10

(30.91

)

)

33.5 7.4 7.4 7.3 7.3 7.2 7.2 7.1 7.1 7.1 7.0 7.0 6.9 6.9 6.8 6.8 6.7 6.7 6.6 6.6 6.5

34.0 7.4 7.3 7.3 7.2 7.2 7.1 7.1 7.0 7.0 6.9 6.9 6.8 6.8 6.7 6.7 6.7 6.6 6.6 6.5 6.5

34.5 7.3 7.3 7.2 7.2 7.1 7.1 7.0 7.0 6.9 6.9 6.8 6.8 6.7 6.7 6.6 6.6 6.5 6.5 6.5 6.4

35.0 7.3 7.2 7.2 7.1 7.1 7.0 7.0 6.9 6.9 6.8 6.8 6.7 6.7 6.6 6.6 6.5 6.5 6.4 6.4 6.3

35.5 7.2 7.2 7.1 7.1 7.0 7.0 6.9 6.9 6.8 6.8 6.7 6.7 6.6 6.6 6.5 6.5 6.4 6.4 6.3 6.3

36.0 7.2 7.1 7.1 7.0 7.0 6.9 6.9 6.8 6.8 6.7 6.7 6.6 6.6 6.5 6.5 6.4 6.4 6.3 6.3 6.2

36.5 7.1 7.0 7.0 7.0 6.9 6.9 6.8 6.8 6.7 6.7 6.6 6.6 6.5 6.5 6.4 6.4 6.3 6.3 6.2 6.2

37.0 7.0 7.0 6.9 6.9 6.9 6.8 6.8 6.7 6.7 6.6 6.6 6.5 6.5 6.4 6.4 6.3 6.3 6.2 6.2 6.1

37.5 7.0 6.9 6.9 6.8 6.8 6.8 6.7 6.7 6.6 6.6 6.5 6.5 6.4 6.4 6.3 6.3 6.2 6.2 6.1 6.1

38.0 6.9 6.9 6.8 6.8 6.7 6.7 6.7 6.6 6.6 6.5 6.5 6.4 6.4 6.3 6.3 6.2 6.2 6.1 6.1 6.0

38.5 6.9 6.8 6.8 6.7 6.7 6.6 6.6 6.6 6.5 6.5 6.4 6.4 6.3 6.3 6.2 6.2 6.1 6.1 6.0 6.0

39.0 6.8 6.8 6.7 6.7 6.6 6.6 6.5 6.5 6.5 6.4 6.4 6.3 6.3 6.2 6.2 6.1 6.1 6.0 6.0 6.0

39.5 6.8 6.7 6.7 6.6 6.6 6.5 6.5 6.5 6.4 6.4 6.3 6.3 6.2 6.2 6.1 6.1 6.0 6.0 6.0 5.9

40.0 6.7 6.7 6.6 6.6 6.5 6.5 6.4 6.4 6.4 6.3 6.3 6.2 6.2 6.1 6.1 6.0 6.0 5.9 5.9 5.9

(30.71

)

)

)

)

)

)

)

)

)

)

)

)

)

)

(27.95

)

)

(27.76

)

700

(27.56

)

Temp.

695

690

685

°C

(27.36

(27.17

)

)

0.0 13.3 13.2 13.1 13.0 12.9 12.8 12.8 12.7 12.6 12.5 12.4 12.3 12.2 12.1 12.0 11.9 11.8 11.7 11.6 11.5

0.5 13.1 13.1 13.0 12.9 12.8 12.7 12.6 12.5 12.4 12.3 12.2 12.1 12.0 11.9 11.8 11.7 11.6 11.5 11.4 11.3

1.0 13.0 12.9 12.8 12.7 12.6 12.5 12.4 12.3 12.2 12.1 12.0 11.9 11.8 11.7 11.6 11.6 11.5 11.4 11.3 11.2

1.5 12.8 12.7 12.6 12.5 12.4 12.3 12.2 12.1 12.0 12.0 11.9 11.8 11.7 11.6 11.5 11.4 11.3 11.2 11.1 11.0

2.0 12.6 12.5 12.4 12.3 12.2 12.2 12.1 12.0 11.9 11.8 11.7 11.6 11.5 11.4 11.3 11.2 11.1 11.1 11.0 10.9

2.5 12.4 12.4 12.3 12.2 12.1 12.0 11.9 11.8 11.7 11.6 11.5 11.4 11.4 11.3 11.2 11.1 11.0 10.9 10.8 10.7

3.0 12.3 12.2 12.1 12.0 11.9 11.8 11.7 11.7 11.6 11.5 11.4 11.3 11.2 11.1 11.0 10.9 10.9 10.8 10.7 10.6

3.5 12.1 12.0 11.9 11.8 11.8 11.7 11.6 11.5 11.4 11.3 11.2 11.1 11.1 11.0 10.9 10.8 10.7 10.6 10.5 10.4

4.0 12.0 11.9 11.8 11.7 11.6 11.5 11.4 11.3 11.3 11.2 11.1 11.0 10.9 10.8 10.7 10.7 10.6 10.5 10.4 10.3

4.5 11.8 11.7 11.6 11.5 11.5 11.4 11.3 11.2 11.1 11.0 10.9 10.9 10.8 10.7 10.6 10.5 10.4 10.3 10.3 10.2

5.0 11.6 11.6 11.5 11.4 11.3 11.2 11.1 11.1 11.0 10.9 10.8 10.7 10.6 10.5 10.5 10.4 10.3 10.2 10.1 10.0

5.5 11.5 11.4 11.3 11.2 11.2 11.1 11.0 10.9 10.8 10.7 10.7 10.6 10.5 10.4 10.3 10.2 10.2 10.1 10.0 9.9

6.0 11.4 11.3 11.2 11.1 11.0 10.9 10.9 10.8 10.7 10.6 10.5 10.4 10.4 10.3 10.2 10.1 10.0 9.9 9.9 9.8

6.5 11.2 11.1 11.0 11.0 10.9 10.8 10.7 10.6 10.6 10.5 10.4 10.3 10.2 10.1 10.1 10.0 9.9 9.8 9.7 9.7

7.0 11.1 11.0 10.9 10.8 10.7 10.7 10.6 10.5 10.4 10.3 10.3 10.2 10.1 10.0 9.9 9.9 9.8 9.7 9.6 9.5

(26.97

)

680

(26.77

)

Atmospheric pressure, in millim e ter s of m ercury and (inc hes of mercury)

675

670

665

660

655

650

645

(26.57

)

(26.38

)

(26.18

)

(25.98

)

(25.79

)

(25.59

)

(25.39

)

640

(25.20

635

(25.00

630

(24.80

)

625

(24.61

)

620

(24.41

)

615

(24.21

)

610

(24.02

)

605

(23.82

)

600

(23.62

)

7.5 10.9 10.9 10.8 10.7 10.6 10.5 10.5 10.4 10.3 10.2 10.1 10.1 10.0 9.9 9.8 9.7 9.7 9.6 9.5 9.4

8.0 10.8 10.7 10.6 10.6 10.5 10.4 10.3 10.2 10.2 10.1 10.0 9.9 9.9 9.8 9.7 9.6 9.5 9.5 9.4 9.3

29

Page 34

PASPort Dissolved Oxygen Sensor Model No. PS-2108

®

Temp.

695

690

685

°C

(27.36

(27.17

)

)

8.5 10.7 10.6 10.5 10.4 10.4 10.3 10.2 10.1 10.0 10.0 9.9 9.8 9.7 9.7 9.6 9.5 9.4 9.3 9.3 9.2

9.0 10.5 10.5 10.4 10.3 10.2 10.2 10.1 10.0 9.9 9.8 9.8 9.7 9.6 9.5 9.5 9.4 9.3 9.2 9.2 9.1

9.5 10.4 10.3 10.3 10.2 10.1 10.0 10.0 9.9 9.8 9.7 9.7 9.6 9.5 9.4 9.4 9. 3 9.2 9.1 9.0 9.0

10.0 10.3 10.2 10.1 10.1 10.0 9.9 9.8 9.8 9.7 9.6 9.5 9.5 9. 4 9.3 9.2 9.2 9.1 9.0 8.9 8.9

10.5 10.2 10.1 10.0 9.9 9.9 9.8 9.7 9.7 9.6 9.5 9.4 9.4 9.3 9.2 9.1 9.1 9.0 8.9 8.8 8.8

11.0 10.1 10.0 9.9 9.8 9.8 9.7 9.6 9.5 9.5 9.4 9.3 9.2 9.2 9.1 9.0 9.0 8.9 8.8 8.7 8.7

11.5 9.9 9.9 9.8 9.7 9.6 9.6 9.5 9.4 9.4 9.3 9.2 9.1 9.1 9.0 8.9 8.8 8.8 8.7 8.6 8.6

12.0 9.8 9.8 9.7 9.6 9.5 9.5 9.4 9.3 9.2 9.2 9.1 9.0 9.0 8.9 8.8 8.7 8.7 8.6 8.5 8.5

12.5 9.7 9.6 9.6 9.5 9.4 9.4 9.3 9.2 9.1 9.1 9.0 8.9 8.9 8.8 8.7 8.6 8.6 8.5 8.4 8.4

13.0 9.6 9.5 9.5 9.4 9.3 9.3 9.2 9.1 9.0 9.0 8.9 8.8 8.8 8.7 8.6 8.5 8.5 8.4 8.3 8.3

13.5 9.5 9.4 9.4 9.3 9.2 9.1 9.1 9.0 8.9 8.9 8.8 8.7 8.7 8.6 8.5 8.5 8.4 8.3 8.2 8.2

14.0 9.4 9.3 9.3 9.2 9.1 9.0 9.0 8.9 8.8 8.8 8.7 8.6 8.6 8.5 8.4 8.4 8.3 8.2 8.2 8.1

14.5 9.3 9.2 9.2 9.1 9.0 8.9 8.9 8.8 8.7 8.7 8.6 8.5 8.5 8.4 8.3 8.3 8.2 8.1 8.1 8.0

15.0 9.2 9.1 9.1 9.0 8.9 8.8 8.8 8.7 8.6 8.6 8.5 8.4 8.4 8.3 8.2 8.2 8.1 8.0 8.0 7.9

15.5 9.1 9.0 9.0 8.9 8.8 8.8 8.7 8.6 8.6 8.5 8.4 8.4 8.3 8.2 8.2 8.1 8.0 8.0 7.9 7.8

(26.97

)

680

(26.77

)

Atmospheric pressure, in millimeters of mercury and (inches of mercury)

675

670

665

660

655

650

645

(26.57

)

(26.38

)

(26.18

)

(25.98

)

(25.79

)

(25.59

)

(25.39

)

640

(25.20

635

(25.00

630

(24.80

)

625

(24.61

)

620

(24.41

)

615

(24.21

)

610

(24.02

)

605

(23.82

)

600

(23.62

)

16.0 9.0 8.9 8.9 8.8 8.7 8.7 8.6 8.5 8.5 8.4 8.3 8.3 8.2 8.1 8.1 8.0 7.9 7.9 7.8 7.7

16.5 8.9 8.8 8.8 8.7 8.6 8.6 8.5 8.4 8.4 8.3 8.2 8.2 8.1 8.0 8.0 7.9 7.8 7.8 7.7 7.7

17.0 8.8 8.7 8.7 8.6 8.5 8.5 8.4 8.3 8.3 8.2 8.2 8.1 8.0 8.0 7.9 7.8 7.8 7.7 7.6 7.6

17.5 8.7 8.6 8.6 8.5 8.5 8.4 8.3 8.3 8.2 8.1 8.1 8.0 7.9 7.9 7.8 7.7 7.7 7.6 7.6 7.5

18.0 8.6 8.6 8.5 8.4 8.4 8.3 8.2 8.2 8.1 8.0 8.0 7.9 7.9 7.8 7.7 7.7 7.6 7.5 7.5 7.4

18.5 8.5 8.5 8.4 8.3 8.3 8.2 8.2 8.1 8.0 8.0 7.9 7.8 7.8 7.7 7.7 7.6 7.5 7.5 7.4 7.3

19.0 8.4 8.4 8.3 8.3 8.2 8.1 8.1 8.0 7.9 7.9 7.8 7.8 7.7 7.6 7.6 7.5 7.4 7.4 7.3 7.3

19.5 8.4 8.3 8.2 8.2 8.1 8.0 8.0 7.9 7.9 7.8 7.7 7.7 7.6 7.6 7.5 7.4 7.4 7.3 7.2 7.2

20.0 8.3 8.2 8.2 8.1 8.0 8.0 7.9 7.8 7.8 7.7 7.7 7.6 7.5 7.5 7.4 7.4 7.3 7.2 7.2 7.1

20.5 8.2 8.1 8.1 8.0 7.9 7.9 7.8 7.8 7.7 7.6 7.6 7.5 7.5 7.4 7.3 7.3 7.2 7.2 7.1 7.0

21.0 8.1 8.1 8.0 7.9 7.9 7.8 7.8 7.7 7.6 7.6 7.5 7.5 7.4 7.3 7.3 7.2 7.2 7.1 7.0 7.0

21.5 8.0 8.0 7.9 7.9 7.8 7.7 7.7 7.6 7.6 7.5 7.4 7.4 7.3 7.3 7.2 7.1 7.1 7.0 7.0 6.9

22.0 8.0 7.9 7.8 7.8 7.7 7.7 7.6 7.5 7.5 7.4 7.4 7.3 7.2 7.2 7.1 7.1 7.0 7.0 6.9 6.8

22.5 7.9 7.8 7.8 7.7 7.6 7.6 7.5 7.5 7.4 7.3 7.3 7.2 7.2 7.1 7.1 7.0 6.9 6.9 6.8 6.8

23.0 7.8 7.7 7.7 7.6 7.6 7.5 7.5 7.4 7.3 7.3 7.2 7.2 7.1 7.0 7.0 6.9 6.9 6.8 6.8 6.7

23.5 7.7 7.7 7.6 7.6 7.5 7.4 7.4 7.3 7.3 7.2 7.2 7.1 7.0 7.0 6.9 6.9 6.8 6.7 6.7 6.6

24.0 7.7 7.6 7.5 7.5 7.4 7.4 7.3 7.3 7.2 7.1 7.1 7.0 7.0 6.9 6.9 6.8 6.7 6.7 6.6 6.6

24.5 7.6 7.5 7.5 7.4 7.4 7.3 7.2 7.2 7.1 7.1 7.0 7.0 6.9 6.8 6.8 6.7 6.7 6.6 6.6 6.5

25.0 7.5 7.5 7.4 7.3 7.3 7.2 7.2 7.1 7.1 7.0 6.9 6.9 6.8 6.8 6.7 6.7 6.6 6.6 6.5 6.4

25.5 7.4 7.4 7.3 7.3 7.2 7.2 7.1 7.1 7.0 6.9 6.9 6.8 6.8 6.7 6.7 6.6 6.6 6.5 6.4 6.4

26.0 7.4 7.3 7.3 7.2 7.2 7.1 7.0 7.0 6.9 6.9 6.8 6.8 6.7 6.7 6.6 6.5 6.5 6.4 6.4 6.3

26.5 7.3 7.2 7.2 7.1 7.1 7.0 7.0 6.9 6.9 6.8 6.8 6.7 6.6 6.6 6.5 6.5 6.4 6.4 6.3 6.3

30

Page 35

Model No. PS-2108 Dissolved Oxygen Sensor

®

Temp.

695

690

685

°C

(27.36

(27.17

)

)

27.0 7.2 7.2 7.1 7.1 7.0 7.0 6.9 6.9 6.8 6.7 6.7 6.6 6.6 6.5 6.5 6.4 6.4 6.3 6.3 6.2

27.5 7.2 7.1 7.1 7.0 7.0 6.9 6.8 6.8 6.7 6.7 6.6 6.6 6.5 6.5 6.4 6.4 6.3 6.3 6.2 6.2

28.0 7.1 7.1 7.0 6.9 6.9 6.8 6.8 6.7 6.7 6.6 6.6 6.5 6.5 6.4 6.4 6.3 6.3 6.2 6.1 6.1

28.5 7.0 7.0 6.9 6.9 6.8 6.8 6.7 6.7 6.6 6.6 6.5 6.5 6.4 6.4 6.3 6.2 6.2 6.1 6.1 6.0

29.0 7.0 6.9 6.9 6.8 6.8 6.7 6.7 6.6 6.6 6.5 6.5 6.4 6.4 6.3 6.2 6.2 6.1 6.1 6.0 6.0

29.5 6.9 6.9 6.8 6.8 6.7 6.7 6.6 6.6 6.5 6.5 6.4 6.3 6.3 6.2 6.2 6.1 6.1 6.0 6.0 5.9

30.0 6.9 6.8 6.8 6.7 6.7 6.6 6.5 6.5 6.4 6.4 6.3 6.3 6.2 6.2 6.1 6.1 6.0 6.0 5.9 5.9

30.5 6.8 6.7 6.7 6.6 6.6 6.5 6.5 6.4 6.4 6.3 6.3 6.2 6.2 6.1 6.1 6.0 6.0 5.9 5.9 5.8

31.0 6.7 6.7 6.6 6.6 6.5 6.5 6.4 6.4 6.3 6.3 6.2 6.2 6.1 6.1 6.0 6.0 5.9 5.9 5.8 5.8

31.5 6.7 6.6 6.6 6.5 6.5 6.4 6.4 6.3 6.3 6.2 6.2 6.1 6.1 6.0 6.0 5.9 5.9 5.8 5.8 5.7

32.0 6.6 6.6 6.5 6.5 6.4 6.4 6.3 6.3 6.2 6.2 6.1 6.1 6.0 6.0 5.9 5.9 5.8 5.8 5.7 5.7

32.5 6.6 6.5 6.5 6.4 6.4 6.3 6.3 6.2 6.2 6.1 6.1 6.0 6.0 5.9 5.9 5.8 5.8 5.7 5.7 5.6

33.0 6.5 6.5 6.4 6.4 6.3 6.3 6.2 6.2 6.1 6.1 6.0 6.0 5.9 5.9 5.8 5.8 5.7 5.7 5.6 5.6

33.5 6.5 6.4 6.4 6.3 6.3 6.2 6.2 6.1 6.1 6.0 6.0 5.9 5.9 5.8 5.8 5.7 5.7 5.6 5.6 5.5

34.0 6.4 6.4 6.3 6.3 6.2 6.2 6.1 6.1 6.0 6.0 5.9 5.9 5.8 5.8 5.7 5.7 5.6 5.6 5.5 5.5

34.5 6.4 6.3 6.3 6.2 6.2 6.1 6.1 6.0 6.0 5.9 5.9 5.8 5.8 5.7 5.7 5.6 5.6 5.5 5.5 5.4

35.0 6.3 6.3 6.2 6.2 6.1 6.1 6.0 6.0 5.9 5.9 5.8 5.8 5.7 5.7 5.6 5.6 5.5 5.5 5.4 5.4

(26.97

)

680

(26.77

)

Atmospheric pressure, in millim e ter s of m ercury and (inc hes of mercury)

675

670

665

660

655

650

645

(26.57

)

(26.38

)

(26.18

)

(25.98

)

(25.79

)

(25.59

)

(25.39

)

640

(25.20

635

(25.00

630

(24.80

)

625

(24.61

)

620

(24.41

)

615

(24.21

)

610

(24.02

)

605

(23.82

)

600

(23.62

)

35.5 6.2 6.2 6.2 6.1 6.1 6.0 6.0 5.9 5.9 5.8 5.8 5.7 5.7 5.6 5.6 5.5 5.5 5.4 5.4 5.3

36.0 6.2 6.1 6.1 6.1 6.0 6.0 5.9 5.9 5.8 5.8 5.7 5.7 5.6 5.6 5.5 5.5 5.4 5.4 5.3 5.3

36.5 6.1 6.1 6.1 6.0 6.0 5.9 5.9 5.8 5.8 5.7 5.7 5.6 5.6 5.5 5.5 5.4 5.4 5.3 5.3 5.2

37.0 6.1 6.1 6.0 6.0 5.9 5.9 5.8 5.8 5.7 5.7 5.6 5.6 5.5 5.5 5.4 5.4 5.3 5.3 5.3 5.2

37.5 6.0 6.0 6.0 5.9 5.9 5.8 5.8 5.7 5.7 5.6 5.6 5.5 5.5 5.4 5.4 5.3 5.3 5.3 5.2 5.2

38.0 6.0 6.0 5.9 5.9 5.8 5.8 5.7 5.7 5.6 5.6 5.5 5.5 5.4 5.4 5.3 5.3 5.3 5.2 5.2 5.1

38.5 6.0 5.9 5.9 5.8 5.8 5.7 5.7 5.6 5.6 5.5 5.5 5.4 5.4 5.4 5.3 5.3 5.2 5.2 5.1 5.1

39.0 5.9 5.9 5.8 5.8 5.7 5.7 5.6 5.6 5.5 5.5 5.4 5.4 5.4 5.3 5.3 5.2 5.2 5.1 5.1 5.0

39.5 5.9 5.8 5.8 5.7 5.7 5.6 5.6 5.5 5.5 5.4 5.4 5.4 5.3 5.3 5.2 5.2 5.1 5.1 5.0 5.0

40.0 5.8 5.8 5.7 5.7 5.6 5.6 5.5 5.5 5.4 5.4 5.4 5.3 5.3 5.2 5.2 5.1 5.1 5.0 5.0 5.0

31

Page 36

PASPort Dissolved Oxygen Sensor Model No. PS-2108

®

Table 2: Salinity correction factors for dissolved oxygen in water (based on

conductivity)

From R. F. Weiss (1970). Temp ° C, temperature in degrees Celsius;

Temp. Conductivity, in microsiemens per centimeter at 25 degrees Celsius

°C 0 1000 2000 3000 4000 5000 6000 7000 8000 9000 10000 11000 12000 13000 14000 15000 16000

0.0 1.000 0.996 0.992 0.989 0.985 0.981 0.9 77 0.973 0.969 0.965 0.961 0.957 0.953 0.950 0.946 0.942 0.938

1.0 1.000 0.996 0.992 0.989 0.985 0.981 0.9 77 0.973 0.969 0.965 0.962 0.958 0.954 0.950 0.946 0.942 0.938

2.0 1.000 0.996 0.992 0.989 0.985 0.981 0.9 77 0.973 0.970 0.966 0.962 0.958 0.954 0.950 0.946 0.942 0.938

3.0 1.000 0.996 0.993 0.989 0.985 0.981 0.9 77 0.974 0.970 0.966 0.962 0.958 0.954 0.951 0.947 0.943 0.939

4.0 1.000 0.996 0.993 0.989 0.985 0.981 0.9 78 0.974 0.970 0.966 0.962 0.959 0.955 0.951 0.947 0.943 0.939

5.0 1.000 0.996 0.993 0.989 0.985 0.981 0.9 78 0.974 0.970 0.966 0.963 0.959 0.955 0.951 0.947 0.944 0.940

6.0 1.000 0.996 0.993 0.989 0.985 0.982 0.9 78 0.974 0.970 0.967 0.963 0.959 0.955 0.952 0.948 0.944 0.940

7.0 1.000 0.996 0.993 0.989 0.985 0.982 0.9 78 0.974 0.971 0.967 0.963 0.959 0.956 0.952 0.948 0.944 0.941

8.0 1.000 0.996 0.993 0.989 0.986 0.982 0.9 78 0.975 0.971 0.967 0.963 0.960 0.956 0.952 0.949 0.945 0.941

9.0 1.000 0.996 0.993 0.989 0.986 0.982 0.9 78 0.975 0.971 0.967 0.964 0.960 0.956 0.953 0.949 0.945 0.941

10.0 1.000 0.996 0.993 0.989 0.986 0.982 0.979 0.975 0.971 0.968 0.964 0.960 0.957 0.953 0.949 0.946 0.942

11.0 1.000 0.996 0.993 0.989 0.986 0.982 0.979 0.975 0.971 0.968 0.964 0.961 0.957 0.953 0.950 0.946 0.942

12.0 1.000 0.997 0.993 0.989 0.986 0.982 0.979 0.975 0.972 0.968 0.965 0.961 0.957 0.954 0.950 0.946 0.943

13.0 1.000 0.997 0.993 0.990 0.986 0.983 0.979 0.975 0.972 0.968 0.965 0.961 0.958 0.954 0.950 0.947 0.943

14.0 1.000 0.997 0.993 0.990 0.986 0.983 0.979 0.976 0.972 0.969 0.965 0.961 0.958 0.954 0.951 0.947 0.943

15.0 1.000 0.997 0.993 0.990 0.986 0.983 0.979 0.976 0.972 0.969 0.965 0.962 0.958 0.955 0.951 0.947 0.944

16.0 1.000 0.997 0.993 0.990 0.986 0.983 0.979 0.976 0.972 0.969 0.966 0.962 0.958 0.955 0.951 0.948 0.944

17.0 1.000 0.997 0.993 0.990 0.986 0.983 0.980 0.976 0.973 0.969 0.966 0.962 0.959 0.955 0.952 0.948 0.945

18.0 1.000 0.997 0.993 0.990 0.987 0.983 0.980 0.976 0.973 0.969 0.966 0.963 0.959 0.956 0.952 0.949 0.945

19.0 1.000 0.997 0.993 0.990 0.987 0.983 0.980 0.976 0.973 0.970 0.966 0.963 0.959 0.956 0.952 0.949 0.945

20.0 1.000 0.997 0.993 0.990 0.987 0.983 0.980 0.977 0.973 0.970 0.966 0.963 0.960 0.956 0.953 0.949 0.946

21.0 1.000 0.997 0.993 0.990 0.987 0.984 0.980 0.977 0.973 0.970 0.967 0.963 0.960 0.957 0.953 0.950 0.946

22.0 1.000 0.997 0.993 0.990 0.987 0.984 0.980 0.977 0.974 0.970 0.967 0.964 0.960 0.957 0.953 0.950 0.947