Page 1

Includes

Teacher's Notes

and

Typical

Experiment Results

Instruction Manual and

Experiment Guide for the

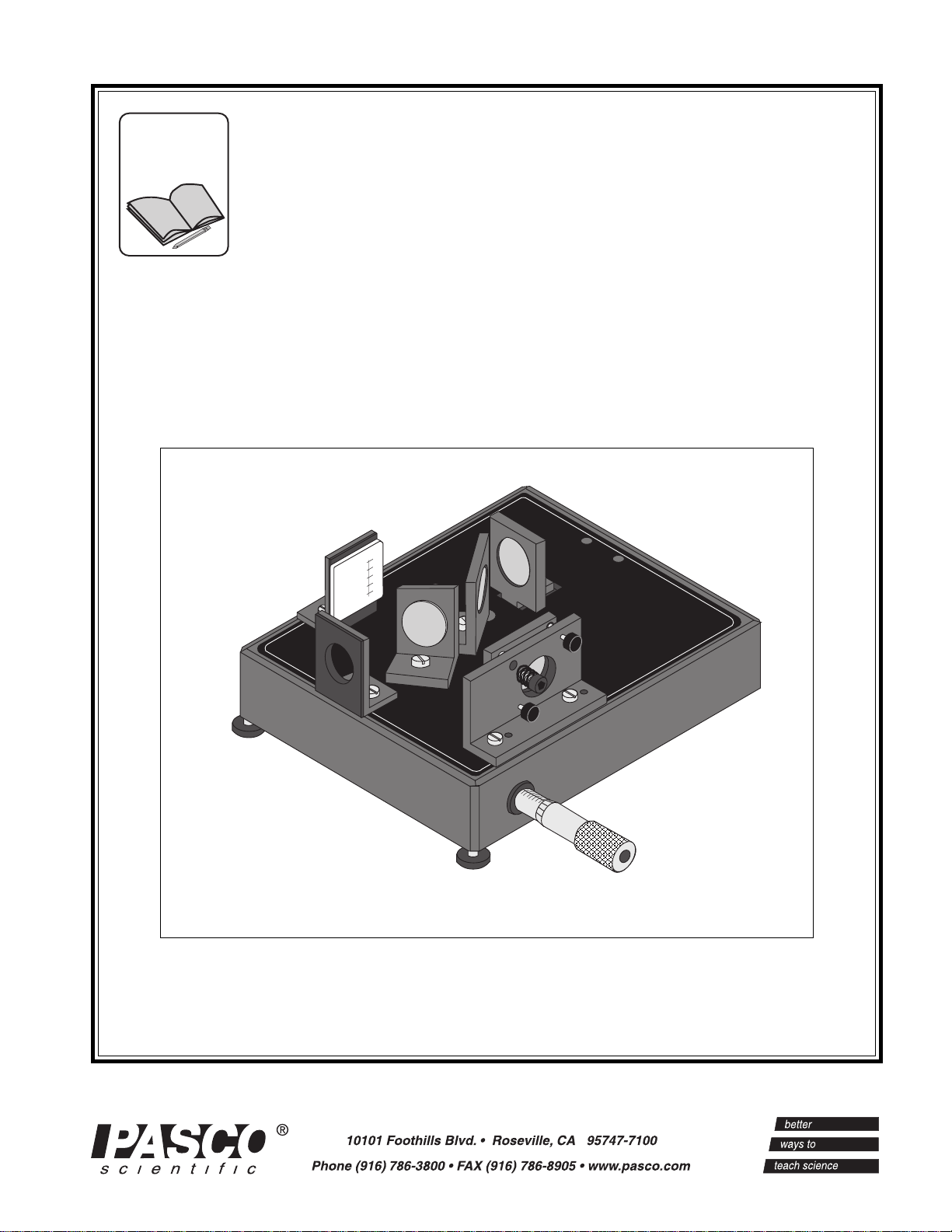

PASCO scientific Models

OS-9255A thru OS-9258A

PRECISION

INTERFEROMETER

012-07137A

5/99

© 1990 PASCO scientific $10.00

Page 2

Page 3

012-07137A Precision Interferometer

T able of Contents

Section Page

Copyright, Warranty, and Equipment Return...................................................ii

Introduction ......................................................................................................1

Equipment ........................................................................................................2

Theory of Operation.........................................................................................4

Michelson

Twyman-Green

Fabry-Perot

Setup and Operation.........................................................................................6

Tips on Using the Interferometer......................................................................9

Sources of Error

Troubleshooting

Experiments

Experiment 1: Introduction to Interferometry ..................................... 11

Experiment 2: The Index of Refraction of Air ...................................13

Experiment 3: The Index of Refraction of Glass ................................15

Suggestions for Additional Experiments ......................................................... 17

Maintenance ....................................................................................................18

Teacher's Guide ........................................................................................... 20-22

i

Page 4

Precision Interferometer 012-07137A

Copyright, Warranty, and Equipment Return

PleaseFeel free to duplicate this manual

subject to the copyright restrictions below.

Copyright Notice

The PASCO scientific 012-05187C Precision

Interferometer manual is copyrighted and all rights

reserved. However, permission is granted to non-profit

educational institutions for reproduction of any part of

the manual providing the reproductions are used only

for their laboratories and are not sold for profit.

Reproduction under any other circumstances, without

the written consent of PASCO scientific, is prohibited.

Limited Warranty

PASCO scientific warrants the product to be free from

defects in materials and workmanship for a period of

one year from the date of shipment to the customer.

PASCO will repair or replace at its option any part of

the product which is deemed to be defective in material

or workmanship. The warranty does not cover damage

to the product caused by abuse or improper use.

Determination of whether a product failure is the result

of a manufacturing defect or improper use by the

customer shall be made solely by PASCO scientific.

Responsibility for the return of equipment for warranty

repair belongs to the customer. Equipment must be

properly packed to prevent damage and shipped postage

or freight prepaid. (Damage caused by improper

packing of the equipment for return shipment will not

be covered by the warranty.) Shipping costs for

returning the equipment after repair will be paid by

PASCO scientific.

Equipment Return

Should the product have to be returned to PASCO

scientific for any reason, notify PASCO scientific by

letter, phone, or fax BEFORE returning the product.

Upon notification, the return authorization and shipping

instructions will be promptly issued.

ä

NOTE: NO EQUIPMENT WILL BE

ACCEPTED FOR RETURN WITHOUT AN

AUTHORIZATION FROM PASCO.

When returning equipment for repair, the units must be

packed properly. Carriers will not accept responsibility

for damage caused by improper packing. To be certain

the unit will not be damaged in shipment, observe the

following rules:

1. The packing carton must be strong enough for the

item shipped.

2. Make certain there are at least two inches of packing

material between any point on the apparatus and the

inside walls of the carton.

3. Make certain that the packing material cannot shift

in the box or become compressed, allowing the

instrument come in contact with the packing carton.

Address: PASCO scientific

10101 Foothills Blvd.

Roseville, CA 95747-7100

Phone: (916) 786-3800

FAX: (916) 786-3292

email: techsupp@pasco.com

web: www.pasco.com

ii

Page 5

012-07137A Precision Interferometer

Introduction

The OS-9255A Precision Interferometer provides both a

theoretical and a practical introduction to interferometry.

Precise measurements can be made in three modes:

Michelson

The Michelson Interferometer is historically important, and

also provides a simple interferometric configuration for

introducing basic principles. Students can measure the

wavelength of light and the indices of refraction of air and

other substances.

Twyman-Green

The Twyman-Green Interferometer is an important

contemporary tool for testing optical components. It has

made it possible to create optical systems that are accurate

to within a fraction of a wavelength.

➤ NOTE: The PASCO Precision Interferometer is

not designed for actual component testing in the

Twyman-Green mode. It is intended only to provide

a simple introduction to this important application of

interferometry.

Fabry-Perot

The Fabry-Perot Interferometer is also an important

contemporary tool, used most often for high resolution

spectrometry. The fringes are sharper, thinner, and more

widely spaced than the Michelson fringes, so small differences in wavelength can be accurately resolved. The

Fabry-Perot interferometer is also important in laser

theory, as it provides the resonant cavity in which light

amplification takes place.

Switching between these three modes of operation and

aligning components is relatively simple, since all mirrors

mount to the base in fixed positions, using captive panel

screws. Lenses, viewing screens, and other components

mount magnetically to the base using the included component holders.

Measurements are precise in all three modes of operation.

A 5 kg machined aluminum base provides a stable surface

for experiments and measurements. All mirrors are flat to

1/4 wavelength, and the built-in micrometer resolves mirror

movement to within one micron.

1

Page 6

Precision Interferometer 012-07137A

Equipment

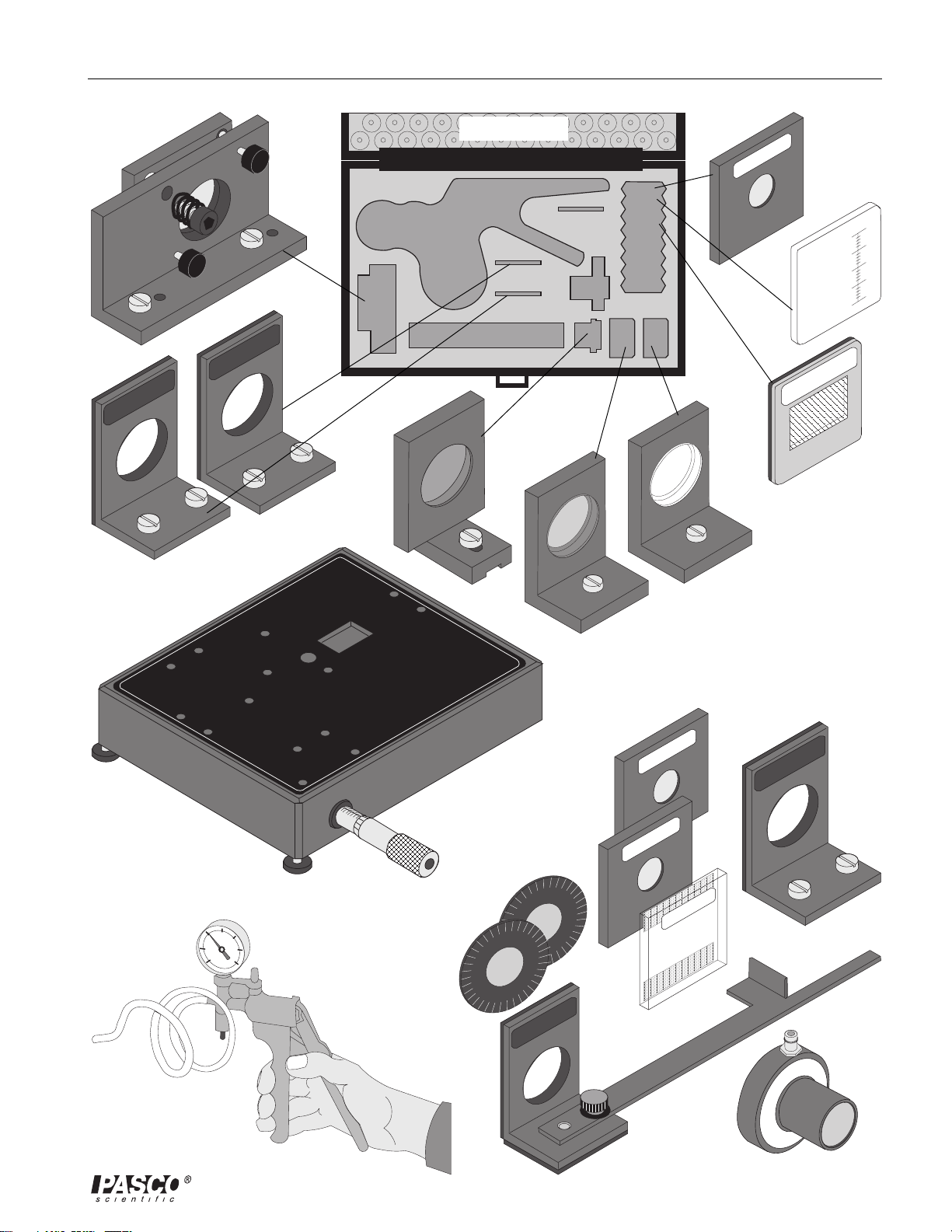

The OS-9255A Precision Interferometer includes the

following equipment:

5 kg Base with built-in micrometer

Adjustable Mirror

Movable Mirror

Beam Splitter

Compensator Plate

(2) Component Holder

Viewing Screen

Lens, 18 mm Focal Length

Diffuser

Fitted Storage Case

Additional Equipment Required –

Laser (OS-9171)

Laser Bench (OS-9172)

➤ NOTE: The preceding equipment includes

everything needed for basic Michelson interferometry. You can produce clear fringes and make

precise measurements of the wavelength of your

source. However, to perform the experiments in this

manual, you will need additional components, such

as the OS-9256A Interferometer Accessories or a

comparable set of your own components.The

Precision Interferometer is available as a complete

system. Please refer to your current PASCO catalog

for details.

Additional Equipment Recommended –

The OS-9256A Interferometer Accessories includes:

Rotating Pointer

Vacuum Cell

Component Holder

Lens, 18 mm Focal Length

Lens, 48 mm Focal Length

Glass Plate

(2) Polarizer

Vacuum Pump with Gauge

➤ NOTE: The OS-9255A Fitted Case also

provides storage for these accessory components.

About Your Light Source

We strongly recommend a laser for most introductory

applications. A spectral light source can be used (see the

Appendix), but that really comprises an experiment in and

of itself for beginning students. A laser source is easy to

use and produces bright, sharp fringes.

The OS-9171 Laser and OS-9172 Laser Alignment Bench

are available from PASCO. However, any low power laser

that operates in the visible range will work well. If you

want to demonstrate the importance of polarization in

interferometry, a non-polarized laser should be used. For

easy alignment, the beam should be approximately 4 cm

above the level of the bench top.

OS-9171 Laser

OS-9172

Laser Alignment

Bench

2

Page 7

012-07137A Precision Interferometer

Adjustable

Mirror

(2) Component

Holder

Movable

Mirror

Fitted Case

Beam

Splitter

Lens

18 mm

Viewing

Screen

Diffuser

Compensator

Plate

Base

OS-9256A

Interferometer

Accessories

(2) Polarizer

Lens

48 mm

Glass

Plate

OS-9255A

Precision Interferometer

Lens

18 mm

Component

Holder

Rotating

Pointer

Vacuum Pump

with Gauge

Vacuum Cell

3

Page 8

Precision Interferometer 012-07137A

Theory of Operation

Interference Theory

A beam of light can be modeled as a wave of oscillating

electric and magnetic fields. When two or more beams of

light meet in space, these fields add according to the

principle of superposition. That is, at each point in space,

the electric and magnetic fields are determined as the

vector sum of the fields of the separate beams.

If each beam of light originates from a separate source,

there is generally no fixed relationship between the electromagnetic oscillations in the beams. At any instant in time

there will be points in space where the fields add to

produce a maximum field strength. However, the oscillations of visible light are far faster than the human eye can

apprehend. Since there is no fixed relationship between

the oscillations, a point at which there is a maximum at one

instant may have a minimum at the next instant. The

human eye averages these results and perceives a uniform

intensity of light.

If the beams of light originate from the same source, there

is generally some degree of correlation between the

frequency and phase of the oscillations. At one point in

space the light from the beams may be continually in

phase. In this case, the combined field will always be a

maximum and a bright spot will be seen. At another point

the light from the beams may be continually out of phase

and a minima, or dark spot, will be seen.

The Michelson Interferometer

In 1881, 78 years after Young introduced his two-slit

experiment, A.A. Michelson designed and built an interferometer using a similar principle. Originally Michelson

designed his interferometer as a means to test for the

existence of the ether, a hypothesized medium in which

light propagated. Due in part to his efforts, the ether is no

longer considered a viable hypothesis. But beyond this,

Michelsons interferometer has become a widely used

instrument for measuring the wavelength of light, for using

the wavelength of a known light source to measure

extremely small distances, and for investigating optical

media.

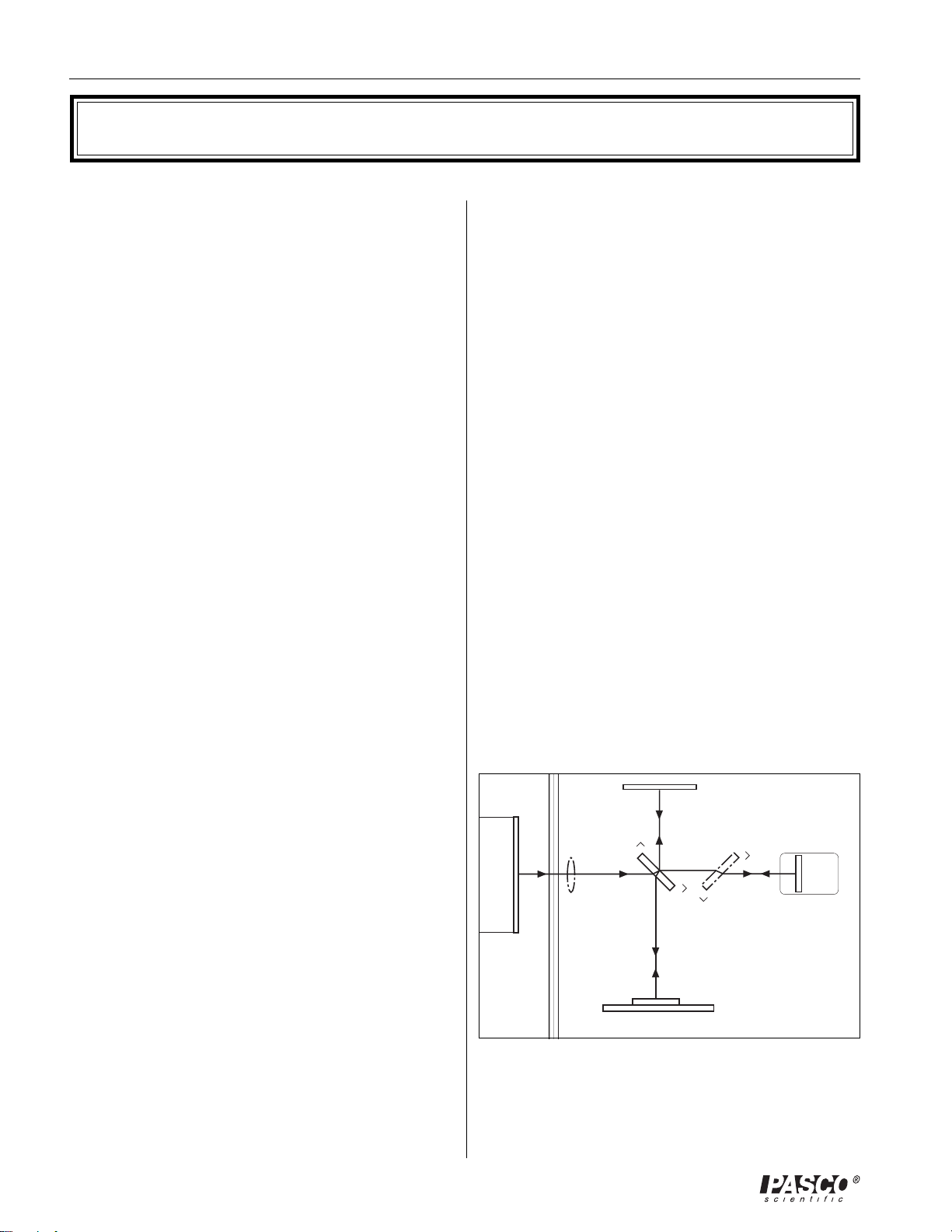

Figure 1 shows a diagram of a Michelson interferometer.

The beam of light from the laser strikes the beam-splitter,

which reflects 50% of the incident light and transmits the

other 50%. The incident beam is therefore split into two

beams; one beam is transmitted toward the movable mirror

(M

), the other is reflected toward the fixed mirror (M2).

1

Both mirrors reflect the light directly back toward the

beam-splitter. Half the light from M1 is reflected from the

beam-splitter to the viewing screen and half the light from

M2 is transmitted through the beam-splitter to the viewing

screen.

Thomas Young was one of the first to design a method for

producing such an interference pattern. He allowed a

single, narrow beam of light to fall on two narrow, closely

spaced slits. Opposite the slits he placed a viewing screen.

Where the light from the two slits struck the screen, a

regular pattern of dark and bright bands appeared. When

first performed, Youngs experiment offered important

evidence for the wave nature of light.

Youngs slits can be used as a simple interferometer. If

the spacing between the slits is known, the spacing of the

maxima and minima can be used to determine the wavelength of the light. Conversely, if the wavelength of the

light is known, the spacing of the slits could be determined

from the interference patterns.

4

Viewing Screen

Beam

Splitter

Laser

Lens

Figure 1. Michelson Interferometer

Compensator

Adjustable Mirror

Plate

Movable Mirror

(M1)

(M2)

Page 9

012-07137A Precision Interferometer

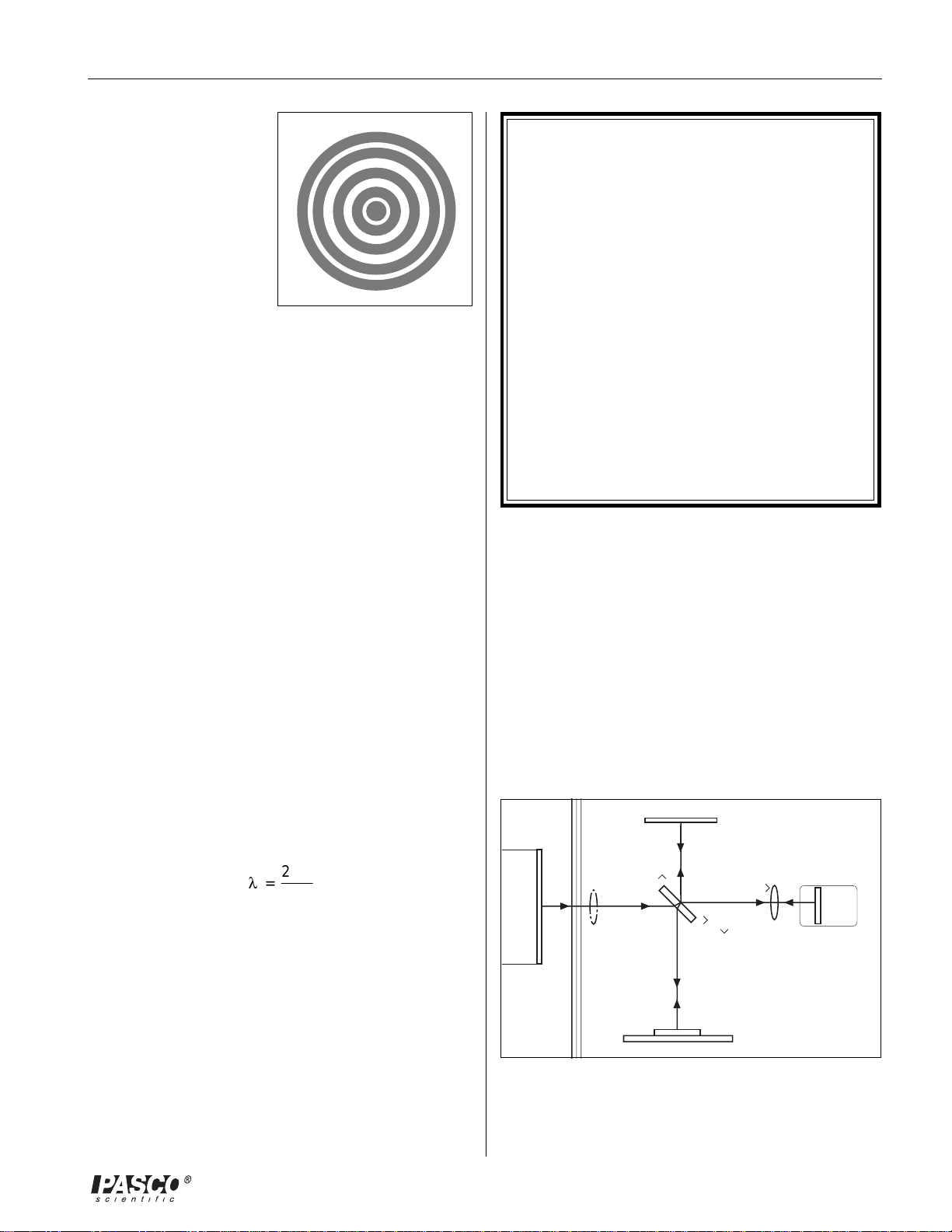

In this way the original

beam of light is split, and

➤ NOTE: Using the Compensator

portions of the resulting

beams are brought back

together. Since the

beams are from the same

source, their phases are

highly correlated. When

a lens is placed between

the laser source and the

beam-splitter, the light ray

Figure 2. Fringes

spreads out, and an

interference pattern of dark and bright rings, or fringes, is

In Figure 1, notice that one beam passes through the

glass of the beam-splitter only once, while the other

beam passes through it three times. If a highly coherent and monochromatic light source is used,

such as a laser, this is no problem. With other light

sources this is a problem.

The difference in the effective path length of the

separated beams is increased, thereby decreasing

the coherence of the beams at the viewing

screen. This will obscure the interference pattern.

seen on the viewing screen (Figure 2).

A compensator is identical to the beam-splitter, but

Since the two interfering beams of light were split from the

same initial beam, they were initially in phase. Their

relative phase when they meet at any point on the viewing

screen, therefore, depends on the difference in the length

without the reflective coating. By inserting it in the

beam path, as shown in Figure 1, both beams pass

through the same thickness of glass, eliminating this

problem.

of their optical paths in reaching that point.

By moving M

, the path length of one of the beams can be

1

varied. Since the beam traverses the path between M1 and

the beam-splitter twice, moving M1 1/4 wavelength nearer

the beam-splitter will reduce the optical path of that beam

by 1/2 wavelength. The interference pattern will change;

the radii of the maxima will be reduced so they now

occupy the position of the former minima. If M1 is moved

an additional 1/4 wavelength closer to the beam-splitter,

the radii of the maxima will again be reduced so maxima

and minima trade positions, but this new arrangement will

be indistinguishable from the original pattern.

By slowly moving the mirror a measured distance d

, and

m

counting m, the number of times the fringe pattern is

restored to its original state, the wavelength of the light (l)

can be calculated as:

2d

m

=

l

m

If the wavelength of the light is known, the same procedure can be used to measure dm.

The Twyman-Green Interferometer

The Twyman-Green Interferometer is a variation of the

Michelson Interferometer that is used to test optical

components. A lens can be tested by placing it in the beam

path, so that only one of the interfering beams passes

through the test lens (see Figure 3). Any irregularities in the

lens can be detected in the resulting interference pattern. In

particular, spherical aberration, coma, and astigmatism

show up as specific variations in the fringe pattern.

Test

Lens

Lens

Figure 3. Twyman-Green Interferometer

5

Page 10

Precision Interferometer 012-07137A

The Fabry-Perot Interferometer

In the Fabry-Perot Interferometer, two partial mirrors are

aligned parallel to one another, forming a reflective cavity.

Figure 4 shows two rays of light entering such a cavity and

reflecting back and forth inside. At each reflection, part of

the beam is transmitted, splitting each incident ray into a

series of rays. Since the transmitted rays are all split from a

single incident ray, they have a constant phase relationship

(assuming a sufficiently coherent light source is used).

The phase relationship between the transmitted rays

depends on the angle at which each ray enters the cavity

and on the distance between the two mirrors. The result is

a circular fringe pattern, similar to the Michelson pattern,

but with fringes that are thinner, brighter, and more widely

spaced. The sharpness of the Fabry-Perot fringes makes it

a valuable tool in high-resolution spectrometry.

As with the Michelson Interferometer, as the movable

mirror is moved toward or away from the fixed mirror, the

fringe pattern shifts. When the mirror movement is equal

to 1/2 of the wavelength of the light source, the new fringe

pattern is identical to the original.

Partial Mirrors

Adjustable Movable

Viewing

Screen

Figure 4. Fabry-Perot Interferometer

Setup and Operation

Laser Alignment

If you are using a PASCO Laser and Laser Alignment

Bench, the setup and alignment procedure is as follows.

If you are using a different laser, the alignment proce-

dure is similar. Adjust your laser so that the beam is

approximately 4 cm above the table top. Then align

the beam as in steps 4 and 5, below.

If you are using a spectral light source instead of a

laser, see Suggestions for Additional Experiments,

near the end of the manual.

To set up and align your PASCO Laser:

1. Set the interferometer base on a lab table with the mi-

crometer knob pointing toward you.

2. Position the laser alignment bench to the left of the

base approximately perpendicular to the interferometer

base and place the laser on the bench.

3. Secure the movable mirror in the recessed hole in the

interferometer base.

4. Turn the laser on. Using the leveling screws on the la-

ser bench, adjust its height until the laser beam is approximately parallel with the top of the interferometer

base and strikes the movable mirror in the center. (To

check that the beam is parallel with the base, place a

piece of paper in the beam path, with the edge of the

paper flush against the base. Mark the height of the

beam on the paper. Using the piece of paper, check that

the beam height is the same at both ends of the bench.)

5. Adjust the X-Y position of the laser until the beam is

reflected from the movable mirror right back into the

laser aperture. This is most easily done by gently sliding the rear end of the laser transverse to the axis of the

alignment bench, as shown in Figure 5.

You are now ready to set up the interferometer in any of

its three modes of operation.

6

Page 11

012-07137A Precision Interferometer

N

E

Laser beam

VIEWING SCREEN

MICHELSON, TWYMAN-GREEN

N

R

O

E

T

T

18 mm FL LENS

R

S

O

L

I

T

E

L

A

H

N

P

S

C

S

O

I

N

S

E

M

M

L

P

A

E

M

E

H

B

O

C

I

C

M

Movable

mirror

Slide the rear of the

laser laterally on the

alignment bench until

ADJUSTABLE MIRROR

MICHELSON, TWYMAN-GREEN

25

5

0

15

-5

10

the beam is reflected

straight back into the

laser aperture.

Figure 5. Aligning the Laser

➤ NOTE:

For ease of installation the placement of the individual

components in the various modes is indicated on the

label.

Component

holder

VIEWING SCREEN

OS-9255A

MICHELSON, TWYMAN-GREEN

Viewing screen

MICHELSON

30

Laser

18 mm FL LENS

Component

holder

BEAM SPLITTER

Beam

splitter

Lens

Interferometer

base

INTERFEROM

Compensator

(optional)

COMPENSATOR

MICHELSON

Movable

mirror

Adjustable mirror

PRECISIO

18mm FL

ADJUSTABLE MIRROR

MICHELSON, TWYMAN-GREEN

5

0

-5

30

25

15

10

1 div =

Thumbscrews

Michelson Mode

1. Align the laser and interferometer base as previously

described. The laser beam should be approximately

parallel with the top of the base, should strike the center

of the movable mirror, and should be reflected directly

back into the laser aperture.

2. Mount the adjustable mirror on the interferometer base.

Position one component holder in front of the laser.

Place the other component holder opposite the adjustable mirror and attach the viewing screen to its magnetic backing. See Figure 6.

3. Position the beam-splitter at a 45 degree angle to the

laser beam, within the crop marks, so that the beam is

reflected to the fixed mirror. Adjust the angle of the

beam-splitter as needed so that the reflected beam hits

the fixed mirror near its center.

4. There should now be two sets of bright dots on the

viewing screen; one set comes from the fixed mirror

and the other comes from the movable mirror. Each

set of dots should include a bright dot with two or more

dots of lesser brightness (due to multiple reflections).

Adjust the angle of the beam-splitter again until the two

sets of dots are as close together as possible, then

tighten the thumbscrew to secure the beam-splitter.

Micrometer

knob

Figure 6. Michelson Mode Setup

5. Using the thumbscrews on the back of the adjustable

mirror, adjust the mirrors tilt until the two sets of dots

on the viewing screen coincide.

6. The compensator is not needed for producing interfer-

ence fringes when using a laser light source. However,

if you wish to use the compensator, it mounts perpendicular to the beam-splitter, as shown.

7. Attach the 18 mm FL lens to the magnetic backing of

the component holder in front of the laser, as shown,

and adjust its position until the diverging beam is centered on the beam-splitter. You should now see circular fringes on the viewing screen. If not, carefully adjust the tilt of the adjustable mirror until the fringes appear.

8. If you have trouble obtaining fringes, see Trouble-

Shooting at the end of this section.

7

Page 12

Precision Interferometer 012-07137A

Twyman-Green Mode

1. Set up the interferometer in the Michelson mode, as

described above.

2. Remove the pointer from the rotational componet

holder. (It is recommended to store the pointer, washer

and thumbscrew in the storage case.) Place the component holder between the beam-splitter and the movable

mirror (see Figure 7). It attaches magnetically. Mount a

second 18 mm FL lens (L

) on its magnetic backing

2

and position it .

3. Remove the original lens (L

) from in front of the laser.

1

Observe the two sets of dots on the viewing screen

one set from the movable mirror and one set from the

adjustable mirror. Adjust the position of L

until both

2

sets of dots are the same size.

4. Adjust the tilt of the adjustable mirror until the two sets

of dots coincide.

5. Replace lens L

screen so it's at least 12 inches from the edge of the

interferometer base. Fringes should appear in the bright

disk of the viewing screen. Fine adjustments of L

may be necessary to find the fringes. A piece of white

paper or cardboard can be used in place of the viewing

screen. A 48 mm FL convex lens may also be used to

magnify the projected image of the fringes.

in front of the laser. Move the viewing

1

1

Fabry-Perot Mode

1. Align the laser and interferometer base as described in

Laser Alignment at the beginning of this section. The

laser beam should be approximately parallel with the

top of the base, should strike the center of the movable

mirror, and should be reflected directly back into the

laser aperture.

2. Mount the adjustable mirror where indicated on the in-

terferometer base and one component holder in front of

the movable mirror. See Figure 8.

3. Place the other component holder behind the movable

mirror and attach the viewing screen to its magnetic

backing. You should see several images of the laser

beam on the viewing screen.

4. Using the thumbscrews, adjust the tilt of the adjustable

mirror until there is only one bright dot on the screen.

5. Now mount the 18 mm FL lens on the front compo-

nent holder. A clear sharp interference pattern should

be visible on the viewing screen. If you use light with

two component wavelengths, instead of a laser, two sets

of fringes can be distinguished on the viewing screen.

Lens

18mm FL

OS-9255A

Adjustable mirror

VIEWING SCREEN

MICHELSON, TWYMAN-GREEN

Movable mirror

PRECISION

INTERFEROMETER

VIEWING SCREEN

OS-9255A

18 mm FL LENS

MICHELSON, TWYMAN-GREEN

N

R

O

E

S

T

L

IT

E

L

H

P

IC

S

M

M

A

E

B

R

O

T

A

N

S

O

N

S

E

L

P

E

M

H

O

IC

C

M

PRECISION

INTERFEROMETER

Lens

18mm FL

18 mm FL LENS

Component

holder

N

LSO

E

LITTER

ICH

SP

M

ICHELSON

COMPENSATOR

M

BEAM

Viewing screen

Component

holder

Rotational

ADJUSTABLE MIRROR

MICHELSON, TWYMAN-GREEN

component holder

30

25

5

0

-5

15

10

1 div = 1 MICRON

ADJUSTABLE MIRROR

MICHELSON, TWYMAN-GREEN

5

0

-5

30

25

15

10

1 div = 1 MICRON

Figure 8. Fabry-Perot Mode Setup

Figure 7. Twyman-Green Mode Setup

8

Page 13

012-07137A Precision Interferometer

Tips on Using the Interferometer

Accurate Fringe-Counting

The following techniques can help you make accurate

measurements.

1. It's not necessary that your interference pattern be per-

fectly symmetrical or sharp. As long as you can clearly

distinguish the maxima and minima, you can make accurate measurements.

2. It's easy to lose track when counting fringes. The fol-

lowing technique can help.

Center the interference

pattern on the viewing

screen using the thumbscrews on the back of the

fixed mirror. Select a reference line on the millimeter scale and line it up

with the boundary between a maxima and a

minima (see Figure 9).

Move the micrometer dial

until the boundary between the next maximum and

minimum reaches the same position as the original

boundary. (The fringe pattern should look the same as

in the original position.) One fringe has gone by.

Figure 9.

Counting Fringes

5. The slip ring at the base of the micrometer knob adjusts

the tension in the dial. Before making a measurement,

be sure the tension is adjusted to give you the best possible control over the mirror movement.

Calibrating the Micrometer

For even more accurate measurements of the mirror

movement, you can use a laser to calibrate the micrometer.

To do this, set up the interferometer in Michelson or

Fabry-Perot mode. Turn the micrometer knob as you

count off at least 20 fringes. Carefully note the change in

the micrometer reading, and record this value as d'. The

actual mirror movement, d, is equal to Nl/2, where l is

the known wavelength of the light (0.6328 µm for a

standard helium-neon laser) and N is the number of fringes

that were counted. In future measurements, multiply your

micrometer readings by d/d' for a more accurate measurement.

ä

NOTE: You can also adjust the micrometer

calibration mechanically. The process is not difficult,

but for most accurate results, the above procedure is

still recommended. See the Maintenance section at

the end of the manual for the mechanical calibration

procedure.

3. When turning the micrometer dial to count fringes, al-

ways turn it one complete revolution before you start

counting, then continue turning it in the same direction

while counting. This will almost entirely eliminate errors due to backlash in the micrometer movement.

Backlash is a slight slippage that always occurs when

you reverse the direction of motion in a mechanical instrument. (Turning the micrometer dial clockwise

moves the movable mirror toward the right. Turning

the dial counter-clockwise moves the mirror toward the

left.) The PASCO micrometer is designed to minimize

backlash. However, by using the technique described

above, you can practically eliminate all effects of backlash in your measurements.

4. Always take several readings and average them for

greater accuracy.

Demonstrations

The PASCO interferometer is not designed for large

demonstrations. However, for small demonstrations, you

can use the 48 mm focal length lens (included in the

Interferometer Accessories) to magnify the fringe pattern

and project it onto a wall or screen. It is helpful to have a

powerful laser for large projections.

Using the Diffuser

It's sometimes more convenient to view the interference

pattern through the diffuser rather than on the viewing

screen. Just place the diffuser where you would normally

place the viewing screen, and look through it toward the

interferometer.

9

Page 14

Precision Interferometer 012-07137A

Sources of Experimental Error

Backlash Although PASCO's carefully designed

mirror movement reduces backlash considerably, every

mechanical system is susceptible to backlash. However,

the effects of backlash can be practically eliminated by

using proper technique when counting fringes (see item 3

under Accurate Fringe-Counting, on the previous page).

Mirror Travel The amount of mirror movement per

dial turn of the micrometer is constant to within 1.5%.

Most of this error occurs at the extreme ends of the

mirrors total possible movement. For very accurate

measurements, see Calibrating the Micrometer, above,

and remember that the mirrors are flat to within 1/4

wavelength across their surface.

Troubleshooting

If you have trouble producing a clear set of interference

fringes, consider the following possible sources of difficulty:

1. Warm up your Laser Many lasers vary in intensity

and/or polarization as they warm up. To eliminate any

possible fringe or intensity variations, allow the laser to

warm up prior to setting up an experiment. (The

PASCO laser should warm up in about 1 hour.)

2. Check your Mirrors The beam-splitter and

movable mirror are carefully mounted in their brackets

to remain perpendicular to the interferometer base

when set up. If the brackets are bent slightly out of

alignment, the resulting fringe patterns will be distorted

somewhat. If they are significantly out of alignment, it

may be impossible to obtain fringes.

ä

IMPORTANT: If the movable mirror doesn't

move when you turn the micrometer dial, see

Micrometer Spacer Replacement in the

Maintenance section at the end of this manual.

Component Specifications

Interferometer Mirrors 3.175 cm in diameter;

0.635 + 0.012 cm thick; flat to 1/4 wavelength on both

sides; coated on one side for 80% reflectance and 20%

transmission.

Beam-Splitter 3.175 cm in diameter; 0.635

thick; flat to 1/4 wavelength on both sides; coated on one

side for 50% reflectance and 50% transmission.

Compensator Identical to the beam-splitter, but

uncoated.

Movable Mirror movement is controlled by the

micrometer that is built-into the interferometer base;

turning the dial clockwise moves the mirror toward the

right (looking from the micrometer side); 25 microns per

micrometer dial revolution (±1% near center of movement); movement through full distance of travel is linear to

within 1.5%.

ä

IMPORTANT: Avoid touching all mirror

surfaces. Minute scratches and dirt can impair the

clarity of interference images. See the Maintenance

section at the end of this manual for cleaning

instructions.

+ 0.012 cm

3. Background Fringes Reflections from the front

and back surfaces of the mirrors and beam-splitter often cause minor interference patterns in the background of the main fringe pattern. These background

patterns normally do not move when the mirror is

moved, and have no impact on measurements made

using the main interference pattern.

4. Convection Currents If the fringe pattern ap-

pears to wave or vibrate, check for air currents. Even

a slight breeze can effect the fringes.

5. Vibration Under normal conditions, the

interferometer base and mirror mounts are stable

enough to provide a vibration free setup. However, if

the experiment table is vibrating sufficiently, it will

effect the interference pattern.

10

Page 15

012-07137A Precision Interferometer

Experiment 1: Introduction to Interferometry

EQUIPMENT NEEDED:

Basic Interferometer (OS-9255A)

Laser (OS-9171)

Laser Alignment Bench (OS-9172)

Interferometer Accessories (OS-9256A)

Component Holder , (2) Calibrated Polarizers

Introduction

Lens

18mm FL

Component holder

OS-9255A

VIEWING SCREEN

MICHELSON, TWYMAN-GREEN

Viewing screen

PRECISION

INTERFEROMETER

In general, an interferometer can be used in

two ways. If the characteristics of the light

source are accurately known (wavelength,

polarization, intensity), changes in the beam

path can be introduced and the effects on the

18 mm FL LENS

splitter

Beam

MICHELSON

BEAM SPLITTER

COMPENSATOR

MICHELSON

Compensator

(optional)

Movable

interference pattern can be analyzed. Experiments 2 and 3 are examples of this procedure. On

the other hand, by introducing specific changes in

the beam path, information can be obtained

ADJUSTABLE MIRROR

MICHELSON, TWYMAN-GREEN

5

0

-5

15

10

about the light source that is being used.

In this experiment, you'll use the interferometer to

measure the wavelength of your light source. If

you have a pair of polarizers, you can also

investigate the polarization of your source.

Procedure

Figure 1.1. Michelson Mode Setup

Adjustment

Thumbscrews

Micrometer

knob

Adjustable

mirror

Part I: Wavelength

1. Align the laser and interferometer in the Michelson mode, so an interference pattern is clearly visible on your

viewing screen. See Setup and Operation for instructions.

2. Adjust the micrometer knob to a medium reading (approximately 50 µm). In this position, the relationship be-

tween the micrometer reading and the mirror movement is most nearly linear.

mirror

30

25

1 div = 1 MICRON

3. Turn the micrometer knob one full turn counterclockwise. Continue turning counterclockwise until the zero on the

knob is aligned with the index mark. Record the micrometer reading.

➤ NOTE: When you reverse the direction in which you turn the micrometer knob, there is a small amount of

give before the mirror begins to move. This is called mechanical backlash, and is present in all mechanical

systems involving reversals in direction of movement. By beginning with a full counterclockwise turn, and then

turning only counterclockwise when counting fringes, you can eliminate errors due to backlash.

4. Adjust the position of the viewing screen so that one of the marks on the millimeter scale is aligned with one of the

fringes in your interference pattern. You will find it easier to count the fringes if the reference mark is one or two

fringes out from the center of the pattern.

5. Rotate the micrometer knob slowly counterclockwise. Count the fringes as they pass your reference mark.

Continue until some predetermined number of fringes have passed your mark (count at least 20 fringes). As you

finish your count, the fringes should be in the same position with respect to your reference mark as they were

when you started to count. Record the final reading of the micrometer dial.

11

Page 16

Precision Interferometer 012-07137A

6. Record d

, the distance that the movable mirror moved toward the beam-splitter according to your

m

readings of the micrometer knob. Remember, each small division on the micrometer knob corre-

6

-

sponds to one µm (10

meters) of mirror movement.

7. Record N, the number of fringe transitions that you counted.

8. Repeat steps 3 through 7 several times, recording your results each time.

9. Go on to part two. If you have time afterward, try setting up the interferometer in Fabry-Perot mode

and repeating steps 3 through 8.

Part II : Polarization (using the Calibrated Polarizer, part of OS-9256A Interferometer Accessories)

1. Place a polarizer between the laser and the beam-splitter. Try several polarization angles. How does

this effect the brightness and clarity of the fringe pattern?

2. Remove that polarizer and place a polarizer in front of the fixed or movable mirror. Try several

polarization angles. How does this effect the fringe pattern?

3. Now try two polarizers, one in front of the fixed mirror, and one in front of the movable mirror. First

rotate one polarizer, then the other. Again, note the effects.

Analysis

Part I

1. For each trial, calculate the wavelength of the light (l = 2d

the Fabry-Perot mode also, calculate the wavelength independently for that data. The same formula

applies.

/N), then average your results. If you tried

m

Part II

1. From your observations in step 1 of the procedure, can you determine the polarization characteristics

of your light source? Does it vary with time?

2. Do your observations from step 2 give you any more information about the polarization of your

source?

3. From your observations in step 3, do cross-polarized beams interfere?

Questions

1. In the calculation to determine the value of l based on the micrometer movement, why was d

multiplied by two?

2. Why move the mirror through many fringe transitions instead of just one? Why take several measure-

ments and average the results?

3. If you tried the Fabry-Perot mode, was your measured l the same? If not, can you speculate about possible

reasons for the difference? Do you have more confidence in one value as opposed to the other?

4. If the wavelength of your light source is accurately known, compare your results with the known

value. If there is a difference, to what do you attribute it?

5. When measuring mirror movement using the micrometer dial on the interferometer, what factors limit

the accuracy of your measurement?

m

6. When measuring mirror movement by counting fringes using a light source of known wavelength,

what factors might limit the accuracy of your measurement?

7. What role does polarization play in producing an interference pattern?

12

Page 17

012-07137A Precision Interferometer

Experiment 2: The Index of Refraction of Air

EQUIPMENT NEEDED:

Basic Interferometer (OS-9255A)

Laser (OS-9171)

Laser Alignment Bench (OS-9172)

Interferometer Accessories (OS-9256A)

Rotational pointer, Vacuum cell, Vacuum pump

Introduction

2

1

In the Michelson interferometer, the characteristics of the

fringe pattern depend on the phase relationships between

the two interfering beams. There are two ways to change

the phase relationships. One way is to change the distance

traveled by one or both beams (by moving the movable

mirror, for example). Another way is to change the

medium through which one or both of the beams pass.

Either method will influence the interference pattern. In

this experiment you will use the second method to

measure the index of refraction for air.

For light of a specific frequency, the wavelength l varies

according to the formula:

l = lo/n;

where lo is the wavelength of the light in a vacuum, and

n is the index of refraction for the material in which the

light is propagating. For reasonably low pressures, the

index of refraction for a gas varies linearly with the gas

pressure. Of course for a vacuum, where the pressure is

zero, the index of refraction is exactly 1. A graph of

index of refraction versus pressure for a gas is shown in

Figure 2.1. By experimentally determining the slope, the

index of refraction of air can be determined at various

pressures.

Index of Refraction (n)

0

0

Gas Pressure (cm Hg)

Figure 2.1. Index of Refraction versus Gas

Pressure

VIEWING SCREEN

OS-9255A

18 mm FL LENS

MICHELSON, TWYMAN-GREEN

ADJUSTABLE MIRROR

MICHELSON, TWYMAN-GREEN

MICHELSON

BEAM SPLITTER

COMPENSATOR

MICHELSON

0

-5

PRECISION

INTERFEROMETER

Vacuum Cell

Air Outlet

30

25

5

15

10

1 div = 1 MICRON

Figure 2.2. Equipment Setup

Procedure

1. Align the laser and interferometer in the Michelson mode. See Setup and Operation.

2. Place the rotational pointer between the movable mirror and the beam-splitter (see Figure 2.2).

Attach the vacuum cell to its magnetic backing and push the air hose of the vacuum pump over the

air outlet hole of the cell. Adjust the alignment of the fixed mirror as needed so the center of the

interference pattern is clearly visible on the viewing screen. (The fringe pattern will be somewhat

distorted by irregularities in the glass end-plates of the vacuum cell. This is not a problem.)

3. For accurate measurements, the end-plates of the vacuum cell must be perpendicular to the laser

beam. Rotate the cell and observe the fringes. Based on your observations, how can you be sure

that the vacuum cell is properly aligned?

13

Page 18

Precision Interferometer 012-07137A

λ

4. Be sure that the air in the vacuum cell is at atmospheric pressure. If you are using the OS-8502 Hand-

Held Vacuum Pump, this is accomplished by flipping the vacuum release toggle switch.

5. Record P

, the initial reading on the vacuum pump gauge. Slowly pump out the air in the vacuum cell. As

i

you do this, count N, the number of fringe transitions that occur. When you're done, record N and also

P

, the final reading on the vacuum gauge. (Some people prefer to begin with the vacuum cell evacuated,

f

then count fringes as they let the air slowly out. Use whichever method is easier for you.)

➤ NOTE: Most vacuum gauges measure pressure with respect to atmospheric pressure (i.e., 34 cm Hg

means that the pressure is 34 cm Hg below atmospheric pressure, which is ~ 76 cm Hg). The actual

pressure inside the cell is:

Analyzing Your Data

As the laser beam passes back and forth between the beam-splitter and the movable mirror, it passes

twice through the vacuum cell. Outside the cell the optical path lengths of the two interferometer beams

do not change throughout the experiment. Inside the cell, however, the wavelength of the light gets longer

as the pressure is reduced.

Suppose that originally the cell length, d, was 10 wavelengths long (of course, it's much longer). As you

pump out the cell, the wavelength increases until, at some point, the cell is only 9-1/2 wavelengths long.

Since the laser beam passes twice through the cell, the light now goes through one less oscillation within

the cell. This has the same effect on the interference pattern as when the movable mirror is moved

toward the beam-splitter by 1/2 wavelength. A single fringe transition will have occurred.

Originally there are N

beam). At the final pressure there are Nf = 2d/lf wavelengths within the cell. The difference between

these values, Ni Nf , is just N, the number of fringes you counted as you evacuated the cell. Therefore:

N = 2d/li - 2d/lf.

P

= P

absolute

= 2d/li wavelengths of light within the cell (counting both passes of the laser

i

atmospheric

– P

gauge

However, l

= l0/ni and lf = l0/nf; where ni and nf are the initial and final values for the index of

i

refraction of the air inside the cell. Therefore N = 2d(ni nf) /l0; so that ni nf = Nl0/2d. The slope of

the n vs pressure graph is therefore:

ni– n

Pi–P

f

f

N

=

2d(Pi–Pf)

0

where Pi = the initial air pressure; Pf = the final air pressure; ni = the index of refraction of air at pressure

Pi; nf = the index of refraction of air at pressure Pf ; N = the number of fringe transitions counted during

evacuation; l0 = the wavelength of the laser light in vacuum (see your instructor);

d = the length of the vacuum cell (3.0 cm).

1. Calculate the slope of the n vs pressure graph for air.

2. On a separate piece of paper, draw the n vs pressure graph.

Questions

1. From your graph, what is n

, the index of refraction for air at a pressure of 1 atmosphere (76 cm Hg).

atm

2. In this experiment, a linear relationship between pressure and index of refraction was assumed. How

might you test that assumption?

3. The index of refraction for a gas depends on temperature as well as pressure. Describe an experiment

that would determine the temperature dependence of the index of refraction for air.

14

Page 19

012-07137A Precision Interferometer

OS-9255A

PRECISION

INTERFEROMETER

-5

0

5

10

15

25

30

ADJUSTABLE MIRROR

MICHELSON, TWYMAN-GREEN

B

E

A

M

S

P

L

I

T

T

E

R

M

I

C

H

E

L

S

O

N

C

O

M

P

E

N

S

A

T

O

R

M

I

C

H

E

L

S

O

N

18 mm FL LENS

VIEWING SCREEN

MICHELSON, TWYMAN-GREEN

1 div = 1 MICRON

Experiment 3: The Index of Refraction of Glass

EQUIPMENT NEEDED:

Basic Interferometer (OS-9255A)

Laser (OS-9171)

Laser Alignment Bench (OS-9172)

Interferometer Accessories

Rotating Table, Glass Plate

Introduction

In Experiment 2, the index of refraction of air was

measured by slowly varying the density of air along a

fixed length of one beam path in the Michelson

Interferometer. That method obviously won't work

with a solid substance, such as glass. Therefore, in

order to measure the index of refraction of glass, it's

necessary to slowly vary the length of glass through

which the interferometer beam passes. This experiment introduces a technique for making such a

measurement.

Procedure

Glass plate

Rotational

pointer

Read Angle of

Inclination on

Degree Scale

1. Align the laser and interferometer in the Michelson

mode. See Setup and Operation.

Figure 3.1. Equipment Setup

2. Place the rotating table between the beam-splitter

and movable mirror, perpendicular to the optical path.

➤ NOTE: if the movable mirror is too far forward, the rotating table won't fit. You may need to

loosen the thumbscrew and slide the mirror farther back.

3. Mount the glass plate on the magnetic backing of the rotational pointer.

4. Position the pointer so that its 0 edge on the Vernier scale is lined up with the zero on the degree

scale on the interferometer base.

5. Remove the lens from in front of the laser. Hold the viewing screen between the glass plate and

the movable mirror. If there is one bright dot and some secondary dots on the viewing screen,

adjust the angle of the rotating table until there is one bright dot. Then realign the pointer scale.

The plate should now be perpendicular to the optical path.

6. Replace the viewing screen and the lens and make any minor adjustments that are necessary to get

a clear set of fringes on the viewing screen.

7. Slowly rotate the table by moving the lever arm. Count the number of fringe transitions that occur

as you rotate the table from 0 degrees to an angle q (at least 10 degrees).

15

Page 20

Precision Interferometer 012-07137A

λ

Data Analysis

In principle, the method for calculating the index of refraction is relatively simple. The light passes

through a greater length of glass as the plate is rotated. The general steps for measuring the index of

refraction in such a case is as follows:

1. Determine the change in the path length of the light beam as the glass plate is rotated. Determine how

much of the change in path length is through glass, d

2. Relate the change in path length to your measured fringe transitions with the following equation:

2nada(θ)+2ngdg(θ)

λ

where n

= the index of refraction of air (see Experiment 2), ng = the index of refraction of the glass

a

plate (as yet unknown), l0 = the wavelength of your light source in vacuum, and N = the number of

fringe transitions that you counted.

Carrying out this analysis for the glass plate is rather complicated, so we'll leave you with the equation

shown below for calculating the index of refraction based on your measurements. Nevertheless, we

encourage you to attempt the analysis for yourself. It will greatly increase your understanding of the

measurement and also of the complications inherent in the analysis.

(q), and how much is through air, da(q).

g

0

(2t – N

2t(1 – cos θ)–Nλ

)(1 – cosθ)

0

0

where t = the thickness of the glass plate.

➤ NOTE: Our thanks to Prof. Ernest Henninger, DePauw University, for providing this equation

from Light Principles and Measurements, by Monk, McGraw-Hill, 1937.

16

Page 21

012-07137A Precision Interferometer

Suggestions for Additional Experiments

Twyman-Green

Twyman-Green operation gives students a quick, qualitative look at how interferometry can be used to test optical

components. See Twyman-Green Mode in the Setup and

Operation section of the manual.

Any distortion of the circular fringe pattern is due to

spherical aberration from the test lens. Turn the lens until

it sits at various angles to the optical path and watch the

fringe pattern change. Distortion here is due partially to

astigmatism from the lens.

Spectral Light Fringes

Although interferometry is easiest with a laser light source,

measurements can be made successfully using any monochromatic source of sufficient brightness. However, if a

laser is not used, it is generally not possible to project the

interference fringes onto a screen. Instead, the fringes are

viewed by looking into the beam-splitter (or into the

movable mirror in Fabry-Perot mode).

If you use a spectral light source with spectral lines at

several different frequencies, it may be necessary to use a

filter that blocks all but one of the spectral wavelengths.

Michelson Mode:

ä

NOTE:

One difficulty when using a non-laser light source in

Michelson mode is that the coherence length of the

light is far less with a non-laser source. Because of

this, the compensator should be used. It mounts

magnetically on the back of the beam-splitter (the

side opposite the thumbscrew).

It's also important that the optical paths of the two

interfering beams should be nearly equal. To ensure

that this is the case, set up the interferometer with a

laser (if you have one) and adjust the movable

mirror position until the fewest possible fringes

appear on the screen. (Theoretically, when the beam

paths are exactly equal, one big maximum should

appear that occupies the whole screen. But this is

usually not possible to achieve in practice due to

optical imperfections.) Then remove the viewing

screen and replace the laser with the spectral light

source. If fringes aren't visible when looking into the

beam-splitter, proceed as follows:

a. Tape two thin pieces of wire or thread to the surface of

the diffuser to form cross-hairs.

b. Place the diffuser between the light source and the

beam-splitter.

c. Adjust the angle of the beam-splitter so that, when look-

ing into the beam-splitter, you can see two images of

the cross-hairs.

d. Adjust the tilt of the fixed mirror until the cross-hairs are

superimposed. You should be able to see the fringe pattern.

Fabry-Perot mode:

a. Tape two thin pieces of wire or thread to the surface of

the diffuser to form cross-hairs.

b. Set up the equipment in Fabry-Perot mode, and place

the diffuser between the light source and the fixed mirror.

c. Look into the movable mirror from behind. Adjust the

tilt of the fixed mirror until the cross-hairs are superimposed. You should be able to see the fringe pattern.

White Light Fringes

With careful alignment, the interferometer will produce

fringes from multi-chromatic or even white light . The

procedure is the same as for any non-laser source, as

described above. However, since it is harder to get a visible

interference pattern, it is strongly recommended that you

first set up the interferometer using a laser. Then substitute

your white light source.

Use a Photometer

Use a photometer, such as PASCO Model OS-9152B, to

scan the fringe patterns. You can compare the intensity

distributions in the Michelson and Fabry-Perot modes. Or

use it to more accurately determine polarization effects. Or

just use it as an aid in counting fringes.

Heat Distribution in Air

With the interferometer in Michelson mode, strike a match

and bring it close to one of the optical paths. Note the

distortions in the fringe pattern. For a more quantitative

approach, you could construct an air tight cell, and heat the

contents to observe the effects of heat on the index of

refraction of air.

17

Page 22

Precision Interferometer 012-07137A

ä

IMPORTANT The Vacuum Cell is not designed to

be heated.

Index of Refraction for Gases

Measure the indices of refraction for various gases.

Caution: The PASCO Vacuum Chamber is NOT designed

Fabry-Perot Spectroscopy

The Fabry-Perot mode is customarily used as a highresolution spectrometer. Very close spectral lines, as in

magnetic splitting, can be resolved much more accurately

than with any but the highest quality diffraction gratings.

to hold positive pressures. You will need to provide your

own gas chamber.

Maintenance

Micrometer Calibration

The micrometer is calibrated before it is shipped. However, if recalibration becomes necessary, use the following

procedure:

1. Turn the interferometer

over, and remove the bottom cover.

2. Loosen the two screws

shown in Figure A1. Slide

the bearing surface toward

the pivot to increase mirror movement per turn of

the micrometer dial. Slide

the bearing surface away

from the pivot to decrease

mirror movement per dial

turn. Tighten the screws

and replace the bottom

cover.

Testing your calibration is most easily performed using a

laser light source of known wavelength, as in

Experiment 1.

Loosen

screws and

slide the

bearing

surface as

required.

Figure A1.

Calibration

To replace the spacer:

1. Turn the interferometer

over, and remove the bottom cover.

Spacer

2. Position the spacer be-

tween the two ball bearings, as shown in Figure

A2. Release the lever, and

check that the spacer is

snugly in place.

3. Replace the bottom panel.

Lever

arm

Figure A2. Spacer

Replacement

Mirror Care

The mirror and beam-splitter surfaces are precision ground

and coated. Dirt or scratches will distort the fringe pattern,

so handle all optical surfaces with care. Clean the surfaces

occasionally with lens tissue.

Vacuum Cell

Clean the glass windows on the vacuum chamber occasionally with lens tissue.

Micrometer Spacer Replacement

In order to provide extremely fine, backlash-free control of

the movable mirror, the mechanical linkage between the

micrometer and the movable mirror is maintained under a

state of spring-loaded compression. This compression also

holds part of the linkage (a spacer) in place. Under normal use,

the spacer will never fall out of position. However, a sudden

jolt can jar the spacer and the spring loose. In this case, the

micrometer will no longer work, and you'll hear the parts

rolling around inside.

18

Storage

Rotate the Micrometer Knob fully IN before storing the

Interferometer.

Page 23

012-07137A Precision Interferometer

Replacement Parts

Component Part No.

Interferometer Base 003-05137

Adjustable Mirror 003-03957

Beam-Splitter 003-03956

Movable Mirror 003-03955

Component Holder 003-05161

Compensator 003-03958

Interferometer Manual 012-05187

Vacuum Pump OS-8502

Component Part No.

Vacuum Cell 003-05162

Rotational Pointer 003-05160

Fitted Case 650-05178

Viewing Screen 003-05119

Diffuser 003-03941

Polarizer 003-04924

Glass Plate 003-04034

Lens, 18mm FL 003-03814

Lens, 48mm FL 003-03806

19

Page 24

Precision Interferometer 012-07137A

Teacher's Guide

Experiment 1: Introduction to Interferometry

Part I General

Dm wavelength

Michelson 1.60 x 10

1.60 x 10

1.60 x 10

Fabry-Perot 1.60 x 10

1.50 x 10

1.55 x 10

average: 630.0 x 109±16.7 x 10

actual: 632.8 x 10

5

5

5

5

5

5

640.0 x 10

640.0 x 10

640.0 x 10

640.0 x 10

600.0 x 10

620.0 x 10

9

9

9

9

9

9

9

9

% diff. 0.44%

Part II General

1. The pattern became somewhat dimmer, due to

absorbtion by the polarizer; but other than that, there

was no variation when we polarized the light coming

into the interferometer.

2. Adding a polarizer in front of the movable mirror had

little effect. The contrast of the interference pattern

reduced, and the pattern rotated when the polarizer was

rotated.

3. There was no pattern unless the two polarizers were in

the same orientation.

Reference to Analysis (Part II)

1. The laser we used was unpolarized, and does not seem

to change polarization with time.

2. No, there was no change. This would support our

hypothesis that the laser used was unpolarized.

3. Cross-polarized beams do not interfere.

Answers to Questions

1. The change in path length is twice the movement of the

mirror.

2. Measuring only many fringes, many times, decreases

the chance of random error affecting our results.

3. They were roughly the same. The Fabry-Perot

measurement could instill more confidence, because the

fringes are sharper and easier to count.

4. The difference is probably due to our uncertainty in

measurement.

5. Limiting factors are play in the system and uncertainty

in our micrometer position.

6. Losing count of fringes, and inexact positioning of the

fringes relative to our reference mark.

7. In order to interfere, the two light beams must have the

same polarization.

20

Page 25

012-07137A Precision Interferometer

Experiment 2: The Index of Refraction of Air

Reference to Procedure

1. The chamber will be properly aligned when the reflec-

tions off the front and back end-plates are aligned with

each other and with the main interference pattern. (This

alignment may actually cause a secondary interference

pattern, but it will be very faint and will not affect your

measurements.)

2. It seems easiest to apply the vacuum first, then count

the fringes as the vacuum was released.

The average slope, starting at a guage reading of 60,

was 3.462x10

-6

.

1.0005

1.0004

1.0003

1.0002

1.0001

1

0.9999

0.9998

0.9997

0.9996

0.9995

0 102030405060708090

Pressure (cm hg)

Answers to Questions

1. Extrapolating from our slope and the known index of

refraction of vacuum,

n

= 1.000263.

atm

2. Measure the index of refraction at various pressures,

and see if it increases linearly. (It does.)

3. Answers will vary; but they should include some way

of heating the air on one arm of the interferometer

without heating the air on the other arm or the interferometer itself.

21

Page 26

Precision Interferometer 012-07137A

0

Experiment 3: The Index of Refraction of Glass

Reference to Procedure

1. The glass plate must be absolutely perpendicular to the

laser for accurate measurement of the index of refraction. When the plate is perpendicular, there will be a

faint secondary fringe pattern (Fabry-Perot interference

between the front and back surfaces of the plate) visible in the center of the view screen.

2. It is important to measure as large an angle as possible,

and measure the angle as carefully as possible.

Reference to Analysis

1. The actual equation, which is derived in Optics of the

Electromagnetic Spectrum, by C.L. Andrews

(Prentice-Hall, 1960) is

2

2

N

λ

(2t –Nλ

ng=

)(1 – cosθ)+(

0

2t(1 –cosθ) –Nλ

The second term is negligible for visible wavelengths,

and may be ignored.

4t

0

)

Notes General

It is often difficult to count large numbers of fringes due to

eyestrain. If you find this to be the case, you may want to

make a circuit such as this:

+5-15v

1k

10k

741

56k 20k

1k 1k

The phototransistor should be mounted in a plate of sheet

steel, which can then be held in the magnetic viewscreen

holder. Mask the transistor with a piece of electrical tape

with a pinhole at the center. Adjust the sensitivity of the

circuit with the 20k potentiometer so that the flashes of the

LED can be counted instead of the actual fringes.

+

This circuit may also be used in conjunction with the

PASCO Series 6500 computer interface so that the fringes

can be counted by computer, if desired.

22

Page 27

012-07137A Precision Interferometer

Technical Support

Feedback

If you have any comments about the product or manual,

please let us know. If you have any suggestions on

alternate experiments or find a problem in the manual,

please tell us. PASCO appreciates any customer

feedback. Your input helps us evaluate and improve our

product.

To Reach PASCO

For technical support, call us at 1-800-772-8700

(toll-free within the U.S.) or (916) 786-3800.

fax: (916) 786-3292

e-mail: techsupp@pasco.com

web: www.pasco.com

Contacting Technical Support

Before you call the PASCO Technical Support staff, it

would be helpful to prepare the following information:

➤ If your problem is with the PASCO apparatus, note:

Title and model number (usually listed on the

label);

Approximate age of apparatus;

A detailed description of the problem/sequence of

events (in case you cant call PASCO right away, you

wont lose valuable data);

If possible, have the apparatus within reach when

calling to facilitate description of individual parts.

➤ If your problem relates to the instruction manual,

note:

Part number and revision (listed by month and year

on the front cover);

Have the manual at hand to discuss your

questions.

23

Page 28

Loading...

Loading...