Page 1

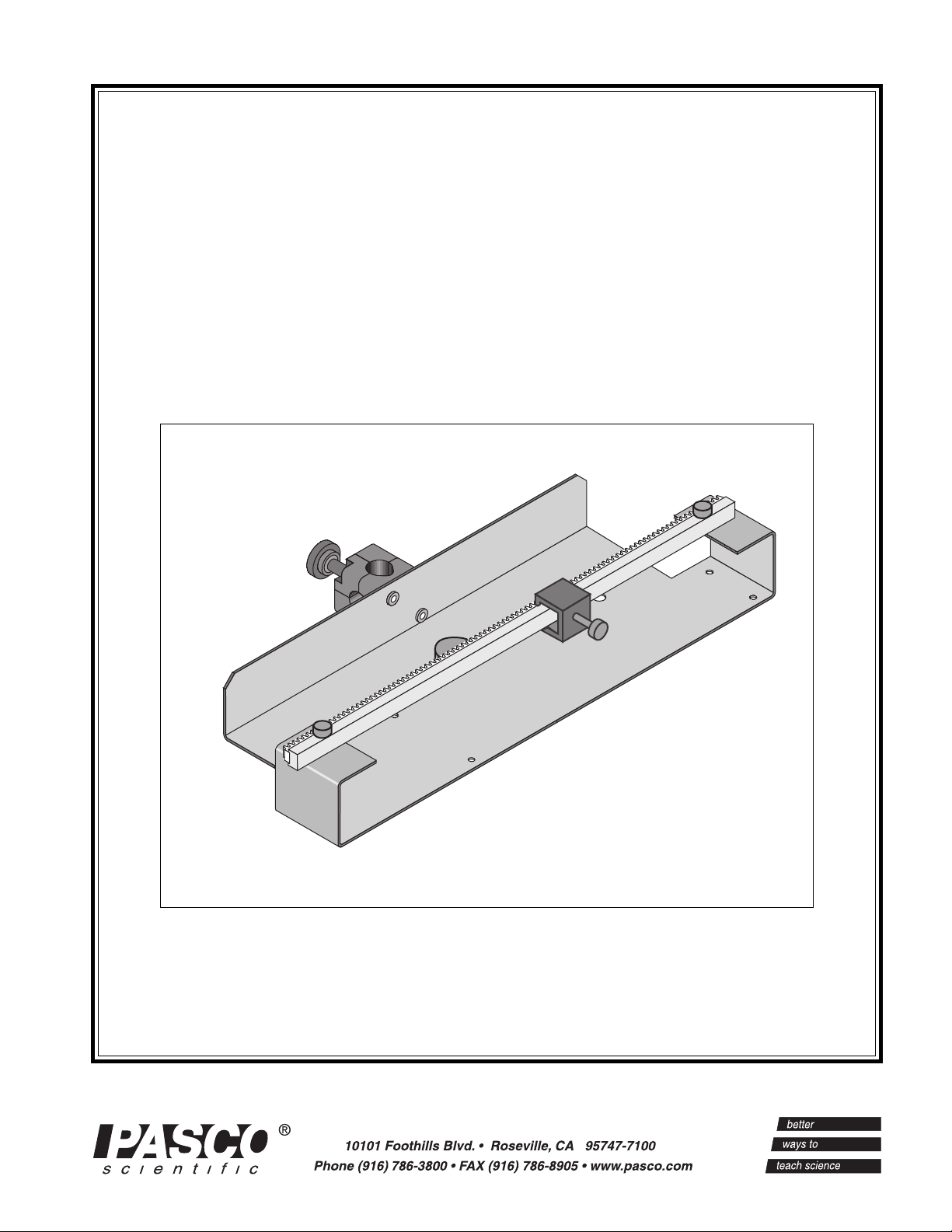

Instruction Manual for

the PASCO scientific

Model OS-8535

LINEAR TRANSLATOR

FOR THE BASIC OPTICS SYSTEM

012-06551A

1/98

© 1998 PASCO scientific $10.00

Page 2

Page 3

012-06551A Basic Optics Linear Translator

T able of Contents

Section Page

Copyright, Warranty, and Equipment Return .....................................................ii

Description .......................................................................................................1

Mounting the Translator on the Optics Bench ....................................................1

Using a Rotary Motion Sensor .......................................................................... 2

Using the Rack Separately.................................................................................3

Suggestions for Using the Linear Translator ......................................................4

Set Up for a Diffraction Pattern Experiment ......................................................5

Technical Support ......................................................................... Inside Back Cover

i

Page 4

Basic Optics Linear Translator 012-06551A

Copyright, Warranty and Equipment Return

Please—Feel free to duplicate this manual

subject to the copyright restrictions below.

Copyright Notice

The PASCO scientific Model OS-8535 Linear Translator

manual is copyrighted and all rights reserved. However,

permission is granted to non-profit educational institutions for reproduction of any part of this manual providing the reproductions are used only for their laboratories

and are not sold for profit. Reproduction under any other

circumstances, without the written consent of PASCO

scientific, is prohibited.

Limited Warranty

PASCO scientific warrants this product to be free from

defects in materials and workmanship for a period of one

year from the date of shipment to the customer. PASCO

will repair or replace, at its option, any part of the product

which is deemed to be defective in material or workmanship. This warranty does not cover damage to the product

caused by abuse or improper use. Determination of

whether a product failure is the result of a manufacturing

defect or improper use by the customer shall be made

solely by PASCO scientific. Responsibility for the return

of equipment for warranty repair belongs to the customer.

Equipment must be properly packed to prevent damage

and shipped postage or freight prepaid. (Damage caused

by improper packing of the equipment for return shipment will not be covered by the warranty.) Shipping costs

for returning the equipment, after repair, will be paid by

PASCO scientific.

Equipment Return

Should this product have to be returned to PASCO

scientific, for whatever reason, notify PASCO scientific

by letter or phone BEFORE returning the product. Upon

notification, the return authorization and shipping instructions will be promptly issued.

➤ NOTE:

NO EQUIPMENT WILL BE ACCEPTED FOR

RETURN WITHOUT AN AUTHORIZATION.

When returning equipment for repair, the units must be

packed properly. Carriers will not accept responsibility

for damage caused by improper packing. To be certain

the unit will not be damaged in shipment, observe the

following rules:

➀ The carton must be strong enough for the item

shipped.

➁ Make certain there is at least two inches of packing

material between any point on the apparatus and the

inside walls of the carton.

➂ Make certain that the packing material can not shift in

the box, or become compressed, thus letting the instrument come in contact with the edge of the box.

Address: PASCO scientific

10101 Foothills Blvd.

Credits

This manual authored by: Dave Griffith

P.O. Box 619011

Roseville, CA 95678-9011

Phone: (916) 786-3800

FAX: (916) 786-8905

ii

Page 5

012-06551A Basic Optics Linear Translator

Introduction

The PASCO OS-8535 Linear Translator is designed to be mounted on the Optics Bench of the OS-8515 Basic Optics

System. The Linear Translator can also be mounted on a rod up to 0.5 inch (12 mm) diameter.

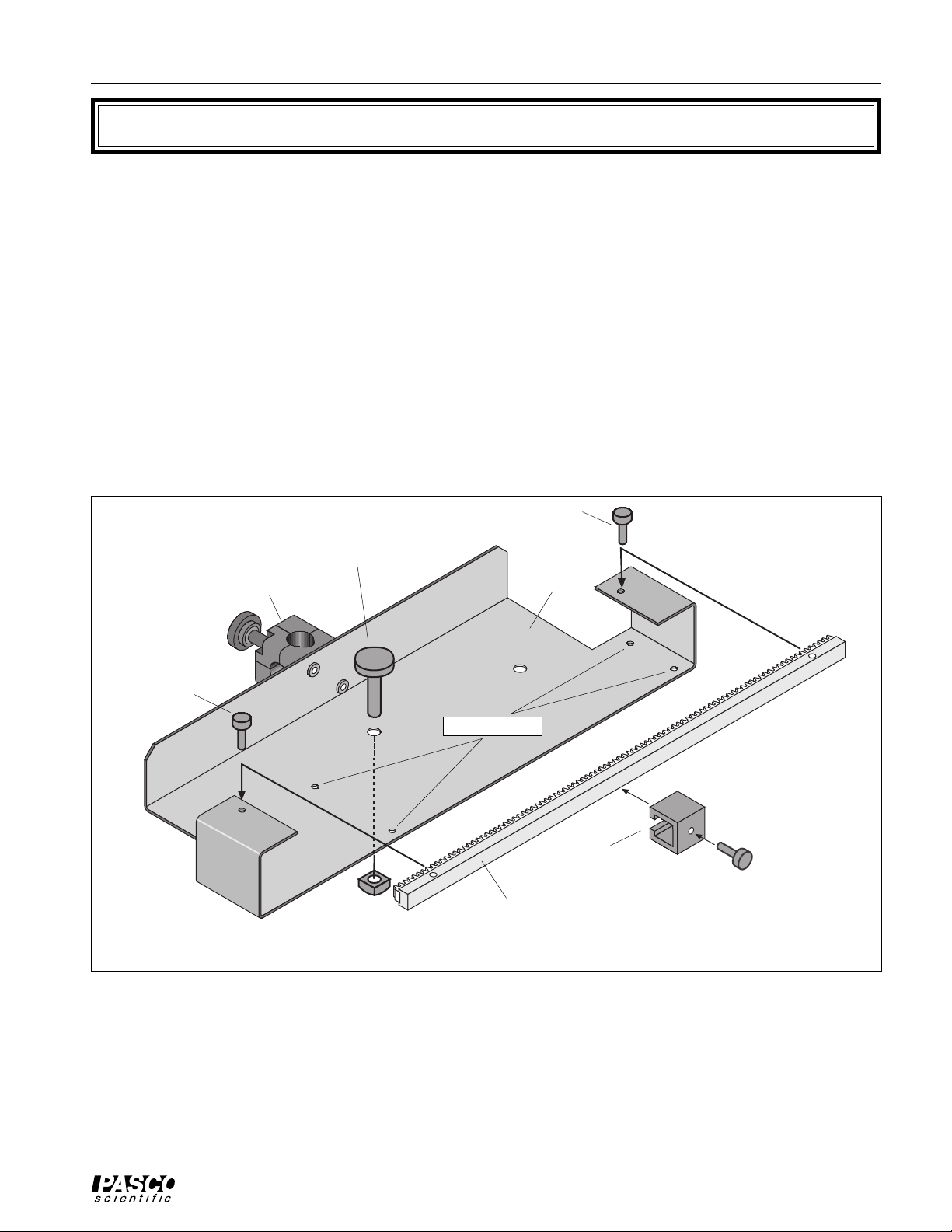

Description

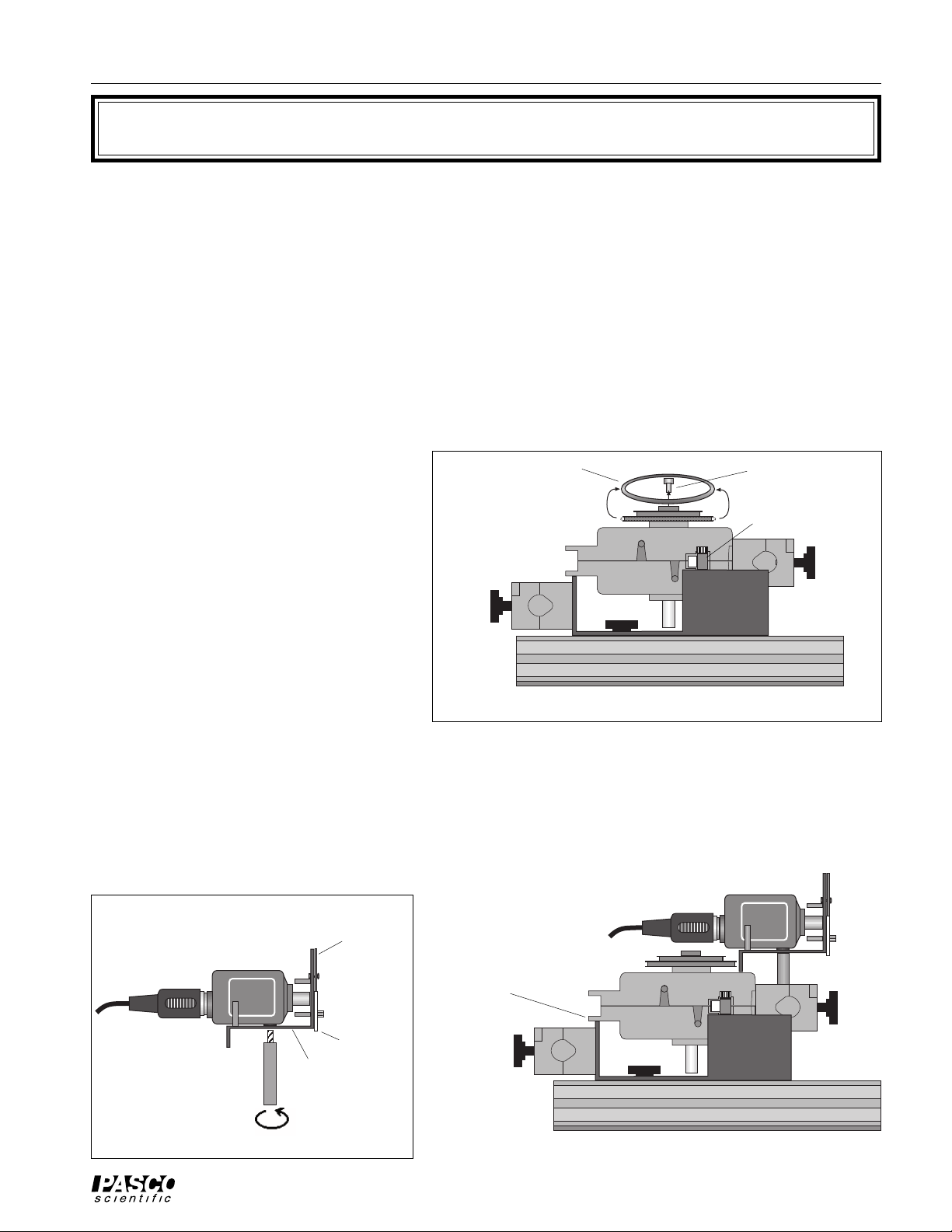

The Linear Translator consists of a base with mounting hardware and an attached rod clamp, a rack, and a rack clamp.

The hole in the base allows it to be stored on a peg. The mounting hardware on the base consists of a thumbscrew and a

square nut. The nut fits into the T-slot in the center of the Optics Bench (part of the OS-8515).

The rack is attached to the top of the base with two thumbscrews. The rack is designed to fit inside the T-slot on the side

the PASCO Model CI-6538 Rotary Motion Sensor (or CI-6625 Rotary Motion Sensor for ULI). The teeth on the rack

engage a gear inside the Rotary Motion Sensor, causing the gear to rotate when the Rotary Motion Sensor moves along

the rack. The Rotary Motion Sensor measures its linear position along the rack.

The rack clamp is attached to the back of the rack with a thumbscrew. The clamp sets the initial or final position of the

Rotary Motion Sensor.

rack

thumbscrew

rod clamp

rack

thumbscrew

base thumbscrew

base

alignment studs

rack clamp

rack

square nut

Figure 1: Linear Translator for Basic Optics

Mounting the Linear Translator on the Optics Bench

You can mount the Linear Translator on the Optics Bench in two ways: with the Rack perpendicular to the Optics

Bench or with the Rack parallel to the Optics Bench.

1

Page 6

Basic Optics Linear Translator 012-06551A

Pependicular Mount

To mount the Linear Translator so the Rack is perpendicular,

leave the mounting hardware (thumbscrew and square nut) in

the center hole. Loosen the thumbscrew by turning the thumbscrew counter-clockwise while holding the square nut. Leave

the square nut on the end of the thumbscrew.

Attach the base to the Optics Bench by inserting the square nut

into the T-slot located along the center of the Optics Bench.

Use the two widely spaced alignment studs on the underside of

the base to align the Linear Translator with the edge of the Optics Bench.

The Linear Translator can be moved to any position along the

Optics Bench while the thumbscrew is loose. Tighten the

The alignment studs rest against the

edge of the Optics Bench

Figure 2: Linear Translator on Optics Bench

thumbscrew to secure the Linear Translator in position.

Parallel Mount

To mount the Linear Translator so the Rack is parallel to

the Optics Bench, move the mounting hardware from the

center hole to the off-center hole (see Figure 3.1).

Turn the Linear Translator so the Rack is parallel to the

Optics Bench. Insert the square nut into the T-slot located along the center of the Optics Bench.

Using a Rotary Motion Sensor

You can mount a PASCO Model CI-6538 Rotary Motion Sensor or the Model CI-6625 Rotary Motion Sensor

for ULI on the rack of the Linear Translator.

The Rotary Motion Sensor has a T-slot into which

you can slide the Rack of the Linear Translator. The

first step is to remove the rack thumbscrews from the

ends of the Rack. Turn the thumbscrews counterclockwise to remove them.

You may also want to remove the Rack Clamp from

the Rack. Turn the rack thumbscrew counter-clockwise until you can slide the Rack Clamp off the end

of the Rack.

Move the mounting hardware to

the off-center hole.

Slide the square nut

into the T-slot.

Figure 3.1

If you are using the three-step pulley on the Rotary

Motion Sensor, hold the Rotary Motion Sensor so the

three-step pulley is on top. Line up the Rack with the

T-slot on the side of the Rotary Motion Sensor. The

teeth on the Rack go through the narrow side of the

T-slot and then engage a gear that is on the shaft of

the Rotary Motion Sensor. Gently push the Rack

through the T-Slot and into the sensor.

The alignment studs rest against

the edge of the Optics Bench.

Figure 3.2: Linear Translator Parallel to Optics Bench

2

Page 7

012-06551A Basic Optics Linear Translator

When the Rack is in the T-slot, put the Rack

Clamp back onto the Rack and tighten its

thumbscrew. Place the Rack with the sensor

back onto the Linear Translator. The back end

Rotary Motion Sensor

of the Rotary Motion Sensor rests on the upright edge of the base of the Linear Translator.

Line up the holes in the ends of the Rack with

the holes on the Linear Translator base. Put the

thumbscrews into the holes and turn them

rack

rack thumbscrew

clockwise to tighten.

If the Linear Translator is mounted parallel to

the Optics Bench, move the rod clamp from the

rack

clamp

end of the Rotary Motion Sensor to the side of

the Rotary Motion Sensor. By doing this, the

Light Sensor will be along the center line of the

Optics Bench when you put the Aperture

Bracket post into the rod clamp of the Rotary

Linear Translator

Motion Sensor.

You will need a Phillips head screwdriver with

a small tip (e.g., #0). Use the screwdriver to remove the two screws from the end of the rod

clamp. Align the rod clamp with the threaded

Figure 4.1: Rotary Motion Sensor onto Linear Translator

holes on the side of the Rotary Motion Sensor.

Replace the screws.

Move the rod clamp to the side

Using the Rack Separately

of the Rotary Motion Sensor

and replace the screws.

The rack of the Linear Translator can be used separately from the Linear Translator. For example, it can

be an accessory to the Rotary Motion Sensor in experiments that do not require the Optics Bench but that do

require the measurement of linear position.

rod clamp

Remove the two rack thumbscrews. Remove the rack

clamp from the rack. Use a Phillips head screwdriver

with a small tipe (e.g., #0) to remove the two screws

from the end of the rod clamp that is on the Linear

Translator. Use one of the rack thumbscrews to attach

the rod clamp to one end of the rack as shown. Use the

rod clamp to hold sensors, etc.

rack

rack thumbscrew

Figure 5: Rod Clamp attached to Rack

rod clamp

Remove the

screws from the

rod clamp.

Optics Bench

Figure 4.2: Rotary Motion Sensor on Linear Translator

Parallel to Optics Bench

3

Page 8

Basic Optics Linear Translator 012-06551A

Suggestions for Using the Linear Translator

Light Intensity of Diffraction Patterns

EQUIPMENT NEEDED

– Optics Bench (part of OS-8515) – Linear Translator (OS-8535)

– Aperture Bracket (OS-8534) – Slit Accessory (OS-8523)

– Diode Laser (OS-8525) – Rotary Motion Sensor (CI-6538)

– Light Sensor (CI-6504A)

Use the Diode Laser and Slit Accessory to produce a diffraction pattern. Mount the Linear Translator on the

Optics Bench so the rack is perpendicular to the Optics Bench. Use the Light Sensor to measure the intensity of

light in the diffraction pattern. Use the Rotary Motion Sensor mounted on the Linear Translator to measure the

position of the Light Sensor as it moves through the diffraction pattern.

Light Sensor on Aperture Bracket

Slit Accessory

Rotary Motion Sensor

Optics Bench

Linear Translator

Figure 6: Light Intensity of Diffraction Patterns

Diode Laser

(The description for this experiment starts on the next page.)

Light Intensity versus Distance

EQUIPMENT NEEDED

– Optics Bench (part of OS-8515) – Linear Translator (OS-8535)

– Aperture Bracket (OS-8534) – Light Source (part of OS-8515)

– Rotary Motion Sensor (CI-6538) – Light Sensor (CI-6504A)

Use the Light Source to produce a “point source” of light. Mount the Linear Translator on the Optics Bench so the

rack is parallel to the Optics Bench. Use the Light Sensor to measure the intensity of the light. Use the Rotary

Motion Sensor mounted on the Linear Translator to measure the position of the Light Sensor as it moves relative

to the Light Source.

Light Source

Linear Translator

Light Sensor on

Aperture Bracket

4

Rotary Motion

Sensor

Figure 7: Light Intensity versus Distance

Optics Bench

Page 9

012-06551A Basic Optics Linear Translator

LIGHT

SENSOR

Set Up for a Diffraction Pattern Experiment

EQUIPMENT NEEDED

– Optics Bench (part of OS-8515) – Linear Translator (OS-8535)

– Aperture Bracket (OS-8534) – Slit Accessory (OS-8523)

– Diode Laser (OS-8525) – Rotary Motion Sensor (CI-6538)

– Light Sensor (CI-6504A)

Introduction

The purpose is to investigate the wave nature of light. A Light Sensor measures the intensity of the interference

pattern created by monochromatic laser light passing through a single or multiple slit. The Rotary Motion Sensor mounted on the Linear Translator measures the relative positions of the maxima in the pattern.

Procedure

1. Put the Linear Translator onto the Optics Bench so the rack is perpendicular

remove “O” ring remove thumbscrew

to the Optics Bench. Mount the Rotary

Motion Sensor onto the Rack of the

Rotary Motion Sensor

rack

Linear Translator as described in the

Introduction. Remove the “O” ring and

thumbscrew from the Rotary Motion

Sensor pulley as shown in Figure 1 so

they will not interfere with the Aperture

Linear Translator

Bracket.

2. Mount the Light Sensor onto the Aper-

Optics Bench

ture Bracket by screwing the Aperture

Bracket post into the threaded hole on

Figure 1

the bottom of the Light Sensor as

shown.

3. Put the post into the rod clamp on the end of the Rotary Motion Sensor. Lower the Aperture Bracket until it

rests on the top of the Rotary Motion Sensor. Tighten the Rod Clamp thumbscrew to hold the Aperture Bracket

and Light Sensor in place.

Light Sensor and

Aperture Bracket

cable to

interface

cable to

interface

Light

Sensor

LIGHT

SENSOR

post

Aperture

Bracket

aperture

disk

screen

Rotary Motion Sensor

rests on the edge of the

Linear Translator

Figure 2

Optics Bench

Figure 3

5

Page 10

Basic Optics Linear Translator 012-06551A

4. Mount the Diode Laser and a Slit Accessory at the other end of the Optics

Bench. For example, put the MULTIPLE SLIT SET into the Slit Acces-

Slit Accessory Diode Laser

sory holder.

5. Plug in the power supply for the Diode

Laser. Turn on the laser.

thumbscrew

6. Rotate the SLIT SET disk on the Slit

Accessory until a slit pattern is in line

with the laser beam. Use the adjustment

screws on the back of the Diode Laser

to adjust the beam if necessary.

Optics Bench

Figure 4

7. Rotate the pulley on the top of the Rotary Motion Sensor to move it along the rack on the

Linear Translator. Move the Rotary Motion/Light Sensor until the white screen on the front of the Aperture

Bracket shows the diffraction pattern.

8. Examine the diffraction pattern on the white screen. If

the pattern is not horizontal, loosen the thumbscrew on

the Slit Accessory. Slowly rotate the Slit Accessory

until the laser beam is centered on the slit pattern you

want and the diffraction pattern is horizontal on the

white screen on the Aperture Bracket. Tighten the

thumbscrew on the Slit Accessory to hold it in place.

laser beam

slit pattern

thumbscrew

S

T

I

L

S

E

L

B

U

O

4

0

0

D

.

5

.

0

0

4

5

0

2

m

.

.

0

0

m

m

:

:

n

i

=

m

=

d

n

a

n

o

i

i

t

h

a

t

r

d

a

i

p

w

e

t

5

i

s

l

t

s

i

l

:

s

=

:

a

=

d

S

T

I

L

V

A

R

I

A

a

d

=

8

0

0

.

.

0

5

.

0

OS-8523

5

6

8

5

0

-

BASIC OPTICS

SLIT ACCESSORY

=

d

4

0

.

0

=

a

3

2

T

L

U

M

1

a= 0.04 0.04

d= 0.125 0.125

0

8

0

.

5

2

0

.

0

MULTIPLE SLIT SET

6

4

6

5

2

1

.

0

4

S

E

L

P

I

Slit Accessory

B

L

E

D

O

U

B

L

E

S

=

L

0

.

0

I

2

4

T

5

t

o

0

.

7

5

a= 0.040.04

d= 0.25

a= 0.040.04

d= 0.250.50

C

a

O

=

d

0

.0

=

4

M

0

.2

0

5

.08

P

0

.2

5

A

R

I

S

O

N

S

9. Rotate the Aperture Disk on the front of the Aperture

Bracket until the narrowest slit opening is in front of

Figure 5

the Light Sensor opening. This reduces the amount of

ambient light that can enter the Light Sensor while the Light

Sensor is between maxima of the diffraction pattern.

Slit Disk

10.Move the Rotary Motion Sensor/Light Sensor along the rack

on the Linear Translator until the center of the difffraction

pattern is aligned with the center of the narrow slit on the

Aperture Disk of the Aperture Bracket. Loosen the Rotary

Motion Sensor rod clamp and adjust the Aperture Bracket and

Light Sensor up or down if necessary.

diffraction pattern

white screen

Figure 6

Data Recording

Refer to Physics Labs with Computers, Volume 2, (PASCO Model CI-7010) for information about data recording using a ScienceWorkshop interface.

6

Page 11

012-06551A Basic Optics Linear Translator

T echnical Support

Feedback

If you have any comments about the product or

manual, please let us know. If you have any suggestions on alternate experiments or find a problem in the

manual, please tell us. PASCO appreciates all customer feedback. Your input helps us evaluate and

improve our product.

To Reach PASCO

For technical support, call us at 1-800-772-8700 (tollfree within the U.S.) or (916) 786-3800.

fax: (916) 786-3292

e-mail: techsupp@pasco.com

web: www.pasco.com

Contacting Technical Support

Before you call the PASCO Technical Support staff, it

would be helpful to prepare the following information:

• If your problem is with the PASCO apparatus, note:

Name and model number (usually listed on the

label);

Approximate age of apparatus;

A detailed description of the problem/sequence of

events (in case you can’t call PASCO right away,

you won’t lose valuable data);

If possible, have the apparatus within reach when

calling to facilitate description of individual parts.

• If your problem relates to the instruction manual,

note:

Part number and revision (listed by month and

year on the front cover);

Have the manual at hand to discuss your questions.

7

Page 12

Loading...

Loading...