Page 1

Instruction Sheet

for the PASCO

Model ME-6617

ROCKET ENGINE TEST BRACKET

012-06418A

10/97

$1.00

Introduction

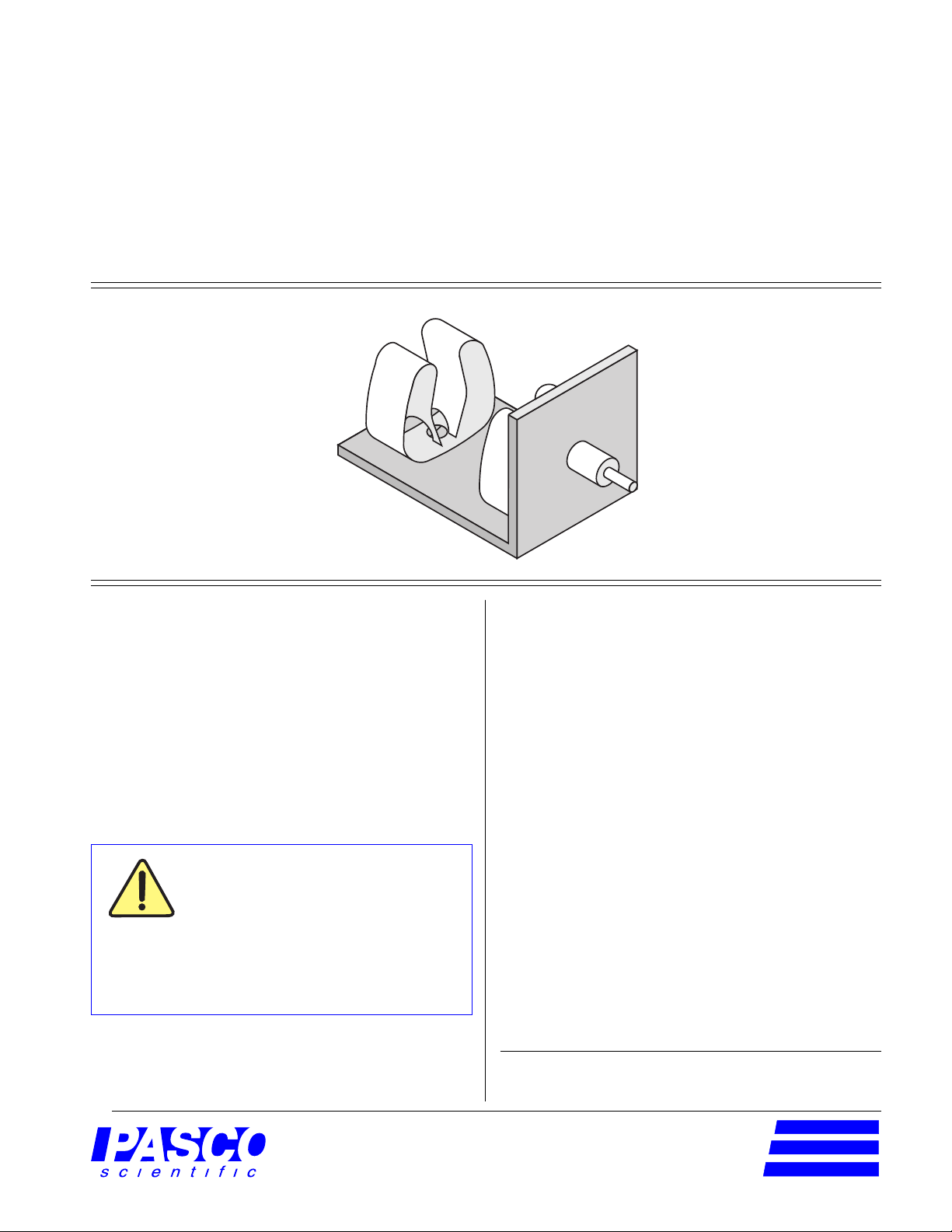

The PASCO ME-6617 Rocket Engine Test Bracket is

designed for use with the PASCO CI-6537 Force Sensor

and a PASCO computer interface to determine the

magnitude of impulse of Estes model rocket engines

(series A D). By permitting the measurement of the

impulse of an Estes model rocket engine, the Rocket

Engine Test Bracket can augment rocketry studies, such

as those detailed in the Estes Educator Teacher

Resources1.

The Rocket Engine Test Bracket

should be used only in a supervised

class setting by personnel who are

familiar with the National Association

of Rocketry Safety Code and after

complying with any state regulations

for igniting rocket engines.

1

For more information, contact Estes Industries, 1295

H. St., Penrose, CO 81240, 1-800-820-0202

1

Equipment

Included:

Rocket Engine Test Bracket

Additional Required:

Estes Model Rocket Engine (series A, B, C, or D)

Estes launch controller

Large Rod Stand (ME-8735)

90 cm support rod (ME-8738)

Force Sensor (CI-6537)

Science Workshop and a PASCO computer inter-

face (300, 500, or 700)

computer

➤

Note: Because of its remote data logging

capability, the PASCO 500 Interface is the most

practical computer interface to use with the

Rocket Engine Test Bracket.

© 1997 PASCO scientific

Editor: Sunny Bishop

®

10101 Foothills Blvd. • P.O. Box 619011 • Roseville, CA 95678-9011 USA

Phone (916) 786-3800 • FAX (916) 786-8905 • web: www.pasco.com

better

ways to

teach science

Page 2

Rocket Engine Test Bracket 012-06418A

➤ Read all the warnings and follow the instructions provided with the Estes Model Rocket Engine and Igniter.

➤ Review the National Association of Rocketry (NAR) Safety Code prior to igniting a rocket engine. Point

number 9 of the NAR Safety Code is of particular importance:

The system I use to launch my model rocket will be remotely controlled and electrically operated. It

will contain a launching switch that will return to off when released. The system will contain a

removable safety interlock in series with the launch switch. All persons will remain at least 15 feet (5

meters) from the model rocket when I am igniting model rocket engines totalling 30 newtonseconds

or less of total impulse . . . I will use only electrical igniters recommended by the engine manufacturer that will ignite model rocket engines within one second of actuation of the launching switch.

➤ Choose an asphalt or concrete launch area free of any combustible material, animals, or people.

➤ Use a remote electrical launching system that includes a safety key feature to ignite the model rocket engine.

Remote electrical launching is the only safe and approved way to ignite model rocket engines.

➤ Install igniters only when you are outdoors and almost ready to launch.

Important Safety Notes

➤ Wear safety glasses when installing the igniter and connecting the cables to the launch controller.

➤ Never put the safety key in the launch controller unless the exhaust area of the rocket engine is clear.

Otherwise, accidental ignition causing injury may result.

➤ Before igniting the rocket engine, check to be sure there are no objects, people, or animals near the exhaust of

the model rocket engine.

➤ Remove the safety key as soon as the rocket engine is ignited.

➤ Do not allow the igniter leads or alligator clips on the cables to touch each other.

➤ Wait 10 minutes after ignition of the rocket engine before touching the Rocket Engine Test Bracketit will

be hot.

➤ Comply with any regulations from your state or country for igniting rocket engines.

➤ Use ony Series AD Estes model rocket engines.

➤ In the event of a misfire, remove the safety key from the controller and wait 60 seconds before disconnecting

the micro-clips. Then replace the igniter.

➤ Never store or transport model rocket engines with igniters installed.

2

Page 3

012-06418A Rocket Engine Test Bracket

➤

Setup

Note: Refer to the Users Guide to Science

Workshop (Sampling Options) for details on

Set up the equipment

adjusting the sampling rate.

1. Remove the hook from the end of the Force Sensor.

Use a small screwdriver to connect the Rocket

Engine Test Bracket to the Force Sensor in place of

the hook (Figure 1).

Remove hook.

Force Sensor

T

E

A

R

Figure 1

Attaching the Rocket Engine Test Bracket to the Force

Sensor

Screw into

threaded

connector.

screwdriver

2. Mount the Force Sensor on the support rod in one of

two ways: horizontally (Figure 2a) or vertically

(Figure 2b).

a

b

Force

Sensor

E

R

A

T

3. Open a Graph display.

➤

Note: If you are using a 500 computer interface,

prepare it for remote data logging (refer to the

Users Guide to Science Workshop (Remote Data

Measurement with the Science Workshop 500

Interface).

Prepare for Ignition

1. Move the equipment to the launch site.

2. Insert the igniter into the rocket engine and spread the

wires apart, leaving the paper separator in place

(Figure 3).

igniter

igniter

plug

tape separator

Wires

must not

touch each

other!

Rocket

Engine Test

Bracket

T

E

A

R

rod stand

at least

80 cm

Figure 2

a) horizontal mount b) vertical mount

3. Insert the model rocket engine into the test stand

with the engines exhaust port pointing away from

the Force Sensor.

Set up Science Workshop

1. Set up the Force Sensor in Science Workshop on ana-

log channel A.

2. Adjust the sampling rate for the Force Sensor to 500

Hz.

a b c d

Figure 3

Inserting the igniter into the model rocket engine

➤

Note: Carefully follow the instructions that

accompany the rocket engine and igniter.

3. Clip the alligator clips of the cables from the launch

controller to the igniter wires.

Note: Do not allow the igniter wires or

alligator clips to touch each other. Be certain that

the safety key is not in the launch controller.

Insure that the cables are well away from the

exhaust area (Figure 4) and the computer

interface is as far away from the exhaust area as

possible.

4. Plug the Force Sensors DIN connector into analog chan-

nel A.

3

Page 4

Rocket Engine Test Bracket 012-06418A

Integration

area = 8.51336 N s

model

rocket

engine

igniter

wires

Keep

exhaust

area clear!

cable clips

Figure 4

Completed experimental setup

Force

Sensor’s

TARE

button

T

E

A

R

5. Press the TARE button on the Force Sensor

➤ Note: For the 500 interface in remote mode,

press the TARE button after the log button has

to electronic

launch controller

to computer

interface

(Figure 4)

Run #1

Force (N)

0 5 10

0 2 4 6 8 10 12 14

Tim e (s)

Figure 5

Graph of typical experimental results of a test of an Estes

C6-3 model rocket engine

Suggested Activity

.

Calculate the expected height of a rocket propelled with

an identical rocket engine from the force and mass data,

and compare with the actual height attained in a flight test.

been pressed and the LED has flashed 10 times.

6. Check the exhaust area to ensure it is clear of any

combustible material, people, or animals.

Data Collection

1. Insert the safety key into the launch controller.

2. Begin recording data and move to 15 feet (5 meters)

away from the Rocket Engine Test Bracket.

3. Ignite the rocket.

4. After the burn, stop recording data.

Data Analysis

1. In Science Workshop, click the statistics button and

select

Integration

the Autoscale button to resize the graph.

2. Select the area under the curve and record the

integrated value (impulse of the rocket engine).

3. Use the smart cursor to determine the time to the

ejection charge.

4. Compare your recorded values with the expected

values for the type of you are using.

from the pop-up menu, and click

Limited Warranty

PASCO scientific warrants the product to be free from

defects in materials and workmanship for a period of one

year from the date of shipment to the customer. PASCO

will repair or replace, at its option, any part of the product

which is deemed to be defective in material or

workmanship. The warranty does not cover damage to

the product caused by abuse or improper use.

Determination of whether a product failure is the result of

a manufacturing defect or improper use by the customer

shall be made solely by PASCO scientific. Responsibility

for the return of equipment for warranty repair belongs to

the customer. Equipment must be properly packed to

prevent damage and shipped postage or freight prepaid.

(Damage caused by improper packing of the equipment

for return shipment will not be covered by the warranty.)

Shipping costs for returning the equipment after repair will

be paid by PASCO scientific.

Address: PASCO scientific

10101 Foothills Blvd.

P.O. Box 619011

Roseville, CA 95678-9011

The exclamation point within an

equilateral triangle is intended to alert the

user of important operating and safety

instructions that will help prevent damage

to the equipment or injury to the user.

Phone: (916) 786-3800

FAX: (916) 786-8905

email: techsupp@pasco.com

web: www.pasco.com

4

Loading...

Loading...