Page 1

Instruction Manual

Manual No. 012-08295A

Energy-Transfer

Friction

Model No. ET-8770

Page 2

Page 3

Energy-Transfer Friction Model No. ET-8770

Table of Contents

Equipment List........................................................ 3-4

Introduction ............................................................. 5

Equipment Setup ..................................................... 5-7

Suggested Experiment .................................................. 8

Experiment 1: Using Friction to Heat a Cylinder ...................................................................... 8-9

Sample Data/Results...................................................10

Appendix A: Temperature-to-Resistance Conversion Chart ........ 10

Appendix B: DataStudio Setup Instructions ....................... 11

Appendix C: Creating Equations in DataStudio....................... 12

Appendix D: Technical Support ....................................... 13

Appendix E: Copyright and Warranty Information .................. 13

2

®

Page 4

Model No. ET-8770 Energy Transfer - Friction

Energy Transfer -

Friction

Model No. ET-8770

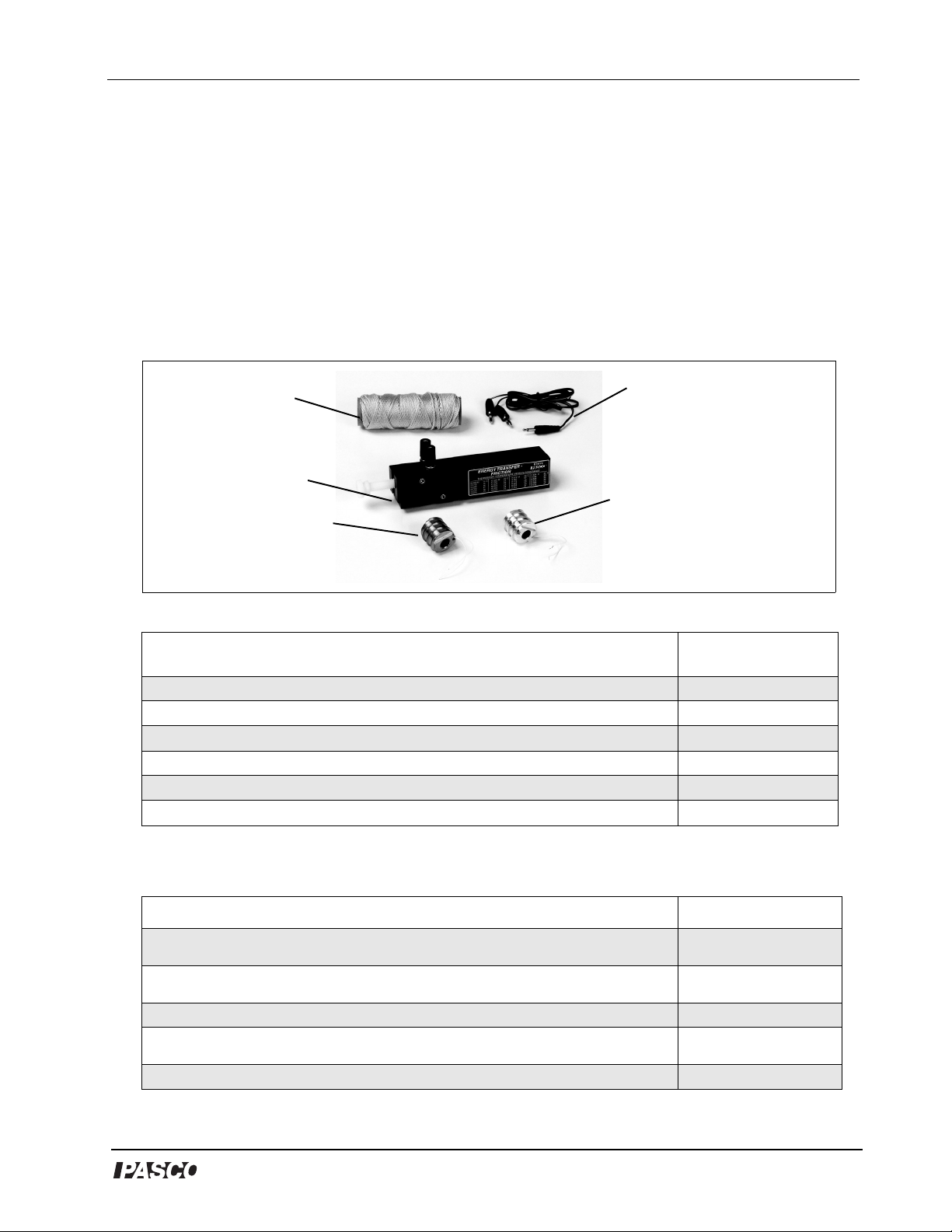

Equipment List

3

1

4

Included Equipment Replacement

1. Base, 29 kg, 15.2 cm

2. Cable Assembly

3. Braided Cord, #18 yellow, 240 feet

4. Brass Thermal Conductor, 10 g

5. Aluminum Thermal Conductor, 4 g

6. Plastic bolt, 1 g

2

5

Model Number*

648-08275

514-08366

699-067

648-08277

648-08276

613-094

*Use Replacement Model Numbers to expedite replacement orders.

Additional Equipment Required

Any PASCO data interface (

DataStudio® software

Hooked Mass Set

Force Sensor or Spring Scales

Rotary Motion Sensor

®

ScienceWorkshop

®

or PASPORT™)

Various

(See PASCO catalog)

Various

(See PASCO catalog)

SE-8759 or SE-8705

PS-2104 or CI-6537 or

SE-8718

PS-2120 or CI-6538

3

Page 5

Energy Transfer - Friction Model No. ET-8770

Additional Equipment Required

Temperature Sensor or Thermistor Sensor or Ohmmeter/Multimeter

C-Clamp

PS-2517*

or PS-2125* or PS-2134*

or CI-6527A**

SE-7285 or SE-7286

A computer

*PASCO’s PASPORT sensors (with PS- prefix) require a PASPORT interface for operation.

**PASCO’s

ScienceWorkshop

sensors (with CI-prefix) require a

ScienceWorkshop

interface for

operation.

NA

4

®

Page 6

Model No. ET-8770 Energy Transfer - Friction

Introduction

The Energy Transfer - Friction (ET-8770) apparatus is for

demonstrating frictional heating. With DataStudio software and a

Force and Rotary Motion Sensor, real-time computer measurement of

this frictional work can be observed.

The apparatus includes a friction base, which was specifically

designed for the attachment of a conductive cylinder, thermistor,

Temperature Sensor or ohmmeter, and a Rotary Motion Sensor.

A conductive cylinder with an embedded 10K thermistor fits into a slot

in the friction base. The cylinder is grooved for the placement of a

braided cord, which wraps around the metal cylinder and pulley of a

PASCO Rotary Motion Sensor.

One aluminum and one brass cylinder, each with a 10K thermistor, are

provided with the apparatus to allow the student to compare the

differences between aluminum and brass with frictional heating.

When the braided cord is attached to a Force Sensor and the student

pulls on the cord, friction is created between the cylinder and the cord.

The frictional work done on the metal cylinder causes an increase in

temperature, which is measured in real-time using a Temperature

Sensor.

Equipment Setup

1. Use a C-clamp to fasten the base to the left-front edge of a table.

2. Weigh the cylinder and record its mass. (If the cylinder is already

installed: Remove the cylinder by turning the plastic bolt

counterclockwise.)

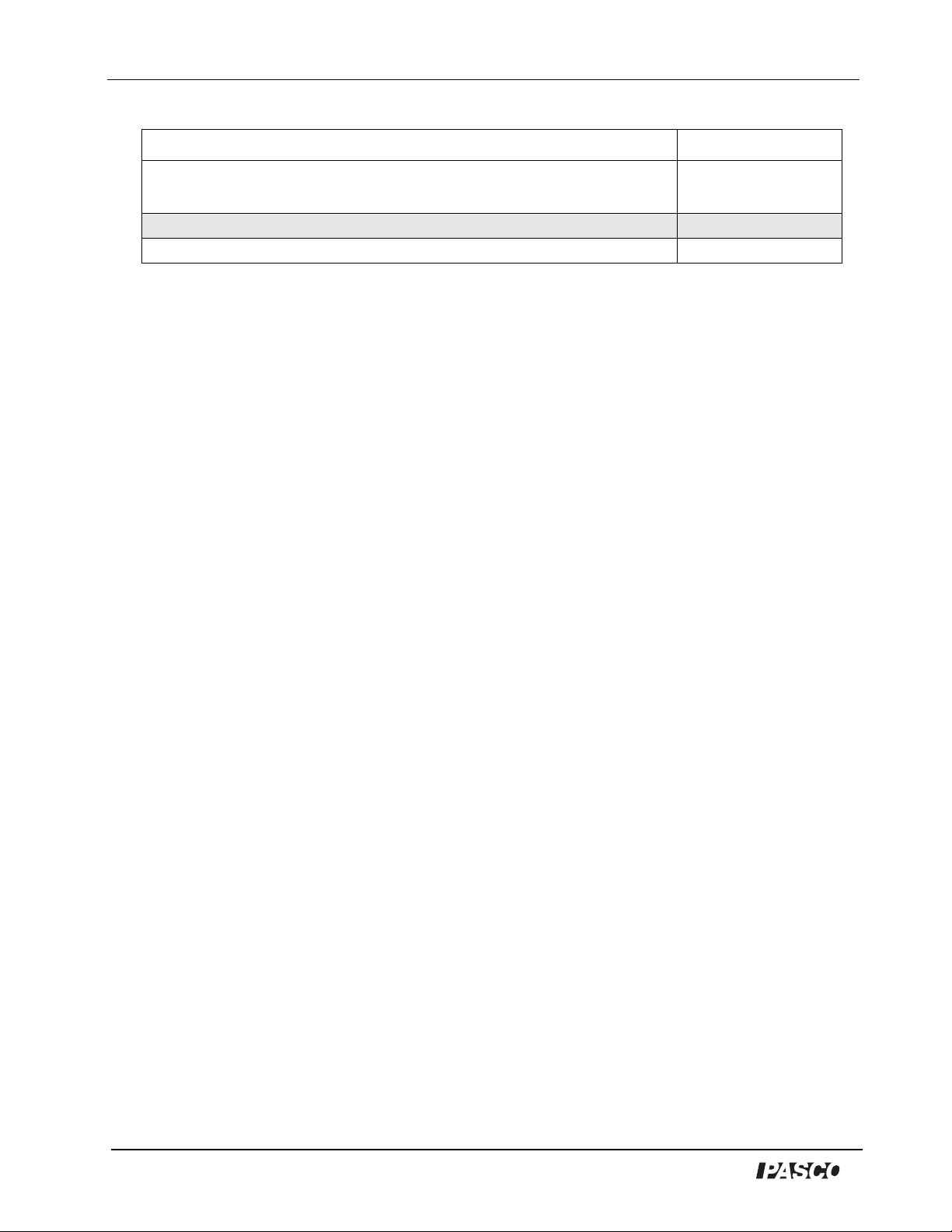

3. Insert the plastic bolt into

the cylinder.

bolt

cylinder

thermistor

banana jacks

wires

4. Place the cylinder next to

the side of the base that

has the hole. Turn the

cylinder, such that the

indented portion is at the

Figure 1: Inserting the cylinder

into the Friction Base

top, with the wires

pointing toward the base of the banana jacks (Figure 1).

5. Turn the bolt clockwise to fasten the cylinder to the apparatus.

®

5

Page 7

Energy Transfer - Friction Model No. ET-8770

6. Loosen the knobs on

the banana jacks and

Pulley

Rotary Motion Sensor

insert the stripped

portion of the wire

in the holes under

the jacks. (Note: Do

jacks

not kink the wires.

(Figure 1).) Screw

the knobs on the

banana jacks to hold

the wires in place.

Do not overtighten.

7. With the cable

Figure 2: Setup with Rotary

Motion Sensor

Attachment Screws

assembly, connect a

Temperature Sensor

(or Thermistor Sensor or ohmmeter) to the thermistor jacks.

(Figure 2).

8. Attach the Rotary Motion Sensor (RMS) to the inside of the base

(using the allen wrench on the cap screw of the RMS). Attach the

RMS, such that the large pulley faces toward the cylinder, but the

away from the table’s edge (Figure 2).

Note: If a Rotary Motion Sensor is not available, an introductory lab

can still be done using a simple average of the work performed, where

the work = average force times distance. Without a Rotary Motion

Sensor, you can measure the distance and manually calculate the work

performed. If a Force Sensor is not available, use a spring scale.

9. Hook a 24” piece of yellow cord to a hanging mass (about 200 g)

and a Force Sensor.

10. With one hand, hold the

hanging mass while you use

the other hand to wrap the

cord over the top groove in

the large pulley and over

each groove in the cylinder

(Figures 2 and 3).

11. Connect the Temperature,

Force and Rotary Motion

Sensors to a computer

interface (ScienceWorkshop

or PASPORT interface).

Figure 3: Wrapping the cord

around the pulley and cylinder

6

®

Page 8

Model No. ET-8770 Energy Transfer - Friction

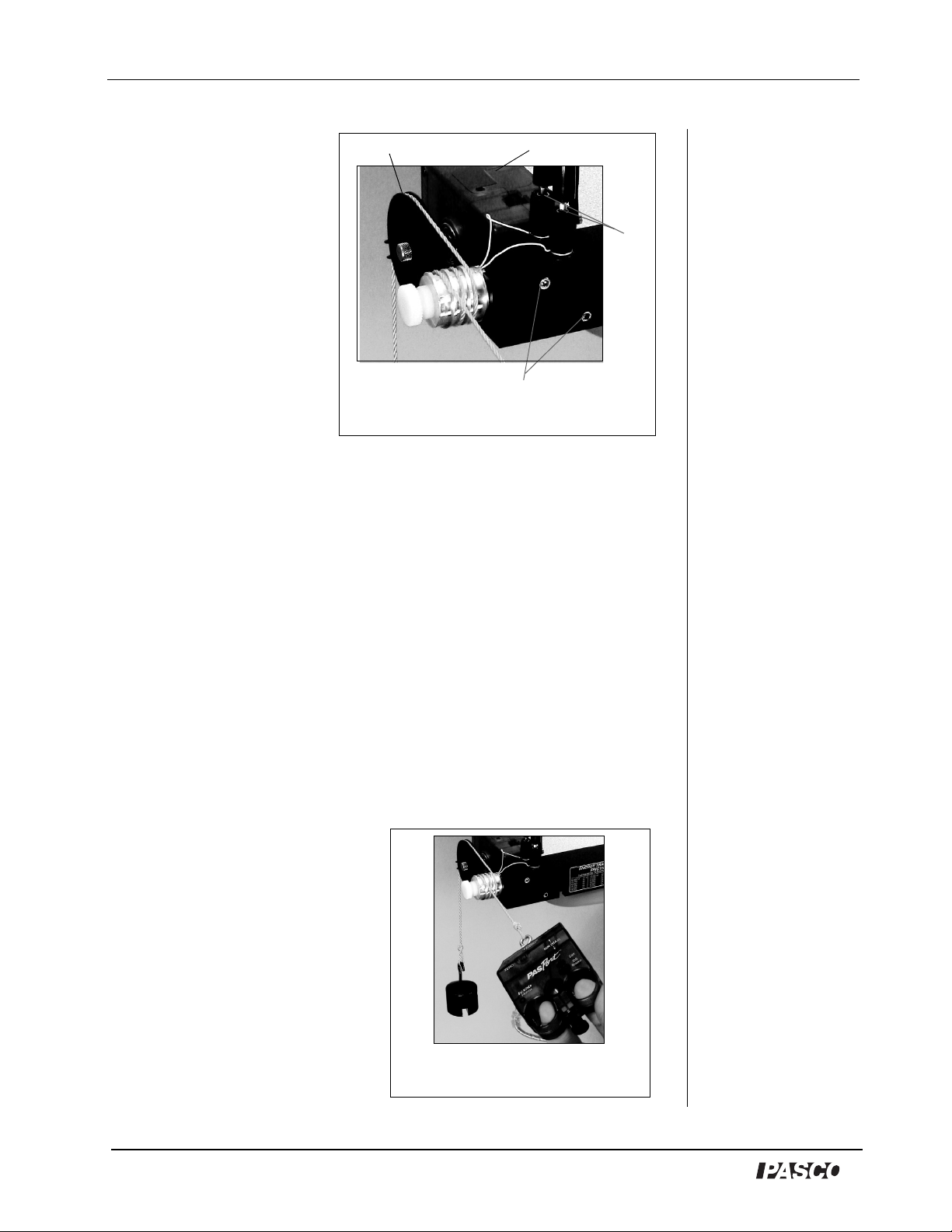

12. In DataStudio, set up

your experiment. (For

instructions, see

appendices B and C of

this manual).

13. In DataStudio, click the

Start button to begin

collecting data.

Note: If using an

ohmmeter, use the

conversion chart on the

front of the friction base to

find the temperature

Figure 4: Complete Setup

change. (If the resistance

reading is outside the range

on the friction base, see the conversion chart in Appendix A).

®

7

Page 9

Energy Transfer - Friction Model No. ET-8770

Suggested Experiment:

Experiment 1: Using Friction to Heat a Cylinder

Equipment Required

Energy Transfer Friction Apparatus

(ET-8770)

Force Sensor (PS-2104 or CI-6537) Rotary Motion Sensor (PS-2120

Temperature Sensor (PS-2515) or

CI-6505 or CI-6527A

DataStudio software (various, see

PA S C O c at a lo g)

Set of Hanging Masses (SE-8759

or 8705)

or CI-6538)

Computer Interface

(

ScienceWorkshop

C-clamp (SE-7285 or SE-7286)

Introduction:

In this experiment, the student

pulls on a cord wrapped around a

pulley, which in turn does the

work to overcome friction

between the cord and the cylinder.

The energy created from the

friction heats the cylinder. With a

Force Sensor connected to an

interface, the computer accurately

measures the work done by the

student.

Figure 1: Experiment

Setup

or PASPORT)

Procedure:

1. Follow the setup instructions on page 5-7 of this manual.

2. Tare the Force sensor in a horizontal position with no force.

3. Cut a short section (about 2 feet) of yellow cord, and tie a loop in

each end. Hook one end to the Force Sensor and the other end to a

mass hanger.

Note: The cord may wear out after a few trials. Replace the cord

before each lab experiment.

4. In DataStudio, enter the mass and specific heat of the cylinder as

experiment constants in the heat equation.

8

®

Page 10

Model No. ET-8770 Energy Transfer - Friction

5. Hang a large enough mass (around 200g) from the pulley, so that

when the cord is pulled back, the Force Sensor moves back

torwards the cylinder. If the mass is too big, you will overshoot the

sensor’s measurement range when you pull. In DataStudio, watch

the small Force vs. Time graph as you pull. Adjust the hanging

mass so that the force doesn’t exceed 50 N.

Note: When using sensors

6. Connect the Force, Rotary Motion, and Temperature Sensors to a

ScienceWorkshop or PASPORT interface. (For DataStudio setup

instructions, see Appendices B and C.)

7. Set the sample rate for both the Force and Rotary Motion Sensors to

50 Hz. Set the sample rate for the Temperature Sensor to 2 Hz (for

PASPORT sensors) or 50 Hz (for ScienceWorkshop sensors).

8. In DataStudio, create a graph of Force vs. Time.

9. In DataStudio, click the Start button and pull on the Force Sensor

with full, even strokes. (Note: With each pull, let the mass pull the

cord back. Don’t let loose too much on the cord, or the cord will

fall out of the groove.)

10. Let the computer keep running after you stop doing work until the

peak temperature is reached.

11. Find the area (work done by the student) under the power vs. time

graph. Compare the heat energy generated in the cylinder to the

total work done. What percentage is transferred? Use the

equation, percent (%) = (heat)/(work) x 100.

to collect data, all sensors

must be of the same type

(either all PASPORT

sensors or all ScienceWorkshop sensors) and

connect to the same type

of interface as the sensor.

Connect all PASPORT

sensors to a PASPORT

interface(s); connect all

ScienceWorkshop sensors

to a ScienceWorkshop

interface(s). Do not mix

PASPORT and ScienceWorkshop sensors in this

experiment. DataStudio

will not run with both

types of sensors connected

at the same time. For

either PASPORT or

ScienceWorkshop instructions, see appendices B

and C in this manual.

12. (Optional): Repeat the experiment with the brass cylinder and

compare your results with the aluminum cylinder. Which cylinder

heated faster? Why?

Note: The work done to heat the cylinder is from the student

overcoming the friction, not from the change in gravitational potential

energy of the hanging mass. The change in gravitational potential

energy does no net work.

®

9

Page 11

Energy Transfer - Friction Model No. ET-8770

Sample Data/Results

Appendix A: Resistance-to-Temperature Conversion

Table

Resistance

(Ohms)

5,776 38 3,888 48

5,546 39 3,742 49

5,326 40 3,602 50

5,118 41 3,468 51

4,918 42 3,340 52

4,726 43 3,216 53

4,544 44 3,098 54

4,368 45 2,986 55

4,202 46 2,878 56

4,042 47 2,774 57

Note: The front of the friction base includes a printed table of resistance-totemperature conversions (from 15°C to 37°C).

Temperature

(Celsius)

Resistance

(Ohms)

Temperature

(Celsius)

10

®

Page 12

Model No. ET-8770 Energy Transfer - Friction

Appendix B: DataStudio Setup Instructions

The instructions below outline the recommended experiment setup for PASPORT and

ScienceWorkshop sensors. Follow the steps specific for the type of sensor and interface (i.e.

PASPORT or ScienceWorkshop). (For a setup example, see “Sample Data” in this manual.)

Procedure Steps

PART I: Plug the

sensors into the

interface:

PART II: Set up your

experiment

PASPORT: a) Plug the Force, Rotary Motion, and Temperature Sensors

into a PASPORT interface. b) Connect the PASPORT interface (i.e.

USB Link, PowerLink, etc.) to a USB port on your USB-compatible

computer. c) When the PASPORTAL window opens, select “Launch

DataStudio.”

OR

ScienceWorkshop: a) Plug the Force, Rotary Motion, and Temperature

Sensors into a

PASPORT: a ) In the Experiment Setup window, scroll to the Force

Sensor, select “pull, positive” and set the sample rate to 50 Hz. b) Scroll

to the Rotary Motion Sensor, select “large pulley, ” “linear velocity,” and

set the sample rate to 50 Hz. c) Scroll to Temperature Sensor, select

“Celsius” and set the sample rate to 2 Hz.

OR

ScienceWorkshop: a) In the Welcome to DataStudio window, double

click “Create Experiment.” b) In the Sensors list, click and drag the Force

Sensor, Rotary Motion and Temperature Sensor icons to channels on

the picture of the interface (i.e. to the same letters in which you have the

sensors connected.) c) In the Experiment Setup window, double click

on each of sensor icons to set the sample rate and select the

measurement units: i) Force Sensor - In the General tab, set the sample

rate to 50 Hz. In the Measurement tab, select “Force(N).” Click OK.

(Note: If calibrating, use the Calibrate tab to tare the Force Sensor at 0

Newtons.) ii) Rotary Motion Sensor - In the General tab, set the sample

rate to 50 Hz. In the Measurement tab, select “position(m)” and “velocity

(m/s).” In the Rotary Motion Sensor tab, select “1440” and “large pulley

(groove).” Click OK. iii) Temperature Sensor - In the General tab, set the

sample rate to 50 Hz. In the Measurement tab, select “C.” Click OK.

ScienceWorkshop

interface. b) Launch DataStudio.

PART III: Create the

power and heat

equations

a) Power equation: Power=F*v, where F= force in Newtons and

v=velocity in m/s. b) Heat equation: Q=m*c*(max(T) - min(T)), where Q

= heat in joules, c=0.896 J/g

°C for the aluminum cylinder (or 0.377 J/g

°C for the brass cylinder), and T=the temperature in degrees Celsius.

[Select “data measurement” for the “F” and “v” and “T” variables. Create

an experiment constant for “m” (the mass) and “c” (the specific heat).

(For instructions, see Appendix C or the DataStudio online help.)]

PART IV: Collect Data a) From the Data list, drag each of the parameters (i.e force,

temperature, power) over a y-axis in a separate graph display. b) Drag

the heat parameter to a Digits display. c) Click the Start button on the

main toolbar.

®

11

Page 13

Energy Transfer - Friction Model No. ET-8770

Appendix C: Creating Equations in DataStudio

Step 2: Type in and/or

build the equation.

(Use the Scientific,

Statistical, and Special

menus, and the

trigonometric functions

to build the equation.)

Click the Accept button.

Step 3: Define the

dependent variables.

Under “Variables,” use

the down arrow to select

a variable or constant,

etc. and click OK.

(Example: For “T,” select

“Data Measurement.” In

the pop-up, select

“Temperature,” and click

OK. Under Variables, for

“m” and “c”, proceed to

step 4, creating the

experiment constant.)

Step 1: Create a new equation. On the main toolbar,

click the Calculate button to open the Calculator

dialog. In the Calculator dialog, click the New button.

Step 4: Enter any experiment

constants. Use the (+) button to

create an experiment constant. Click

New, then enter the name, value and

units for the constant. Click the

Accept button. Go back to the

Variables menu and select “experiment

constant” (e.g. for “m” and “c”). Click

OK.

Step 6: Save the

equation. Click

the Accept

button.

Step 5: Label the

units. Click on the

Properties button to

open the Data

Properties dialog and

enter the name and

units. (Example: In

the Data Properties

dialog, type “specifc

heat” in the name box

and “J/g

units box.)

°C ” in the

12

Note: Each time you build a new equation, click the New button. To edit a completed

equation, double click on the equation in the Data list, make your changes, and click the

Accept button to save your changes.

®

Page 14

Model No. ET-8770 Energy Transfer - Friction

Appendix D: Technical Support

For assistance with the Energy-Transfer Friction Apparatus (ET-8770) or any other PASCO

products, contact PASCO as follows:

Address: PASCO scientific

10101 Foothills Blvd.

Roseville, CA 95747-7100

Phone: (916) 786-3800

FAX: (916) 786-3292

Web: www.pasco.com

Email: techsupp@pasco.com

Appendix E: Copyright and Warranty Information

Copyright Notice

The PASCO scientific 012-08295A Energy - Transfer Friction Manual is copyrighted and all

rights reserved. However, permission is granted to non-profit educational institutions for

reproduction of any part of the 012-08295A Energy - Transfer Friction Manual, providing

the reproductions are used only for their laboratories and are not sold for profit. Reproduction

under any other circumstances, without the written consent of PASCO scientific, is

prohibited.

Limited Warranty

PASCO scientific warrants the product to be free from defects in materials and workmanship

for a period of one year from the date of shipment to the customer. PASCO will repair or

replace, at its option, any part of the product which is deemed to be defective in material or

workmanship. The warranty does not cover damage to the product caused by abuse or

improper use. Determination of whether a product failure is the result of a manufacturing

defect or improper use by the customer shall be made solely by PASCO scientific.

Responsibility for the return of equipment for warranty repair belongs to the customer.

Equipment must be properly packed to prevent damage and shipped postage or freight

prepaid. (Damage caused by improper packing of the equipment for return shipment will not

be covered by the warranty.) Shipping costs for returning the equipment after repair will be

paid by PASCO scientific.

®

13

Loading...

Loading...