Page 1

Instruction Manual and

Experiment Guide for the

PASCO scientific

Model CI-6734

SODIUM ION SELECTIVE

ELECTRODE

012-06615A

9/97

© 1997 PASCO scientific $7.50

®

10101 Foothills Blvd. • P.O. Box 619011 • Roseville, CA 95678-9011 USA

Phone (916) 786-3800 • FAX (916) 786-8905 • web: www.pasco.com

better

ways to

teach science

Page 2

Sodium Ion Selective Electrode 012–06615A

Always use eye protection

and gloves when working

with chemicals.

Page 3

012–06615A Sodium Ion Selective Electrode

Table of Contents

Introduction......................................................................................................................................... 1

Theory .................................................................................................................................................. 1

Equipment ........................................................................................................................................... 2

Included ........................................................................................................................................ 2

Additional Required...................................................................................................................... 2

Required Solutions.............................................................................................................................. 2

General Preparation ........................................................................................................................... 4

Electrode Preparation.................................................................................................................... 4

Electrode Slope Check Using Science Workshop .......................................................................... 4

Measurement....................................................................................................................................... 5

Measuring Hints............................................................................................................................ 5

Sample Requirements ................................................................................................................... 5

Units of Measurement................................................................................................................... 5

Measurement Procedure .................................................................................................................... 6

Direct Measurement of Sodium ....................................................................................................6

Low Level Sodium Determination ............................................................................................... 7

Electrode Characteristics ................................................................................................................... 8

Reproducibility ............................................................................................................................. 8

Interferences.................................................................................................................................. 8

Temperature Influences................................................................................................................. 9

Electrode Response ..................................................................................................................... 10

Limits of Detection ..................................................................................................................... 10

pH Effects ................................................................................................................................... 10

Electrode Life ............................................................................................................................. 11

Maintenance .......................................................................................................................................11

Electrode Storage ........................................................................................................................ 11

Specifications..................................................................................................................................... 12

Troubleshooting Guide ..................................................................................................................... 12

Glassware/Plastic-ware ............................................................................................................... 12

Electrode ..................................................................................................................................... 12

Standards & Reagents ................................................................................................................. 13

Sample ........................................................................................................................................ 13

Technique .................................................................................................................................... 13

Troubleshooting Hints ...................................................................................................................... 13

Technical Support ............................................................................................................................. 17

i

Page 4

Copyright, Warranty , and Equipment Return

PleaseFeel free to duplicate this manual

subject to the copyright restrictions below.

Copyright Notice

The PASCO scientific 012-06615 A manual is

copyrighted and all rights reserved. However,

permission is granted to non-profit educational

institutions for reproduction of any part of the Sodium

Ion Selective Electrode manual providing the

reproductions are used only for their laboratories and

are not sold for profit. Reproduction under any other

circumstances, without the written consent of PASCO

scientific, is prohibited.

Limited Warranty

PASCO scientific warrants the product to be free from

defects in materials and workmanship for a period of

one year from the date of shipment to the customer.

PASCO will repair or replace at its option any part of

the product which is deemed to be defective in

material or workmanship. The warranty does not

cover damage to the product caused by abuse or

improper use. Determination of whether a product

failure is the result of a manufacturing defect or

improper use by the customer shall be made solely by

PASCO scientific. Responsibility for the return of

equipment for warranty repair belongs to the

customer. Equipment must be properly packed to

prevent damage and shipped postage or freight

prepaid. (Damage caused by improper packing of the

equipment for return shipment will not be covered by

the warranty.) Shipping costs for returning the

equipment after repair will be paid by PASCO

scientific.

Credits

Author: Peter Boyle

Editor: Steve Miller

Equipment Return

Should the product have to be returned to PASCO

scientific for any reason, notify PASCO scientific by

letter, phone, or fax BEFORE returning the product.

Upon notification, the return authorization and

shipping instructions will be promptly issued.

ä

NOTE: NO EQUIPMENT WILL BE

ACCEPTED FOR RETURN WITHOUT AN

AUTHORIZATION FROM PASCO.

When returning equipment for repair, the units must

be packed properly. Carriers will not accept

responsibility for damage caused by improper

packing. To be certain the unit will not be damaged in

shipment, observe the following rules:

➀ The packing carton must be strong enough for the

item shipped.

➁ Make certain there are at least two inches of packing

material between any point on the apparatus and the

inside walls of the carton.

➂ Make certain that the packing material cannot shift in

the box or become compressed, allowing the

instrument come in contact with the packing carton.

Address: PASCO scientific

10101 Foothills Blvd.

P.O. Box 619011

Roseville, CA 95678-9011

Phone: (916) 786-3800

FAX: (916) 786-3292

email: techsupp@pasco.com

web: www.pasco.com

ii

Page 5

012–06615A Sodium Ion Selective Electrode

E=E

S

X

E

X

X

γ

C

1

C

X

Introduction

The PASCO scientific Sodium Ion Selective Electrode is used to quickly, simply, accurately, and economically

measure sodium ions in aqueous solutions.

Theory

The Sodium Ion Selective Electrode is composed of a sodium-selective glass membrane bonded to a glass body.

When the membrane is in contact with a solution containing sodium ions, an electrode potential develops across

the membrane. This electrode potential is measured against a constant reference potential, using an ISE Amplifier

and a ScienceWorkshop computer interface. The level of sodium ions, corresponding to the measured potential, is

described by the Nernst equation.

log

+

0

where:

= measuredelectrodepotential

= referencepotential(a constant)

E

0

mV

S = electrodeslope( ≈ 59

decade

)

= level ofsodiumionsin solution

The activity, X, represents the effective concentration of free sodium ions in the solution. The activity is related to

the free ion concentration, C

, by the activity coefficient, γ by:

ƒ

=

ƒ

Activity coefficients may vary, depending on the total ionic strength, I, determined as:

I =

ΣCXZ

2

2

X

where:

= concentrationofion

X

ZX= charge of ion X

Σ = sum of all of the types of ions in the solution

In the case of high and constant ionic strength relative to the sensed ion concentration, the activity coefficient, γ is

constant and the activity, X, is directly proportional to the concentration.

1

Page 6

Sodium Ion Selective Electrode 012–06615A

To adjust the background ionic strength to a high and constant value, ionic strength adjuster is added to samples

and standards. The recommended ISA for sodium is an ammonium chloride/ammonium hydroxide buffer.

Solutions other than this may be used as ionic strength adjusters as long as ions that they contain do not interfere

with the electrode’s response to sodium ions.

Equipment

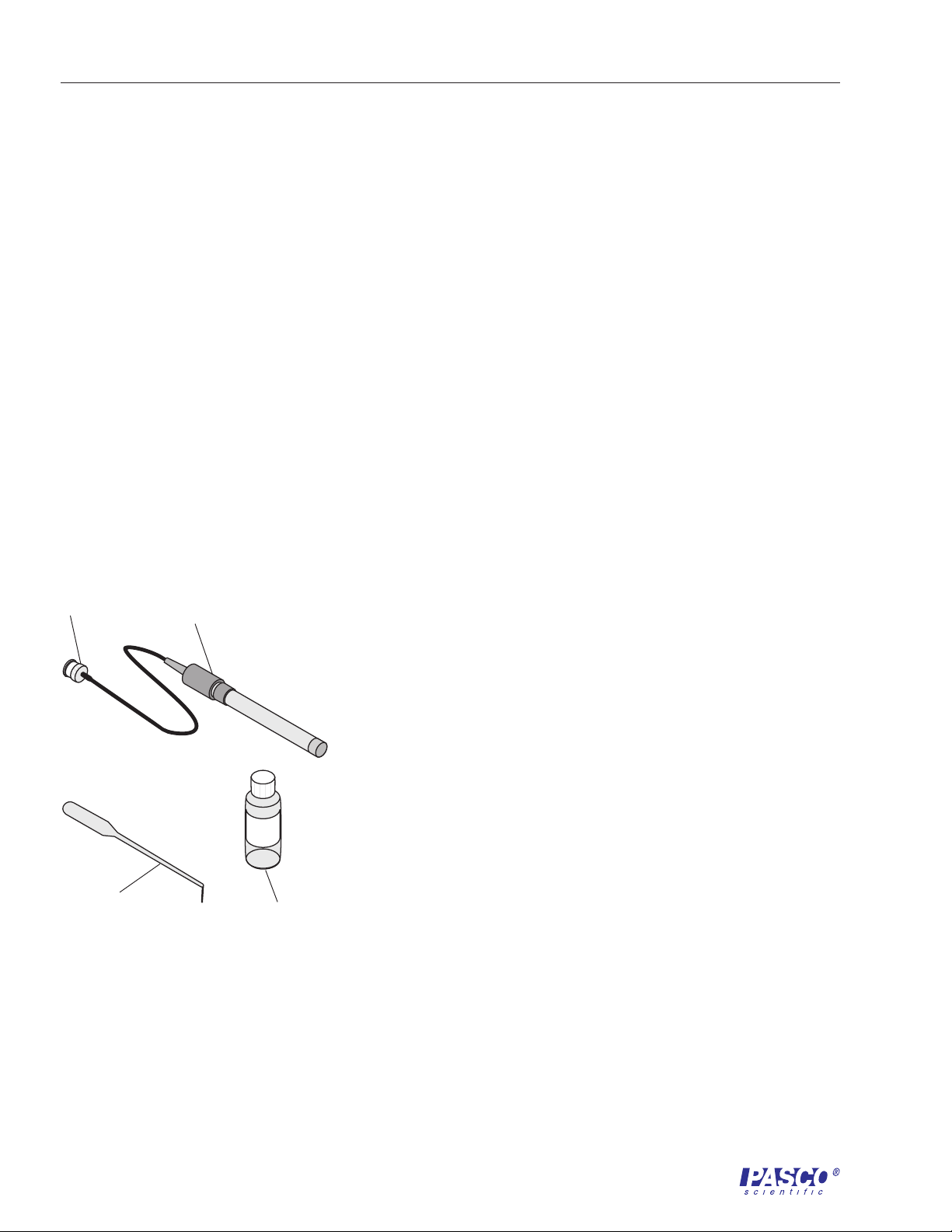

Included:

to ISE

Amplifier

• Sodium Ion Selective

Electrode

• Sodium Ion Selective

Electrode fill solution

• pipette for fill solution

Sodium Ion Selective

Electrode

Additional Required:

Required Equipment

• PASCO CI-6738 ISE (Ion Selective Electrode) Amplifier

• Science Workshop 2.2.5 or higher

• PASCO Science Workshop Computer Interface

• Semilogarithmic 4-cycle graph paper for preparing

calibration curves.

• magnetic stir plate

• Lab-ware made of plastic, not glass, for all low level

measurements.

Required Solutions

The stock solutions described in this section may be created as

described in the text or ordered directly from PASCO. The solutions

available for order, and their respective prices are listed on the ‘ISE

Working Solution Price List’.

• Deionized or distilled water for solution and standard

preparation.

filling pipette

Figure 1.

Included Equipment

2

R

O

R

O

1

e

f

e

r

0

1

3

S

e

n

c

e

Fi

l

l

4

M

K

E

L

P

M

A

n

tio

u

l

o

S

I

C

filling

solution

• Ionic Strength Adjuster (ISA), 4 M NH

Cl/4 M NH4 OH

4

To prepare this solution, half fill a 1000 ml volumetric flask

with distilled water and add 214 grams of reagent-grade

ammonium chloride (NH

concentrated ammonium hydroxide (NH

Cl). Under a hood, add 270 ml of

4

OH), swirl the

4

flask gently to dissolve the solid, and allow to cool. Fill the

flask to the mark with distilled water, cap, and upend

several times to mix the solution.

• Sodium Electrode Storage Solution, 5 M NaCl

To prepare this solution, add 29.2 grams of reagent-grade

sodium chloride (NaCl) to 100 ml of distilled water. To

each 100 ml storage solution, add 2 ml of ISA.

Page 7

012–06615A Sodium Ion Selective Electrode

ä

Note: Electrodes must not be stored in distilled water or air. Do not rinse with

distilled water.

• Dilute Electrode Rinse Solution

To prepare this solution from your own laboratory stock, add 20 ml of ISA to a one liter volumetric flask

and fill to the mark with distilled water. Use this solution to rinse the electrode between measurements.

• Sodium Standard, 0.1 M NaCl

To prepare this solution, half fill a one liter volumetric flask with distilled water and add 5.84 grams of

reagent-grade NaCl. Swirl the flask gently to dissolve the solid. Fill the flask to the mark with distilled water,

cap, and upend several times to mix the solution.

• Sodium Standard, 1,000 ppm Na

+

To prepare this solution, half fill a one liter volumetric flask with distilled water and add 2.542 grams of

reagent grade NaCl. Swirl the flask gently to dissolve the solid. Fill the flask to the mark with distilled water,

cap, and upend several times to mix the solution.

• Sodium Standard, 100 ppm Na

+

To prepare this solution, half fill a one liter volumetric flask with distilled water and add 0.254 grams of

reagent grade NaCl. Swirl the flask to dissolve the solid. Fill the flask to the mark with distilled water, cap,

and upend several times to mix the solution.

3

Page 8

Sodium Ion Selective Electrode 012–06615A

General Preparation

fill hole

Electrode Preparation

1. Remove the rubber cap covering the electrode tip and

the rubber insert covering the filling hole of the Sodium

Ion Selective Electrode. Fill the electrode with the

included filling solution to a level just below the fill

hole. No preparation is required with a sealed reference

electrode.

a

rubber

sleeve

rubber cap

2. Connect the Sodium Ion Selective Electrode to the ISE

Amplifier and insert the DIN connector of the ISE

Amplifier into analog channel A or B on a PASCO

Computer Interface (Figures 2b and 2c).

Electrode Slope Check Using ScienceWorkshop

(check electrodes each day)

1. To a 150 ml glass beaker, add 100 ml of distilled water

and 2 ml of ISA. Place the beaker on a magnetic stirrer

and begin stirring at a constant rate. Start the

ScienceWorkshop software, select the Ion Selective

Electrode sensor, open a Digital display, change the

number of digits to the right of the decimal from 1 to 3,

and begin monitoring data. Lower the electrode tip into

the solution.

2. Using a pipette, add 1 ml of 0.1 M or 1,000 ppm sodium

standard to the beaker. When the reading has stabilized,

record the voltage reading indicated in the Digits display.

3. Using a pipette, add 10 ml of the same sodium standard

used above to the beaker. When the reading has stabilized,

record the voltage reading indicated in the Digits display.

4. Determine the difference between the two readings. A

difference of 59 ± 4mV indicates correct electrode

operation assuming the solution temperature is between

20 °C and 25 °C. See the Troubleshooting sections if

the potential change is not within this range.

b

Insert DIN

connector into

analog channel

A or B .

Rotate ring

c

one-quarter

turn to secure

electrode

connector

Figure 2

Equipment Setup. a: filling the electrode

with filling solution; b & c: connecting the

electrode to the ISE Amplifier and to the

computer interface

ISE Amplifier

➤ Note: Slope is defined as the change in potential observed when the concentration

changes by a factor of 10.

4

Page 9

012–06615A Sodium Ion Selective Electrode

Measurement

Measuring Hints

• All samples and standards should be at the same temperature for precise measurement, preferably ambient

temperature. A difference of l °C in temperature will result in about a 2% measurement error. The electrodes

should not be used above 70 °C.

• Constant, but not violent, stirring is necessary for accurate measurement. Magnetic stirrers can generate

sufficient heat to change the solution temperature. To counteract this effect, place a piece of insulating

material, such as a styrofoam sheet, between the stirrer and the beaker.

• Always rinse the electrodes with electrode rinse solution from a wash bottle between measurements. Use

a clean, dry tissue to prevent cross contamination. Never use distilled water.

• Store the electrodes in electrode storage solution between measurements. Do not store in air or distilled

water. Always soak new electrodes overnight in electrode storage solution prior to first use. When making

low level sodium measurements, use a dilute sodium chloride storage solution. Add 1 ml of ISA to 100 ml

of dilute storage solution.

• Plastic lab-ware should be used for low level measurements (< 1 ppm).

• All measurements should be made in basic solution. All samples and standards should be adjusted to a pH

> 9 with ISA.

• For samples with high ionic strength, prepare standards whose composition is similar to the sample.

• Always check to see that the membrane is free from air bubbles after immersion into standard or sample.

Sample Requirements

• The sample measuring range is pH 9–12. Use the ISA recommended to adjust the pH for best accuracy.

Make sure that the samples and standards are at the same temperature. The glass electrode sensing bulb will

not be attacked by most organic solvents.

Units of Measurement

Sodium concentrations are measured in units of parts per million, equivalents per liter, soles per liter, or any other

convenient concentration unit. Table 1 indicates some of the concentration unit conversion factors.

T ABLE 1 Concentration Unit Conversion Factors

ppm Na

229.90 1.0 X 10

+

22.99 1.0 X 10

2.30 1.0 X 10

moles/liter Na

+

-2

-3

-4

5

Page 10

Sodium Ion Selective Electrode 012–06615A

Measurement Procedure

Direct Measurement

Direct measurement is a simple procedure for measuring a large number of samples. A single meter reading is all

that is required for each sample. The ionic strength of samples and standards should be made the same by adjustment

with ISA for all sodium solutions. The temperature of both sample solution and of standard solutions should be the

same.

Direct Measurement of Sodium

ä

Note: A calibration curve is constructed on semilogarithmic paper. The measured

electrode potential (linear axis) is plotted against the standard concentration (log axis). In

the

linear region of the curve, only two standards are necessary to determine a calibration

curve. Calibration solutions close to the anticipated value of the “unknown” should be

chosen. In the

measurement procedures given are for the linear portion of the curve. The nonlinear

portion of the curve requires the use of low level procedures.

nonlinear region, additional points must be measured. The direct

1. By serial dilution of the 0.1 M or 1,000 ppm standards, prepare 100 ml of l0

-2

M, l0

-3

M, and l0-4 M or

100 and 10 ppm sodium standards. Add 2 ml of ISA per 100 ml of standard. Prepare standards with a

composition similar to the samples if the samples have an ionic strength above 0.l M

2. Place the most dilute solution (l0

-4

M or 10 ppm) in a beaker Place the beaker on the magnetic stirrer and

begin stirring at a constant rate. After assuring that ScienceWorkshop is operating, lower the electrode

tip into the solution. When the reading has stabilized, record the voltage reading indicated in the Digits

display.

3. Place the mid-range solution (l0

-3

M or 100 ppm) in a beaker. Place the beaker on the magnetic stirrer

and begin stirring. After rinsing the electrodes with electrode rinse solution, blot dry and immerse the

electrode tip in the solution. When the reading has stabilized, record the voltage reading indicated in the

Digits display.

4. Place the most concentrated solution (l0

-2

M or 1,000 ppm) in a beaker. Place the beaker on the magnetic

stirrer and begin stirring. After rinsing the electrodes with electrode rinse solution, blot dry and immerse

the electrode tip in the solution. When the reading has stabilized, record the voltage reading indicated in

the Digits display.

5. Using the semilogarithmic graph paper, plot the voltage reading (linear axis) against the concentration

(log axis). Extrapolate the curve down to about 5.0Xl0

-5

M. For measurements below this level, follow

the instructions for low-level measurement. A typical calibration curve can be found in Figure 3.

6

Page 11

012–06615A Sodium Ion Selective Electrode

+140

+100

10-fold change

+60

~59 mV

electrode

+20

potential

(mV)

-20

-60

10

0.1 1 10

-6

10

-5

10

(ppm)

- 4

10

100 1,000

-3

10

-2

10

-1

Na+ concentration (M)

Figure 3

Typical sodium electrode calibration curve

6. To a clean, dry 150 ml beaker, add 100 ml of sample and 2 ml of ISA. Place the beaker on the magnetic

stirrer and begin stirring. After rinsing the electrode tip with electrode rinse solution, blot dry and place

the electrode tip in the solution. When the reading has stabilized, record the Voltage reading in the Digits

Display. Using the calibration curve, determine the sample concentration.

7. The calibration should be checked every two hours. Assuming no change in ambient temperature, place

the electrode tip in the mid-range standard. After the reading has stabilized, compare it to the original

reading recorded in step 3 above. A reading difference by more than 0.5 mV or a change in the ambient

temperature will necessitate the repetition of steps 2-5 above. A new calibration curve should be prepared

daily.

Low Level Sodium Determination

This procedure is recommended for solutions with ionic strength less than 1.0x10

less than lxl0

-5

M or 1 ppm. If the solution is high in ionic strength, but low in sodium, use the same procedure, but

prepare a calibration solution with a composition similar to the sample. Use plastic lab-ware for low sodium

measurements.

-2

M and a sodium concentration

1. Using 20 ml of standard ISA, dilute to 100 ml with distilled water.

2. Dilute 20 ml of the outer chamber filling solution to 100 ml with distilled water and fill the reference

electrode if using a double junction reference electrode.

3. Dilute 1 ml of the 0.l M standard to 100 ml to prepare a 1.0Xl0

-3

M standard solution for measurements

in moles per liter. Dilute 10 ml of the 1000 ppm standard solution to 100 ml to prepare a 100 ppm standard

solution for measurements in ppm. Add 1 ml of low level ISA to each 100 ml of standard. Standards should

be prepared fresh daily.

4. Using a 150 ml plastic beaker, add 100 ml of distilled water and 1 ml of low level ISA. Add NH

OH, if

4

necessary, to adjust the pH above 9. Place the beaker on the magnetic stirrer and begin stirring at a constant

rate.

5. Place the electrode tip in the solution. Assure that ScienceWorkshop is operating.

7

Page 12

Sodium Ion Selective Electrode 012–06615A

6. Add increments of the l.0xl0

-3

M or 100 ppm standard as given in Table 2 below.

7. After the reading has stabilized, record the Voltage reading in the Digits display after each addition.

T ABLE 2: Step-wise Calibration for Low Level Sodium Measurements

Added

Concentration

Step Pipette Volume (ml) ppm M

1 A 0.1 0.10 l.0 X l0

2 A 0.1 0.20 2.0 X l0

3 A 0.2 0.40 4.0 X l0

4 A 0.2 0.60 6.0 X l0

5 A 0.4 0.99 9.9 X 10

6 B 2.0 2.91 2.9 X l0

7 B 2.0 4.76 4.8 X l0

-6

-6

-6

-6

-6

-5

-5

Pipette A = 1 ml graduated pipette

Pipette B = 2 ml pipette

Solutions: additions of 100 ppm or 1.0 X l0

-3

M standard to 100 ml of solution prepared in step 3 above

8. On semilogarithmic graph paper, plot the millivolt reading (linear axis) against the concentration (log

axis) as in Figure 3.

9. Rinse the electrodes with electrode rinse solution and blot dry.

10. To a 150 ml plastic beaker add 100 ml of sample and 1 ml of low level ISA. Place the beaker on the

magnetic stirrer and begin stirring. Adjust the pH, if necessary, to above 9. Lower the electrode tip into

the solution. After the reading has stabilized, record the Voltage reading in the Digits Display and

determine the concentration from the low level calibration curve.

11. Prepare a new low level calibration curve daily. Check the calibration curve every two hours by repeating

steps 3-8.

Electrode Characteristics

Reproducibility

Electrode measurements reproducible to +2% can be obtained if the electrode is calibrated every hour. Factors such

as temperature fluctuations, drift, and noise limit reproducibility. Reproducibility is independent of concentration

within the electrode’s operating range.

Interferences

Table 3 lists some common cations that, if present in high enough levels, will cause electrode interferences and

measurement errors or electrode drift when using the sodium ion electrodes.

Most samples do not contain or contain very little of the cations shown in Table 3. The ammonium ion (NH

4

in the recommended ISA, will not result in an error if all samples and standards have the same level of ISA present.

8

+

), found

Page 13

012–06615A Sodium Ion Selective Electrode

Electrode drift and slow response could indicate the presence of high interference from the ions listed. Soak the

electrodes in electrode storage solution when this happens to restore proper response. See Measuring Hints

section.

TABLE 3: Levels of Interfering Ions Resulting in a 10% Error at Specified Levels of Sodium

Interference 1.0X10

Li

K

Rb

NH

Ag

Tl

+1

+1

+1

+1

4

+1

+1

5X10

1X10

3X10

3X10

3X10

5X10

-4

M 1.0X10

-4

M 5X10

-2

M 1X10

-1

M3 M

-1

M3 M

-9

M 3X10

-2

M 5X10

-3

M 1.0X10

-3

M 5X10

-1

M1 M

-8

M 3X10

-1

M

Interference 1 ppm 10 ppm 100 ppm

+1

Li

K

Rb

NH

Ag

Tl

+1

+1

+1

4

+1

+1

1.5 ppm 15 ppm 150 ppm

17 ppm 170 ppm 1,700 ppm

1.1X104 ppm 1.1X105 ppm

1.8X103 ppm 1.8X104 ppm

0.0001 ppm 0.001 ppm 0.01 ppm

4.5X103 ppm 4.5X104 ppm

Temperature Influences

-2

M

-2

M

-7

M

Samples and standards should be at the same temperature, since electrode potentials are influenced by changes in

temperature. A l °C difference in temperature results in a 2% error at the l0

-3

M level. Because of solubility equilibria

on which the electrode depends, the absolute potential of the reference electrode changes slowly with temperature.

The slope of the electrode, as indicated by the factor “S” in the Nernst equation, also varies with temperature. Table

4 indicates the variation of theoretical slope with temperature.

Provided that temperature equilibria has occurred, the sodium ion electrodes can be used at temperatures from -5 °

to 70 °C. Room temperature measurements are recommended, since measurements at temperatures markedly

different from room temperature may require equilibrium times up to one hour. The electrode should not be used

at temperatures above 70 °C, since damage to the membrane may result.

T ABLE 4: T emperature vs. V alues for the Electrode Slope

Temperature ( ºC) “S”

0 54.20

10 56.18

20 58.16

25 59.16

30 60.15

40 62.13

50 64.11

9

Page 14

Sodium Ion Selective Electrode 012–06615A

Electrode Response

Plotting the electrode potential against the sodium concentration on semilogarithmic paper results in a straight line

with a slope of about 59 mV per decade. (Refer to Figure 1.)

The time needed to reach 99% of the stable electrode potential reading, the electrode response time, varies from

one minute or less for sodium concentrations above 1.0X10

to Figure 4.)

+125

+100

+75

+50

-5

M to several minutes near the detection limit. (Refer

10

-3

M to 10

-2

M NaCl

electrode

potential

(mV)

+25

-25

-50

-75

-3

10

0

-3

10

-3

10

1234

M to 10

-6

M NaCl

M to 10

M to 10

-4

M NaCl

-5

M NaCl

time (minutes)

Figure 4

Typical sodium electrode time response to step changes in NaCl

Limits of Detection

The upper limit of detection in pure sodium solutions is 1 M. In the presence of other ions, the upper limit of detection

is above l0

developing at the reference electrode and the salt extraction effect influence this upper limit. Some salts may extract

into the electrode membrane at high salt concentrations, causing deviation from the theoretical response. Either

dilute samples between l M and l0

Free sodium ion concentration down to l.0Xl0

below l0

occur from glassware due to removal from container walls.

-1

M sodium, but two factors influence this upper limit. Both the possibility of a liquid junction potential

-1

M or calibrate the electrode at 4 or 5 intermediate points.

-6

M or 0.1 ppm can be measured in basic solutions. For measurements

-5

M or 1 ppm, use plastic lab-ware (and low level procedures) since a significant pickup of sodium may

pH Effects

The electrode response to sodium ions is greatly influenced by the pH of the solution. Hydrogen ion interferes with

measurements of low level sodium ion measurements, although the electrode can be used over a wide pH range.

(See Figure 5.)

10

Page 15

012–06615A Sodium Ion Selective Electrode

-1

M Na

+

+180

10

+160

electrode

potential

(mV)

+140

+120

+100

+80

+60

+40

+20

H+ Ion

Interference

0

468 12

10

-2

M Na

+

-3

-4

M Na

M Na

102

+

+

14

10

10

pH

Figure 5

Electrode potential behavior vs. solution pH in pure NaCl solution at 25 °

The edge of the shaded area (the straight line) shown in Figure 5 indicates a minimum pH at which dilute sodium

measurements can be made with less than 10% hydrogen ion interference.

The pH should be adjusted to a pH greater than 9 by the addition of ISA to all standards and samples for optimal

results over the entire concentration range of sodium. Additional ammonium hydroxide may be necessary to adjust

the pH to the desired level in some cases.

Electrode Life

The sodium electrode will last six months in normal laboratory use. On-line measurements might shorten

operational lifetime to several months. In time, the response time will increase end the calibration slope will decrease

to the point calibration is difficult and electrode replacement is required.

Maintenance

Electrode Storage

The Sodium Ion Selective Electrode should be stored in the sodium electrode storage solution, never in air or in

distilled water. A more dilute sodium chloride solution (with pH adjusted through the use of ISA) may be used for

storage before low level measurements. For longer storage (longer than two weeks), rinse and dry the sensing glass

and cover the glass tip with any protective cap shipped with the electrode. The reference portion of the combination

electrode (or the outer chamber of the reference electrode) should be drained of filling solution, if refillable, and

the rubber insert placed over the filling hole.

11

Page 16

Sodium Ion Selective Electrode 012–06615A

Specifications

Concentration Range: Saturated to 1.0Xl0

pH Range: 5 to 12 (depending on pH level)

-6

M (0.02 ppm)

Temperature Range: -5

Resistance: < 200 mohm

Reproducibility: ±2%

Storage: store in 5 M NaCl with added ISA

Size: length = 110 mm

°C

– 70 °C

diameter = 12 mm

cable length = 1 m

Troubleshooting Guide

The goal of troubleshooting is the isolation of a problem through checking each of the system components in turn:

the meter, the glassware, the electrodes, the standards and reagents, the sample, and the technique.

Glassware/Plastic-ware

Clean glassware is essential for good measurement. Be sure to wash the glassware/plastic-ware well with a mild

detergent and rinse very well with distilled or deionized water. Clean glassware will drain without leaving water

droplets behind.

Electrode

The electrodes may be checked by using the procedure found in the sections entitled Electrode Slope Check.

1. Be sure to use distilled or deionized water when following the procedures given in Electrode Slope

Check.

2. If the electrode fails to respond as expected, see the sections Measuring Hints and Electrode Response.

Repeat the slope check.

3. If the electrode still fails to respond as expected, substitute another Sodium Ion Selective Electrode (if

available) that is known to be in good working order for the questionable electrode.

4. If the problem persists, the reagent may be of poor quality, interferences in the sample may be present,

or the technique may be faulty. (See Standards & Reagents, Sample, and Technique sections below.)

5. If another electrode is not available for test purposes, or if the electrode in use is suspect, review the

instruction manual and be sure to:

- Clean and rinse the electrode thoroughly.

- Prepare the electrode(s) properly.

- Use the proper filling solution.

- Adjust the pH and the ionic strength of the solution by the use of the proper ISA.

- Measure correctly and accurately.

12

- Review Troubleshooting Hints.

Page 17

012–06615A Sodium Ion Selective Electrode

Standards & Reagents

Whenever problems arise with the measuring procedure that has been used successfully in the past, be Sure to check

the standard and reagent solutions. If in doubt about the credibility of any of the solutions, prepare them again. Errors

may result from contamination of the ISA, incorrect dilution of standards, poor quality distilled/deionized water,

or a simple mathematical miscalculation.

Sample

Look for possible interferences, complexing agents, or substances which could affect the response or physically

damage the sensing electrode (or the reference electrode) if the electrodes work perfectly in the standard, but not

in the sample.

Try to determine the composition of the samples prior to testing to eliminate a problem before it starts. (See

Measuring Hints, Sample Requirements, and Interferences.)

Technique

Be sure that the electrode’s limit of detection has not been exceeded. Be sure that the analysis method is clearly

understood and is compatible with the sample.

Refer to the instruction manual again. Reread General Preparation and Electrode Characteristics.

If trouble still persists, call PASCO Technical Support.

Troubleshooting Hints

Symptom Possible Causes Next Step

Out of Range Reading defective electrode check electrode operation

electrodes not plugged in unplug electrodes and reseat electrodes

properly

reference electrode not filled replenish reference filling solution

electrodes not in solution put electrodes in solution

air bubble on membrane remove bubble by re-dipping electrode

13

Page 18

Sodium Ion Selective Electrode 012–06615A

Symptom Possible Causes Next Step

Noisy or Unstable electrode exposed to interferences soak overnight in electrode storage solution

Readings (readings

continuously or rapidly defective electrode replace electrode

changing)

ISA not used use recommended ISA

stirrer not grounded ground stirrer

Drift (reading slowly samples and standards at different allow solutions to come to room temperature

changing in one direction) temperatures before measurement

electrode exposed to interferences soak overnight in electrode storage solution

incorrect reference filling solution use recommended filling solution

pH too acidic adjust pH with ISA

ISA not used use recommended ISA

Low Slope or No Slope standards contaminated or prepare fresh standards

incorrectly made

standard used as ISA use ISA

electrode exposed to interferences soak overnight in electrode storage solution

pH too acidic adjust pH with ISA

air bubble on membrane remove bubble by re-dipping probe

14

Page 19

012–06615A Sodium Ion Selective Electrode

Symptom Possible Causes Next Step

“Incorrect Answer” incorrect scaling of semilog paper plot voltage potential on the linear axis.

(but calibration curve On the log axis, be sure concentration

is good) numbers within each decade are increasing

with increasing concentration.

incorrect sign be sure to note sign of millivolt reading

correctly

incorrect standards prepare fresh standards

wrong units used apply correct conversion factor:

1.0X10

-3

M = 23.0 ppm as Na

+1

sample pH too acidic adjust pH with ISA

15

Page 20

Sodium Ion Selective Electrode 012–06615A

16

Page 21

T echnical Support

Feedback

If you have any comments about the product or

manual, please let us know. If you have any

suggestions on alternate experiments or find a problem

in the manual, please tell us. PASCO appreciates any

customer feedback. Your input helps us evaluate and

improve our product.

To Reach PASCO

For technical support, call us at 1-800-772-8700

(toll-free within the U.S.) or (916) 786-3800.

fax: (916) 786-3292

e-mail: techsupp@pasco.com

web: www.pasco.com

Contacting Technical Support

Before you call the PASCO Technical Support staff,

it would be helpful to prepare the following

information:

➤ If your problem is with the PASCO apparatus,

note:

- Title and model number (usually listed on the

label);

- Approximate age of apparatus;

- A detailed description of the problem/

sequence of events (in case you can’t call

PASCO right away, you won’t lose valuable

data);

- If possible, have the apparatus within reach

when calling to facilitate description of

individual parts.

➤ If your problem relates to the instruction manual,

note:

- Part number and revision (listed by month and

year on the front cover);

- Have the manual at hand to discuss your

questions.

Page 22

Loading...

Loading...