Page 1

Includes

Teacher's Notes

and

Typical

Experiment Results

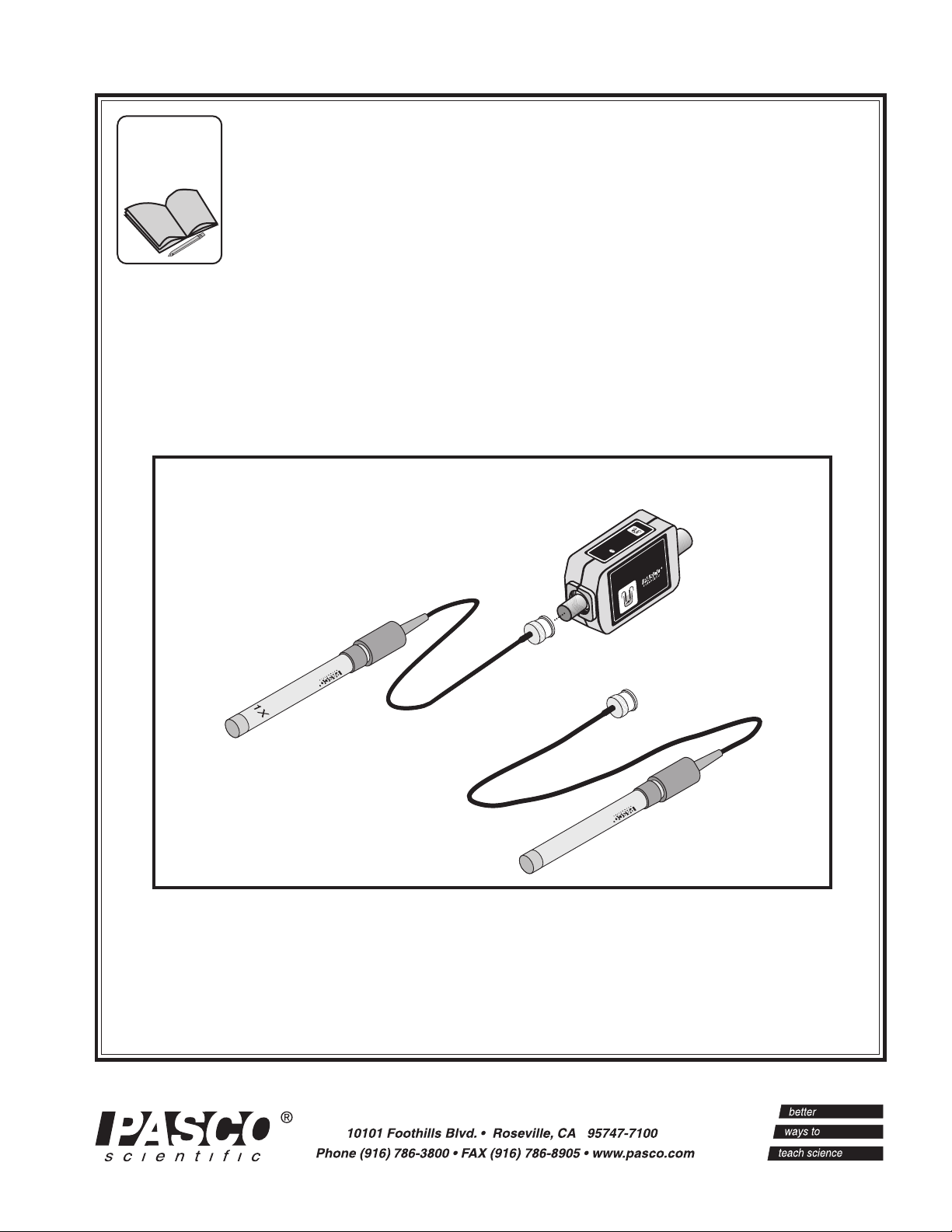

CONDUCTIVITY SENSOR

Instruction Manual and

Experiment Guide for the

PASCO scientific

Model CI-6729 (1X) and

Model CI-6739A (10X)

012-06485B

12/97

R

S

A

E

N

2

L

G

0

E

E

K

C

2

K

T

2

0

0

CONDUCTIVITY

SENSOR

CI-6729

CI-6739A

CONDUCTIVITY

699-06620

CONDUCTIVITY

699-06621

10X

© 1997 PASCO scientific $7.50

Page 2

Conductivity Sensor 012–06485B

Always use eye protection,

gloves, and an apron when

working with chemicals.

Caution: Follow all local

regulations for the safe handling,

use, storage, and disposal of the

chemicals used in the experiments

described in this manual.

Page 3

012–06485B Conductivity Sensor

Table of Contents

Section Page

Copyright, Warranty, and Equipment Return ................................................................ ii

Introduction ...................................................................................................................1

Equipment .....................................................................................................................1

Maintenance

Cleaning ...................................................................................................................2

Storage .....................................................................................................................2

Specifications ...........................................................................................................2

Theory—Principles of Operation of the Conductivity Sensor .....................................3–6

Setup and Calibration

Set up Science Workshop

®

..................................................................................................................................... 7

Calibration ...............................................................................................................7

Single-Point Calibration ...........................................................................................8

Experiments

Experiment 1: Introduction to the Operation of the Conductivity Sensor ................. 9–10

Experiment 2: Concentration Dependence of Conductivity in Aqueous Solutions . 11–12

Experiment 3: Temperature Dependence of Conductivity in Dilute

Aqueous Solutions ......................................................................... 13–15

Experiment 4: Acid-Base Titration with the Conductivity Sensor ..........................17–18

Teacher’s Notes ................................................................................................... 19–22

Appendix

Table 1: Conductivity of Various Water Samples at 25°C ...........................................23

Table 2: Table of Conductivity vs. Concentration for Common Solutions ................... 24

Table 3: Table of Conductivity vs. Concentration for Common Solutions ................... 25

Table 4: Conversion Chart to Estimate TDS of Aqueous Solutions .............................26

Table 5: Table of High Accuracy Reference Solution for Calibration ..........................26

Table 6: Sample Illustrating the Application of Conductivity to Agriculture ................27

Technical Support ..................................................................................... Back Cover

i

Page 4

Conductivity Sensor 012–06485B

Copyright, Warranty, and Equipment Return

Please—Feel free to duplicate this manual

subject to the copyright restrictions below.

Copyright Notice

The PASCO scientific Conductivity Sensor manual

(012-06485A) is copyrighted and all rights reserved.

However, permission is granted to nonprofit

educational institutions for reproduction of any part

of the Conductivity Sensor manual providing the

reproductions are used only for their laboratories

and are not sold for profit. Reproduction under any

other circumstances, without the written consent of

PASCO scientific, is prohibited.

Limited Warranty

PASCO scientific warrants the product to be free from

defects in materials and workmanship for a period of

one year from the date of shipment to the customer.

PASCO will repair or replace at its option any part

of the product which is deemed to be defective in

material or workmanship. The warranty does not

cover damage to the product caused by abuse or

improper use. Determination of whether a product

failure is the result of a manufacturing defect or

improper use by the customer shall be made solely by

PASCO scientific. Responsibility for the return of

equipment for warranty repair belongs to the

customer. Equipment must be properly packed to

prevent damage and shipped postage or freight

prepaid. (Damage caused by improper packing of the

equipment for return shipment will not be covered by

the warranty.) Shipping costs for returning the equipment after repair will be paid by PASCO scientific.

Equipment Return

Should the product have to be returned to PASCO

scientific for any reason, notify PASCO scientific by

letter, phone, or fax BEFORE returning the product.

Upon notification, the return authorization and

shipping instructions will be promptly issued.

➤➤

➤ NOTE: NO EQUIPMENT WILL BE

➤➤

ACCEPTED FOR RETURN WITHOUT AN

AUTHORIZATION FROM PASCO.

When returning equipment for repair, the units must

be packed properly. Carriers will not accept responsibility for damage caused by improper packing. To

be certain the unit will not be damaged in shipment,

observe the following rules:

➀ The packing carton must be strong enough for the

item shipped.

➁ Make certain there are at least two inches of packing

material between any point on the apparatus and the

inside walls of the carton.

➂ Make certain that the packing material cannot shift in

the box or become compressed, allowing the

instrument come in contact with the packing carton.

Address: PASCO scientific

10101 Foothills Blvd.

P.O. Box 619011

Roseville, CA 95678-9011

Credits

Authors: Dominic Calabrese and Steve Miller

Editor: Sunny Bishop

ii

Phone: (916) 786-3800

FAX: (916) 786-3292

email: techsupp@pasco.com

web: www.pasco.com

Page 5

012–06485B Conductivity Sensor

CONDUCTIVITY

SENSOR

CI-6729

CI-6739A

2K

20K

2

00

RANGE

SELEC

T

699-06620

C

O

N

D

U

C

TIV

ITY

699-06621

C

O

N

D

U

C

TIV

ITY

10X

Introduction

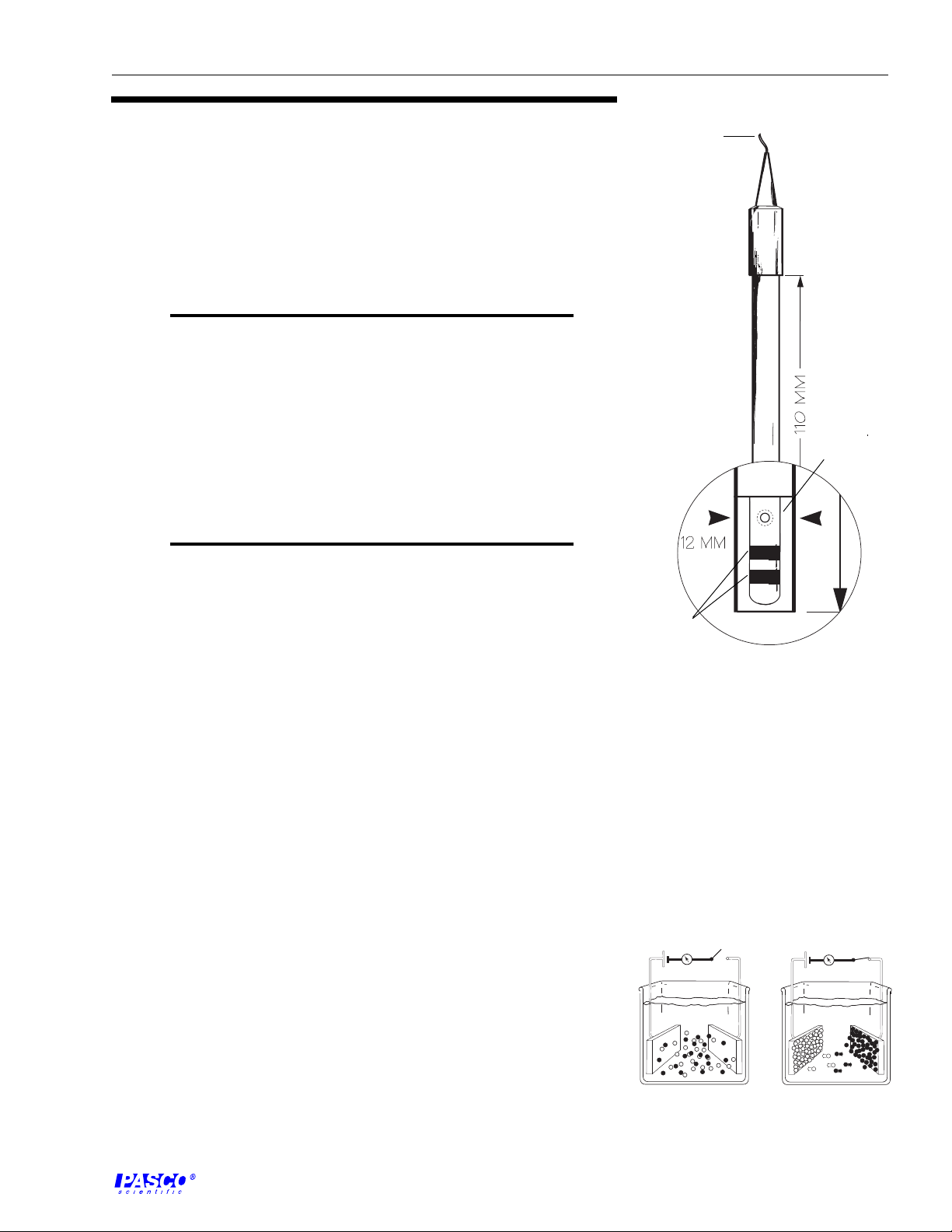

The PASCO CI-6729 and CI-6739A Conductivity Sensors are

used with a PASCO Science Workshop

®

computer interface to

investigate factors that influence the electrical conductivity of

liquids. The Conductivity Sensor consists of a signal conditioning

amplifier and either a 1X or 10X conductivity electrode. The

signal conditioning amplifier box is capable of working with

either electrode. Students can use this sensor to explore the

effects of temperature and concentration on the electrical

transport properties of aqueous solutions, especially in

applications relating to ecological systems.

The Conductivity Sensor is designed for use in aqueous solutions

at temperatures ranging from 0 °C to 80 °C. The 1X conductivity

electrode provided with the CI-6729 Conductivity Sensor has a

range of up to 20,000 microsiemens per centimeter. The 10X

conductivity electrode, provided with the CI-6739A, has a range

up to 200,000 microsiemens per centimeter. In order to achieve

maximum performance of the Conductivity Sensor, soak the

electrode in distilled water for 5 to 10 minutes before use to assure

complete wetting of the electrodes. The electrode may also be

calibrated at approximately the same temperature as the test solution

for concentration or total dissolved solids (TDS) measurements.

➤ Conductivity Sensors are used

in many practical applications

including:

• Environmental Monitoring

• Oceanography-Salinity

• Agriculture

• Waste Systems

• Beverage Industries

• Electroplating

interface cable with 8-pin

DIN connectors

connector for

amplifier box

Equipment

connector for

computer

interface

Provided With CI-6729 (1X)

• 1X conductivity electrode with 3-foot BNC cable

• Conductivity Sensor Amplifier box with 8-pin DIN

connector and BNC connector

• interface cable with DIN connector

amplifier box

Provided With CI-6739A (10X)

• 10X conductivity electrode with 3-foot BNC cable

• Conductivity Sensor Amplifier box with 8-pin DIN

connector and BNC connector

• interface cable with DIN connector

Additional equipment required

• Any PASCO Science Workshop® computer interface

• computer

Replacement Electrodes

• 1X conductivity electrode: 699-06620

• 10X conductivity electrode: 699-06621

conductivity

electrodes

1

Page 6

Conductivity Sensor 012–06485B

Maintenance

Cleaning

To ensure accurate and reproducible results, the electrode cell must be clean.

A dirty cell will contaminate the solution and change the conductivity of the

liquid.

Cells can be cleaned with detergent and/or dilute nitric acid (1%) by dipping

or filling the cell with cleaning solution and stirring for three minutes.

Storage

Although the best method to store the electrode is by immersing it in deionized

water, the electrode can be stored dry in its container. If the cell is stored dry,

it should be soaked in distilled water for 5 to 10 minutes before use.

Specifications:

CI-6729 (1X conductivity electrode)

• Range: 20k scale: 0–20,000 µS/cm

2k scale: 0–2,000 µS/cm

200 scale: 0–200 µS/cm

• Conductivity electrode cell constant: 1.0 ± 0.1

• Accuracy: without calibration < 10%

after calibration < 1%

• Resolution: 20k scale, ± 10 µS

2k scale, ± 1.0 µS

200 scale, ± 0.1 µS

• Temperature range 0–80°C

• Electrode body: Epoxy

CI-6739A (10X conductivity electrode)

• Range: 20k scale: 0–200,000 µS/cm

2k scale: 0–20,000 µS/cm

200 scale: 0–2000 µS/cm

• Conductivity electrode cell constant: 10 ± 1.0

• Accuracy: without calibration < 10%

after calibration < 1%

• Resolution: 20k scale, ± 100 µS

2k scale, ± 10 µS

200 scale, ± 1.0 µS

• Temperature range: 0–80°C

• Electrode body: Epoxy

2

Page 7

012–06485B Conductivity Sensor

Theory—Principles of Operation

of the Conductivity Sensor

What is Conductivity?

Conductivity (or specifically, electrolytic conductivity) is defined as the ability

of a substance to conduct electric current. It is the reciprocal of the more

commonly encountered term, resistivity. All substances possess conductivity

to some degree, but the amount varies widely, ranging from extremely low

(insulators such as benzene and glass) to very high (silver, copper, and metals

in general). Most industrial interest is in the conductivity measurement of

liquids that generally consist of ionic compounds dissolved in water. These

solutions have conductivities approximately midway between insulators and

metallic conductors. This conductivity can be measured quite easily by

electronic means, allowing a simple test that can tell much about the quality

of the water or the makeup of the solution. A broad line of conductivity

equipment is available to measure liquids ranging from ultrapure water (low

conductivity) to concentrated chemical streams (high conductivity).

Units of Conductivity

The units of measurement used to describe conductivity and resistively are

quite fundamental and are frequently misused. Once the units are known,

various waters can be quantitatively described.

The basic unit of resistance is the familiar ohm. Conductance is the

reciprocal of resistance, and its basic unit is the siemens (S), formerly called

mho. In discussions of bulk material, it is convenient to talk of its specific

conduct-ance, now commonly called its conductivity. This is the conductance

as measured between the opposite faces of a 1 cm cube of the material

(Figure 1).

This measurement has units of siemens/centimeter (S/cm). The units

microsiemens/centimeter (µS/cm) and millisiemens/centimeter (mS/cm)

are most commonly used to describe the conductivity of aqueous solutions.

The corresponding terms for specific resistance (or resistivity) are

ohm - centimeter (Ω · cm), megaohm - centimeter (M Ω · cm) and

kiloohm - centimeter (k Ω · cm).

Users of ultra pure water prefer to use resistivity units of M

measurement in these units tends to spread the scale out in the range of

interest. These same users frequently use k

Ω

· cm when dealing with less

pure water such as tap water.

Ω

· cm, because

conducting surface

A

Pt

Figure 1

Conductivity Cube

B

Pt

L

L

H

A

A

W

3

Page 8

Conductivity Sensor 012–06485B

However when dealing with a chemical solution ranging from extremely

dilute to very concentrated chemical, use of conductivity units of µS/cm and

mS/cm are common. In these applications, conductivity has the advantage

of an almost direct relationship with impurities, especially at low

concentration. Hence, a rising conductivity reading shows increasing

impurities, or a generally increasing concentration in the case of a chemical

stream (with some exceptions in concentrated solutions). See Table 1 for a

comparison of resistance and conductivity.

Table 1. Conductivity Of Various Aqueous Solutions At 25 0C

Solution Conductivity Resistivity

Pure water 0.05 µS/cm 18 MΩ · cm

Power plant boiler water 0.05–1 µS/cm 1–18 MΩ · cm

Distilled water 0.5 µS/cm 2 MΩ · cm

Deionized water 0.1–10 µS/cm 0.1–10 MΩ · cm

Demineralized water 1–80 µS/cm 0.01–1 MΩ · cm

Mountain water 10 µS/cm 0.1 MΩ · cm

Drinking water 0.5 –1 mS/cm 1–2 kΩ · cm

Waste water 0.9–9 mS/cm 0.1–1 kΩ · cm

KCl solution (0.0l M) 1.4 mS/cm 0.7 Ω · cm

Potable water maximum 1.5 mS/cm 0.7 Ω · cm

Brackish water 1–80 mS/cm 0.01–1 Ω · cm

Industrial process water 7–140 mS/cm rarely stated

Ocean water 53 mS/cm rarely stated

10% NaOH 355 mS/cm rarely stated

100/0 H

2504

31% HNO

3

432 mS/cm rarely stated

865 mS/cm rarely stated

Conductivity Electrodes (Cells)

Simple conductivity sensors are constructed of an insulating material imbedded

with platinum, graphite, stainless steel or other metallic pieces. These metal

contacts serve as sensing elements and are placed at a fixed distance apart to

make contact with a solution whose conductivity is to be determined. The length

between the sensing elements, as well as the surface area of the metallic piece

determine the electrode cell constant, defined as length/area (Figure 1). The cell

constant is a critical parameter affecting the conductance value produced by the

cell and handled by the electronic circuitry.

A cell constant of 1.0 will produce a conductance reading approximately equal

to the solution conductivity. For solutions of low conductivity, the sensing

4

Page 9

012–06485B Conductivity Sensor

electrodes can be placed closer together, reducing the length between them

and producing cell constants of 0.1 or 0.01. This will raise the conductance

reading by a factor of 10 to 100 to offset the low solution conductivity and

give a better signal to the conductivity meter. On the other hand, the sensing

electrodes can be placed farther apart to create cell constants of 10 or 100

for use in highly conductive solutions. Table 2 lists the optimum conductivity

range for cells with different cell constants.

Table 2. Optimum Conductivity Range For Cells

With Different Cell Constants

Cell Constant Conductivity

0.01 0–20 µS/cm

0.1 0–200 µS/cm

1.0 0 –2000 µS/cm

10.0 0–200,000 µS/cm

to amplifier box

glass rod

The conductivity electrode provided with the CI- 6729 has a cell constant of

1.0 and is designed to achieve optimum performance over a range of 0 to

20,000 µS (Figure 2). This performance is achieved by using a cylindrical

cell geometry and platinized platinum conductors embedded on a glass rod.

For measurements of conductivity greater than 20,000 µS, the 10x electrode

should be used.

Conductivity Sensor Amplifier

The Conductivity Sensor amplifier has two distinct functions. First, it provides

a signal or voltage used to drive the conductivity electrode, and second, it

senses the electrical current the electrode passes when placed in the solution

to be tested.

If the voltage and current are known, then the resistance of the cell can be

determined. If the resistance of the cell is known, then the conductivity can

be determined by taking the inverse of the resistance and multiplying by the

conductivity cell constant. While it is instructional to know how the sensor

determines conductivity, Science Workshop handles the calculations and

reports conductivity for the 1x cell directly. If the 10x conductivity electrode

is used, the value reported by Science Workshop should be multiplied by ten.

platinized

platinum

conductors

Figure 2

Schematic view of the cell for the

CI-6729 Conductivity Electrode.

E

E

+

-

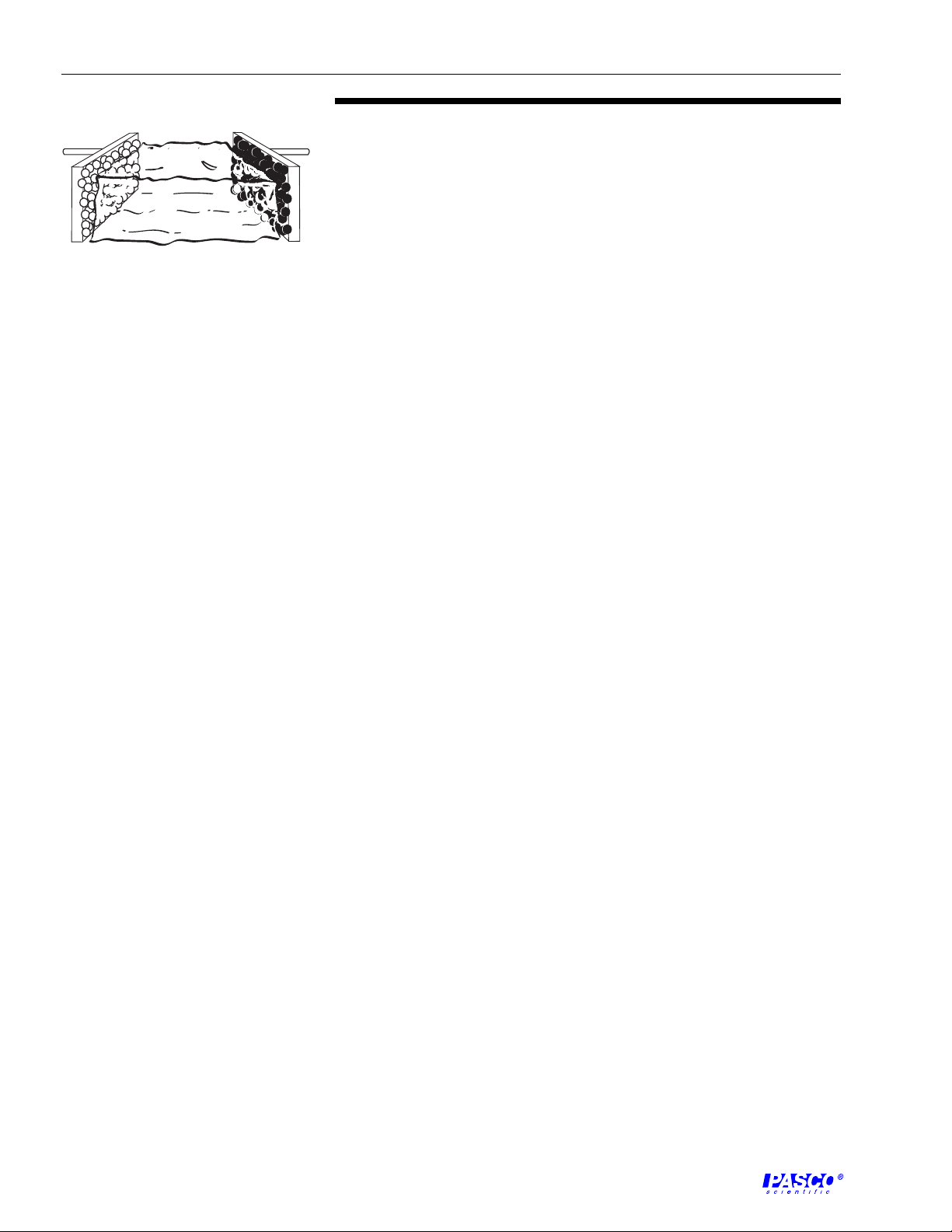

When a potential is a applied to the conductivity cell, the ions in solution are

influenced by the charge on the cell’s electrodes and begin to migrate toward

the electrodes (Figure 3).

Figure 3

Conductivity Cell in operation

5

Page 10

Conductivity Sensor 012–06485B

+

Figure 4

Polarized Electrode

➤ Approximate conductivities

°°

(at 25

°

C) and impurity

°°

concentrations (in ppm) of

various water samples are given

below.

-

Sample Conductivity

Pure H20 0.055 µS/cm (0.027 ppm)

Distilled H20 0.5 µS/cm (0.206 ppm)

City H20 50 µS/cm (25 ppm)

Ocean H20 53 mS/cm (35,000 ppm)

After a fairly short period of time most of the ions in solution will move

to the electrodes and the current flow through probe will begin to

decrease. This process is called polarization (Figure 4). Polarization

causes the conductivity probe’s output to be low if not corrected.

One method used to reduce the effects of polarization is to alternate the

polarity of the voltage applied to the electrode. Polarization of the

electrode and the associated build up of oxidation/reduction byproducts is prevented if the voltage is alternated quickly enough.

Conductivity Measurements

The conductivity of an electrolytic solution is dependent on several

factors, including the concentration of the solute, the degree of dissociation of the solute, the degree of dissociation of the molecules

present in the solution, the valiancy of the ion(s) present in the

solution, the mobilities of ions that are formed upon dissociation, and

the temperature of the solution. In general, ion mobilities remain

constant over a specific concentration range, depending on the solute

in solution. Within the specific concentration range, the conductivity

of a solution will increase in proportion to an increase in solute

concentration.

Since temperature is a measure of the average kinetic energy of an atom,

ion, or molecule, any change in temperature of a solution will strongly

affect the mobility of the species present in the electrolyte. Therefore,

the conductivity of the solution will also change. As a result, the

conductivity of a solution whose concentration is known is always

quoted for a specific temperature. Several tables in the Appendix

illustrate the temperature dependence of conductivity for specific

electrolytic solutions.

Concentration or total dissolved solid (TDS) measurements can also be

accurately determined by correlating the conductivity of a solution with

reference tables or graphs. TDS measurements are generally used to

estimate the salt content of water samples. A rule of thumb used to

estimate TDS in mg/L (ppm) is to divide the measured conductivity in

microsiemens per centimeter (µS/cm) by two. Table 4 in the Appendix

is a conversion chart for TDS measurements involving NaCl and

CaCO

Appendix.

. Additional references of conductivity data are also listed in the

3

6

Page 11

012–06485B Conductivity Sensor

Setup and Calibration

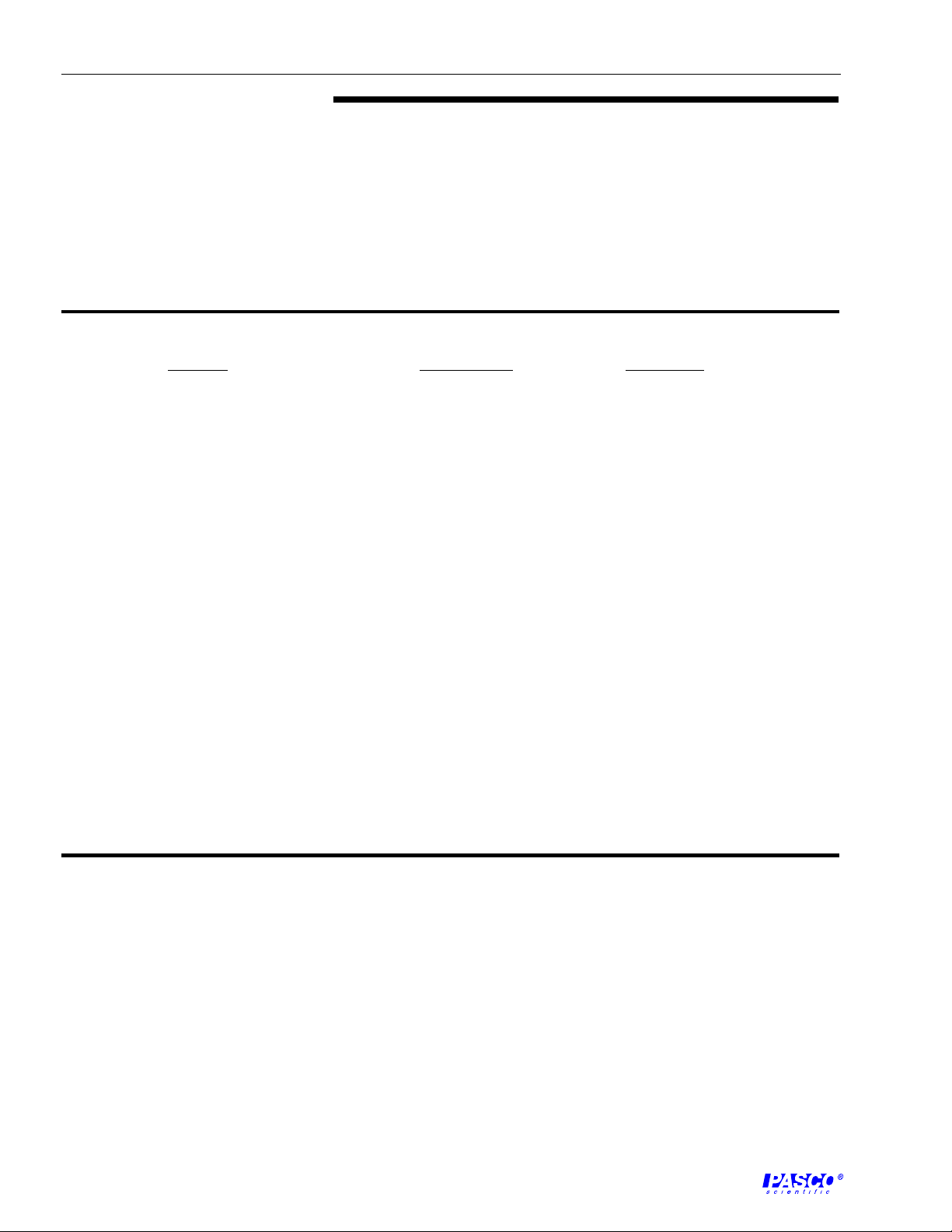

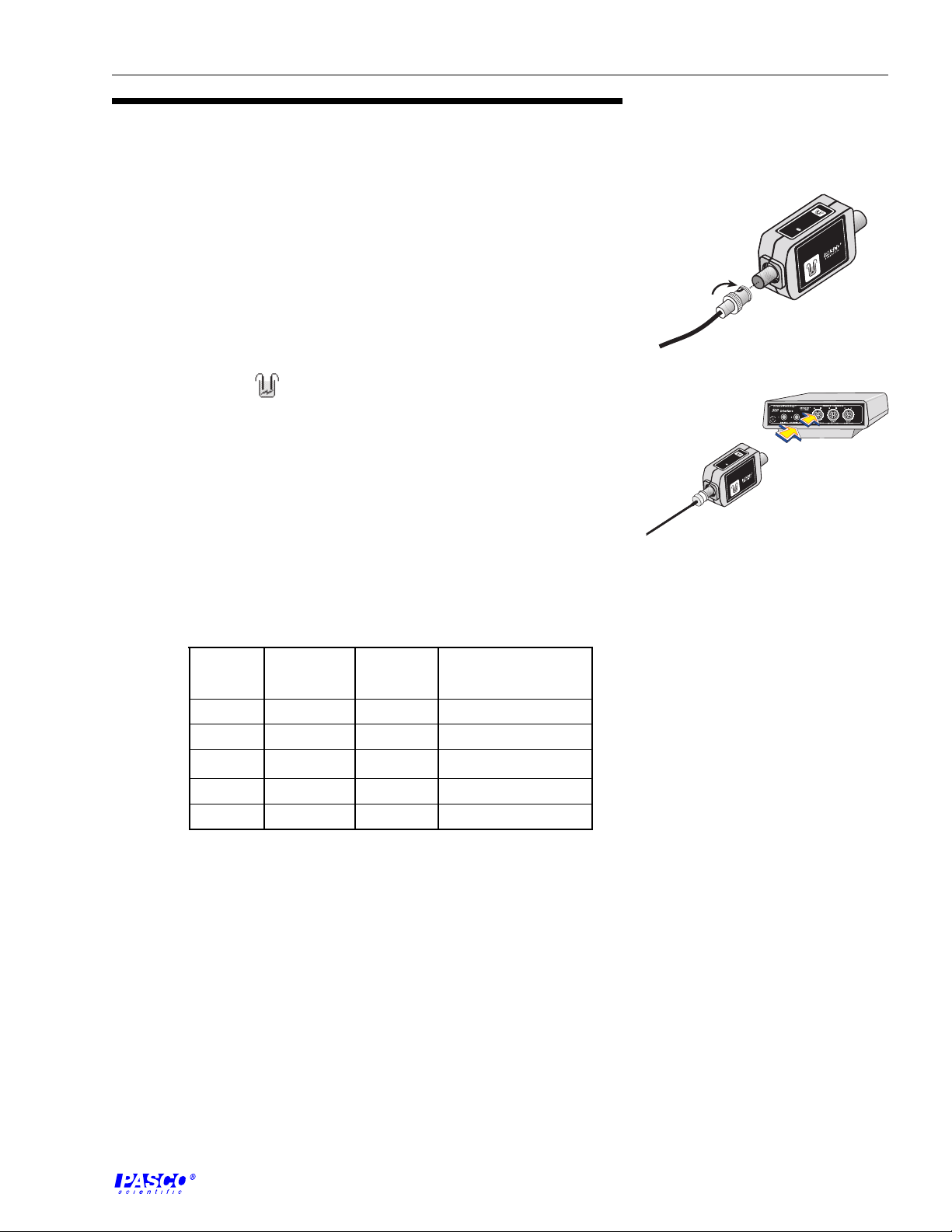

Set up

Science Workshop

1. Attach electrode to the amplifier box (Figure 5a).

2. Plug the 8-pin DIN connector of the amplifier box into any analog

channel on a PASCO computer interface (Figure 5b).

3. Launch Science Workshop, drag the analog plug icon to the analog

channel icon, and select Conductivity Sensor.

4. In the Experiment Setup window, drag a Graph display to the Conductivity

Sensor icon (

), and select the appropriate conductivity range to be

displayed. (The range setting selected on the amplifier box must match

the display range for the graph.)

➤➤

➤

A Digits display may also be used to display conductivity.

➤➤

Calibration

Prepare one of the weight percent NaCl solutions given in the table below

by weighing out in air the desired mass (mg) of NaCl in a 1-liter flask. Add

500 ml of deionized water and stir the solution to dissolve the salt. Add the

remaining 500 ml of deionized water and stir the solution.

RAN

SEL

20K

GE

ECT

2K

20

a

0

CONDUCTIVITY

CONDU

SENSOR

SENSOR

CTIVITY

I-6729

I-6729

C

C

I-6739A

C

b

R

S

A

E

N

2

L

G

0

E

E

K

C

2

K

T

2

0

0

CONDUCTIVITY

SENSOR

9

2

7

6

-

I

C

Figure 5

Plug the sensor into the computer

interface.

%Weight

(approx.)

0.001

0.01

0.1

1.0

10.0

➤➤

➤

For direct measurements of conductivity greater than 20,000

➤➤

Mass of

NaCl (mg)

10

100

1,000

10,000

100,000

TDS ppm

or mg/liter

10

100

1,000

10,000

100,000

Conductivity (µS/cm)

at 25 °C

21.4

210

1,990

17,600

140,000

µS the 10x electrode should be used. The 1x electrode may be

used if a 10:1 dilution of the solution to be measured is made. If

the 10:1 dilution method is used remember to multiply the value

indicated by 10.

➤➤

➤

For measurements that require very high accuracy, a KCl

➤➤

standard should be used (see Table 5 in the Appendix).

Other calibration solutions can be prepared using the tables and graphs in the

Appendix.

7

Page 12

Conductivity Sensor 012–06485B

Single-Point Calibration

➤ Always calibrate the

electrode before measuring

absolute (rather than relative)

concentrations.

1. Open the Conductivity Sensor calibration dialog box by double-

clicking the Conductivity Sensor icon in the Experiment Setup

window.

2. Make sure that the low value is set at 0.000 µS/cm and 0.000 volts

(default values). If these values are not set at zero, enter 0.000 in

the dialog boxes for Low Value of µS/cm and Volts.

3. Place the Conductivity Sensor into the calibration solution. In the

High Value box type a value in µS/cm that corresponds to the

known weight percent solution. As soon as the voltage reading

stabilizes, click Read to enter the HighValue.

➤ Note: This manual has been written with the assumption that the

user has a basic familiarity with Science Workshop and has access to

the User’s Guide for Science Workshop. Users can gain basic skills by

viewing the training video and by doing the tutorial within Science

Workshop. Another useful resource is the Quick Reference Card for

Science Workshop.

8

Page 13

012–06485B Conductivity Sensor

Experiment 1: Introduction to the Operation of the

Conductivity Sensor

Purpose

The purpose of this experiment is to learn the basic operation of the Conductivity Sensor.

Materials and Equipment Needed

• Conductivity Sensor • 150 ml distilled or deionized H2O

• Science Workshop version 2.2.5 or higher • 150 ml tap H

• PASCO computer interface • 150 ml mineral H

• computer • 150 ml bottled drinking H

• 250 ml beaker (5) • wash bottle of distilled or deionized H

• Conductivity Sensor manual

O

2

O

2

O

2

O

2

Procedure

1. Soak the Conductivity Electrode in distilled or deionized H2O for 5–10 minutes.

2. Set up the Conductivity Sensor according to the procedure detailed in the Conductivity

3. Make sure all water samples are at room temperature. Define a labeling scheme to identify

4. Insert the Conductivity Electrode into the first 150 ml water sample. Wait until the display

5. Remove the electrode and rinse it with the wash bottle.

6. Repeat steps 4 and 5 with the remaining samples. Note that you might need to switch to the

κ(distilled or deionized H

Sensor manual (select Digits display only). Select the 200 scale on the amplifier box.

➤ Note: Calibration is not needed for this experiment.

the water samples.

stabilizes, and record the conductivity value below.

2k scale for one or more of samples.

O) =__________ µS/cm κ(tap H2O) =___________ µS/cm

2

κ(bottled H

Data Analysis

O) = __________ µS/cm κ(mineral H2O) =__________ µS/cm

2

9

Page 14

Conductivity Sensor 012–06485B

Some vendors of drinking and mineral water list the total dissolved solids (TDS) in parts per million. Using the rule of

thumb described in the Theory section of the Conductivity Sensor manual and calculate the TDS of the drinking water

and the mineral water.

TDS drinking H

Compare your results with those listed on the bottles.

Questions

1. Which sample has the highest level of impurities?

2. Why is it important to have all the water samples at the same temperature?

O = __________ ppm TDS mineral H2O = __________ ppm

2

10

Page 15

012–06485B Conductivity Sensor

Experiment 2: Concentration Dependence of Conductivity in

Aqueous Solutions

Purpose

The purpose of this experiment is to explore the relationship between concentration and conductivity

in aqueous solutions.

Materials and Equipment Needed

• Conductivity Sensor • 150 ml distilled or deionized H2O

• Science Workshop version 2.2.5 or higher • citric acid crystalline powder

• PASCO computer interface • stirring rod

• computer • 150 ml bottled drinking H

• 250 ml beaker (5) • wash bottle of distilled or deionized H

• Conductivity Sensor manual

Procedure

O

2

O

2

1. Soak the Conductivity Electrode in distilled or deionized H2O for 5–10 minutes.

2. Set up the Conductivity Sensor according to the procedure detailed on pages 6–7 of the

manual (select Digits display only). Select the 20k scale on the amplifier box. Calibration

is not needed for this experiment.

3. Make sure all water samples are at room temperature (i.e. same temperature).

4. In the Experiment Setup window, click Sampling Options, and select the Keyboard

check box. In the Parameter box, type Mass, and in the Units box, type grams.

5. Click the Graph display to make it active. Click the Horizontal Axis Input button

(

6. Add 0.25 grams of citric acid into the distilled/deionized water. Stir the solution until the

crystals have dissolved.

7. Click REC to begin recording data. (The Keyboard Sampling window will open. Move the

window so you can see the other displays.) In the Keyboard Input box, type the number of

grams added (0.25 grams) to the solution for Entry #1 and click Enter.

), and select Mass (grams).

8. Add citric acid in 0.25 gram increments for the first 2.0 grams. in the Keyboard Input box,

type in the total mass of citric acid added to the solution for each increment. (Make sure the

reading on the Digits display stabilizes first.)

9. After two grams have been added, increase the increments to 0.5 grams until 5.0 grams of

citric acid have been added to the solution. Then increase the increments to 1.0 gram until

11

Page 16

Conductivity Sensor 012–06485B

15.0 grams of citric acid have been added. In the Keyboard Input box continue to type the

total mass of citric acid added to the solution for each increment. Note that as more acid is

added to the solution, additional time will be needed to dissolve the crystals.

10. When the 15.0 grams have been added increase the increments to 5.0 grams. Click Stop

Sampling after 60 grams of citric acid have been added to the solution.

11. Remove the electrode and rinse it with the wash bottle.

Questions

1. Describe your results.

2. Explain the behavior of the conductivity vs. mass graph at high concentrations.

12

Page 17

012–06485B Conductivity Sensor

Experiment 3: Temperature Dependence of Conductivity in

Dilute Aqueous Solutions

Purpose

The purpose of this experiment is to explore the relationship between temperature and conductivity

in aqueous solutions.

Materials and Equipment Needed

• Conductivity Sensor • sodium chloride (NaCl)

• Temperature Sensor • 200 ml 0.005 M sodium hydroxide (NaOH)

• Temperature Sensor Teflon FEP cover • 400 ml distilled or deionized H

• Science Workshop version 2.2.5 or higher • 250 ml Erlenmeyer flask or beaker (5)

• PASCO computer interface • hot plate with magnetic stirrer

• computer • base and support rod

• Conductivity Sensor manual • mass balance

• graduated cylinder • buret clamps (2)

• apron, gloves, and goggles

Procedure

O

2

1. Soak the Conductivity Electrode in distilled or deionized H2O for 5–10 minutes.

2. Prepare a 0.1% NaCl solution by dissolving 200 mg of NaCl in 200 ml of distilled or deionized

O. Prepare a 0.4% NaCl solution by dissolving 800

H

2

mg of NaCl in 200 ml of distilled or deionized H

O.

2

Prepare a 0.005 M NaOH solution by dissolving 200

mg of NaOH in 1000 ml of distilled or deionized H

O.

2

to computer

interface

A graduated cylinder should be used to measure 200

ml of H

O. Pour 150–200 ml of the solution into the

2

250 ml flask or beaker and place it on the hot plate.

The distilled H

O for the samples should be at room

2

temperature or below.

3. Insert the Temperature Sensor into the Teflon FEP

cover to isolate the grounded tip of the Temperature

Sensor from the conductive solution. Place the

Conductivity Electrode and Temperature Sensor into

the flask or beaker. Both electrodes should be supported

with buret clamps that are mounted on base and

support rods (see Figure 3.1).

Temperature

Sensor and

Teflon cover

conductivity

electrode

beaker &

spin bar

magnetic

stir-hot

plate

Figure 3.1

Experiment Setup

13

Page 18

Conductivity Sensor 012–06485B

4. Set up the Conductivity Sensor according to the procedure detailed in pages 6–7 of the

manual. Select the 20k scale on the amplifier box.

➤ Calibration is not needed for this experiment.

5. Plug the Temperature Sensor into analog channel B of the interface box. In the Experiment

Setup window of Science Workshop, drag the analog plug icon to the analog channel B

icon, and select Temperature Sensor.

6. Open a Digits display by dragging Digits icon to the Temperature Sensor icon.

7. Click the Horizontal Axis Input button, and select Analog B, Temp.

8. Define a labeling scheme to identify the solutions.

9. In the Experiment Setup window, click Sampling Options, select Slow under Periodic

Samples, and set the sampling rate to 1 per 5 seconds.

10. Insert the Conductivity Electrode into the first 200 ml water sample. Turn on the hot plate

and magnetic stirrer. The heat and the stirring controls should be set to a mid-range value.

Click the REC. Tap the Conductivity Electrode occasionally to avoid the formation of air

bubbles in the electrode’s cell. When the temperature of the solution reaches 60 °C, click

STOP.

11. Remove the temperature and conductivity electrodes, and rinse them with the wash bottle.

12. Repeat steps 9 and 10 with the other solutions.

Data Analysis

1. Click the Graph display to make it active. Click the Statistics button ( ) to open the

Statistics area on the right side of the graph.

2. On the Experiment menu, select Run 1.

3. Click the Autoscale button (

4. Click the Statistics Menu button (

5. Click on the Smart Cursor button (

the temperature is 25 °C. Divide the value of the slope by the conductivity reading at 25 °C

and multiply by 100% to determine percent change/°C at 25 °C. Record your results in the

Data Table. (The temperature dependence of the electrical conductivity is expressed usually

expressed in this manner.)

) to re-scale the Graph display to fit the data.

), and select Curve Fit ➤ Linear Fit.

). Move the cursor to the place in the graph where

14

Page 19

012–06485B Conductivity Sensor

Data Table

Solution percent/ °C at 25 °C

1000 ppm NaCl

4000 ppm NaCl

1000 ppm NaOH

Questions

1. Describe the effect of temperature change on the conductivity of the solutions.

2. Compare the experimentally determined values of the percent/ °C at 25 °C for the 4 samples.

3. What are some factors that affect the conductivity of a solution?

15

Page 20

Conductivity Sensor 012–06485B

16

Page 21

012–06485B Conductivity Sensor

Experiment 4: Acid-Base Titration with the Conductivity Senso

Purpose

The purpose of this experiment is to explore the electrical transport processes of an acid-base

titration. In addition, this experiment will explore the possibility of using a Conductivity Sensor

to find the equivalence point.

Materials and Equipment Needed

• Conductivity Sensor • 10 ml pipette

• Science Workshop version 2.2.5 or higher • distilled or deionized H

• Temperature Senor Teflon FEP cover • was bottle of distilled or deionized H

• PASCO computer interface • 250 ml beaker (2)

• computer • magnetic stirrer & spin bar

• 100 ml graduated cylinder • 0.03 M hydrochloric acid (HCl)

• buret and buret clamps (2) • 0.5 M sodium hydroxide (NaOH)

• Conductivity Sensor manual • buffer solutions: low pH (4) and high pH (10)

• apron, gloves, and goggles

O

2

O

2

Optional Materials

• 0.03 M acetic acid

Procedure

1. Soak the conductivity electrode in distilled or deionized H2O for 5–10 minutes.

2. Set up the Conductivity Sensor according to the procedure detailed in pages 6–7 of the

manual. Select the 20k scale on the amplifier box. (Calibration is not needed for this

experiment.)

3. In the Experiment Setup window, click Sampling Options , and select the Keyboard

check box In the Parameter box, type Volume, and in the Units box, type ml.

4. Click the Graph Display for the Conductivity Sensor. Click the Horizontal Axis Input

button, and select Volume (ml).

5. Use a graduated cylinder to measure 150 ml of 0.03 M HCl solution in a clean dry 250 ml

beaker.

6. Carefully put the spin bar into the beaker. Place the beaker with the 0.03 M HCl solution

and spin bar on the magnetic stirrer. Add a few drops of indicator into the 0.03 M HCl

solution.

7. Use a buret clamp and the base and support rod to position the conductivity electrode so the

cell is in the 0.03 M HCl solution, but will not interfere with the spin bar.

17

Page 22

Conductivity Sensor 012–06485B

8. Rinse the 50 ml buret with a few ml of the 0.5 M sodium

hydroxide (NaOH) solution. Dispose of the rinse solution as

directed.

9. Use a second buret clamp to attach the buret to the support

rod. Arrange the buret above the beaker so that you can use

rod, support

stand, and

buret clamps

the buret to add precise amounts of solutions to the beaker

(Figure 4.1).

10. Fill the buret with 0.5 M NaOH solution to the 0 mark on the

buret. Be sure to start the titration with the buret filled with

0.5 M NaOH solution and the volume used at exactly 0.00

ml.

11. Turn on the magnetic stirrer.

12. Click REC. (The Keyboard Sampling window will open.

Move the window so you can see the other displays.) Do

magnetic

stir plate

not add any titrant for the first reading. In the Keyboard

Input box, type 0.00 for Entry #1 and click Enter.

13. Add 0.5 M NaOH to the 0.03 M HCl solution in increments

Figure 4.1

Experiment Setup

of 1 ml. In the Keyboard Input box, type the total volume of

titrant added to the HCl solution, and click Enter. (Make sure the reading on the Digits

display stabilizes first.)

buret

conductivity

electrode

beaker &

spin bar

14. Repeat step 13 until 5 ml of titrant is added.

15. After 5 ml of titrant has been added, add 3–10 drops of 0.5 M NaOH per increment.

16. After approximately 5 ml of 0.5 M NaOH is added past the equivalence point, increase

17. When the conductivity reaches 15,000–20,000 µs/cm, click Stop Sampling and turn off the

(Optional) Repeat the experiment using 150 ml 0.03 M acetic acid.

Questions

1. Based on your observations, how can the Conductivity Sensor be used to determine the

Decrease your increments as you approach the equivalence point. Note that 3 drops is

approximately the smallest increment that will yield a noticeable change in the volume of

titrant added to the solution. As you approach the equivalence point, you will see patches of

pink in the solution for each drop of titrant added. Continue to type in the total volume of 0.5

M NaOH added after each increment. Observe the values of the conductivity near the

equivalence point.

your increments to 1 ml larger, and continue typing the total volume of titrant added.

magnetic stirrer. Rinse the sensor with the wash bottle.

equivalence point?

18

2. How much 0.5 M NaOH titrant was required to reach the equivalence point?

Page 23

012–06485B Conductivity Sensor

Teacher’s Notes

These experiments are designed to familiarize the student with the operation of the Conductivity

Sensor. In addition, these experiments illustrate various factors that affect sensor readings. We

recommend that the experiments are performed in order, with the student building on the

information from previous experiments.

Notes on Experiment 1

1. This experiment is designed to familiarize students with the basic operations of the

Conductivity Sensor, and the effects of impurities on water samples. In addition to the

water samples listed in this experiment, students can carry out ecological investigations by

measuring the conductivity of water samples taken from streams, ponds, lakes or the ocean.

The student can calibrate the sensor (as described on page 6 and 7) if very accurate

measurements are desirable.

ä

Students will need access to pages 6–7 of the manual.

Below are some sample data. The bottled water was Crystal Geyser and the mineral water was

Perrier.

κ(distilled or deionized H

κ(bottled H

O) = ________ µS/cm κ(mineral H2O) = ________ µS/cm

2

Data Analysis

TDS distilled or deionized H2O = __________ ppm TDS tap H2O = __________ ppm

TDS bottled =__________ ppm TDS mineral = __________ ppm

Answers to questions

1. The mineral water should have the highest levels of impurities in it.

2. Since temperature is related to the velocity of the ions in the solutions, change in temperature

will affect the transport of electric charges in the solution, resulting in a change in the

conductivity of the solution.

O) = ________ µS/cm κ(tap H2O) = ________ µS/cm

2

470

148 747

2

74

374

35

Notes on Experiment 2

It is assumed that the student has completed experiment 1 before carrying out this experiment.

Students must keep stirring the solution until all crystals have been dissolved before each

conductivity measurement. As the concentration increases the amount of time required to stir

19

Page 24

Conductivity Sensor 012–06485B

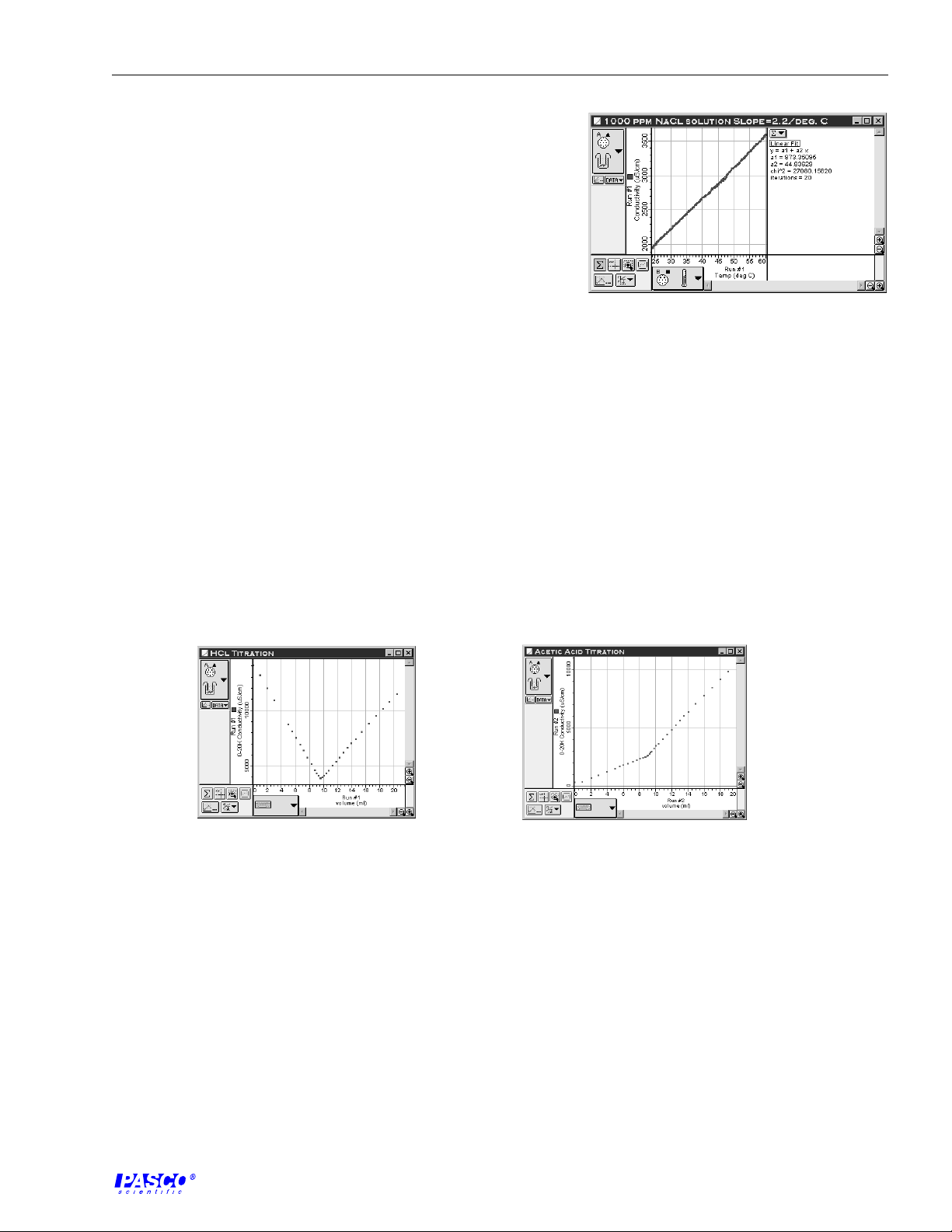

the solution will increase. Students can use a magnetic stirrer, if

available. An example of the data is shown in Figure TG-1.

Answers to Questions

1. Students should find that at low concentrations the

conductivity increases linearly with added mass of the citric

acid. At higher concentrations the conductivity will begin

to deviate from linearity and eventually decrease when the

concentration is very high.

2. As the concentration increases, the electrolytes are more

likely to collide. Therefore, their mobility decreases.

Furthermore, the degree of dissociation of the solvent

decreases as the solution approaches saturation. As the

solution approaches saturation, the concentration dependence of conductivity deviates from

linearity. At low concentrations the mobility of the ions and the degree of dissociation of the

molecules remain constant, thus the dependence is linear.

Figure TG-1

Notes on Experiment 3

It is assumed that the student has completed experiments 1 and 2 before carrying out this

experiment.

1. If bubbles form inside the conductivity cell, the conductivity reading will be reduced, since

the they will form an insulating layer on one or both of the cell electrodes. This is more

likely to occur at higher temperatures. One can eliminate the bubbles by increasing the

setting on the magnetic stirrer to allow the solution to flow through the cell. This effect can

also be eliminated by tapping/shaking the electrode.

2. If time is limited, the solutions could be prepared before the laboratory period begins.

Data Analysis

The table below lists typical experimental results. In general, ionic salts at low to moderate

concentrations have a temperature dependence of 2% / °C at 25 °C. Acids, bases, and

concentrated salt solutions have somewhat lower values, typically 1.5% / °C. On the other

hand, ultra pure water has by far the largest slope, 5.2% / °C.

Answers to Questions

Solution percent/ °C at 25 °C

1000 ppm NaCl

2.1

20

4000 ppm NaCl

1000 ppm NaOH

2.0

1.9

Page 25

012–06485B Conductivity Sensor

1. The conductivity increases linearly with temperature over

the observed temperature region.

2. The slopes are approximately equal for all the solutions.

3. Temperature, concentration, and solubility will effect the

conductivity of a solution.

Figure TG-2

Typical experimental results

Notes on Experiment 4

1. It is important that the student take great care in titrating

the solution near the equivalence point. Then students will easily see the discontinuity in the

conductivity (κ) vs. Volume of titrant added graph. Typical data sets are shown in Figure

TG-3.

2. In more advanced courses the teacher can modify this experiment so that the student can

calculate the molarity of an HCl solution whose concentration is unknown.

3. As usual, the teacher should instruct students on the dangers of acids and bases, and their

Figure TG-3

Typcial experimental results

proper disposal.

Answers to Questions

1. The equivalence point is easily determined by observing the point where the slope of the line

of Concentration vs. Volume of added titrant changes.

2. Students should find that about 9 ml of titrant must be added to the acid solution to reach the

equivalence point.

21

Page 26

Conductivity Sensor 012–06485B

22

Page 27

012–06485B Conductivity Sensor

6

6

9

9

6

6

6

8

3

3

6

0

3

3

6

Appendix

Table 1—Conductivity of Various Water Samples at 25 °C

Resistivity in ohm-cm 100M 10M 1M .1M 10K 1K 100 10 1

Conductivity in

microsiemens/cm .01 .1 1 10 100 1000 10K 100K 1000K

2345

Ultra pure Water

Demineralized Water

Condensate

Natural Waters

Cooling Tower Coolants

% Level of Acids, Bases & Salt

5% Salinity

2% NaOH

20% HCL

Contacting Electrodes

Electrode-less Systems

2345

2345678

2345678

23456789012345

23456789012345

23456789012345

234567890123456789012345

23456789012345678901234567890121234567

2

2

234567890123456789012345678901212345678901234567890123456789

234567890123456789012345678901212345

2

2

Typical Values

23

Page 28

Conductivity Sensor 012–06485B

Table 2—Table of Conductivity vs. Concentration for Common Solutions

Conductivity (G) in microsiemens/cm (micromhos/cm) at 25 °C (77 °F)

Wt. % ppm NaCl NaOH HCI H2SO

mg/liter

000.0001

000.0003

000.001

000.003

000.01

000.03

000.1

000.3

001.0

003.0

005.0

010.0

020.0

030.0

040.0

050.0

075.0

100.00

Point of

Maximum

Solubility

0.0001

0.0003

0.0010

0.0030

0.0100

0.0300

0.1,000

0.3,000

110,000

Rarely Used

▲▲

▲

▲▲

00002.2

00006.5

00021.1

000064

000210

000617

01,990

05,690

17,600

48,600

78,300

140,000

226,000

sat

sat

sat

sat

sat

Point of

Maximum

26%

00006.2

00018.4

00061.1

000182

000603

0 1,780

0 5,820

16,900

53,200

144,000

223,000

358,000

414,000

292,000

191,000

150,000

sat

sat

Point of

Maximun

Abt. 50%

00011.7

00035.0

000116

000340

001,140

003,390

011,100

032,200

103,000

283,000

432,000

709,000

850,000

732,000

sat

sat

sat

sat

Point of

Maximun

37%

00008.8

00026.1

00085.6

000251

000805

002,180

006,350

015,800

103,000

048,500

141,000

237,000

427,000

709,000

828,000

770,000

182,000

010,000

Point of

Maximun

—

4

HNO

3

00006.8

000220

000867

000199

000657

001,950

006,380

018,900

060,000

172,000

275,000

498,000

763,000

861,000

820,000

717,000

340,000

050,000

Point of

Maximun

—

HF Acetic*

Acid

000010

000230

000899

000290

000630

001,490

002,420

005,100

011,700

034,700

062,000

118,000

232,300

390,000

NA

NA

7.8 (0 °C)

0 4 (0

Point of

Maximun

—

00004.2

00007.4

00015.5

00030.6

000063

000114

000209

000368

000640

01,120

01,230

01,530

01,600

01,405

01,080

00740

00168

°C)

Point of

Maximun

< 1

—

Point(s) of

Maximum

Conductivity

Maximum

Conductivity

*HAc data at 18 °C

Point(s) of

Maximum

26%

Maximum

244,000

Point(s) of

Maximum

16%

aximum

412,000

Point(s) of

Maximum

18.5%

aximum

852,000

Point(s) of

31%

92.5%

830,000

139,000

Point(s) of

Maximum

31%

aximum

862,000

Point(s) of

Maximum

Abt. 35%

aximum

NA

Point(s) of

Maximum

19%

aximum

1,600

24

Page 29

012–06485B Conductivity Sensor

Table 3—Table of Conductivity vs. Concentration for Common Solutions

Conductivity (G) in microsiemens/cm (micromhos/cm) at 25 °C (77 °F) Except Where Noted

Wt . % ppm H3PO4 NH4OH N H3 CaCl2 KNO3 CuSO4 CO2 SO2

000.0001

000.0003

000.001

000.003

000.01

000.03

000.1

000.3

001.0

003.0

005.0

010.0

020.0

030.0

040.0

050.0

075.0

100.00

Point of

Maximum

Solubility

mg/liter

0 1

0.0003

0.0010

0.0030

0.0100

0.0300

0.1,000

0.3,000

110,000

Rarely Used

▲▲

▲

▲▲

00003.9

00011.5

00036.5

0107

0342

0890

2,250

4,820

10,500

23,000

35,000

60,700

123,000

182,000

223,000

231,000

135,000

48,000*

Poin

Maximun

—

00004.1

00018.3

0017

0031

0058

0102

0189

0329

0490

0790

0958

1,115

0968

0725

0460

0285

sat

—

Point of

13.6%

(1 atm)

00006.6

0014

0027

0049

0084

0150

0275

0465

0810

1,110

1,115

1,120

0435

sat

sat

sat

sat

< 1

Point of

28%

(1 atm)

00002.4

00026.7

00 24

00 71

0 230

0 670

2,080

5,900

18,000

50,000

74,000

130,000

195,000

190,000

120,000

sat

sat

sat

Point of

Maximun

46%

00001.3

0004

0013

0139

0130

0390

1,300

3,700

11,500

32,000

52,000

95,000

171,000

sat

sat

sat

sat

sat

Point of

Maximun

22%

00000.6

00001.8

0016

0118

0158

0160

500

1,450

4,600

13,000

21,500

36,500

sat

sat

sat

sat

sat

sat

Point of

Maximun

17.5%

00001.2

00001.9

00013.9

00036.8

0012

0020

0039

sat

sat

sat

sat

sat

sat

sat

sat

sat

sat

< 1

Point of

.15%

(1 atm)

00006.4

0018

0054

0150

0450

1,200

3,600

7,900

17,200

32,700

42,000

61,000

sat

sat

sat

sat

sat

< 1

Point of

11.7%

(1 atm)

Point(s) of

Maximum

Conductivity

Maximum

Conductivity

*Estimated

Point(s) of

Maximum

47%

aximum

234,000

Point(s) of

Maximum

2.67%

1,120

(18 °C)

Point(s) of

Maximum

5.5%

1,120

(18 °C)

Point(s) of

31%

24%

830,000

204,000

Point(s) of

Maximum

22%

aximum

185,000

Point(s) of

Maximum

17.5%

aximum

52,000

Point(s) of

Maximum

.15%

aximum

48

Point(s) of

Maximum

11.7%

aximum

66,000

25

Page 30

Conductivity Sensor 012–06485B

Table 4—Conversion Chart to Estimate TDS of Aqueous Solutions

Specific

conductance

micromhos/cm*

.055

.056

.063

.071

.083

.100

.125

.167

.250

.500

1.000

1.250

1.667

2.500

5.000

10.000

20.000

40.000

80.000

158.730

312.500

625.000

1,250.000

2,500.000

5,000.000

10,000.000

Specific

resistance

megohmos-cm*

18.240

18.000

16.000

14.000

12.000

10.000

8.000

6.000

4.000

2.000

1.000

.800

.600

.400

.200

.100

.050

.025

.0125

.0063

.0032

.0016

.0008

.0004

.0002

.0001

As Ion

none

.036

.041

.046

.054

.065

.081

.108

.163

.325

.650

.813

1.083

1.625

3.250

6.500

13.000

26.000

52.000

103.175

203.125

406.250

812.500

1,625.000

3,250.000

6,500.000

Parts Per Million

none

.028

.031

.036

.042

.050

.063

.083

.125

.250

.500

.625

.833

As NaCl**

3

1,000.000

2,000.000

4,000.000

As CaCO

1.250

2.500

5.000

10.000

20.000

40.000

79.635

156.250

312.500

625.000

1,250.000

2,500.000

5,000.000

none

.022

.025

.029

.033

.040

.050

.067

.100

.200

.400

.500

.667

1.000

2.000

4.000

8.000

16.000

32.000

63.492

125.000

250.000

500.000

Gr./Gal.

as

CaCO

none

.002

.002

.002

.002

.003

.004

.005

.007

.015

.029

.037

.049

.073

.146

.292

.585

1.170

2.340

4.641

9.137

18.273

36.550

73.099

146.199

292.398

3

*At 25 °C

**At 25 °C, given specific conductance values included in this table.

Table 5 —Table of High Accuracy Reference Solution for Calibration*

Reference

Solution

A

B

C

D

* Excluding the conductivity of the water used to prepare the solutions. These tabulated conductivity values are in international

units. When using measuring instruments calibrated in absolute units, multiply the tabular values by 0.999505

Approximation

Normality of

Solution

1

0.1

0.01

0.001

Method of Preparation

74.2480 g of KCI weighed in air per 1 L

of solution at 20 °C

7.4365 g of KCI weighed in air per 1 L

of solution at 20 °C

0.7440 g of KCI weighed in air per 1 L

of solution at 20 °C

Dilute 100 mL of solution C to 1 L at 20 °C

Temp., °C

0

18

25

0

18

25

0

18

25

0

18

25

Electrical

Conductivity,

µS/cm

65,176

97,838

111,342

7,138

11,167

12,856

773.6

1,220.5

1,408.6

77.69

127.54

148.93

26

Page 31

012–06485B Conductivity Sensor

Table 6 —Sample Illustrating the Application of Conductivity to Agriculture*

TDS (mg/l)

EC in Millimhos

500

1000

2000

3000

4000

5000

6000

per cm. at 25ûC

7000

8000

Beets

Spinach

Tomato

Broccoli

Cabbage

Potato

Corn

Sweetpotato

Lettuce

Bell pepper

The indicated salt tolerances

apply to the period of rapid plant

growth and maturation, from the

late seeding stage onward.

Crops in each category are

ranked in order of decreasing

salt tolerance. Width of the bar

next to each crop indicates the

effect of increasing salinity on

yield. Crosslines are placed at

10, 25, and 50% yield reductions.

Onion

Carrot

Beans

25%

*From:

10%

Environmental Chemistry: Air and Water Pollution (2nd ed.)

Foresman, and Company, Glenview, Illinois) p. 133, 1976.

50%

H. Stephen Stover and Spencer L. Seager (Scott,

Sources of Conductivity Data

1. International Critical Tables, Vol. VI, 230–258; McGraw Hill,

1929.

2. Handbook of Chemistry and Physics, 78th Edition; CRC Press,

1997.

3. Electrolyte Solutions, Robinson and Stokes: Butterworths, 1959.

27

Page 32

Conductivity Sensor 012–06485B

28

Page 33

012–06485B Conductivity Sensor

Technical Support

Feedback

If you have any comments about the product or manual,

please let us know. If you have any suggestions on

alternate experiments or find a problem in the manual,

please tell us. PASCO appreciates any customer feedback.

Your input helps us evaluate and improve our product.

To Reach PASCO

For technical support, call us at 1-800-772-8700 (tollfree within the U.S.) or (916) 786-3800.

fax: (916) 786-3292

e-mail: techsupp@pasco.com

web: www.pasco.com

Contacting Technical Support

Before you call the PASCO Technical Support staff, it

would be helpful to prepare the following information:

ä

If your problem is with the PASCO apparatus, note:

- Title and model number (usually listed on the

label);

- Approximate age of apparatus;

- A detailed description of the problem/sequence of

events (in case you can’t call PASCO right away,

you won’t lose valuable data);

- If possible, have the apparatus within reach when

calling to facilitate description of individual parts.

ä

If your problem relates to the instruction manual,

note:

- Part number and revision (listed by month and year

on the front cover);

- Have the manual at hand to discuss your

questions.

29

Page 34

Loading...

Loading...