Page 1

Instruction Manual

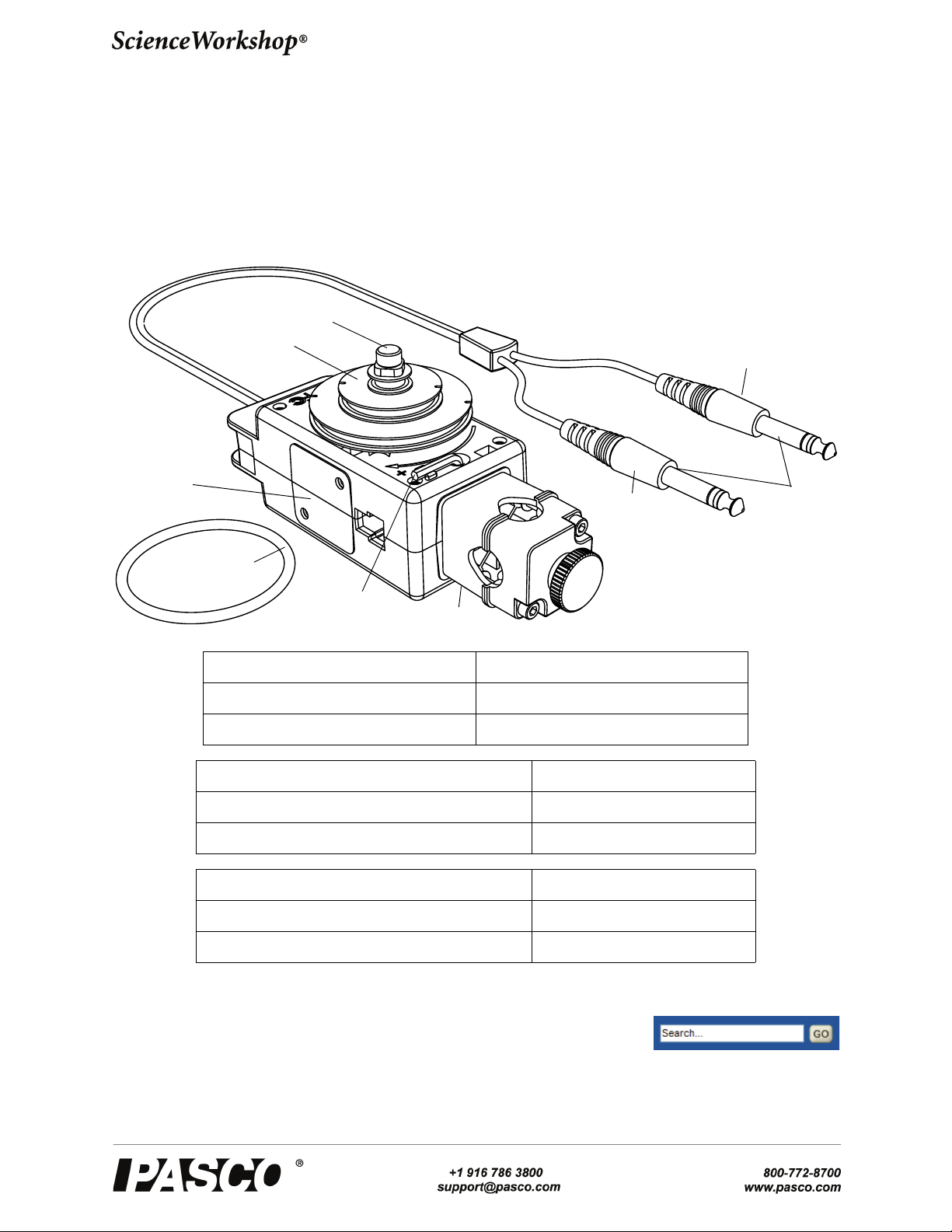

Sensor Phonon

Plugs

Rod clamp

O-ring for

Three-step

Pulley

Three-step

pulley

Hex Key

(Allen wrench)

Thumbscrew

T-Slot

Additional

mounting

position for

rod clamp

(1 of 2)

Yellow Plug

Black Plug

Rotary Motion Sensor

CI-6538

012-13990A

Equipment Included Equipment Included

Rotary Motion Sensor (CI-6538) Three-step Pulley and O-ring

Rod Clamp Hex Key (Allen wrench)

Required Items* Information

PASCO Interface see www.pasco.com

PASCO Data Acquisition Software see www.pasco.com

Items to Consider* Information

*See the PASCO catalog or the PASCO web site at www.pasco.com for more information.

Experiments for the Rotary Motion Sensor in electronic format are available to download

from the PASCO web site at www.pasco.com. For downloadable experiments, go to

www.pasco.com and enter CI-6538 in the Search window. Check the User Resources tab.

PASPORT Digital Adapter PS-2159

Phone Jack Extender Cable (2) PI-8117

Page 2

®

Model No.CI-6538 Quick Start

Sensor Pho-

non Plugs

DIGITAL

INPUT ports

Black Plug

Yellow Plug

• SETUP: For more information on setting up the software and recording data, refer to the

Online Help System and the User’s Guide for the data acquisition software.

Equipment used with the sensor Equipment used with the sensor

Mini-Rotational Accessory (CI-6691) Physical Pendulum Set (ME-9833)

Linear Motion Accessory (CI-6888) Torsion Pendulum Accessory (ME-6894)

Chaos/Driven Harmonic Accessory (CI-6689A) Track String Adapter (ME-6569)

“A” Base Rotational Adapter (CI-6690 Centripetal Force Pendulum (ME-9821)

Gyroscope Mounting Bracket (ME-8963) Linear Translator (OS-8535)

Dynamics Track Mount Accessory (CI-6692) Polarization Analyzer (OS-8533A)

Three-Step Pulley Accessory (CI-6693) Computer-Based Thermal Expansion (TD-8579)

Rotating Platform (ME-8951) Three-Axis Gyroscope (ME-8960)

Quick Start

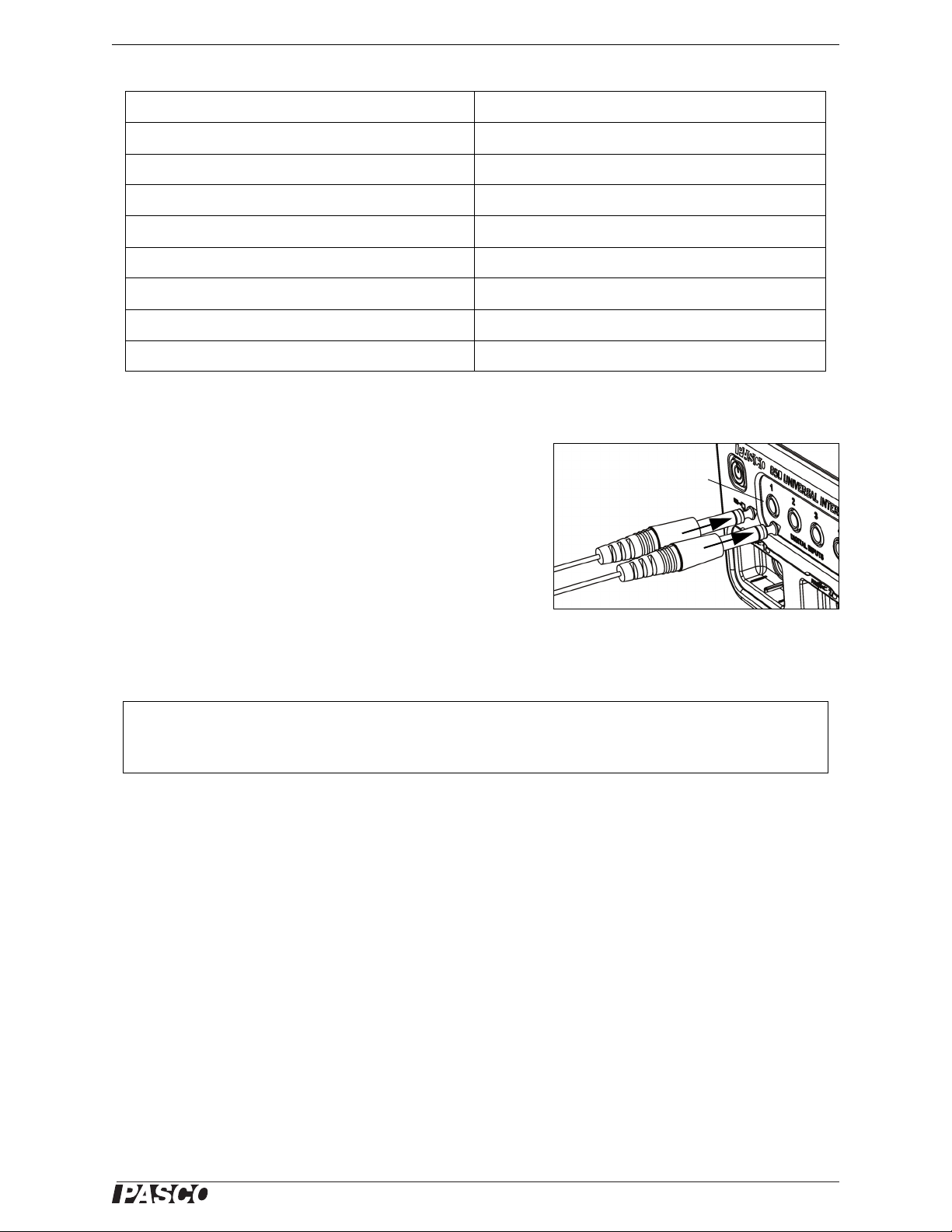

• Plug the Sensor Phone Plugs into two adjacent DIGITAL

INPUT ports of a PASCO interface (such as the 850 Universal Interface). For example, plug the yellow plug into DIGITAL INPUT 1 and the black plug into DIGITAL INPUT 2.

• NOTE: If you are using a PASPORT-only PASCO interface,

connect the Sensor Phone Plugs to the PS-2159 PASPORT

Digital Adapter and then plug the adapter into the interface.

• Start the PASCO data acquisition software (such as PASCO

Capstone). Set up a data display in the software.

• Click “Record” or touch ‘Start’ to begin recording data. Turn the shaft of the Rotary Motion Sensor.

Introduction

The ScienceWorkshop CI-6538 Rotary Motion Sensor is a versatile position and motion measuring device. It

measures angles to a resolution of 0.09°, and detects the direction of motion. Markings on the outside of the case

indicate which is the default positive direction. The optical code wheel inside the sensor has 4000 divisions per

revolution (360°), and the maximum speed is 30 revolutions per second.

The sensor comes with a removable three-step pulley (10 millimeter (mm), 29 mm, and 48 mm diameters), and a

rubber “O”-ring that fits into the largest diameter step. The three-step pulley can be attached to either end of the

shaft, and can be placed large-diameter down or large-diameter up on the shaft. A tab on the inside of the pulley

matches a notch on the outside of the shaft. The pulley has a notch and a small hole in the outer edge of the largest and second largest steps for attaching a string. The thumbscrew hex key tool can be used to remove the rod

clamp from the end of the sensor so it can be mounted on either the right-hand or left-hand side.

The end of the sensor where the cord exits the case has a platform for mounting a Super Pulley with Table Clamp

(not included). The T-slot through the sensor is for inserting the optional Linear Motion Accessory rack

(CI-6888). The gear teeth on the rack mesh with the gear teeth on the optical code wheel inside the sensor.

012-13990A

2

Page 3

®

Model No.CI-6538 Introduction

Rod clamp

Case

Rod clamp

mounting

positions

Dynamics

Track Mount

Accessory

PAS CO t r ac k

Support rod

Dynamics

Track Mount

Accessory

Square

nut into

T-slot

Mounting rod

Hanging

mass

PASCO

Cart

PASCO

Track

Mounting the Rotary Motion Sensor

The rod clamp fits rods up to 12.7 mm in diameter, such as the

ME-8736 45 cm Stainless Steel Rod, and the rod clamp can be

attached to the sensor in three different locations: at the end opposite to the cable and on either side of the case.

Use the included hex key to loosen the two screws that hold the

rod clamp on the Rotary Motion Sensor case. The two screws do

not need to come out all the way; they are held inside the rod

clamp by small O-rings. Move the rod clamp to one of the additional mounting positions on either side of the case and use the

hex key to tighten the screws in place.

It is possible to mount the Rotary Motion Sensor horizontally on

a support rod with the Three-step Pulley facing up or facing sideways. You can mount the sensor vertically with the pulley facing

forward. The sensor can also be mounted on the short rod that is part of the Dynamics Track Mount Accessory

(CI-6692).

Mounting the Rotary Motion Sensor on a PASCO Track

Use the Dynamics Track Mount Accessory (CI-6692) to mount the

Rotary Motion Sensor on a PASCO track. Slide the square nut of the

Dynamics Track Mount Accessory into the T-slot on the side of the

track. Adjust the position of the mounting rod.on the Dynamics Track

Mount Accessory.

012-13990A

When mounted on a track as shown, a

Rotary Motion Sensor could be used to

measure the motion of a PASCO Cart as it

is pulled by a string suspended over the

Three-step Pulley of the sensor and

attached to a hanging mass.

3

Page 4

®

Rotary Motion Sensor Introduction

Adapter

Bracket

Rotary

Motion

Sensor

3-step

Pulley

3-step

Pulley

Shoulder

Screw

Rotating

Shaft

Rotary

Motion

Sensor

Adapter

Bracket

Top View Bottom View

“O” Ring

3-step

Pulley

Gyroscope

Mounting

Bracket

Slotted

guide

arm

Mini-Rotational

Accessory Rod

Rod

guides

Cylindrical

mass

Shaft

Screw

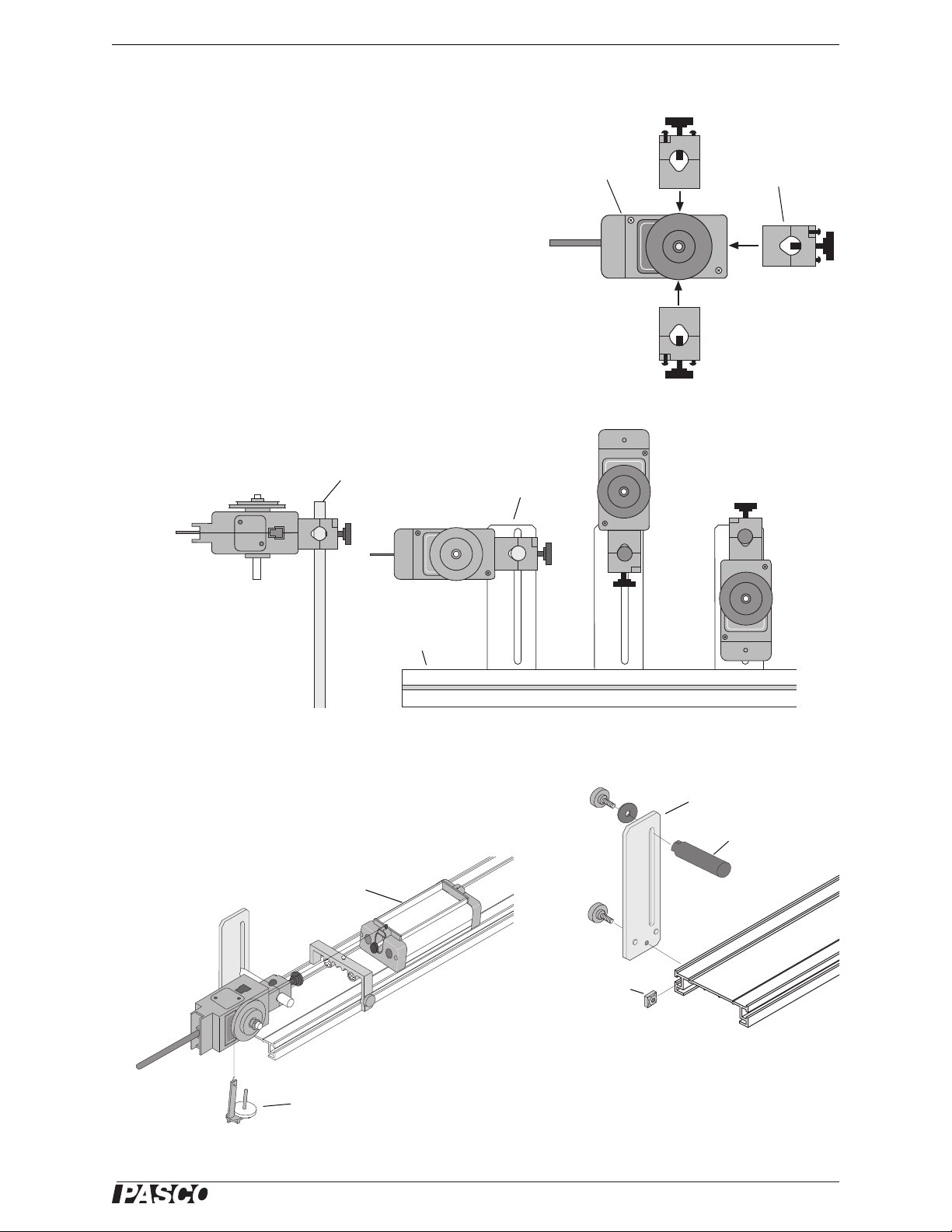

Mounting the Rotary Motion Sensor to a Large “A” Base

The Rotary Motion Sensor can be mounted on the base of the Rotating

Platform (ME-8951) using the “A” Base Rotational Adapter (CI-6690,

available separately).

The “A” Base Rotational Adapter includes an adapter bracket, a

three-step pulley, a drive belt (“O” ring), and a shoulder screw.

See the PASCO web site at www.pasco.com for more information.

Mounting the Rotary Motion Sensor to a Gyroscope

Use the Gyroscope Mounting Bracket (ME-8963, available separately)

to mount the Rotary Motion Sensor to the Three-Axis Gyroscope

(ME-8960). Remove the gyroscope assembly from the vertical shaft of

the large “A” base. Mount the Gyroscope Mounting Bracket onto the

vertical shaft. Remove the rod clamp and the three-step pulley from the

Rotary Motion Sensor, and mount the sensor on the Gyroscope Mounting Bracket with the thumbscrews included with the bracket. Mount

the slotted guide arm onto the shaft of the Rotary Motion Sensor.

Replace the gyroscope assembly on the vertical shaft.

See the PASCO web site at www.pasco.com for more information.

Attaching Accessories to the Rotary Motion Sensor

Attaching the Mini-Rotational Accessory to the Rotary Motion Sensor

To mount the rod of the Mini-Rotational Accessory to the Rotary Motion

Sensor, orient the 3-step Pulley so that the large diameter step is away

from the sensor case. The large diameter step has two pair of rod guides

opposite each other on the top edge. Align the rod with the rod guides

and use the captive screw in the center of the rod to attach the rod and

pulley onto the sensor’s shaft.

Attach the center of the rod to the 3-step Pulley and shaft and mount the

cylindrical masses at the ends of the rod to investigate the rotational inertia (moment of inertia) of point masses.

Attach the end of the rod to the 3-step Pulley and shaft. Mount a cylindrical mass on the rod to use the rod as a pendulum. Investigate the period

of oscillation of the pendulum when the amount of mass or the position

of the mass is changed. Investigate the period of oscillation as the amplitude of the swing is changed.

4

Page 5

®

Model No.CI-6538 Introduction

Pendulum Setup

Point Mass Setup

Disk

Mass

Magnet

Disk (phantom

image)

Magnet Damping

Attachment

String

Spring (2)

Dynamics Track

Mount Accessory

String

Mechanical

Oscillator/Driver

PASCO Track

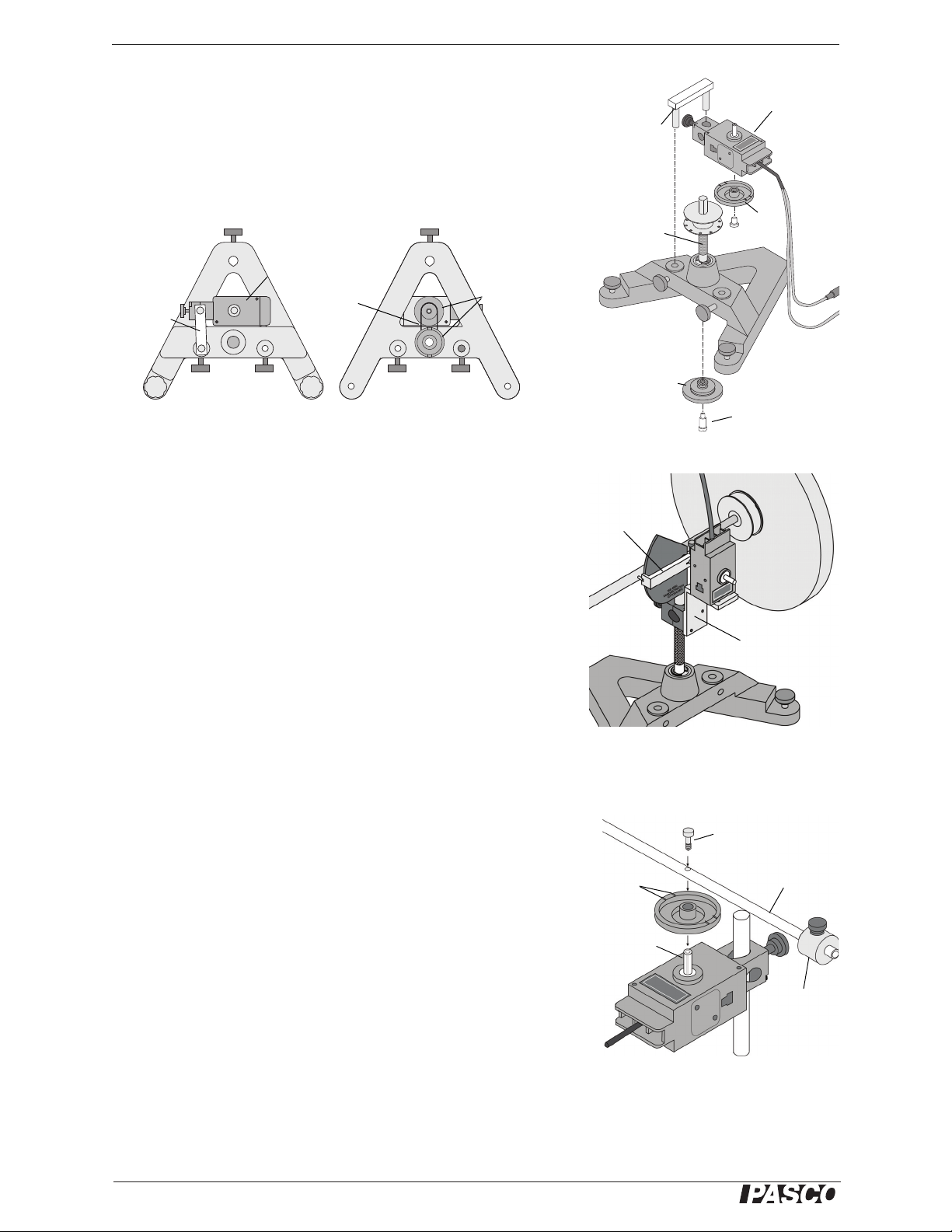

Chaos/Harmonic Motion Accessory Setup

Super Pulley

with Table

Clamp

String to

hanging mass

Disk

Rotary Motion

Sensor with

3-step Pulley

Attaching the Chaos/Harmonic Motion Accessory to the Rotary Motion Sensor

The Chaos/Harmonic Motion Accessory (CI-6689A) is a driven damped physical pendulum. Various types of

phase plots can be made as the driving frequency, driving amplitude, initial conditions, and amount of damping

are varied.

The Magnetic Damping Attachment attaches to either side of the Rotary Motion

Sensor in the same way as the rod clamp is attached. A small cylindrical mass

attaches to the threaded hole in the edge of the disk to form the physical pendulum. Mount the disk with the small mass to the 3-step Pulley and shaft.

One way to drive the Chaos/Harmonic Motion Accessory is with the Mechanical Oscillator/Driver (ME-8750) and a power supply. Any PASCO track can be

used to mount and align all the components.

Using the Mini-Rotational Disk

For other rotational inertia experiments, mount

the Rotary Motion Sensor with the disk horizontal. Mount a Super Pulley with Clamp

(ME-9448B) on the platform at the cable end of

the sensor. To provide a known torque, wrap a

string around one of the steps of the 3-step Pulley. Arrange the end of the string over the Super

Pulley and attach a hanging mass.

Perform a conservation of angular momentum

experiment by dropping the ring onto the disk as

it is rotating.

012-13990A

5

Page 6

®

Rotary Motion Sensor Introduction

Downloadable Experiments

Experiments for the Rotary Motion Sensor in electronic format are available to download from the PASCO web

site at www.pasco.com. For downloadable experiments, go to www.pasco.com and enter CI-6538 in the Search

window.

Check the “User Resources” tab and then download the experiments..

Three suggested experiments are:

• Rotational Inertia of a Point Mass

• Rotational Inertia of Disk and Ring

• Conservation of Angular Momentum.

Please see the next page for information about using the Rotary Motion Sensor with data acquisition software.

6

Page 7

®

Model No.CI-6538 Introduction

Sensor

Phone Plugs

DIGITAL

INPUT ports

Black Plug

Yellow Plug

PASCO Capstone Hardware Setup panel

850 Universal

Interface

Click the

“Add Sensor/Instrument” button

Select “ScienceWorkshop Digital Sensors”

Add Sensor or Instrument Window

Using the Rotary Motion Sensor with Data Acquisition Software

• Plug the Rotary Motion Sensor Phonon Plugs into two DIGITAL INPUT ports of a compatible PASCO interface (such

as the 850 Universal Interface, ScienceWorkshop 750 USB

Interface, or the ScienceWorkshop 500 Interface with

USB/Serial Adapter). For example, plug the yellow plug

into DIGITAL INPUT 1 and the black plug into DIGITAL

INPUT 2.

• NOTE: If you are using a PASPORT-only PASCO interface

(such as the SPARK SLS), connect the Sensor Phonon Plugs

to a PS-2159 PASPORT Digital Adapter and then plug the adapter into the interface.

• Turn on the compatible interface and start the PASCO data acquisition software.

PASCO Capstone Sensor Setup

• In PASCO Capstone, click “Hardware Setup” in the Tools

palette to open the Hardware Setup panel.

• Confirm that the Hardware Setup panel shows the interface you are using.

• NOTE: If the interface you are using does not appear in the

Hardware Setup panel, click the “Choose Interface” button

and select your interface from the list of choices.

• In the Hardware Setup window, click the “Add Sensor/Instrument” button to open the “Add Sensor or Instrument” window.

• In the Add Sensor or Instrument window, click the “Sensor

or Instrument Type” menu and select “ScienceWorkshop

Digital Sensors” from the list of choices.

012-13990A

7

Page 8

®

Rotary Motion Sensor Introduction

Select “Rotary Motion Sensor” and click OK

Rotary Motion

Sensor icon

Confirm the Rotary Motion Sensor

Sensor Properties

icon

Selected Sensor

Click the Sensor Properties icon

Rotary Motion Sensor Properties window

• In the list of ScienceWorkshop Digital Sensors, select

“Rotary Motion Sensor” and then click “OK”.

• In the Hardware Setup panel, confirm that the icon of the

Rotary Motion Sensor appears with the icon of the interface you

are using.

• At the lower right corner of the Hardware Setup panel is the Sensor Properties icon. Click the Sensor Properties icon to open the

Properties window

.

• In the Properties window, select the sensor’s “Resolution”. The choices for the resolution are “Low: 360 counts

per revolution” and “High: 1440 counts per revolution”.

• NOTE: The required resolution depends on the rate at

which the Rotary Motion Sensor will rotate during the

experiment. In general, if the sensor is connected to a

PASCO 850 Universal Interface, choose “High: 1440

counts per revolution”. Otherwise, if the sensor will rotate

quickly during the experiment, select “Low: 360 counts

per revolution”. If the sensor will rotate slowly and a finer

resolution is required, choose “High: 1440 counts per revolution”.

8

Page 9

®

Model No.CI-6538 Introduction

Select “Linear Accessory”

Create a Graph display

Graph display

icon

Click the “Select

Measurement”

menu button

Select “Angular Velocity”

Click “Record”

Click “Stop”

• SETUP: For more information on setting up the data acquisition software and recording data,

refer to the Online Help System and the User’s Guide for the data acquisition software.

• Select the “Linear Accessory” you are using from the list

of choices in the menu, and click “OK”. NOTE: See the

experiment for information about which choice to select.

PASCO Capstone Display Setup

• Set up a data display. For example, drag the Graph icon

from the Displays palette onto the workbook page, or double-click the icon to create a Graph display..

• Set up the Graph display to show Angular Velocity (rad/s) on the vertical

axis. Click the “Select Measurement” menu button on the vertical axis

and pick Angular Velocity (rad/s) from the menu. Time (s) automatically

shows on the horizontal axis.

PASCO Capstone Data Collection

• Click ‘Record’ in the lower left corner of the PASCO Capstone window

• Turn the shaft of the Rotary Motion Sensor back-and-forth. View the data

• Click “Stop” to end data recording.

.

to begin recording data. (The “Record” button changes to “Stop”.)

in the Graph display.

012-13990A

9

Page 10

®

Rotary Motion Sensor Introduction

SPARK SLS screen for the

Rotary Motion Sensor

Touch

“OK”

Touch “Rotary

Motion Sensor”

Touch “Rotary Motion

Sensor” and then touch “OK”

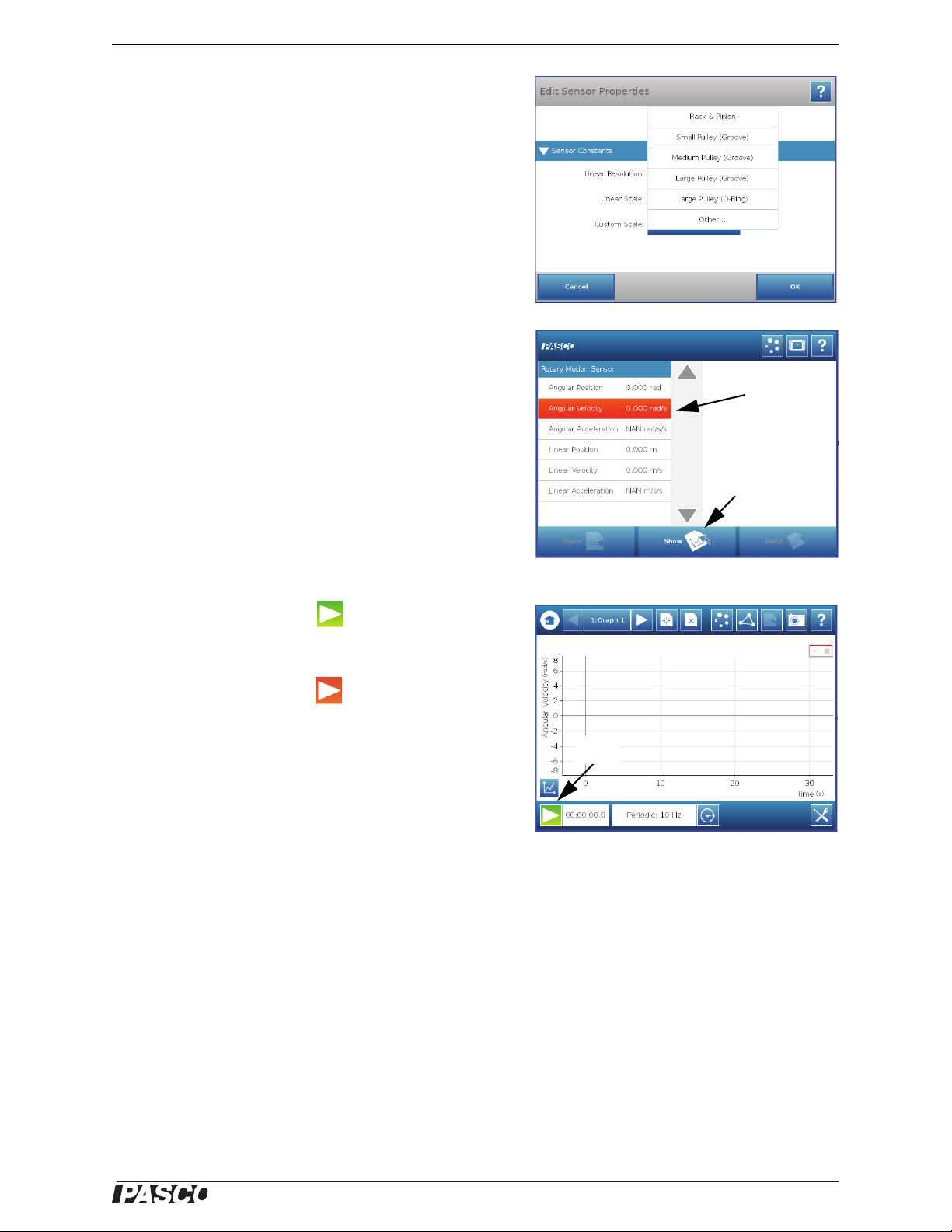

Edit Sensor Properties window

Select the Linear Resolution

SPARKvue Setup

• When the SPARKvue compatible device starts up, it

shows the Home Screen for a moment, and then shows a

screen that lists various digital sensors, including the

Rotary Motion Sensor.

• Touch “Rotary Motion Sensor” and then touch “OK. The

“Edit Sensor Properties” screen opens.

• In the Edit Sensor Properties screen, touch “Linear Resolution” and touch a choice (360 or 1440) from the

menu.

• NOTE: The required resolution depends on the rate at

which the Rotary Motion Sensor will rotate during the

experiment. In general, if the sensor will rotate quickly

during the experiment, select “360”. If the sensor will

rotate slowly and a finer resolution is required, choose

“1440”.

10

Page 11

®

Model No.CI-6538 Introduction

Touch “Linear Scale” and tap a choice

Touch

“Show”

Touch “Angu-

lar Velocity”

Touch “Angular Velocity” and

then tap “Show”

Tou ch “ Star t ”

Tap

“Start”

• Touch “Linear Scale” and touch a choice from the menu

(such as “Large Pulley (Groove)). Tap “OK”. The screen

shows the Rotary Motion Sensor’s list of parameters.

• Touch “Angular Velocity” in the list of parameters and

then touch the “Show” button to open a graph display of

Angular Velocity versus Time.

• Touch the Start button ( ) to begin recording data.

Turn the shaft of the sensor and view the data in the display.

• Touch the Stop button ( ) to end data recording.

• SETUP: For detailed information on setting up the data acquisition software and recording data,

refer to the User’s Guide and the online help for the data acquisition software.

012-13990A

11

Page 12

®

Rotary Motion Sensor Introduction

Technical Support

For assistance with any PASCO product, contact PASCO at:

Address: PASCO scientific

Web: www.pasco.com

10101 Foothills Blvd.

Roseville, CA 95747-7100

Phone: +1 916-786-3800 (worldwide)

Email support@pasco.com

800-772-8700 (U.S.)

Limited Warranty For a description of the product warranty, see the PASCO catalog. Copyright The PASCO scientific Instruction

Manual is copyrighted with all rights reserved. Permission is granted to non-profit educational institutions for reproduction of any part

of this manual, providing the reproductions are used only in their laboratories and classrooms, and are not sold for profit. Reproduction under any other circumstances, without the written consent of PASCO scientific, is prohibited. Trademarks PASCO, PASCO

Capstone, and ScienceWorkshop are trademarks or registered trademarks of PASCO scientific, in the United States and/or in other

countries. For more information visit www.pasco.com/legal.

Product End of Life Disposal Instructions:

This electronic product is subject to disposal and recycling regulations that vary by country and region. It is your

responsibility to recycle your electronic equipment per your local environmental laws and regulations to ensure that it

will be recycled in a manner that protects human health and the environment. To find out where you can drop off your

waste equipment for recycling, please contact your local waste recycle/disposal service, or the place where you purchased the product.

The European Union WEEE (Waste Electronic and Electrical Equipment) symbol (to the right) and on the product or its packaging indicates that this product must not be disposed of in a standard waste container.

12

Loading...

Loading...