Page 1

Instruction Sheet

for the PASCO

Model CI-6526

Type K Temperature Sensor

Introduction

The PASCO Model CI-6526 Type-K Thermocouple Temperature Sensor is designed

to be used with a PASCO CI computer interface or a PASPORT USB

interface with an Analog Adapter

(PS-2158). A thermocouple works

because junctions between dissimilar metals or alloys in an electrical circuit

give rise to an electromotive force or voltage if they

are at different temperatures. This type of thermocouple is made from a chromel and alumel wire junction.

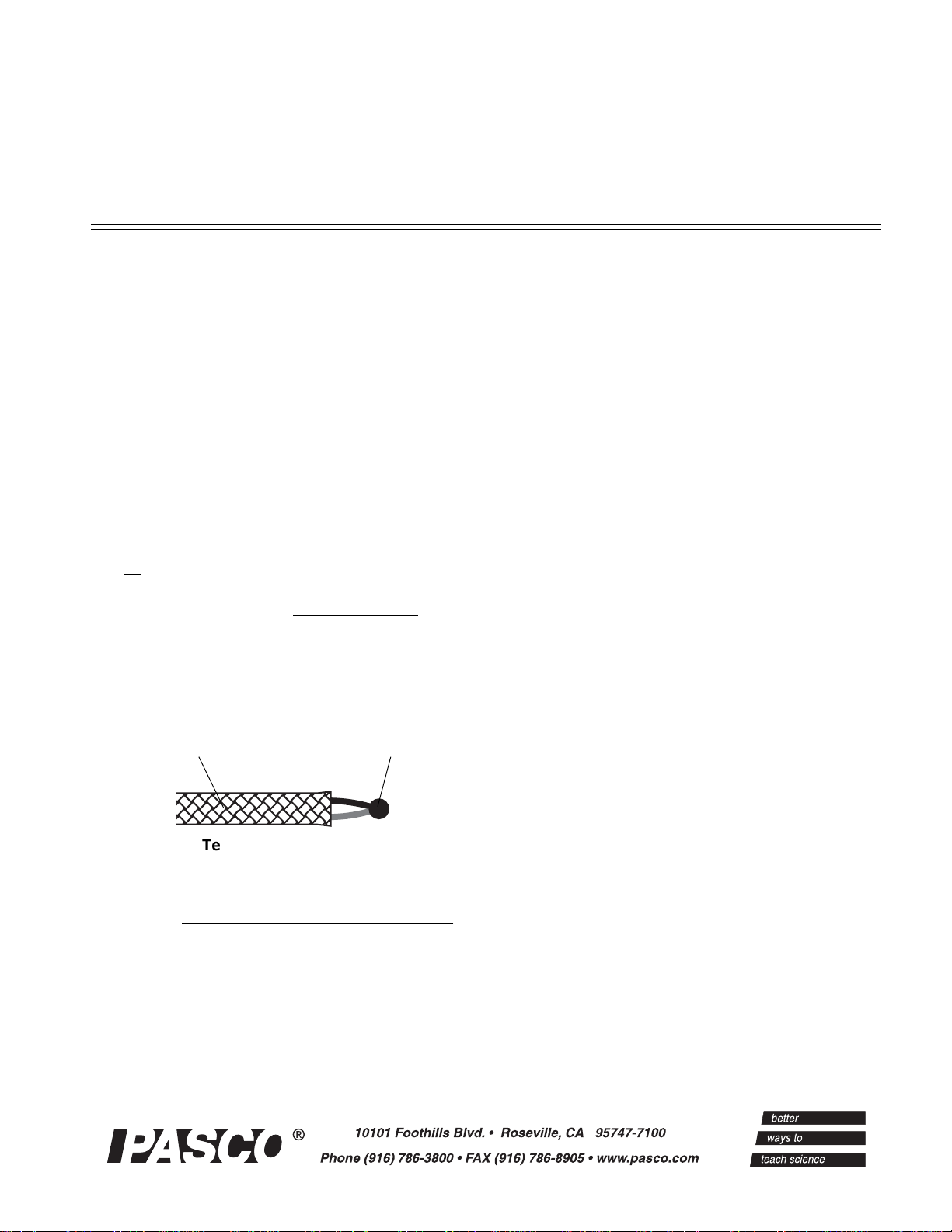

Range

The tip of the 003-05590 Type-K Thermocouple

Probe can withstand temperatures between -180°C

and +1260°C. However, the insulation material that

covers all but the tip of the sensor has a maximum

temperature of +482°C. You can use the sensor to

insulation (maximum

temperature: +482°C)

tip (maximum

temperature: +1260°C)

012-05563D

low zero degrees Celsius. The Type-K Thermocouple

can be used in water and mild chemical solutions; but

it is well suited for dry measurements.

The sensor consists of the Type-K probe (Model

PS-2155) and the sensor electronics box. The sensor

box has a socket made from chromel and alumel that

is mounted very close to the AD595 integrated circuit

(IC). The IC provides the cold junction compensation

as long as the IC temperature is equal to the junction

temperature made by the socket and copper connections. The overall output voltage-to-temperature ratio

is 10 milliVolts per degree Celsius. The output voltage

range is -2.000 (at

-200°C) to +10.000 Volts (at +1,000°C).

Temperature Range of

003-05590 Type-K Thermocouple Probe

measure high temperatures such as those in a candle

flame if you keep the insulated portion of the sensor

out of the flame.

The thermocouple characteristics are fairly linear from

zero degrees Celsius up to the maximum temperature

with an error less than 3°C ± 3% of the reading over

the full range. Note that the error becomes larger be-

Additional Equipment Needed

• Computer Interface such as a PASCO CI interface or a PASPORT USB interface with an Analog Adapter (PS-2158).

Optional Equipment

• The sensor box accepts any Type-K thermocouple, such as the CI-6536 High Temperature

Type-K Thermocouple Probe. The High Temperature Type-K Thermocouple Probe is housed

in a 30.5 cm (12”) inconel metal cover (maximum temperature = +1148°C). Therefore, it can

be used in an open flame or for other high temperature measurements.

Page 2

Type K Temperature Sensor 012-05563D

Operation

Connecting and Using the Sensor

Attach the probe’s two prong connector to the sensor

box at the port marked TYPE K THERMOCOUPLE

PROBE INPUT. The two prong connector can go into

the port only one way because one of the prongs is

wider than the other. Connect the 8-pin DIN plug

from the sensor box to Analog Channel A, B, or C on

the computer interface box.

Touch the bare wire end of the sensor to the object to

be measured or place the sensor end into the solution

to be measured. To prevent damage to the sensor or

the insulating material,

the sensor in a flame or put the insulation in contact

with a heat source above +482°C.

➤ NOTE: IF YOU NEED TO MEASURE A

TEMPERATURE HIGHER THAN +400 °C,

USE THE CI-6536 HIGH TEMPERATURE

TYPE-K THERMOCOUPLE PROBE. (See the

PASCO catalog for more information.)

do not put the insulated part of

put voltage can be converted directly into a temperature. For example, an output voltage of 1.234 Volts

equals a temperature of 123.4 °C.

However, you can calibrate the sensor using a twopoint calibration process.

To calibrate the sensor you will need an accurate thermometer, ice water (0 °C), and boiling water (100 °C).

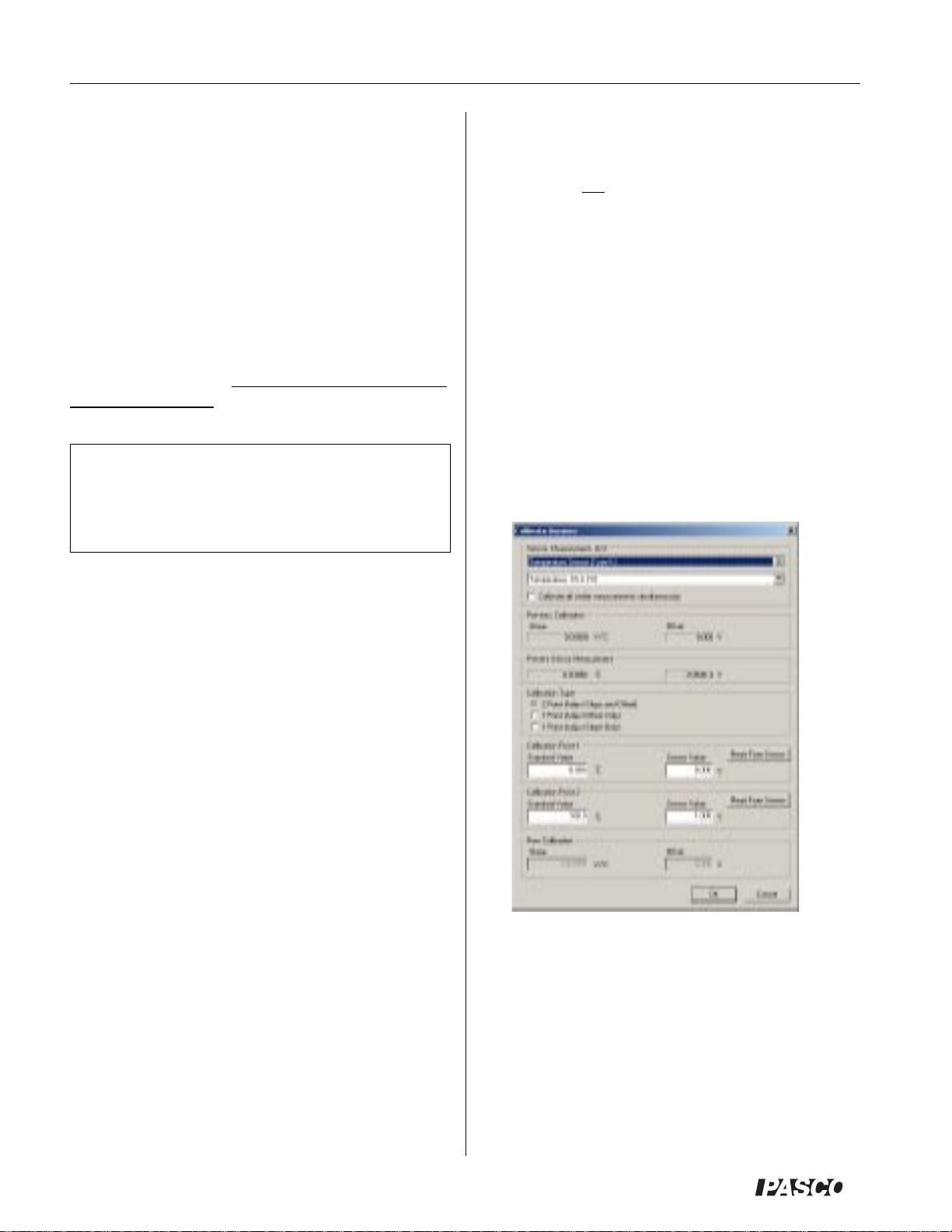

Calibrating the Sensor Using DataStudio

Assume for this example that the Type-K Thermocouple Temperature Sensor is connected to Analog

Channel A of the interface and that you do not have

any other sensors connected to the interface.

Start the DataStudio program. Select “Setup” from the

DataStudio toolbar. The interface and sensor should

appear in the setup window.

Select “Calibrate Sensors…” from the Experiment

Setup toolbar. Be sure that “2 point (Adjust Slope and

Offset)” is selected under “Calibration Type”.

Using the Sensor in Mild Chemical Solutions

The Type-K Thermocouple is designed to be used in

water and mild chemical solutions when measuring

the temperature of a liquid. The bare wire end of the

thermocouple has been tested for several minutes in

the following chemicals without damage:

acetone sodium hydroxide (lye)

household bleach ethylene glycol butyl ether

isopropyl alcohol ethylene glycol (antifreeze)

naphtha sulfuric acid (battery acid)

vinegar glacial acetic acid

paradichlorobenzene water

• Carefully rinse off any chemicals after each use.

Using the optional Teflon Sensor Cover

A package of ten Teflon Sensor Covers is available

from PASCO (part number CI-6549). See the PASCO

catalog for more information.

Use the optional Teflon FEP sensor cover when the

thermocouple probe must be placed in strong chemical solutions that may damage the probe.

Calibrating the Sensor

The sensor is designed to produce 0.003 V ± 0.005 V

at 0 °C and 10 milliVolts per degree C. Therefore, the

sensor does not need to be calibrated. Instead, the out-

Calibration Point #1: Place the bare wire end of the

thermocouple in the ice water. Also put the thermometer in the ice water. The monitor screen will show the

voltage value produced by the sensor. When the thermometer reading is almost zero, enter the reading in

the “Standard Value” box for Calibration Point 1, then

click the “Read From Sensor” button for Calibration

Point 1.

Calibration Point #2: Place the sensor and thermometer in boiling water. The monitor screen will show the

new voltage produced by the sensor. When the ther-

2

®

Page 3

012-05563D Type K Temperature Sensor

mometer reading reaches a peak, enter the reading in

the “Standard Value” box for Calibration Point 2, then

click the “Read From Sensor” button for Calibration

Point 2. Cilck “OK” at the bottom of the calibratiion

screen and close the Experiment Setup window.

You can save your calibration as a DataStudio docu-

ment by selecting “Save As…” from the File menu.

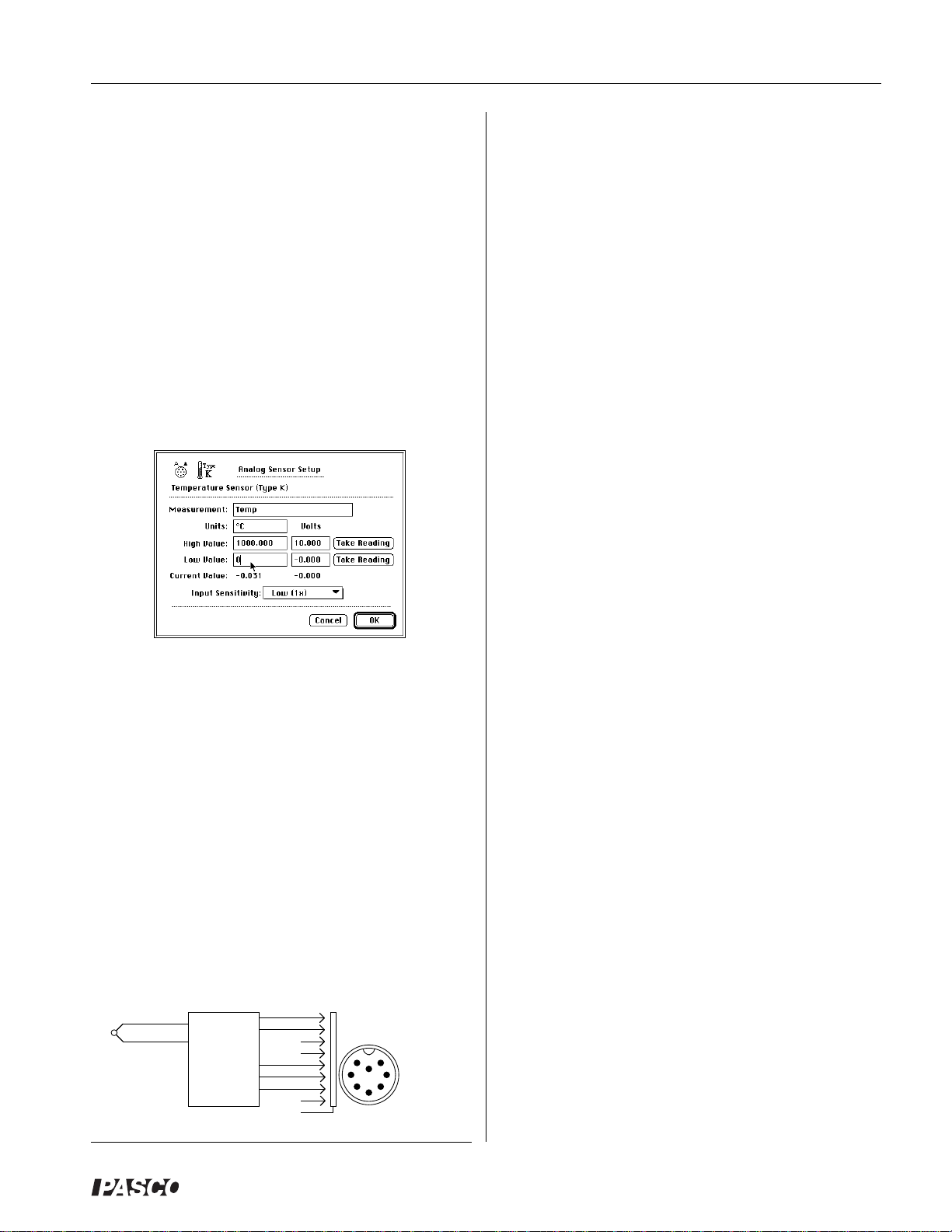

Calibrating the Sensor Using Science Workshop

Start the Science Workshop program. Click-and-drag

the analog sensor plug icon to Analog Channel A. Select “Temperature Sensor (Type-K)” from the list of

analog sensors.

You can save your calibration as a Science Workshop

document by selecting “Save As…” from the File

menu.

Limited Warranty

PASCO scientific warrants this product to be free from

defects in materials and workmanship for a period of

one year from the date of shipment to the customer.

PASCO will repair or replace, at its option, any part of

the product which is deemed to be defective in material or workmanship. This warranty does not cover

damage to the product caused by abuse or improper

use. Determination of whether a product failure is the

result of a manufacturing defect or improper use by

the customer shall be made solely by PASCO scientific. Responsibility for the return of equipment for

warranty repair belongs to the customer. Equipment

must be properly packed to prevent damage and

shipped postage or freight prepaid. (Damage caused

by improper packing of the equipment for return shipment will not be covered by the warranty.) Shipping

costs for returning the equipment, after repair, will be

paid by PASCO scientific.

Calibration Point #1: Place the sensor and thermometer in the ice water. In the Experiment Setup window,

double-click on the Type-K sensor icon to open the

Analog Sensor Setup dialog box.

The dialog box will show the “Current Value” of the

voltage produced by the Type-K sensor. When the

voltage value is almost zero, click on the bottom

“Take Reading” button. Enter the thermometer reading in the box labeled “Low Value:”.

Calibration Point #2: Place the sensor and thermometer in the boiling water. The “Current Value” will

show the new voltage produced by the sensor. When

the voltage value reaches a peak, click on the top

“Take Reading” button. Enter the thermometer reading in the box labeled “High Value:”.

YEL +

2

1

RED -

TYPE K

THERMOCOUPLE

PROBE

CHROMEL

ALUMEL

CI-6526

TEMPERATURE

SENSOR

Schematic Diagram

1

2

3

4

5

6

7

8

S

P1

7

6

1

4

8

2

S

8-PIN DIN PLUG

3

PINS FACING YOU

5

Equipment Return

Should this product have to be returned to PASCO

scientific, for whatever reason, notify PASCO scientific by letter or phone BEFORE returning the product.

Upon notification, the return authorization and shipping instructions will be promptly issued.

➤ NOTE: NO EQUIPMENT WILL BE

ACCEPTED FOR RETURN WITHOUT AN

AUTHORIZATION.

When returning equipment for repair, the units must

be packed properly. Carriers will not accept responsibility for damage caused by improper packing. To be

certain the unit will not be damaged in shipment, observe the following rules:

➀ The carton must be strong enough for the item

shipped.

➁ Make certain there is at least two inches of packing

material between any point on the apparatus and

the inside walls of the carton.

➂ Make certain that the packing material can not shift

in the box, or become compressed, thus letting the

instrument come in contact with the edge of the

box.

®

3

Page 4

Type K Temperature Sensor 012-05563D

4

®

Loading...

Loading...