XR914 Light Reactive Welding Helmet

Instruction Guide

MAINTENANCE

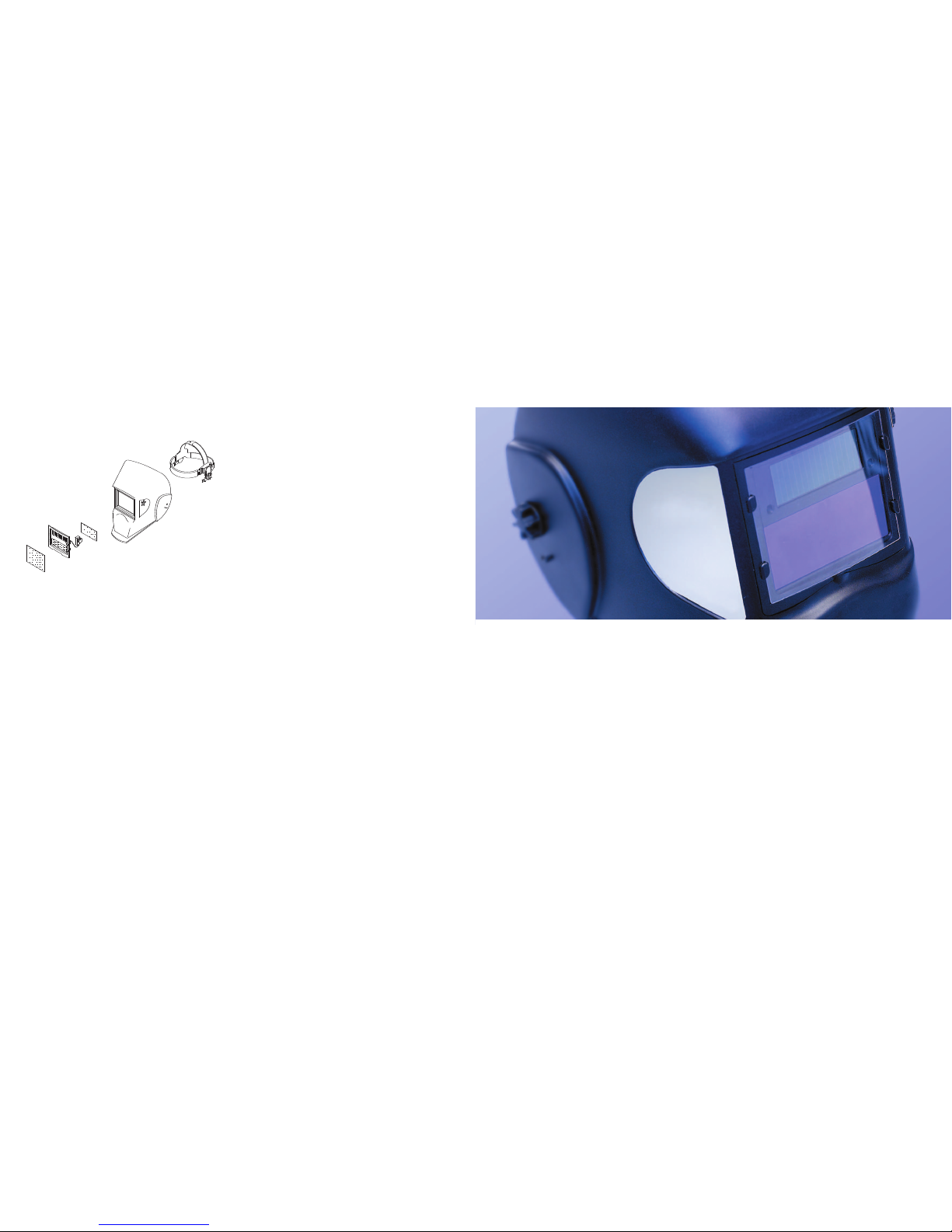

REPLACEMENT OF FRONT COVER LENS

• Remove the front cover lens by pulling outwards at the base of the

lens using the finger slot provided.

• Make sure the protective films are removed from the new cover lens.

• Place the new cover lens in the recess at the front of the helmet.

• Locate the cover lens under the 2 lugs at the left of the cartridge and

then flex the lens so that it can be inserted under the lugs on the right

hand side of the cartridge.

NOTE - Do not use the helmet without the cover lens in place.

REPLACEMENT OF INNER COVER LENS

• The welding inner cover lens is removed by pulling out the top edge.

• The new inner cover lens is assembled after the protective film is

removed. Locate one of the sides by inserting the edge under the

hook at the side and bend the lens in the middle part and locate the

lens under the hook at the other side.

REPLACEMENT OF WELDING FILTER

• Prise off the shade adjusting knob from the outside of the helmet and

unscrew the plastic locking nut below.

• From inside the helmet push inwards the two barbs on the left side of

the helmet to release them and push the cartridge forwards gently.

• The cartridge can now be removed from the front of the helmet.

FAULTFINDING

IRREGULAR DARKENING

• Headband has been set unevenly so the distance between the eyes

and the lens is different from the left to the right.

AUTO DARKENING FILTER DOES NOT DARKEN OR FLICKERS

• Front cover lens is soiled, clean or replace

• Photo sensors are dirty, wipe clean with a soft lint-free cloth.

• Welding current is too low, select the slow position on the filter and

ensure the view of the weld is unobstructed.

• Change to high sensitivity.

POOR VISION

• Ensure the cover lens and the filter cartridge are clean.

• Ensure the shade number is correct and adjust accordingly.

• Ensure ambient light is not too low.

XR914

Helmet Shell

XR914H

Complete Helmet

WARRANTY

We warrant to the purchaser that the product will be free from defects in

material and workmanship for the period of 18 months from the date of

the sale to the buyer. The manufacturers sole obligation under this

warranty is limited to making replacement or repairs, or to refund the

purchase price of the product with defects.

This warranty does not cover product malfunctions or damages, which

result from the product being tampered, misused or abused. The

operation instructions must be followed; failure to do will void the

warranty. The manufacturer is not responsible for any indirect damage,

which arises out of the use of the product.

INSPECTION

• Carefully inspect your Auto Darkening Welding Filter regularly.

• Cracked, pitted or scratched filter glass or cover lenses reduce vision

and seriously impair protection.

• These should be replaced immediately to avoid damage to the eyes.

• Inspect the complete helmet frequently and replace wor n or damaged

parts.

CLEANING

• Clean the helmet with mild soap and lukewarm water.

• Clean the welding filter with a clean lint-free tissue or cloth.

• Do not immerse in water.

• Do not use solvents.

XR420

Front Cover Lens

XR400

Cartridge

XR430

Inside Cover Lens

XR440

Adjustable Headband

XR410

Front Velcro

Cover

PARTS LIST

XR914 Light Reactive Welding Helmet

GENERAL INFORMATION

This XR914 Light Reactive Helmet will not protect against severe

impact hazards, such as fractured grinding wheels or abrasive discs,

explosive devices or corrosive liquids. Machine guards or eye splash

protection must be used when these hazards are present.

All light reactive welding filters are for use in Arc welding or cutting

applications. The unit is suitable for all Arc welding processes such as

MIG, MAG, TIG, SMAW, Plasma Arc, and Carbon Arc.

Use this helmet only for face and eye protection against harmful rays,

sparks and spatter from welding and cutting.

The XR914 Light Reactive Helmet is not suitable for “overhead”

welding applications, Laser welding or Laser cutting applications.

In the event of electronic failure, the welder remains protected against

UV and IR radiation according to Shade 16.

The light reactive welding filter should always be used with original

inner and outer cover lenses.

The manufacturer is not responsible for any modifications to the

welding filter or the use of the filter in any other manufacturer’s helmet.

Protection can be seriously impaired if unapproved modifications are

made.

WARNING

Please read and understand all instructions prior to using the

XR914 Light Reactive Welding Helmet.

Viewing Area 98mm x 44mm / 3.86” x 1.76”

Cartridge Size 122mm x 100mm x 9mm / 4 ” x 3 ”x 3 ”

UV/IR Protection Permanent Shade DIN16

Light State DIN Shade 4

Dark State DIN Shade 9 to 13 Variable

Power Supply

Solar cells with built in rechargeable battery

(estimated 6 year life)

Power On/Off Fully Automatic

Switching Time Light to dark 0.00004 seconds

Light to Dark

0.25 - 0.35 seconds - fast position

0.60 - 0.80 seconds - slow position

Operating Temp -5ºC to +70ºC (23ºF to 131ºF)

Storage Temp -20ºC to +70ºC (-4ºF to -158ºF)

Helmet Material HighImpact Polyamide Nylon

TotalWeight 430g

Minimum

Amperage 40 Amps

Required

TECHNICAL SPECIFICATION

DO

Ensure the front cover lens is fitted before use and remove protective

film.

Ensure that the lens is clean and there is no dirt or spatter covering the

2 sensors at the front of the filter cartridge.

Inspect all parts for signs of wear or damage. Any scratched or

cracked parts should be replaced prior to use.

DON’T

Never place the helmet on a hot surface.

Never open or tamper with the filter cartridge.

OPERATION

1. ADJUST THE WELDING HELMET ACCORDING TO YOUR

INDIVIDUAL REQUIREMENTS

The headband should be adjusted both in diameter and height. The angle

between face and helmet should also be adjusted and is recommended

to be 10º - 12º.

2. ON/OFF

The solar unit automatically switches on when exposed to light.

3. SELECT THE SHADE NUMBER

Five different shade numbers, 9, 10, 11, 12 and 13, are available in the

dark state.

The shade number can be selected by turning the shade on the side of

the helmet

The set shade is indicated by the arrow on the switch.

4. SELECT DELAY TIME

By moving the selector switch on the rear of the cartridge the time taken

for the lens to lighten after welding can be altered.

FAST

The lens will lighten after welding in 0.25 to 0.35 second dependant

upon ambient temperature and shade set. This setting is ideal for tack

welding or production welding with short welds.

SLOW

The lens will lighten in 0.6 to 0.8 seconds dependant upon the

ambient temperature and set shade. This setting is ideal for welding at

high amperages where there is an after glow from the weld.

5. SELECT SENSITIVITY

By moving the selector switch on the rear of the cartridge the sensitivity

to ambient light changes can be altered.

LOW

Suitable for high amperage welding and welding in bright sunlit

conditions.

HIGH

Suitable for low amperage welding and use in poor light conditions.

Suitable for use with steady arc process such as Tig welding.

RECOMMENDED SHADE NUMBERS

WELDING PROCESS 0.5 1 2.5 5 10 15 20 30 40 60 80 100 125 150 175 200 225 250 275 300 350 400 450 500

Covered Electrode Shade 9 Shade 10 Shade 11 Shade 12 Shade13 14

MIG Plate Welding Shade 10 Shade 11 Shade 12 Shade 13 14

MIG Sheet Metal Shade 10 Shade 11 Shade 12 Shade 13 Shade 14 15

TIG Shade 9

Shade 10 Shade 11 Shade 12 Shade 13 Shade 14

MAG Shade 10 Shade 11 Shade 12 Shade 13 Shade 14 Shade15

Ar

c Gouging Shade 10 11 12 13 14 15

Plasma Cutting Shade 11 Shade 12 Shade 13

Plasma W

elding

4

5 6 7 8 9 10 11 12 13 14 15

CURRENT AMPERES

5

5

116

6

115

5

116

6

1

1

2

2

Please dispose of packaging for the product in a responsible manner. It is suitable

for recycling. Help to protect the environment, take the packaging to the local

amenity tip and place into the appropriate recycling bin.

Never dispose of electrical equipment or batteries in with your domestic waste.

If your supplier offers a disposal facility please use it or alternatively use your local

amenity tip and dispose in the correct manner. This will allow the recycling of raw

materials and help protect the environment.

Loading...

Loading...