ISSUE 2

User Manual

DP231C

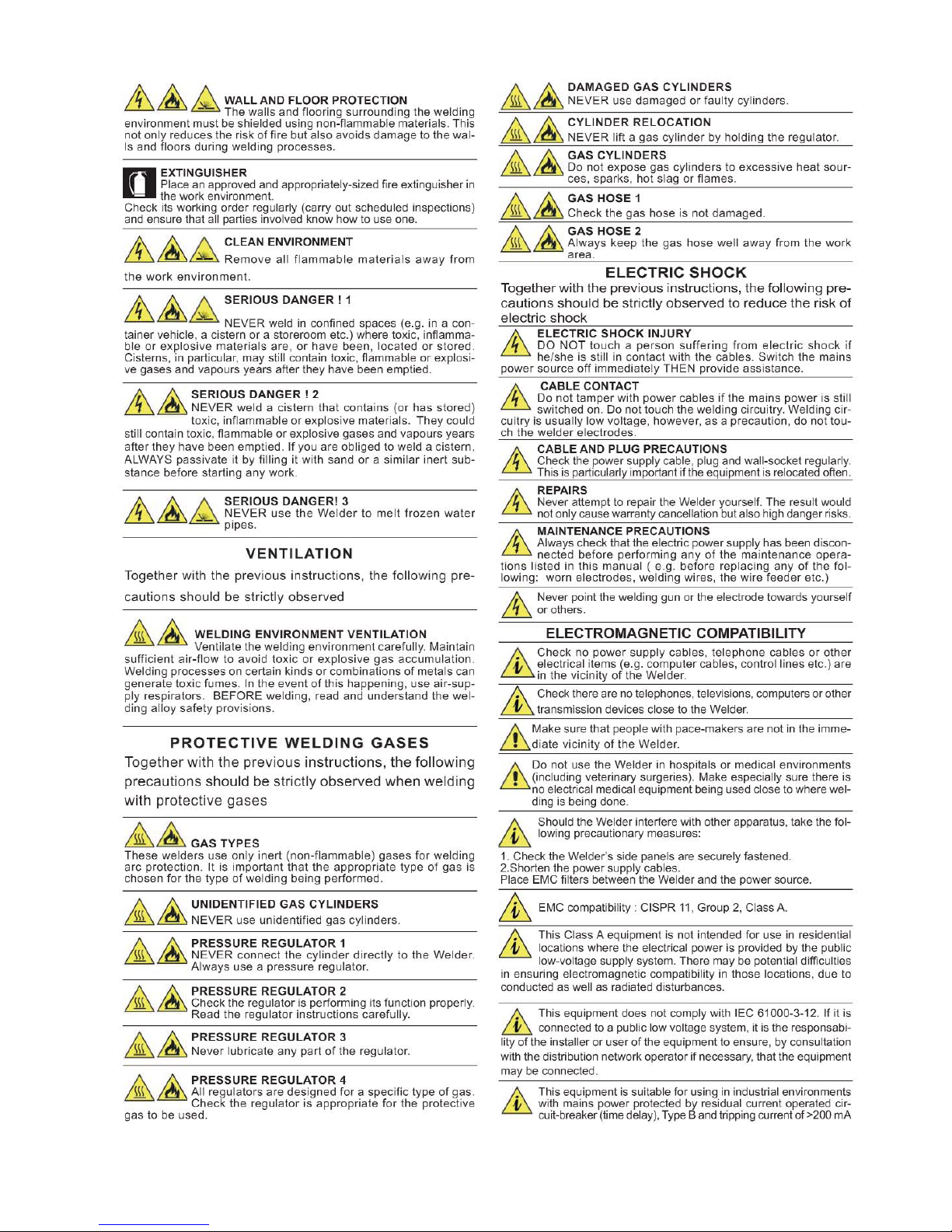

DATA PLATE

1. MANUFACTURER’S NAME, ADRESS AND COMPANY LOGO

2. MODEL

3. SERIAL NUMBER

4. BLOCK DIAGRAM

5. WELDING OUTPUT

6. SUITABLE FOR ENVIRONMENT WITH INCREASED HAZARD OF

ELECTRIC SHOCK

7. POWER SUPPLY

8. DEGREE OF PROTECTION

9. TYPE OF WELDING OUTPUT CURRENT

10. INPUT VOLTAGE

11. RATED INPUT VOLTAGE

12. MAXIMUM RATED INPUT CURRENT

13. MAXIMUM EFFECTIVE INPUT CURRENT

14. APPLICABLE STANDARDS

15. RANGE OF WELDING VOLTAGE-CURRENT

16. DUTY CYCLE

17. RATED WELDING CURRENT

18. CONVENTIONAL LOAD VOLTAGE

19. YEAR OF CONSTRUCTION

CONSTRUCTION SPECIFICATIONS:

WEIGHT [Kg]: 23

Dimensions:

Width [mm]: 220

Depth [mm]: 560

Height [mm]: 480

Protection rating: IP 21S

Height S.L.M. [m]: 1000

Usage temp. [°C]: -10/+40

Storage temp. [°C]: -20/+55 T

est temp. [°C]: 40

Applicable standards: EN.60974-1 EN.60974-10

Group/Class: Gruppo 2 Classe A

Thermal protection: Termostato Incorporato

ELECTRICAL INPUT :

Line voltage: 230

No. phases: 1

Frequency [Hz]: 50/60

Effective line current [A]: 21,6

Maximum line current [A]: 40,3

Input Power [kVA]: 5

Circuit protection: Time-delay fuses or Co K magnetothermal curve

OUT-PUT CHARACTERISTICS:

Static characteristics: Cadente

Fill Diameter: 0.6-0.8-1.0-1.2

Welding mode: MIG/MAG

Weld current range: from 15A / 14,75V to 235A / 25,75V

Open circuit voltage [V]: 55

Output current and tension: Duty [%]: 35 60 100

I2 [A]: 220 160 130

U2 [V]: 25 22 20,5

Welding mode: TIG

Weld current range: from 15A / 10,6V to 235A / 19,4V

Open circuit voltage [V]: 55

Out-put current and tension: Duty [%]: 35 60 100

I2 [A]: 220 160 130

U2 [V]: 18,8 16,4 15,2

Welding mode: MMA

Weld current range: from 15A / 10,6V to 185A / 17,4V Open circuit voltage [V]: 55

Duty [%]: 35 60 100

I2 [A]: 185 138 109

U2 [V]: 27,4 25,52 24,36 6 1.

GENERAL SPECIFICATIONS AND NOTES

FOR CONSULTING THIS MANUAL

The “DP231C” welders are made using

INVERTER technology. They are extremely

compact and versatile devices that can be used

in all those situations that require minimum

obstruction, combined with the highest

performance.

These welders use both manual and

synergic MMA, TIG and MIG/MAG (short arc,

pulse or double pulse).

The innovative operator interface system, which

uses a large 5,7” TFT colour screen, allows for

simple and intuitive use of the equipment, without

renouncing on the possibility to personalise all of

the welding settings.

All of the main parameters of the machine

are stored on a memory card (SD-Card), keeping

the equipment constantly up-dated with the

latest welding developments. If the memory card

is removed the equipment will cease to function,

providing an optimal antitheft system and

safeguard against inappropriate use. Thanks

to the advanced control techniques adopted,

the product is extremely reliable and easy to

use. This instruction manual provides detailed

information on the machine settings: reading the

entire manual will allow you to appreciate the

extreme exibility and practicality of use.

Caution: the device must only be used in the

manner and for the purpose described in this

manual. Never use inappropriately or for any

other purpose.

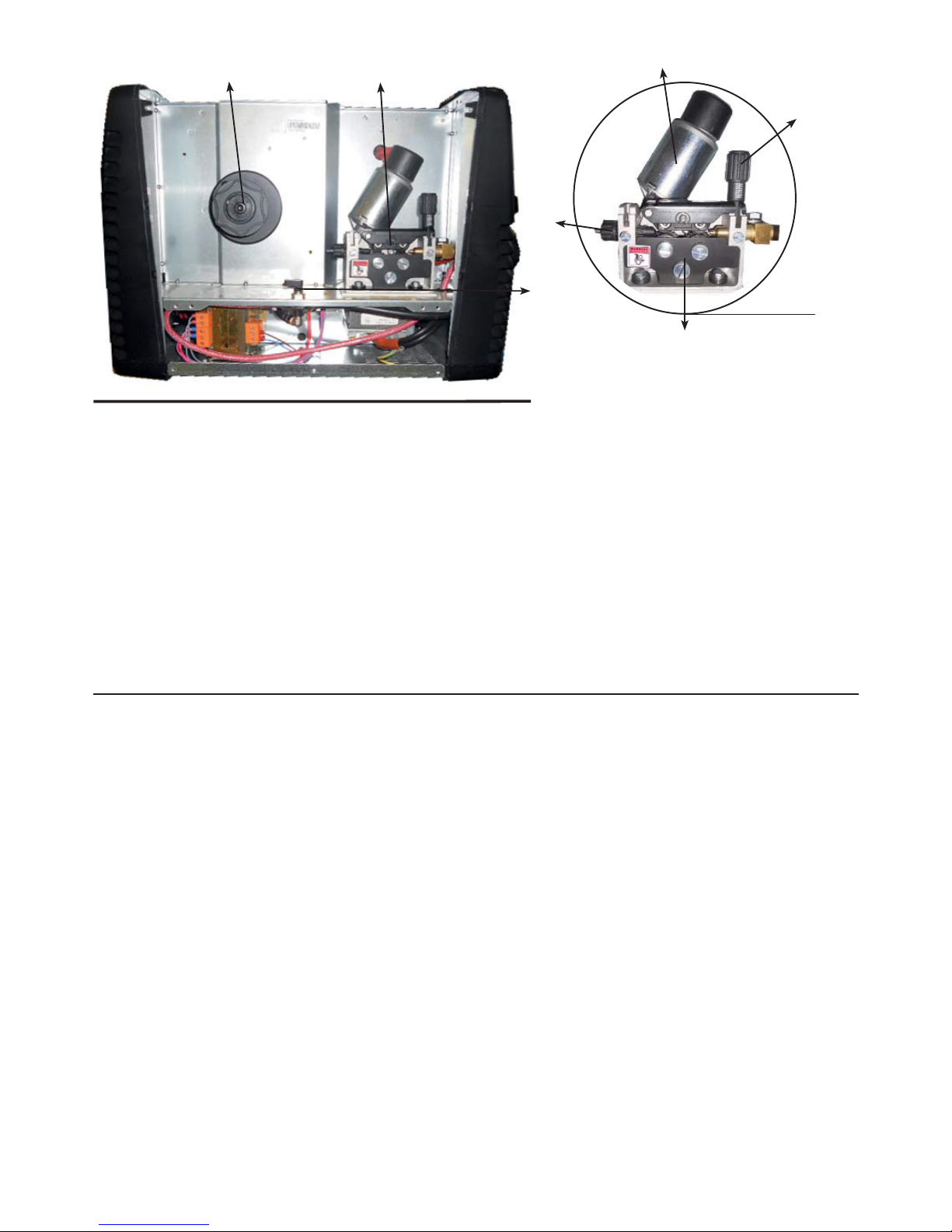

2. DESCRIPTION OF THE EQUIPMENT using this selector you can choose the

gas outlet dedicated for each welding

process

INTERNA L TAP

1

2

3

4

5

6

7

89

10

11

12

13

14

15

16

Fig.1

Fig.2

17

18

19

20

21

8. USB port: only for technical assistance.

9. Knob for setting the main welding parameter:

the main welding parameter can be set with

this knob: Welding MMA/TIG: sets the welding

current.

11. Air grills (must never be obstructed).

12. “-” dinse front connector: negative pole inlet.

Connection socket TIG torch mode. MMA Mode:

Ground clamp MIG Mode: Ground clamp

13. Connector for remote control.

14. “+” dinse front connector: positive pole inlet.

MMA Mode:Electrode holder TIG Mode:Ground

clamp MIG Mode with gas: Not used

15. Gas Outlet: MMA Mode: inactive TIG Mode:

Gas connection to the welding torch (Internal

tap positioned on TIG GAS) MIG Mode with gas:

inactive (internal tap positioned on MIG GAS) 16.

EUROCONNECTOR (SEPARATED TROLLEY):

quick connector for welding torch. This connector

is used to supply welding gas to the torch, the

electrical contacts of the torch button and the

welding current.

FIGURE 2:

17. ON-OFF switch: turns the machine on and

off.

18. Input cable: connection cable to the mains

power equipped.

19. Welding gas inlet MMA Mode: Not used TIG

Mode: GAS connection to the cylinder MIG Mode

with gas: GAS connection to the cylinder

20. Fuse

21.Connector for supplying power to the

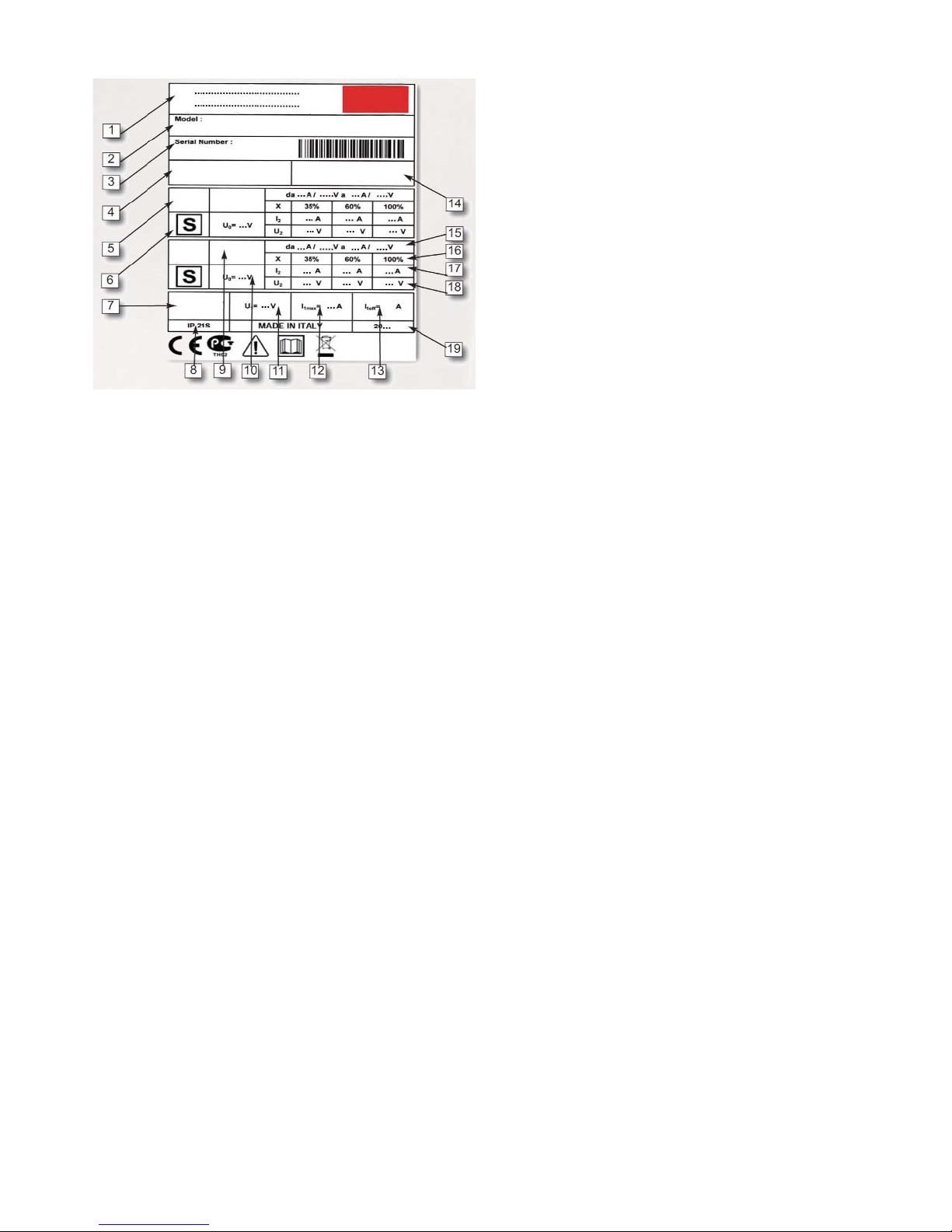

Graphic display: The display 5.7 inch color’’

shows different screens depending on whether

the machine is in welding mode or setting mode.

In welding mode, the display is divided into ve

main parts:

Part 1: State of the machine

Part 2: Meaning of the active buttons (buttons 2,

3, 4, 5 of g. 1)

Part 3: Value of the measurements set

Part 4: Type of process selection

Part 5: Indicates the values set for the various

welding parameters (to change the set value,

highlight the value with knob 10 and press to

conrm; the value is highlighted as a contrast.

Change the value by turning the knob and conrm

the new value by pressing knob 10 again).

Highlighted value: Indicates the welding

parameter that is being changed with knob 10.

VIEWS: - At start-up, the Parweld logo and the

Firmware revision are displayed.

CONTROL BUTTONS: (2, 3, 4, 5,6 in g.1)

Each control button is associated with a specic

function shown on the display.

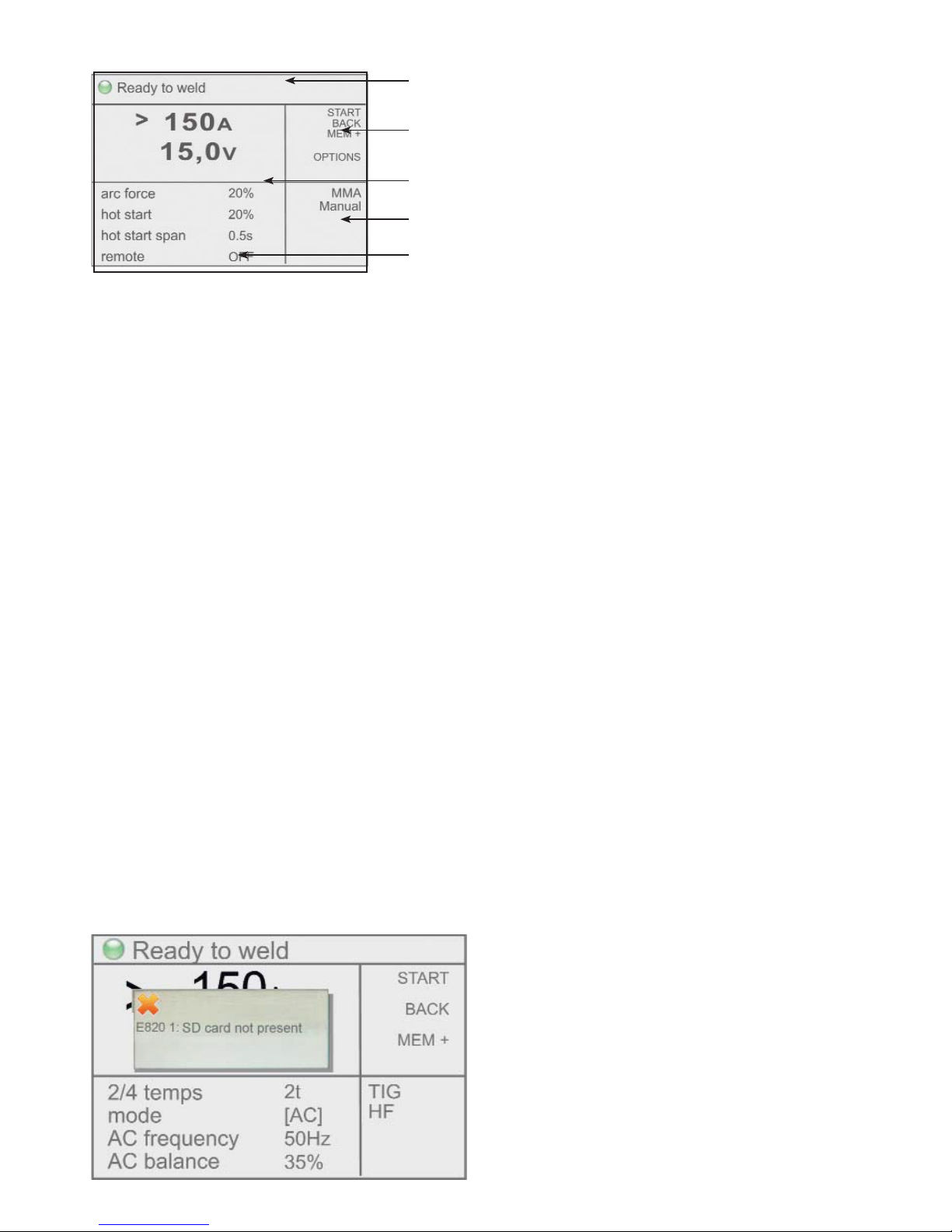

7.SD slot: This slot, covered by a special plastic

cover, must contain the SD-Card supplied with

the machine; without this card, the machine

remains inactive and a special signal is reported

on the display.

liquid cooling system (Optional): Warning the

connector contains dangerous voltages: NEVER

use it for purposes other than those for which it

was specically designed.

Part 1

Part 2

Part 3

Part 4

Part 5

FIGURE 3: 22. WIRE SPOOL SUPPORT The

300mm MIG welding spool requires an external

support

23. WIRE FEEDER SYSTEM: see gure 3A for

a more detailed image.

24. WIRE-FEEDER MOTOR

25. WIRE TENSION REGULATOR: Adjusts the

tension of the welding wire.

26. INLET OF THE WIRE FEEDER MOTOR

27. WIREFEEDER SPOOLS

28. GAS VALVE: The Gas Valve can be rotated

in three positions.

GAS MIG Position: The tap feeds the

Euroconnector with the gas from the cylinder

connection (19) (For MIG with GAS welding).

GAS TIG Position: The tap feeds the front

connection (14) with the gas from the cylinder

connection (19) (For TIG welding).

22 23

24

25

26

27

28

Fig.3A

Fig.3

WELDING WIRE

To load the welding wire, follow these instructions

carefully, in the order described below. Warning:

before inserting the wire, always remove the gas

nozzle and the wire feeder tip from the welding

torch.

1. Disconnect the cable from the power supply

(18 of Fig. 2).

Caution: before proceeding with the next

step, make sure the torch cable (Fig. 4) is well

extended and that the welding wire does not

have any bends or burrs. Failure to follow these

precautions could damage the wire-feeding tube

inside the torch. Once the wire has been threaded

through the torch, attach the wire-feeder tip and

the gas nozzle.

N.B. When changing the diameter of the wire,

make sure that the correct cable of the wirefeeder spool is facing towards the inside of the

machine. To do so, ensure that the diameter and

type of wire is legible (facing towards the outside

of the machine) Remember that the spools with

2. Unscrew the

ball-grip knob in

the centre of the

spool support of the

welding wire (22 of

Fig. 3).

3. If necessary,

depending on the

size of the spool

used, remove the

bearing spool.

4. Remove the

plastic wrap from the

new spool and place

the spool on the

appropriate support

(22 of Fig. 3).

4. Replace the ballgrip knob.

5. Please note that

the hex socket (M8)

situated in the centre

of the spool support

is part of the wire

tension system.

6. Lower the roll

feeder (25 of Fig.

3A)

7. Insert the wire

into the inlet tube

(26 of Fig. 3A) of

the wire feeder

motor. .

8. Run the wire

under the wire

feeder spools all the

way to the out-let of

the Euroconnector.

9. Lower the

upper spools

10. Lift the knob of

plastic (25 of Fig

3A) of the pressure

regulator of the

wire.

a ‘V’ cable are suitable for feeding iron and

steel wire. The spools with a ‘U’ are suitable for

aluminium wire.

4. MIG/MAG WELDING To choose this welding

mode use switch 10, select MIG and press

conrm.

Switch 9 adjusts the machine power.

There are three principal MIG-MAG welding

modes:

1.Manual short arc

2.Synergic short arc

3.Pulsed arc synergic

4.1 Manual Short Arc MIG Welding

By turning switch 10 it is possible to choose from

the different MIG-MAG welding modes; press

the switch to select the desired option.

MIG/MAG welding (Metal Inert Gas and Metal

Active Gas) is continuous wire feed welding that

provides a higher current density compared to

welding with a uxcovered electrode; this allows

increased penetration and speed and the joint

can be lled with less strokes. Welding is carried

out by melting a metallic electrode, consisting of

a continuous wire, in a welding pool at a constant

speed, controlled by the welding torch. When

the wire starts to feed, it touches the area that

requires welding, creating an electric arc; the arc

melts the wire, which is then deposited on the

workpiece.

This welder can be used with the following types

of wire:

1. Solid wire: must always be used with a gas

shield.

2. Flux cored for gas welding: the centre of the

wire contains a mineral product that improves

the quality of the weld (this must always be used

with gas).

The correct method for connecting the torch and

the earth cable can be seen in the table below:

WELDING

PROCESS

Euroconnettor

16 of Fig.1

‘+’ Front

socket 14

of Fig.1

‘-’ Front

socket 12

of Fig.1

MIG/MAG

TORCH

CABLE

NOT

USED

EARTH

CABLE

Once selected the follow screen will appear: Wire

speed: This sets the speed of the welding wire.

The welding current and the wire speed must be

adjusted, taking into consideration the thickness

of the workpiece. Larger pieces will require a

higher wire speed.

For best results, the wire speed must be adjusted

during welding.

soft-start: This adjusts the contact speed of the

wire, creating a softer weld spark; the higher the

level the lower the contact speed.

Inductance: This adjusts the variation speed of

the welding current for a sharper (low levels) or

softer arc (high levels).

2t-4t-4Bi-level: This allows the user to set the 2

step or 4 step functions

2t: : In 2 step mode, the machine will weld for as

long as the torch trigger is held down.

4t: In 4 step mode, one press of the torch trigger

will start the welding process; press the button

again and the welder will stop.

4Bi: NIn 4 step bi-level mode, one press of

the torch trigger will start the welding process;

successively, brief pressure on the trigger (for

a duration of less than 1s) will make the welder

pass from the welding current to the second

level and vice versa. Pressing the torch trigger

for lengthy periods of time will halt the welding

process.

Spot welding: This allows the user to set (when

different to 0) the maximum welding duration in

seconds.

Pause: This allows the user to set (when different

to 0) the duration of the pause between two

successive tacks.

Pre gas time: This allows the user to set the time

of the gas supply, before feeding the welding

current.

Post gas time: This allows the user to set the

time of the gas supply, when the welding current

stops.

Burnback: This allows the use to adjust the

length of the wire at the end of the torch when

the welding process ends.

Hot start : This allows the user to set the welding

ignition current to create a soft weld spark; this is

generally used with the softstart setting.

Water pump: This turns the water system ON or

OFF, if present.

4.2 Synergic Short Arc MIG WELDING Synergic

MIG welding allows the user to easily adjust

the weld settings, according to the different

materials that require welding. During synergic

welding, switch 9 of Fig 1 simultaneously adjusts

the tension or the speed of the wire. The other

parameters are automatically adjusted to the

set power, according to the diameter and type

of wire selected. The percentage of the length of

the arc can be varied using the ‘welding tension’

setting. Welding quality can be further improved

by adjusting the ‘electronic inductance’ and

‘deposit’ settings.

Turn switch 10 to choose from the different MIG-

MAG welding options; press the switch again to

conrm the chosen option.

Once selected, the screen with the welding wire

material options will appear:

Settings that do not appear on the screen are

accessible by turning switch 10.

Once the type of wire has been selected (using

switch 10), the settings page for the welding wire

diameter will appear.

L2 span: When the two level mode is active the

duration of the second power level can be set.

L2 amplitude: When the two level mode is active

the second power level (L2) can be set with

respect to the set power (level L1).

2t-4t-4bilevel: This function adjusts the 2 step or

4 step settings.

2t: In 2 step mode, the machine will weld for as

long as the torch trigger is pressed down.

4t: : In 4 step mode, press the trigger once to

start the torch, press again to stop the torch.

4Bi: In 4 step Bi- Level mode, press the trigger

once to start the torch, successively, briey

pressing the trigger (for less than 1s) will cause

the set welding current to pass to second level

and vice versa. Prolonged pressure on the torch

trigger will halt the welding process.

2nd level: This option is for setting the values the

wire speed, corresponding to the second power

level, which is active when the values of the

2t-4t-4bi-level is set to 4bi.

Initial/nal current: it allows to switch up (ON) or

down (OFF) mode with starting/nal current.

Initial current: allows setting the value at which

the welding current is brought to immediately

after the striking of the electric arc

Initial time: allows setting the time of the current

established by the Initial Current parameter. In

4t/4bi mode this time is irrelevant and the initial

current is kept for as long as the torch button is

held down.

Ramp ls- > l1: allows setting the duration of the

upslope of the welding current.

Ramp l1- > lf: allows setting the duration of the

downslope of the welding current

Final current: allows setting the value at which

the welding current is brought to on completion

of the downslope

Final time: allows setting the time of the current

established by the Final Current parameter. In

4t/4bi mode, this time is irrelevant and the nal

current is kept for as long as the torch button is

held down.

Spot welding: This sets the maximum welding

duration (when different to 0), in seconds.

Pause: This sets the duration of the pauses

(when different to 0), between two successive

tacks.

Pre gas time: This sets the gas supply time

before the welding current is supplied.

Post gas time: This sets the gas supply time after

the welding current supply ends. 13

Burnback: This adjusts the length of the wire in

Selecting this option will take you to the welding

screen:

Arc length: This changes the length of the electric

weld arc with respect to the pre-set synergic

values.

Deposit: This modies the deposit of the ller

material (velocity of the wire) with respect to the

pre-set synergic values. I

nductance: This changes the variation speed of

the welding current to achieve a sharper (low

values) or softer arc (high values).

Double short: This activates (ON) or deactivates

(OFF) the two level option, i.e. the continuous

switching between two different welding tension

levels.

L1 span: When the two level mode is active the

duration of the rst power level can be set.

the tip of the torch, when the welding process

comes to an end. Soft-start: this adjusts the

contact speed of the wire, to obtain a soft weld

spark; the higher the values the lower the contact

speed. Hot-start: This sets the weld ignition

current, in order to achieve a softer weld spark;

this is generally used with the soft-start option.

Water pump: When present, this turns the water

system ON or OFF.

4.3 Pulse synergic MIG WELDING

Pulse synergic MIG welding allows obtaining

a relatively cold welding bead and good

penetration.

The low energy input makes this welding process

particularly suitable for thin layers and for

materials such as stainless steel and aluminium.

During welding with synergic adjustment, the

wire speed (i.e. welding power) can be adjusted

with knob 9 shown in Fig.1.

The other parameters are automatically adjusted

to the set power depending on the type and

diameter of the wire selected. By turning switch

10 it is possible to choose from the different MIG-

MAG welding modes;press the switch to select

the desired option. Once selected, the screen

with the welding wire material options will appear

Once the type of wire has been selected(using

switch 10), the settings page for the welding wire

diameter will appear. The wire’s diameters could

not be available for all models.

Selecting this option will take you to the welding

screen:

Arc length: This changes the length of the electric

weld arc with respect to the pre-set msynergic

values.

Deposit: This modies the deposit of the

ller material (velocity of the wire) with respect to

the pre-set synergic values.

Double pulse: This activates (ON) or

deactivates(OFF) the two level option, i.e. the

continuous switching between two different

welding tension levels.

Settings that do not appear on the screen are

accessible by turning switch 10.

L1 span: When the two level mode is active the

duration of the rst power level can be set.

L2 span: When the two level mode is active the

duration of the second power level can be set.

L2 amplitude: When the two level mode is active

the second power level (L2) can be set with

respect to the set power (level L1).

2t-4t-4bilevel: This function adjusts the 2 step or

4 step settings.

2t: In 2 step mode, the machine will weld for as

long as the torch trigger is pressed down.

4t: : In 4 step mode, press the trigger once to

start the torch, press again to stop the torch.

4Bi: In 4 step Bi- Level mode, press the trigger

once to start the torch, successively, briey

pressing the trigger (for less than 1s) will cause

the set welding current to pass to second level

and vice versa. Prolonged pressure on the torch

trigger will halt the welding process.

2nd level: This option is for setting the values the

wire speed, corresponding to the second power

level, which is active when the values of the

2t-4t-4bi-level is set to 4bi.

Initial/nal current: it allows to switch up (ON) or

down (OFF) mode with starting/nal current.

Initial current: allows setting the value at which

the welding current is brought to immediately

after the striking of the electric arc

Initial time: allows setting the time of the current

established by the Initial Current parameter. In

4t/4bi mode this time is irrelevant and the initial

current is kept for as long as the torch button is

held down.

Ramp ls- > l1: allows setting the duration of the

upslope of the welding current.

Ramp l1- > lf: allows setting the duration of the

downslope of the welding current

Final current: allows setting the value at which

the welding current is brought to on completion

of the downslope

Final time: allows setting the time of the current

established by the Final Current parameter. In

4t/4bi mode, this time is irrelevant and the nal

current is kept for as long as the torch button is

held down.

Spot welding: This sets the maximum welding

duration (when different to 0), in seconds.

Pause: This sets the duration of the pauses

(when different to 0), between two successive

tacks.

Pre gas time: This sets the gas supply time

before the welding current is supplied.

Post gas time: This sets the gas supply time after

the welding current supply ends. 13

Burnback: This adjusts the length of the wire in

the tip of the torch, when the welding process

comes to an end. Soft-start: this adjusts the

contact speed of the wire, to obtain a soft weld

spark; the higher the values the lower the contact

speed. Hot-start: This sets the weld ignition

current, in order to achieve a softer weld spark;

this is generally used with the soft-start option.

Water pump: When present, this turns the water

system ON or OFF.

WORK-

PIECE

THICK-

NESS

WIRE

DIAMETER

WELDING

CURRENT

ARC

mm mm A

0.8 - 1.0 0.6 - 0.8 60-100 Short-Arc

1.5 - 2.0 0.8 - 1.0 80-120 Short-Arc

2.0 - 3.0 1.0 - 1.2 100-130 Short-Arc

3.0 - 4.0 1.2 120-200 Short-Arc

> 4.0 1 150÷200 Spray-Arc

> 4.0 1.2 200÷300 Spray-Arc

5. MIG WELDING CONECTOR

The connector for the welding cables comes with

a quick connect system that uses appropriate

connectors.

5.1. MIG TORCH We would advise you to carry

out regular controls on the condition of the

welding torch;in particular, always check the

nozzle the wire feeder tip and the internal liner of

the torch. These parts must be kept well-cleaned

and intact. If the wire stops threading correctly.

replace the liner. N.B. Each wire and diameter

corresponds to an appropriate wire feeder tip

and liner. Always make sure you are using the

correct type.

5.2 CONNECTOR FOR MIG WELDING with a

traditional torch

1) Connect the earth cable to the appropriate

‘-‘ socket on the front of the device (12 of Fig

1).Insert the connector by lining up the key with

the groove and turn in a clockwise direction until

it stops. Do not fasten too tightly!

2) Connect the torch to the appropriate socket

in the front of the device (16 di Fig 1),turning the

connector in a clockwise direction until it stops.

Do not fasten too tightly!

Warning: the machine is provided with sockets

for the MIG welding torch (Fig 4) This accessory

has a long life-time if periodical controls of the

gas nozzle and the wire feeder tip are carried out

(Fig 4A) (Fig 4B).These parts must be kept wellcleaned and intact. Replace the wire liner when

the wire no longer threads correctly.

5.3 CONNECTOR FOR MIG WELDING with a

Spool or Push-Pull torch

1) Connect the earth cable to the appropriate ‘-‘

socket. (12 of gure 1). Insert by lining up the key

with the groove and turn in a clockwise direction

until it stops. Do not fasten too tightly!

2) Connect the torch to the appropriate socket

on the front of the device (16 of Fig 1),turning in

a clockwise direction until it stops. Do not fasten

too tightly!

3) Insert the connector of the torch into the

appropriate female socket.

MIG WELDING: Connect the pressure regulator

to the cylinder, after which attach the gas tube

of the torch to the latter. MIG welding is usually

carried out with a constant current, with a positive

pole (“+ “see g.5).

SHORT ARC (short-circuit transfer):this brings

the electrode into direct contact with the

weld pool, which creates a short-circuit that

extinguishes the arc, after which the arc reignites

and the cycle is repeated.

. - the tension directly inuences the appearance

of the welding seam, but the dimensions of

the welding surface can be varied, according

to requirements, by manual movement of the

torch to obtain variable deposits with a constant

tension.

- the speed of the movement of the wire is in

relation to the welding current.

7. ADJUSTING THE WELDER

Once the welding tension has been set, maintain

the length of the electric arc between 5 and 10

mm and adjust the wire speed to achieve the best

welding results. Initially, carry out a welding test

on a well-cleaned sample, free of any coating,

rust or paint.

NOTE The torch trigger controls the following

functions:

- gas ow

- wire movement

- welding current

Fig.5

SPRAY ARC (spray transfer):

this allows the droplets to detach from the

tip of the electrode, which successively reach

the weld pool.

The fact the arc is visible, reduces the need

for the operator to strictly observe the adjustment

tables, allowing for direct control of

the welding pool.

The MIG torch cable

is connected to the

Euroconnector(16

ofg.1), whilst

the earth cable of

the work piece is

connected to the

‘-‘socket on the

front(12 di g.1).

At this stage adjust the welding current using

the potentiometer (9 of Fig.1), situated on the

front panel. The diameter of the electrode and

the welding current settings must be selected

according to the thickness of the workpiece.

6. STRIKING AN ARC IN MIG WELDING The

MIG-MAG welding process is when an electric arc

is created between a consumable wire and the

workpiece, protected within a gas atmosphere.

This atmosphere can be either inert (Argon) or

active (CO2 or a mixture of Argon and CO2).The

wire is continuously fed through a torch by a wire

feeder to the weld pool. A solid wire or ux-cored

wire can be used. The transfer methods of the

ller material dene different arc types:

8. HOW TO ACHIEVE THE BEST

WELDING RESULTS

Hold the torch at an angle of 45° from the

workpiece. Keep the gas nozzle (Fig. 4A) at

a distance of approximately 6 mm from the

workpiece.

2. Move the torch with a continuous movement,

using a push, not pull, motion. This will guarantee

the gaseous shield of the arc.

3. Avoid welding in high winds. If the wind is

too strong it could carry the gas away from the

welding pool, creating a porous (weak) weld.

4. Keep the wire clean: never use rusty wire.

5. Make sure the torch cable is free of dents

or coils, which could compromise the correct

movement of the wire.

6. When changing the wire spool, always clean

the wire feed tube with compressed air.

9. MMA WELDING To select this welding mode,

use switch 10, select MMA and press conrm.

Always make sure that the earth and the

electrode clamp holder are kept far apart.

9.1 MMA WELDING Manual This mode can be

accessed using switch 10.

Electric arc welding with a covered MMA (Metal

Manual Arc) electrode or SMAW (Shielded Metal

Arc Welding) is a manual welding procedure that

takes advantage of the heat generated by the

electric arc, which strikes between a covered

earthed electrode and the workpiece. This

procedure allows for the creation of joints in any

position, in the workshop, outdoors, in conned

areas or places that are difcult to access.

With the DP231C it is possible to weld any

type of electrode and diameter. The spark of

the arc occurs by placing the electrode close

to the workpiece. The correct connection of the

electrode clamp holder and the earth cable can

be seen in the table below:

WELDING

PROCESS

Front Socket

+

14 di Fig.1

Front Socket

-

12 di Fig.1

MMA

ELECTRODE

CLAMP

HOLDER

EARTH CA-

BLE

Selecting this option will take you to the welding

screen: Switch 9 in g. 1 adjusts the welding

current (very thick workpieces require a higher

current).

Furthermore, switch 10 adjusts the parameters

shown in the gure below:

Arc Force: This sets the current increase ratio in

relation to the welding current, that the welder

can force, in order to keep the arc appropriately

ignited in any position.

Hot Start: This sets the current increase ratio in

relation to the welding current, that the welder

can force when the arc is ignited, to improve the

quality of the same.

Hot start span: This sets the time period when

the jot start current is forced.

Remote: This switches the remote control (which

connects to socket 13 of g.1) of the current

intensity ON or OFF.

10 WELDING TABLE Use the table below to

calculate the welding current, according to the

type of electrode used:

ELECTRODE

DIAMETER

WELDING

CURRENT

ELECTRODE

LENGTH

mm A mm

2.0 45-60 300

2.5 60-100 300

3.25 90-140 450

4.0 140-170 450

5.0 190-230 450

11. CONNECTION FOR MMA WELDING

The Dinse connector is inserted by lining-up the

key with the groove and turning the connector in

a clockwise direction until it stops. The electrode

clamp holder and earth must be connected

to the ‘+’ and ‘-‘ terminals, according to the

specications of the electrodes used.

. IGNITING THE MMA ARC

This is carried out by stopping a while over the

last crater (i.e. the end of the welding seam),

returning slowly on the previously deposited

seam for approximately two centimetres and,

only at this point, moving the electrode away

from the workpiece to turn off the arc.

Create the contact

for igniting the arc

at a distance of

approximately 5

cm from the initial

welding point.

Immediately move

the electrode

towards the

workpiece, without

touching it, in order

to keep the arc

ignited.

Quickly bring the

electrode, without

turning off the arc,

towards the point

where the welding

seam will begin.

Begin welding,

advancing slowly.

The distance

between the tip of

the electrode and the

workpiece must be as

identical as possible

to the diameter of

the electrode in use.

process; press the

button again to stop

welding. 4Bi:

WELDING

PROCESS

Front socket +

14 di Fig.1

Front socket -

12 di Fig.1

TIG CAVO MASSA

CAVO

TORCIA

13. TIG WELDING To select this welding mode :

turn switch 10, select TIG and press conrm.

Inert gas (Argon) welding with an infusible

Tungsten electrode and arc (often call TIG

(Tungsten Inert Gas) for short, is a welding

procedure whereby the heat is produced by an

arc that strikes between a tungsten electrode

(which is not consumable) and the workpiece.

The welding is carried out by fusing the edges

of the workpiece or by adding other ller material

using specic types of rod to create a joint. The

torch is ignited by touching the workpiece with

the electrode and then lifting. The TIG procedure

can be adapted to any work position and can

also be applied to very thin sheets of metal (0,20,3 mm). The TIG procedure is distinguished by

the ease with which the arc can be controlled, a

powerful and concentrated thermal source and

the simple manner in which the ller material can

be controlled. This makes the TIG procedure

particularly suitable for precision welding on a

wide variety of thicknesses, in difcult positions

and on pipes which require full penetration. The

TIG procedure can be used on various types of

metals, such as, ferrous materials, alloys, nickel,

copper, titanium, magnesium. During welding,

potentiometer 9 in g. 1, for example, regulates

the welding current. The correct connection of the

torch and earth cable is shown in the following

table:

13.1 TIG WELDING (Lift-Arc) Button 9 controls

the current and the machine power.

Select this option and the welding screen will

appear:

Make sure that the pulse setting is switched off.

If not, use the menu and set the option PULSE

to OFF, as shown in the above gure. During

welding it is possible to adjust the current using

button 9 in g. 1. Both the welding current values

and the relative arc tension used will be displayed

continually on the screen.

ADJUSTMENTS AND SETTINGS:

Button 10 adjusts the welding settings on the

screen: prolonged pressure on the torch trigger

will stop the welding process.

2t-4t-4bilevel: This function sets the 2 tempi or 4

tempi mode.

2t: In 2 tempi mode, the machine welds for the

entire time the torch trigger is pressed down.

4t: In 4 step mode, pressing the torch trigger

once starts the welding process; press the button

again to stop welding.

4Bi: In 4 step Bi-Level mode, press the torch

trigger once to start welding. Successively, brief

pressure on the trigger (less than 1s) makes the

initial current settings.

slope up: This sets the upslope of the welding

current.

slope down: This sets the duration of the downslope time of the welding current.

end current: this sets the values of the welding

current on completion of the downslope.

end time: This sets the time period when the

current established in the end current settings is

applied.

post gas time: This sets the gas supply time at

the end of the supply of the welding current.

pulse mode: This allows for the activation (ON)

or deactivation (OFF) of the pulse welding mode;

when the pulse welding mode is active, for a

certain period of time, the machine will supply

the welding current and for another period of time

the current dened in the I background settings

will be supplied. The number of current pulses

for a set period of time are based on the values

of the frequency settings.

background current: This sets the base current

used during pulse mode.

pulse frequency: This sets the pulse frequency

when pulse welding mode is active.

pulse balance: When pulse welding mode is

active, this sets the ratio between the time the

welding current and the base current is applied.

water pump: Where present, this turns the water

system ON or OFF.

remote: This turns the remote control of the

current intensity supplied ON or OFF.

spot welding: This sets the maximum welding

duration (if different to 0), in seconds.

14. CONNECTOR FOR TIG WELDING

1) Connect the earth cable to the appropriate ‘+’

socket on the front of the device (18 of g 1).

Insert by lining-up the key with the groove and

turn in a clockwise direction until it stops. Do not

fasten too tightly!

2) Connect the torch to the appropriate ‘-‘ socket

on the front of the device (17 of g 1).

3) Insert by lining-up the key with the groove and

turn in a clockwise direction until it stops. Do not

fasten too tightly!

4) Insert the torch pulse signal connector into the

socket (part 2 of the display);

TIG WELDING: Before connecting the gas make

sure the cylinder contains pure Argon gas. Never

use any other type of gas. Connect the pressure

regulator to the cylinder, after which, connect the

latter to the gas tube of the torch. TIG welding is

usually carried out with a constant current, with a

negative pole (‘-‘ see g.6).

The diameter of the electrode and the welding

current settings must be selected according to

the thickness of the workpiece.

15. IGNITION OF THE TIG ARC Rest the ceramic

of the TIG torch on the workpiece (step 1 of g.7);

bring the tungsten electrode into contact with the

workpiece, then press the torch trigger, whilst

moving in a circular motion where the ceramic is

positioned (see step 2 of g.7).

The cable

of the TIG

torch is then

inserted into

the negative

socket (12 of

g.1), whilst

the earth

cable of the

workpiece is

connected to

the positive

socket. (14

of g.1). At

this stage it

is possible

to adjust

the welding

current

using the

potentiometer

(9 of g. 1)

on the front

panel.

Where: Sw is the torch trigger

P is the potentiometer for controlling the current.

17.1 REMOTE CONTROL OF THE WELDING

CURRENT With remote connector 13 in Fig. 1, it

is possible to adjust the current near to the point

where the welding is being carried out. To do

so, it is necessary to create a connection with

potentiometer P, shown in gure 8. The value of

the potentiometer is not a critical factor: between

2.2kOhm and 10kOhm 1/2W can be used.

Turn the potentiometer and select the welding

current in a range between zero and the set

value.

18. CONNECTING THE OUTPUTS

Connection of the welding cables occurs via a

Dinse quick-connect system with appropriate

connectors.

19. CONNECTING THE GAS CYLINDER

AND THE GAS REGULATOR For TIG and

MIG welding only. For MMA welding, skip this

paragraph entirely.

Fig.9

1

2

3

4

5

6

At this stage, ignite the arc by moving the electrode

away from the workpiece a few millimetres (step

3 of g.7). While maintaining the same distance

from the weld pool, whilst keeping the torch

trigger held down. Release the button to interrupt

the welding process.

16.POWER CONNECTOR

Before connecting the machine check the

tension, number of phases and the power

supply frequency. The admissible power supply

is indicated in the ‘Specic Techniques’ section

on page 5 of this manual and on the information

plate on the machine. Check that the earth

of the welder has been connected correctly.

Furthermore, make sure that the plug provided

with the equipment is compatible with the local

grid sockets. Make sure that the power supply

provides sufcient power for the machine to

function (tension ranges) The power supply

grid protection devices to be used are listed in

the ‘Specic techniques’ section of the present

manual. The machine is provided with a specic

power cable that does not usually require an

extension lead; in the event an extension lead is

required, use one of the same capacity [length?

sezione?] or higher than the machine in use,

according to the length of the cable. A 2.5 mm²

three-pole cable + earth, of the same size or

larger.

17. REMOTE CONNECTION Figure 8 shows

the connections of the remote connector (13 of

g 1).

1. Connect the pressure regulator (2) to the

cylinder (3). Make sure the regulator is suitable

for the cylinder pressure. Attach the connector

nut (6) of the regulator (2) to the cylinder (3).

(Do not screw too tightly; excessive force could

damage the valve (1) of the cylinder (3).)

2. Connect the gas tube (4) to the regulator (2)

and secure with a cable tie (5).

3. Make sure that the gas tube is connected to

the welder correctly.

Inappropriate handling and use could cause

serious accidents. Never stack the cylinders or

expose to excessive heat, ames or sparks. Do

not bash the cylinders together. Contact your

supplier for further information on the use and

maintenance of the cylinders.

Warning: Never use damaged cylinders: in this

case, advise your supplier immediately.

20. ORDINARY MACHINE MAINTENANCE

Every three months periodically remove dust from

the suction nozzle using compressed air. Always

direct the air from the inside towards the outside

of the machine to avoid blowing dirt inside the

welder. When carrying out this operation, always

make sure the machine is not connected to the

power supply.

22. MEMORISING THE WORK POINT As

illustrated in the previous paragraphs, the

welder allows for a notable personalisation of

the work point (when used both manually and

synergically). The work point for a workpiece

can be saved in the memory and rapidly recalled

at a later date. To save a work point follow the

instructions below:

1. Select ready to weld on the display.

2. Set the appropriate parameters for the welding

mode required.

5- Press switch 10 to conrm the selected letter.

6- Repeat steps 2 and 3 to complete the name.

7- Conrm the name by pressing the TICK button

again . From this moment onwards the work

point will be memorised with its own name and

displayed with the other welding procedures.

Meaning of the back :

sp button: cancels the previous letter

inserted.

Cancel: cancels the operation.

OK: conrms the name of the work point

. 23. LOCKING A WORK POINT

The welder can lock the functions of switch

9 and 10, so that once a work point has been

saved it cannot be changed, unless modied by

a member of staff with a password, which can be

dened at the discretion of the user. To proceed

with locking a work point, it is necessary to rst

enter the necessary parameters for the required

welding settings. Once this has been done,

proceed as follows:

1. Press switch 9 of g. 1 for approximately 5

seconds; the message in Fig. A will appear.

3- Press the MEM+ button (4 of g 1).

4- Turn switch 10 (g 1), chose the rst letter of

the name with which you want to save the work

point.

After which, select button 1 of g. A, with the

name ‘Lock’ on the black and white display and

the symbol for the colour display.

2. You will then be asked to enter the password,

which must be kept safe to make future

modications of the work point, should the need

arise.

To enter the password, proceed as follows:

1- Turn switch 10 (g 1) and select the rst letter

of the password.

2- To conrm the selection press switch 10.

3- Repeat steps 2 and 3 to complete the

password.

4- Conrm by pressing the switch again. Fig.A

Fig.B 24

3. Once the password has been conrmed

the display will show the message in Fig. C, a

lock symbol in the area 1 of the display and the

functions Unlock and Reset pw (reset password)

which correspond to buttons 2 and 3 (g. 1)

respectively, in area 2 of the display;

4. To exit the lock option of the work stage, briey

press switch 9 in g. 1;

5. Should the need to modify the work stage

arise, activate the ‘Unlock’ option by pressing the

function button. The unlock function will require

the user to enter the password that was set and

activated as described above.

6. The reset password option can be activated

by pressing the (Reset pw) button.

WARNING: The Reset Password option

should only be used when there is no way of

tracing the work stage and when the Lock/

Unlock password has been lost. To use this

function contact the constructor technical

support department directly.

1. Control panel

2. Power control board

3. Motor control board

4. Welding process control panel

5. Power Inverter

6. Auxiliary transformer

EC declaration of conformity

Hereby we declare that the machines as stated below

Type: DP231C

Conform to the EC Directives: 73/23/EEC and 89/336/EEC

European standard: EN/IEC 60974-1

This is to certify that the tested sample is in conformity with all provisions of the above detailed EU directives and product standards.

RoHS Compliance Declaration

Directive 2002/95/ec of the European Parliament

Restriction of use of certain hazardous substances in electrical and electronic equipment

Type: DP231C

The above listed products are certied to be compliant with the rohs directive with all homogeneous component parts being controlled to ensure

material contents as per the list below.

Cadmium 0.01% by weight

Lead 0.1% by weight

Mercury 0.1% by weight

Hexavalent chromium 0.1% by weight

Polybrominated biphenyl’s (pbbs) 0.1% by weight

Polybrominated diphenyl ethers (pbdes) 0.1% by weight

It should be noted that under specic exempted applications, where lead is used as an alloying element the following limits are applied in

accordance with the regulations.

Copper and copper alloy parts use less than 4% by weight of each homogeneous component.

Steel and steel alloy parts use less than 4% by weight of each homogeneous component.

Aluminium and aluminium alloy parts use less than 4% by weight of each homogeneous component.

Only dispose off in authorised sites for electrical and electronic waste do not dispose of with general refuse or landll waste.

WEEE Statement

WEEE (Waste Electrical & Electronic Equipment) 2002/96/EC

In relation to implementing the legislation, Parweld has established relevant recycling and recovery methods. We have been fully compliant

against the marking requirements since August 2005. Parweld is registered in the UK with the Environment agency as detailed below. For

WEE compliance outside the UK please contact your supplier/Importer

Parweld is registered with a compliance scheme Ofcial registration number is WEE/FD0255QV

When your equipment reaches the end of its service life you should return it to Parweld where it will be reconditioned or processed for

recycling.

Statement of warranty

Limited Warranty:

Parweld Ltd, hereafter, “Parweld” warrants its customers that its products will be free of defects in workmanship or material. Should any failure

to conform to this warranty appear within the time period applicable to the Parweld products as stated below, Parweld shall, upon notication

thereof and substantiation that the product has been stored, installed, operated, and maintained in accordance with Parweld’s specications,

instructions, recommendations and recognized standard industry practice, and not subject to misuse, repair, neglect, alteration, or accident,

correct such defects by suitable repair or replacement, at Parweld’s sole option, of any components or parts of the product determined by

Parweld to be defective.

Parweld makes no other warranty, express or implied. This warranty is exclusive and in lieu of all others, including, but not limited to any

warranty of merchantability or tness for any particular purpose.

Limitation of Liability:

Parweld shall not under any circumstances be liable for special, indirect or consequential damages, such as, but not limited to, lost prots and

business interruption. The remedies of the purchaser set forth herein are exclusive and the liability of Parweld with respect to any contract, or

anything done in connection therewith such as the performance or breach thereof, or from the manufacture, sale, delivery, resale, or use of any

goods covered by or furnished by Parweld whether arising out of contract, negligence, strict tort, or under any warranty, or otherwise, shall not,

except as expressly provided herein, exceed the price of the goods upon which such liability is based. No employee, agent, or representative

of Parweld is authorized to change this warranty in any way or grant any other warranty.

Purchaser’s rights under this warranty are void if replacement parts or accessories are used which in Parweld’s sole judgement may impair the

safety or performance of any Parweld product.

Purchaser’s rights under this warranty are void if the product is sold to purchaser by non-authorized persons.

Parweld Limited

Bewdley Business Park

Long Bank

Bewdley

Worcestershire

England

DY12 2TZ

tel. +44 1299 266800

fax. +44 1299 266900

www.parweld.com

info@parweld.co.uk

Parweld Limited

Bewdley Business Park

Long Bank

Bewdley

Worcestershire

England

DY12 2TZ

tel. +44 1299 266800

fax. +44 1299 266900

web: www.parweld.com

email: info@parweld.co.uk

Contact Your Local Distributor:

Loading...

Loading...