5-Port PC/104 10/100 Fast Ethernet Switch

MNL-0490-01 Rev D4 REF. ECO-3163 01 Feb 10

USER MANUAL

PRV-1059

RUGGED SOLUTIONS FOR REAL WORLD APPLICATIONS

www.parvus.com

PRV-1059 User Manual

Disclaimer

Although the information contained herein has been carefully verified, Parvus Corporation assumes no responsibility for

errors that might appear in this document, or for damage to property or persons resulting from improper u se of this man ual or

related software. Parvus reserves the right to change the contents and form of this document, as well as the features and

specifications of its products at any time without notice. T he information in this pub lication does not r epresent a commitment

on the part of Parvus. This document contains proprietary information that is protected by copyright. All rights are res erved.

No part of this document may be photocopied, reproduced, or translated into another language without the prior written

consent of Parvus.

Parvus Corporation

3222 S. Washington St.

Salt Lake City, Utah, USA 84115

Phone: +1 (801) 483-1533

Toll-Free: +1 (800) 483-3152

Main: +1 (801) 483-1533

Fax: +1 (801) 483-1523

Email:

Sales: sales@parvus.com

Support: tsupport@parvus.com

Web-site: http://www.parvus.com

Send us your comments and feedback: feedback@parvus.com

Parvus is a U.S. subsidiary of the Eurotech Group ( www.eurotech.com), a globa l family of technolo gy companies focu sed on

innovative embedded and high performance computing solutions.

Trademarks

All trademarks both marked and not marked, appearing in this document, are the property of their respective owners.

WEEE

The information below is issued in compliance with the regulations as set out by the 2002/96/CE directive, subsequently

superseded by 2003/108/CE, and refers electrical and elec tronic equipment and the management of their waste (WEEE).

When disposing of a dev ic e, incl uding a ll of i ts com ponents, subassemblies and materials that are an integral part of the

product, you should take the WEEE directive into consideration.

This symbol has been attached to the equipment or, in the case that this is not possible, on the packaging,

instruction literature and/or the guarantee sheet. By using this symbol it states that the device has been

marketed after August 13th 2005, and implies that you must separate all of its components when possible, and

dispose of them in accordance with local waste disposal legislations.

Because of the substances present in the equipment, an improper use or disposal of the refuse can cause damage to

human health and to the environment.

With reference to WEEE, it is compulsory not to dispose of the equipment with normal urban refuse; arrangements should be

instigated for separate collection and disposal.

For more detailed information about recycling of WEEE, please contact your local waste collection body.

In case of illicit disposal, sanctions will be levied on transgressors.

RoHS

This devic e, including all it components, subassemblies and the consumable materials that are an integral part of the

product, ha s been manufa ctured in com pliance with the European directive 2002/95/EC known as the RoHS directive

(Restrictions on the use of certain Hazardous Substances), this directive targets the reduction of certain hazardous

substances previously used in electrical and electronic equipment (EEE).

Page 2 of 27 MNL-0490-01 RevD4 REF. ECO-3163 Effective: 01 Feb 10

PRV-1059 User Manual

Table of Contents

Table of Contents .................................................................................................................................................. 3

Chapter 1 Introduction...................................................................................................................................... 5

Functional Description ......................................................................................................................................... 5

Features............................................................................................................................................................... 6

About PC/104....................................................................................................................................................... 6

Chapter 2 Quick Start-up.................................................................................................................................. 7

Installation............................................................................................................................................................ 7

Installing Network Cables and Establishing Connectivity ............................................................................. 7

Chapter 3 Connector Description.................................................................................................................... 8

Molex Connectors................................................................................................................................................ 8

Connector Placement .......................................................................................................................................... 8

10/100 Ethernet Switch (w/ local RJ-45 Jacks)............................................................................................. 8

10/100 Ethernet Switch (w/ 4-pin Molex Ethernet Connectors).................................................................... 9

Connector Pinouts.............................................................................................................................................. 10

Molex Ethernet Pin Description: Ports 0-4.................................................................................................. 10

CON2/J101: 2-Pin Power Connector.......................................................................................................... 10

Parallel LED Ports:...................................................................................................................................... 10

J1/J3: PC/104 Bus....................................................................................................................................... 11

Chapter 4 Operational Description................................................................................................................ 12

Switch Data Flow ............................................................................................................................................... 12

Media Access Controllers.................................................................................................................................. 12

Backoff......................................................................................................................................................... 12

Half- and Full-Duplex Flow Control............................................................................................................. 13

Address Management........................................................................................................................................ 13

Address Translation Unit............................................................................................................................. 13

Address Searching...................................................................................................................................... 13

Address Learning........................................................................................................................................ 13

Address Aging............................................................................................................................................. 14

Auto-Negotiation ................................................................................................................................................ 14

Auto MDI-/MDIX Crossover ............................................................................................................................... 14

Port-Based VLAN............................................................................................................................................... 14

VLAN Software Quick Start Setup Guide .......................................................................................................... 16

Software Guide .................................................................................................................................................. 17

Com Port ..................................................................................................................................................... 17

Setting the Egress Ports.............................................................................................................................. 18

Operation of VLAN GUI Window................................................................................................................. 19

Menu Operation........................................................................................................................................... 20

Chapter 5 Specifications................................................................................................................................. 21

MNL-0490-01 RevD4 REF. ECO-3163 Effective: 01 Feb 10 Page 3 of 27

PRV-1059 User Manual

Tec

hnical Specification...................................................................................................................................... 21

Electrical...................................................................................................................................................... 21

Environmental Specifications............................................................................................................................. 21

Temperature................................................................................................................................................ 21

Reliability (MTBF)............................................................................................................................................... 21

Mechanical......................................................................................................................................................... 21

Weight ......................................................................................................................................................... 21

Dimensions.................................................................................................................................................. 22

Chapter 6 Troubleshooting............................................................................................................................. 24

Technical Assistance ......................................................................................................................................... 24

Returning For Service........................................................................................................................................ 24

Chapter 7 Contact Info.................................................................................................................................... 25

Eurotech Group Worldwide presence............................................................................................................... 26

Page 4 of 27 MNL-0490-01 RevD4 REF. ECO-3163 Effective: 01 Feb 10

PRV-1059 User Manual

Chapter 1 Introduction

This section provides a functional description of the PRV-1059.

Functional Description

PRV-1059 is a rugged VLAN-capable 5-port PC/104 Fast Ethernet switch featuring very low power consum ption

and highly reliable extended-temperature operation up to +85°C (185°F). Supporting auto-MDI-MDIX network

installation, the board is designed for simple plug-and-play operation, enabling up to five embedded computing

devices to be networked together using 10BaseT or 100BaseTX Local Area Network (LAN) connections.

Field programmable, port-based VLAN functionality is supported on select models. This powerful feature

enables any combination of ports to be connected together in subnets for use in a small secure or non -secure

network. Fully IEEE 802.3 and IEEE 802.3u compliant, its five transceiver ports are flexibly designed so that any

port can serve as an uplink. The module can either be used as a standalone net work switch (no processor board

required) or in combination with embedded systems that support a PC/104 (ISA) bus.

The card integrates fully independent media access controllers (MACs), an embedded frame buffer memory,

and a high-speed address look-up engine, along with support for auto-crossover, auto-polarity, auto-negotiation,

and bridge loop prevention.

Qualified to MIL-STD-810 environmental standards, the compact PRV-1059 switch is ideally suited to spaceconstrained, high reliability aviation, industrial, military, and transportation applications where extreme

temperature and high shock/vibration exist. The unit is only 3.550” x 3.775” (90x96 mm) in size. All versions

include mounting holes to facilitate simple installation, as well as support for local or remote monitoring of LED

activity for data RX/TX and connectivity.

Ethernet connections are made through either onboard RJ-45 jacks or right-angle, locking Molex connectors.

The 4-pin Molex headers enable embedded systems to optionally mount RJ-45 jacks in a faceplate, endcap or

enclosure using a Parvus cable set (sold separately), which includes five female Molex to RJ-45

adapters. Power connections can be made through either the PC/104 (ISA) bus or externally through a 2-p in

Molex connector.

MNL-0490-01 RevD4 REF. ECO-3163 Effective: 01 Feb 10 Page 5 of 27

PRV-1059 User Manual

Features

RJ-45 jack or Molex Ethernet connectors

LED activity indicators

Link/activity and speed LED’s available on separate connectors

Low power dissipation

Store-and-forward switching mode

5 Auto-configured ports (straight/twist cable connections)

Auto-negotiation and speed auto-sensing support

Ports can work at 10Mbps or 100 Mbps, full duplex or half duplex mode

Simple networking installation through auto-MDI/MDIX (All ports can act as uplink)

VLAN capability on select models

Pause frame-based switch fabric delivers true non-blocking switchi ng

Back pressure-based flow control of half duplex ports

Baseline wander correction circuitry

Highly integrated DSP-based 10/100 switch

Look-up engine supports as many as 1,024 MAC address entries

2-Pin Power Header for External Power Connections (select models only)

16-bit PC/104 Bus (select models only)

About PC/104

The PC/104 specification is characterized by its small form-factor (3.550" x 3.775"), stackable 104-pin/socket

ISA bus connector, and reduced bus signal drive, making PC/104's size, durability, expandability, reliability,

quality, and power consumption ideal for embedded computing. PC/104 technology leverages the same readily

available development tools used with personal desktop computers to dramatically improve time-to-market for

embedded systems development. The full PC/104 specification can be found at the PC/104 Consortium Web

site: http://www.pc104.org/technology/pc104_tech.html

Page 6 of 27 MNL-0490-01 RevD4 REF. ECO-3163 Effective: 01 Feb 10

PRV-1059 User Manual

Chapter 2 Quick Start-up

This section describes the installation of the PRV-1059.

Installation

The non-VLAN switch does not require drivers or software configuration. Users can immediately use any of the

features of the product simply by attaching the cables and supplying power to the unit through either the PC/104

bus or 2-pin power header, depending on the version purchased. The VLAN-enabled switch req uires use of the

Parvus cable (sold separately) and software to configure the VLAN settings. Configuration and connection of the

VLAN switch is described in chapter 5.

Carefully remove the board from its anti-static bag. For PC/104 applications, make sure power is turned off, then

carefully line up all pins before insertion. Attach the 10/100 Ethernet Switch into a PC/104 card stack by mating

PC/104 bus connector to PC/104 bus connector.

Installing Network Cables and Establishing Connectivity

The following types of cabling can be used with the 10/100 Ethernet Switch:

10BaseT Category 3,4 or 5 UTP/STP

100BaseTX Category 5 UTP/STP

Twisted-pair crossed cabling (10BaseT or 100BaseT) is recommended yet not required for the uplink connection

(switch-to-switch). Straight cabling for the remaining port connections (switch-to-PC) is similarly recommended,

but not required.

The board supports Auto MDI-/MDIX Crossover, which allows it to determine whether or not it needs to cross

over between receive/transmit pairs, virtually eliminating the need for an external crossover cable. If it

interoperates with a device that cannot automatically correct for crossover, the swit ch makes the necessary

adjustment prior to commencing auto-negotiation. Similarly, if the switch interoperates with a device that

implements MDI-MDIX crossover, a random algorithm determines which device performs the crossover.

The IEEE802.3ab specification, although well-written, does not clearly specify all linking conditions which may

occur between the various modes of operation of Ethernet, taking into account auto-crossover, auto-n egotiation,

and forced modes of operation (10/100 forced speeds using either full or half duplex). As a result, mixing autocrossover with forced modes of operation may lead to initial link problems whenever a cable is first “live”

connected. Also, because of incompatibilities between various switch IC manufactures related to the IEEE

802.3ab specification, occasionally, link connectivity is not established immediately. When plugging in a new

cable, if a link is not established within about 10 seconds (usually much faster!), then the user should simply

cycle the power to the switch, turning it off and back on. In all cases, cycling power should result in a successful

link, even when auto-detecting through forced modes of operation (10-base T/half, 10-base T/full, 100–base

T/half and 100-base T/full). If it isn’t possible to cycle power, then cycling power of the associated link partner

may be an option. At worst, and in rare cases, if power cannot be cycled, then eventually (within several minutes

at the most) a link should successfully be established. Therefore, in these extreme rare cases, patience may be

needed. However, once link is established, the switch will not miss packets outside of normal collision events,

even when operating in harsh conditions using very long cables up to 100-meters in length.

MNL-0490-01 RevD4 REF. ECO-3163 Effective: 01 Feb 10 Page 7 of 27

PRV-1059 User Manual

Chapter 3 Connector Description

This chapter provides a brief description of the connectors located on the 10/100 Ethernet Switch.

Molex Connectors

Connector Part Numbers

Ethernet (4-pin right angle) P/N: 22-12-2044; mating P/N: 10-11-2043

Power (2-pin right angle) P/N: 22-12-2024; mating P/N: 10-11-2023

LED’s (4-pin straight) P/N: 22-11-2042; mating P/N: 10-11-2043

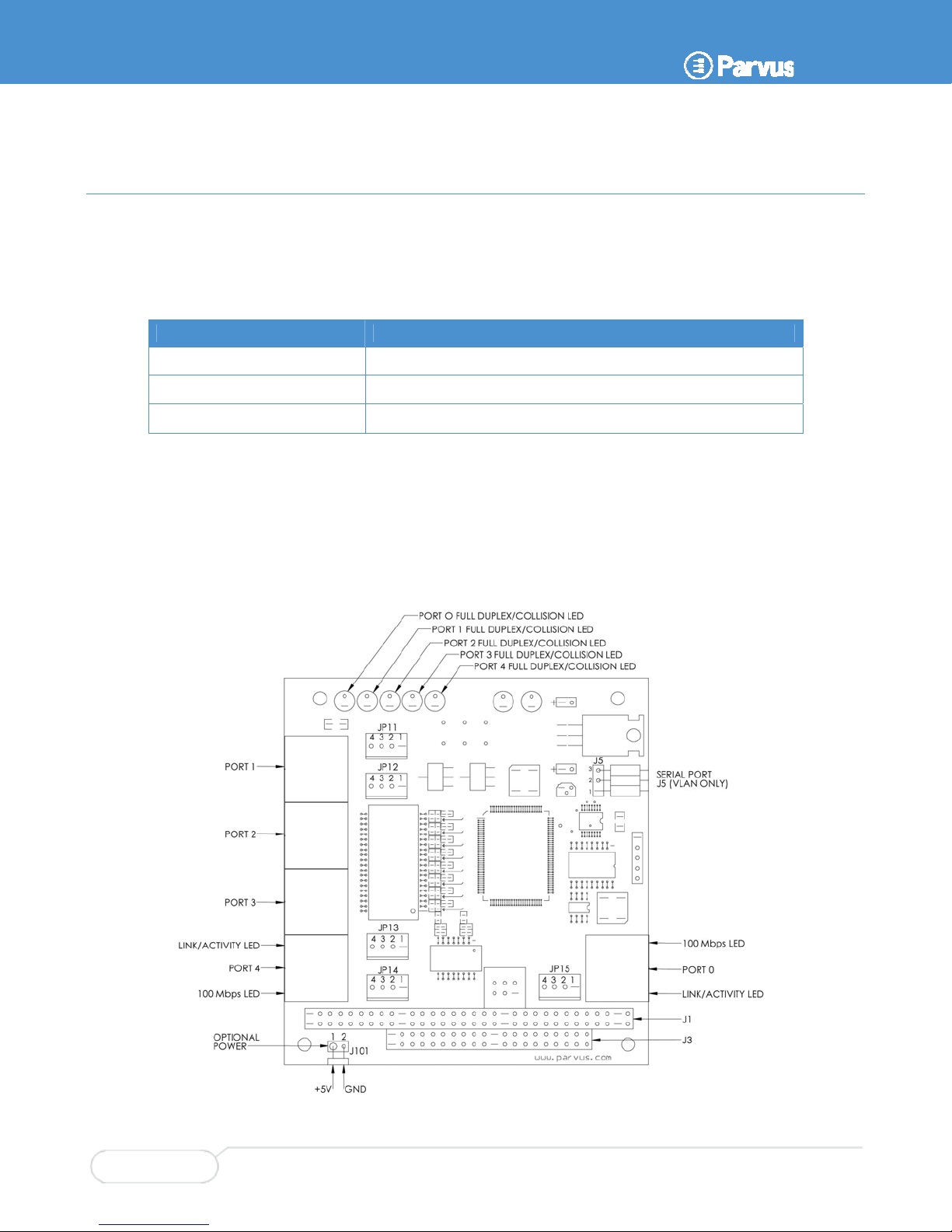

Connector Placement

10/100 Ethernet Switch (w/ local RJ-45 Jacks)

Page 8 of 27 MNL-0490-01 RevD4 REF. ECO-3163 Effective: 01 Feb 10

PRV-1059 User Manual

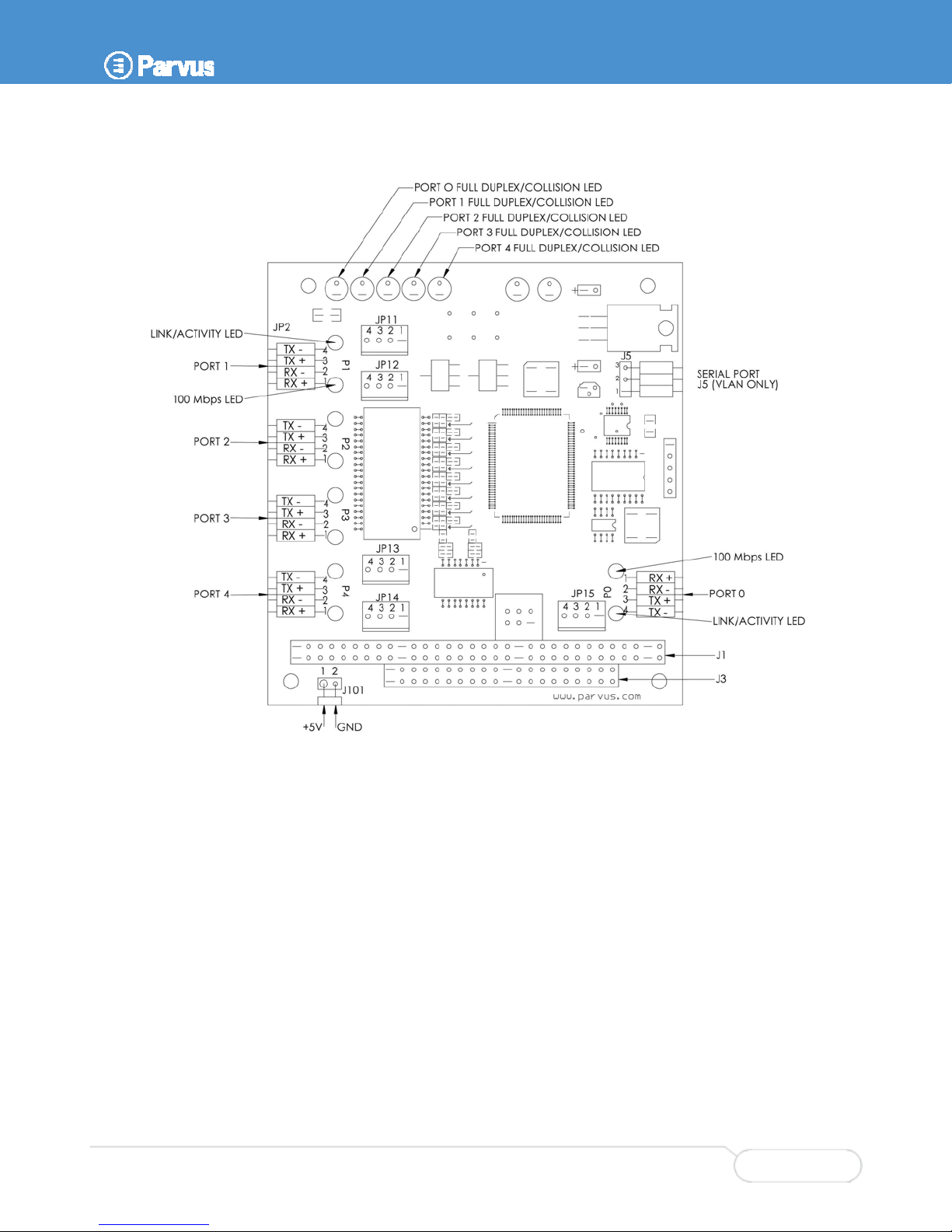

10/100 Ethernet Switch (w/ 4-pin Molex Ethernet Connectors)

MNL-0490-01 RevD4 REF. ECO-3163 Effective: 01 Feb 10 Page 9 of 27

PRV-1059 User Manual

Connector Pinouts

Molex Ethernet Pin Description: Ports 0-4

Molex Connector P/N: 22-12-2044; mating P/N: 10-11-2043

Pin Signal

1 RX +

2 RX 3 TX +

4 TX-

CON2/J101: 2-Pin Power Connector

(Not Loaded on PC/104 Versions)

Molex Connector P/N: 22-12-2024; mating P/N: 10-11-2023

Pin Signal

Pin 1 +5VDC (closest to mounting hole)

Pin 2 GND

Parallel LED Ports: For All LED Ports JP11 through JP15

Molex Connector P/N: 22-11-2042; mating P/N: 10-11-2043

Pin Signal

Pin 1 +3.3v

Pin 2 100/10 baseT (speed)

Pin 3 +3.3v

Pin 4 Link/Activity

Page 10 of 27 MNL-0490-01 RevD4 REF. ECO-3163 Effective: 01 Feb 10

PRV-1059 User Manual

J1/J3: PC/104 Bus

Pin Row A Row B Row C Row D

0 -- -- GND GND

1 /Iock GND /SBHE /MCS16

2 SD7 Rstdrv LA23 /IOCS16

3 SD6 +5v LA22 IRQ10

4 SD5 IRQ9 LA21 IRQ11

5 SD4 -5v LA20 IRQ12

6 SD3 DRQ2 LA19 IRQ15

7 SD2 -12v LA18 IRQ14

8 SD1 /Exfer LA17 /DA0

9 SD0 +12v /MR DRQ0

10 Iordy (key) /MW /DA5

11 AEN /SMW SD8 DRQ5

12 SA19 /SMR SD9 /DA6

13 SA18 /IOW SD10 DRQ6

14 SA17 /IOR SD11 /DA7

15 SA16 /DA3 SD12 DRQ7

16 SA15 DRQ3 SD13 +5v

17 SA14 /DA1 SD14 /MSTR

18 SA13 DRQ1 SD15 GND

19 SA12 /Rfrsh (key) GND

20 SA11 SCLK -- -21 SA10 IRQ7 -- -22 SA9 IRQ6 -- -23 SA8 IRQ5 -- -24 SA7 IRQ4 -- -25 SA6 IRQ3 -- -26 SA5 /DA2 -- -27 SA4 TC -- -28 SA3 BALE -- -29 SA2 +5v -- -30 SA1 OSC -- -31 SA0 GND -- -32 GND GND -- --

The PC/104 bus always uses Row A and B, while Row C and D are for 16 bit systems. B10 and C19 are keyed

locations. For more information about the PC/104 specification, please visit the PC/104 Consortium Web site:

http://www.pc104.org/technology/pc104_tech.html

e. Only +5v and GND are used. All other signals are just pass-through.

Not

MNL-0490-01 RevD4 REF. ECO-3163 Effective: 01 Feb 10 Page 11 of 27

PRV-1059 User Manual

Chapter 4 Operational Description

This chapter explains the operation of the switch.

Switch Data Flow

The switching portion of the PRV-1059 receives good packets from the MAC’s, proce s ses them, and forwards

them to the appropriate MACs for transmission. Processing the frames is the key activity, and involves the

Ingress Policy, the Queue Controller, the Output Queues, and the Egress Policy blocks shown below. Each port

has it’s own Ingress and Egress Policies.

Media Access Controllers

Five independent Media Access Controllers (MACs) perform the 802.3 protocol functions, including frame

formatting, frame stripping, CRC checking, CSMA/CD enforcement, collision handling, etc. Before a packet can

be sent out, the transmit block must check if the line is available for transmission. The transmit line is available

all the time when the port is in full-duplex mode, but the line could be busy receiving a packet if the port is in halfduplex mode. If the line is busy, the transmitter waits by deferring its transmission. When the line is available, the

transmission insures a minimum interpacket gap of at least 96 bits has occurred and then transmits a 56-bit

preamble and an 8-bit Start of Frame Delimiter (SFD) ahead the basic frame.

For half-duplex mode, the switch also monitors the collision signals while it is transmitting. If a collision is

detected (i.e. both transmitter and receiver of a half-duplex MAC are active at the same time), the MAC transmits

a JAM pattern and then delays the retransmission for a random time period determined by the IEE 802.3 backoff

algorithm. In full-duplex mode, the collision signal and backoff algorithm is ignored.

Backoff

In half-duplex mode, the Ethernet Switch’s MACs implement a truncated binary exponential backoff

algorithm, starting with a randomly small backoff time followed by progressively longer and longer

random backoff times. The random times prevent two or more MACs from always attempting retransmission at exactly the same time. The progressively longer backoff times give a wider random

range giving congested links a better chance of finding a winning transmitter. The MACs will rest the

progressively longer backoff time circuit after 16 consecutive re-transmit trials.

Page 12 of 27 MNL-0490-01 RevD4 REF. ECO-3163 Effective: 01 Feb 10

PRV-1059 User Manual

Half- and Full-Duplex Flow Control

Half- and Full-duplex flow control is used to throttle the end station to avoid dropping packets during

network congestion. When the free buffer space is almost empty or the output queue is almost full, the

MACs force a collision in the input port when sensing an incoming packet. Full-Duplex uses frame

pauses to handle the congestion.

Address Management

The switching function of the module involves the learning how to switch packets to the correct MACs, and only

to the correct ones. The switch learns what port to which an end station is connected by remembering each

packet’s Source Address, and the port number the packet came in on.

When a packet is directed to an unlearned MAC address, the packet is transmitted to all of the ports. When an

end-station responds back, its address is learned and stored until it is aged (see se ction 3.4.4). Once a MAC

address/port is learned, all future packets directed to that address will be forwarded solely to that port.

When an end station is moved from one port to another, a new MAC address/port number association will have

to be learned, and the new one replaced. For this to occur, the old association needs to expire or “age”. These

issues are handled by the “Aging” function (see section 3.4.4).

Address Translation Unit

The Lookup Engine or Address Translation Unit (ATU) reads the Destination Address (DA) and Source

Address (SA) from each received packet, performing all address searching, learning and aging functions

for all five ports at “wire speed” rates. It uses a hashing technique for quick storage and retrieval. If

there is a hash collision, there is a four entry bin to hold MAC address with the same hash. The address

table has storage for up to 1024 entries in the embedded SRAM, and has a default 300 secon d (5 min)

aging time.

Address Searching

The address search engine searches the address database to obtain the output port number, called the

Destination Port Vector (DPV), for each frame’s Destination Address (DA). It arbitrate s de stination

address requests from the ports and grants one lookup at a time. The MAC address is hashed, and then

data is read from the SRAM table and compared to the MAC address for a match. If the compare

matches, the DPV is returned to the output port queue manager, where is may be modified by the

VLANTable data. When no match is found, a unique default DPV is returned to the output port queue

manger, which typically sends the frame to all ports (to learn the MAC address).

Address Learning

An address-learning engine is used to learn the source address. Up to 1024 MAC address/port number

mappings can be stored in the address table.

MNL-0490-01 RevD4 REF. ECO-3163 Effective: 01 Feb 10 Page 13 of 27

PRV-1059 User Manual

Whe

n a frame comes in, the MAC address gets hashed into the database. If no match is found, the

MAC address/port association needs to be learned. Learning consists of the following: the frame is

forwarded to all of the ports, awaiting a response from one the ports. Once a port responds, the

association is made and “learned” into the address table. If multiple ports respond, the associations are

not learned. Once a MAC address/port is learned, all future packets directed to that address will be

forwarded solely to that port.

Address Aging

Continuous address aging ensures an up-to-data address table and rapid address look-up. Once a

node is disconnected from the network segment, or if it becomes inactive, its entry is removed from the

address table. Every time a MAC address is found in the address table, the age is refreshed, keeping it

active. Aging occurs by default every 5 minutes.

Each MAC address entry in the address table contains an age value, Entry_State. The initial value of

Entry_State is 0xE. Aging occurs with a sweep of the table, the ATU reads each entry in the address

table and decrements its Entry_State. Once the Entry_state of a MAC address reaches zero, the entry

is killed and purged from the table. The speed at which aging occurs is default at 300 seconds.

Auto-Negotiation

Auto negotiating occurs when the switch negotiates with a link partner to determine the speed and duplex with

which to operate. It the partner is unable to negotiate, the switch goes to a detection mode to determine the

speed and the duplex will lock at half-duplex.

Auto MDI-/MDIX Crossover

The board determines whether or not it needs to cross over between pairs, virtually eliminating the need for an

external crossover cable. If it interoperates with a device that cannot automatically correct for crossover, the

switch makes the necessary adjustment prior to commencing auto-negotiation. Similarly, if the switch

interoperates with a device that implements MDI-MDIX crossover, a random algorithm determines which device

performs the crossover.

Port-Based VLAN

Select models of the PRV-1059 support field programmable, port-based VLAN functionality. Port-based VLANs

are a type of VLAN where packet forwarding decisions are based on the MAC address of the destination and its

associated port. With this powerful feature any combination of ports can be connected together in subnets for

use in a small secure or non-secure network.

The following diagrams are similar to those which can be seen within the Parvus VLAN software and are

included to illustrate the concept of VLAN on the PRV-1059. Figure 1 below shows a switch and all five ports

with no restrictions; any port can talk to any other port. This is the state of non-VLAN switches and is also the

factory default setting for the VLAN-enabled switch.

Page 14 of 27 MNL-0490-01 RevD4 REF. ECO-3163 Effective: 01 Feb 10

PRV-1059 User Manual

Figure 1) Non-VLAN configured state.

Unlike Figure 1 above, a VLAN configured switch limits which ports can communicate with each other. The

following diagram is a sample of the way that the switch may be setup.

Figure 2) Known VLAN configuration

Figure 2 is VLAN configuration where Ports 0, 1, and 2 form a VLAN. Note that port 2 may talk to port 0 but

NOT to port 1. In contrast, port 0 may talk to either port 1 or 2, and port 1 may talk to port 0 or 2.

Furthermore, ports 3 and 4 are configured to form a different VLAN and can talk to each other, but not to

the first VLAN.

Figure 3 shows another possible VLAN configuration. In this setup, port 1 can talk to all other ports. Ports 0, 3,

and 4 can only talk to port 1 and port 2 is not allowed to send data to any ports.

MNL-0490-01 RevD4 REF. ECO-3163 Effective: 01 Feb 10 Page 15 of 27

Figure 3) Additional Known Configuration

PRV-1059 User Manual

VLAN Software Quick Start Setup Guide

In order to change the VLAN configuration on the PRV-1059 5-port Switch, Parvus has provided the user with a

simple-to-use GUI program. Implementation of the program is through an RS-232 serial cable connection

between a COM port on the host computer and the serial port on the switch.

The following steps describe the process required to setup the VLAN software from an administrator’s (user’s)

standpoint:

I. Connect the serial port of the PRV-1059 (J5) to the COM port of the CPU using the Parvus

VLAN serial cable (PRV-1304-01, sold separately).

II. Download the ParVLAN software for the PRV-1059 from www.parvus.com/support

III. Unpack the zip file and run setup.exe to install the software

Once the switch is

VLAN configuration.

connected and the software installed, you will be able program the switch with the desired

Page 16 of 27 MNL-0490-01 RevD4 REF. ECO-3163 Effective: 01 Feb 10

PRV-1059 User Manual

Software Guide

This section describes how to use the VLAN GUI program to set up VLAN configurations on the PRV-1059. A

screen shot of the program is shown below.

Figure 4) VLAN GUI Window

Com Port

In order to program the PRV-1059, the computer running the software must be connected to the serial port of the

switch. The default COM port for the host computer is set to COM 1. If the user uses a different COM port, the

COM port setting can be changed by selecting the COMM menu located at the top left of the GUI window.

MNL-0490-01 RevD4 REF. ECO-3163 Effective: 01 Feb 10 Page 17 of 27

PRV-1059 User Manual

Setting the Egress Ports

Since port-based VLANs only govern outgoing traffic, it necessary to define the egress for all ports. An egress

port is defined as the port to which data packets are sent. A visual example is provided below.

Figure 5) Egress Port

Port-based VLAN egress ports for Figure 5:

Egress port for Port 0 : Port 4

Egress port for Port 1 : Port 2

Egress port for Port 2 : Port 1

Egress port for Port 3 : Port 4

Egress port for Port 4 : Port 3

Each port can only send data to its egress port. In this example, each port has only one egress port, but on the

PRV-1059 it is possible for each to have between zero and four egress ports.

There are 5 egress port configuration schemes ranging from “Set Egress Ports for Port 0” to “Set Egress Ports

for Port 4” on left side of the VLAN GUI window. The user can enable any possible VLAN configuration by

checking or un-checking these boxes. When each of these check-boxes is checked, there is a coordinate

displayed in the “New VLAN Configuration” graphics indicating the setting of the VLAN with a line and an arrow

pointing to the port where the data packet will be sent. There are also “all PORTs” and “Clear” buttons on right of

each scheme which can be used to set or clear all check-boxes.

Page 18 of 27 MNL-0490-01 RevD4 REF. ECO-3163 Effective: 01 Feb 10

PRV-1059 User Manual

Operation of VLAN GUI Window

Figure 6) Manipulations of VLAN GUI Window

In the above figure, The GUI is divided into four areas:

a) Text display window area for “Sent Command to Switch” and “Received Reply from Switch”

b) VLAN graphic window area for “New VLAN Configuration” and “Current VLAN Setting”

c) VLAN operation button area for “Apply”, “Reset”, “Query”, “Update”, “Clear all”, “SET”, “GET” and

“Exit”.

d) Parvus logo area.

The operation button area is the most important area because all VLAN configurations, setting displays,

executing the VLAN commands will be implemented by these buttons.

a) Apply– causes the “Ne

allowing the user to test the VLAN settings. Note that as soon as the switch is powered off, the

MNL-0490-01 RevD4 REF. ECO-3163 Effective: 01 Feb 10 Page 19 of 27

w VLAN Configuration” to be written to the registers of the PRV-1059

PRV-1059 User Manual

setting

s in the registers will be lost. The Program menu item on the top left of the GUI must be used

to write the configuration to the firmware.

b) Reset– resets the 5-port Ethernet switch. This clears all VLAN settings and allows all ports to talk to

each other through the switch.

c) Query– queries the switch’s current VLAN settings. T he graphics displaying the current VLAN

settings on the switch will show up on the right top of the GUI window.

d) Update– copies the graphics of “Current VLAN Settings” to the “New VLAN Configuration” window

in order to easily change or modify VLAN settings based on the current VLAN settings. Note this

does not affect current VLAN settings in the switch, unless the Apply button is pressed.

e) Clear all– clears the graphics of “New VLAN Configuration” and un-checks all the check boxes for

the five VLAN configuration schemes. Note this does not affect the current VLAN settings of the

switch.

f) SET– This button is used for internal troubleshooting or testing by Parvus. Typing a command in the

text box on the top right of the GUI window, and then pressing this button will set the switch’s

registers.

g) GET– This button is used for internal troubleshooting or testing by Parvus. Pressing this button will

show the contents of the switch’s registers in the text box of “Receive Reply from Switch”.

h) Exit– Pressing this button will exit the operation of VLAN program.

Menu Operation

a) File– consists of the Password and Exit functions. The Password function is not implemented in

VLAN program version V2.0.9. The Exit function exits the program.

b) COMM– allows user to select a COM Port on the host computer.

c) Program– writes the current VLAN settings to an EEPROM on the PRV-1059. Note that every time

when you re-configure the switch using the apply button, the new VLANs a re o nly valid until power

is lost. Once you save your new VLAN settings by using the Program function, the microcontroller

on the board reads the contents from the EEPROM when the switch is powered on and initializes

the registers to set the VLANs on the switch.

d) Firmware– displays the firmware version of the microcontroller’s current software.

e) Help– has an “About” window to display the Parvus Logo and the program version number.

Page 20 of 27 MNL-0490-01 RevD4 REF. ECO-3163 Effective: 01 Feb 10

PRV-1059 User Manual

Chapter 5 Specifications

This chapter provides the specifications for the PRV-1059.

Technical Specification

Electrical

Requirements +5VDC Input

Power Consumption Max: +5 VDC @ 0.44A or 2.2 Watts (0.45W base + 0.35W per port used)

Environmental Specifications

This section describes the environmental standards that the PRV-1059 has either been desig ned to meet or

tested to.

Temperature

Operating: -40ºC to +85ºC

Non-Operating: -55ºC to +100ºC

Reliability (MTBF)

The following table shows the predicted values for reliability of the PRV-1059] as a Mean Time Between Failure s

(MTBF)

1.503 Million Hours @ 40°C (Per MIL-HDBK-217F, Ground Benign, Controlled GB, GC)

157,971 Hours @ 40°C (Per MIL-HDBK-217F, Airborne Inhabit Fighter, AIF)

60,164 Hours @ 40°C (Per MIL-HDBK-217F, Airborne Rotary Winged, ARW)

Mechanical

This section provides details related to the mechanical construction of the PRV-1059.

Weight

The PRV-1059 assembly weighs up to 88.6 grams (0.195 lbs.)

MNL-0490-01 RevD4 REF. ECO-3163 Effective: 01 Feb 10 Page 21 of 27

PRV-1059 User Manual

Dimensions

3.550” x 3.775”

RJ-45 Version

rning: PC/104 specifications state that max height may only be 0.435”. Be sure that the board height

Wa

of 0.52” for the RJ-45 version will operate in your application. This applies to the RJ-45 version only.

Page 22 of 27 MNL-0490-01 RevD4 REF. ECO-3163 Effective: 01 Feb 10

PRV-1059 User Manual

Molex Version Molex Version

Note: The external power connector (J101) on models without the PC/104 bus is a right angle two-pin

Molex connector that extends from the board .32”

Note: For further information about the mechanical dimensions of ISA and PCI buses please refer

to the PC/104 Consortium site (www.pc104.org

MNL-0490-01 RevD4 REF. ECO-3163 Effective: 01 Feb 10 Page 23 of 27

)

PRV-1059 User Manual

Chapter 6 Troubleshooting

Technical Assistance

If you have a technical question or if you cannot isolate a problem with your product, please call or e-mail the

Parvus Technical Support team:

Email: tsupport@parvus.com

Phone: +1 (801) 433-4322

Fax: +1 (801) 483-1523

Returning For Service

Before returning any Parvus product, please fill out a Returned Material Authorization (RMA) request form

available for download from the following website under the support section:

www.parvus.com

Email this form to the email address listed above to receive authorization for shipment. An RMA number will be

emailed back to you as soon as possible.

Note. You must have the RMA number in order to return any product for any reason.

Pack the module in an anti-static material and ship it in a sturdy cardboard box with enough packing material to

adequately cushion it.

Warning! Any product returned to Parvus improperly packed will immediately void the warranty for

that particular product!

Page 24 of 27 MNL-0490-01 RevD4 REF. ECO-3163 Effective: 01 Feb 10

PRV-1059 User Manual

Chapter 7 Contact Info

Main Phone: +1 (801) 483-1533

Fax: +1 (801) 483-1523

Sales

+1(800) 483-3152 or (801) 483-1533,

sales@parvus.com

Product Technical Support

+1 (801) 433-6322,

tsupport@parvus.com

Customer Feedback

feedback@parvus.com

Company contact info:

®

Parvus

3222 S. Washington St.

Salt Lake City, Utah, USA 84115

(801) 483-1533, FAX (801) 483-1523

Web-site: http://www.parvus.com

Corporation

MNL-0490-01 RevD4 REF. ECO-3163 Effective: 01 Feb 10 Page 25 of 27

ASIA

A

Eurotech Group Worldwide presence

MERICAS

USA

EUROTECH

Toll free +1 888.941.2224

Tel. +1 301.490.4007

Fax +1 301.490.4582

E-mail: sales.us@eurotech.com

E-mail: support.us@eurotech.com

We

b: www.eurotech-inc

PARVUS

Tel. +1 800.483.3152

Fax +1 801.483.1523

E-mail: sales@parvus.com

E-mail: tsupport@parvus.com

b: www.parvus.com

We

.com

EUROPE

Italy

EUROTECH

Tel. +39 0433.485.411

Fax +39 0433.485.499

E-mail: sales.it@eurotech.com

E-mail: support.it@eurotech.com

We

b: www.eurotech.com

Uni

ted Kingdom

EUROTECH

Tel. +44 (0) 1223.403410

Fax +44 (0) 1223.410457

E-mail: sales.uk@eurotech.com

E-mail: support.uk@eurotech.com

We

b: www.eurotech.com

France

EUROTECH

Tel. +33

Fax +33 04.78.70.08.24

E-mail: sales.fr@eurotech.com

E-mail: support.fr@eurotech.com

We

b: www.eurotech.com

Fi

nland

EUROTECH

Tel. +358 9.477.888.0

Fax +358 9.477.888.99

E-mail: sales.fi@eurotech.com

E-mail: support.fi@eurotech.com

We

b: www.eurotech.com

04.72.89.00.90

Japan

ADVANET

Tel. +81 86.245.2861

Fax +81 86.245.2860

E-mail: sales@advanet.co.jp

E-mail: tsupport@advanet.co.jp

We

b: www.advanet.co.jp

Chi

na

VANTRON

Tel. +86 28.85.12.39.30

Fax +86 28.85.12.39.35

E-mail: sales@vantrontech.com.cn

E-mail: support.cn@eurotech.com

We

b: www.vantrontech.com.cn

www.parvus.com

Loading...

Loading...