Page 1

P

R

AR

T

NER

Wor

M

a

k

shop

nu

a

l

Page 2

Workshop Manual

Petrol power cutters

Contents

General recommendations .................................................. 2

1. Starter unit ......................................................................... 3

2. Ignition system ............................................................... 11

3. Fuel system ..................................................................... 19

4. Centrifugal clutch ........................................................... 41

5. Cylinder and piston ........................................................ 47

6. Crankshaft and crankcase ............................................. 59

7. Cutting equipment .......................................................... 77

8. Tools................................................................................. 85

9. Technical data ................................................................. 93

This manual covers models:

K 650/700 Active

K 950/1250 Active

©

Copyright Partner Industrial Products, Sweden

1

Page 3

General recommendations

Keep this in mind:

Do not start the engine unless the clutch and clutch drum

!

are fitted.

!

Do not touch hot parts, e.g. silencer and clutch, before they

have cooled sufficiently to avoid burn injuries.

!

Avoid getting petrol or oil on the skin or in the mouth. Use

protective cream on the hands. This reduces the risk of

infection and makes it easier to wash off dirt. Prolonged

exposure to engine oil can be hazardous to health.

!

Never start the engine indoors. The exhaust fumes are

toxic!.

Wipe up spilled oil immediately from the floor to avoid

!

slipping.

!

Do not use tools which are worn or have a poor fit, e.g. nuts

and screws.

+Always work on a clean work bench.

+Always work in a logical way to make sure that all parts are

correctly fitted and that screws and nuts are tightened.

+Use special tools where so recommended in order to do the

work correctly.

Fire hazard

Handle petrol with respect since it is highly inflammable.

Do not smoke, and make sure that there are no naked flames or

sparks in the vicinity.

Make sure that there is a functioning fire extinguisher in the

vicinity.

Do not try to extinguish a petrol fire with water.

Use an anti-spill fuel can.

Special tools

Some work procedures in this Workshop Manual require the

use of special tools. In each section where this is appropriate

the tool and order number are illustrated.

We recommend the use of special tools partly to avoid personal

injury and partly to eliminate expensive damage to the

components in question.

Sealing surfaces and gaskets

Make sure that all sealing surfaces are clean and free from the

residue of old gaskets. Use a tool which will not damage the

sealing surface when cleaning it. Scratches and irregularities

are removed with a fine, float cut file.

Sealing rings

Always replace a sealing ring which has been dismantled. The

sensitive sealing lip can easily be damaged and result in poor

sealing capacity. The surface which the seal seals must also be

completely undamaged. Lubricate the sealing lip with grease

before it is fitted and make sure that it is not damaged, e.g. by

the shoulder and splines on a shaft. Use tape or a conical

sleeve as protection. It is important that the sealing ring is

correctly turned for it to function as intended.

Toxic fumes

Read the instructions carefully when using cleaning liquids.

Make sure that there is adequate ventilation when handling petrol

and other viscous liquids.

The engine exhaust fumes are toxic. Test run the engine outdoors.

!

WA RN I NG

The engine exhaust from this product

contains chemicals known to the State

of California to cause cancer, birth

defects or other reproductive harm.

2

Page 4

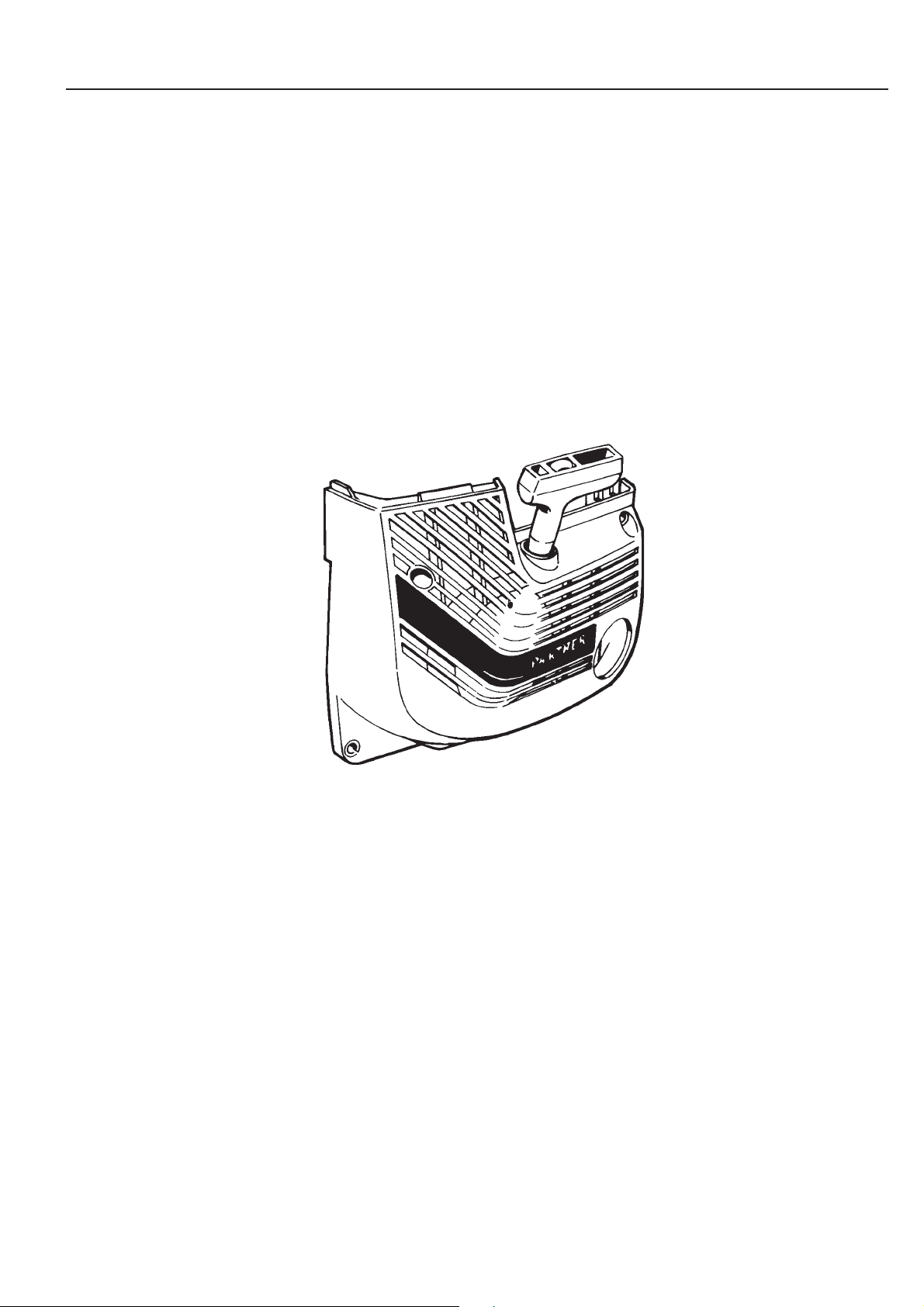

Starter unit

1.

1

Contents

Dismantling of the starter unit ..............................................4

Replacing the starter cord without dismantling the pulley ... 5

Dismantling ...........................................................................7

Assembly .............................................................................. 8

3

Page 5

1

Starter unit

!

WARNING!

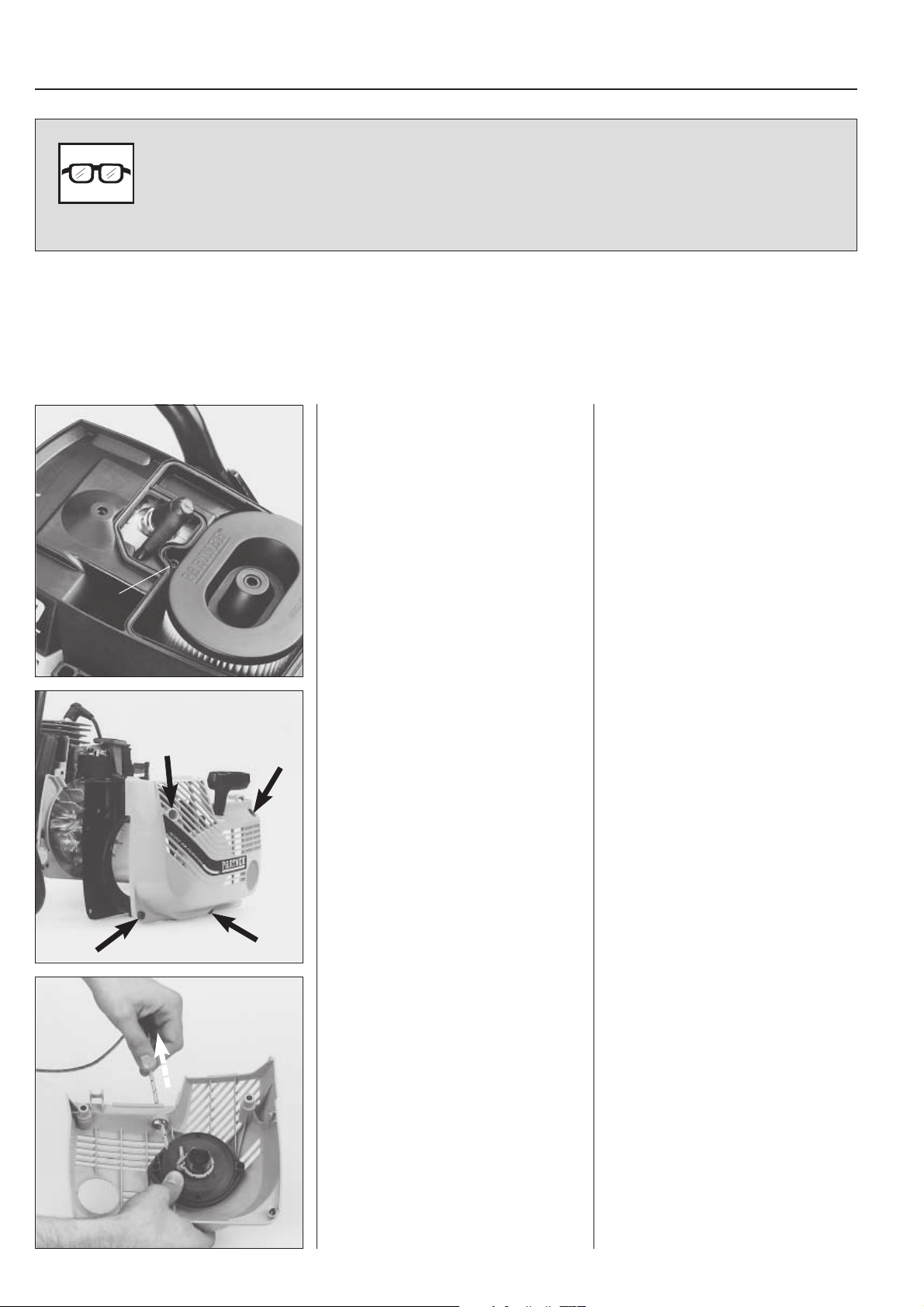

When working on the starter unit wear protective glasses to avoid eye injuries in the

event that the return spring flies out.

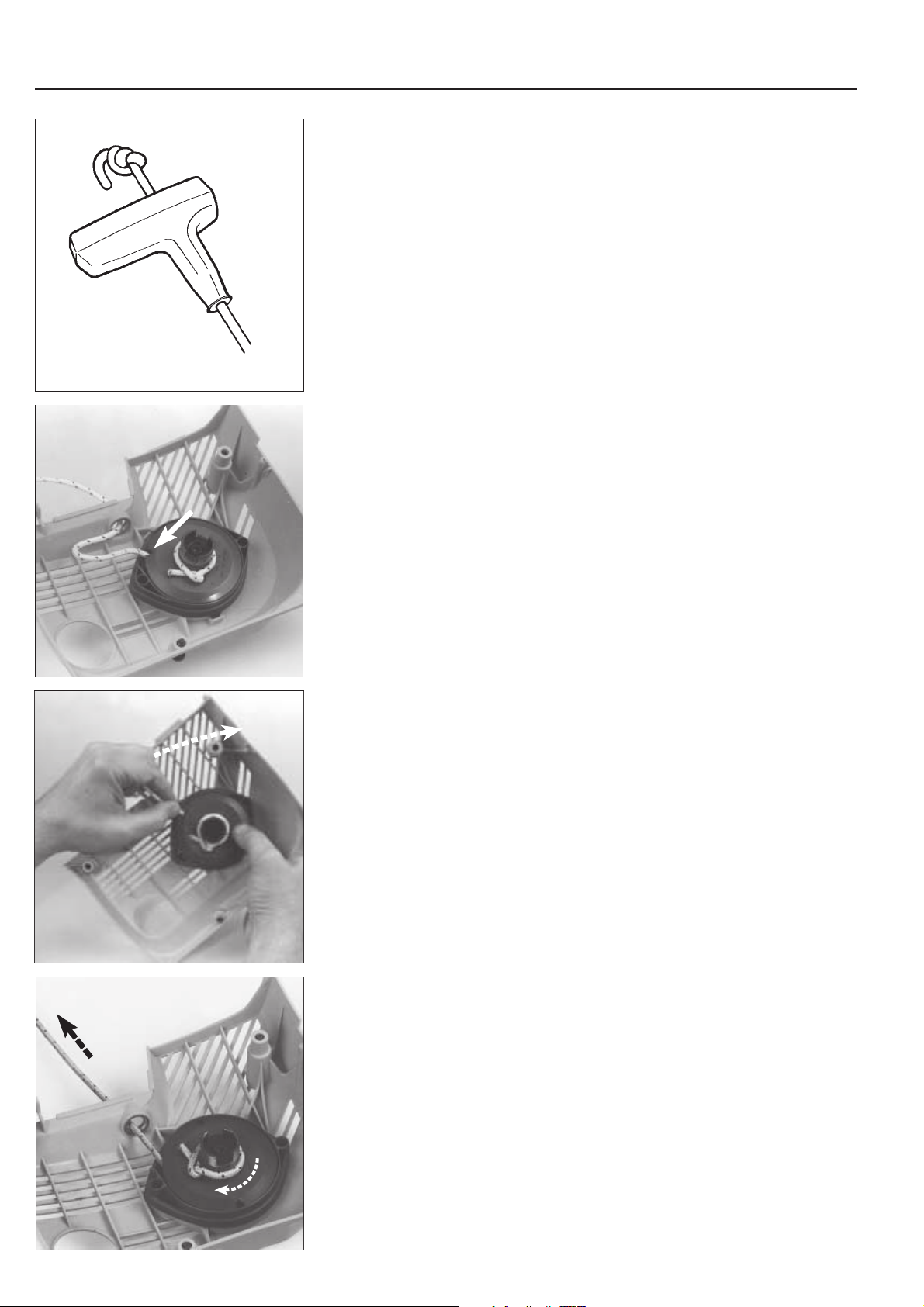

Dismantling of the

starter unit

Mod. 650, 700

Dismantle the air filter cover, intermediate

wall and cylinder cover.

A

Dismantle the starter unit from the engine

body.

Dismantling of the

starter unit

Mod. 650, 700

Untighten the screws for the air filter

cover.

Lift off the cover and intermediate wall.

Release the screw (A) and lift off the

cylinder cover.

Untighten all the screws and lift off the

starter unit.

Release the spring tension.

4

Release the spring tension.

Pull out the starter rope approx. 30 cm

(12 in).

Hold the pulley with your thumb and place

the cord in one of the recesses in the

pulley.

Page 6

Starter unit

1

Allow the pulley to slowly rotate backwards.

Remove the starter handle.

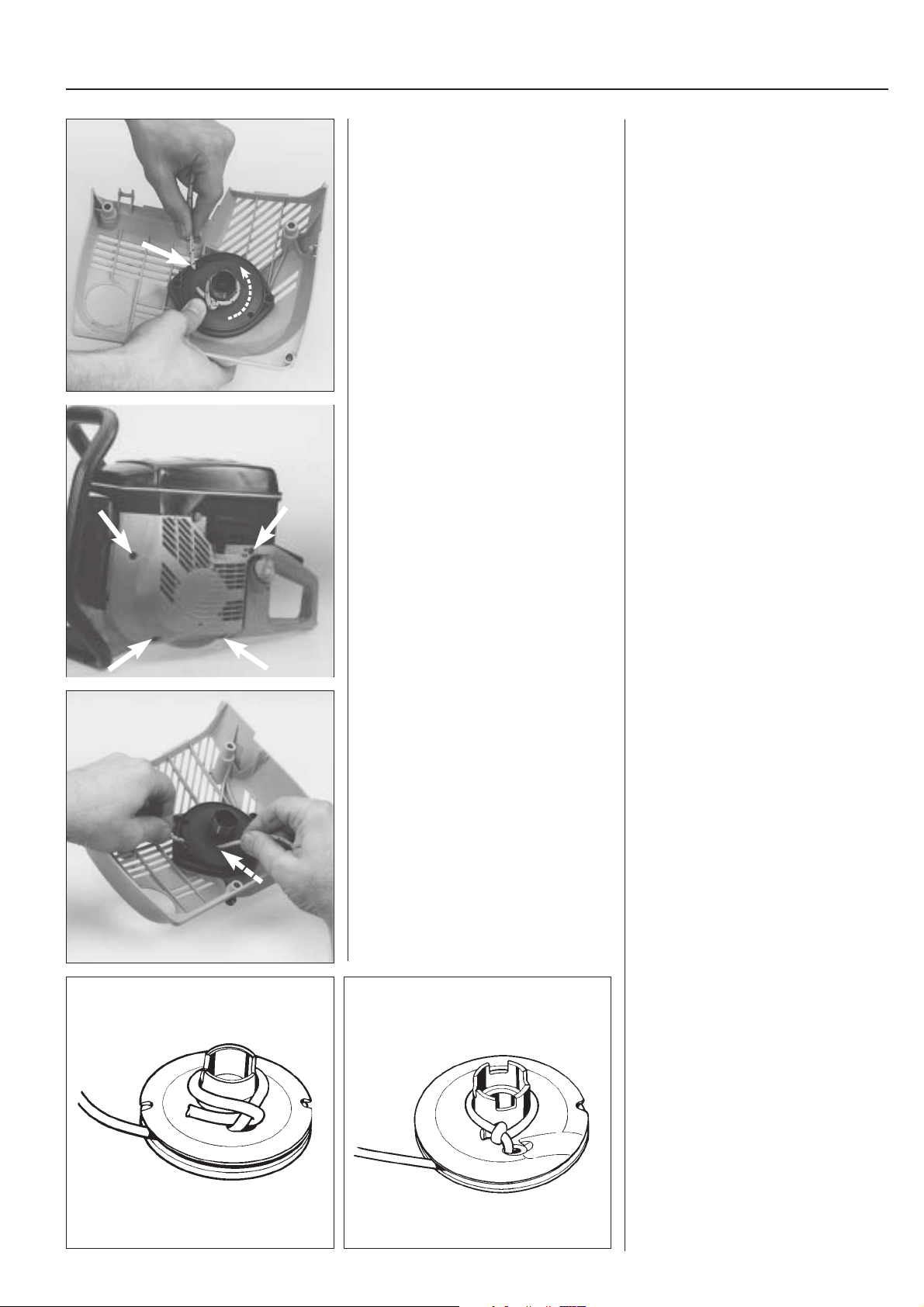

Mod. 950, 1250

Remove the screws which hold the starter unit, and lift off the starter unit.

The next stage in the dismantling work

follows mod. 650/700.

Allow the pulley to slowly rotate backwards.

NOTE!

Brake the rotation with the thumb.

Untie the knot on the starter rope and

remove the starter handle.

Tips!

The knot may be difficult to untie. It is

easier if it first is tapped with a hammer

while placed on a hard surface.

Mod. 950, 1250

Remove the screws which hold the starter unit, and lift off the starter unit.

NOTE!

The air filter and cylinder covers do not

need to be dismantled.

The next stage in the dismantling work

follows mod. 650/700.

K650/700

K950

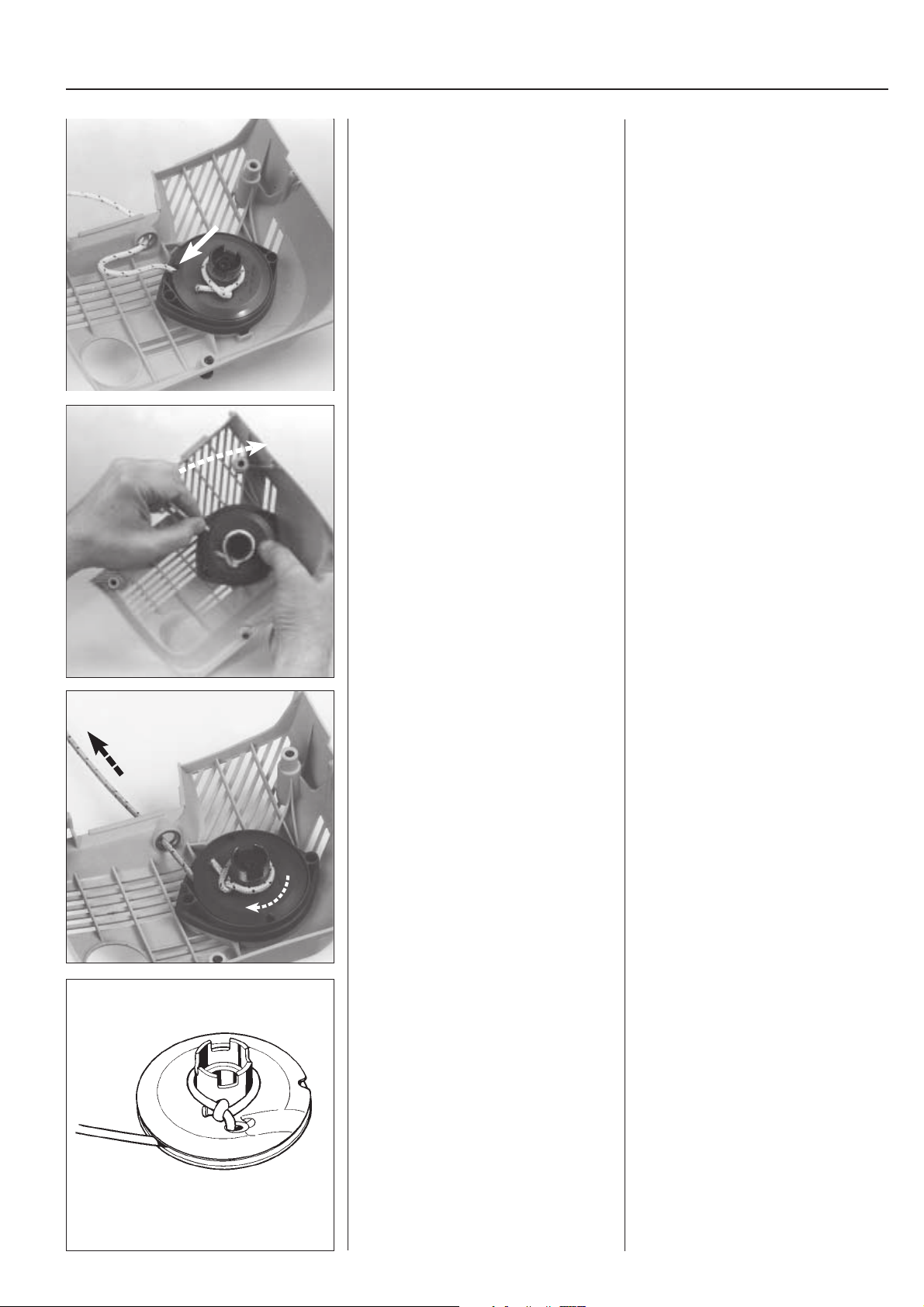

Replacing the starter

cord without dismantling the pulley

Mod. 650, 700, 950, 1250

Remove any remaining rope from the

pulley and check that the return spring

recoils.

Insert the new starter rope through the

hole in the pulley.

K1250

Replacing the starter

cord without dismantling the pulley

Mod. 650, 700, 950, 1250

Remove any remaining rope from the

pulley.

Check that the return spring and its

attachment in the pulley has not been

damaged by turning the pulley clockwise.

Enter the new starter rope through the

hole in the pulley as shown in the illustration.

Anchor the rope round the hub on the

pulley as shown in the illustration.

Pull the rope tight and make sure that the

free end is as short as possible.

Cord lengths

Models 650, 700, 950: 1150 mm.

Models 1250: 1250 mm.

These lengths apply to Ø 4 mm cord.

5

Page 7

1

Starter unit

Anchor the starter rope in the starter

handle with a double knot.

Te ns i on the retur n spring.

Check that the spring tension is completely

released, and lift the starter cord up into

the cut-out in the pulley.

Insert the rope through the rope guide in

the starter housing and anchor it in the

starter handle with a double knot.

Te ns i on the retur n spring.

1. Check that spring tension is competely

released.

2. Lift the starter cord up into the cut-out

in the pulley.

Max

Wind the pulley 7 turns

Pull the cord out completely and check

that the pulley can be turned at least a

further half turn.

clockwise.

3. Wind the pulley 7 turns

Be careful and brake the pulley with

your thumb.

4. Pull the cord out completely and check

that the pulley can be turned at least

a further half turn.

clockwise.

+1/2

6

Page 8

Starter unit

1

Dismantling

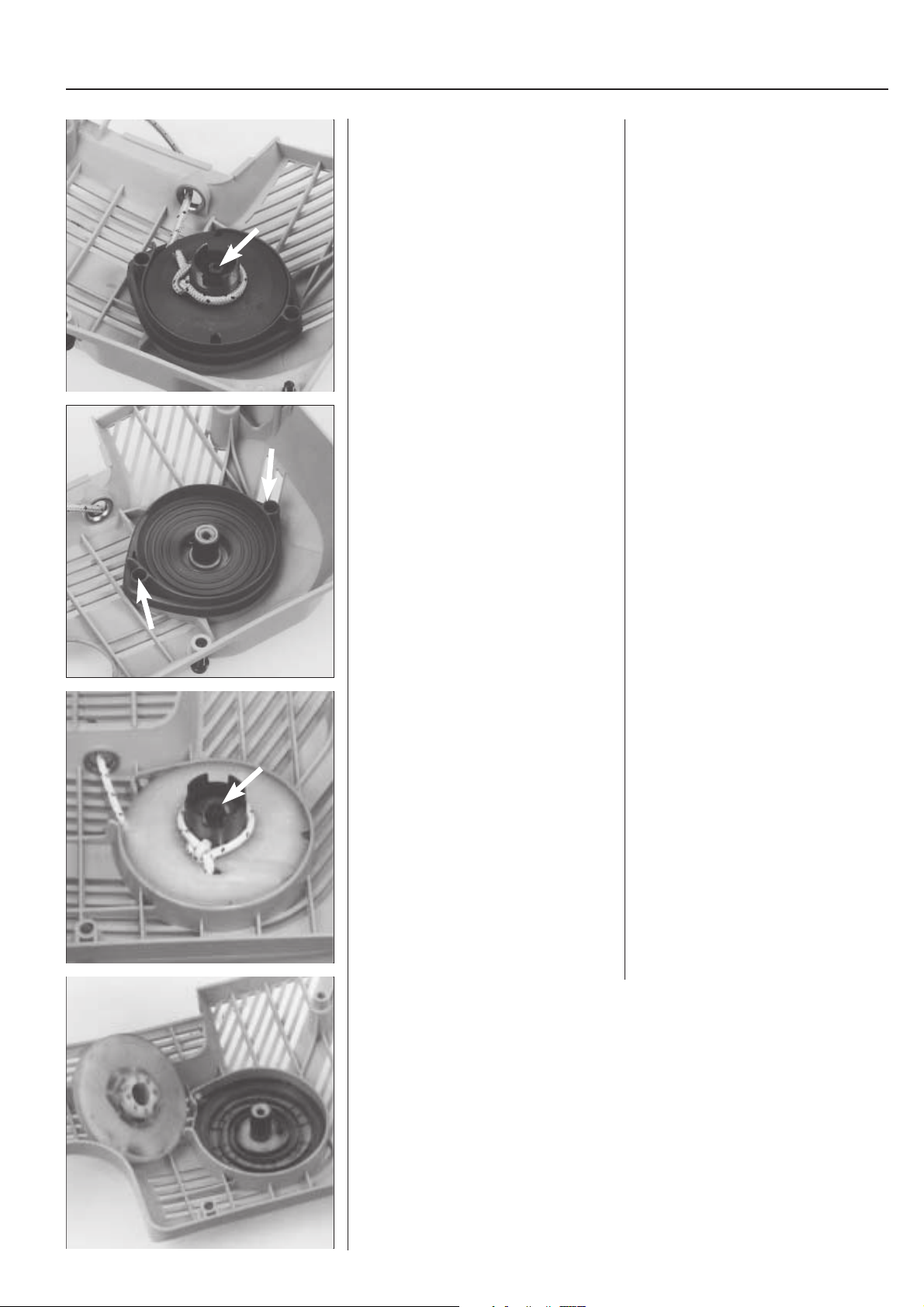

Mod. 650, 700, 950

Remove the screw in the centre of the

pulley and lift off the pulley.

Dismantle the spring cassette.

WARNING!

!

The return spring in the spring cassette is pre-tensioned and can if not

handled carefully during dismantling/fitting fly out and cause personal injury.

Dismantling

Mod. 650, 700, 950

Remove the screw in the centre of the

pulley.

Lift off the pulley.

Remove the screws and lift off the spring

cassette.

WARNING!

!

The return spring in the spring cassette is pre-tensioned and can if not

handled carefully during dismantling/fitting fly out and cause personal injury.

Mod. 1250

Remove the screw in the centre of the

pulley and lift off the pulley.

Make sure that the return spring is

completely released, and dismantle the

pulley.

WARNING!

!

The return spring is

starter unit cover.

Observe care during dismantling/assembly, the spring can fly out and cause

personal injury.

not

placed in a separate cassette but i s p la ced directly in the

Mod. 1250

Remove the screw in the centre of the

pulley and lift off the pulley.

Make sure that the return spring is

completely released.

Remove the screw and washer in the

centre of the pulley.

Carefully lift off the pulley.

7

Page 9

1

Starter unit

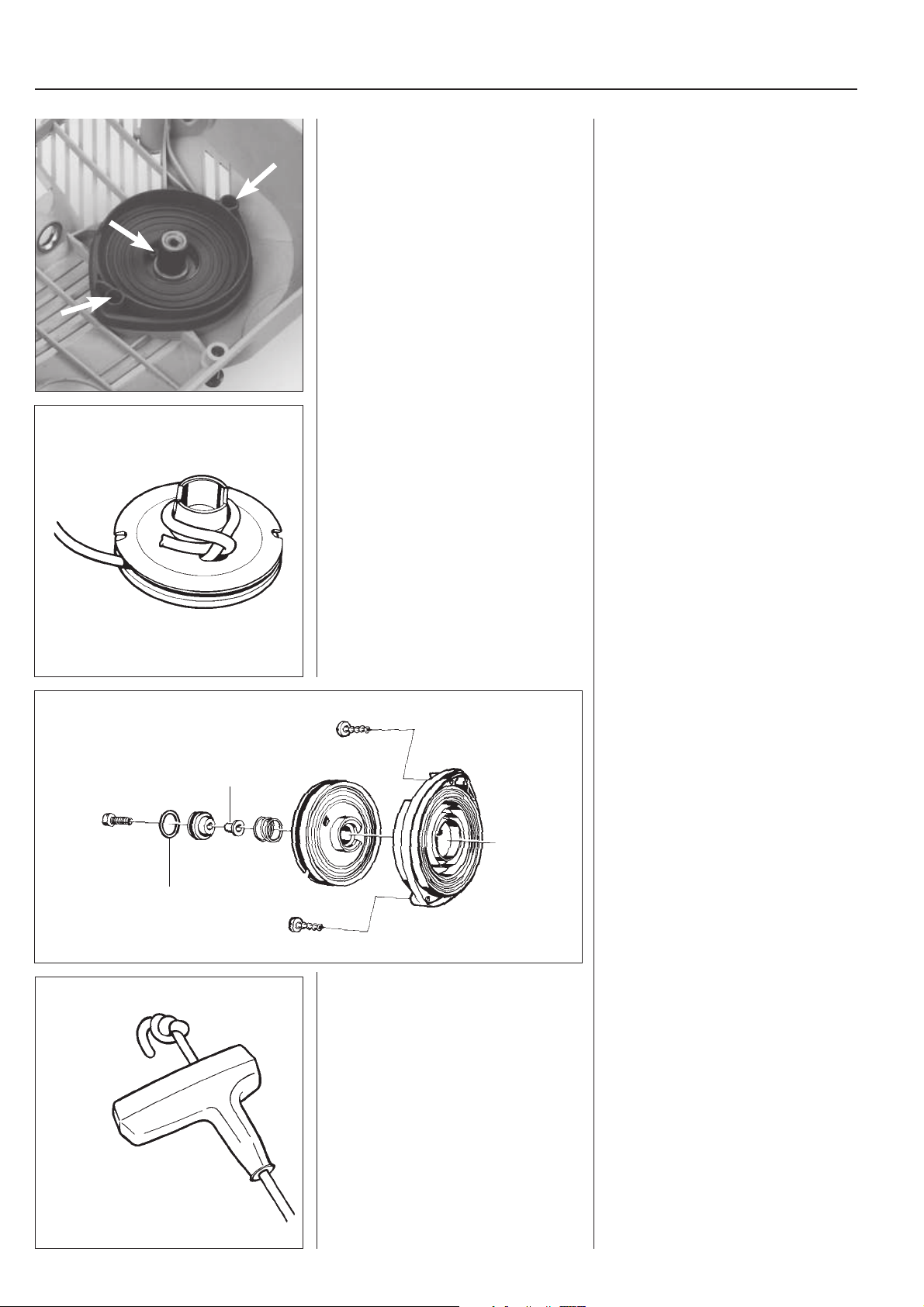

Assembly

Mod. 650, 700, 950

Clean the starter unit components and fit

the spring cassette.

Anchor the cord in the pulley.

Push the pulley on the shaft stem.

Assembly

Mod. 650, 700, 950

Clean the different starter unit parts.

Lubricate the return spring with oil and

place the spring cassette in the starter

unit housing.

Make sure that the spring end is not

clenched.

Tighten the screws.

Anchor the cord round the pulley hub as

shown in the illustration.

Push the cord down on the shaft journal in

the starter unit housing.

Make sure that the return spring grips in

the pulley.

Lubricate the starter housing stem and

pulley with a few drops of oil.

Fit the other parts in the pulley hub.

NOTE!

Turn the metal sleeve (B) correctly.

B

C

Anchor the starter cord in the starter

handle with a double knot.

Check that the O-ring (C) is undamaged.

Lubricate it with a few drops of oil.

Tighten the centre screw and check that

the pulley can turn freely.

Enter the cord through the cord guide in

the starter unit and anchor it in the starter

handle with a double knot.

8

Page 10

Starter unit

1

Te ns i on the retur n spring.

Check that the spring tension is completely

released, and lift the starter cord up into

the cut-out in the pulley.

Wind the pulley 7 turns

clockwise.

Te ns i on the retur n spring.

1. Check that spring tension is competely

released.

2. Lift the starter cord up into the cut-out

in the pulley.

3. Wind the pulley 7 turns

Be careful and brake the pulley with

your thumb.

clockwise.

Max

+1/2

Pull the cord out completely and check

that the pulley can be turned at least a

further half turn.

Mod. 1250

Press a new return spring down in the

starter unit cover.

Lubricate the spring with a few drops of

oil.

Anchor the cord in the pulley.

Push the pulley down onto the shaft journal.

4. Pull the cord out completely and check

that the pulley can be turned at least

a further half turn.

Mod. 1250

Press down a new return spring in the

starter unit cover.

NOTE!

Do not remove the lock round the spring,

but push down the spring all round by

using your thumbs.

Lubricate the spring with a few drops of

oil.

Anchor the starter cord round the hub of

the pulley as shown in the diagram.

Push the cord wheel down on the shaft

journal in the starter unit housing.

Make sure that the spring grips the cord

wheel.

Lubricate the bearing with a few drops of

oil.

9

Page 11

1

Anchor the starter cord in the starter

handle with a double knot.

Fit the starter unit and other parts in the

reverse order to dismantling.

Enter the cord through the cord guide in

the starter unit and anchor it in the starter

handle with a double knot.

Fit the starter unit.

Pull out the starter cord a little. Place the

starter unit in position. Release the starter cord and check that the pawls engage

the pulley.

Tighten the screws.

10

Page 12

Ignition system

2.

2

Contents

The principle of the ignition system ............................ 12

Checking the ignition spark ........................................ 13

Replacing the spark plug protection ........................... 15

Dismantling ................................................................. 15

Starter pawls ............................................................... 17

Assembly .................................................................... 17

11

Page 13

2

Ignition system

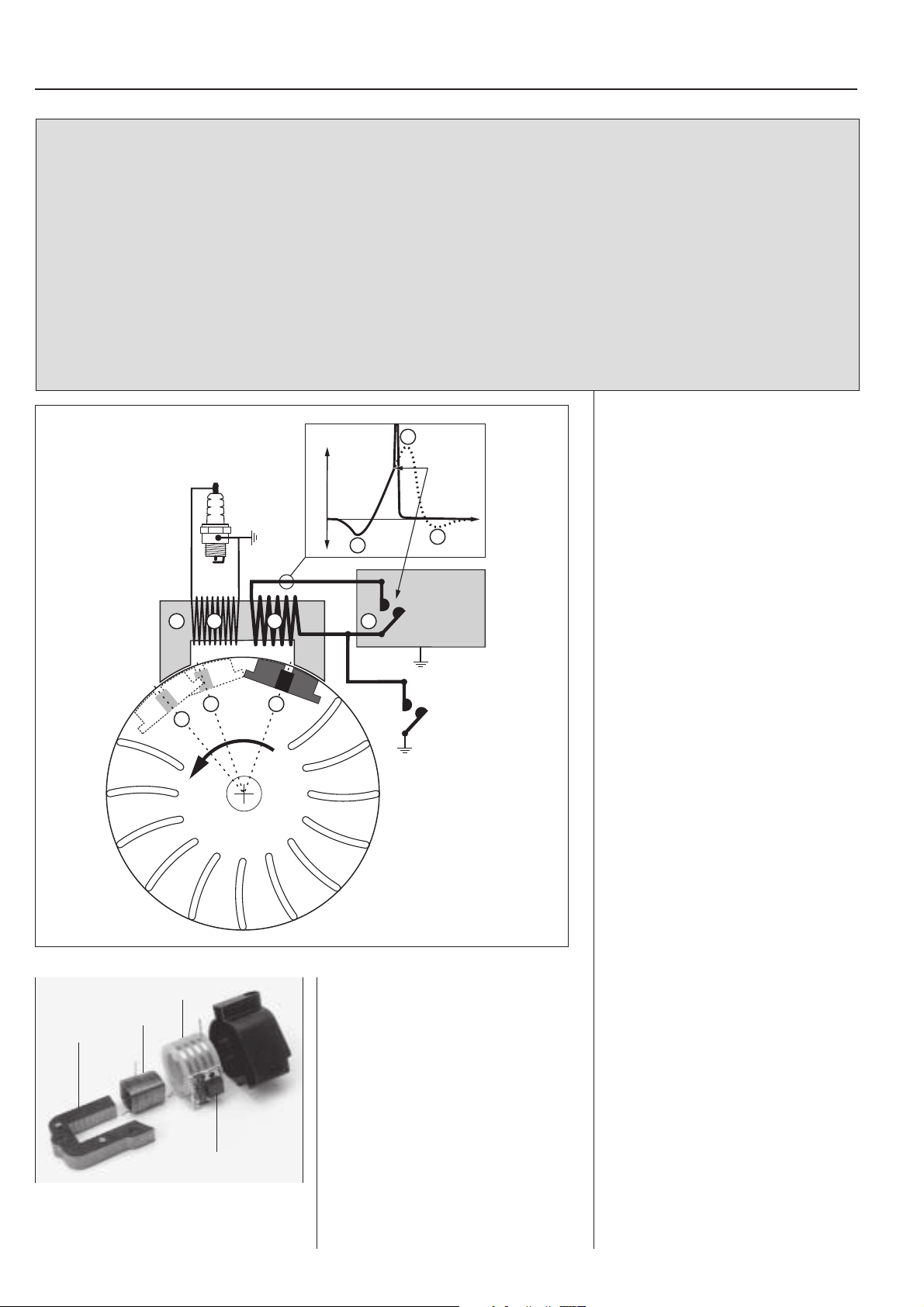

The engine is fitted with an electronic ignition system consisting of flywheel, ignition coil and trigger

unit.

The ignition system has no moving parts. A defective

component cannot be repaired but must be replaced

with a new one.

The ignition spark in an electronic ignition system

has a very short burn time and may therefore be

experienced as weak, and sometimes be dif ficult to

see during trouble shooting.

2

+

Volts

0

1

A

N

S

N

2

3

B

A

C

S

1

DBC

The ignition module components are

completely enclosed to protect them from

moisture and dirt.

In the event of a failure in the ignition

module it must be replaced with a new

one.

E

3

G

E = Ignition point

F = Trigger unit

G = Stop switch

NOTE!

During all test running of the cutting saw the

clutch and clutch cover must be fitted before the

engine is started!

Principle of the ignition

system

The ignition system is completely enclosed and no after-adjustment of the

ignition point is possible or necessary.

The ignition module is built up of an iron

core (C). Round this lies the primary coil

(A) which consists of a small number of

turns of thick copper wire. Outside this

lies the secondary coil (B) which has a

F

very large number of turns of copper

wire.

The trigger unit (F) is fitted on the

secondary coil and has the purpose of

breaking the current (D) in the primary

winding at exactly the right time, i.e. just

before the piston reaches the top dead

centre.

When the permanent magnet (1) on the

flywheel passes the ignition module’s

iron core, an electric current is generated

in the primary coil (A). At the breaking

moment the current in the primary coil

rises from 5 volts to approx. 200 volts by

means of induction.

In the secondary coil (B) a high voltage

(approx. 20 000 volts) is simultaneously

transformed to the spark plug.

Models K650,K700, K950 and K1250

have a built-in overspeeding protection

in the electronic unit which limits the

unloaded speed of the engine to about

9 750 rpm.

The ignition module components are

completely enclosed to protect them from

moisture and dirt.

In the event of a failure in the ignition

module it must be replaced with a new

one.

12

F

A = Primary coil

B = Secondary coil

C = Iron core

F = Trigger unit

Page 14

Ignition system

2

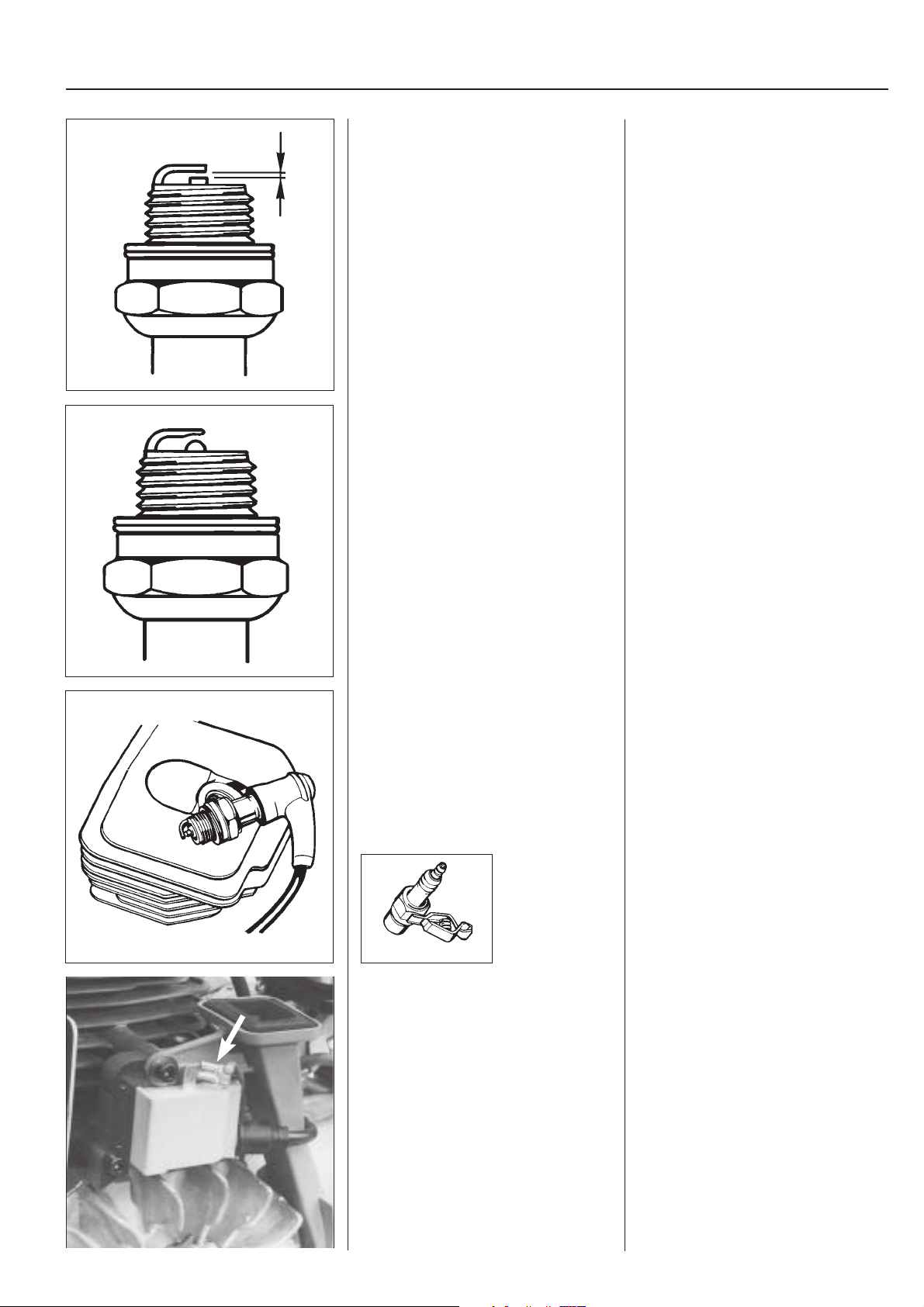

Checking ignition spark

Clean the electrodes and check the

electrode gap.

If the electrodes are worn down more

than 50% the plug should be replaced.

Checking ignition spark

Dismantle the plug and clean it from soot

by means of a wire brush.

Check the electrode gap. It should be 0.5

mm (.020 in).

Adjust the gap to the correct distance with

the side electrode.

If the electrodes are worn down more

than 50% the plug should be replaced.

If the gap is too wide this results in strain

on the ignition module and the risk of

short circuiting.

Check if there is a spark by pulling the

engine over with the starter.

Try with test plug No. 502 71 13-01 if

there is no spark.

502 71 13-01

Try with a new plug.

If there is no spark disconnect the stop

switch wire.

If necessary replace the switch.

Check if there is a spark by pulling the

engine over with the starter.

Ground the plug to the cylinder and briskly

pull the starter handle.

Make sure that the stop switch is in the

start position.

There should be a spark between the

electrodes.

If there is no spark try with test plug No.

502 71 13-01!

If there is a spark the fault lies in the plug.

Replace the plug.

Try with a new plug.

If there is still no spark remove the short

circuiting cable from either the ignition

module or the stop switch.

If there is now a spark the fault lies in the

stop switch.

Replace the switch.

13

Page 15

2

Ignition system

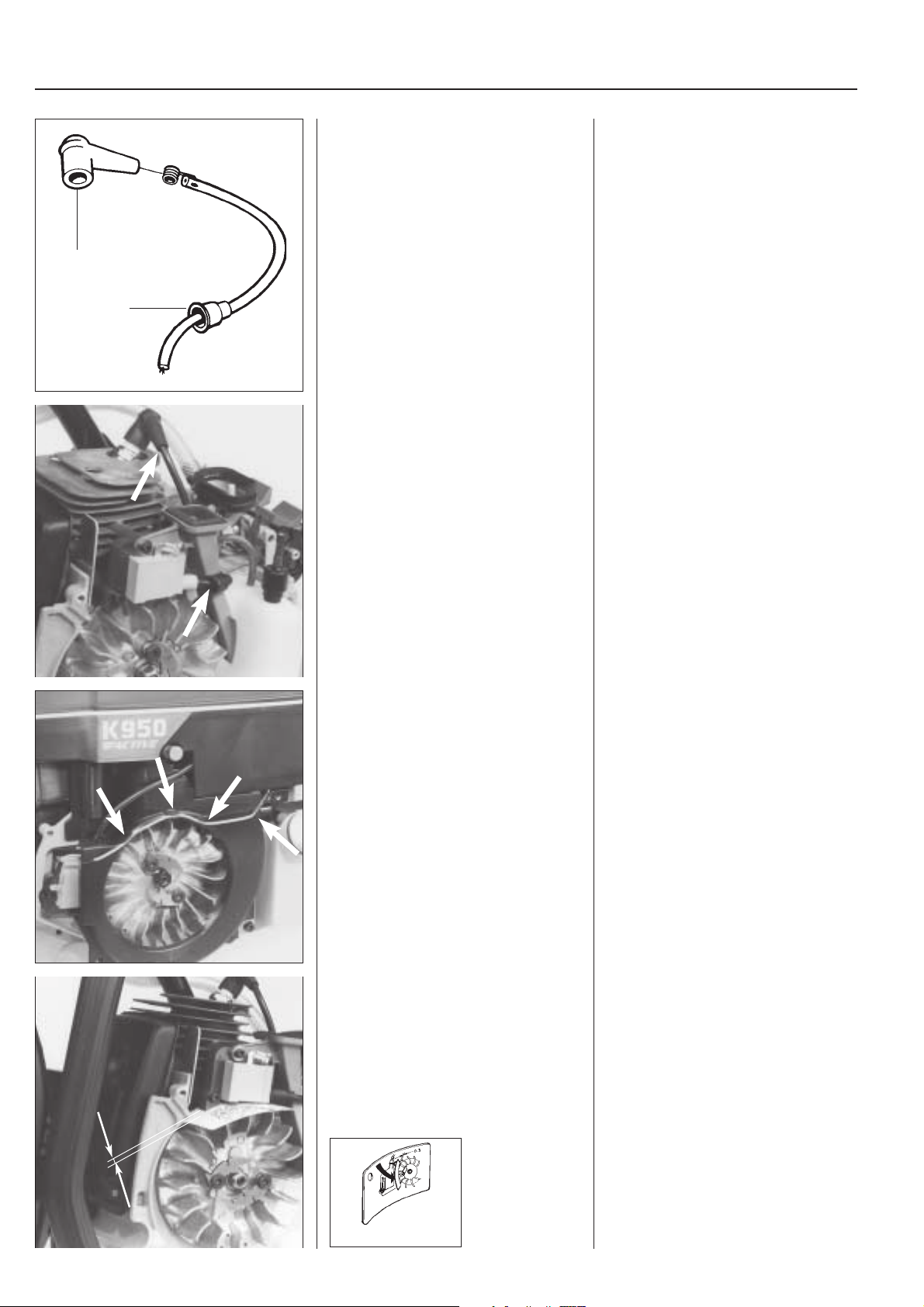

Check the ignition cable’s connections.

A

B

Grease the cable ends before fitting.

Still no spark?

Check the plug connection.

Pull off the rubber protection at the plug

(A) and ignition module (B) and check

that the ignition cable is undamaged. If

necessary cut off a piece of the cable to

ensure good contact.

Grease the cable ends to simplify fitting

and to prevent moisture penetrating into

the connections.

0,3 – 0,5 mm

Check the other cables and connections. Still no spark?

Check the other cables and connections

for poor contact (dirt, corrosion, cable

break and damaged insulation).

Tips!

Use an Ohm meter to check if there is a

cable break, e.g. as a result of pinching.

Check the air gap. Still no spark?

Check the air gap between the flywheel

magnet and ignition module. The gap

should be 0.3 – 0.5 mm (0.012–0.020").

Use air gap measure 502 51 34-06.

14

502 51 34-06

Page 16

Ignition system

2

Adjust the air gap.

502 51 34-06

Replacing spark plug

protection

1. Take the ignition cable through the

plug protection.

2. Fit the contact spiral on the ignition

cable.

Adjust where appropriate the air gap to

the correct distance.

• Release the screws holding the

ignition module.

• Position the feeler gauge on the

magnets of the flywheel and press the

ignition module against flywheel.

• Tighten the screws and check the air

gap again.

If there is still no spark then the ignition

system should be replaced.

Replacing spark plug

protection

1. Grease the ignition cable with a little

grease and take it through the plug

protection.

2. Cut off a piece of the ignition cable

(approx. 5 mm, 3/16") to obtain full

contact with the spark plug protection.

3. Fit the contact spiral on the ignition

cable and make sure that the wire is

folded along the cable.

4. Pull the contact spiral in the plug

protection.

NOTE!

It is important that the point on the contact

spiral meets the middle of the ignition

cable to prevent sparking.

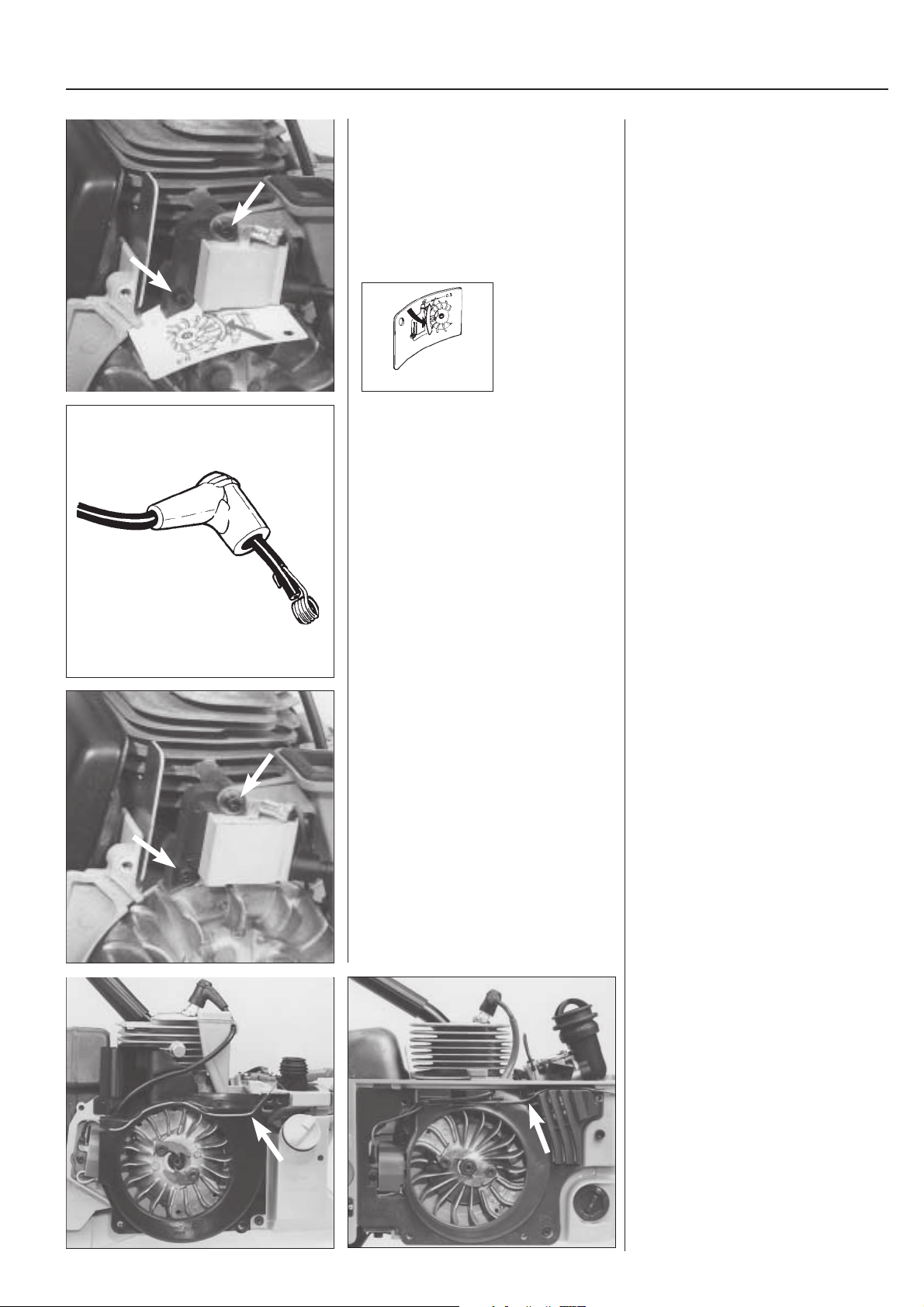

Dismantling

Mod. 650, 700

Dismantle the cylinder cover, plug, starter unit, and air conductor.

Dismantle the ignition module and release the other cable connections.

K 950 K 1250

Dismantling

Mod. 650, 700

Dismantle the plug, cylinder cover, starter unit, and air conductor.

Dismantle the ignition module by removing the two screws.

Release the other cable connections and

lift off the ignition module.

Mod. 950, 1250

Dismantle the starter unit, air filter cover,

air filter and cylinder cover.

Remove the air conductor.

Note the position of the cables so that

they can be replaced in the same way.

15

Page 17

2

Ignition system

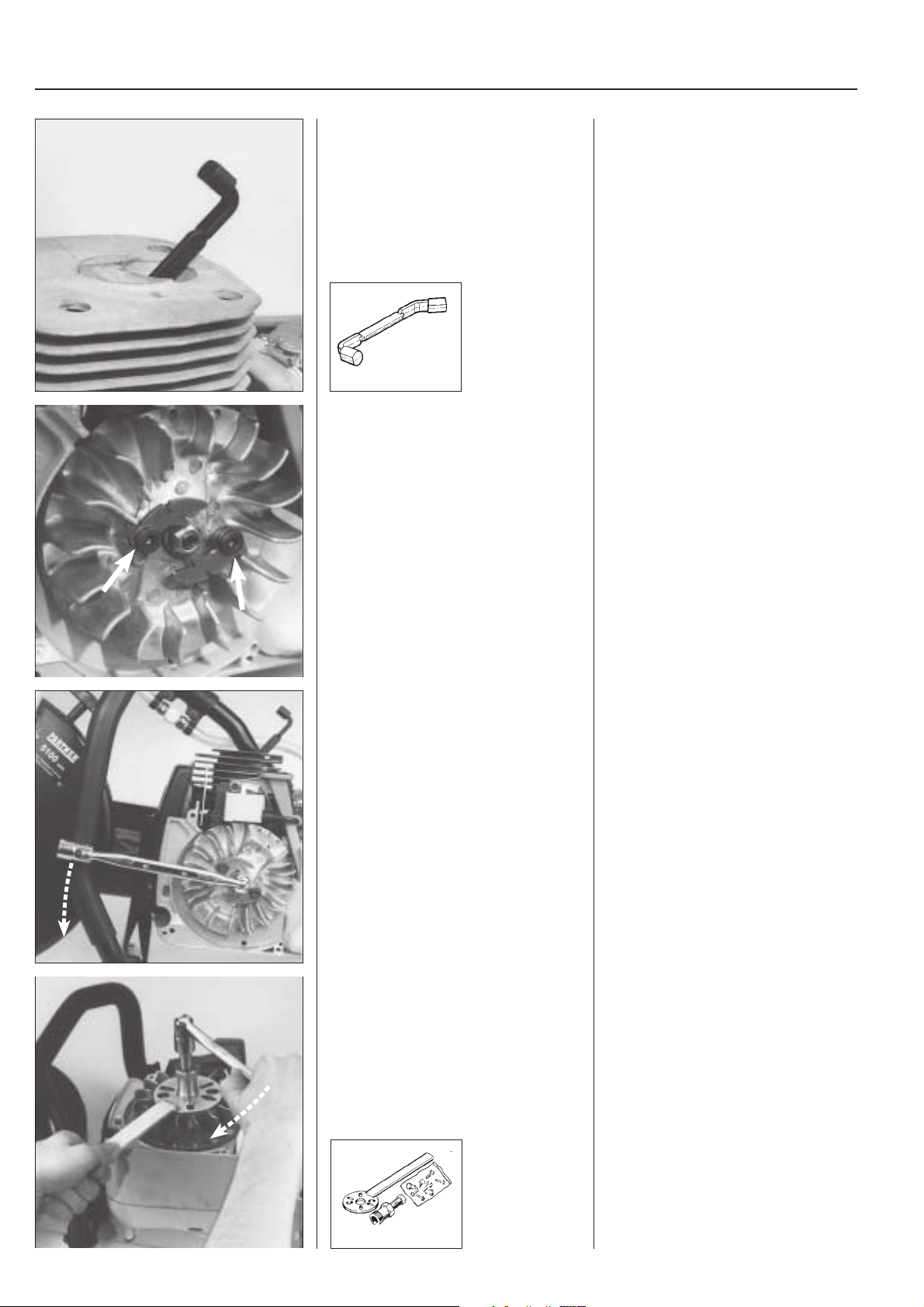

Fit piston stop No. 502 54 15-01 in the

spark plug hole.

502 54 15-01

Mod. 650, 700, 950, 1250

Dismantle the starter pawls.

Insert piston stop No. 502 54 15-01 in the

sparking plug hole.

Make sure that the piston stop does not

come out through the exhaust port, it

must rest against the front of the cylinder

wall when the piston approaches Top

Dead Centre.

Mod. 650, 700, 950, 1250

Dismantle the starter pawls by releasing

the screws. Make sure the small washer

which lies next to the flywheel is not lost.

Remove the flywheel nut. Remove the flywheel nut by means of a

suitable box spanner.

Pull off the flywheel. Remove the flywheel by means of fly-

wheel puller 502 51 49-02, which is

screwed tight in the holes for the pawls.

NOTE!

Centre the flywheel puller over the shaft

centre. Select suitable screws and tighten

the withdrawing tool.

16

502 51 49-02

Page 18

Ignition system

2

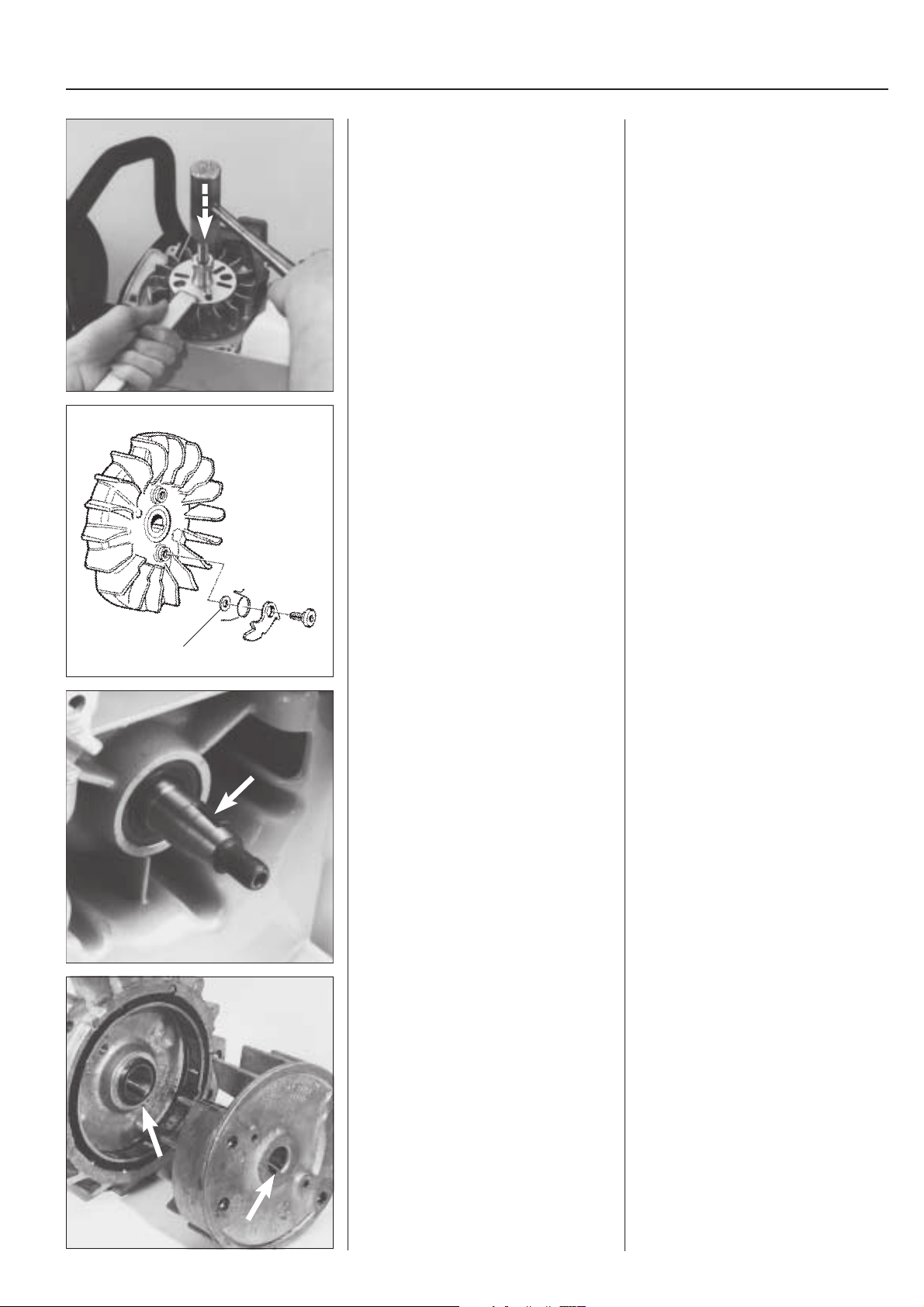

Tips!

Ta p t he flywheel puller screw sharply with

a hammer if the flywheel sits tight.

Starter pawls

Mod. 650, 700, 950, 1250

Check the starter pawls for wear and

damage.

Replace damaged parts.

The pawls are mounted on the flywheel

with a contact screw.

Pay attention to the spacer washer (A)

during dismantling and assembly.

Tips!

The flywheel may sit very tightly on the

shaft. To simplify dismantling - tap the

flywheel pullers screw sharply a few

times. Hold the engine in the air with the

handle on the flywheel puller.

Starter pawls

Mod.650, 700, 950, 1250

Check the starter pawls for wear and

damage.

Replace damaged parts.

The pawls are mounted on the flywheel

with contact screw and spacer washer

(A).

It is important not to forget the washer

during assembly.

Check that the pawls move freely.

A

Assembly

Check that the keyway and key in the

crankshaft are undamaged. (Mod. 650,

700, 1250)

Check that the keyway and the cast key

(mod. 950) in the flywheel are undamaged.

Fit the flywheel.

Assembly

Check that the keyway and key in the

crankshaft are undamaged. (Mod. 650,

700, 1250)

Fit where appropriate a new key and

make sure that it is positioned correctly in

the keyway.

Check that the keyway and the cast key

(mod. 950) in the flywheel are undamaged.

Fit the flywheel and check that the key

and keyway are correctly positioned

before the flywheel nut is tightened.

Tighten the nut with tightening torque 25–

35 Nm.

17

Page 19

2

Ignition system

0,3 – 0,5 mm

Fit the ignition module.

Adjust the air gap (0.3 –0.5 mm/0.012–

0.020").

Fit the other cables.

Fit the other parts in the reverse order to

dismantling.

502 51 34-06

Fit the ignition module.

Adjust the air gap to the correct size (0.3

–0.5 mm/0.012–0.020").

See also page 14–15.

Fit the other cables and make sure that

they are correctly positioned in the cable

grooves etc. so that they cannot be

damaged.

Fit the other parts in the reverse order to

dismantling.

18

Page 20

Fuel system

3.

Contents

Air filter ......................................................................... 20

Centrifugal cleaning (Active) ....................................... 21

Fuel filter ...................................................................... 22

Carburettor, dismantling/assembly .............................. 23

Carburettor design ....................................................... 25

Jets .............................................................................. 25

Speed limiter ................................................................ 26

Compensation device for blocked air filter .................. 26

Disassembly of the carburettor ................................... 27

Assembly of the carburettor ........................................ 30

Carburettor setting ....................................................... 32

Ta nk air v en t . .. . .. ... . .. .... . .. .... . .. .... . .. .... . .. .... . .. .... . .. .... . .. ... 34

Throttle control ............................................................. 35

Trouble shooting .......................................................... 40

19

Page 21

3

Fuel system

In addition to the fuel tank and carburettor, the fuel

system also includes the air filter, fuel filter and

tank vent.

All these components interact to ensure that the

engine will have the optimum mixture of fuel and

air to make it as efficient as possible. Very small

deviations in the carburettor setting, or fouling of

Air filter

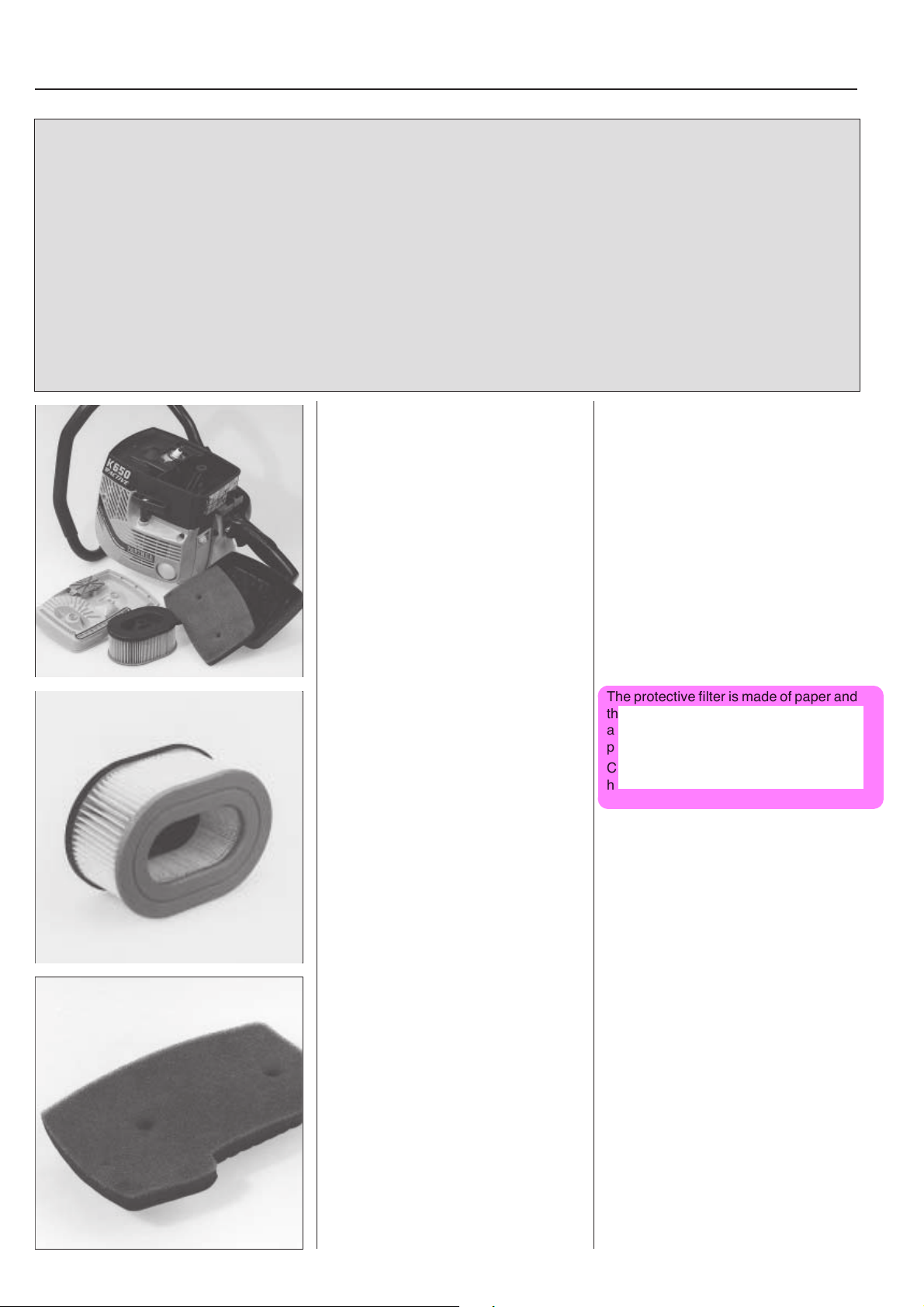

Mod. 650, 700, 950, 1250

Release the screws and lift off the air filter

cover with the main filter, intermediate

wall and protective filter.

the air filter, have a great effect on the running and

efficiency of the engine.

There are different makes of carburettors on our

different models, but the function and repair

techniques are basically the same.

! WARNING!

Do not clean the air filter in petrol. Health

hazard!

Air filter

Mod. 650, 700, 950, 1250

Release the two screws which hold the

air filter cover (mod. 1250 three screws).

Lift off the cover with main filter, intermediate wall and protective filter.

Clean the protective filter by tapping it

against your hand.

Clean the main filter carefully in lukewarm

soapy water.

Soak it in air filter oil (Partner) and squeeze

out the excess before refitting.

The protective filter is made of paper and

therefore must not be cleaned in water or

any other liquid, and neither with compressed air.

Clean the filter by tapping it against your

hand.

Clean the main foam plastic filter in

lukewarm soapy water. Air dry the filter

and soak it in air filter oil and squeeze out

the excess before refitting.

If the filter is damaged it should be replaced

with a new one.

20

Page 22

Fuel system

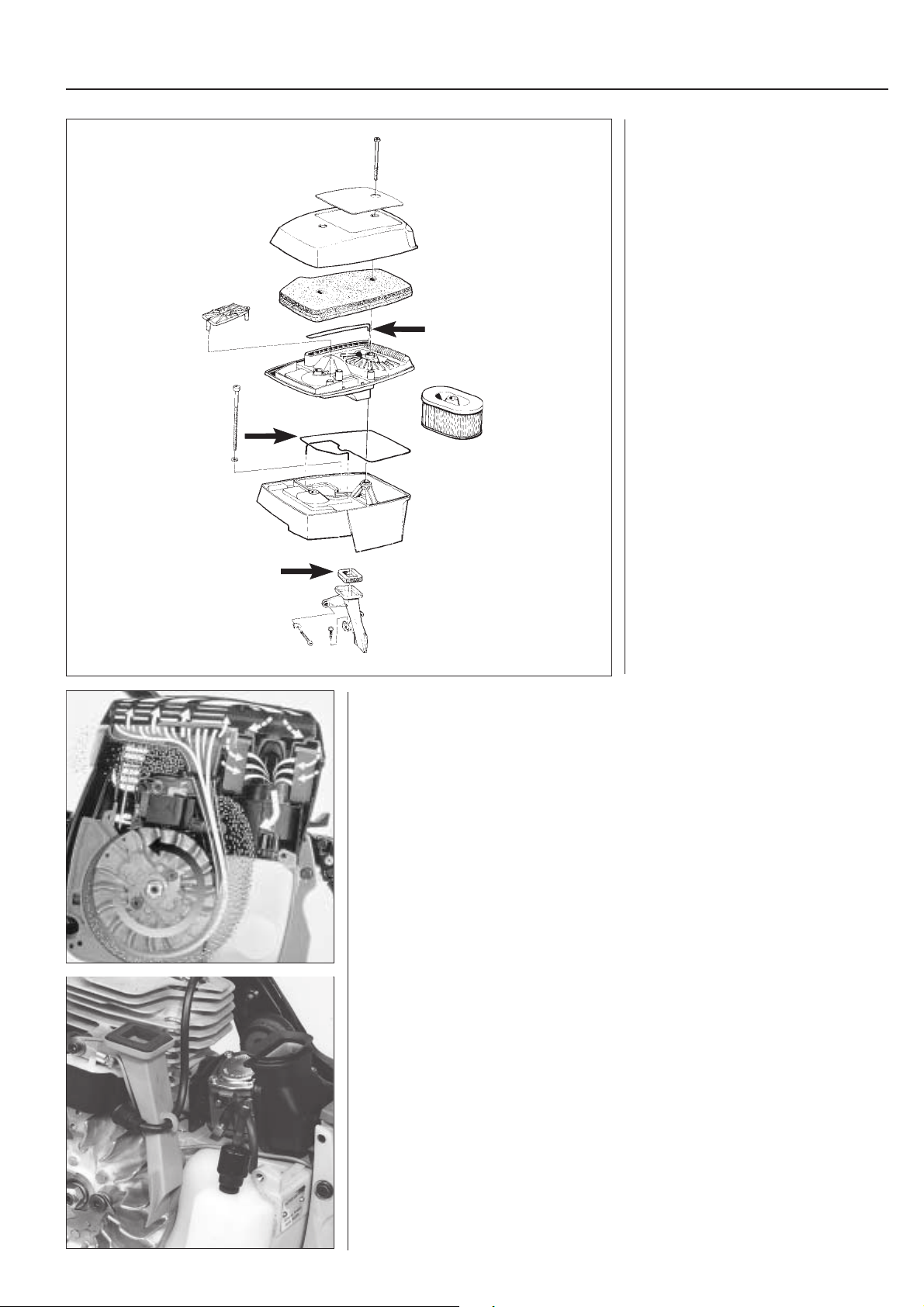

K650/700

3

When the filter and covers are fitted it is

very important to make sure that all the

seals are undamaged and correctly

positioned.

Seals which do not seal properly result in

less efficient centrifugal cleaning and rapid blockage of the air filter.

Increased wear on the piston and cylinder barrel as a result of inferior air cleaning

shortens the engine’s service-life.

Centrifugal cleaning (Active)

Mod. 650, 700

Considerably longer cleaning intervals for the air filter are achieved by using the

centrifugal force during the filtering of the intake air to the carburettor.

By means of using the centrifugal force the heavier impurities are thrown out towards

the periphery of the air spiral and on past the cylinder.

The air to the carburettor is taken up by the centrifugal cleaning nozzle and the finer

impurities are effectively captured in air filter.

For centrifugal cleaning to be as efficient as possible it is important that:

1. The centrifugal cleaning nozzle is clean from deposits.

2. The connection of the nozzle to the carburettor chamber is tight.

3. The nozzle attachments are not broken.

4. The fan spiral and air conductor are clean.

The centrifugal cleaning nozzle is accessible for cleaning or replacement after

dismantling the starter unit and air conductor.

21

Page 23

3

Fuel system

Fuel filter

Mod. 650, 700

The fuel filter can be taken out through

the tank's filler hole.

502 50 83-01

Clean the filter externally if it is not too

severely fouled.

Replace the filter if necessary.

Fuel filter

Mod. 650, 700

On the fuel pipe in the tank there is a fuel

filter. This is accessible through the filler

hole. Pull out the filter with your fingers or

by means of tool 502 50 83-01.

Remove the tank cap completely.

If the filter is not too severly fouled it can

be cleaned externally by means of a brush.

Otherwise it must be replaced.

Check the fuel pipe for cracking and

leakage.

NOTE!

Make sure that the filter's connecting collar

is pressed as far as possible in the fuel

pipe.

A

Mod. 950, 1250

The easiest way to take the fuel filter out

through the fuel tank refill hole is with tool

502 50 83-01.

Mod. 950, 1250

The fuel filter is located on the hose in the

fuel tank. It is accessible through the refill

hole.

Remove the tank fuel cap completely.

Pull out the filter with tool 502 50 03-01.

Pull the metal ring (A) from the filter

connection and then pull the filter off the

hose to either clean it or replace it.

A

502 50 83-01

Fuel hose

All models

Remove the fuel filter and connect

pressure tester No. 501 56 27-01. Pump

up the pressure to about 100 kPa and

observe whether any bubbles are formed.

Fuel hose

All models

Remove the fuel filter and connect

pressure tester No. 501 56 27-01.

Pump up the pressure to about 100 kPa.

Leakage and cracks in the hose are easy

to detect if any bubbles are formed.

22

30

3

5

5

2

40

0

2

200

250

4

150

5

15

300

100

0

5

350

10

50

5

400

5

5

0

0

0

6

501 56 27-01

Page 24

Fuel system

3

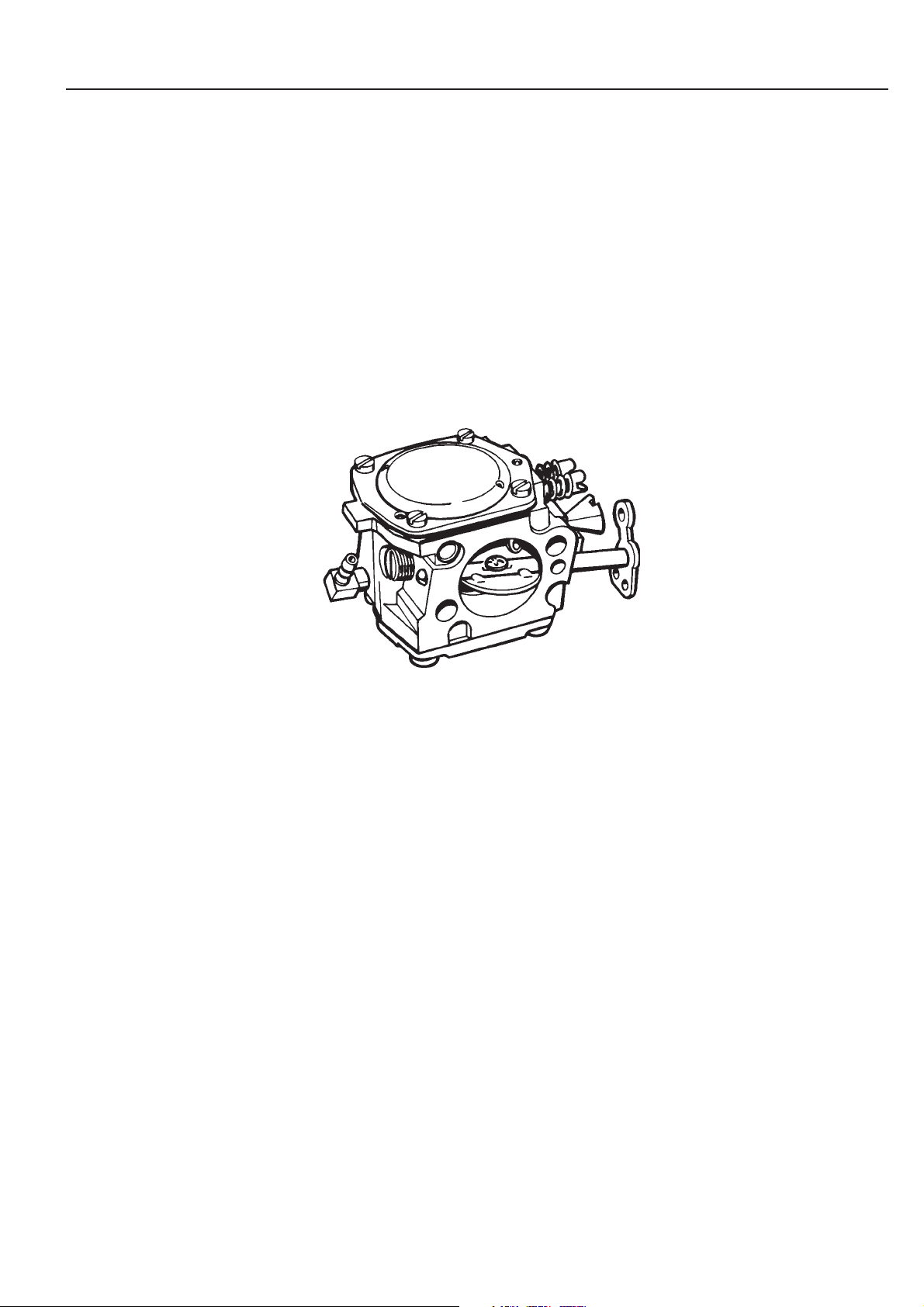

Carburettor

Dismantling, all models

Dismantle all covers and air filters so that

the carburettor becomes accessible.

Blow clean the carburettor chamber with

compressed air.

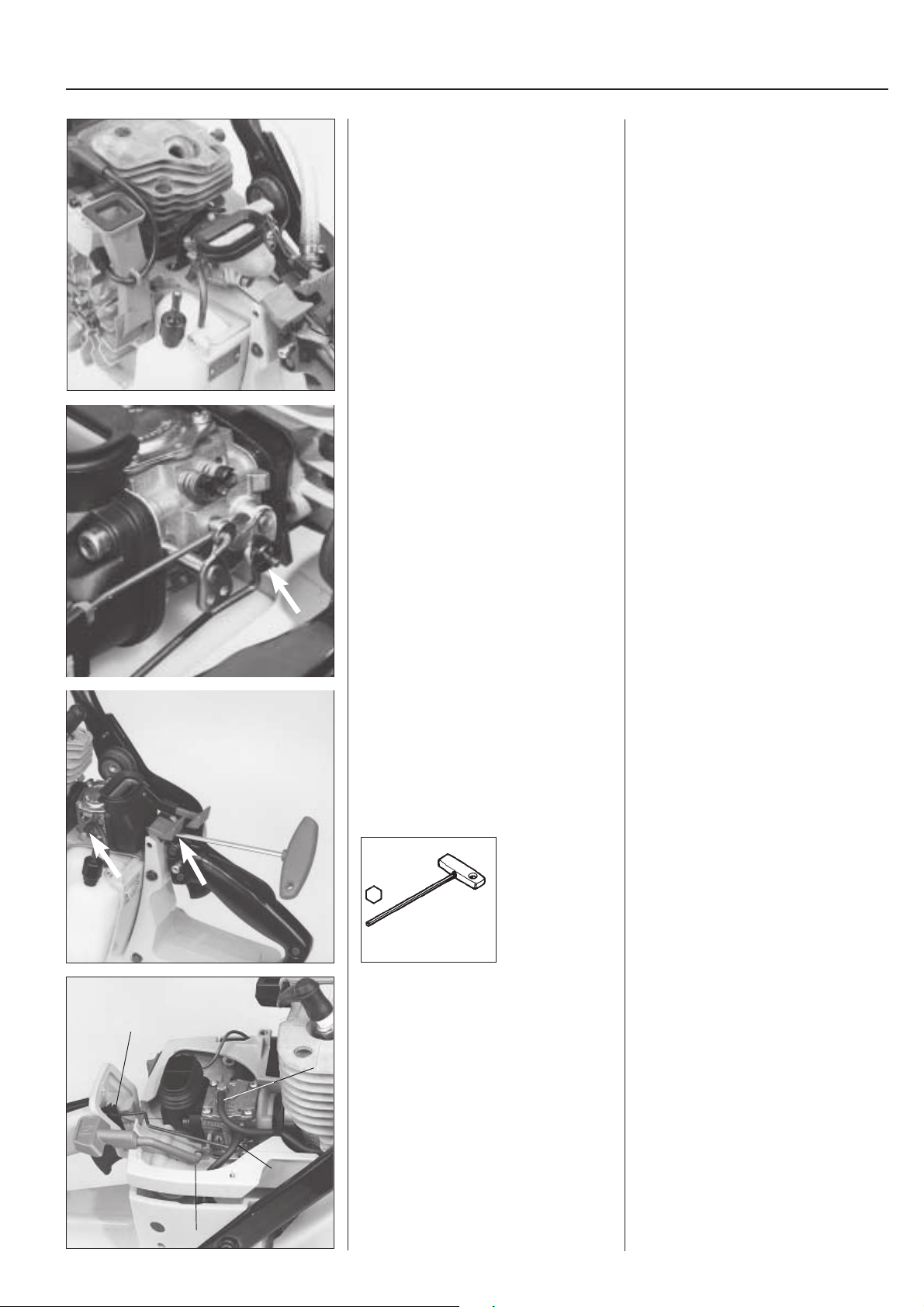

Mod. 650, 700

Remove the screw guide and lock washer which holds the throttle push rod at

the lever.

Carburettor

Dismantling, all models

Dismantle all covers and air filters so that

the carburettor becomes accessible.

Close the choke flap to prevent dirt penetrating into the engine.

Blow clean the carburettor chamber with

compressed air.

Mod. 650, 700

1. Remove the screw guide from the

carburettor’s adjusting screws.

2. Bend away the lock washer which

holds the throttle push rod at the lever

by means of a screwdriver.

NOTE!

EPA-models have fixed jets and consequently do not have screwdriver guides.

Remove the fuel hose.

Release the carburettor screws and lift

off the carburettor together with the choke

control, air filter connection, and middle

piece.

502 50 18-01

Carburettor

4

2

Mod. 950

Blow clean the carburettor area with

compressed air before the carburettor is

removed.

1

3. Remove the fuel hose from the carburettor.

4. Unscrew the carburettor screws. Insert

hex key 502 50 18-01 through the

hole in the stop control when the left

screw is to be unscrewed.

5. Lift off the carburettor together with

the choke control, air filter connection

and middle piece.

For service procedures see ”Disassembly

of carburettor”.

Carburettor

Mod. 950

Dismantle all covers and air filter. Blow

clean the carburettor area with

compressed air.

Dismantle the following:

1. Impulse hose

2. Fuel hose

3. Choke lever

4. Throttle lever (from throttle control)

3

23

Page 25

3

Fuel system

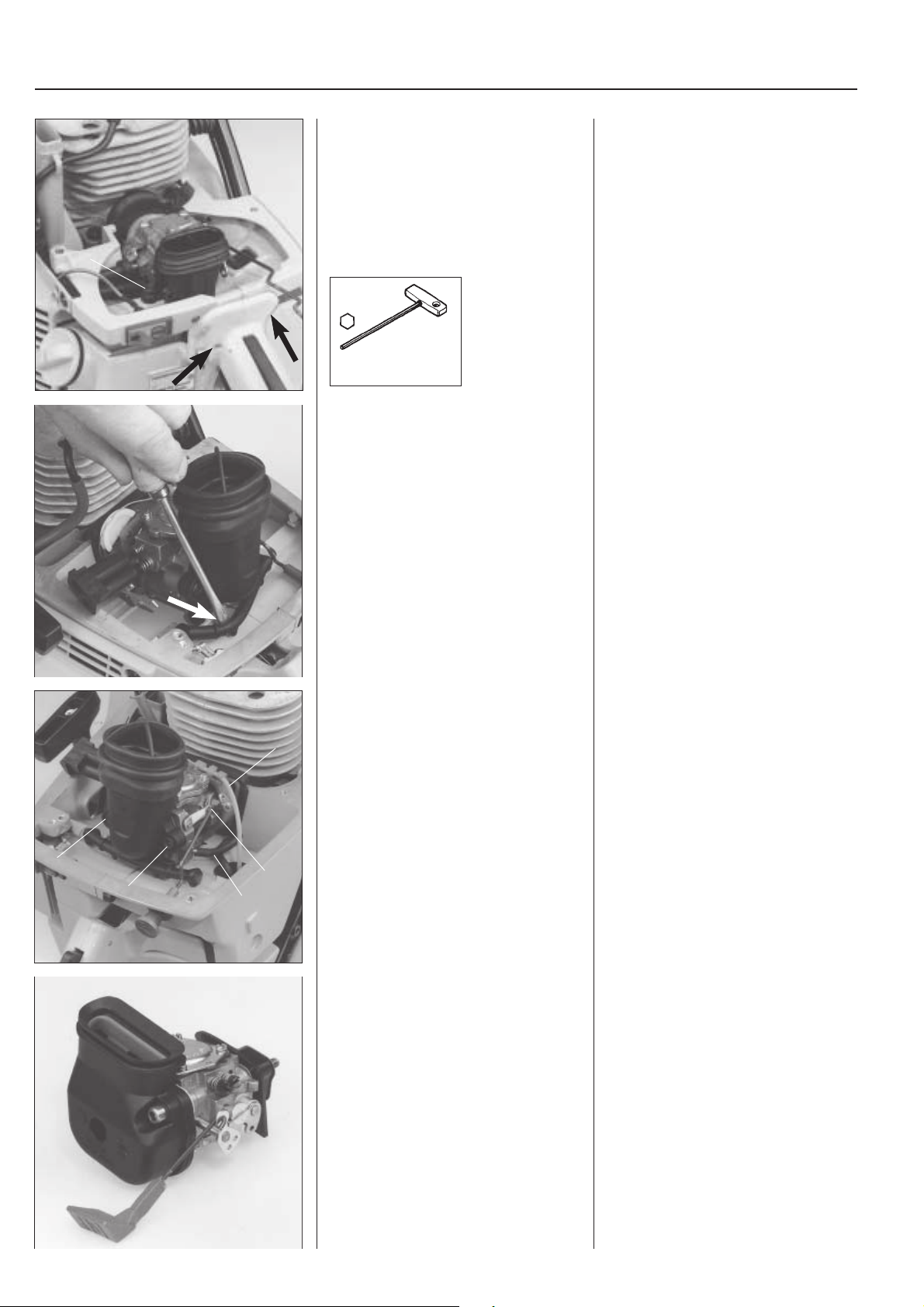

Dismantle the screw (A) and then the two

carburettor screws.

Lift off the carburettor.

A

502 50 18-01

Mod. 1250

Press off the rubber support from the

carburettor intake.

Remove the screw (A) and then the two

carburettor screws.

Insert key 502 50 18-01 through the hole

in the crankcase and tank part.

Lift off the carburettor together with the air

filter connection and throttle lever.

Fit in the reverse order to dismantling.

Mod. 1250

Press off the rubber support from the

carburettor intake with a screwdriver.

NOTE!

Do not pull off the support from the

crankcase since it is difficult to refit without

separating the crankcase and tank part.

Dismantle the fuel hose.

Unscrew the carburettor screws, remove

4

2

3

2

1

the choke lever and hook off the throttle

wire.

Fit in reverse order to dismantling.

Assembly

Mod. 650, 700

Fit the carburettor in the reverse order to

dismantling.

1. Dismantle the fuel hose.

2. Unscrew the carburettor screws.

3. Remove the choke lever from the

lever on the carburettor.

4. Hook off the throttle wire

Lift off the carburettor together with the

intake neck.

Fit in the reverse order to dismantling.

Assembly

Mod. 650, 700

Fit the carburettor to the cylinder in the

reverse order to dismantling.

Use new seals.

Place the air filter connection (with

screws), choke control and middle piece

on the carburettor.

Hold the complete carburettor unit against

the cylinder. Press down the choke control

in its guide and tighten the screws. Check

that the seal closest to the cylinder is

correctly positioned! Connect the throttle

push rod and fit the screw guide over the

carburettor’s adjusting screws.

24

Page 26

Fuel system

3

Carburettor design

D

F

C

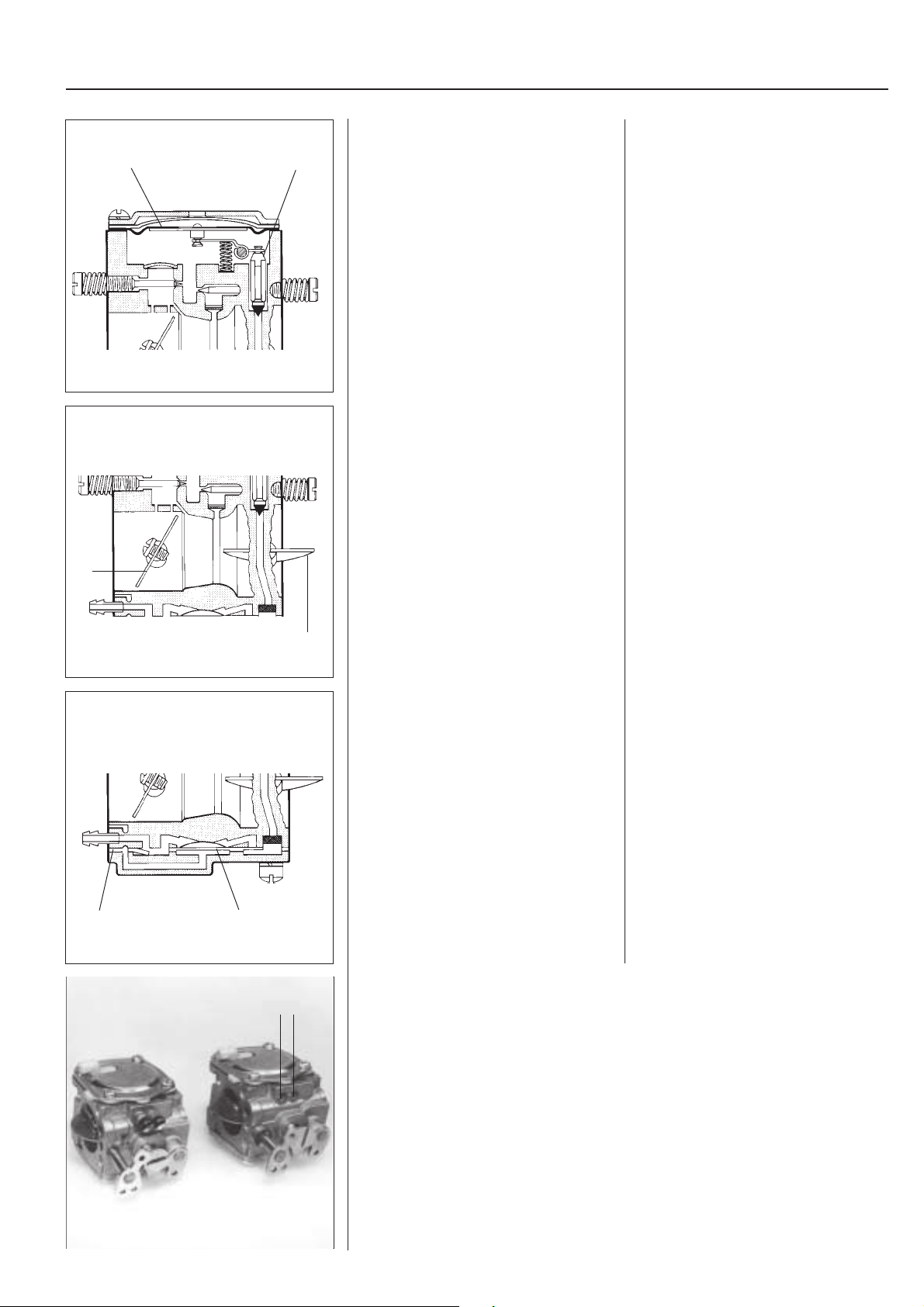

The carburettor can be divided into three

different functional units: the metering

section, mixing section, and pumping

section.

Metering section

The nozzles and control function for the

fuel are placed here.

The mixing section

The fuel and air are mixed here.

Carburettor design

The carburettor can be divided into three

different functional units: the metering

section, mixing section, and pumping

section.

Metering section

The nozzles and control function for the

fuel are placed here.

The needle valve (C) and metering diaphragm (D) are vital parts for the functioning of the carburettor.

The mixing section

The fuel and air are mixed to the correct

proportions in this part of the carburettor.

The choke (E) and throttle valves (F) are

placed here.

The main jet nozzle is located in the

middle of the venturi (the narrowest point

on the inlet).

E

Pumping section

This pumps fuel from the tank to the

carburettor.

H

G

Pumping section

The pump diaphragm (G) which pumps

fuel from the tank to the carburettor’s

metering unit is located here.

The membrane is activated by pressure

variations in the engine crankcase via an

impulse channel (H).

If the channel is blocked, e.g. by grease

or an incorrectly turned gasket, the pump

will not function and the engine will not

start.

Jets

A A

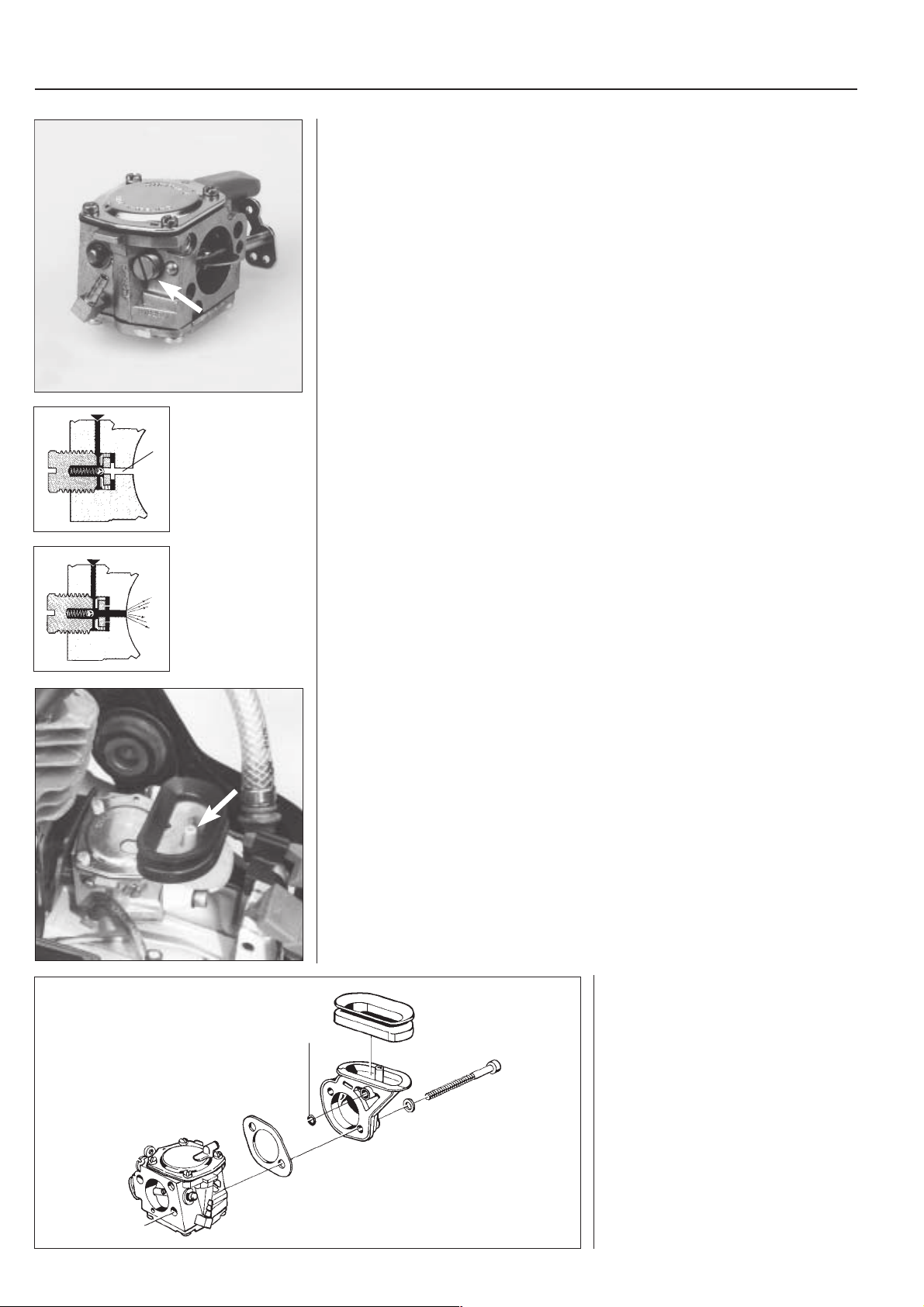

EPA-models have fixed carburettor jets, which means that the fuel/air mixture can not

be adjusted manually.

The right-hand carburettor in the illustration has fixed jets (A).

The nozzles can be cleaned and possibly changed once the sealing plugs have been

removed.

25

Page 27

3

Fuel system

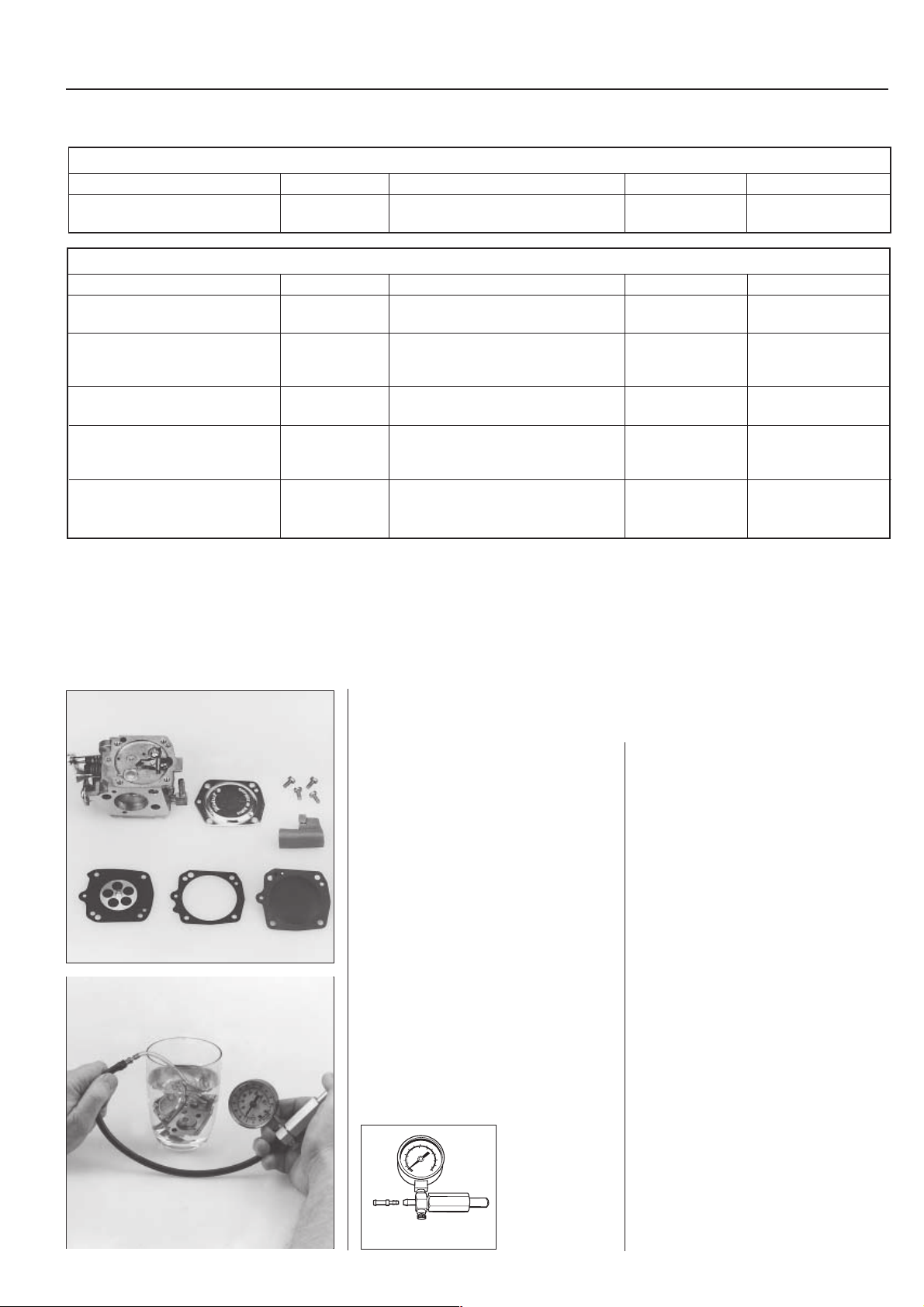

Speed limiter

Mod. 650, 700

A speed limiter is fitted on the side of the carburettor housing.

The speed limiter is fixed with Loctite and should not be released during servicing of

the carburettor.

When the engine speed is less than 9,200 rpm the ball seals the extra fuel channel (A).

The pressure of the spring presses the ball against the seat with a precise proven

A

pressure.

9600 r/min

When the engine speed exceeds the speed limit (9,600 ± 400 rpm) the spring-loaded

ball opens the extra fuel channel (A). The engine thereby receives extra fuel, begins to

putter and stops overspeeding.

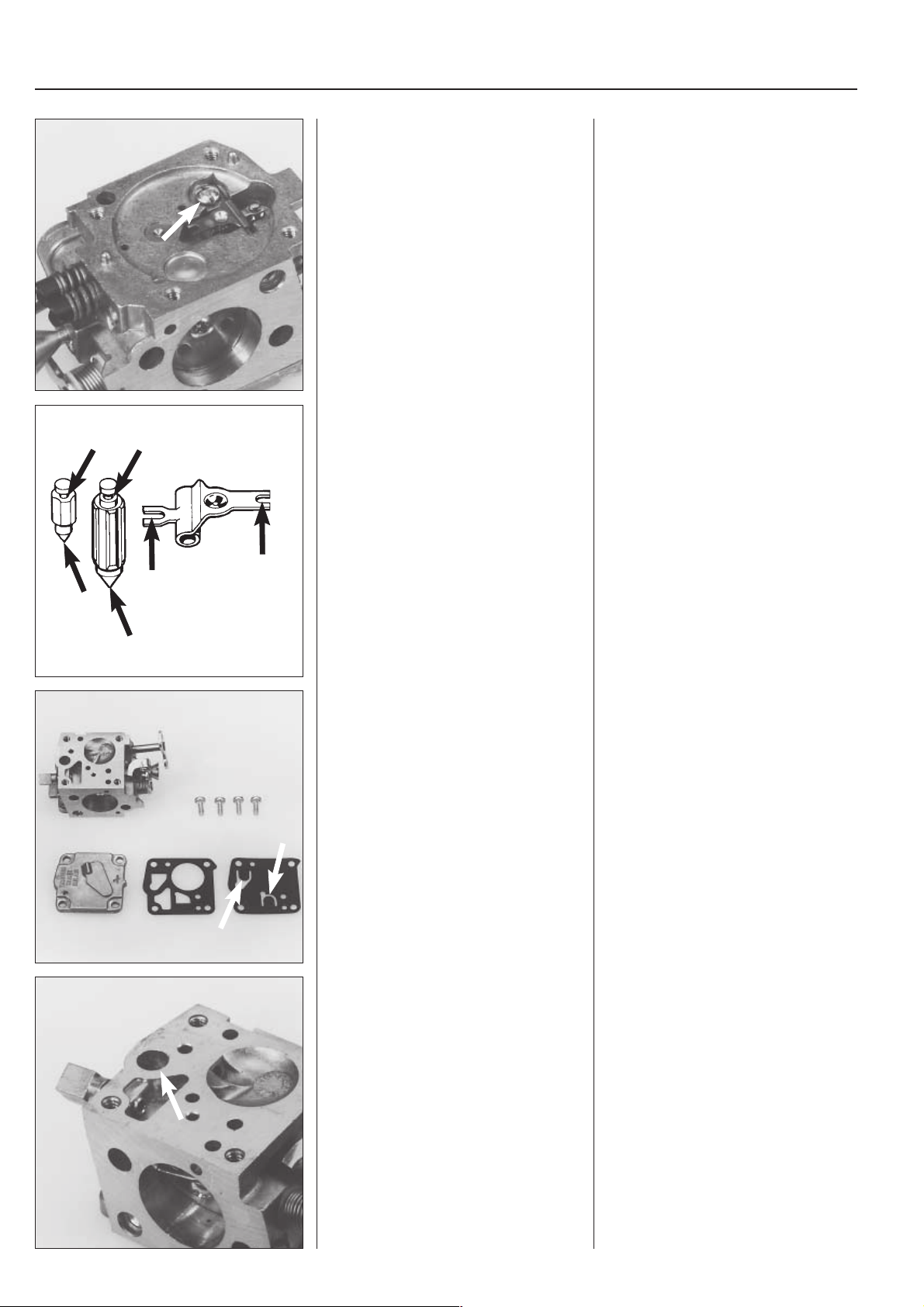

Compensation insert for blocked air filter

The carburettor has been fitted with a compensation insert to prevent the engine

receiving an increasing amount of fuel as the air filter becomes blocked. This transfers

the underpressure in the carburettor’s inlet to the top of the metering diaphragm, as

opposed to the atmospheric pressure in a standard carburettor. The pressure difference

between the top and bottom of the diaphragm therefore remains constant and does not

increase as the air filter becomes blocked. The fuel supply to the carburettor’s main jet

nozzle is therefore always maintained at the correct level.

Check that the small O-ring (A) is in place

when the air filter union is installed.

A

It is important for correct function of the

compensation device that the O-ring is

neither damaged or missing.

26

Page 28

Fuel system

Combinations of carburettors, induction pipe, seals, screwdriver guides

K650 Active, K700 Active

Carburettor Induct. pipe Seal Insert, seal Screwdriver guide

HS175E 503 28 03-20 506 21 41-01 506 22 65-01 Black

Not compensated Black

K650 Active II, K700 Active II

Carburettor Induct. pipe Seal Insert, seal Screwdriver guide

HS175F 503 28 04-03 506 21 41-01 506 25 34-01 506 25 33-01 Blue

Compensated, blue insert Black Moulded Blue

HS175G 503 28 04-04 506 21 41-01 506 25 34-01 506 25 33-01 Blue

Compensated,blue insert Black Moulded Blue

Small needle valve

HS175G 503 28 04-08 506 26 72-01 506 26 85-01 –

Comp., green insert, EPA Blue Moulded

HS175L 503 28 04-15 506 31 16-01 506 26 85-01 –

Comp., yellow insert, EPA Yellow Moulded

To we r m odel

HS175L, 503 28 04-16 506 31 16-01 506 26 85-01 Grey

Comp., grey insert, EPA Grey Moulded

To we r m odel

Rubber foam, bonded to cyl. housing

3

There are different sizes and versions of carburettors on the different models, but in

terms of servicing they are all treated in the same way.

Dismantling of the

carburettor

Remove the screw driver guide and cover

for the metering diaphragm.

Check the diaphragm for damage.

Replace if necessary.

Dismantling of the

carburettor

Remove the screw driver guide over the

adjusting screws.

Remove the 4 screws for the metering

diaphragm cover.

Lift off the compensation insert and the

diaphragm.

Check the diaphragm for holes and wear.

Replace the diaphragm if necessary.

Pressure test the metering system.

Connect pressure tester 501 56 27-01 to

the fuel pipe nipple.

Submerge the carburettor in a basin with

petrol to simplify inspection for leaks.

Pressure test with 0.5 bar.

No leakage is permissible.

30

3

5

5

2

4

0

0

2

200

250

4

150

5

15

300

100

0

5

350

10

50

5

400

5

5

0

0

0

6

501 56 27-01

27

Page 29

3

Fuel system

In the event of leakage - dismantle the

needle valve.

Check the needle valve and lever for

wear.

Replace damaged parts with new ones.

In the event of leakage dismantle the

needle valve.

Release the screw and lift off the lever,

shaft, needle valve and spring.

Check the needle valve for damage at the

point and the groove for the lever.

Check the lever for wear in the grooves

for the needle valve and the diaphragm.

Replace damaged parts with new ones.

If the new needle valve also leaks the

fault may be that the seat for the valve is

damaged.

Remove the pump diaphragm.

Check the diaphragm for damage.

Remove the fuel strainer.

Remove the screws which hold the cover

over the pump diaphragm.

Lift off the cover, gasket and diaphragm.

Check the diaphragm for damage on the

valve tongues. Hold it up to a lamp to

inspect for holes in the material.

Carefully remove the fuel strainer, e.g. by

using a needle.

28

Page 30

Fuel system

3

Unscrew the nozzle needles.

L

H

On EPA models which have fixed nozzles, the nozzles can be cleaned or changed once

the seal plugs have been removed.

Carefully drill a small hole (Ø 2 mm) in the plug and prise it away with a pointed tool.

NOTE!

Use a suitable-sized drift when the plug is installed, to give correct sealing.

Unscrew the nozzle needles.

NOTE!

Notice the two types of needles and how

they are positioned (e.g. the H-needle is

slightly shorter than the L-needle).

Dismantle the welch plug (1) and main jet

nozzle (2).

1

2

Check the valves and valve shafts for

wear.

Replace if necessary.

Drill a small hole in the welch plug (1) and

carefully remove it with a pointed tool.

Press out the main jet nozzle (2) with a

suitable mandrel.

Dismantle valves and valve shafts. If these

parts are worn the engine will pink.

Always replace the valve and valve shafts

at the same time.

29

Page 31

3

Fuel system

650/700

Assembly of the

carburettor

Blow clean the carburettor housing.

Fit a new welch plug.

Fit a new main jet nozzle.

Fit the valves and valve shafts.

NOTE!

Use Loctite on the valve screws.

Fit the pump unit parts in the reverse

order to dismantling.

Assembly of the

carburettor

Blow clean the carburettor housing.

Fit a new welch plug.

Use a suitable mandrel to achieve complete tightness.

Press in a new main jet nozzle. It should

lie flush with the carburettor housing.

Fit the valves and valve shafts.

NOTE!

Check that the valves are correctly turned and that they seal completely in

closed position.

Use Loctite on the valve screws.

Tips!

Number designations on the valves

should be able to be read from outside.

Fit the different parts in the metering unit

in the reverse order to dismantling.

Replace the fuel strainer if it is damaged

or cannot be cleaned.

Fit the pump unit parts in the reverse

order to dismantling.

Place the pump diaphragm closest to the

carburettor housing, followed by the

gasket and cover.

Fit the different parts in the metering unit

in the reverse order to dismantling.

NOTE!

The H-needle is slightly shorter than the

L-needle.

30

Check that the lever is level with the

carburettor housing.

High setting = too much fuel.

Low setting = too little fuel

Page 32

Fuel system

3

Check that the carburettor is tight.

No leakage is permissible at 50 kPa

pressure.

30

3

5

5

2

4

0

0

2

200

250

4

150

5

15

300

100

0

5

350

10

50

5

400

5

5

0

0

0

6

501 56 27-01

Fit the metering diaphragm and compensation insert for air filter blocking.

Connect pressure tester

No. 501 56 27-01 to the fuel inlet in the

carburettor.

Pump up to 50 kPa pressure.

Submerge the carburettor in a jar with

petrol to simplify inspection for leakage.

No leakage is permissible.

Place the gasket on the carburettor

housing and then the metering diaphragm.

NOTE!

Make sure that the pin on the diaphragm

goes into the groove on the lever.

Fit the blue compensation insert and then

the cover.

Tillotson HS

Mod. 950

The carburettor is of Tillotson (HS 282A)

manufacture, and has in principle the

same design as the carburettor for mod.

650, 700.

The speed limiter, however, has been

replaced by an electronic limit via the

ignition system.

The adjustable jets have been re-placed

by fixed jets.

A = Main jet (high speed)

D

A

C

B

B = Low speed jet (behind washer

plug)

C = Idle screw

D = Main nozzle

E

E = Part throttle jet

F = Fuel screen

The service method for this carburettor is

F

the same as for mod. 650, 700.

The main jet (A) can be dismantled for

cleaning or replacement.

To g ai n ac cess to th e l ow s pe ed jet (B ) t he

welch plug must be removed.

31

Page 33

3

Walbro WG 9

Fuel system

A

C

B

E

D

Mod. 1250

The carburettor on this model is of Walbro

manufacture.

The service method is the same as for the

Tillotson carburettor. Note the small Oring (A) placed on the compensation

device.

This carburettor does not have a speed

limiter either.

A = O-ring

B = Main nozzle

C = Main jet (high speed)

D = Low speed needle

E = Adjuster screw for idle speed

F = Fuel screen

The main jet (C) can be dismantled for

cleaning or replacement.

F

Fit the carburettor on the engine in the reverse order to dismantling. Use new gaskets

Check that the gaskets are turned the right way round so that the impulse channel is

not blocked.

H

T

L

Carburettor setting (not EPA models)

WARNING!

!

When test running the engine in connection with the adjustment of the

carburettor the clutch, cutting arm and cutting disc must always be fitted.

Otherwise there is a risk that the clutch may release and cause serious

personal injury.

Function

The purpose of the carburettor is to supply a combustible mixture of air and fuel to the

cylinder.

The volume of this mixture is regulated with the throttle control.

The composition of the mixture of air and fuel is regulated with the adjustable nozzles

”H” and ”L”.

32

The carburettor should be adjusted if:

● The cutting disc rotates when the engine is idling.

● The engine speed does not go down to idle from full throttle within 3-5 seconds.

● The engine does not run on idle.

● The engine does not respond quickly to the throttle.

● The engine seems to lack power.

NOTE!

EPA models have carburettors with fixed jets "H" and "L". This means that they can not

be adjusted

Page 34

7/8

Fuel system

The adjustment of the carburettor may vary somewhat depending on the humidity,

H

L

T

1 1/4

temperature and air pressure.

L= Low speed nozzle

H= High speed nozzle

T= Adjuster screw for idling

● With the L and H nozzles the fuel volume is adjusted to the air flow which the

opening of the throttle control permits. If they are screwed clockwise the air/fuel

mixture becomes lean (less fuel) and if they are screwed anti-clockwise the air/

fuel mixture will become rich (more fuel).

A lean mixture gives higher revs and a rich mixture gives lower revs.

● The T-screw regulates the position of the throttle control during idling. If the Tscrew is screwed clockwise a higher idling speed will be obtained, and if it is

screwed anti-clockwise a lower idling speed will be obtained.

Basic setting (not EPA models)

The carburettor is given a basic setting when tested at the factory. This basic setting is

slightly ”richer” than the optimum setting and should be maintained during the first few

hours the engine is used, after which it should be fine adjusted. The basic setting can

vary between:

H= 7/8 to 1 turn

L= 1 to 1 1/4 turn

The basic setting should be made when the engine is switched off.

Check that the air filters are clean.

Screw the nozzle needles (H) and (L) carefully to the bottom (clockwise).

Then unscrew them to the recommended basic setting.

Start the engine and run until warm, for about 5 minutes.

If the engine’s idling speed is too high or too low adjust it with the idling adjuster screw

(T) until the cutting disc just stops/begins to rotate (approx. 2,500 rpm).

Check with tachometer 502 71 14-01.

3

501 60 02-02

502 71 14-01

Low speed nozzle (L) (not EPA models)

Run at full throttle a few times and check that the engine accelerates without delay. If

an adjustment is necessary try to achieve maximum idling speed by slowly turning the

low speed nozzle (L) clockwise until the engine hesitates from lack of fuel, and then

open the nozzle (anti-clockwise) 1/8 of a turn.

Check the acceleration of the engine.

NOTE!

If the low speed nozzle is set too lean (L-needle screwed in too far) this will result in

difficulty starting the engine. After a correct adjustment of the low speed nozzle (L) the

high speed nozzle (H) can be adjusted.

High speed nozzle (H) (not EPA models)

The engine has a carburettor with built-in speed limiter.

At maximum revs the engine receives an extra volume of fuel which prevents the engine

overspeeding. The speed limiter has a fixed setting and cannot be adjusted.

Screw in the H-needle to the limiting position where the engine begins to falter during

acceleration. Use short, rapid bursts from idling speed.

From this position the H-needle is then opened less than 1/8 of a turn (45°), which gives

the carburettor setting for maximum engine power.

Check with a tachometer that the engine does not overspeed the permissible maximum

speed (9,600 ± 400 rpm).

!

WARNING!

If the high speed nozzle is set too lean (screwed in too far clockwise) this will

reduce the power of the engine and can result in overheating and subsequent

damage to the engine.

The high speed nozzle (H) should be adjusted for maximum power and not

maximum speed.

33

Page 35

3

Mod. 650/700

L = 1 1/4

H = 7/8

Fuel system

Fine adjustment of the idling screw (T)

Adjust the idling speed with the adjuster screw (T).

The idling speed should be adjusted after the high and low speed nozzles have been

adjusted.

If it is necessary to adjust the idling screw turn the screw (T) first clockwise until the

cutting disc begins to rotate, and then anti-clockwise until the cutting disc stops rotating.

The idling speed is correctly adjusted when the engine speed (approx. 2,500 rpm) is

stable in all working positions.

There should be a good margin between the idling speed and the speed at which the

cutting disc begins to rotate.

WARNING!

!

Do not use the machine if the idling speed cannot be adjusted so that the

cutting disc stops rotating.

Mod. 950

L = fast / fixed / Fest / fixé

H = fast / fixed / Fest / fixé

Mod. 1250

L = 1 1/4

H = fast / fixed / Fest / fixé

B

A

Correctly adjusted carburettor

A correctly adjusted carburettor implies that the engine accelerates without hesitation

and does not putter at full throttle.

● If the L-nozzle is set too lean it can be difficult to start the engine and will result in

poor acceleration.

● If the H-nozzle is set too lean this will result in reduced power, poor acceleration and/

or engine damage.

● If the L- and H-nozzles are set too rich this will result in acceleration problems or low

working speed.

Tank air vent

All models

The tank air vent has a great influence on the function of the carburettor. If it is not

working properly then either overpressure or underpressure will develop in the fuel

tank.

Overpressure results in flooding the carburettor.

Underpressure implies a reduction of the fuel flow to the carburettor, or no fuel flow at

all.

The purpose of the tank air vent is to ensure that there is atmospheric pressure in the

fuel tank during all operating conditions.

Mod. 650, 700

The tank air vent consists of a nonreturn valve (A) which opens at a certain pressure

in both directions.

In one end of the valve (the smooth connection) a sintered metal filter (B) is connected

to prevent dirt from penetrating into the fuel tank.

34

Mod. 950

The tank vent valve (B) is accessible

when the tank part and crankcase have

B

A

been separated. It cannot be repaired

and must be replaced if it is defective.

Remember to clean the small metal filter

(A) in the end of the hose.

Mod. 950

The fuel tank venting is conducted via a

non return valve of the same design as on

the other machine models.

It is accessible when the tank unit and

crankcase are separated.

Remember when servicing to clean the

small metal filter (A) placed in the end of

the hose.

The non return valve (B) cannot be repaired and must be replaced if it is defective.

Page 36

Fuel system

3

Mod. 1250

Separate the tank unit and crankcase.

Prise away the non-return valve with a

screwdriver.

Install new components in reverse order.

Do not forget to clean the metal filter (A).

Mod. 1250

Separate the tank unit and crankcase just

enough to gain access to the tank vent.

Put a screwdriver between the fueltank

and the non-return valve.

Press the valve straight out from the

fueltank.

Install new components in reverse order

from removal.

The non-return valve can not be cleaned,

it must be replaced by a new one during

service.

Do not forget to clean the small metal

filter (A).

A

Function check

Empty the fuel tank and screw on the tank cap.

Connect a pressure gauge to the fuel hose.

Overpressure

2

Pump up a pressure of 50 kPa (0.5 kp/cm

The pressure should fall to 20 kPa (0.2 kp/cm2) within 60 seconds.

Underpressure

Reduce the pressure to –50 kPa (0.5 kp/cm

The pressure should increase to 20 kPa (0.2 kp/cm2) within 30 seconds.

If the tank air vent is not working it must be replaced with a new one. It cannot be cleaned

or repaired.

Throttle control

Dismantling, assembly

Mod. 650, 700

Remove the four screws which hold the

left-hand half of the grip.

).

2

).

Throttle control

Dismantling, assembly

Mod. 650, 700

Remove the four screws which hold the

left-hand half of the rear grip. Note that

they have different lengths.

505 38 13-08

35

Page 37

3

Fuel system

Lift off the half of the grip and the throttle

control.

Note the washer under the throttle control

and the sleeve inside the control.

Lift off the half of the grip.

NOTE!

One end of the return spring for the throttle

control catch goes in the hole on the

throttle control.

Lift off the throttle control. Note the washer under the throttle control and the

sleeve inside the control so that they are

not lost during cleaning.

Fit in the reverse order to dismantling.

Replace damaged or worn parts.

Fit all parts in the left-hand half of the grip.

1. Place the spring for the throttle control

catch in position round the pin with the

hole in it.

2. Place the throttle control catch in position.

36

Hook in the spring in the hole in the

throttle control and move it to the correct

position opposite the screw hole.

Lock the throttle control with the catch

and insert the screw in the throttle control’s

supporting sleeve.

3. Push the sleeve in the throttle control

from underneath.

4. Hold the sleeve in position with your

forefinger and hook the spring in the

hole in the throttle control.

5. Move the throttle control to the correct

position opposite the screw hole.

6. Press in the start throttle catch and

lock the throttle control in start position.

7. Insert the screw in the throttle control’s

supporting sleeve.

Page 38

Fuel system

3

Fix the spacer washer with a little grease

on the right-hand grip half.

Hook the throttle lever in the throttle control

and place the grip half in position.

Screw tight the screws and check the

function of the throttle control.

1

2

3

Mod. 950

Separate the tank unit and crankcase.

Press out the bearing pins (1) and (3) and

dismantle the safety catch and throttle

control.

8. Place the spacer washer in position

on the right-hand grip. Fix it with a

little grease.

9. Hook the throttle lever in the throttle

control and place the grip half in position.

NOTE!

Check that the spacer washer has not

moved.

10. Screw tight the screws and check the

function of the throttle control.

Mod. 950

Separate the tank unit and crankcase.

(Where appropriate see chapter on vibration damper.)

1. Press out the bearing pin (1) with an

appropriate punch (Ø 2.5 mm) far

enough so that the safety catch (2)

can be removed.

2. Press out the bearing pin (3) far

enough so that the throttle control can

be removed, where appropriate by

bending it with a screwdriver.

Fit the throttle control in the reverse order

to dismantling.

Fit the safety catch.

The spring should be to the right of the

catch (seen from behind).

Press in the bearing pin and check the

function of the catch.

Fit the throttle control in the reverse order

to dismantling.

1. Place the spring on the throttle control

and push in into the rear grip.

2. Press in the bearing pin and check

that the throttle control moves easily.

Fit the safety catch

3. Make sure that the throttle control

spring is on the right-hand side of the

catch (seen from behind) and that it

goes into the recess.

4. Press down the catch throttle lock in

the grip and press in the pin.

Check that the throttle lcok functions

properly.

37

Page 39

3 Fuel system

Mod. 1250

Separate the tank unit and crankcase,

and press off the three bearing pins.

Press the safety catches forwards/

downwards and lift them up at the back

edge.

Mod. 1250

Separate the tank unit and crankcase.

(Where appropriate see chapter on vibration damper.)

Press off the three bearing pins with a

suitable punch (Ø 2.5 mm).

Press down the safety catch, and press it

forwards (where appropriate with a small

screwdriver) so that it can be lifted up at

the back edge.

Pull the throttle control forwards and out

of the rear grip.

Inspect the different parts and replace

those which are damaged or worn.

Pull the throttle control forwards, out from

the rear grip. To simplify dismantling,

press with a small screwdriver on the

lever which the throttle wire is attached

to.

Inspect the different parts and replace

damaged or worn parts with new ones.

TIP!

Bend the end of the spring to a closed

loop. This simplifies fitting and prevents

the spring from being pressed out from

the recess at the hole where the spring

should slide freely.

38

Page 40

Fuel system

3

Fit the throttle control and safety catch in

the reverse order to dismantling.

Check that the spring on the catch goes

into the hole in the throttle control.

1. Push the throttle control with attached

throttle wire into the rear grip.

2. Enter the back edge of the safety

catch into the grip.

3. Check that the spring goes into the

hole in the throttle control.

4. Press down the safety catch until it

clicks into the throttle control.

5. Press in the three bearing pins and

check that the throttle control and

safety catch function as intended.

39

Page 41

3

Trouble-shooting chart

Fuel system

●●●●●●●

●●●

●● ●●●●●●●

●● ● ●●

●● ●●

●● ●● ● ● ● ● ●● ●●●●

●● ● ● ●

●●●● ●●

●

Metering system

26. Worn lever

27. Set too high

28. Set too low

29. Not free

30. Distorted

31. Improperly installed

Air system

12. Plugged air filter

13. Defective manifold gasket

14. Loose carburettor mounting screws

15. Worn throttle assembly

16. Incorrect throttle assembly

17. Loose throttle valve screw

32. Leaking (air/fuel)

33. Worn button

34. Improper assembly

35. Defective gasket

36. Loose diaphragm rivet

37. Hole in diaphragm

38. Loose cover screws

18. Throttle shaft too tight

19. Bent throttle linkage

20. Defective throttle spring

21. Bent throttle stop lever

22. Choke not functioning properly

23. Worn choke shaft

24. Worn choke valve

39. Foreign matter

40. Binding

25. Worn throttle valve

41. Worn needle body or tip

40

12345678910111213141516171819202122232425262728293031323334353637383940

Start

Start

A. Hard starting

●●● ● ●●●

A

B

C

carburettor

B. Fuel dripping from

C. Floods when

●●●●●● ●● ●●●●

Idle

D

engine is not

running

Idle (Low speed)

●

E

D. Will not idle

F

E. Rich idle

G

F. I dl e s with L-n ee dle

H

J

closed

G. Irregular idle

●●●●●●●●●●●● ●● ●● ●●●

●●●●●●● ●●●●●● ● ● ●

●● ● ● ●

●● ●●

Acceleration, deceleration

K

L

M

High speed

N

frequent adjustment

H. "L"-needle needs

idling

J. Loads up while

Acceleration and

deceleration

closing throttle

K. Will not accelerate

L. Engine stops when

●●●●●●●●● ●● ● ● ●●●●●

●●● ●●●●●

O

P

tion

M. Over-rich accelera-

Fuel system

3. Plugged tank vent

4. Plugged tank filter

5.Restricted fuel line

6. Dirt in fuel passage

throttle

High speed

N. Will not run at full

O. Low power

P. W il l n o t 4 c y cl e

7. Loose, damaged fuel line

8. Leak in pulse system

9. Restricted pulse channel

10. Loose pump cover screws

11. Def ect ive pu mp di aph rag m

Adjustments

1. Low speed needle (L)

2. High speed needle (H)

Page 42

Centrifugal clutch

4.

Contents

Dismantling, all models .............................................. 42

Dismantling, mod. 650, 700 ........................................ 42

Dismantling, mod. 950, 1250 ...................................... 44

Assembly, mod. 650, 700 ........................................... 45

Assembly, mod 950, 1250 .......................................... 46

41

Page 43

4

Centrifugal clutch

The centrifugal clutch has the purpose of

transferring the power between the engine and

the cutting equipment. As the name implies it

works according to the centrifugal principle.

This principle implies that the clutch's friction

shoes are slung outwards towards the clutch

drum at a specific engine speed. When the friction

against the drum becomes suf ficient it is driven

round at the same speed as the engine.

There is a certain degree of slip between the

clutch and the clutch drum during acceleration,

Dismantling

All models

Dismantle the complete cutting equipment

and unscrew the plug.

but also in the reverse case if the cutting equipment

should stick. This avoids irregular load alternations

on the crankshaft.

The engagement speed is carefully tested to that the

engine can run at idling speed without the cutting

equipment rotating.

!

WARNING!

Never start or test run the engine if the clutch

cover is removed. The clutch can come loose

and cause personal injury.

Dismantling

All models

Dismantle the front and rear belt cover,

cutting arm with cutting disc, and drive

belt.

Remove the air filter cover and air filter,

and unscrew the plug.

Mod. 650, 700

Fit piston stop No. 502 54 15-01 in the

spark plug hole.

Dismantle the clutch clockwise by means

of a suitable box spanner.

502 54 15-01

Ta ke th e clutch a pa rt.

Use pliers No. 502 50 49-01 and press

out the one clutch shoe.

Mod. 650, 700

Fit piston stop No. 502 54 15-01 in the

sparking plug hole.

Dismantle the clutch clockwise by means

of a suitable box spanner.

NOTE!

Do not drop the washer which lies behind

the clutch drum.

Press out the one clutch shoe with pliers

No. 502 50 49-01 as shown in the illustration.

42

502 50 49-01

Page 44

Centrifugal clutch

4

Place an object which is approx. 5.5 mm

(0.22") thick between the clutch shoe and

the spoke.

Bend away the clutch spring.

Clean and inspect the clutch parts for

damage and wear.

Min. 1 mm

Place an object (e.g. a nut) which is

approx. 5.5 mm (0.22") thick between the

clutch shoe and the spoke on the clutch

hub on the back of the clutch.

Bend away the clutch spring with a

screwdriver.

Clean and inspect the clutch hub’s spokes

and the clutch shoes for wear.

There must be material thickness of at

least 1 mm (0.04") left at the most worn

point on the clutch shoes.

All the shoes must be replaced at the

same time.

Inspect the wear on the clutch drum, the

pulley and the inner diameter.

It must not exceed 75.5 mm (2.97").

Replace the needle bearing if the clutch

drum is loose on the shaft.

Check the wear on clutch drum’s inner

diameter. It must not exceed 75.5 mm

(2.97"). If so, replace the clutch drum.

Check also the wear on the pulley. If the

side surfaces are heavily worn and/or

damaged the clutch drum must be

replaced.

If the needle bearing in the clutch drum is

worn (the drum is loose on the shaft) it

should be replaced with a new one.

Press out the bearing with a vice and a

suitable sleeve (Ø 17.5 mm, 0.69").

43

Page 45

4

Centrifugal clutch

Mod. 950, 1250

Dismantle all the cutting equipment and

unscrew the plug.

Fit piston stop No. 502 54 15-01 and

dismantle the clutch clockwise.

502 54 15-01

Remove the clutch springs with a small

screwdriver.

Mod. 950, 1250

Dismantle the front and rear belt covers,

cutter arm with cutter disc and drive belt.

Remove the air filter covers and air filter,

and remove the plug.

Fit the piston stop No. 502 54 15-01 in the

plug hole and dismantle the clutch

clockwise.

Remove the clutch springs with a small

screwdriver.

Min. 1 mm

Clean and inspect the clutch parts for

damage and wear.

Inspect the clutch drum for wear on the

mating surfaces for the centrifugal clutch

and drive belt.

Clean and inspect the clutch hub spokes

and the clutch shoes for wear.

There must be at least 1 mm of material

left at the most worn part of the clutch

shoes.

All the shoes must be replaced at the

same time.

Inspect the clutch drum for wear on the

mating surfaces for the centrifugal clutch

and drive belt.

The inner diameter of the clutch drum

must not exceed 79.8 mm.

Replace worn parts.

44

Page 46

Centrifugal clutch

4

Assembly

Mod. 650, 700

Press in the new needle bearing until it is

flush with the

drum’s hub.

Fit together the centrifugal clutch.

Place two clutch shoes and the spring on

the clutch hub.

outer edge

of the clutch

Assembly

Mod. 650, 700

Press in the new needle bearing with a

vice and a suitable sleeve until it is flush

with the

hub.

Fit together the centrifugal clutch.

Place two clutch shoes and the spring on

the clutch hub.

NOTE!

The spring’s coupling point should lie

opposite one of the hub’s spokes.

outer edge

of the clutch drum’s

Fit the remaining clutch shoe. Fit the remaining clutch shoe. Use pliers

No. 502 50 49-01 and a screwdriver.

502 50 49-01

Check that the lubrication hole in the

crankshaft is not blocked.

If necessary clean with a steel wire.

Check that the lubrication hole in the

crankshaft is not blocked.

If necessary clean with a steel wire.

45

Page 47

4

Centrifugal clutch

The clutch drum’s bearing is lubricated

automatically with the oil in the fuel mixture

which is pressed out through the channel

in the crankshaft.

The clutch drum’s bearing is lubricated

automatically with the oil in the fuel

mixture.

When the piston moves down in the cylinder the fuel mixture in the crankcase is

compressed. A small part of this mixture

is pressed out through the channel in the

crankshaft and provides the needle

bearing with sufficient lubrication.

Lubricate the clutch drum’s needle bearing

with a little grease and fit the clutch drum

on the crankshaft.

Fit the spacer washer and centrifugal

clutch.

Mod. 950, 1250

Fit the clutch shoes.

Fit the springs from the back of the clutch.

Check that the lubrication hole in the

crankshaft is open.

Clean it with a piece of wire if necessary.

A

Mod. 950, 1250

Fit the clutch shoes on the hub.

Fit the springs from the back of the clutch

by pressing them in place with your thumbs

or with a screwdriver.

Check that the lubrication hole in the

crankshaft is open.

Clean it with a piece of wire if necessary.

NOTE!

Remember the spacer sleeve (A) behind

the clutch drum when the clutch is refitted

on the crankshaft.

46

Page 48

Cylinder and piston

5.

Contents

Dismantling ................................................................. 48

Cleaning, inspection ................................................... 50

Analysis and procedures ............................................ 51

Service tips ................................................................. 55

Wear tolerances .......................................................... 55

Assembly .................................................................... 55

Decompression valve ................................................. 57

Compression test ........................................................ 58

47

Page 49

5

Cylinder and piston

The cylinder and piston are two of the components

which are exposed to the greatest tensions in the

engine. They must, for example, withstand high

revs, large heat variations, and high pressure. They

must also be resistant to wear . Despite these severe

working conditions it is relatively unusual for

serious piston and cylinder malfunctions to occur .

A contributory factor to this is the new lining materials in the cylinder bore, new types of lubricating

oils, and refined technology during manufacturing.

Dismantling

General

The dismantling work is basically the same for all models. In the event that the work

methodology differs for any particular model this is reported separately.

Dismantle the following:

Cylinder cover, carburettor cover, starter unit, plug, air filter, carburettor, inlet manifold,

muffler with heat shield, and on certain models also heat cover, ignition module,

flywheel and Active nozzle.

See respective sections in the Workshop Manual for detailed instructions.

During service work on these components cleanliness is of extreme importance. It is therefore

recommended that the cylinder and the area around it are well cleaned before it is dismantled from

the crankcase.

Mod. 650, 700

Dismantle the decompression valve.

Dismantle the cylinder.

505 38 13-08

Dismantle the piston from the connecting

rod.

Mod. 650, 700

Dismantle the decompression valve

before the cylinder screws are unscrewed.

Unscrew the cylinder screws and lift the

cylinder straight up.

NOTE!

Place a cloth in the crankcase opening to

prevent dirt from dropping down in the

crankcase when the cylinder is lifted off.

Dismantle the piston from the connecting

rod.

Remove the circlip by means of a pair of

flat pliers.

Press the gudgeon pin out, using drift No.

505 38 17-05.

48

505 38 17-05

Page 50

Cylinder and piston

5

Mod. 950

Dismantle all components so that the

cylinder becomes accessible.

Dismantle the carburettor and screws

that hold the spacing piece to the crankcase.

502 50 18-01

Remove the screw which holds the vibration damper to the grip.

Dismantle the damper from the cylinder.

Mod. 950

Dismantle all components so that the

cylinder becomes accessible.

Remove the start valve, blue centrifugal

nozzle and muffler.

Note the nut in the nut recess on the

crankcase at the lower muffler screws,

and make sure it is not dropped.

Dismantle the carburettor and the two

screws that hold the spacing piece to the

crankcase.

Remove the screw which holds the vibration damper to the grip.

Insert key 502 50 18-01 in the centre of

the vibration damper and unscrew the

screw which holds the damper to the

cylinder.

502 50 18-01

Unscrew the cylinder screws and lift off

the cylinder

Dismantle the intake pipe and impulse

hose. If there are signs of cracking replace

with new parts.

502 50 64-01

Mod. 1250

A

B

Dismantle all the necessary parts to gain

access to the cylinder, including the cutting

equipment.

501 69 17-02

502 50 18-01

Unscrew the cylinder screws with key

502 50 64-01.

Lift the cylinder straight up and place a

clean cloth in the crankcase opening to

prevent dirt from dropping down into the

crankcase.

Dismantle the intake pipe and impulse

hose.