Page 1

K3600 MKII

Operator ′ s manual

Please read the operator’s manual carefully and

make sure you understand the instructions before

using the machine.

Page 2

2 –

English

KEY TO SYMBOLS

Key to symbols

WARNING! The machine can be a

dangerous tool if used incorrectly or

carelessly, which can cause serious or fatal

injury to the operator or others.

Please read the operator’s manual carefully

and make sure you understand the

instructions before using the machine.

Always wear:

• Approved protective helmet

• Approved hearing protection

• Protective goggles or a visor

This product is in accordance with applicable

EC directives.

Other symbols/decals on the machine refer to special

certification requirements for certain markets.

Always disconnect the machine from the

hydraulic hoses before inspection and/or

maintenance of the machine.

Always wear approved protective gloves.

Regular cleaning is required.

Visual check.

Protective goggles or a visor must be worn.

Page 3

English

– 3

CONTENTS

Contents

KEY TO SYMBOLS

Key to symbols ............................................................. 2

CONTENTS

Contents ...................................................................... 3

WHAT IS WHAT?

What is what on the power cutter? ............................... 4

SAFETY INSTRUCTIONS

Steps before using a new power cutter. ....................... 5

Personal protective equipment ..................................... 5

Machine ′ s safety equipment ........................................ 5

Checking, maintaining and servicing the machine ′ s

safety equipment .......................................................... 6

General safety precautions .......................................... 6

General working instructions ....................................... 7

SETTINGS AND ADJUSTMENTS

Drive ............................................................................. 10

Fitting the blade ........................................................... 10

Hydraulic hoses ........................................................... 12

Water hose ................................................................... 12

Water supply ................................................................ 12

Water dosage ............................................................... 12

STARTING AND STOPPING

Starting and stopping ................................................... 13

MAINTENANCE

Maintenance ................................................................ 14

Dismantling the complete guide roller .......................... 14

Assembling the complete guide roller .......................... 14

Drive wheel .................................................................. 15

Replacing the support rollers/guide rollers .................. 15

Reconstructing the blade ............................................. 16

Couplings ..................................................................... 16

Hydraulic hoses ........................................................... 16

Maintenance schedule ................................................. 17

Blades conforming to EN13236 ................................... 17

TROUBLE SHOOTING

Mechanics .................................................................... 18

TECHNICAL DATA

Extending the hydraulic hoses ..................................... 19

EC-declaration of conformity ........................................ 20

Page 4

4 –

English

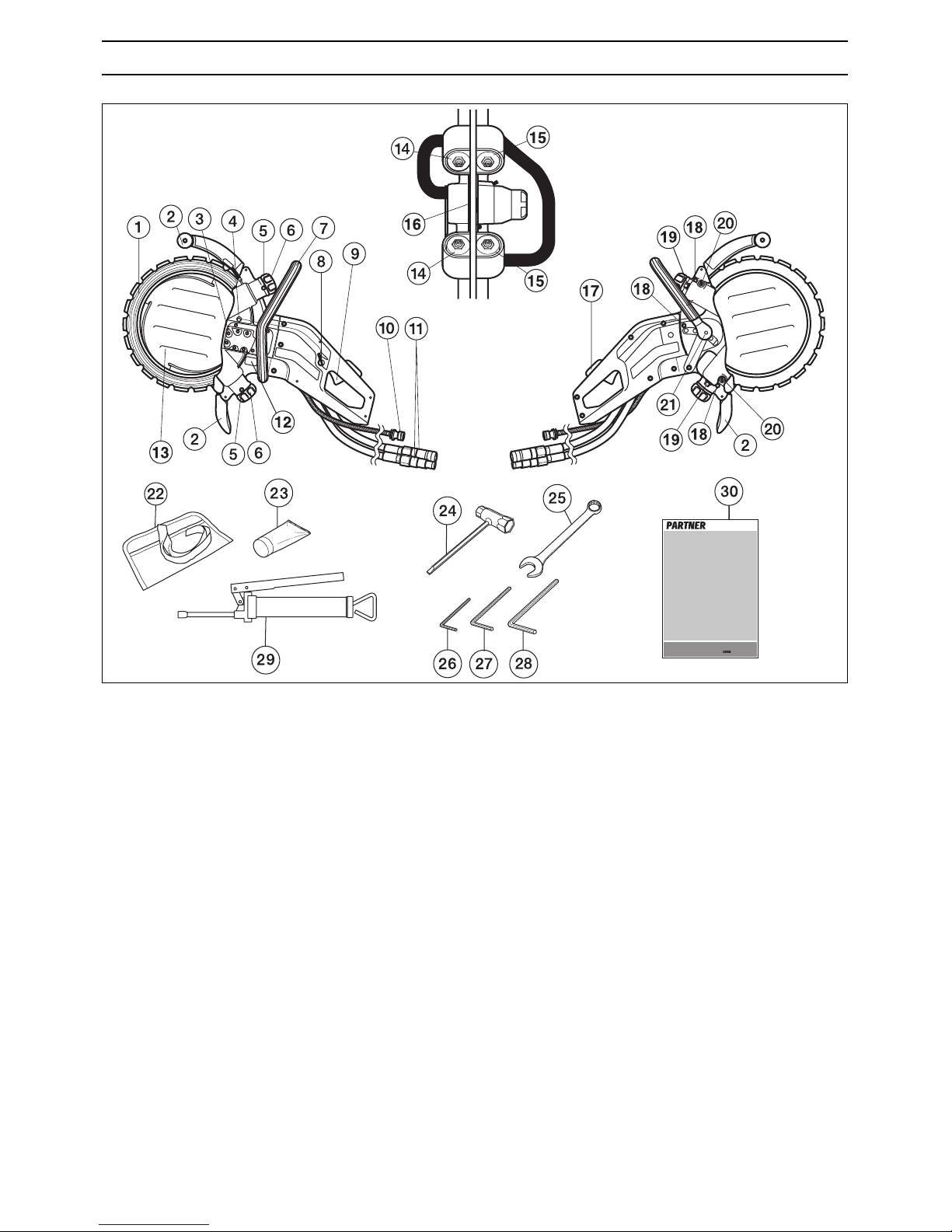

WHAT IS WHAT?

What is what on the power cutter?

1 Diamond blade

2 Blade guard/spray guard

3 Hydraulic motor

4 Locking button for the drive wheel

5 Grease nipples

6 Control for the guide rollers

7 Front handle (adjustable)

8 Water adjustment control

9 Switch

10 Water connector

11 Couplings for hydraulic hoses

12 Rating plate

13 Water disc

14 Support rollers

15 Guide rollers

16 Drive wheel

17 Switch lock and ON/OFF valve for the water

18 Cover screws

19 Locking nuts for the support rollers

20 Adjuster screws

21 Switch lock for the front handle

22 Tool bag

23 Bearing grease

24 Combination spanner

25 19 mm combination spanner

26 4 mm hex key

27 5 mm hex key

28 6 mm hex key

29 Grease gun

30 Operator ′ s manual

Page 5

English

– 5

SAFETY INSTRUCTIONS

Steps before using a new power

cutter.

• This machine is a hydraulically operated power cutter

intended for free-hand cutting. The machine should be

connected to a hydraulic unit with an oil flow of 35-42

litres/min and a maximum pressure of 150 bar.

• Please read the operator’s manual carefully.

• Check the cutting blades mounting, see the chapter

”Assembly”.

Let your Partner dealer check the power cutter and make

essential adjustments and repairs.

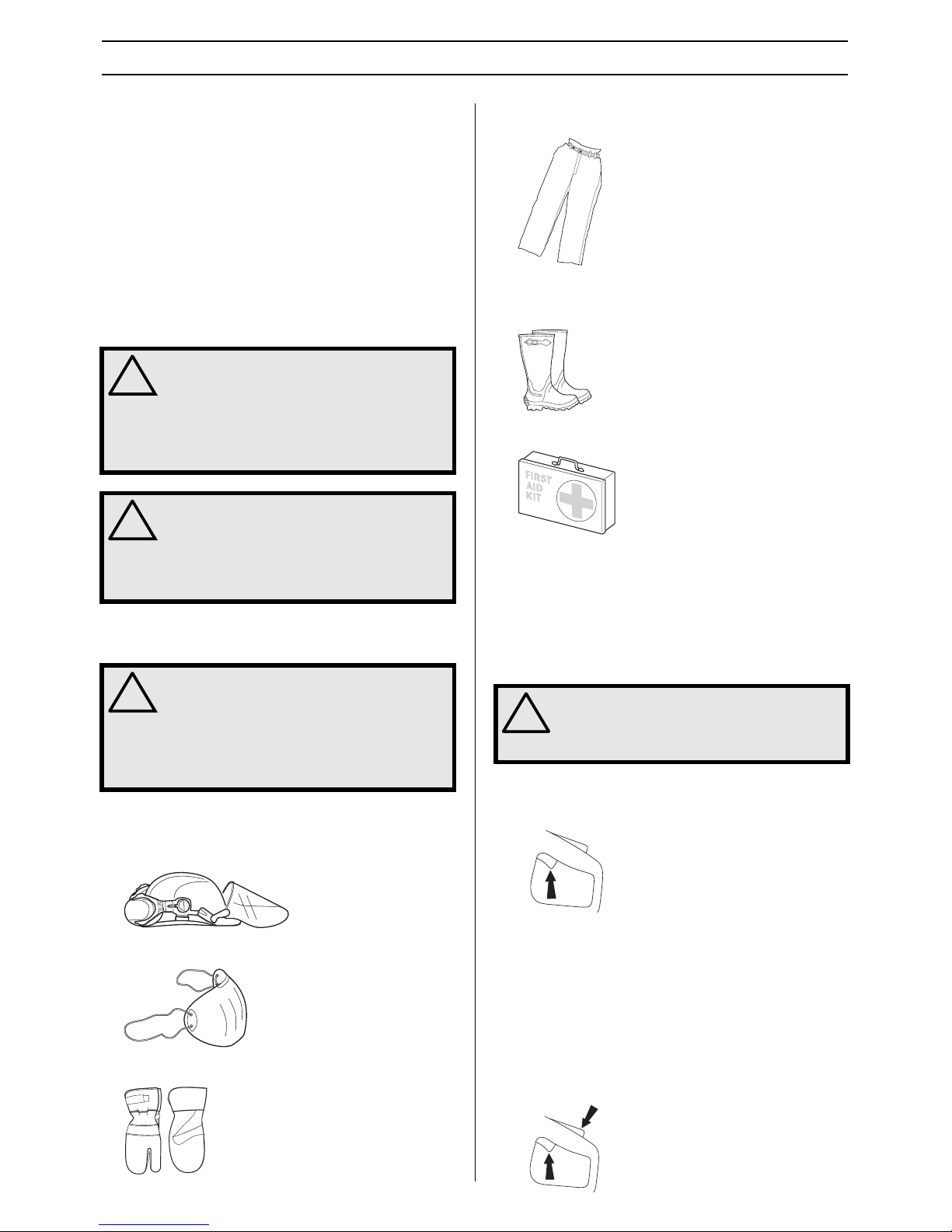

Personal protective equipment

• Protective helmet

• Hearing protection

• Protective goggles or a visor

• Breathing mask

• Heavy-duty, firm grip gloves.

• Tight-fitting, heavy-duty and comfortable clothing that

permits full freedom of movement.

• Use leg-guards recommended for the material to be cut.

• Boots with steel toe-caps and non-slip sole

• Always have a first aid kit nearby.

Machine ′′

′′

s safety equipment

This section describes the machine ′ s safety equipment, its

purpose, and how checks and maintenance should be carried

out to ensure that it operates correctly. See the ”What is

what?” section to locate where this equipment is positioned

on your machine.

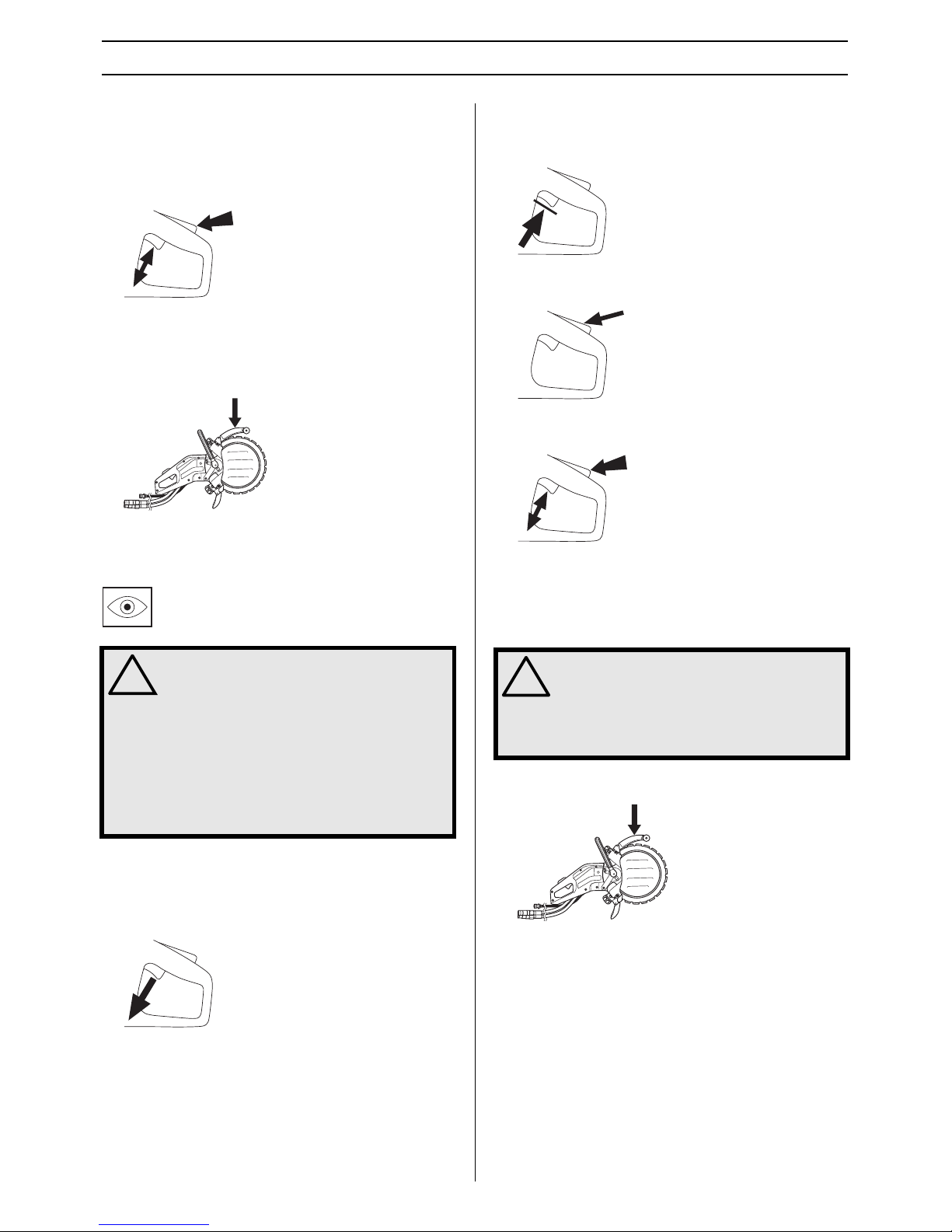

Switch

The switch is used to start and stop the machine.

Switch lock and ON/OFF valve for the

water

The switch lock is designed to prevent accidental operation of

the switch. The ON/OFF valve for the water supply is also

controlled with the switch lock.

When the switch lock (A) is pressed in this opens the water

valve and releases the switch (B). As long as the switch is

pressed in the switch lock remains pressed in and the water

valve open.

!

WARNING! Under no circumstances may the

design of the machine be modified without

the permission of the manufacturer. Always

use genuine accessories. Non-authorized

modifications and/or accessories can result

in serious personal injury or the death of the

operator or others.

!

WARNING! Use of products which cut, grind,

drill, sand or shape material can generate

dust and vapors which may contain harmful

chemicals. Know the nature of the material

being worked on and wear appropriate dust

mask or respirator protection.

!

WARNING! You must use approved personal

protective equipment whenever you use the

machine. Personal protective equipment

cannot eliminate the risk of injury but it will

reduce the degree of injury if an accident

does happen. Ask your dealer for help in

choosing the right equipment.

!

WARNING! Never use a machine that has

faulty safety equipment! Carry out the

inspection, maintenance and service

routines listed in this section.

A

B

Page 6

6 –

English

SAFETY INSTRUCTIONS

When you release your grip on the handle this resets both the

switch and the switch lock. This takes place via two

independent return spring systems. This position causes the

machine to stop and the switch to be locked.

The water valve returns to the stop position when the handle

is released.

Blade guard

This guard is fitted above the blade and is designed to prevent

parts of the blade or cutting fragments from being thrown

towards the user.

Checking, maintaining and servicing

the machine ′′

′′

s safety equipment

Checking the starting and stopping

functions of the switch

Start the machine, release the switch, and check that the

machine and blade stop.

Checking the switch lock

Check that the switch is locked when the switch lock is in its

home position.

Press the switch lock and check that it returns to its home

position when released.

Check that the switch and switch lock move freely and that

their return spring systems function.

Start the machine, release the switch, and check that the

machine and blade stop.

Checking the blade guard

Check that the guard is complete and without any cracks or

deformations.

General safety precautions

• A power cutter is designed to cut hard materials, such as

masonry. Observe the increased risk of kickback when

cutting soft materials. See instructions under the heading

How to avoid kickback.

• Do not use the power cutter until you have read the entire

contents of this Operator’s Manual.

All servicing, in addition to the points listed in the section

”Control, maintenance and service of the power cutter’s

safety equipment”, should be carried out by trained

service specialists.

!

WARNING! All servicing and repair work on

the machine requires special training. This is

especially true of the machine

′′

′′

s safety

equipment. If your machine fails any of the

checks described below you must contact

your service agent. When you buy any of our

products we guarantee the availability of

professional repairs and service. If the

retailer who sells your machine is not a

servicing dealer, ask him for the address of

your nearest service agent.

!

WARNING! Always check that the guard is

correctly fitted before starting the machine.

Also check that the blade is fitted correctly

and is not damaged in anyway. A damaged

blade can cause personal injuries. See

instructions under the heading Assembly.

Page 7

English

– 7

SAFETY INSTRUCTIONS

• Never use the machine if you are tired, if you have drunk

alcohol, or if you are taking medication that could affect

your vision, your judgement or your co-ordination.

• Wear personal protective equipment. See instructions

under the heading Personal protective equipment.

• Never use a machine that has been modified in any way

from its original specification.

• Never use a machine that is faulty. Carry out the checks,

maintenance and service instructions described in this

manual. Some maintenance and service measures must

be carried out by trained and qualified specialists. See

instructions under the heading Maintenance.

• Never allow anyone else to use the machine without first

ensuring that they have understood the contents of the

operator’s manual.

Transport and storage

Do not store or transport the power cutter with the blade fitted.

Store the power cutter in a lockable area so that it is out of

reach of children and unauthorised persons.

The blade should be removed from the machine after use and

stored well. Store the blade in the dry.

General working instructions

Basic safety rules

• Look around you:

- To ensure that people, animals or other things cannot

affect your control of the machine.

- To make sure that none of the above might come into

contact with the cutting equipment.

• Do not use the machine in bad weather, such as dense

fog, rain, strong wind, intense cold, etc. Working in bad

weather is tiring and can lead to dangerous conditions,

e.g. slippery surfaces.

• Never start to work with the power cutter before the

working area is clear and you have a firm foothold. Look

out for any obstacles with unexpected movement. Ensure

when cutting that no material can become loose and fall,

causing operating injury.Take great care when working on

sloping ground.

• Make sure that no clothes or parts of the body come in

contact with the cutting equipment when it is rotating.

• Keep at a safe distance from the cutting equipment when

it is rotating.

• The guard for the cutting equipment must always be on

when the machine is running.

• Ensure that the working area is sufficiently illuminated to

create a safe working environment.

• Do not move the machine when the cutting equipment is

rotating.

• Always ensure you have a safe and stable working

position.

• Make sure that no pipes or electrical cables are routed in

the area to be cut.

Cutting

General

• Start cutting with the machine running at maximum

speed.

• Always hold the machine in a firm grip with both hands.

Hold it so that the thumbs and fingers grip round the

handles.

Cutting technique

The technique described below is of a general character.

Check the details of each blade concerning individual cutting

characteristics.

!

WARNING! This section describes basic

safety directions for using a power cutter.

This information is never a substitute for

professional skills and experience. If you get

into a situation where you feel unsafe, stop

and seek expert advice. Contact your dealer,

service agent or an experienced power

cutter user. Do not attempt any task that you

feel unsure of!

!

WARNING! The safety distance for the power

cutter is 15 metres. You are responsible to

ensure that animals and onlookers are not

within the working area. Do not start cutting

until the working area is clear and you are

standing firmly.

!

WARNING! Overexposure to vibration can

lead to circulatory damage or nerve damage

in people who have impaired circulation.

Contact your doctor if you experience

symptoms of overexposure to vibration.

These symptoms include numbness, loss of

feeling, tingling, pricking, pain, loss of

strength, changes in skin colour or

condition. These symptoms normally appear

in the fingers, hands or wrists.

Page 8

8 –

English

SAFETY INSTRUCTIONS

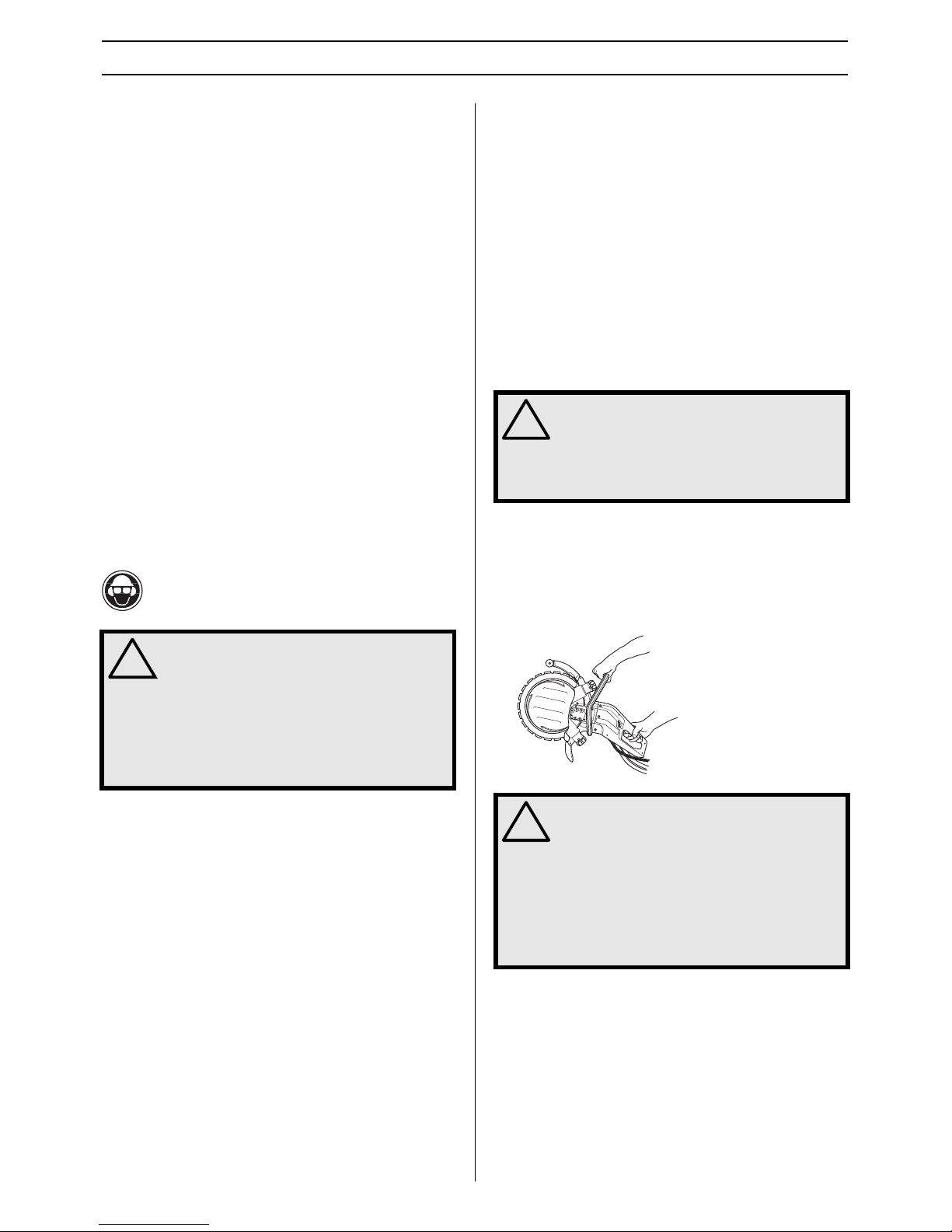

• Support the work piece in such a way that it is possible to

predict what will happen, and so that the cut remains open

while cutting.

• Check that the blade is not in contact with anything when

the machine is started.

• Always cut at maximum speed.

• Start cutting gradually, let the machine work without

forcing or pressing the blade.

• Move the blade slowly backwards and forwards to give a

small contact surface between the blade and material to

be cut. This will mean the blade temperature is kept down

resulting in efficient cutting.

• Feed the machine in line with the blade. Side pressure can

destroy the blade and is extremely dangerous.

Cutting depth

K3600 MKII can cut up to a depth of 260 mm (10 inches).

Making a guide cut of 50-70 mm (2-3 inches) first, gives you

better control of the machine. This means the water disc can

penetrate into the workpiece and help control the machine.

Attempting to saw the entire depth in one run takes longer.

Working with several runs, 3 to 4 when the cut is 260 mm (10

inches) in depth, is much quicker.

Large work

Cuts exceeding 1 m - secure a batten along the line to be cut.

The batten acts as a guide. Use this guide to make a marking

cut along the entire length of the cut, 50-70 mm (2-3 inches)

in depth. Remove the guides once the marking cut has been

made.

Small work

First make a shallow marking cut, max 50-70 mm (2-3 inches)

in depth. Now make the final cut.

Cutting sequence

First make the lower horizontal cut. Now make the two vertical

cuts. Finish with the upper horizontal cut.

Remember to divide the blocks up into manageable pieces so

that they can be transported and lifted safely.

CAUTION! If the upper horizontal cut is made before the

lower horizontal cut, the work piece will fall on the blade and

jam it.

!

WARNING! Under all circumstances avoid

cutting with the side of the blade, as this will

definitely result in damage, breakage or can

cause serious injuries. Only use the cutting

section.

Do not pull the power cutter to one side, this

can cause the blade to jam or break

resulting in injury to people.

Page 9

English

– 9

SAFETY INSTRUCTIONS

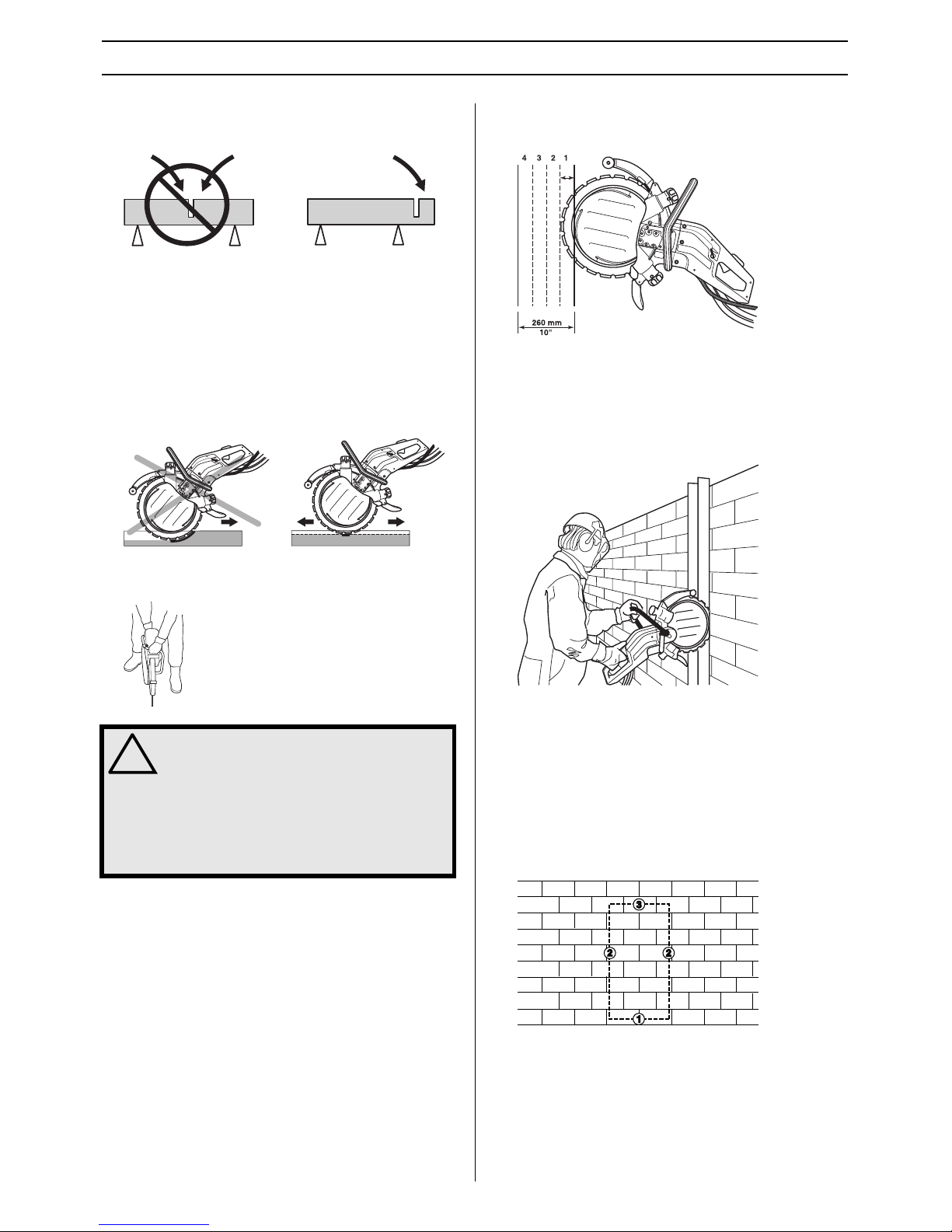

How to avoid kickback

What is kickback?

The word kickback is used to describe the sudden reaction

that causes the power cutter and cutting blade to be thrown

from an object when the upper quadrant of the blade, known

as the kickback zone, touches an object.

General rules

• Never start to cut with the upper quadrant of the blade as

shown in the figure, also known as the kickback zone.

• Always hold the machine in a firm grip with both hands.

Hold it so that the thumbs and fingers grip round the

handles.

• Keep a good balance and a firm foothold.

• Always cut at maximum speed.

• Stand at a comfortable distance from the work piece.

• Take care when inserting the blade in an existing cut.

• Never cut above shoulder height.

• Be alert to movement of the work piece or anything else

that can occur, which could cause the cut to close and

pinch the blade.

Pull in

Pull in occurs when the discs lower section suddenly stops or

when the cut closes. (To avoid, see the heading ”Basic rules”

and ”Jamming/rotation”, here below.)

Pinching/rotation

If the cut is pressed together this can lead to jamming. The

machine can be pulled down suddenly with a very powerful

jerk.

How to avoid pinching

Support the work piece in such a way that the cut remains

open during the cutting operation and when the cut is

finished.

Diamond blades

Diamond blades consist of a steel body provided with

segments that contain industrial diamonds.

Always use a sharp diamond blade. Sharpen the blade by

cutting in a soft material such as sandstone or brick.

Diamond blades are available in several hardness classes. A

"soft" diamond blade has a relatively short service life and

large cutting capacity. It is used for hard materials such as

granite and hard concrete. A "hard" diamond blade has a

longer service life and reduced cutting capacity, and should

be used for soft materials such as brick and asphalt.

Diamond blades are ideal for masonry, reinforced concrete

and other composite materials. Diamond blades are not

recommended for cutting metal.

Water cooling

Diamond blades should be sprinkled with water while cutting

to cool the blade and to bind dust that forms while cutting.

Sharpening diamond blades

Diamond blades can become dull when the wrong feeding

pressure is used or when cutting certain materials such as

heavily reinforced concrete. Working with a blunt diamond

blade causes overheating, which can result in the diamond

segments coming loose.

Sharpen the blade by cutting in a soft material such as

sandstone or brick.

Vibrations on diamond blades

The blade can become out of round and vibrate if a too high

feed pressure is used.

A lower feed pressure can stop the vibration. Otherwise

replace the blade. The blade shall be intended for the material

to be cut.

!

WARNING! Kickback can happen very

suddenly and violently; kicking the power

cutter and cutting blade back at the user. If

this happens when the cutting blade is

moving it can cause very serious, even fatal

injuries. It is vital you understand what

causes kickback and that you can avoid it by

taking care and using the right working

technique.

!

WARNING! Cool diamond blades

continuously with water to prevent

overheating that can cause the diamond

blade to break and pieces being thrown off

resulting in injury and damage.

Page 10

10 –

English

SETTINGS AND ADJUSTMENTS

Drive

On account of the machine’s unique design the driving power

is not transferred at the centre of the blade. The flanges on the

two guide rollers run in the blade’s grooves. Springs on the

guide rollers press out the rollers, which in turn press the Vshaped edge on the inside diameter of the blade against the

V-shaped groove in the drive wheel. The drive wheel is fitted

on an axle which is driven by the hydraulic motor.

This allows a total cutting depth of 260 mm (10 inches) with a

350 mm (14 inches) diamond blade.

1 Blade

2 Support rollers

3 Drive wheel

4 Guide rollers

5 V-shaped edge

Basic service

As the blade is used the inside diameter and the groove in the

drive wheel become worn.

The ring cutter will also work well in the future if:

• the drive wheel is not too worn

A) New

B) Worn

• the guide rollers are not too worn

A) New

B) Worn

• adjustment between the rollers and blade is correct.

The roller setting should be checked twice during the life of

the diamond blade, once after fitting the blade and when the

blade is semi worn.

Fitting the blade

We offers a number of blades for different materials in its

range. Check with your PARTNER dealer to see which blades

are best suited for your usage.

• Wipe off any dirt from the surface of the blade.

• Loosen the locking nuts on the support roller cover.

• Unscrew the adjuster screws a few turns.

!

WARNING! Always disconnect the power

cutter from the hydraulic connection when

performing a service. Unexpected blade

movements can cause serious injuries.

!

WARNING! It is forbidden to reconstruct a

used blade. A used blade may be weakened.

A reconstructed blade can crack or break

into pieces and seriously injury the operator

or other persons.

!

WARNING! Check that the blade is not

damaged before fitting it on the machine.

Damaged blades can disintegrate and cause

serious personal injury.

Page 11

English

– 11

SETTINGS AND ADJUSTMENTS

• Loosen the knob to offload the springs.

• Pull out the lock for the front handle and move the handle

to the service position.

• Remove the three screws holding the support roller guard

using a 6 mm hex key and lift off the cover.

• Fit the blade.

CAUTION! The blade has two grooves (A) on one side that

act as guide grooves for the guide rollers.

Ensure that the V-shaped edge of the blade enters the

drive wheel and that the blade’s guide groove fits in the

guide rollers. Also see under the heading Drive.

• Press in the guide roller if necessary, so that it climbs into

the groove on the blade.

• Fit the support roller guard and ensure that the flanges on

the guide rollers still enter the blade’s grooves correctly.

Now tighten the three screws fully.

• Rotate the blade and make sure that the support rollers

are not clamped against the blade.

• Adjust the adjuster screws so that the support rollers

make contact against the blade.

• Adjust so you can easily stop the support rollers using

your thumb when the blade is rotated. The support rollers

should only follow the blade occasionally.

• Tighten the locking nuts on the support roller guard.

• Rotate the blade and make sure you can still hold the

rollers with your thumb when the blade is rotated.

Page 12

12 –

English

SETTINGS AND ADJUSTMENTS

CAUTION! The machine should be upright. If the machine

lies on its side the weight of the blade makes it difficult to

make a correct adjustment.

• Tighten the knobs fully and the machine is ready to use.

Hydraulic hoses

• Before connecting the hoses: Ensure that the couplings

are clean, both on the machine and the hoses.

• Connect the pressure hose (A) from the hydraulic system

to the female coupling on the machine.

• Connect the other hydraulic coupling (B) to the male

coupling. This hose leads oil back to the container.

CAUTION! Two hose kits can be connected when hose

lengths exceeding 18 m are required. Do not connect more

than two kits as the couplings cause large power loss. See the

Technical data.

CAUTION! Make sure that the hoses can not be loosened

accidentally by turning the safety catches on the couplings to

the locked position before using the machine.

Water hose

Connect the water hose to the water supply. The water flow is

activated by opening the check valve. Minimum water flow: 4

l/min Note that the machine’s hose nipple is fitted with a filter.

Water supply

When you press in the switch lock (A) the water valve opens.

The water valve remains open and the switch lock (A) remains

pressed in as long as the switch (B) is held pressed in.

Water dosage

The water flow can be adjusted during operations with your

thumb.

Ample water flow is needed for maximal blade life.

CAUTION! The water pressure and water flow is extremely

important for the blade’s cooling and service life. Inadequate

cooling shortens the life of the guide rollers, drive wheel and

the blade.

!

WARNING! The power cutter must not be

connected to a hydraulic pressure

exceeding 150 bar (3000 psi).

!

WARNING! When the machine is in operation

the hoses are under extreme pressure. Do

not try to connect or disconnect the hoses

when the hydraulic system is operational.

This can result in serious personal injuries.

Page 13

English – 13

STARTING AND STOPPING

Starting and stopping

Starting

• Grip the front handle with the left hand.

• Grip the rear handle with the right hand. When you grip

the rear handle this releases the switch lock.

Stopping

The machine is stopped by releasing the switch.

!

WARNING! Note the following before

starting:

Make sure you are standing properly and

that the blade can not come into contact

with anything.

Keep people and animals well away from the

working area.

Check that the power source (the hydraulic

unit) supplies the correct oil flow and oil

pressure.

Page 14

14 – English

MAINTENANCE

Maintenance

Dismantling the complete guide

roller

• Remove the support roller cover.

• Lift off the blade.

• Unscrew the knob.

First turn the knob a few turns until you feel a resistance.

The guide roller then follows the knob out and stops when

it feels a resistance.

The guide roller is pressed into the knob. In order to loosen

the guide roller, you need to continue turning the knob until it

loosens completely.

• The guide roller can now be pulled out of the chassis

Assembling the complete guide

roller

• Screw the knob until it bottoms, and then loosen the knob

2 turns.

• Insert the guide roller in the chassis

• Now press the guide roller into the knob.

Lubricate the guide roller’s sleeve using grease. Fit the

grease gun on the grease nipples (A) and pump in grease

until clean grease emerges from the overflow hole (B).

• Fit the blade. See the heading Fitting the blade.

Important notes:

• The support rollers do not drive the blade.

• Incorrect adjustment can result in damage to the blade.

• If the blade rotates slowly or stops, stop cutting

immediately and trouble shoot.

!

WARNING! Inspection and/or maintenance

should be carried out with the hydraulic

hoses disconnected.

A

B

Page 15

English – 15

MAINTENANCE

Drive wheel

1 Lock the axle using the locking button. See the

instructions under the heading What is what?.

2 Loosen the centre screw and remove the washer.

3 You can now lift off the drive wheel.

CAUTION! Replace the drive wheel when fitting a new blade.

A worn drive wheel can result in the blade slipping and

becoming damaged.

Inadequate water flow drastically shortens the life of the drive

wheel.

Replacing the support rollers/guide

rollers

• Remove the support roller cover.

• Check the rollers for wear.

• Use a 19 mm spanner and 5 mm hex key to replace the

rollers.

Lubricate using bearing grease inside the rollers before the

new rollers are fitted.

• Replace the guide rollers when half of the flange on the

rollers is worn.

A) New

B) Worn

• Replace the support rollers when the roller surface is flat,

(or) when the groove on the roller surface has worn away.

A) New

B) Worn

When worn rollers are replaced with new ones, you must

adjust the rollers against the blade.

See the instructions under the heading Settings and

adjustments.

Page 16

16 – English

MAINTENANCE

Reconstructing the blade

Couplings

1 Water

2 Water filter

3 Return

4 Pressure

IMPORTANT! If the coupling is dirty, the dirt can enter the oil

and cause increased wear on the hydraulic motor, hydraulic

pump, valves, etc. It can also prevent the coupling from

sealing correctly.

Always clean the couplings before connecting to the hydraulic

system and the machine. Make sure the lock moves easily.

Clean the water filter if necessary.

Hydraulic hoses

Check the hydraulic hoses everyday before the machine is

used. Cracked, creased or weakened hoses must be

replaced.

!

WARNING! Ring cutter blades must not be

reconstructed. Due to its design, a ring

cutter blade is exposed to other strains than

a centre driven 14 inch diamond blade.

Firstly, the drive wheel is driven on the inner

diameter of the blade so that both the

surfaces of the drive wheel and the blade are

exposed to wear. The core of the blade

becomes thinner and the guide wider, which

prevents the blade being driven by the

wheel. Secondly, the blade is exposed to

loads from the rollers and from the actual

cutting process when the blade is not held

completely straight. Strain builds up in the

blade until it cracks or breaks if it has been

reconstructed. A shattered blade can cause

serious personal injuries to the user or other

persons. For this reason PARTNER does not

approve ring cutting blades that have been

reconstructed. In some cases an individual

segment may be reconstructed. Contact

your PARTNER dealer for instructions.

Page 17

English – 17

MAINTENANCE

Maintenance schedule

CAUTION! The chart is based on daily use of the equipment.

Blades conforming to EN13236

Partner K3600 MKII only conforms to 98/37/EC and EN13236 together with the blades listed below:

Note: The blades are available in different hardnesses for different materials, this is stated with two digits, XX.

Daily Twice a week

Support and guide rollers

Check the support rollers with regard to wear. X

Check the guide rollers with regard to wear. X

Lubricate the guide rollers. X

Hydraulic System

Inspect the hydraulic hoses. X

Inspect and clean the water nozzle. X

Drive system

Check the condition of the drive wheel. X

Water system

Inspect and clean the water nozzles on the water disc. X

Inspect the water adjustment control. X

Check the filter in the water coupling. X

Controls

Check that the controls work. X

Blade

Check the condition of the blade guard. X

Check the water disc. X

Type Diameter, mm

Partner-Dimas

PXR XXD 350

ELR XXD (5,6 / .220) 350

SLR XXD 350

R550D-0355 (5,6 mm) 350

R530D-0355 350

R510D-0355 (5,6 mm) 350

Page 18

18 – English

TROUBLE SHOOTING

Mechanics

Symptom Probable cause

The blade does not rotate. Roller knobs not tightened fully.

The blade not fitted on guide rollers correctly.

Rollers tensioned too much.

Possible faulty hose connection to the hydraulic system.

Possible faulty hose connection to the drive source or other hydraulic problem.

The blade rotates too slowly. Roller knobs not tightened fully.

Worn drive wheel.

The V-shaped inner diameter of the blade is worn.

The springs on the guide rollers are weakened.

Dirty overpressure valve in the hydraulic system.

Valve knob on the hydraulic motor does not move the correct distance.

Defective roller bearings.

Inadequate oil flow, check the hydraulic oil flow.

The blade jumps out of its position. Roller setting too loose.

Worn guide rollers.

The blade not fitted on guide rollers correctly.

Damaged blade.

The blade warps. Rollers tensioned too much.

Blade overheating.

Segments break. Bent, twisted or badly maintained blade.

Continue to use the blade only if one segment is missing or leave for reconstruction when the

blade is worn max 50 %.

The blade cuts too slowly. Wrong blade for the material in question.

Check that the right amount of water reaches the blade.

The blade slips.

The guide rollers does not move in and out freely. A seized roller can not press the blade hard

enough against the drive wheel.

Worn drive wheel. Abrasive material and too little water when cutting increases the wear on

the wheel.

Worn guide roller flange. When more than 2/3 of the width of the flange is worn the blade can

slip.

The blade’s groove and inner edge are worn. Caused by inferior flushing of abrasive material

and/or a worn drive wheel causing the blade to slip.

Page 19

English – 19

TECHNICAL DATA

*We recommend the use of environmentally approved hydraulic oil.

**With high ambient temperatures use oil with a higher viscosity.

Note 1: Noise emissions in the environment measured as sound power (L

WA

) in conformity with EC directive 2000/14/EC.

Extending the hydraulic hoses

When extending the hydraulic hoses, the inside diameter of the hose must be increased according to the table to counteract power

loss.

Technical data K3600 MKII

Blade diameter, mm/inches 350/14”

Cutting depth, mm/inches 260/10”

Max. peripheral speed, m/s / r/min 55/3000

Max.motor speed, r/min 17000

Hydraulic motor Geared motor (open centre valve)

Max. hydraulic pressure, bar/ (psi) 150 / 2200

Oil flow, min-max, l/min 35-42

Height, mm/inches 410/16

Length, mm/inches 715/28

Width, mm/inches 260/10

Weight, excl. blade, kg 8,3

Weight ring blade, kg 0,8

Specifications hydraulic oil* 150 VG 32 (10W)**

Oil temperature (operational), °C60

Water consumption, l/min 4

Hydraulic couplings 1/2' FF according to HTMA regulations. (thread 3/8')

Noise emissions

(see note 1)

Sound power level, measured dB(A) 110

Sound power level, guaranteed L

WA

dB(A) 111

Sound levels

Equivalent sound pressure level at the operator’s ear,

according to ISO/DIS 15744 and ISO/DIS 11201, dB (A)

99

Vibration levels

Handle vibrations measured according to ISO/DIS 8662-4

Front handle, m/s

2

4,3

Rear handle, m/s

2

6,0

Extension, m

Inside diameter of the hydraulic hose,

inches

Up to 30 m 1/2

30-45 5/8

45-100 3/4

Page 20

20 – English

TECHNICAL DATA

EC-declaration of conformity

Partner Industrial Products, SE-433 81 Partille, Sweden, tel: +46-31-949000, declares under sole responsibility that the power

cutter Partner K3600 from 2002’s serial numbers and onwards (the year is clearly stated in plain text on the rating plate with

subsequent serial number), complies with the requirements of the COUNCIL’S DIRECTIVES:

of June 22, 1998 ”relating to machinery” 98/37/EC, annex IIA.

of May 8, 2000 ”relating to the noise emissions in the environment” 2000/14/EC.

The following harmonised standards have been applied: ISO/DIS 15744, ISO/DIS 11201.

SMP Svensk Maskinprovning AB, Fyrisborgsgatan 3, SE-754 50 Uppsala, Sweden, has carried out voluntary type approval for

Husqvarna AB.

The certificate has the number: 01/169/010 – K3600 MKII.

Partille January 3, 2002

Ove Donnerdal, Development Manager

Page 21

Page 22

´®z*x||¶6r¨

´®z*x||¶6r¨

Page 23

Page 24

´®z*x||¶6r¨

2004-12-22

´®z*x||¶6r¨

1088929-26

www.partner-industrial.com

Loading...

Loading...