Page 1

K2500

Operator´s manual

Please read the operator’s manual carefully

and make sure you understand the

instructions before using the machine.

Page 2

2 –

English

KEY TO SYMBOLS

Key to symbols

WARNING! The machine can be a

dangerous tool if used incorrectly or

carelessly, which can cause serious or fatal

injury to the operator or others.

Please read the operator’s manual carefully

and make sure you understand the

instructions before using the machine.

Always wear:

• Approved protective helmet

• Approved hearing protection

• Protective goggles or a visor

This product is in accordance with applicable

EC directives.

Other symbols/decals on the machine refer to special

certification requirements for certain markets.

Always disconnect the machine from the

hydraulic hoses before inspection and/or

maintenance of the machine.

Always wear approved protective gloves.

Regular cleaning is required.

Visual check.

Protective goggles or a visor must be worn.

Page 3

English

– 3

CONTENTS

Contents

KEY TO SYMBOLS

Key to symbols ............................................................. 2

CONTENTS

Contents ...................................................................... 3

WHAT IS WHAT?

What is what on the power cutter? ............................... 4

SAFETY INSTRUCTIONS

Steps before using a new power cutter. ....................... 5

Personal protective equipment ..................................... 5

Machine ′ s safety equipment ........................................ 5

Checking, maintaining and servicing the machine ′ s

safety equipment .......................................................... 6

General safety precautions .......................................... 6

General working instructions ....................................... 7

Cutting blades .............................................................. 9

ASSEMBLY

Assembly ..................................................................... 11

Fitting the cutting blade ................................................ 11

Guard for the blade ...................................................... 11

STARTING AND STOPPING

Starting and stopping ................................................... 12

MAINTENANCE

Maintenance ................................................................ 13

TECHNICAL DATA

Cutting equipment ........................................................ 15

EC-declaration of conformity ........................................ 15

Page 4

4 –

English

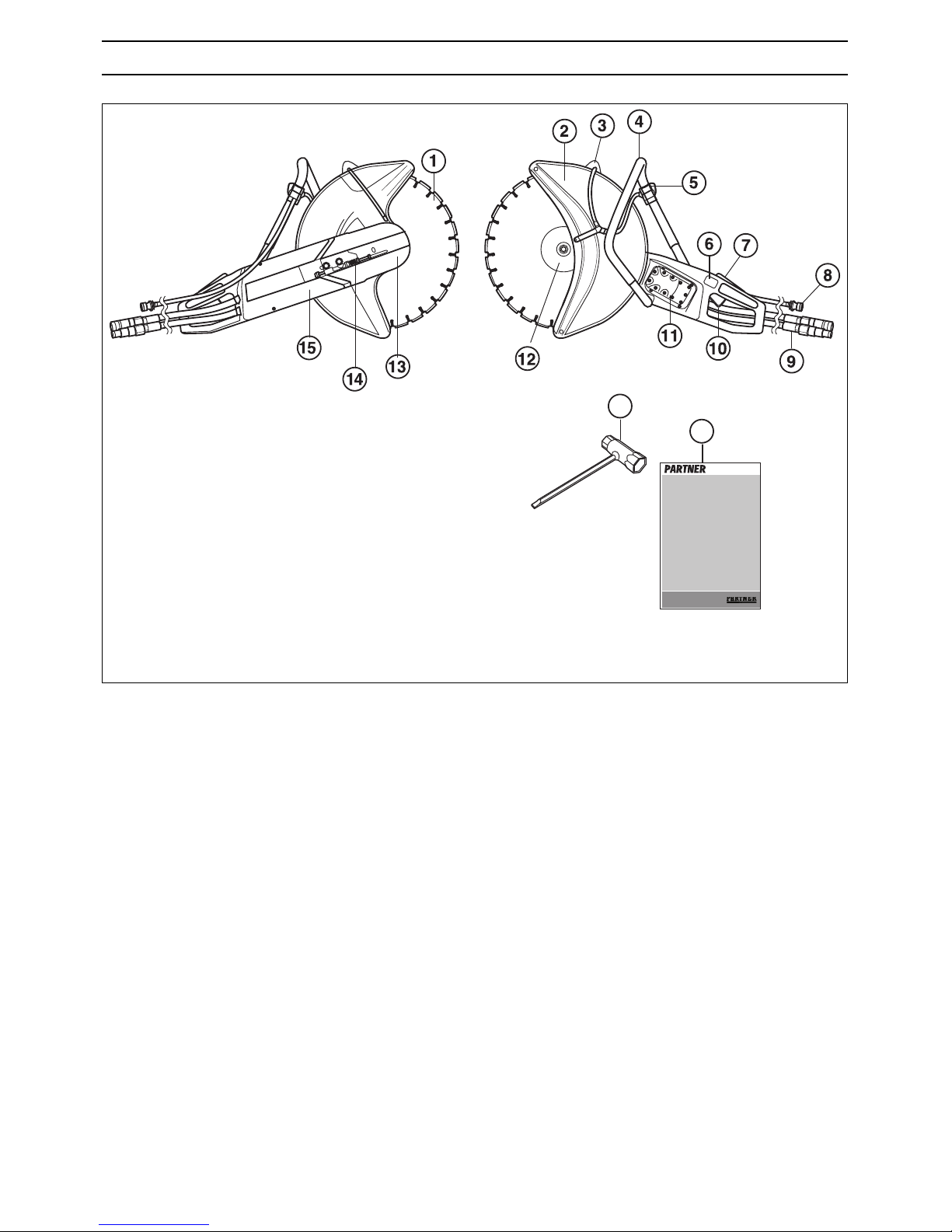

WHAT IS WHAT?

What is what on the power cutter?

16

17

1 Cutting blade

2 Guard for the blade

3 Catch for the guard

4 Front handle

5 Water tap

6 Rating plate

7 Switch lock

8 Water connection with filter

9 Hydraulic hoses

10 Switch

11 Hydraulic motor

12 Flange washer

13 Belt guard

14 Belt tensioner

15 Cutting arm

16 Combination spanner

17 Operator ′ s manual

Page 5

English

– 5

SAFETY INSTRUCTIONS

Steps before using a new power

cutter.

• This machine is a hydraulically operated power cutter

intended for free-hand cutting. The machine should be

connected to a hydraulic unit with an oil flow of 35-42

litres/min and a maximum pressure of 150 bar.

• Please read the operator’s manual carefully.

• Check the cutting blades mounting, see the chapter

”Assembly”.

Let your Partner dealer check the power cutter and make

essential adjustments and repairs.

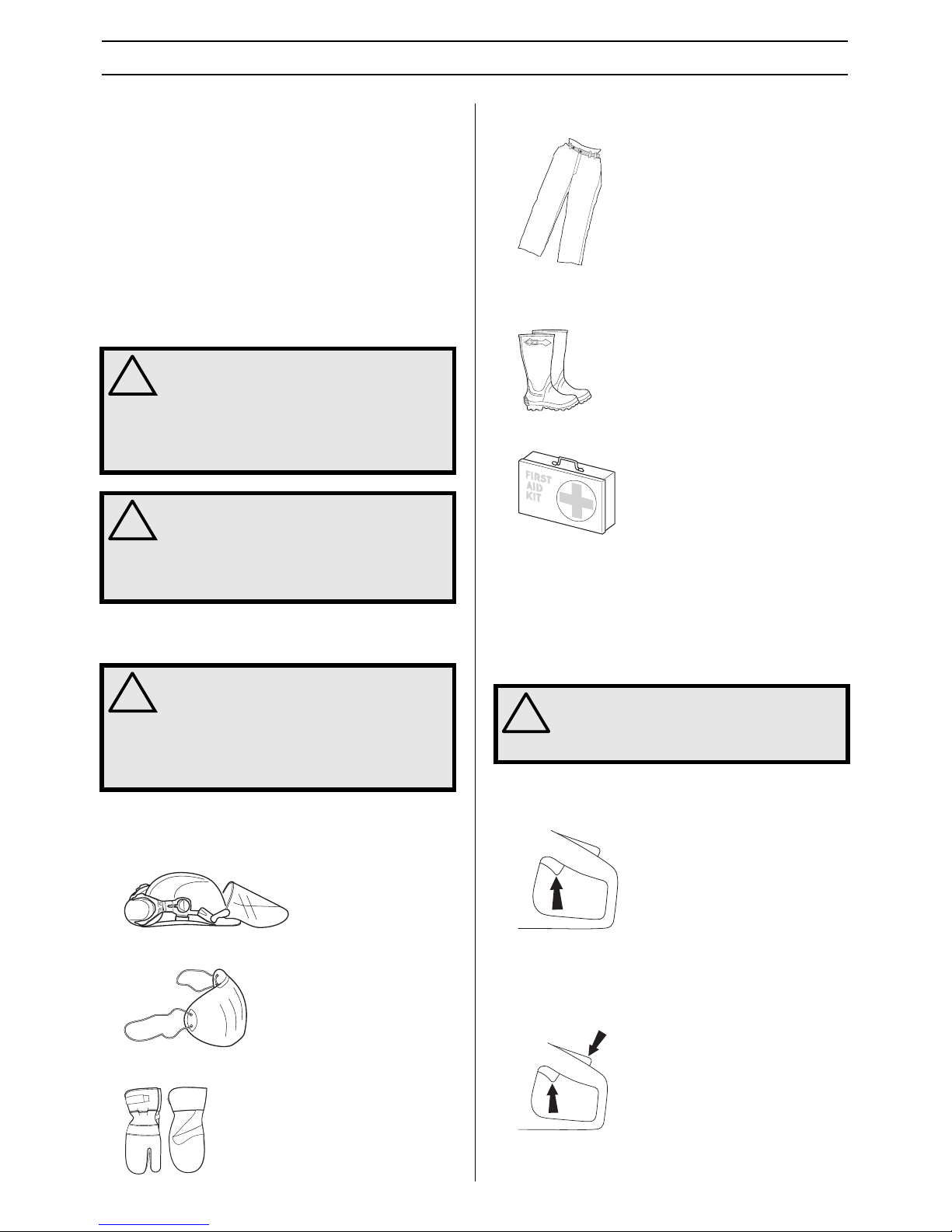

Personal protective equipment

• Protective helmet

• Hearing protection

• Protective goggles or a visor

• Breathing mask

• Heavy-duty, firm grip gloves.

• Tight-fitting, heavy-duty and comfortable clothing that

permits full freedom of movement.

• Use leg-guards recommended for the material to be cut.

• Boots with steel toe-caps and non-slip sole

• Always have a first aid kit nearby.

Machine ′ s safety equipment

This section describes the machine ′ s safety equipment, its

purpose, and how checks and maintenance should be carried

out to ensure that it operates correctly. See the ”What is

what?” section to locate where this equipment is positioned

on your machine.

Switch

The switch is used to start and stop the machine.

Switch lock

The switch lock is designed to prevent accidental operation of

the switch. When the lock (A) is pressed in this releases the

switch (B).

The switch lock remains pressed as long as the switch is

pressed.

!

WARNING! Under no circumstances may the

design of the machine be modified without

the permission of the manufacturer. Always

use genuine accessories. Non-authorized

modifications and/or accessories can result

in serious personal injury or the death of the

operator or others.

!

WARNING! Use of products which cut, grind,

drill, sand or shape material can generate

dust and vapors which may contain harmful

chemicals. Know the nature of the material

being worked on and wear appropriate dust

mask or respirator protection.

!

WARNING! You must use approved personal

protective equipment whenever you use the

machine. Personal protective equipment

cannot eliminate the risk of injury but it will

reduce the degree of injury if an accident

does happen. Ask your dealer for help in

choosing the right equipment.

!

WARNING! Never use a machine that has

faulty safety equipment! Carry out the

inspection, maintenance and service

routines listed in this section.

A

B

Page 6

6 –

English

SAFETY INSTRUCTIONS

When you release your grip on the handle this resets both the

switch and the switch lock. This takes place via two

independent return spring systems. This position causes the

machine to stop and the switch to be locked.

Guard for the blade

This guard is fitted above the cutting blade and is designed to

prevent parts of the blade or cutting fragments from being

thrown towards the user.

Checking, maintaining and servicing

the machine ′ s safety equipment

Checking the starting and stopping

functions of the switch

Start the machine, release the switch, and check that the

machine and blade stop.

Checking the switch lock

Check that the switch is locked when the switch lock is in its

home position.

Press the switch lock and check that it returns to its home

position when released.

Check that the switch and switch lock move freely and that

their return spring systems function.

Start the machine, release the switch, and check that the

machine and blade stop.

Checking the blade guard

Check that the guard is complete and without any cracks or

deformations.

General safety precautions

• A power cutter is designed to cut hard materials such as

concrete/stone and steel/iron. Observe the increased risk

of kickback when cutting soft materials. See instructions

under the heading How to avoid kickback.

• Do not use the power cutter until you have read the entire

contents of this Operator’s Manual.

All servicing, in addition to the points listed in the section

”Control, maintenance and service of the power cutter’s

safety equipment”, should be carried out by trained

service specialists.

• Never use the machine if you are tired, if you have drunk

alcohol, or if you are taking medication that could affect

your vision, your judgement or your co-ordination.

• Wear personal protective equipment. See instructions

under the heading Personal protective equipment.

• Never use a machine that has been modified in any way

from its original specification.

!

WARNING! All servicing and repair work on

the machine requires special training. This is

especially true of the machine ′ s safety

equipment. If your machine fails any of the

checks described below you must contact

your service agent. When you buy any of our

products we guarantee the availability of

professional repairs and service. If the

retailer who sells your machine is not a

servicing dealer, ask him for the address of

your nearest service agent.

!

WARNING! Always check that the guard is

correctly fitted before starting the machine.

Check that the cutting blade is fitted

correctly and does not show signs of

damage. A damaged cutting blade can cause

personal injury. See instructions under the

heading Assembly.

Page 7

English

– 7

SAFETY INSTRUCTIONS

• Never use a machine that is faulty. Carry out the checks,

maintenance and service instructions described in this

manual. Some maintenance and service measures must

be carried out by trained and qualified specialists. See

instructions under the heading Maintenance.

• Never allow anyone else to use the machine without first

ensuring that they have understood the contents of the

operator’s manual.

Transport and storage

Do not store or transport the power cutter with the cutting

blade fitted.

Store the power cutter in a lockable area so that it is out of

reach of children and unauthorised persons.

All blades should be removed from the cutter after use and

stored carefully. Store cutting blades in dry, frost free

conditions.

Special care should be taken with abrasive discs. Abrasive

discs must be stored on a flat, level surface. If blades are

supplied with a backing pad then a spacer should be used to

keep them flat. If an abrasive disc is stored in humid

conditions, this can cause imbalance and result in injury.

Inspect new blades for transport or storage damage.

General working instructions

Basic safety rules

• Look around you:

- To ensure that people, animals or other things cannot

affect your control of the machine.

- To make sure that none of the above come into contact

with the cutting blade.

• Do not use the machine in bad weather, such as dense

fog, rain, strong wind, intense cold, etc. Working in bad

weather is tiring and can lead to dangerous conditions,

e.g. slippery surfaces.

• Never start to work with the power cutter before the

working area is clear and you have a firm foothold. Look

out for any obstacles with unexpected movement. Ensure

when cutting that no material can become loose and fall,

causing operating injury.Take great care when working on

sloping ground.

• Make sure that no clothes or parts of the body come in

contact with the cutting equipment when it is rotating.

• Keep at a safe distance from the cutting equipment when

it is rotating.

• The guard for the cutting equipment must always be on

when the machine is running.

• Ensure that the working area is sufficiently illuminated to

create a safe working environment.

• Do not move the machine when the cutting equipment is

rotating.

• Always ensure you have a safe and stable working

position.

• Make sure that no pipes or electrical cables are routed in

the area to be cut.

Cutting

General

• Start cutting with the machine running at maximum

speed.

• Always hold the machine in a firm grip with both hands.

Hold it so that the thumbs and fingers grip round the

handles.

Cutting technique

The technique described below is of a general character.

Check information for each blade regarding individual cutting

characteristics (for example, a diamond blades requires less

feeding pressure than an abrasive discs).

• Support the work piece in such a way that it is possible to

predict what will happen, and so that the cut remains open

while cutting.

!

WARNING! This section describes basic

safety directions for using a power cutter.

This information is never a substitute for

professional skills and experience. If you get

into a situation where you feel unsafe, stop

and seek expert advice. Contact your dealer,

service agent or an experienced power

cutter user. Do not attempt any task that you

feel unsure of!

!

WARNING! The safety distance for the power

cutter is 15 metres. You are responsible to

ensure that animals and onlookers are not

within the working area. Do not start cutting

until the working area is clear and you are

standing firmly.

!

WARNING! Overexposure to vibration can

lead to circulatory damage or nerve damage

in people who have impaired circulation.

Contact your doctor if you experience

symptoms of overexposure to vibration.

These symptoms include numbness, loss of

feeling, tingling, pricking, pain, loss of

strength, changes in skin colour or

condition. These symptoms normally appear

in the fingers, hands or wrists.

Page 8

8 –

English

SAFETY INSTRUCTIONS

• Check that the blade is not in contact with anything when

the machine is started

• Always cut at maximum speed.

• Start cutting smoothly, allowing the machine to work

without forcing or pressing in the blade.

• Move the blade slowly forwards and backwards to achieve

a small contact area between the blade and the material

to be cut. This reduces the temperature of the blade and

ensures effective cutting.

• Feed down the machine in line with the blade. Pressure

from the side can damage the blade and is very

dangerous.

• The guard for the cutting equipment should be adjusted so

that the rear section is flush with the work piece. Spatter

and sparks from the material being cut are then collected

up by the guard and led away from the user.

Sharpening diamond blades

Diamond blades can become dull when the wrong feeding

pressure is used or when cutting certain materials such as

heavily reinforced concrete. Working with a blunt diamond

blade causes overheating, which can result in the diamond

segments coming loose.

Sharpen the blade by cutting in a soft material such as

sandstone or brick.

Blade vibration

The blade can become out-of-round and vibrate if an

excessive feed pressure is used.

A lower feed pressure can stop the vibration. Otherwise

replace the blade. The blade must be of the recommended

type for the material to be cut.

How to avoid kickback

What is kickback?

The word kickback is used to describe the sudden reaction

that causes the power cutter and cutting blade to be thrown

from an object when the upper quadrant of the blade, known

as the kickback zone, touches an object.

General rules

• Never cut with the cutting blades upper quadrant, i.e. the

kickback zone.

• Always hold the machine in a firm grip with both hands.

Hold it so that the thumbs and fingers grip round the

handles.

• Keep a good balance and a firm foothold.

• Always cut at maximum speed.

• Stand at a comfortable distance from the work piece.

• Take care when inserting the blade in an existing cut.

• Never cut above shoulder height.

• Be alert to movement of the work piece or anything else

that can occur, which could cause the cut to close and

pinch the blade.

Pull in

Pull in occurs when the discs lower section suddenly stops or

when the cut closes. (To avoid, see the heading ”Basic rules”

and ”Jamming/rotation”, here below.)

!

WARNING! Under all circumstances avoid

cutting using the side of the blade; it will

almost certainly be damaged, break and can

cause immense damage. Only use the

cutting section.

Do not pull the power cutter to one side, this

can cause the blade to jam or break

resulting in injury to people.

!

WARNING! Kickback can happen very

suddenly and violently; kicking the power

cutter and cutting blade back at the user. If

this happens when the cutting blade is

moving it can cause very serious, even fatal

injuries. It is vital you understand what

causes kickback and that you can avoid it by

taking care and using the right working

technique.

Page 9

English

– 9

SAFETY INSTRUCTIONS

Pinching/rotation

If the cut is pressed together this can lead to jamming. The

machine can be pulled down suddenly with a very powerful

jerk.

How to avoid pinching

Support the work piece in such a way that the cut remains

open during the cutting operation and when the cut is

finished.

Cutting blades

General

Cutting blades are available in two basic designs; abrasive

discs and diamond blades.

Always remove the cutting blade when the machine is

transported.

Make sure that the right bushing is used for the cutting blade

to be fitted on the machine. See the instructions under the

heading Assembling the cutting blade.

High-quality blades are often most economical. Lower quality

blades often have inferior cutting capacity and a shorter

service life, which results in a higher cost in relation to the

quantity of material that is cut.

Water cooling

After using an abrasive disc with water cooling, run the disc

dry for about half a minute. If an abrasive disc is stored in

humid conditions, this can cause imbalance and result in

injury.

Hand-held, high-speed machines

Our cutting blades are manufactured for high-speed, portable

power cutters. If blades from other manufacturers are used,

ensure that the blades conform to all regulations and

demands that concern this type of power cutter.

Special blades

Some cutting blades are designed for stationary equipment

and for use with attachments.Such cutting blades must not be

used on portable power cutters.

Always contact local authorities and make sure you are

following applicable directives.

Abrasive discs

The cutting material on abrasive discs consists of grit bonded

using an organic binder. ”Reinforced blades” are made up of

a fabric or fibre base that prevents total breakage at maximum

working speed if the blade should be cracked or damaged.

A cutting blade’s performance is determined by the type and

size of abrasive corn, and the type and hardness of the

bonding agent.

Check that the blade is approved for the same or higher

speed according to the aproval plate of the engine. Never use

a cutting blade with a lower speed rating than that of the

power cutter.

Ensure the blade it not cracked or damaged in any other way.

!

WARNING! A cutting blade may burst and

cause injury to the operator.

Never use a cutting blade at a lower speed

rating than that of the power cutter.

Never use a cutting blade for any other

materials than that it was intended for.

!

WARNING! Water cooling, which is used

when cutting concrete, cools the blade and

increases its service life while also reducing

the formation of dust. Disadvantages include

difficulties at very low temperatures, the risk

of damaging floors and other structural

elements, and the risk of slipping.

Abrasive discs, types and use

Intended Use

Disc type Material Water cooling

Concrete

Concrete, asphalt,

stone masonry, cast

iron, aluminium,

copper, brass, cables,

rubber, plastic, etc.

Can be used to reduce

dust. Run the disc dry

for about a half minute

after using an abrasive

disc with water

cooling.

Metal

Steel, steel alloys and

other hard metals.

NOT recommended

Page 10

10 –

English

SAFETY INSTRUCTIONS

Test the abrasive disc by hanging it on your finger and tapping

it lightly with a screwdriver or the like. If the disc does not

produce a resonant, ringing sound it is damaged.

Diamond blades

Diamond blades consist of a steel body provided with

segments that contain industrial diamonds.

Diamond blades ensure lower costs per cutting operation,

fewer blade changes and a constant cutting depth.

When using diamond blades make sure that it rotates in the

direction indicated by the arrow on the blade.

Always use a sharp diamond blade. Sharpen the blade by

cutting in a soft material such as sandstone or brick.

Diamond blades are available in several hardness classes. A

"soft" diamond blade has a relatively short service life and

large cutting capacity. It is used for hard materials such as

granite and hard concrete. A "hard" diamond blade has a

longer service life and reduced cutting capacity, and should

be used for soft materials such as brick and asphalt.

Material

Diamond blades are ideal for masonry, reinforced concrete

and other composite materials. Diamond blades are not

recommended for cutting metal.

Diamond blades for wet cutting

Diamond blades for wet cutting should have water poured

over them during the cutting to cool the blade and bond the

dust.

Diamond blades for dry cutting

Diamond blades for dry cutting are a new generation of

blades that do not require water cooling. However, the blades

will still be damaged by excessive heat. It is most economical

to allow the blade to cool by simply lifting it out from the cut

every 30–60 seconds and letting it rotate in the air for 10

seconds.

!

WARNING! Cool diamond blades for wet

cutting continuously with water to prevent

overheating, which can cause the blade to

break up and eject pieces that can cause

injury.

Page 11

English

– 11

ASSEMBLY

Assembly

Fitting the cutting blade

Partner’s blades are approved for hand-held power cutters.

Blades are manufactured with three different diameters of

centre holes: 20 mm (0.787"), 22.2 mm (7/8") and 25.4 mm

(1"). Bushings can be fitted on the machine axle to adjust the

machine to the centre hole of the blade. Use a bushing with

the correct diameter! The blades are marked with the

diameter of the centre hole.

The blade is placed on the bushing (C) between the inner

flange washer (A) and the flange washer (B). The flange

washer is turned so that it fits on the axle.

Tightening torque for the bolt holding the blade is: 15-25 Nm

(130-215 in.lb).

The axle can be locked by inserting a screwdriver or the like

in the hole in the belt guard.

When a diamond blade is mounted on the power cutter make

sure that the diamond blade will rotate in the direction

indicated by the arrow on the blade.

When the blade is replaced with a new one, check the flange

washers and the drive axle. See instructions under the

heading Checking the drive axle and flange washers.

Checking the drive axle and flange

washers

Check that the threads on the drive shaft are undamaged.

Check that the contact surfaces on the blade and the flange

washers are undamaged, of the correct dimension, clean,

and that they run properly on the drive axle.

Do not use warped, notched, indented or dirty flange

washers. Do not use different dimensions of flange washers.

Cutting arm

It is possible to turn the cutting arm 180 ° so that the blade

comes on the other side of the cutting arm. This simplifies

cutting close to obstacles such as walls and floors etc. The

cutting arm and drive belt are released in the same way as

when replacing the drive belt. See instructions under the

heading Replacing the drive belt.

Turn the arm 180 ° , replace the respective parts, and screw

them secure in the same way as before.

If you are using a diamond blade you must also turn it so that

it rotates in the right direction. A diamond blade must rotate in

the direction shown by the arrow marking on the blade.

Guard for the blade

The guard must always be fitted on the machine.

The guard for the cutting equipment should be adjusted so

that the rear section is flush with the work piece. Spatter and

sparks from the material being cut are then collected up by

the guard and led away from the user.

!

WARNING! Always disconnect the machine

from the hydraulic hoses before cleaning,

assembly and maintenance.

Page 12

12 – English

STARTING AND STOPPING

Starting and stopping

Starting

• Grip the front handle with your left hand.

• Grip the rear handle with the right hand. When you grip

the rear handle this releases the switch lock.

Stopping

The machine is stopped by releasing the switch.

!

WARNING! Note the following before

starting:

Make sure you have a secure footing and

that the cutting blade cannot touch anything.

Keep people and animals well away from the

working area.

Page 13

English – 13

MAINTENANCE

Maintenance

Tensioning the drive belt

The drive belt is fully enclosed and well protected from dust

and dirt.

When the drive belt is to be tensioned, release the nuts

holding the cutting arm.

Screw the adjuster screw so that the square headed nut

comes opposite the marking on the cover. This automatically

ensures that the belt has the correct tension.

Tighten the two nuts holding the cutting arm.

Replacing the drive belt

First release the nuts and then the adjuster screw to release

the belt tension.

Unscrew the nuts and lift off the front belt guard.

The cutting arm is now loose and can be removed from the

machine. Remove the rear belt guard by releasing the two

screws holding the guard.

Take off the old belt and fit the new one. Fit the cutting arm to

the machine and tension the belt with the adjuster screw. A

new drive belt should be re-tensioned after running for about

30 minutes.

Checking the drive axle and flange

washers

Check that the threads on the drive shaft are undamaged.

Check that the contact surfaces on the blade and the flange

washers are undamaged, of the correct dimension, clean,

and that they run properly on the drive axle.

Do not use warped, notched, indented or dirty flange

washers. Do not use different dimensions of flange washers.

Water cooling

Check that the water tap functions. To open the water tap, turn

the tap to open position.

To turn off the water, turn the tap to closed position.

Water filter

Check and clean the filter if necessary.

!

WARNING! Inspection and/or maintenance

should be carried out with the hydraulic

hoses disconnected.

Page 14

14 – English

MAINTENANCE

´®z*xzr¶6,¨

´®z*xzr¶6,¨

Daily maintenance

Carry out the following checks daily before using the machine.

1 Check that nuts and screws are tight.

2 Check that the power source (the hydraulic unit) supplies

the correct oil flow and oil pressure.

3 Check that the hydraulic hoses and couplings are clean

and undamaged.

4 Connect the machine hoses with the hoses from the

power source.

5 Start the power source and check that the power cutter

functions by starting the machine with the switch in the

rear handle. Check that the blade stops when the switch

is released.

6 Checking the blade guard

7 Check the condition of the cutting blade.

8 Check the tension of the drive belt.

Page 15

English – 15

TECHNICAL DATA

Note 1: Handle vibrations are measured according to ISO 8662-4

Cutting equipment

EC-declaration of conformity

(Applies to Europe only)

Partner Industrial Products, SE-433 81 Partille, Sweden, tel: +46-31-949000, declares under sole responsibility that the power

cutter Partner K2500 dating from 2004 serial numbers and onwards (the year is clearly stated on the rating plate, followed by the

serial number), complies with the requirements of the COUNCILíS DIRECTIVE:

of June 22, 1998 ”relating to machinery” 98/37/EC, annex IIA.

The following standards have been applied: EN 292-2

Let your Partner dealer check the power cutter and make essential adjustments and repairs.

The supplied power cutter conforms to the example that underwent EC type examination.

Partille January 23, 2004

Ove Donnerdal, Development Manager

Technical data K2500

Engine

Hydraulic oil flow, l/min / gpm 35-42 / 9-11

Working pressure, bar / psi 130-140 / 2000

Max. working pressure, bar / psi 150 / 2200

Max. speed of output shaft, rpm 4300

Drive system, V-belt SPZ

Weight

Power cutter without cutting blade, kg 8,3

Noise levels

Noise pressure level at the operators ear, max speed,

measured according to ISO/DIS 15744, ISO/DIS 11201, dB (A)

84,5

Noise power level, max. speed, measured according to ISO/DIS

15744 and ISO/DIS 11201, dB (A)

105

Vibration levels

(see note 1)

Front handle, m/s

2

7,5

Rear handle, m/s

2

5,2

Cutting blade Max. peripheral speed, m/s

16" 100

Page 16

´®z*xzr¶6,¨

2004-11-24

´®z*xzr¶6,¨

1088908-26

www.partner-industrial.com

Loading...

Loading...